Patents

Literature

41results about How to "Realize automated construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

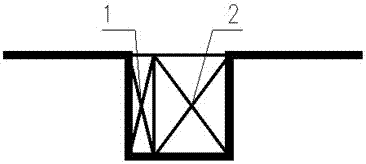

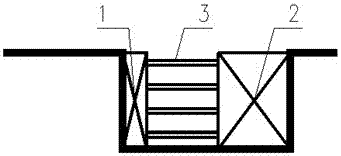

Tunneling and assembling structure and construction method of comprehensive pipe gallery

ActiveCN104912101ARealize integrated constructionRealize automated constructionArtificial islandsExcavationsArchitectural engineeringUtility tunnel

The invention relates to a tunneling and assembling structure and a construction method of a comprehensive pipe gallery. According to the construction method, shield backrest equipment is arranged at the first end of a foundation pit, a U-shaped shield mechanism is arranged at the second end of the foundation pit, and a middle part is arranged between the shield backrest equipment and the U-shaped shield mechanism. The middle part comprises an expanded jack or a combination of the expanded jack and one or more prefabricated pipe gallery sections, or a section of pit slot or a combination of the section of pit slot and one or more one or more prefabricated pipe gallery sections, or one or more prefabricated pipe gallery sections. The tunneling and assembling structure and the construction method of the comprehensive pipe gallery have the advantages that construction efficiency and economic efficiency of the comprehensive pipe gallery are improved effectively.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

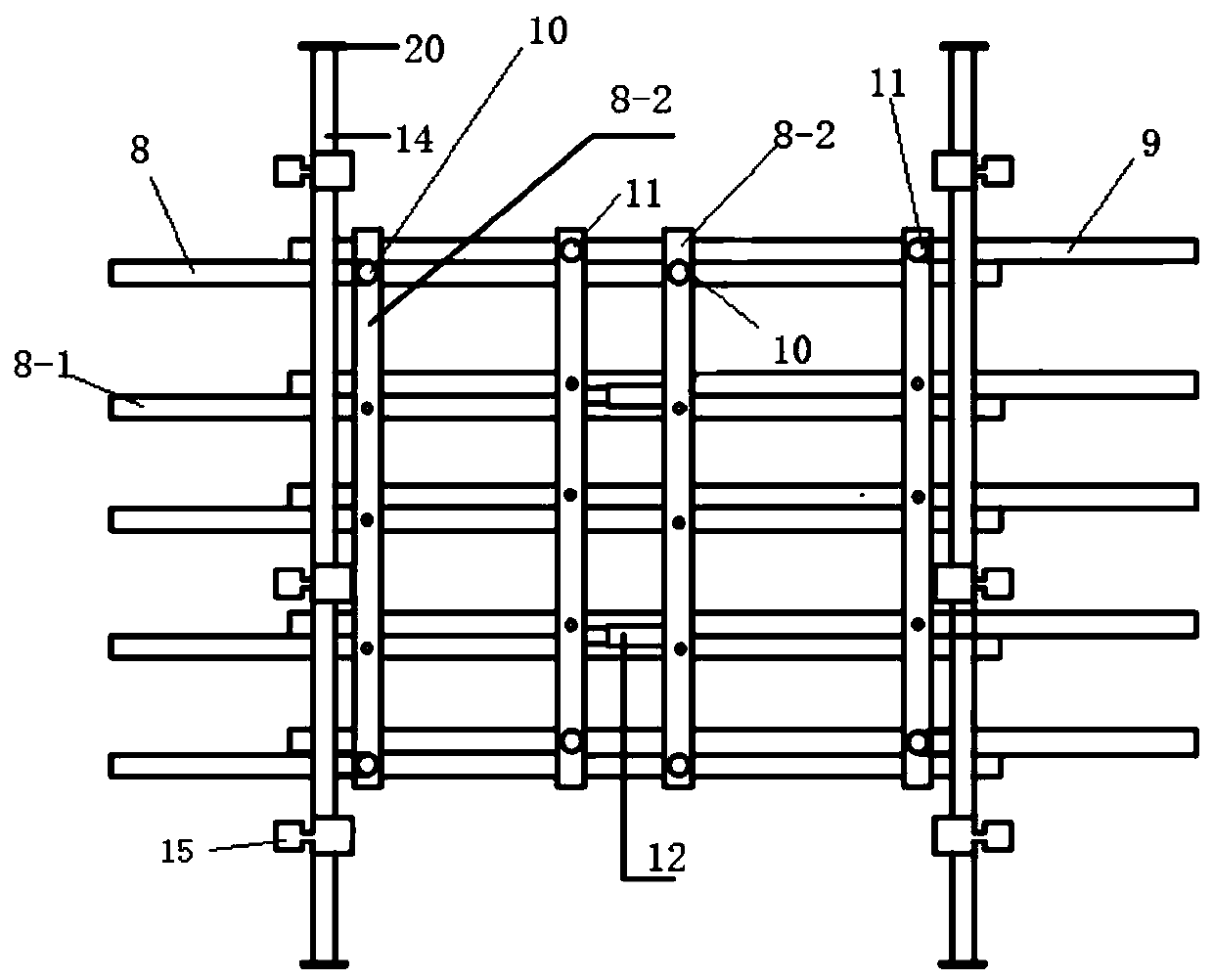

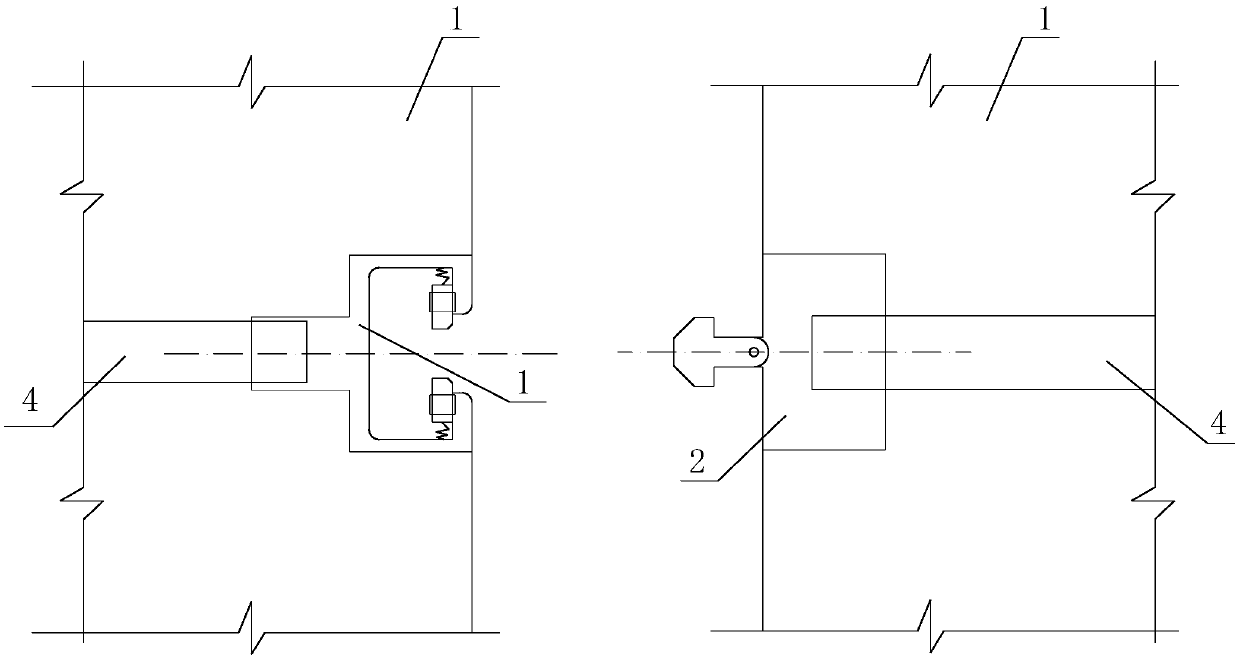

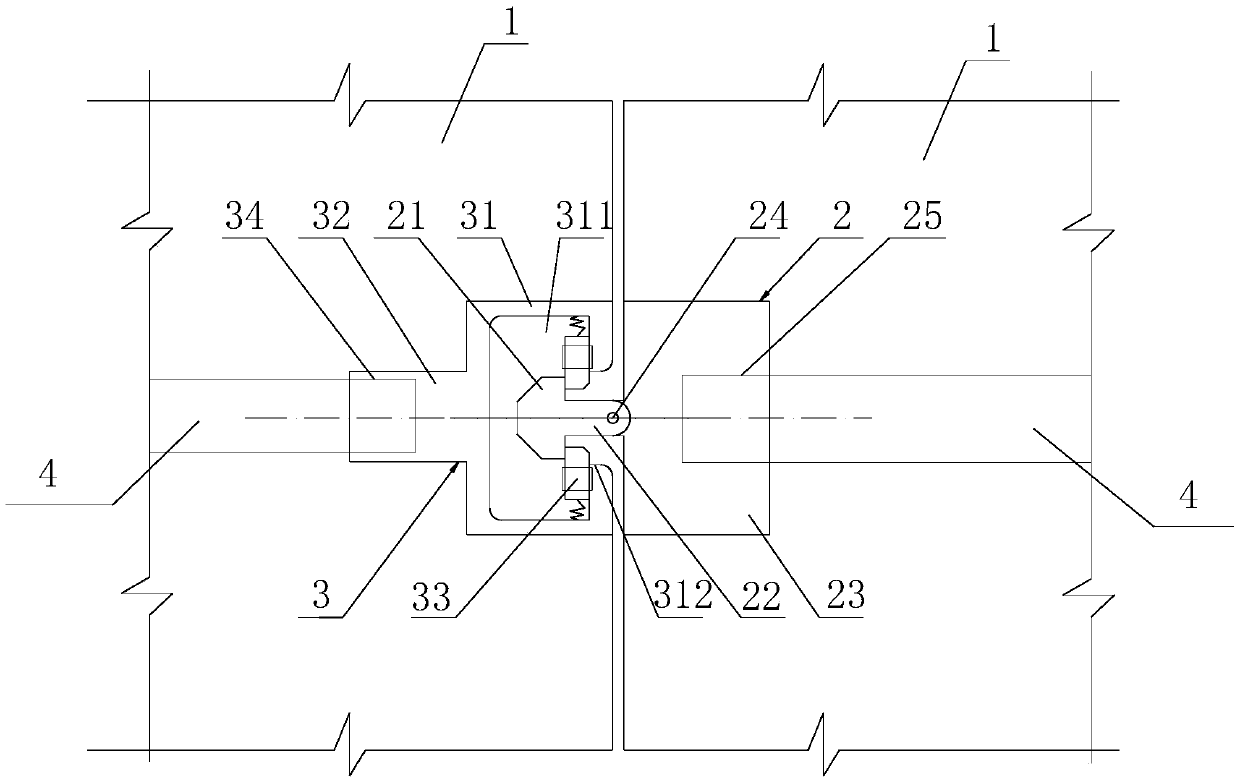

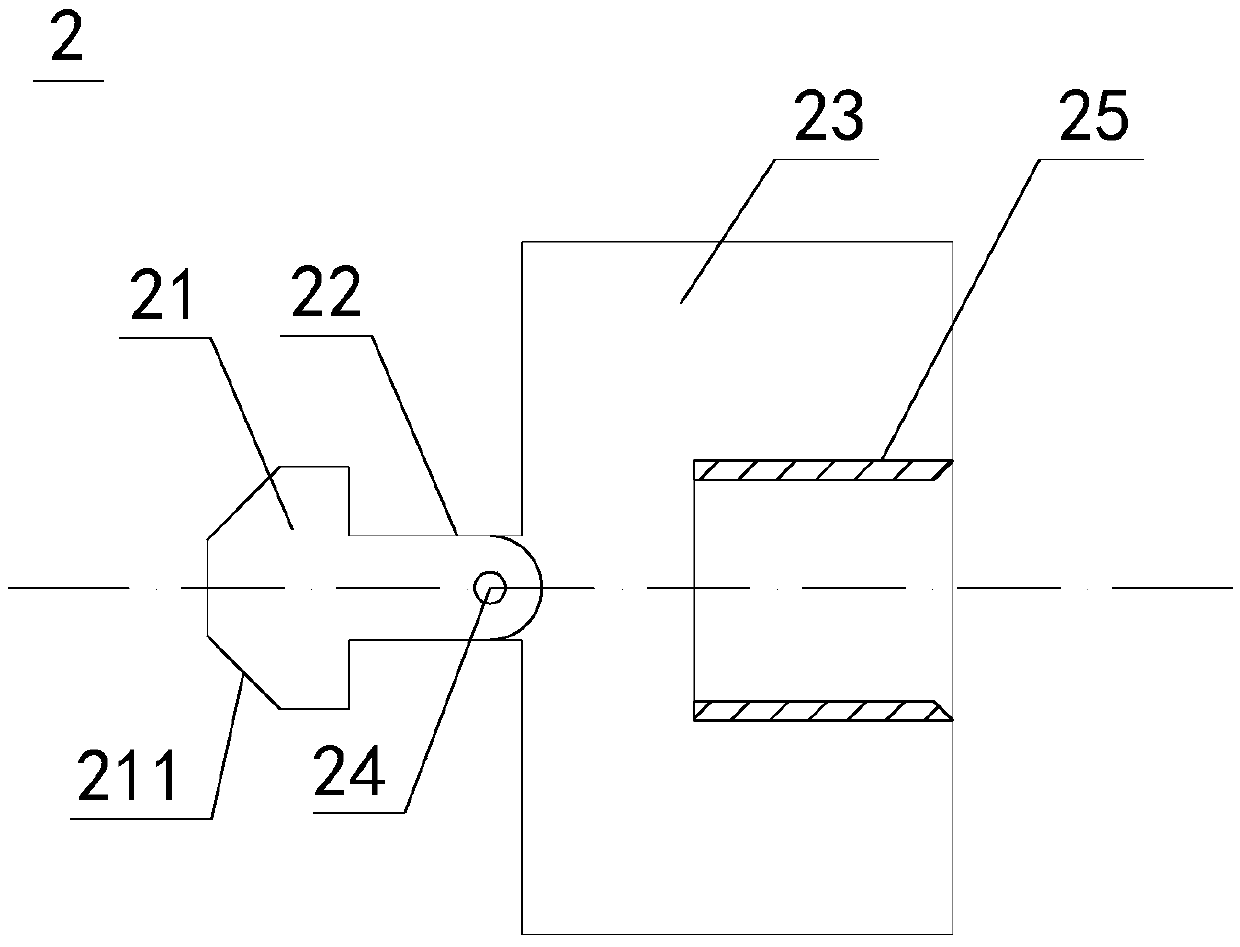

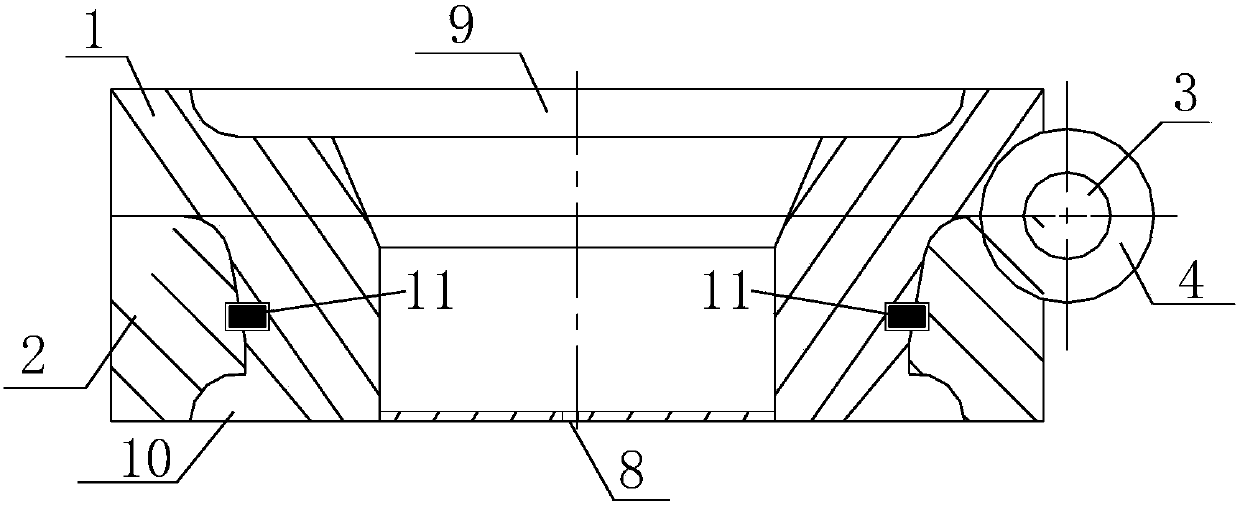

Segment longitudinal seam connecting assembly, tunnel segment structure and construction method

