Factory circulating water fish culture system and using method thereof

A technology of circulating water and industrialization, applied in fish farming, application, animal husbandry, etc., can solve the problems of advanced, practical and economical incompatibility, high operating cost, hindering development, etc., and achieve low operating cost. , less mechanical power equipment, solving the effect of advanced nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing, the present invention will be further described.

[0055] A factory-like circulating water fish farming system,

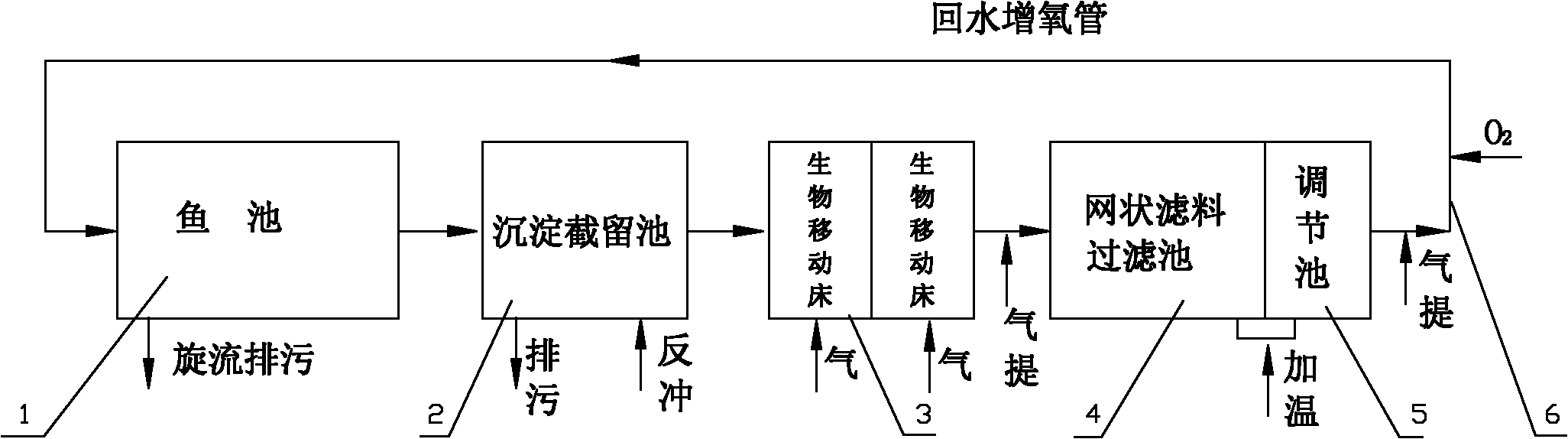

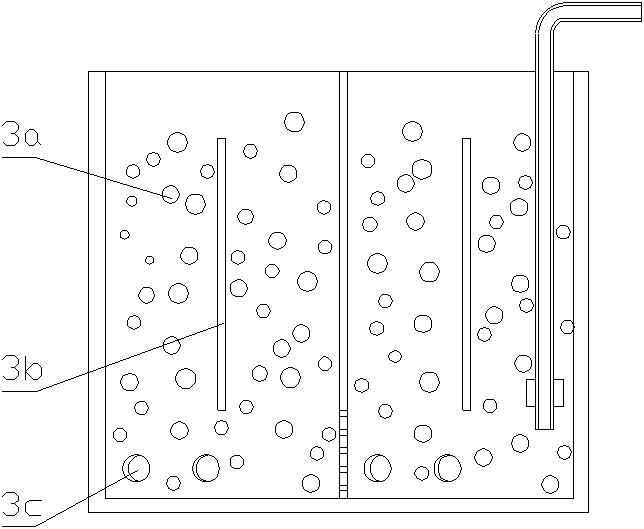

[0056] The circulating water fish farming system includes a fish pond 1, a sediment retention pond 2, a biological moving bed 3, a mesh filter pond 4, a regulating pond 5 and a backwater of the same width from front to back, and the same height of the top of the pond. The aeration tube 6 consists of six parts;

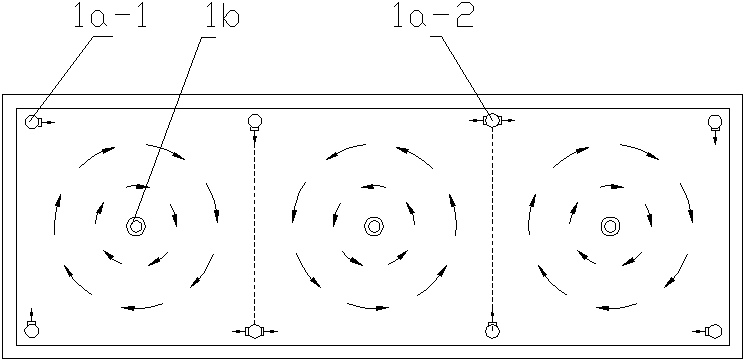

[0057] The fish pond 1 is a rectangular structure, the length is N times the width, and N units are formed. At the bottom of the center of each unit of the fish pond 1, a sewage collection outlet 1b is opened, and water spray pipes 1a are vertically arranged at the four corners of each unit. There are 6-9 nozzles evenly distributed on the spray pipe from the water surface to the bottom of the pool. The nozzles are divided into one-way nozzles 1a-1 and 180-degree two-way nozzles 1a-2. The configuration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com