Modularization positioning fixture and positioning fixture assembly

A positioning fixture and modular technology, applied in the direction of manufacturing tools, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of abnormal wear, deformation, long processing cycle and design cycle of sealing rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

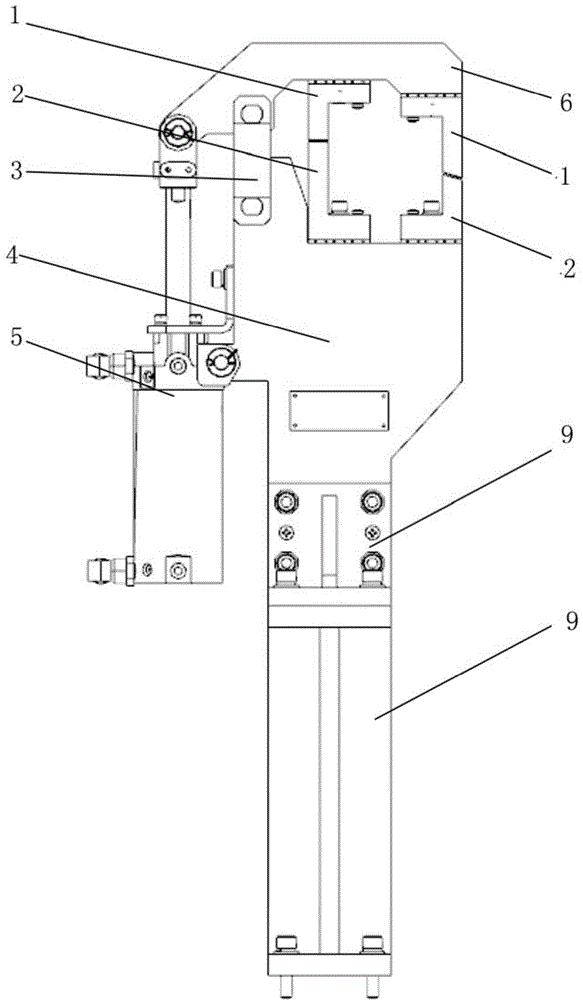

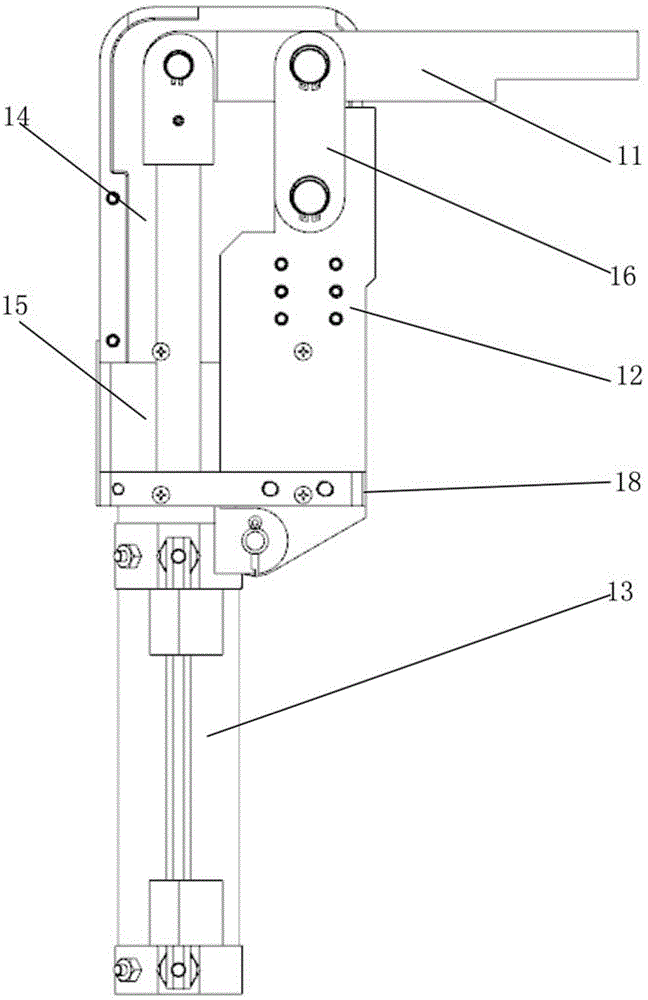

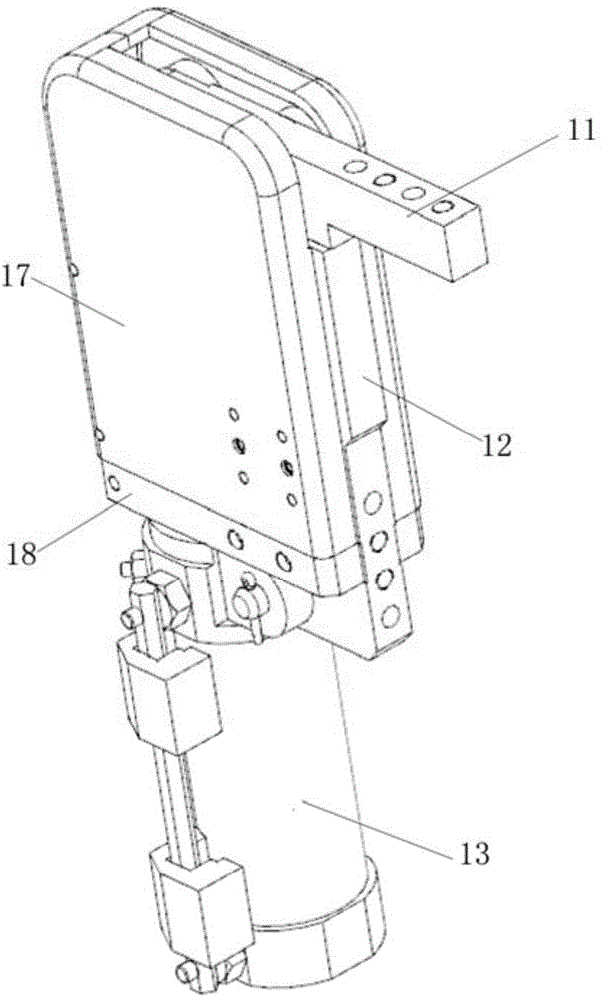

[0036] The following with attached Figure 1 to Figure 6 A modular positioning fixture and a positioning fixture assembly of the present invention will be further described in detail.

[0037] A modular positioning fixture of the present invention, please refer to Figure 1 to Figure 6, comprising a pressure head 11, a first connecting plate 12, a first clamping cylinder 13 and a dust cover 14, one end of the pressure head 11 is hinged to the front end of the extension rod of the first clamping cylinder 13, the pressure The middle part of the head 11 is hinged with the first connecting plate 12 , and the dust cover 14 is arranged around the outer periphery of the protruding rod of the first clamping cylinder 13 . In this way, the protruding rod of the first clamping cylinder 13 stretches out or retracts, driving the ram 11 hinged thereto to move, and the ram 11 moves between the first clamping cylinder 13 and the first connecting plate 12 hinged thereto. Press down or lift u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com