ActiveCN105484764ACapable of toleranceEasy connection and constructionUnderground chambersTunnel liningButt jointEngineering

The invention discloses a segment longitudinal seam connecting assembly, a tunnel segment structure and a construction method. The segment longitudinal seam connecting assembly comprises a longitudinal seam male part and a longitudinal seam female part, wherein the longitudinal seam male part comprises a gradient section cylinder, a connecting plate and a base, one end of the connecting plate is fixedly connected to the side face of the gradient section cylinder, and the other end of the connecting plate is connected with the base; the longitudinal seam female part comprises a front section and a rear section, a gradient section cylindrical cavity matched with the gradient section cylinder is formed in the front section, a through hole matched with the connecting plate in shape and size and communicated with the gradient section cylindrical cavity is formed in one end, away from the rear section, of the front section, the longitudinal seam female part is wholly pre-buried into a segment, a groove capable of containing the longitudinal seam male part is formed in the segment, and the longitudinal seam female part is located at one side of the groove. The tunnel segment structure has certain tolerance capacity, is adaptive to construction environment and capable of achieving simultaneous butt joint of segments in the longitudinal and circumferential directions, and has the advantages of being fast and convenient to construct and easy to construct automatically.

Owner:SHANGHAI CONSTRUCTION GROUP

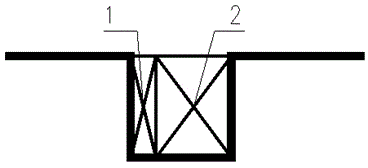

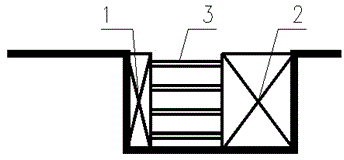

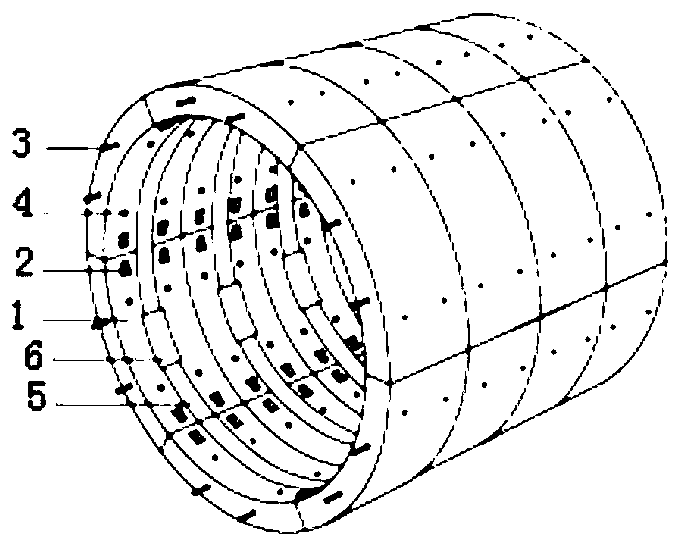

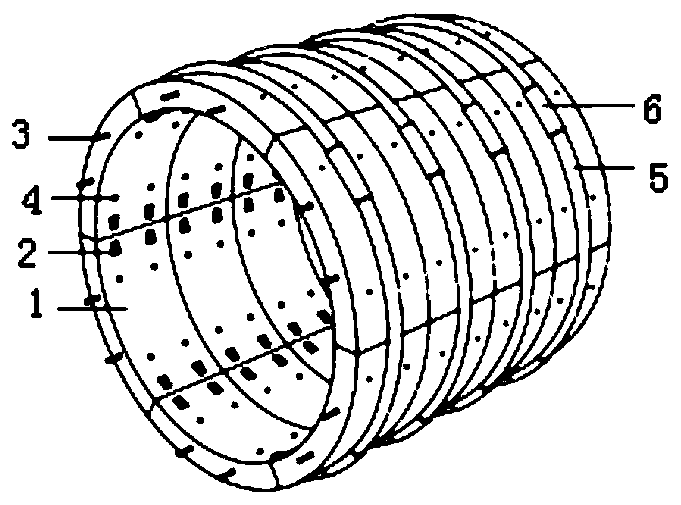

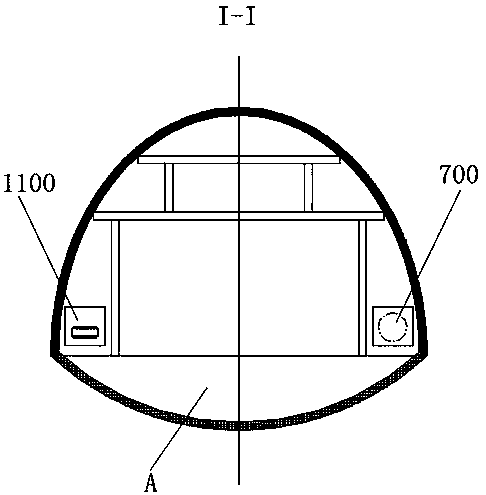

Composite supporting structure, construction system and method

ActiveCN111425216AImprove support strengthRealize automated constructionUnderground chambersMine roof supportsArchitectural engineeringPipe

The invention relates to a composite supporting structure, and a construction system and method. The composite supporting structure comprises a plurality of arc plate rings which are longitudinally arranged along a roadway, wherein a steel pipe concrete ring is arranged on the inner side surface or the outer side surface of each arc plate ring; each arc plate ring is formed by splicing a pluralityof arc plates; each steel pipe concrete ring is formed by splicing a plurality of steel pipes in a segmented manner; and the arc plate rings and the steel pipe concrete rings can jointly support thewall of the roadway. The supporting structure is high in bearing capacity, and the construction system is high in construction efficiency and low in labor intensity.

