CL-20 explosive crystal refinement method based on counter solvent ultrasonic extraction technology

An extraction technology and crystal refinement technology, which is applied in solvent extraction, solid solvent extraction, gaseous solvent extraction, etc., can solve the problems of high cost, harsh experimental conditions, unfavorable batch preparation, etc., and achieve good reproducibility and production high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

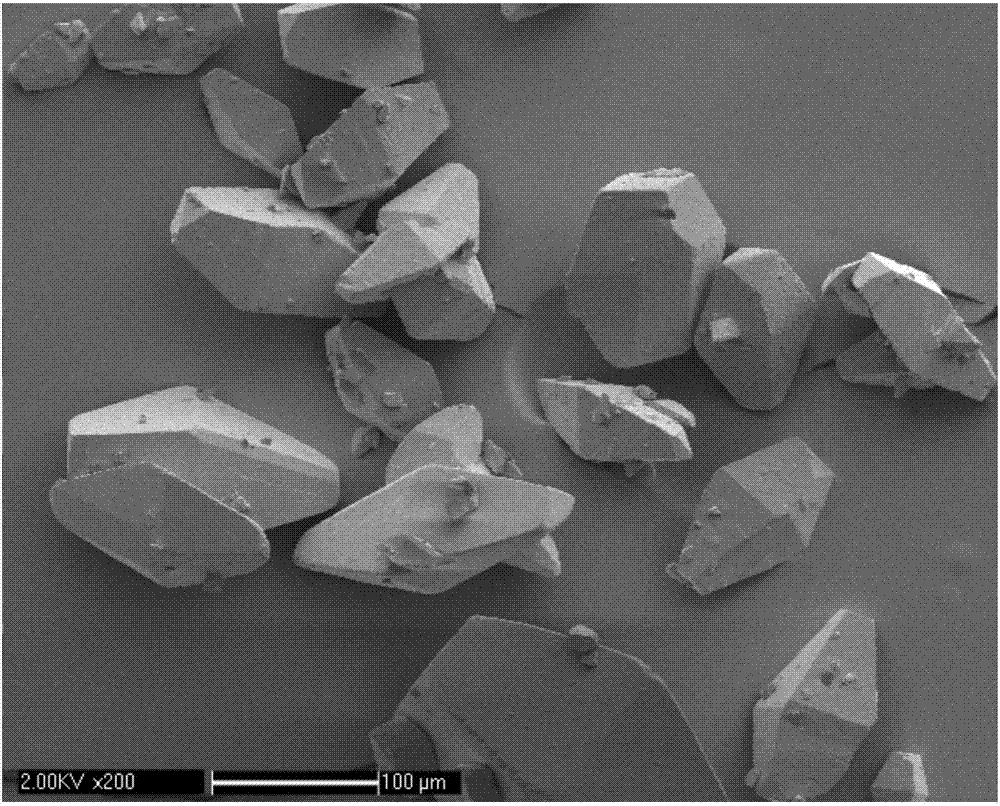

Embodiment 1

[0052] (1) Take 70ml of N,N-dimethylformamide (DMF) and place it in a 150ml three-neck flask, weigh 10g of CL-20 raw material and add it, heat it in a water bath to 90°C, and stir it mechanically until the crystals are completely dissolved. The solution was naturally cooled by the cooling crystallization method, and after crystallization for 1 h, it was filtered and washed to obtain CL-20 solvate crystals, about 12 g.

[0053] (2) XRD was used to characterize the phase of the solvate, and after confirming that all the obtained crystals were solvate, they were placed in an airtight container for use.

[0054] (3) The CL-20 solvate crystals are quickly added to 150ml of ethanol anti-solvent (the mass ratio of solvate to anti-solvent is about 1:10), and the solution is ultrasonically treated at the same time, and the ultrasonic power is 300W. For agglomeration, 0.02 g of sorbitan monooleate surfactant was added dropwise in the anti-solvent.

[0055] (4) After ultrasonication for...

