Semiconductor structure and forming method thereof

A technology of semiconductor and dry etching, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as sidewall 33 damage, uneven mask layer thickness, and affect the quality of fins, so as to avoid The effect of excessive thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] As mentioned in the background art, the performance of the semiconductor structure formed in the prior art still needs to be further improved.

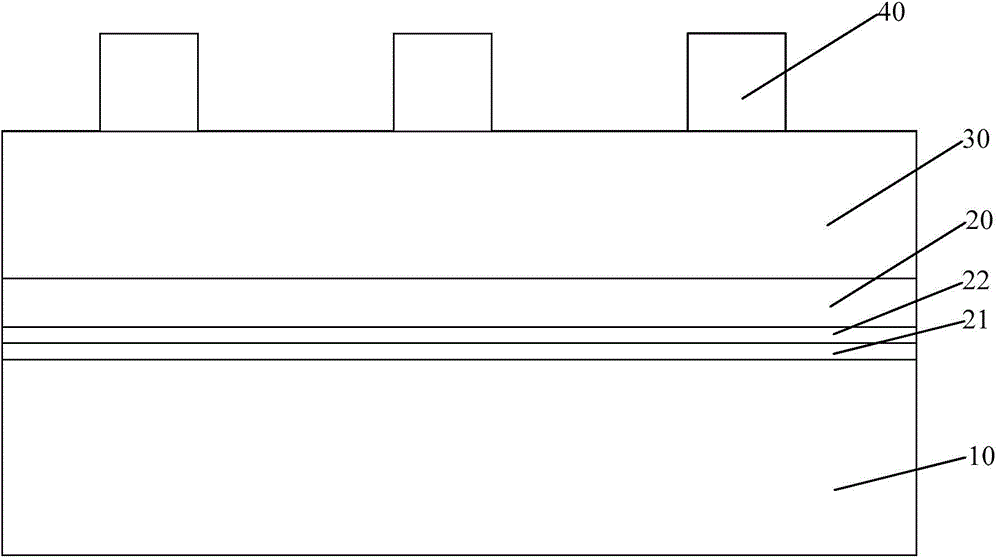

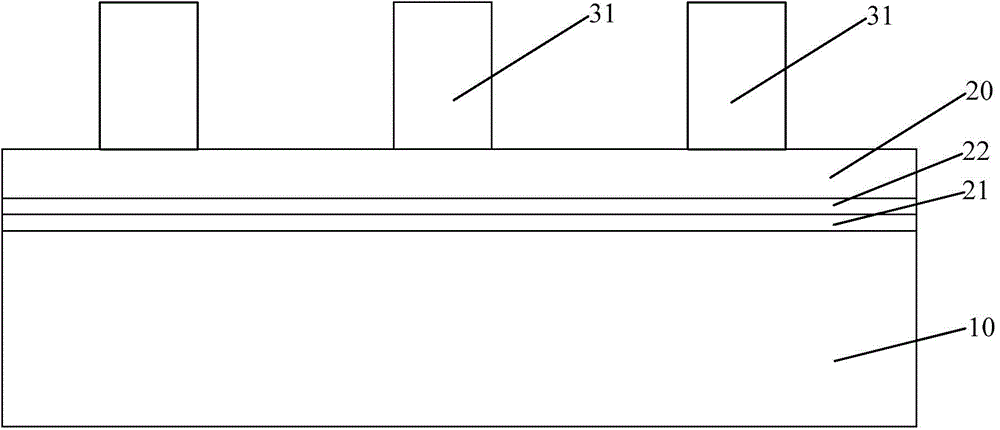

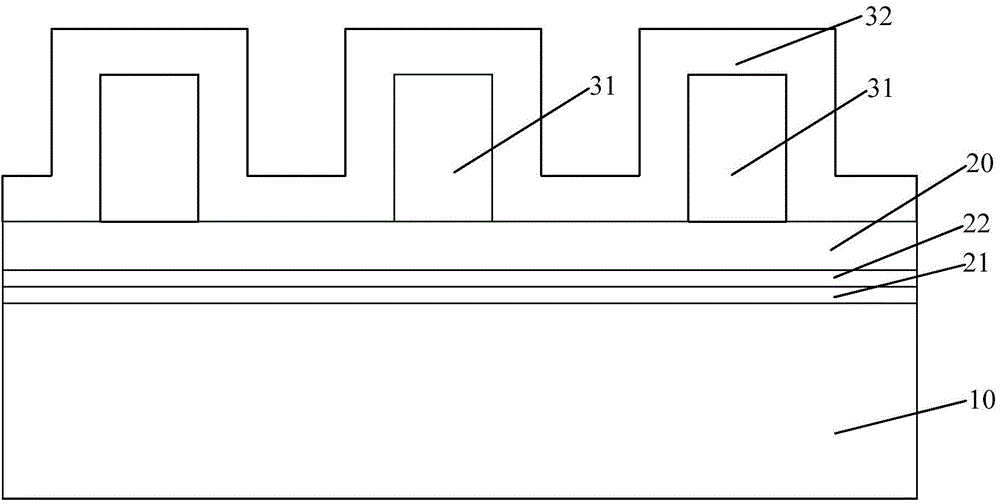

[0044] Research has found that in the actual process, the sacrificial layer 31 (please refer to Figure 4 ) is generally made of materials that are easier to remove such as amorphous carbon or polysilicon layer. When the material of the sacrificial layer 31 is amorphous carbon, the etching selectivity of the amorphous carbon and silicon oxide is relatively low, and in the process of removing the sacrificial layer 31, it is easy to cause damage to the silicon oxide layer 20 (please refer to Image 6 ), so that the thickness of the mask layer is not uniform.

[0045] Please refer to Figure 7 , using the sidewall 33 as a mask to etch the mask layer and the semiconductor substrate 10 to form the fin portion 11 . Due to the non-uniform thickness of the mask layer, the finally formed fins 11 have non-uniform heights. Thus affec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com