Owner:SHANDONG JIANZHU UNIV +1

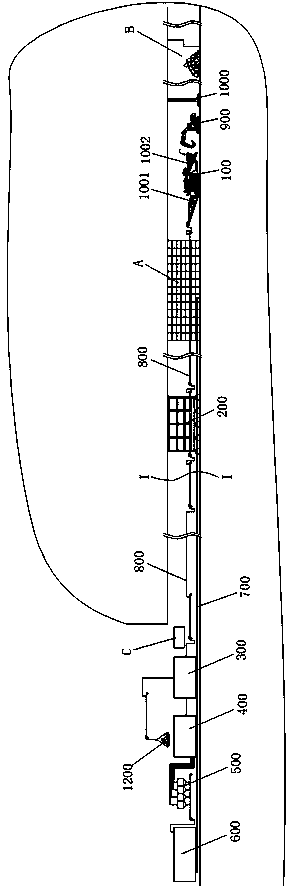

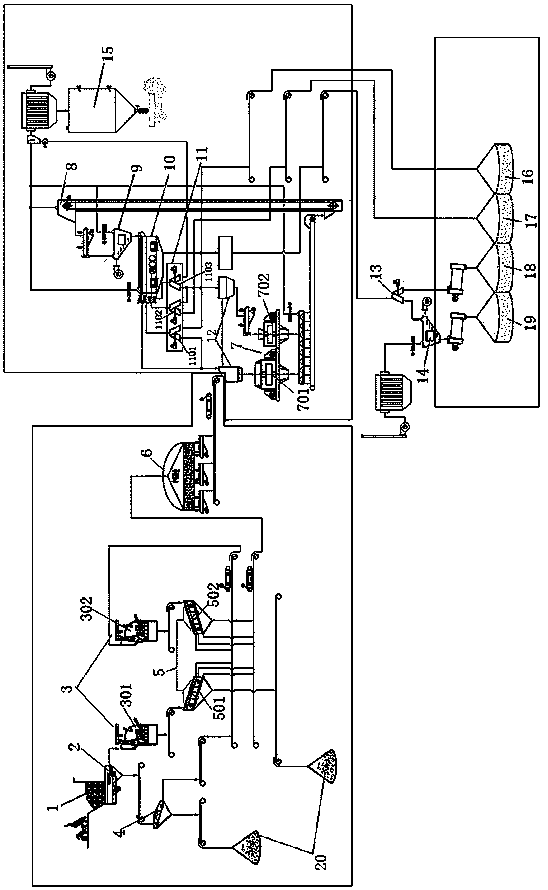

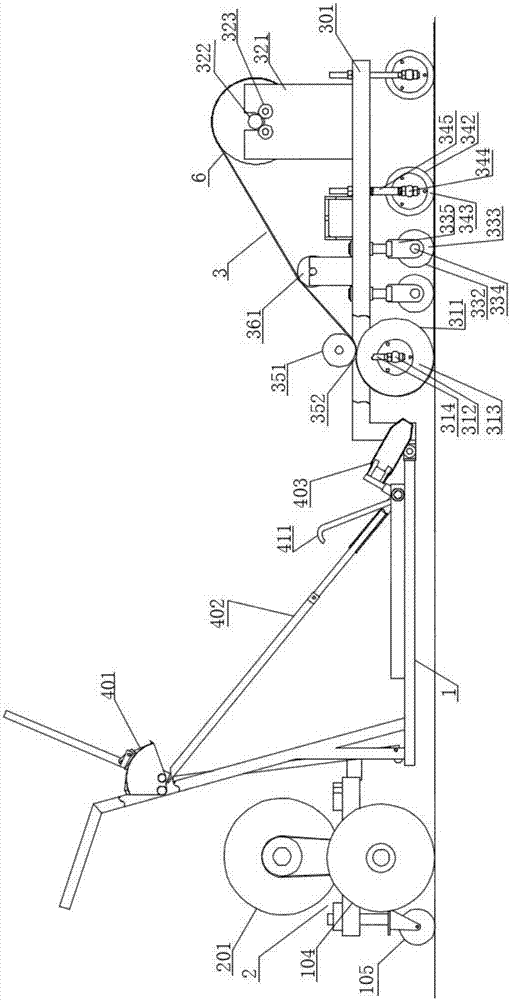

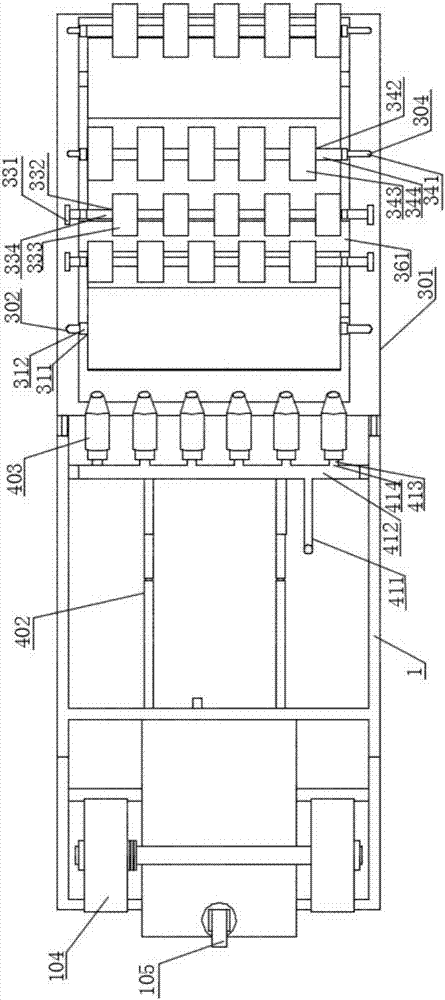

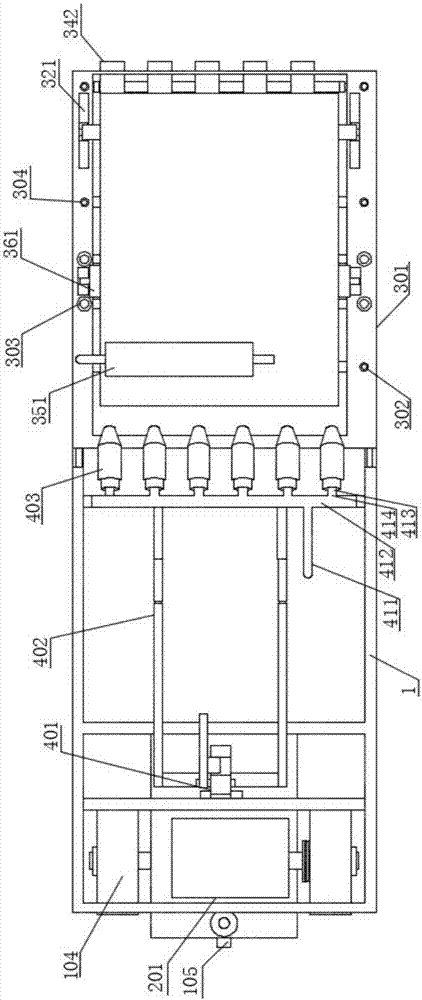

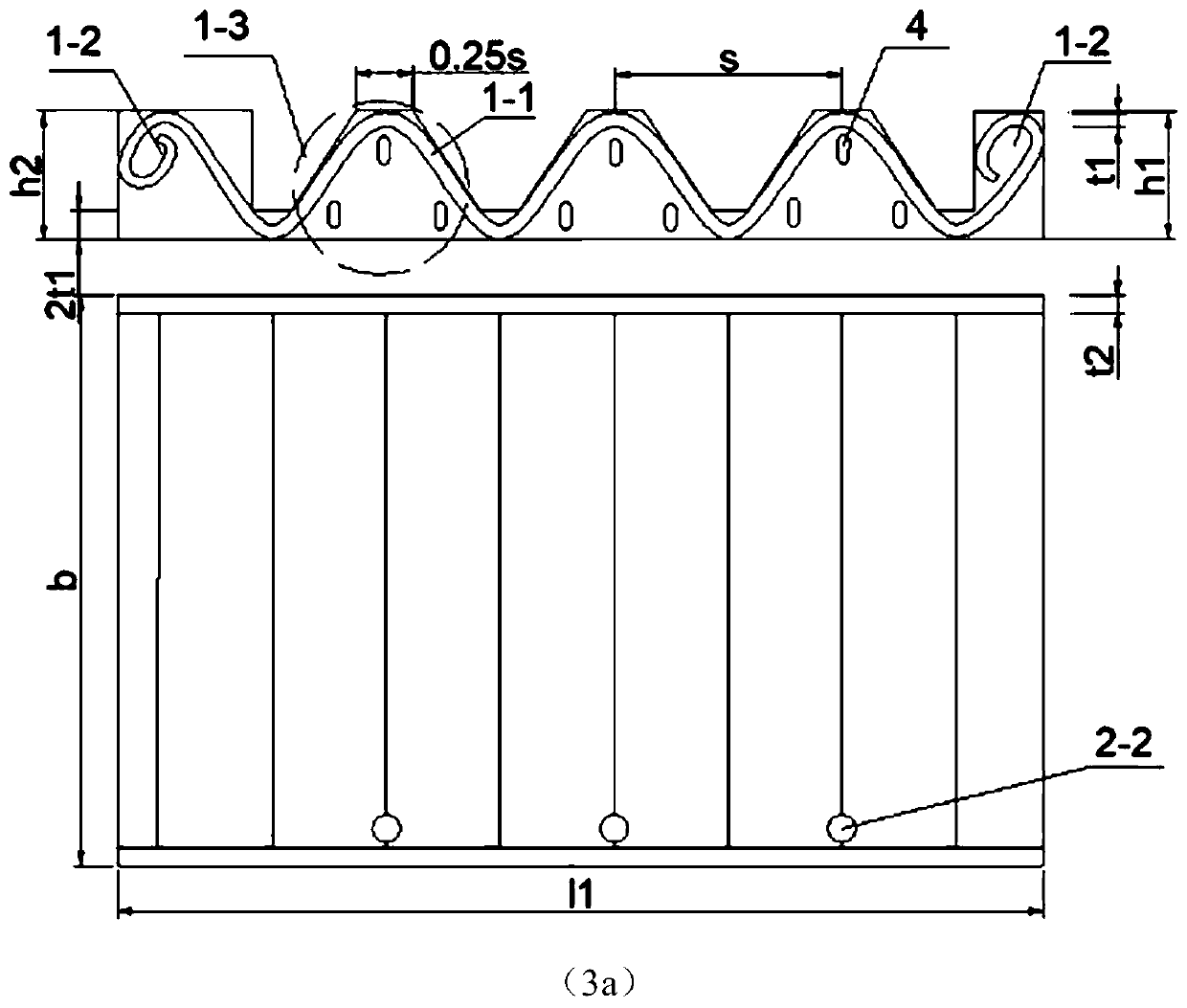

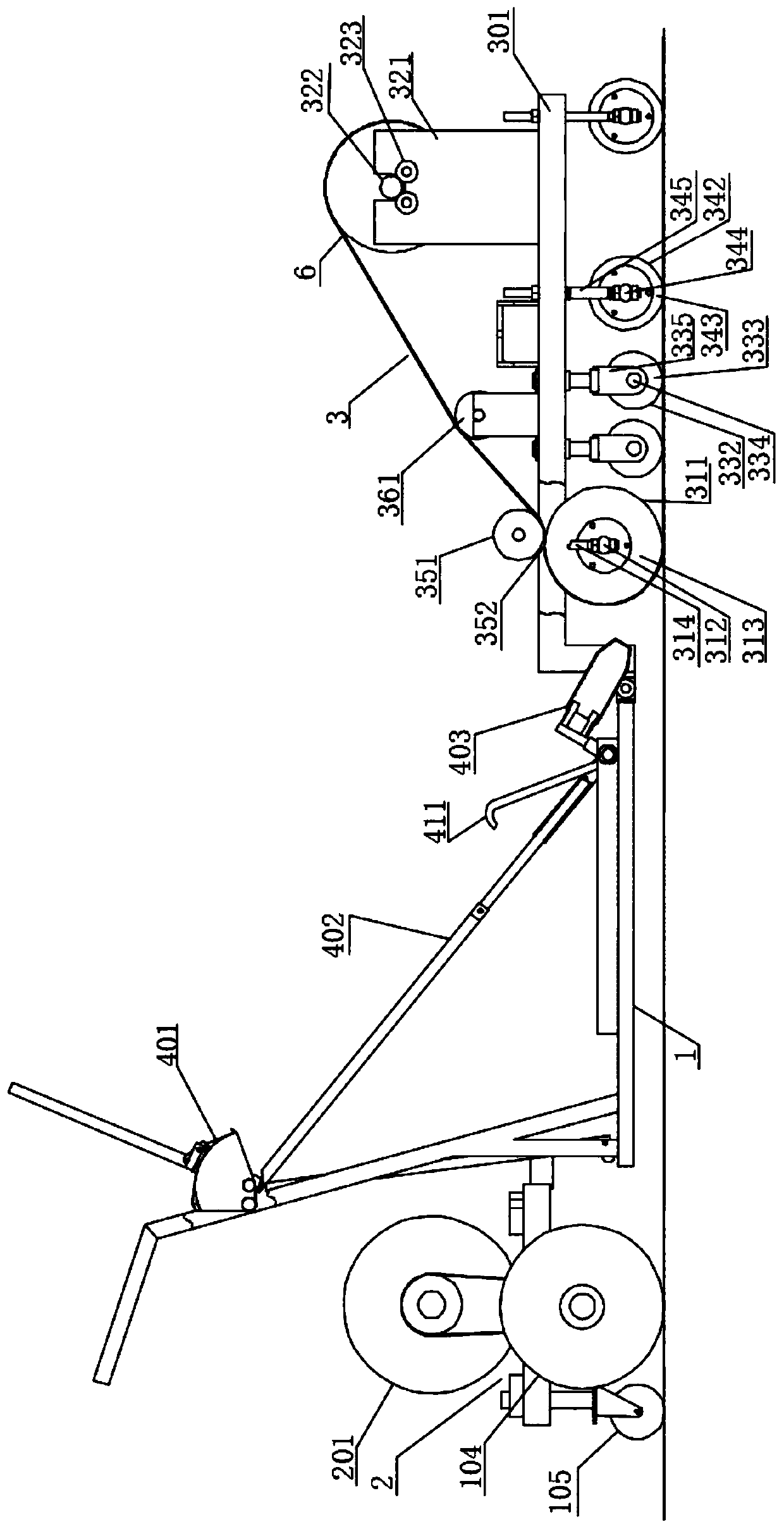

Tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment and process

PendingCN110130920ASolve the transportation problemReduce in quantityTunnelsMixing operation plantSlagMaterial resources

The invention discloses a tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment and process. The tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment comprises mobile crushing equipment, wherein a discharging port of the mobile crushing equipment is sequentially connected with a material pre-sorting system, an aggregate processing system and a concrete processing system through a telescopic conveying belt group, and a discharging port of the concrete processing system is connected with aconcrete belt conveying system; after materials in a tunnel blasting area B are preliminarily crushed by the moving crushing equipment, the materials are transported into the pre-sorting system and the aggregate processing system to prepare fine aggregates and fine sand with different gradations, finally transported into the concrete processing system to prepare concrete, and transported to a tunnel construction area through the concrete belt conveying system for concrete construction after penetrating through a lining trolley. The manpower and material resources are reasonably utilized and distributed, the automatic construction of a tunnel is achieved, high flexibility and good safety performance are achieved, and the construction efficiency and quality of the tunnel are greatly improved.

Owner:GUIZHOU CHENGZHI HEAVY IND SCI TECH

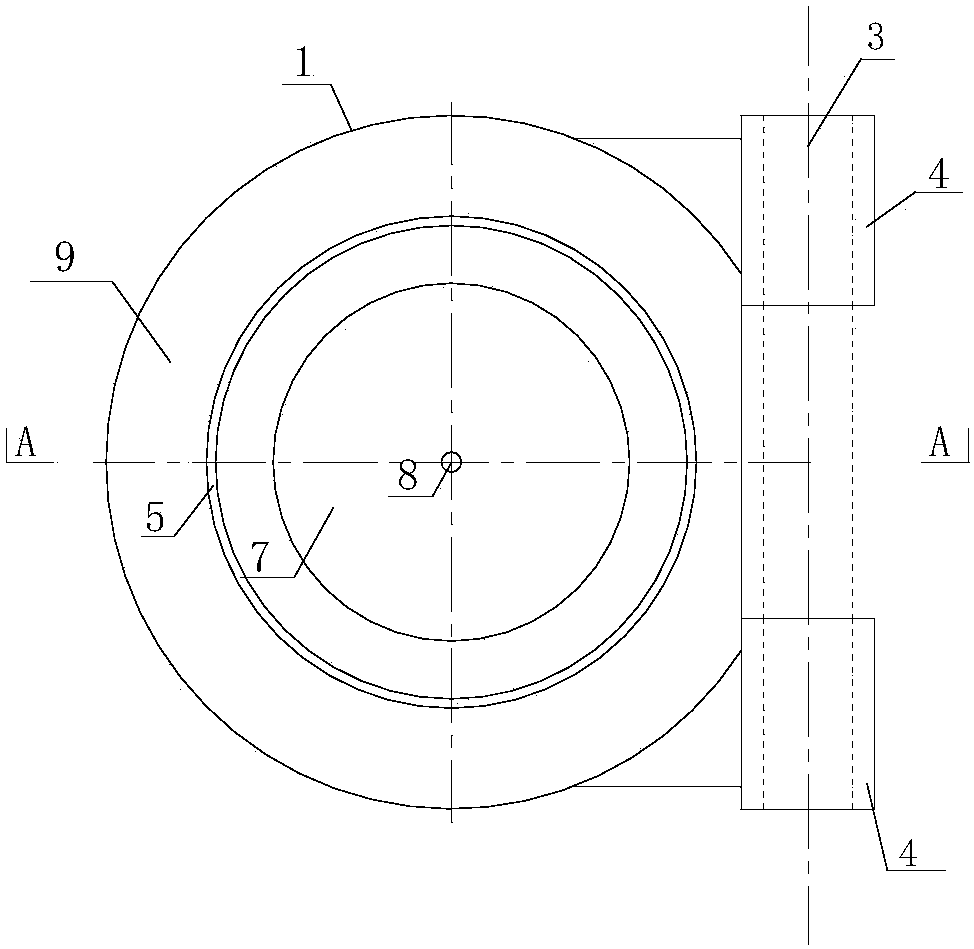

