Capacitor testing device and capacitor testing method

A testing device and capacitor technology, applied in the field of capacitors, can solve the problem of inability to record the power-on test time, voltage drop, current, inductance, DC resistance and reactance temperature historical data of the capacitor under test, and inability to generate a very intuitive capacitance performance curve graph. Qualified products output alarm and other problems to achieve the effect of eliminating resonance, eliminating influence and improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

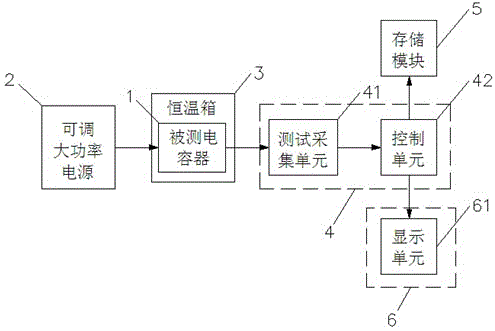

[0045] see figure 1 , as shown in the legend therein, a capacitor testing device for performance testing of the capacitor under test 1, including:

[0046] A power supply module, including an adjustable high-power power supply 2, the adjustable high-power power supply 2 is connected to the capacitor under test 1 and provides a working voltage for the capacitor under test 1;

[0047] A constant temperature box 3, the temperature of which is adjustable and used to place the measured capacitor 1;

[0048] A test module 4 includes a test acquisition unit 41 and a control unit 42, the test acquisition unit 41 connects the capacitor under test 1 and collects the voltage value, current value and temperature value of a plurality of groups of capacitor under test 1; the control unit 42 connects the test acquisition The unit 41 receives and calculates the capacity values of multiple sets of measured capacitors 1, and draws the temperature characteristic curve, withstand voltage chara...

Embodiment 2

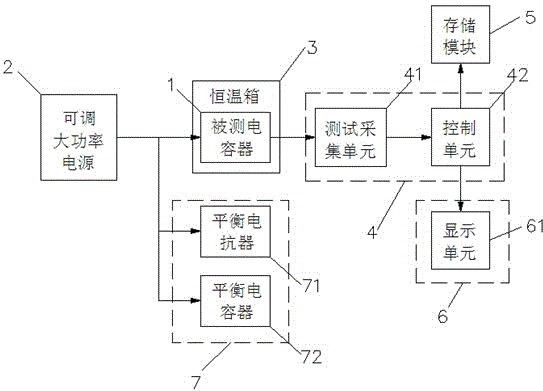

[0073] see figure 2 , as shown in the legend therein, the rest are the same as the first embodiment, the difference is that the above-mentioned test device also includes a current for eliminating the influence of the action of the capacitor under test 1 on the adjustable high-power power supply 2 The balance module 7 , the current balance module 7 includes a balance reactor 71 and a balance capacitor 72 , the balance reactor 71 and the balance capacitor 72 are respectively arranged in parallel with the measured capacitor 1 and connected to the adjustable high-power power supply 2 .

[0074] By setting the balance reactor 71 and the balance capacitor 72, the system current can be balanced, resonance can be eliminated, and the influence of the action of the measured capacitor 1 on the adjustable high-power power supply 2 can be eliminated.

Embodiment 3

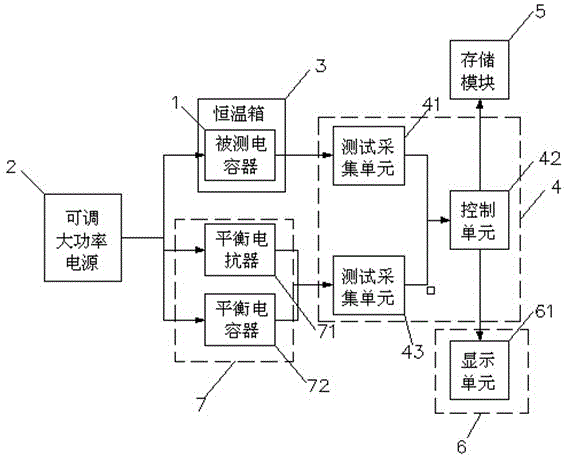

[0076] see image 3 , as shown in the legend therein, the rest are the same as those in Embodiment 2, the difference is that the test module 4 also includes a monitoring acquisition unit 43, and the monitoring acquisition unit 43 is respectively connected to the adjustable high-power power supply 2 and the balance reactor 71 And balance capacitor 72 and collect the voltage value, current value and temperature value of adjustable high-power power supply 2, balance reactor 71 and balance capacitor 72; Control unit 42 connects monitoring acquisition unit 43 and receives adjustable high-power power supply 2, balance reactance The voltage value, current value and temperature value of the reactor 71 and the balance capacitor 72; the display unit 61 is connected to the control unit 42 and displays the voltage value, current value and temperature value of the adjustable high-power power supply 2, the balance reactor 71 and the balance capacitor 72.

[0077] By arranging the monitoring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com