Machine vision-based overprint error detection method

An error detection and machine vision technology, applied in instruments, image data processing, calculation, etc., can solve the problems of large amount of calculation and large positioning mark overlap detection error, and achieve simple calculation method, cost saving, fast and effective positioning mark center Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

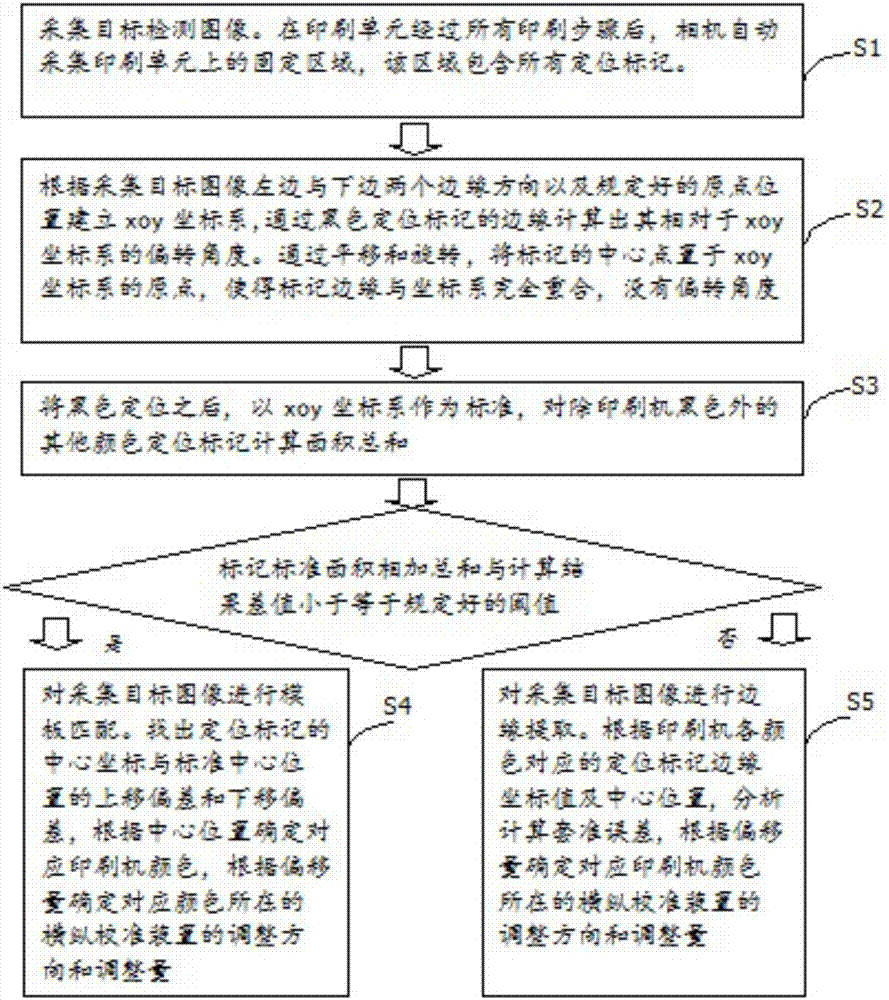

[0027] Such as figure 1 As shown, this embodiment provides a method for detecting overprint errors based on machine vision, which specifically includes the following steps:

[0028] s1 collects target detection images. After a printing unit has passed through all printing steps, the camera automatically captures a fixed area on the printing unit that contains all positioning marks.

[0029] s2 establishes the xoy coordinate system according to the left and bottom edge directions of the collected target image and the specified origin position, and calculates its deflection angle relative to the xoy coordinate system through the edge of the black positioning mark. By translation and rotation, the center point of the mark is placed at the origin of the xoy coordinate system, so that the edge of the mark coincides completely with the coordinate system, and there is no deflection angle;