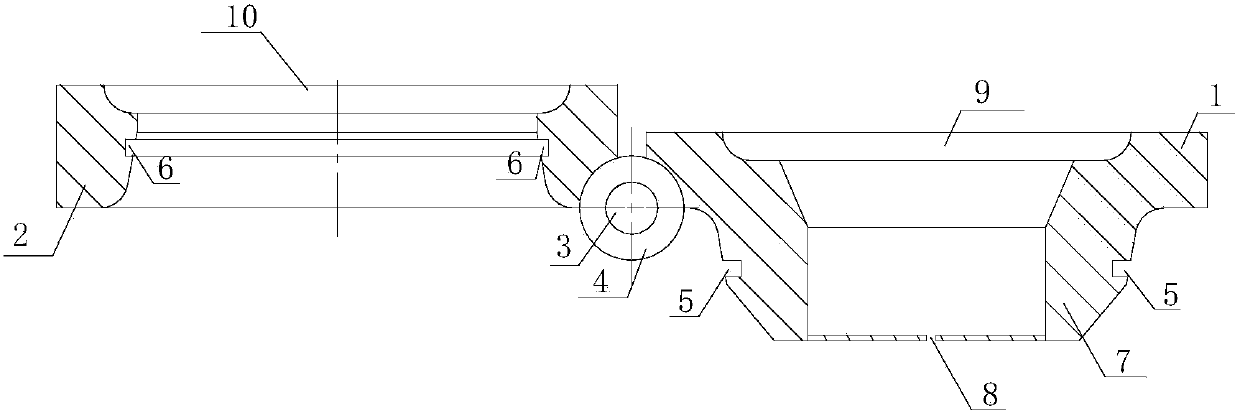

Segment circular seam connection component, tunnel segment structure and construction method

ActiveCN105507924AImprove toleranceFirmly connectedUnderground chambersTunnel liningUniversal jointButt joint

The invention discloses a segment circular seam connection component, a tunnel segment structure and a construction method. The segment circular seam connection component comprises a circular seam convex part and a circular seam concave part, and the circular seam convex part and the circular seam concave part are pre-embedded in two segments requiring circular butt joint. The circular seam convex part comprises a head portion, a neck portion and a tail portion in sequential connection, an outer diameter of the head portion is larger than that of the neck portion, and the neck portion is connected with the tail portion through a universal joint. The circular seam concave part comprises a front portion and a rear portion, the front portion and the rear portion are connected with each other, the front portion is internally provided with an inner cavity, one end, away from the rear portion, of the front portion is provided with an opening communicated with the inner cavity, a plurality of slider mechanisms are arranged around the opening of the front portion, and an inner diameter of the opening is larger than an outer diameter of the head portion. The segment circular seam connection component has an allowance performance and is adaptive to construction environments and capable of meeting the requirements on stress, deformation and water resistance in construction and use of lining segments 1. In addition, simultaneity in longitudinal and circular butt joint of the segments can be realized, and quickness and convenience in construction, easiness for mechanization and automation in construction are achieved.

