Device and method for extracting tobacco essence through superheated steam distillation

A technology of superheated steam and distillation device, applied in the field of tobacco chemistry, can solve the problems of reduced distillation effect, low yield of semi-volatile essential oil, reduced water vapor amount, etc. The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

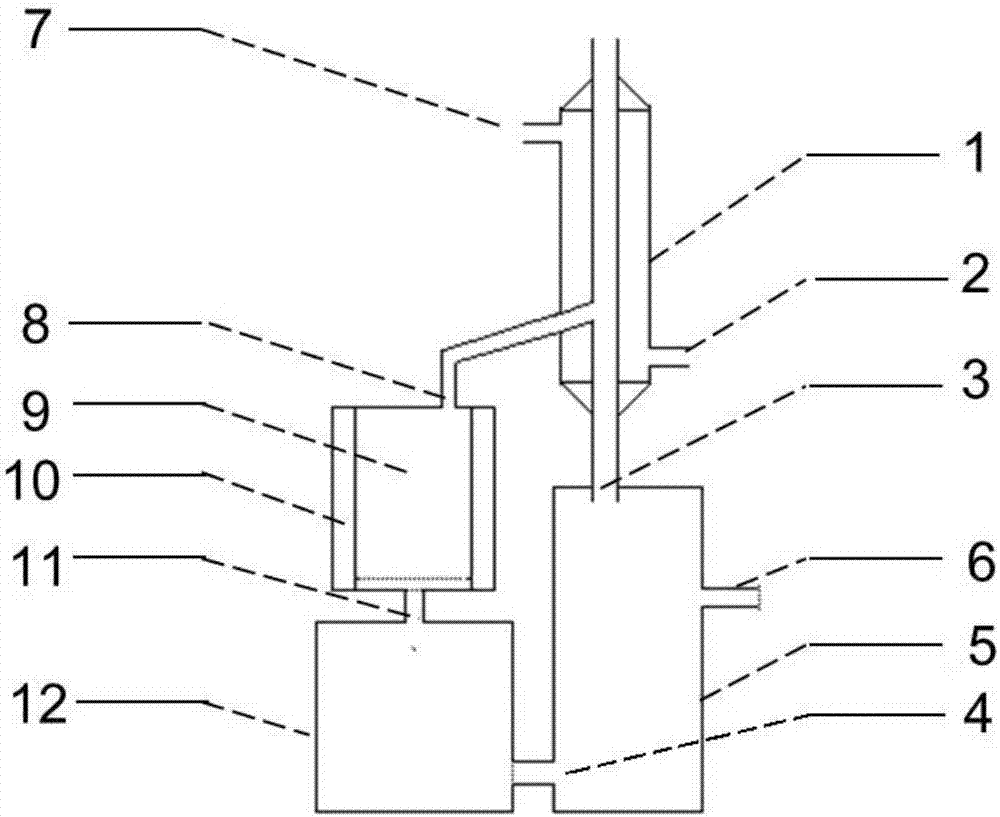

[0025] Such as figure 1 The shown device for extracting tobacco essential oil by superheated steam distillation includes an extraction tank 9 with a heating device 10 on its outer layer. 11 through the upper port of the hot water steam generating device 12;

[0026] The oil-water separator 5, its upper port communicates with the lower port of the condensation pipe 1 through the condensate outlet 3, wherein the upper part communicates with the upper part of the superheated steam generator 12 through the water outlet 4, and the lower part has an oil outlet 6.

[0027] The outer layer heating device 10 of the extraction tank 9 is a water vapor heating interlayer.

[0028] The outer layer of the condensation pipe 1 is a condensed water interlayer, the condensed water inlet 2 is arranged at the lower part of the condensed water interlayer, and the condensed water outlet 7 is arranged at the upper part.

[0029] The volume of the extraction tank 9 is 50-100L.

[0030] The working...

Embodiment 2

[0032] Using the superheated steam generating device in Example 1 to extract the volatile components in the tobacco, the specific steps are as follows:

[0033] 10kg of tobacco leaves are ground into tobacco powder with a pulverizer, put into a 100L extraction tank, add 1L of 5wt% citric acid aqueous solution (effect: the tobacco leaves contain a large amount of volatile nicotine and other alkaline substances, if extracted, Will affect the quality of volatility, citric acid is combined with alkaline substances to become ionic compounds, less volatile, and denser than water), and then extracted with water vapor in a superheated steam generating device. The condensed water inlet of the condenser pipe is fed with cold water, and the water vapor heating interlayer of the extraction tank is fed with water vapor. After the volatile components extracted by the water vapor are condensed by the condenser pipe, the water vapor becomes liquid water and enters the oil and water together wi...

Embodiment 3

[0035] Use the superheated steam generating device among the embodiment 1 to extract the volatile components in the Radix Glycyrrhizae, concrete steps are as follows:

[0036] Put 5 kg of licorice powder into a 50L extraction tank, then extract it with the water vapor in the superheated steam generating device, the condensed water inlet of the condensation pipe is fed with cold water, and the water vapor heating interlayer of the extraction tank is passed into water vapor, and the water vapor After the extracted volatile components are condensed by the condenser tube, the water vapor turns into liquid water and enters the oil-water separator together with the volatile components. After being separated by the oil-water separator, the water re-enters the superheated steam generator through the water outlet, and the water is obtained. Recycling; the extraction time is 1 to 3 hours. After the extraction is completed, the oily component released from the oil outlet at the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com