Extraction apparatus

An extraction device and extraction agent technology, applied in solvent extraction, gaseous solvent extraction, liquid solution solvent extraction, etc., can solve problems such as inability to distribute, difficult to achieve uniformity, uncontrollable oil film thickness on the surface of the dispersed phase of bubbles in the oil film, etc. Achieve the effect of uniform size, easy separation and long contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0023] Preferred embodiment:

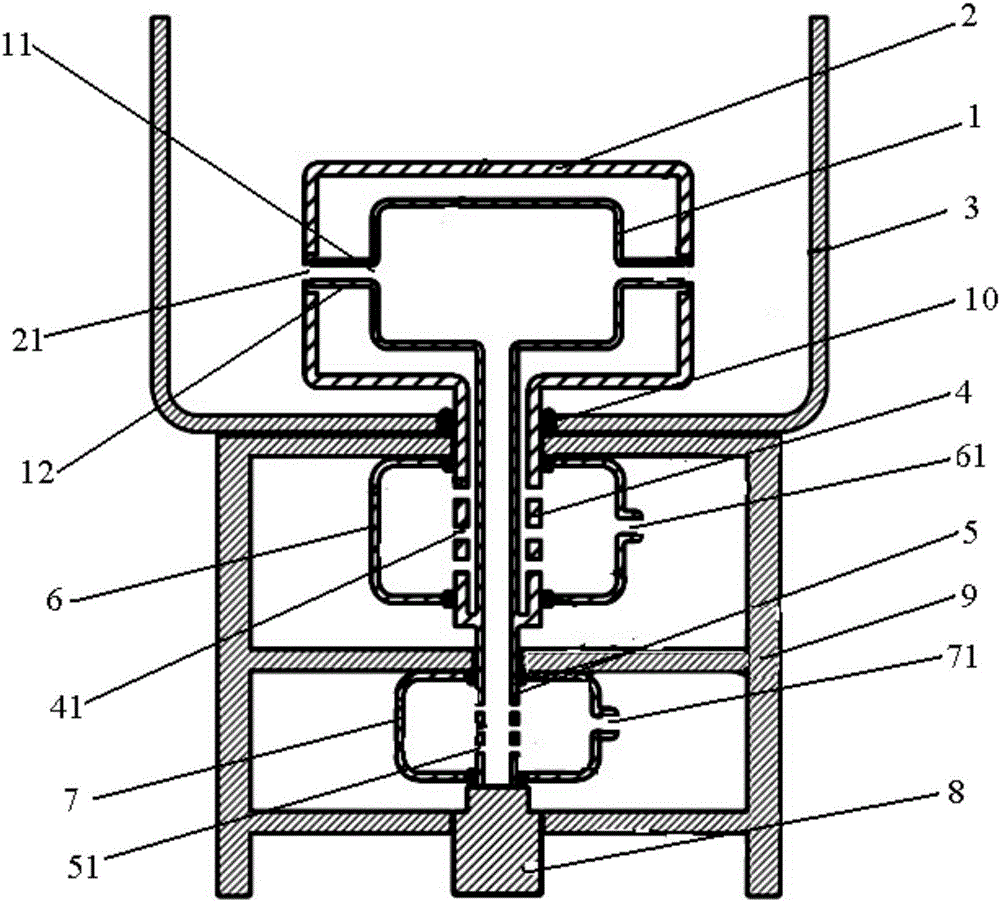

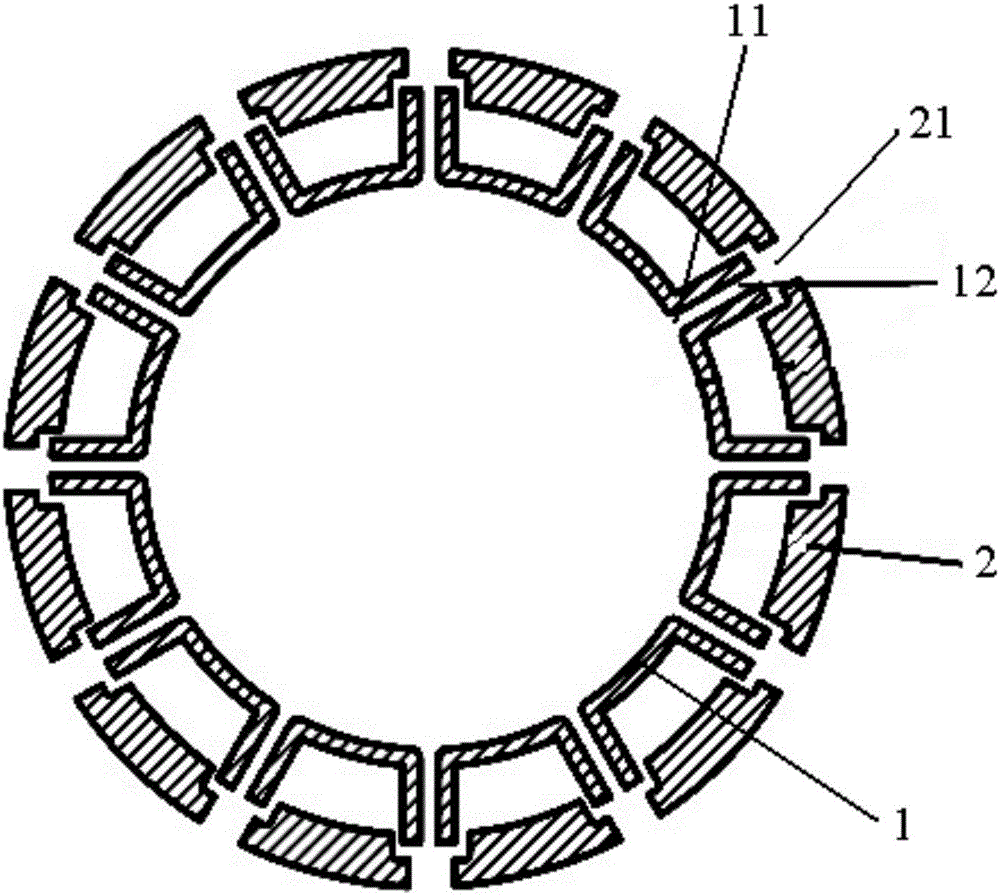

[0024] This preferred embodiment provides an extraction device, which is mainly used in a large phase extraction system. see figure 1 and figure 2 The extraction device provided in this preferred embodiment includes a gas chamber 1 and a first solvent chamber 2 sleeved outside the gas chamber 1, the gas chamber 1 and the first solvent chamber 2 are placed in the second solvent chamber 3, and the first solvent chamber 2 is used to contain the light phase extractant, the second solvent chamber 3 is used to contain the heavy phase to-be-extracted liquid, the first solvent chamber 2 communicates with the extractant source located outside the second solvent chamber 3, and the gas chamber 1 is connected to the second solvent chamber The gas source outside the chamber 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com