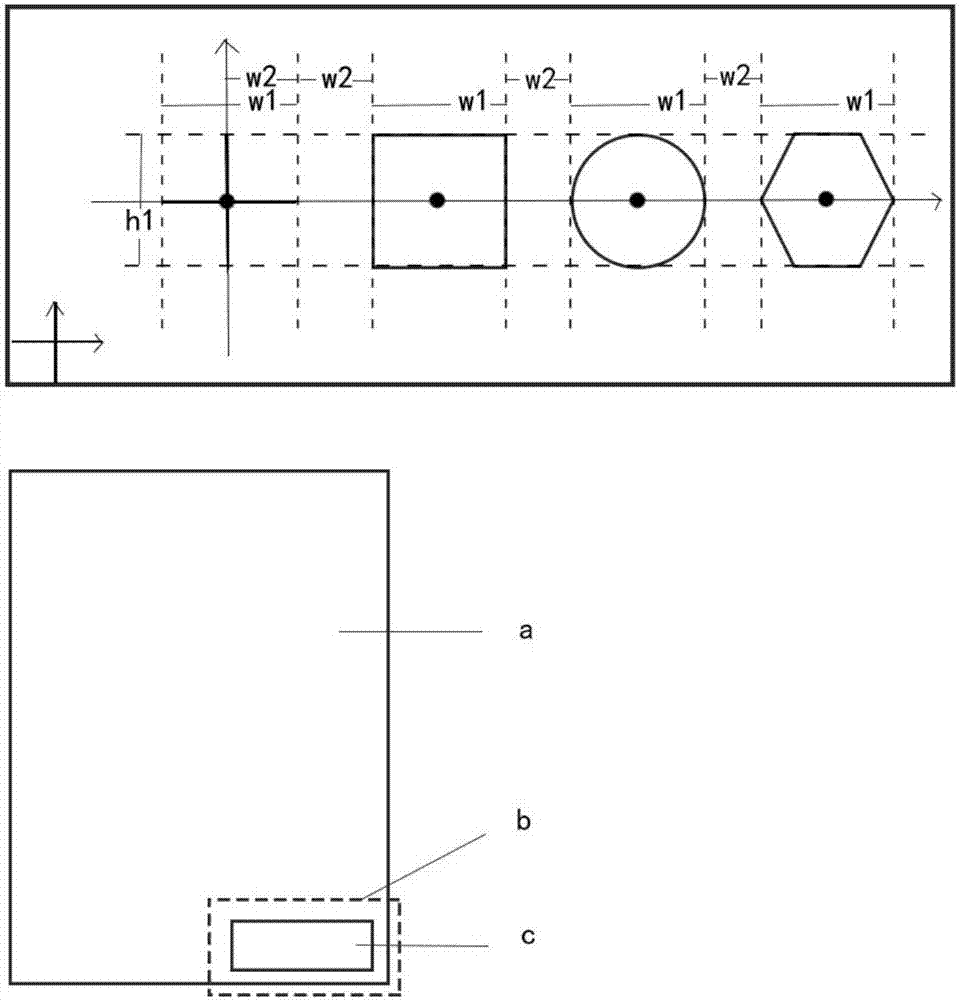

[0030] Specifically, taking a four-color printing machine as an example, figure 2 It is a ...

Embodiment 2

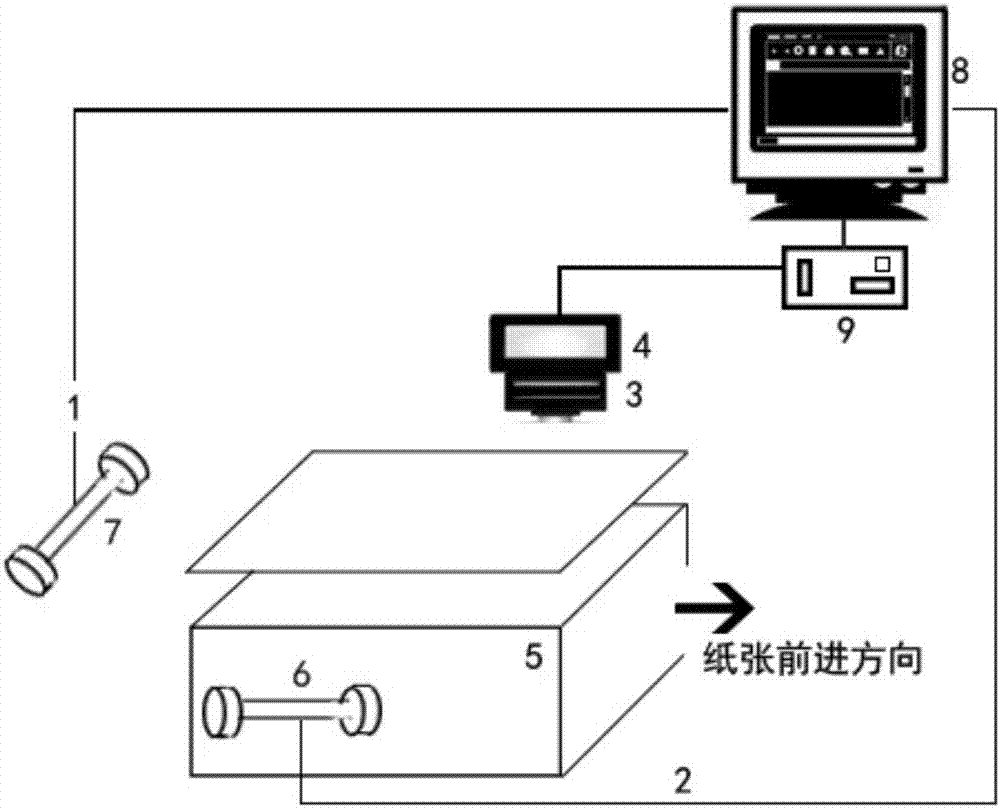

[0041] Such as image 3 As shown, this embodiment provides an overprint error detection device based on machine vision, which is suitable for automatic overprint error detection and calibration using the overprint error detection method in the above-mentioned embodiment 1, including an industrial computer 8, which is installed with Overprint error detection system, to realize the processing procedure of embodiment 1;

[0042] It also includes a black and white linear array CCD camera 3 for image acquisition, an LED light source 4 for lighting, a four-color printing machine 5, a horizontal calibration device 6 and a vertical calibration device 7;

[0043] The horizontal calibration 6 and the vertical calibration device 7 are connected to the industrial computer 8, and the calibration devices 6 and 7 are installed on the printing press 5 to calibrate printing according to the returned overprint error;

[0044] Also comprises board 9, described LED light source 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com