Method for preparing supercritical low-odor and low-emission polypropylene material

A polypropylene material, supercritical technology, applied in separation methods, chemical instruments and methods, gaseous solvent extraction, etc., can solve problems such as difficult to long-term solutions to odor problems, and achieve the effect of eliminating physical damage and eliminating pungent odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

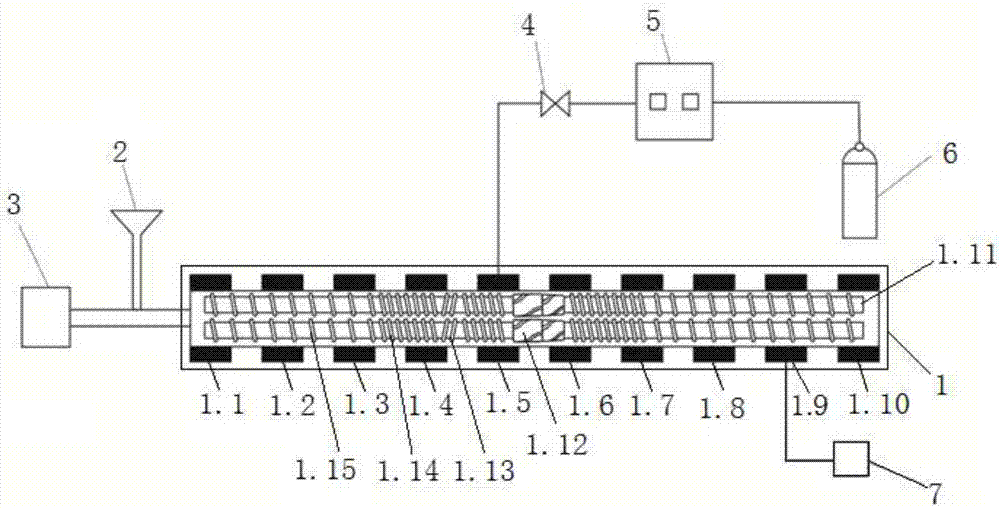

[0028] A method for preparing a supercritical low-odor, low-emission polypropylene material. The polypropylene material is mixed and added to a twin-screw extruder equipped with a vacuum. The middle part of the twin-screw extruder is introduced into supercritical carbon dioxide to make Supercritical carbon dioxide and polypropylene materials are mixed, melted and extruded in a closed, high-pressure screw barrel to produce supercritical low-odor and low-emission polypropylene materials.

[0029] like figure 1As shown, the twin-screw extruder 1 includes twin-screws 1.11 arranged side by side inside the screw barrel, and ten temperature control zones are arranged in turn inside the screw barrel, located in the first temperature control zone 1.1, the second temperature control zone 1.2, and the third temperature control zone. The surface of the twin-screw 1.11 between the temperature control zone 1.3, the seventh temperature control zone 1.7, the eighth temperature control zone 1....

Embodiment 2

[0042] Prepare Example 2 with the preparation process of Example 1 and the twin-screw extruder, that is, 75 parts of PP resin, 25 parts of filler, 5 parts of toughening agent, 0.5 part of antioxidant, and 0.4 part of light stabilizer are mixed and added to the equipment In the twin-screw extruder with vacuum, the supercritical carbon dioxide is introduced into the middle of the twin-screw extruder, and the vacuum is drawn at the same time, so that the supercritical carbon dioxide and the polypropylene material are mixed, melted and extruded in a closed, high-pressure screw barrel, while A supercritical low-odor, low-emission polypropylene material is produced.

[0043] Wherein, the polypropylene used is a mixture of homopolymerization and copolymerization in a weight ratio of 1:4, the elastomer is an ethylene-butylene copolymer, the light stabilizer is a hindered amine, and the filler is a talcum powder. During the preparation process, Introduce supercritical carbon dioxide fl...

Embodiment 3

[0045] The preparation method and materials are the same as in Example 2, except that in the preparation process, the fluid flow rate of feeding supercritical carbon dioxide is 20m 3 / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com