Owner:SHANGHAI CONSTRUCTION GROUP

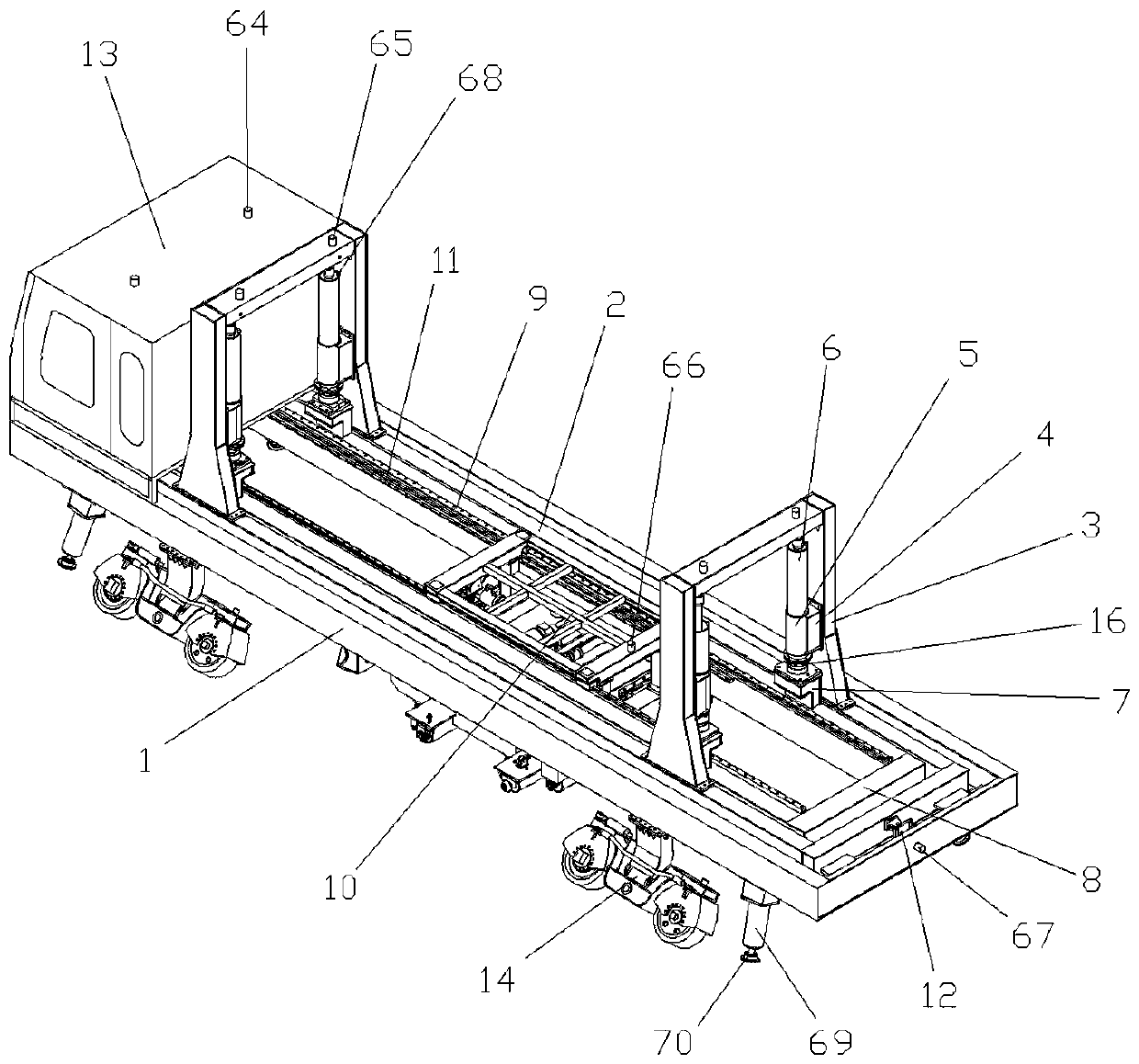

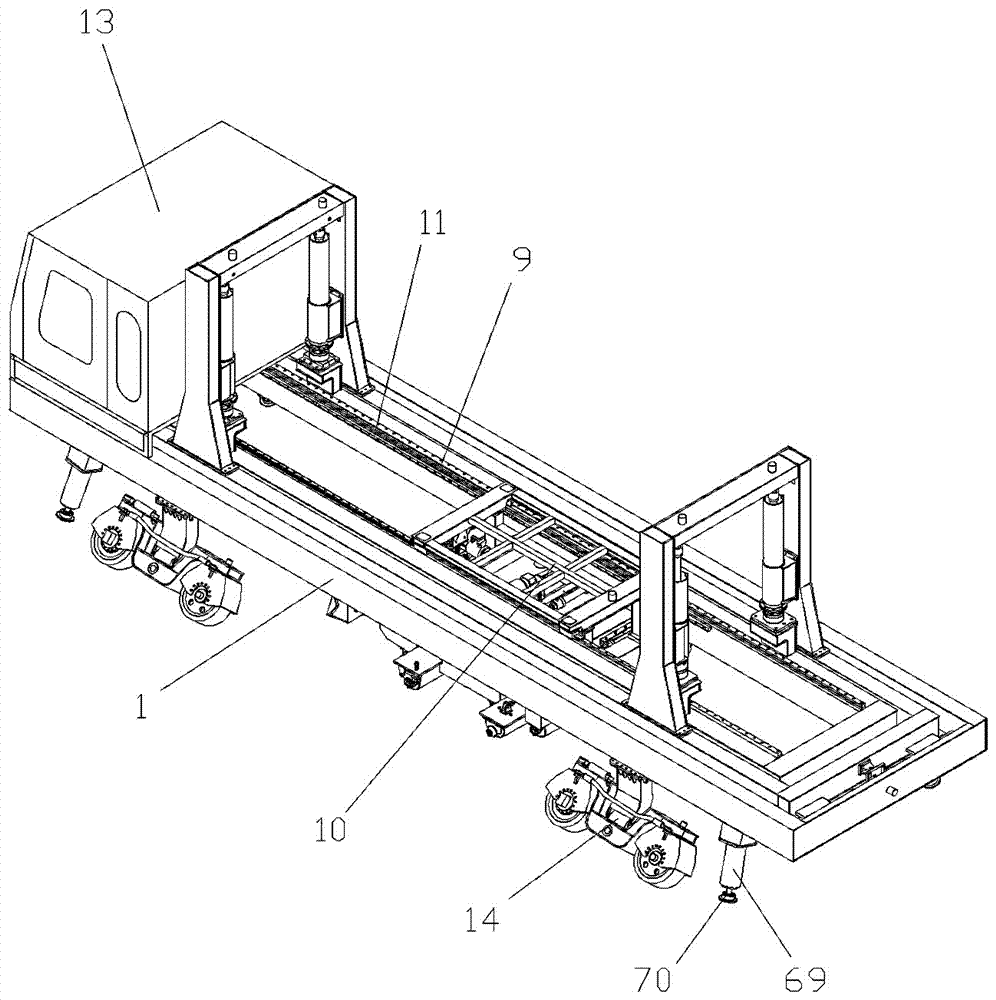

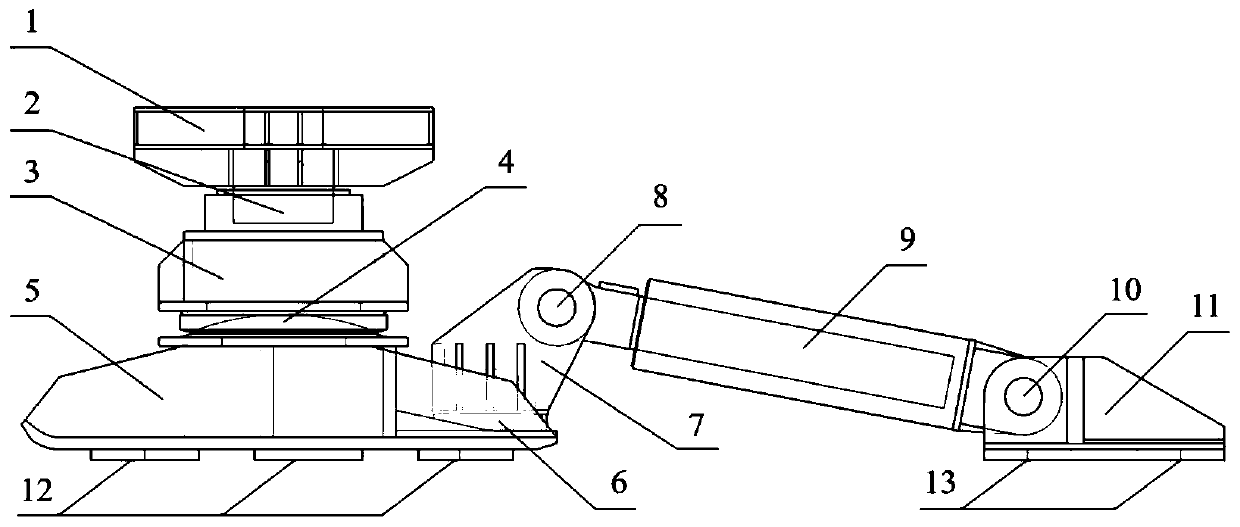

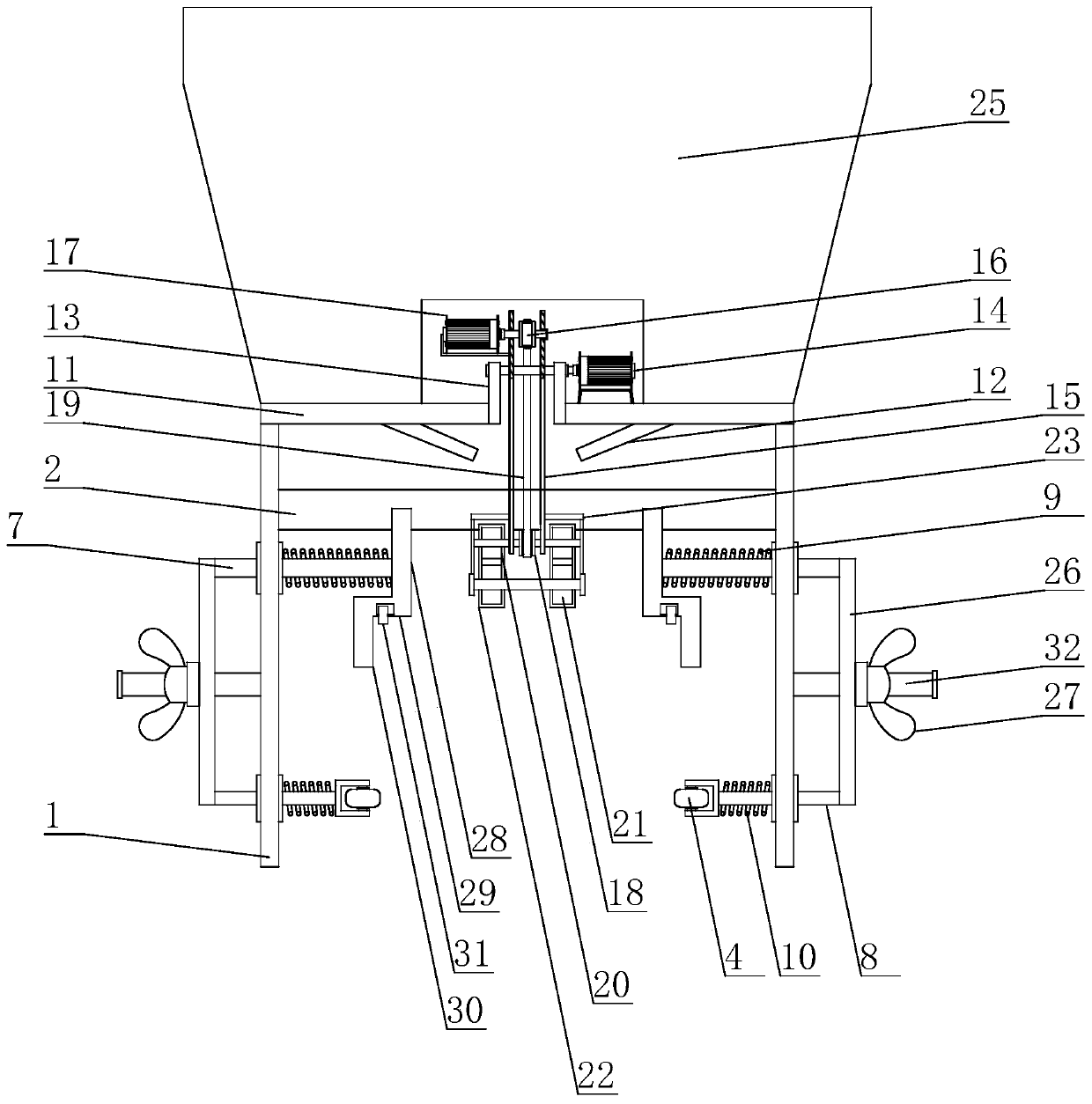

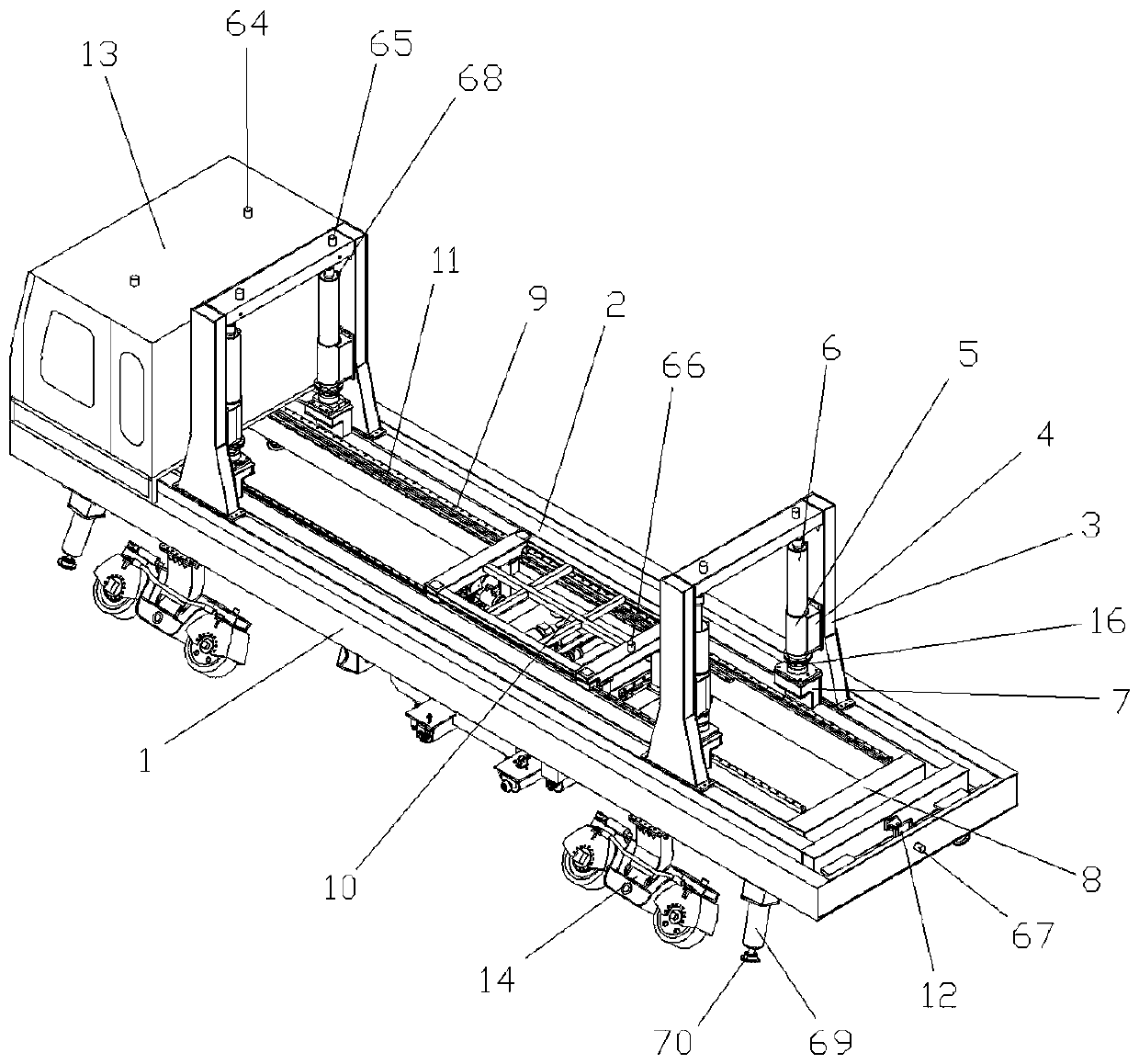

Trackless intelligent paver

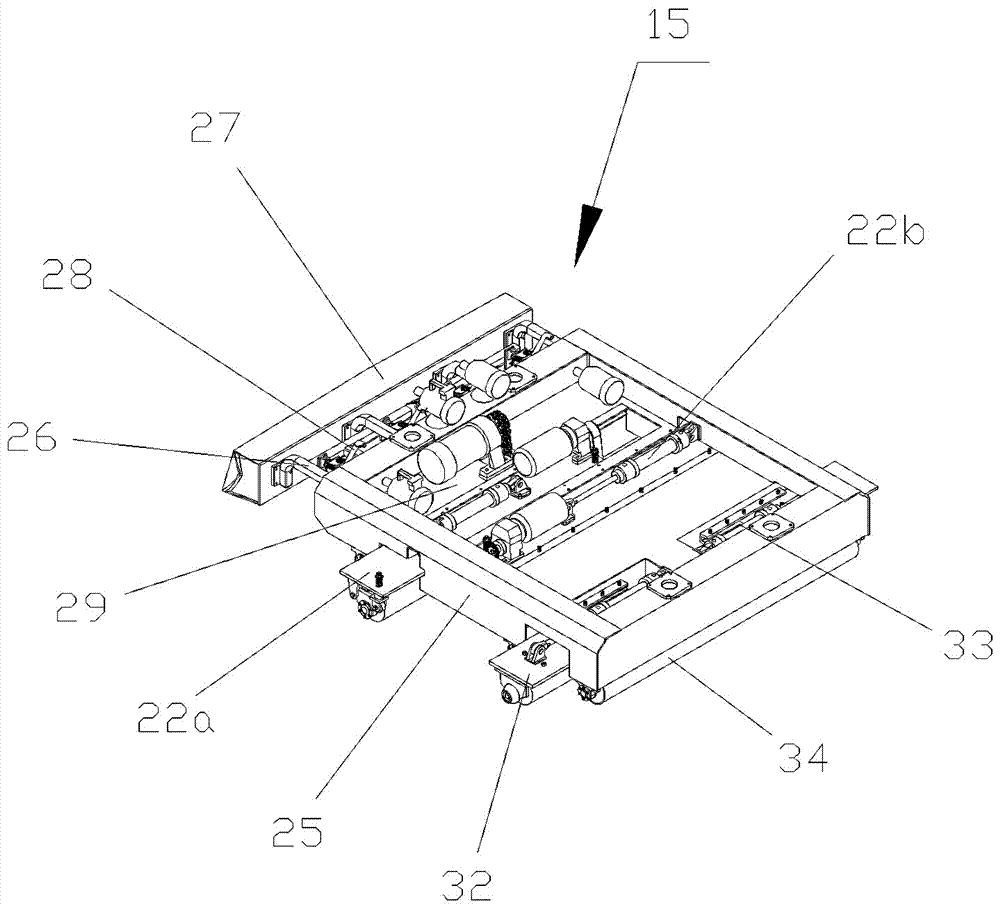

ActiveCN107700320ARealize automated constructionGood construction performanceRoads maintainenceVehicle frameControl room

The invention relates to a trackless intelligent paver which comprises a support frame (1); the support frame is connected with a control room (13) and a walking device (14), the support frame is internally connected with a translational vehicle frame (2), the translational vehicle frame is connected with an adjustment frame (8) via a hanger frame (3), and the adjustment frame is connected with apaving vehicle (10); the paving vehicle comprises a walking frame (17), the walking frame is connected with a paving device (15), the paving device comprises a paving frame (25), the paving frame is provided with a soil paving bucket (27), a vibrating device (28), a material homogenizing device (29), a vibrating roller device (30) and a flattening roller device (31) from front to back successively. The trackless intelligent paver has the advantages that the device is used for paving rail cement concrete in tunnels, achieves concrete paving in rectangular cross sections, circular tunnels, horseshoe-shaped tunnels and other cross-section roadbed slab subgrades, adjusts the working attitude according to the change of working conditions, meets various construction requirements, can realize automated construction, and has high construction effect.

