Method for separating ginger essential oil from gingerol-rich oleoresin ginger through low-pressure supercritical CO2 extraction

A gingerol ginger oil and supercritical technology, applied in the field of extraction and separation of natural products, can solve the problems of heat-sensitive component damage, huge investment, and small-scale extraction system, and achieve the effect of reducing extraction pressure and extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

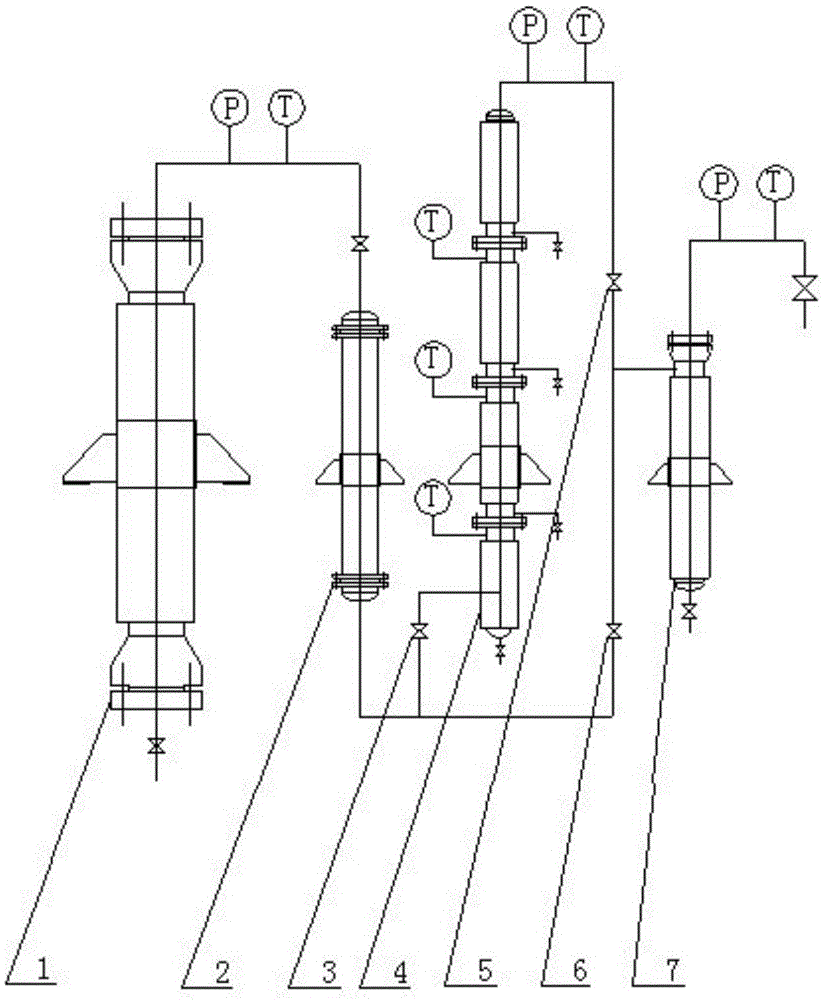

[0036] Such as figure 1 As shown, this embodiment provides a low-pressure supercritical CO 2 The system for extracting and separating ginger essential oil and ginger oleoresin rich in gingerol is arranged in sequence along the process path, including extraction device 1, heat exchange and heating device 2, rectification tower 4, and separation tower 7.

[0037] The extraction device 1 is provided with an extraction liquid outlet at the top and CO at the bottom. 2 Fluid injection port

[0038] The top of the heat exchange and temperature rise device 2 is connected with the extraction liquid outlet;

[0039] The bottom of the rectification tower 4 and the bottom of the heat exchange and temperature rise device 2 are connected through a first connecting pipe, and a first valve 3 is provided on the first connecting pipe;

[0040] The upper part of the separation tower 7 is provided with CO 2 Extraction liquid inlet and volatile light component inlet, with supercritical CO on the top 2 Flui...