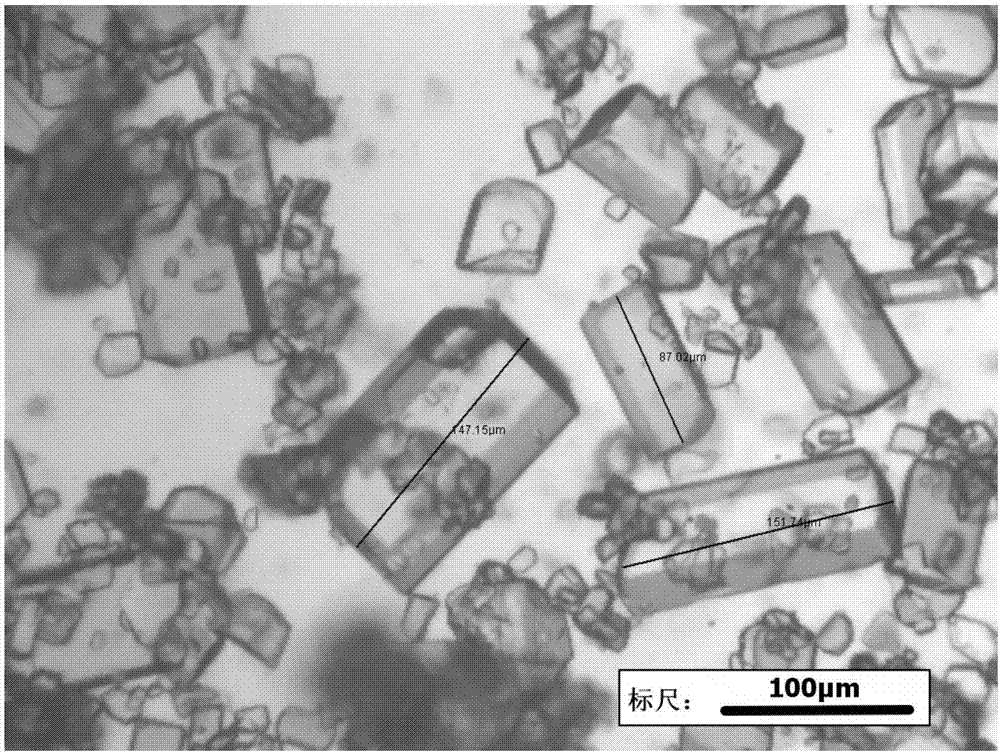

Embodiment 2

[0057] (1) Measure 120ml of dimethyl carbonate (DMC) into a 250ml rotary evaporating flask, weigh 10g of CL-20 raw material and add it, heat it in a water bath to 60°C, stir mechanically until the crystals are completely dissolved, and use the solvent evaporation method The solution was rotary evaporated, crystallized for 1 h, filtered and washed to obtain CL-20 / DMC solvate crystals.

[0058] (2) XRD was used to characterize the phase of the solvate, and after confirming that all the obtained crystals were solvate, they were placed in an airtight container for use.

[0059] (3) Quickly add CL-20 solvate crystals into 180ml of diethyl ether anti-solvent, and at the same time, ultrasonically treat the solution with an ultrasonic power of 700W. alcohol surfactants.

[0060] (4) After ultrasonication for 5 minutes, filter, wash, and dry, take a small amount of samples for XRD characterization to confirm that the solvent has been completely removed, and confirm that the refined CL...

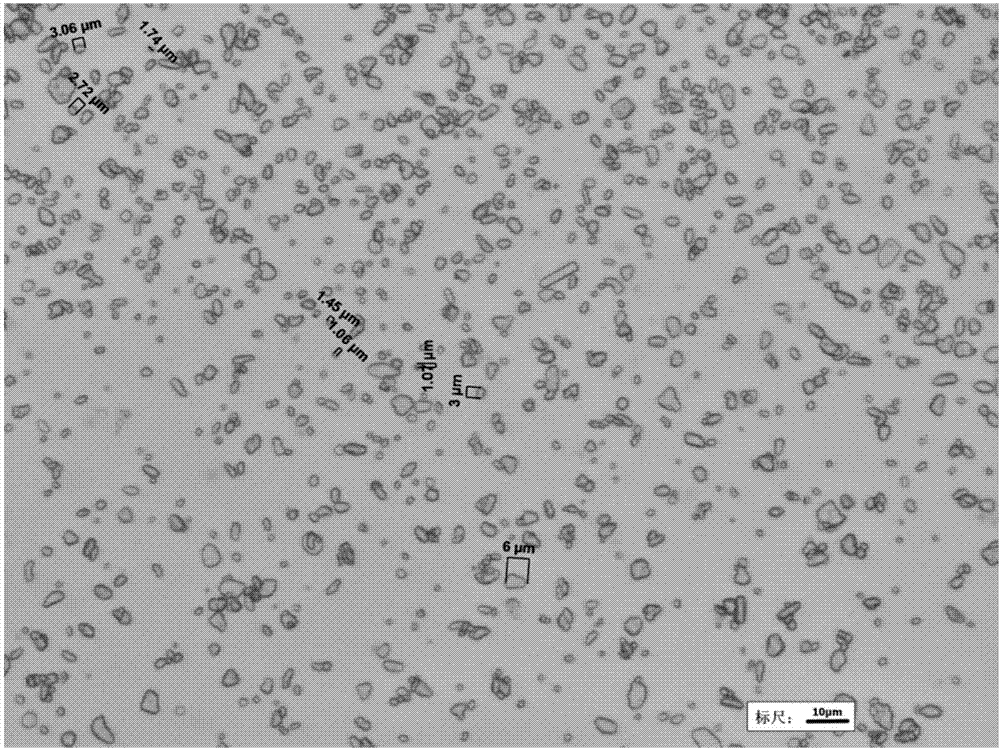

Embodiment 3

[0062] (1) Measure 30ml of dioxane (DIO) into a 250ml three-neck flask, weigh 10g of CL-20 raw material and add it. At room temperature (20°C), mechanically stir until the crystals are completely dissolved. Solvent method 100ml of deionized water was used as a non-solvent, added at a rate of 5ml / min, stirred for 1 hour to crystallize, filtered and washed to obtain CL-20 / DIO solvate crystals.

[0063] (2) XRD was used to characterize the phase of the solvate, and after confirming that all the obtained crystals were solvate, they were placed in an airtight container for use.

[0064] (3) CL-20 solvate crystals are quickly added in 150ml of n-heptane anti-solvent, and the solution is ultrasonically treated at the same time. The ultrasonic power is 100W. Vinylpyrrolidone surfactant.

[0065] (4) After ultrasonication for 30 minutes, filter, wash, and dry, take a small amount of samples for XRD characterization to confirm that the solvent has been completely removed, and confirm t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com