Owner:ANHUI XINGYU TRACK EQUIP

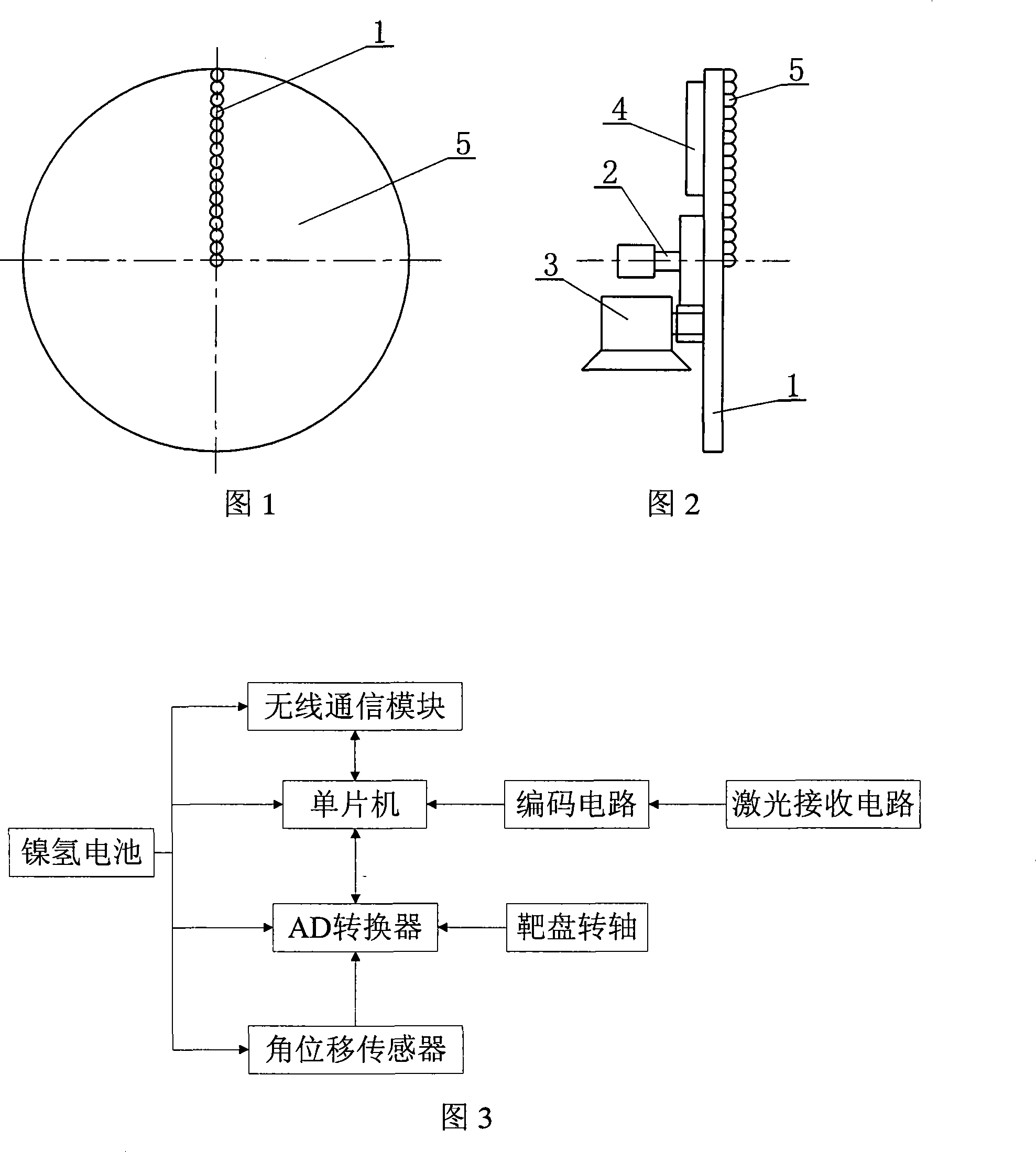

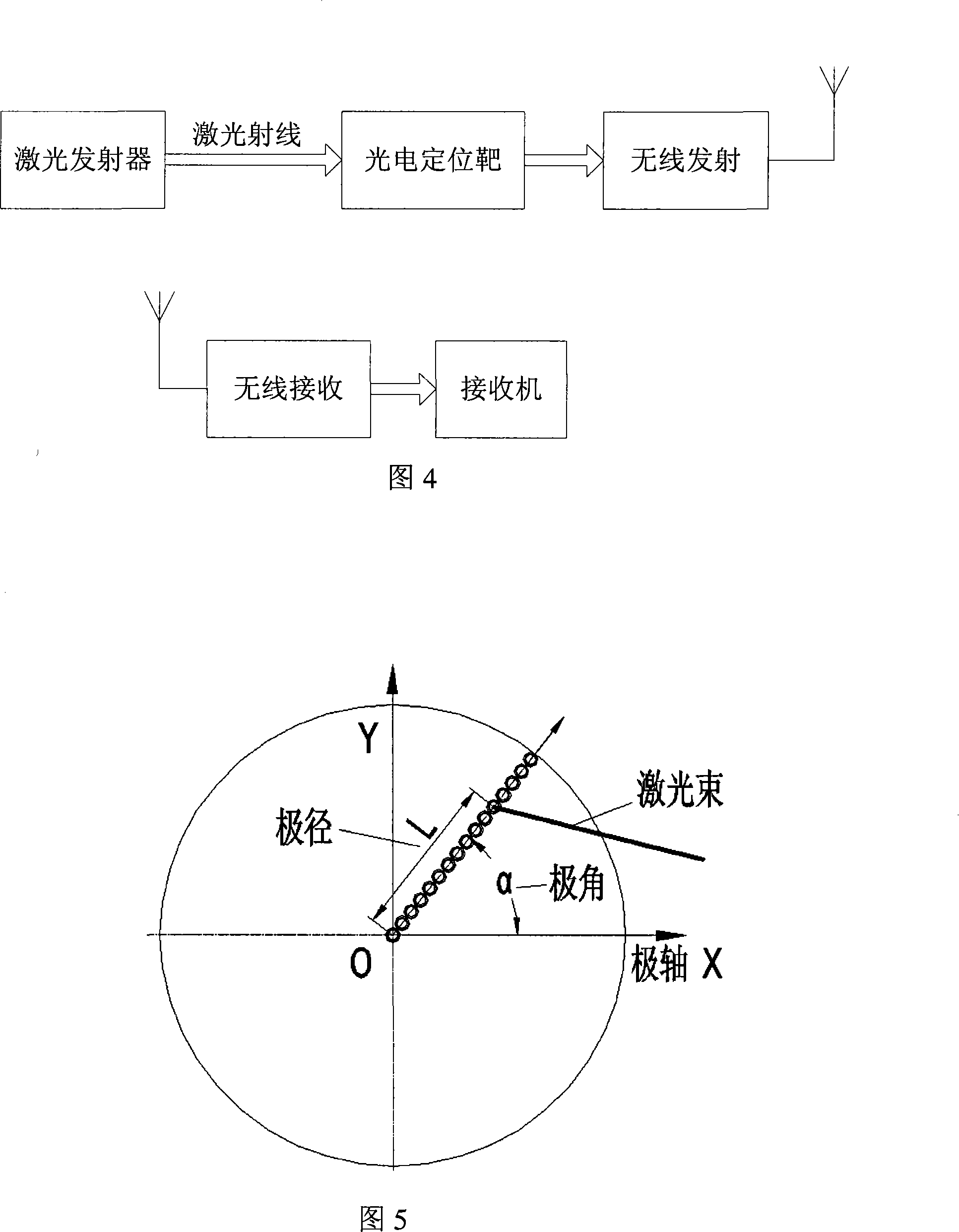

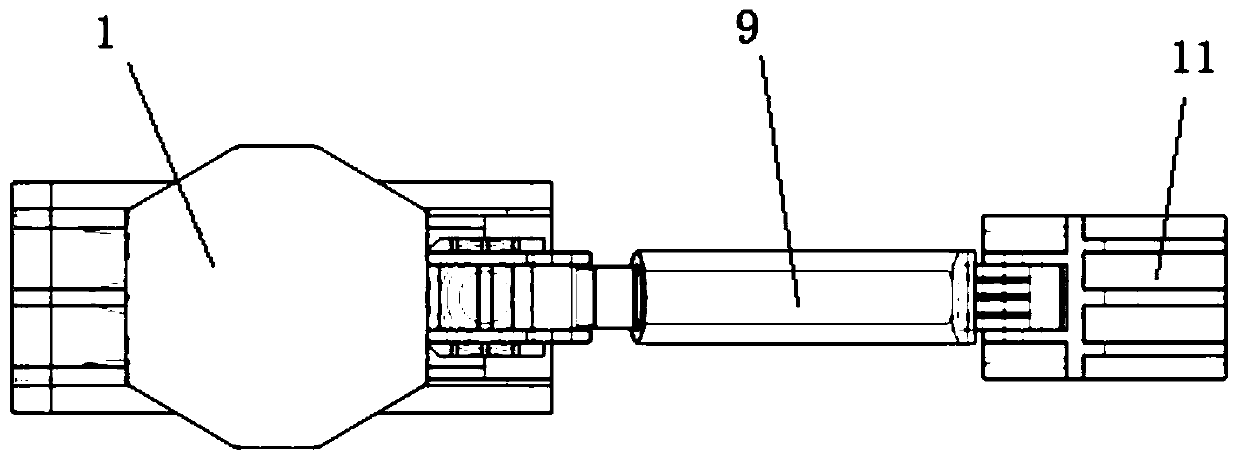

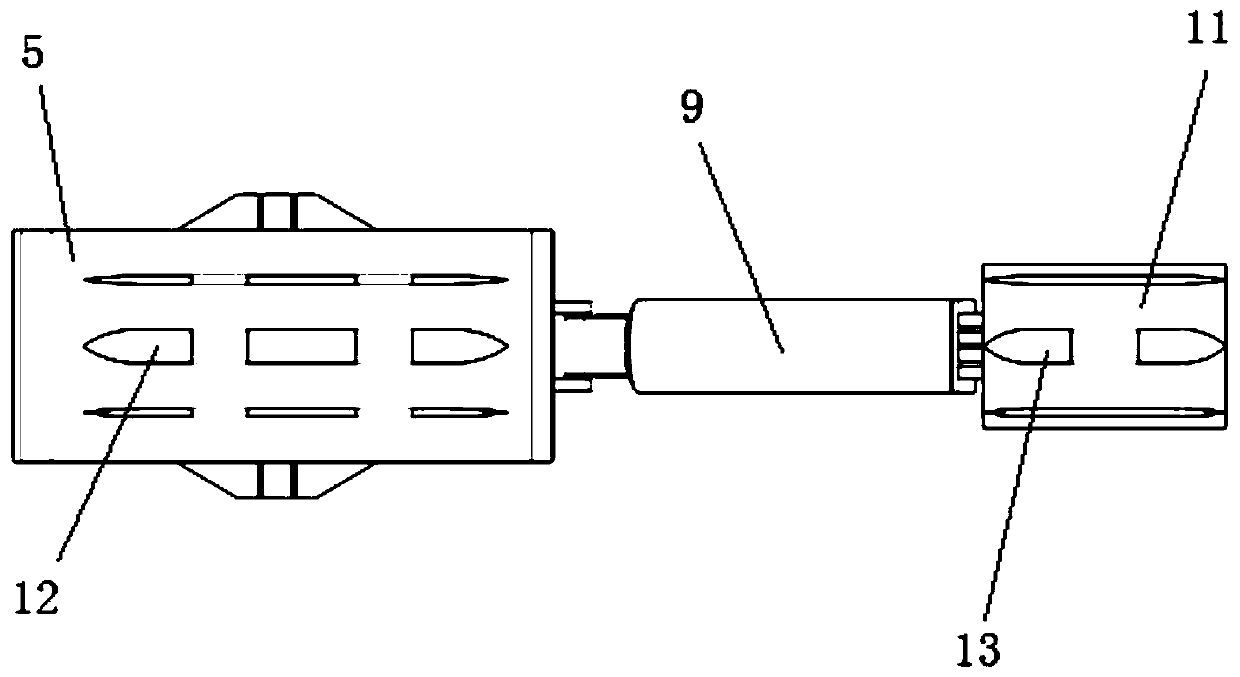

Construction mechanical arm photoelectric positioning apparatus

InactiveCN101236069ARealize automated constructionPhotoelectric target is simple and reliableTransmission systemsUsing optical meansComputer moduleDrive motor

Disclosed is a photoelectric location device of a construction manipulator, which relates to a photoelectric location device. The device comprises a hardware portion and a software portion, which is characterized in that the hardware portion comprises a mechanical target disk, a target disk rotation shaft, a driving motor, an electronic component and a photosensitive diode, the outer surface of the mechanical target disk is equipped with the photosensitive diode or a photo tape, the inner surface is equipped with the driving motor, the target disk rotation shaft and the electronic component. The control procedure of a single chip and connection circuits between modules are the software portion. The location device of the invention can realize single target location, double target location or triple target location of the work-piece handled by the construction manipulator according to the concrete using condition. The photo target of the device is simple and reliable, which is favorable for the construction manipulator to realize automatic construction.

Owner:SHENYANG JIANZHU UNIVERSITY

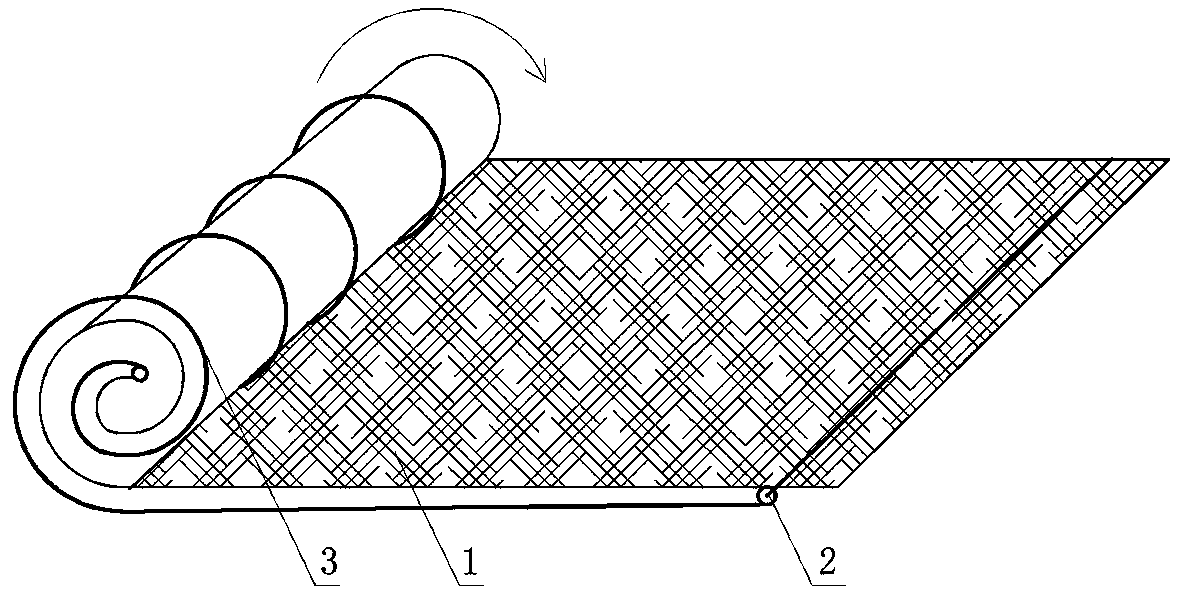

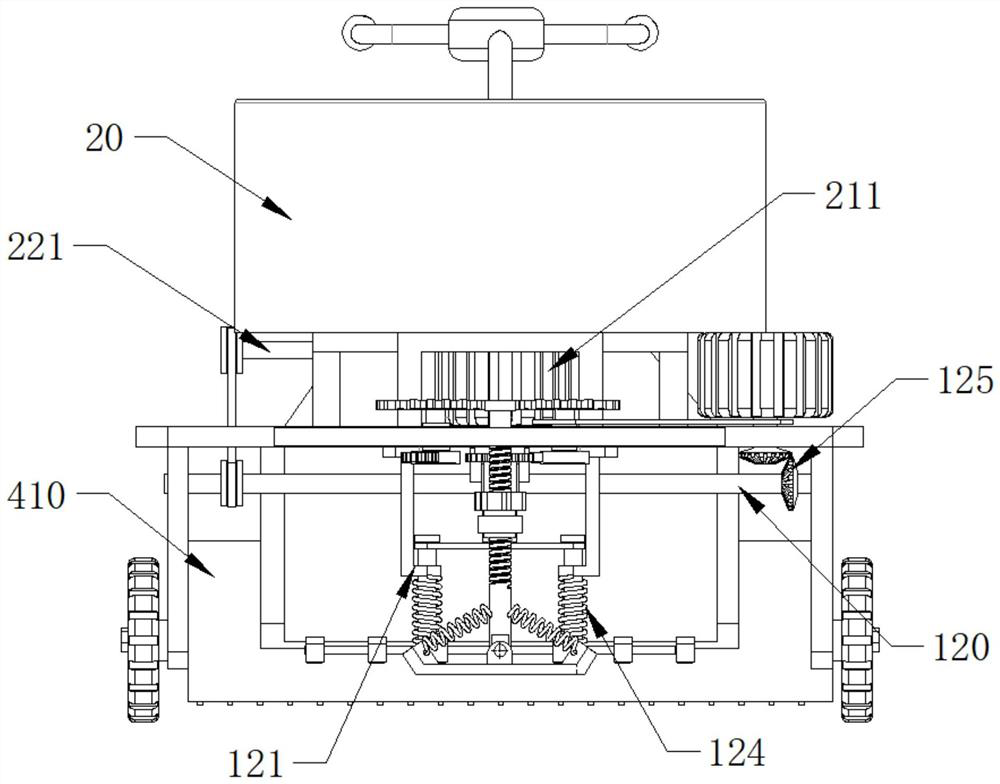

Small coiled material automatic unrolling trolley and method for unrolling coiled material

The invention relates to the technical field of building construction, in particular to a small coiled material automatic unrolling trolley and a method for unrolling a coiled material. The small coiled material automatic unrolling trolley comprises a moving chassis. One end of the moving chassis is connected with a traction advancing mechanism, and the other end of the moving chassis is connected with a coiled material laying-pressing mechanism. The coiled material laying-pressing mechanism comprises a laying-pressing platform connected with the moving chassis. The lower end of the laying-pressing platform is in coupling connection with a laying through roller. A coiled-material-wound storing roller is erected on the laying-pressing platform through a storing support. One end of the coiled material is wound around the storing roller, and the other end of the coiled material covers the laying through roller and is pressed on the ground through the bottom end of the laying through roller. By means of the laying-pressing mechanism and a spray nozzle, the problem that the coiled material needs to be manually heated and then laid on the surface of a building, so that the working efficiency is low, and when the surface of the building is uneven, large gaps usually exist between the coiled material and the sinking parts or protruding parts of the building is solved.