Embodiment 2

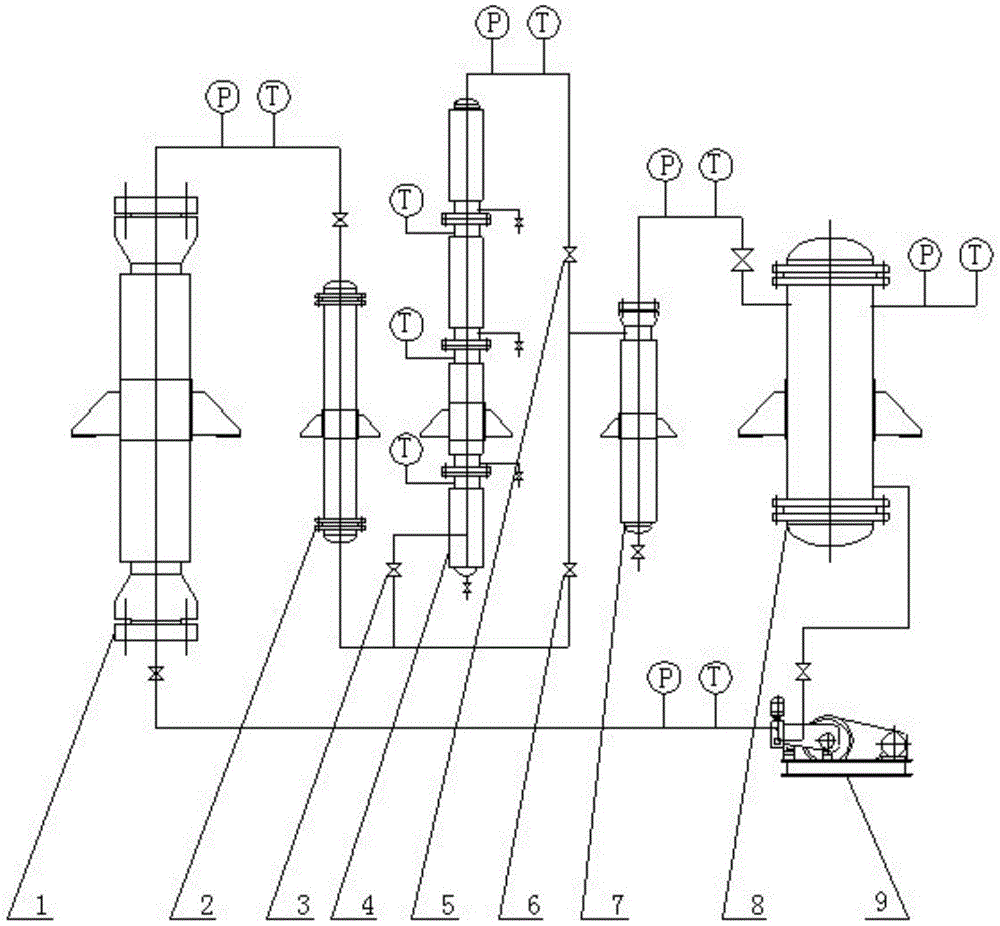

[0052] Such as figure 2 As shown, this embodiment provides another low-pressure supercritical CO 2 The system for extracting and separating ginger essential oil and ginger oleoresin rich in gingerol is arranged in sequence along the process path, including extraction device 1, heat exchange and heating device 2, rectification tower 4, separation tower 7, and buffer tank 8.

[0053] The extraction device 1 is provided with an extraction liquid outlet at the top and CO at the bottom. 2 Fluid injection port

[0054] The top of the heat exchange and temperature rise device 2 is connected with the extraction liquid outlet;

[0055] The bottom of the rectification tower 4 and the bottom of the heat exchange and temperature rise device 2 are connected through a first connecting pipe, and the first connecting pipe is provided with a first valve 3; the rectifying tower 4 is arranged in order from bottom to top The first rectification unit, the second rectification unit, the third rectificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com