Owner:东方雨虹民用建材有限责任公司

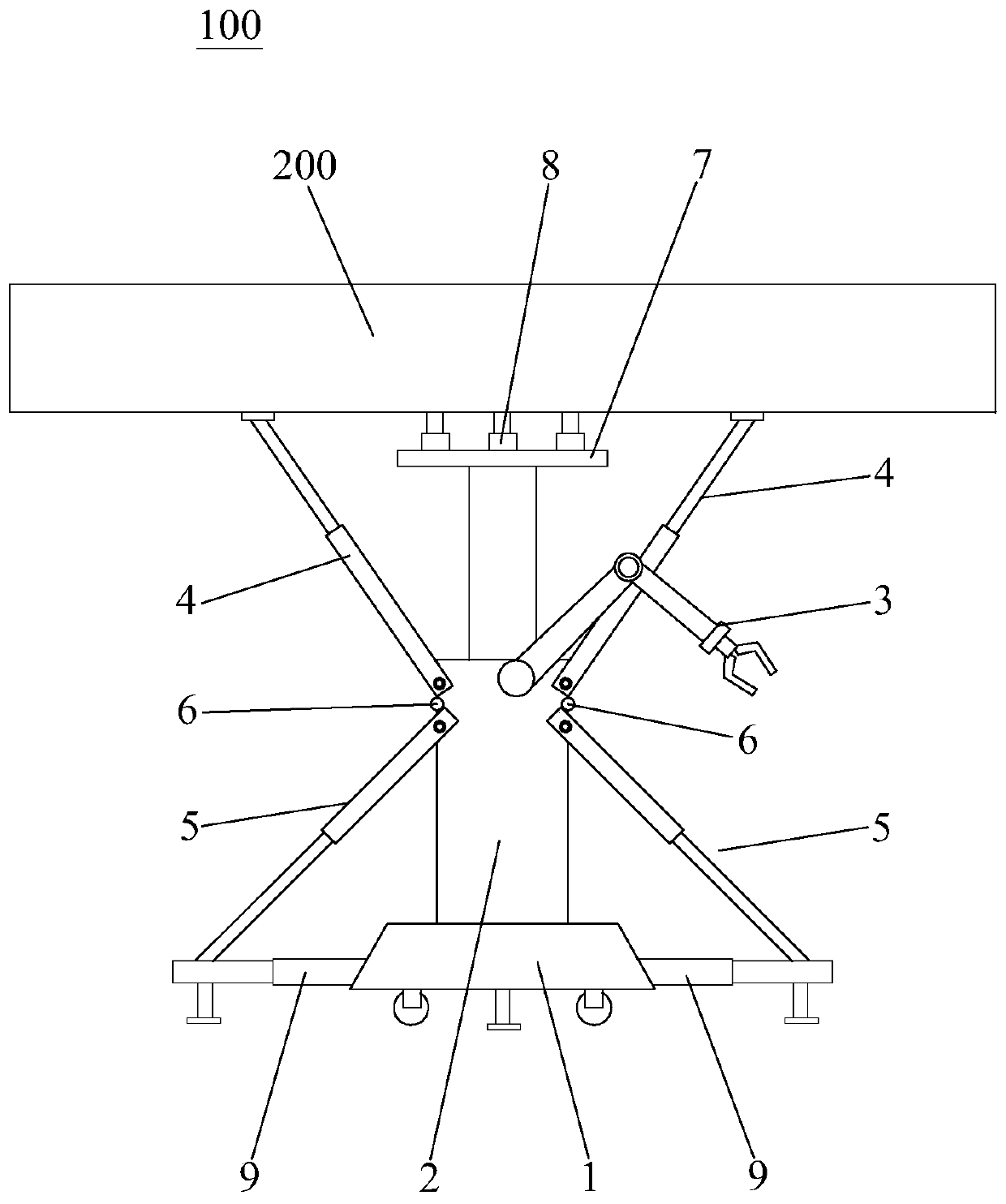

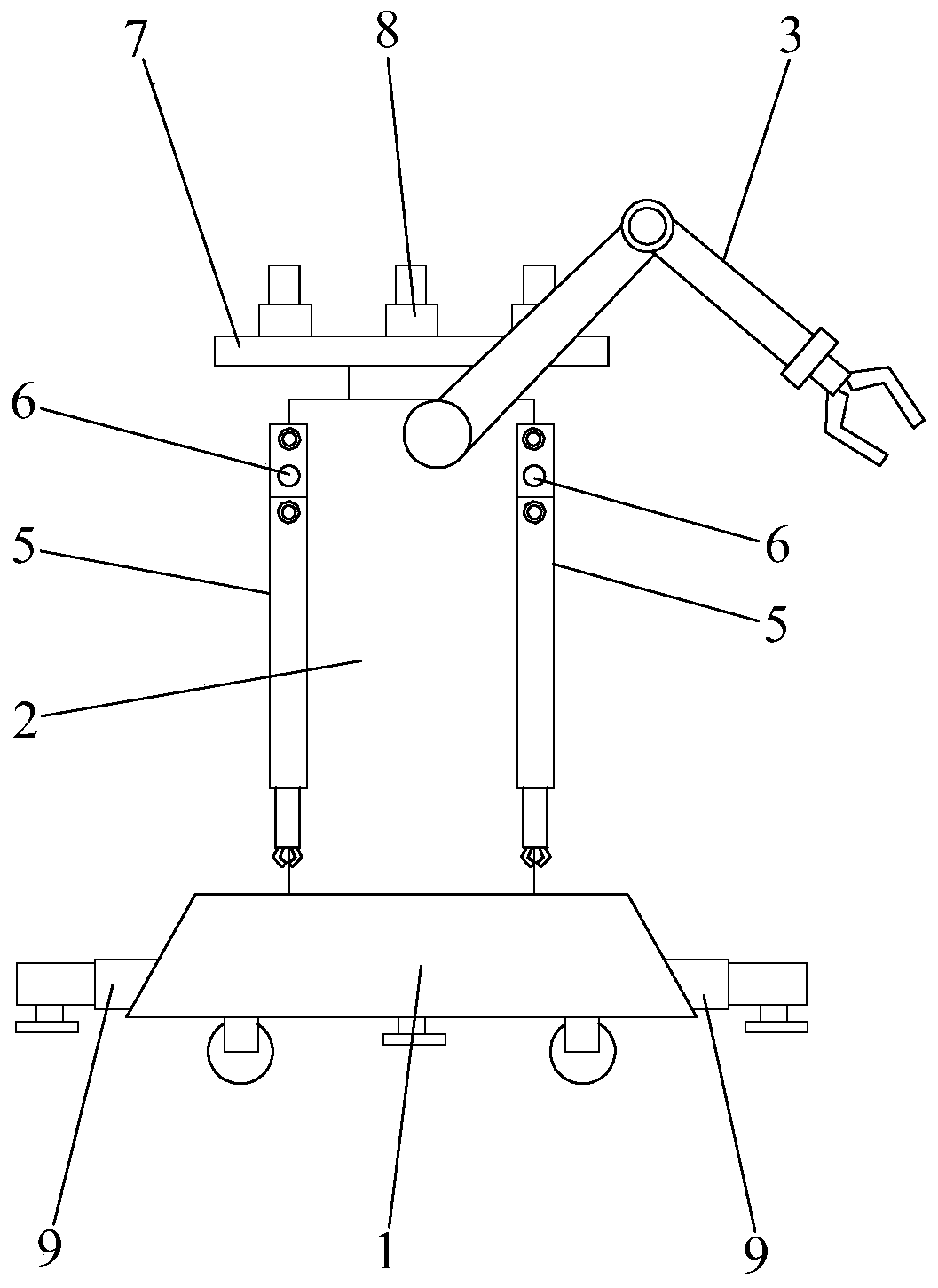

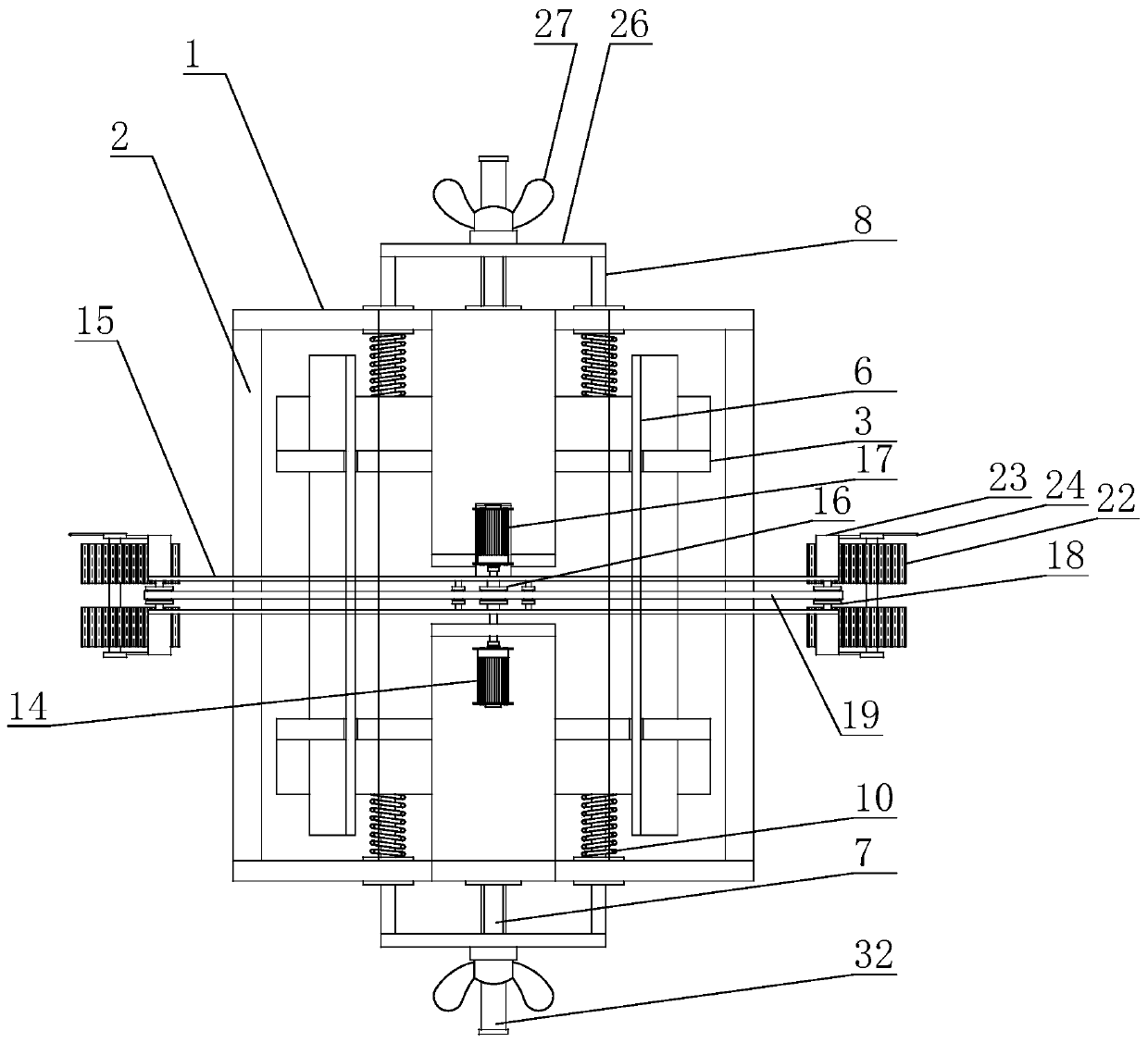

Building supporting robot

PendingCN111550081AAchieve supportAchieve precise positioningProgramme-controlled manipulatorShoresFloor slabControl system

The invention discloses a building supporting robot. The robot comprises a traveling device, a lifting device, a grabbing device, leveling devices and a control system, wherein the lifting device is arranged on the traveling device, the output end of the lifting device can stretch out to support a building, the grabbing device is arranged on the traveling device and used for installing a buildingmold at the output end of the lifting device, the leveling devices are arranged on at least one side of the lifting device, the output ends of the leveling devices can stretch out to support and adjust the two ends of the building mold, and the control system controls the actions of the traveling device, the lifting device, the grabbing device and the leveling devices. The building supporting robot can automatically travel and support a floor slab mold or a beam mold of a building, automatic construction is achieved, and the building construction efficiency is effectively improved.

Owner:正如(广东)机器人科技有限公司

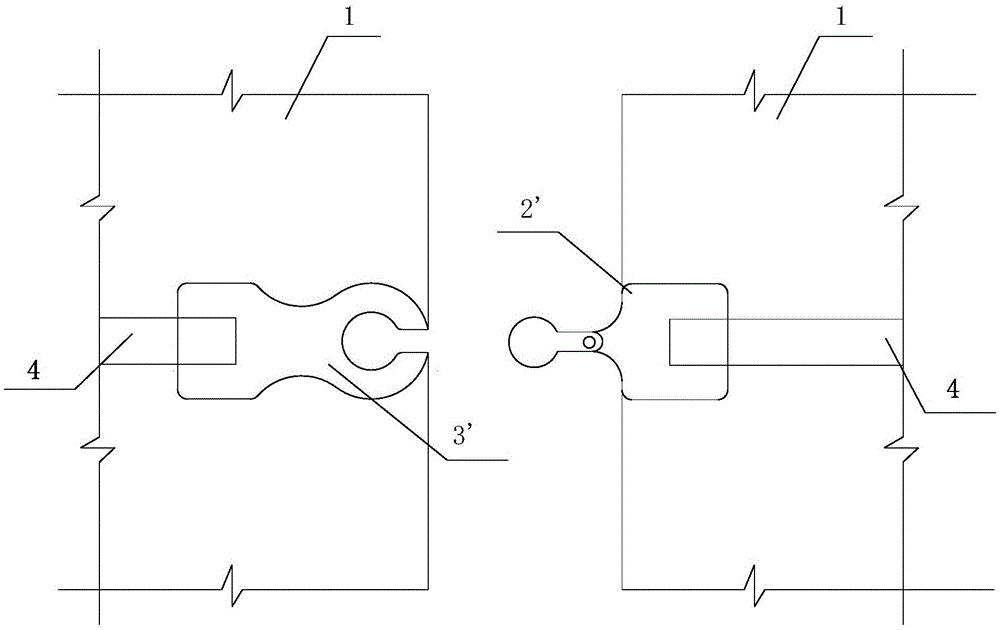

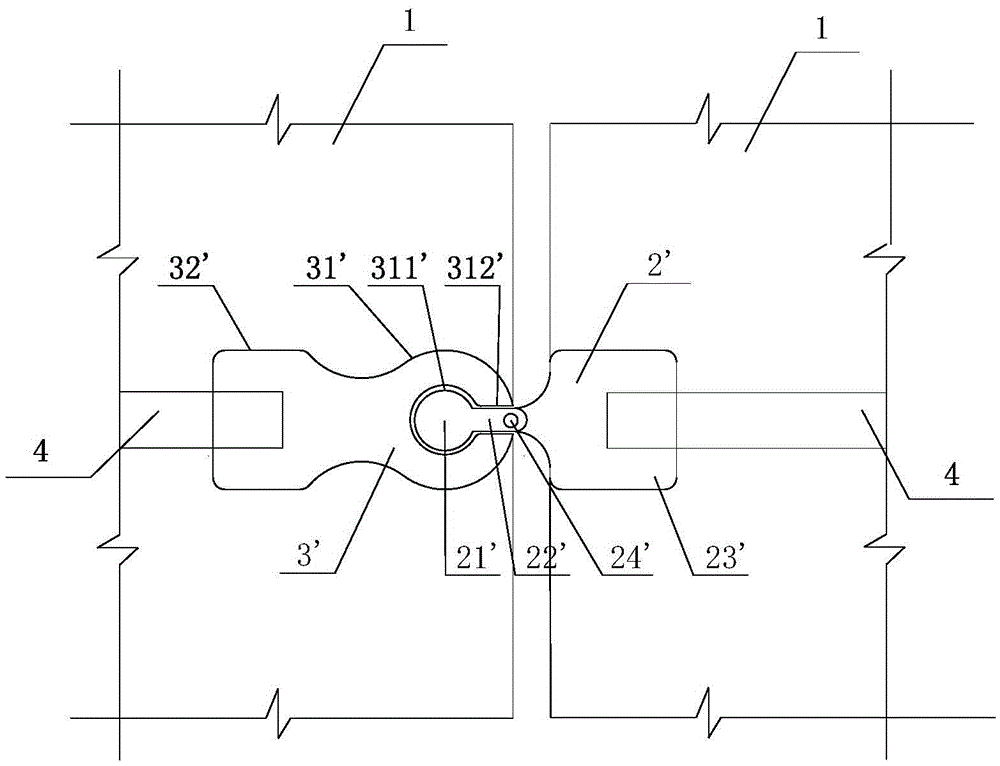

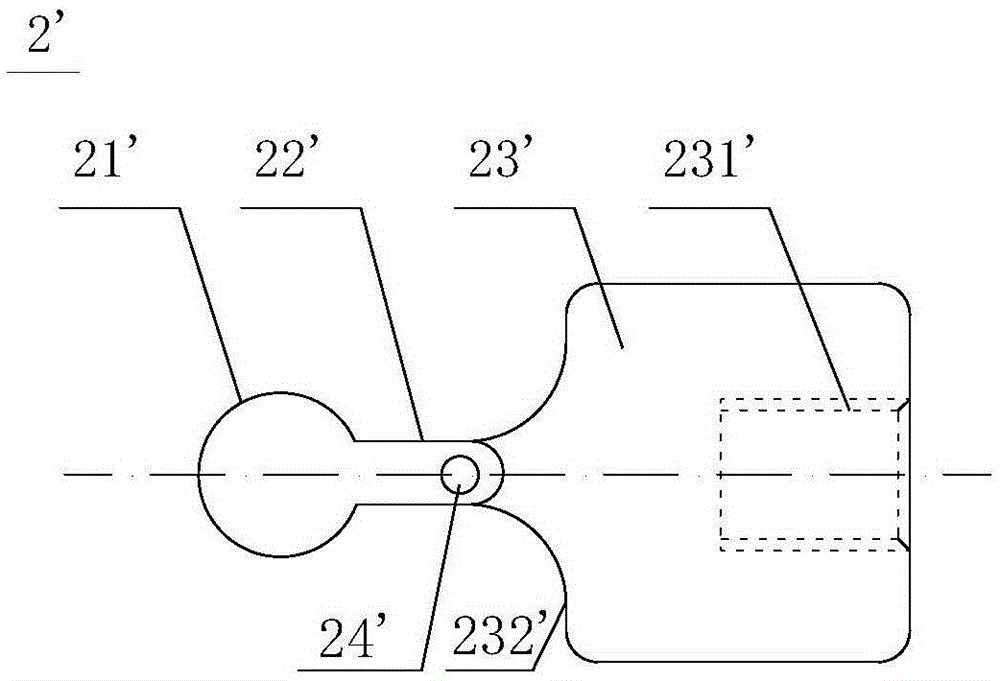

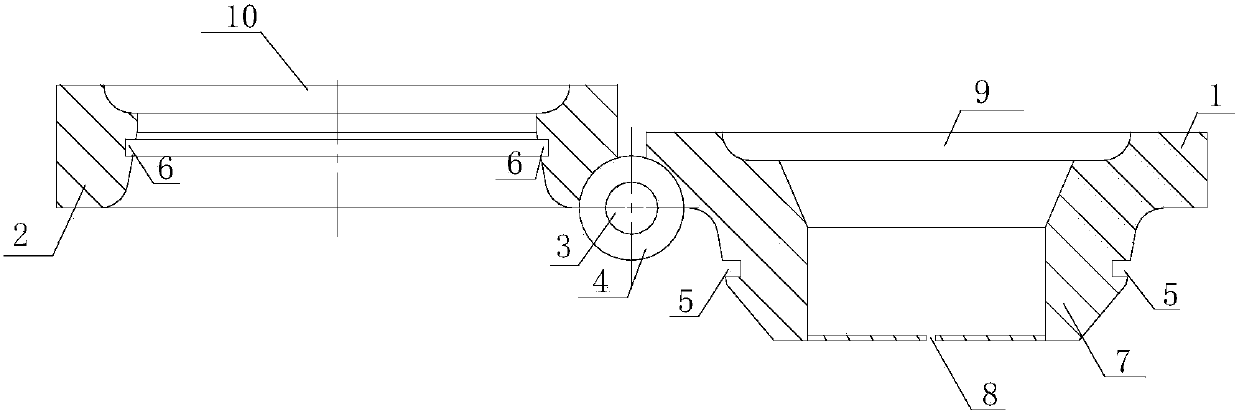

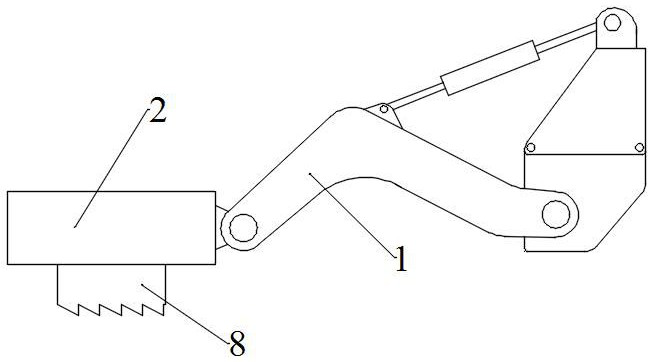

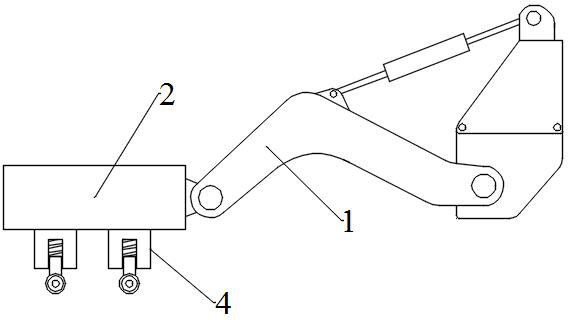

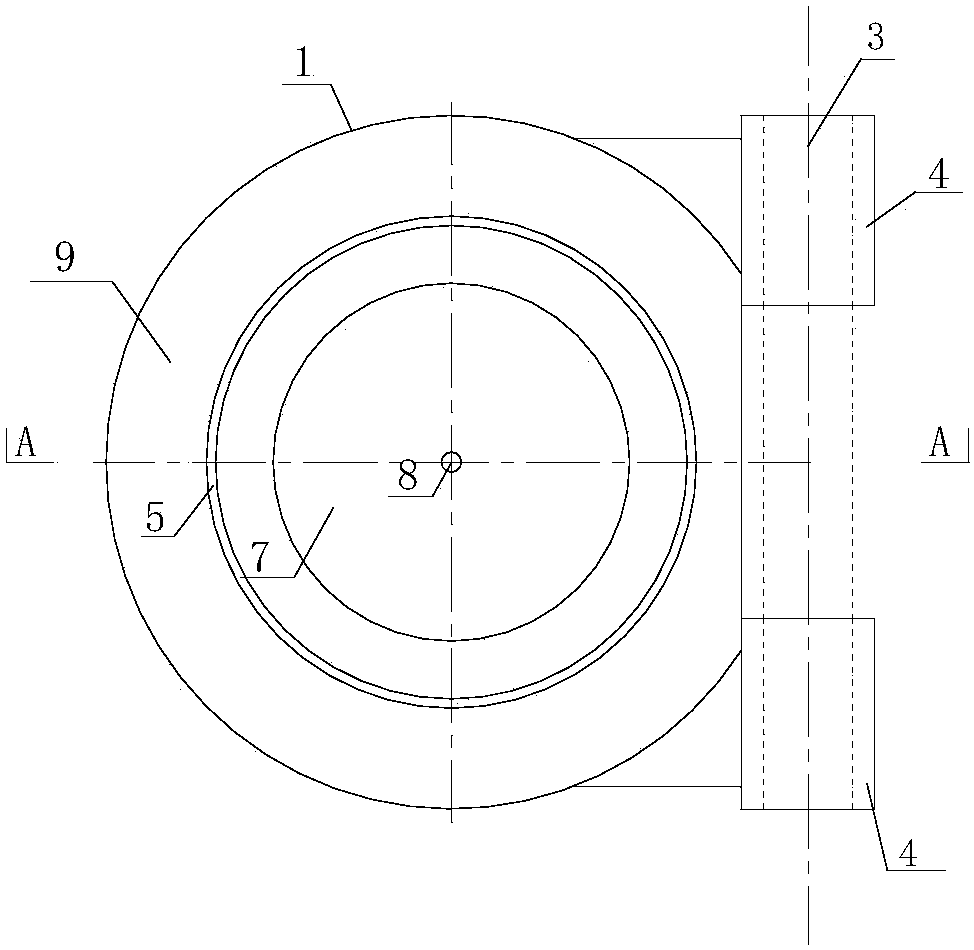

Automatic construction node hinge device suitable for confined concrete lagging jack

ActiveCN105952481ASimple structureEasy to operateUnderground chambersTunnel liningArchitectural engineeringH shaped

The invention discloses an automatic construction node hinge device suitable for a confined concrete lagging jack. The automatic construction node hinge device comprises a hinge buckle and a hinge groove which are movably connected by virtue of a hinge shaft, wherein the hinge groove is internally hollow, so that the lower end of the hinge buckle is wrapped in the hinge groove; and the lower end of the hinge buckle is provided with a first retainer ring clamping groove, a second retainer ring clamping groove is formed in the corresponding position of the hinge groove, and the hinge buckle and the hinge groove are fixedly buckled. The automatic construction node hinge device is simple in structure and convenient and flexible to install; and the application range is wide, and the node hinge device can be used for different lagging jacks in various shapes, sizes and sectional forms such as a mine U-shaped steel lagging jack, an H-shaped steel lagging jack, and for the confined concrete lagging jacks in various sectional forms and sizes. The node hinge device can be used for connecting nodes of an underground engineering lagging jack and is particularly suitable for connecting confined concrete lagging jacks.

Owner:SHANDONG UNIV +1

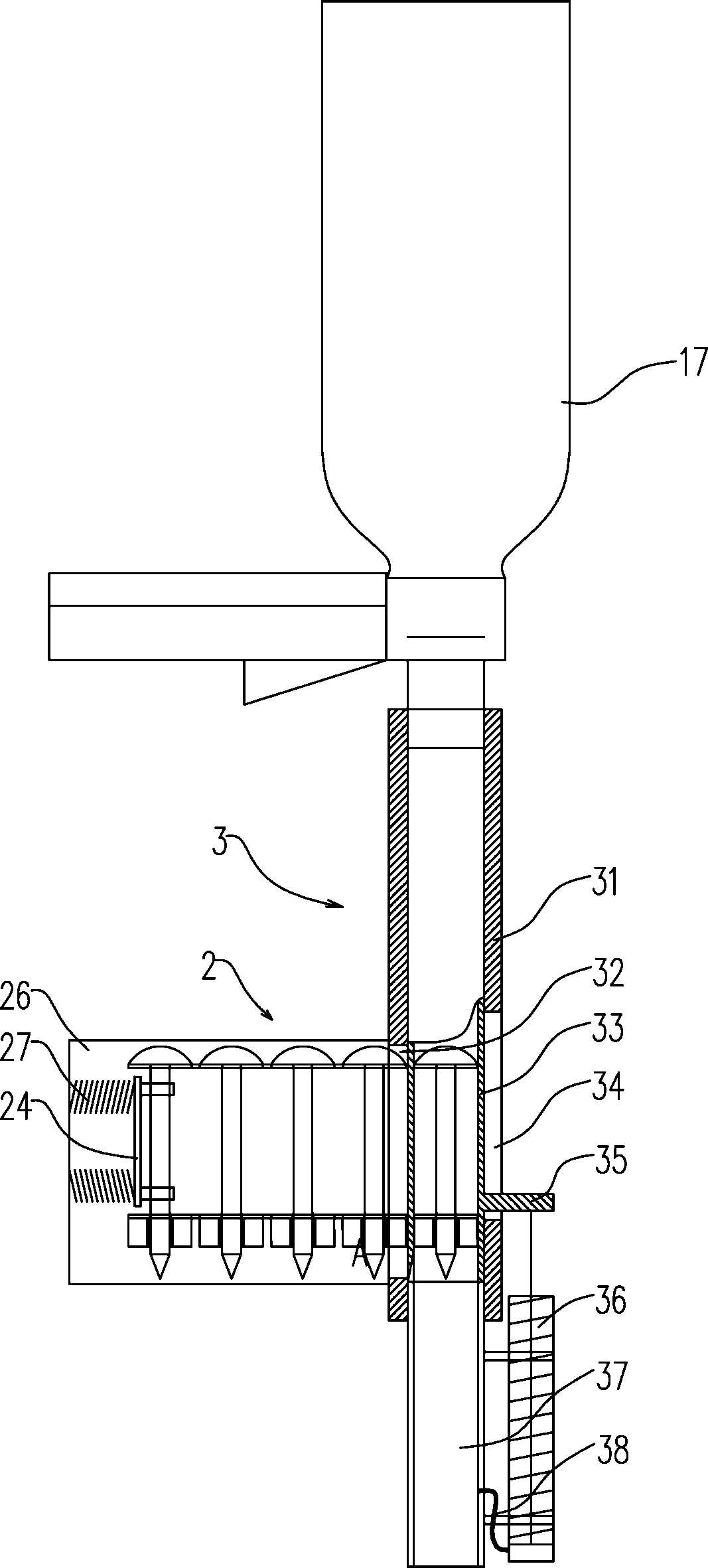

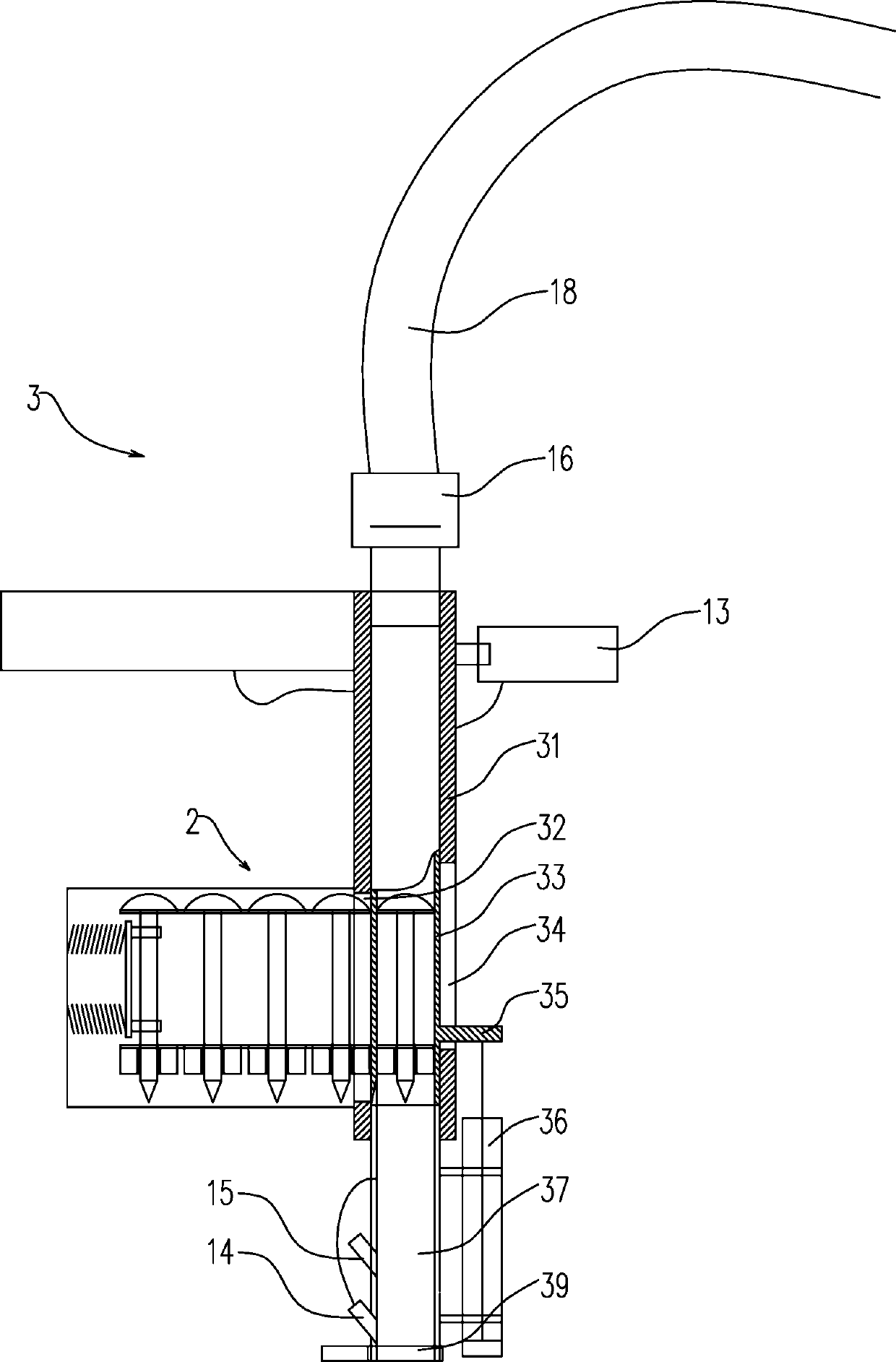

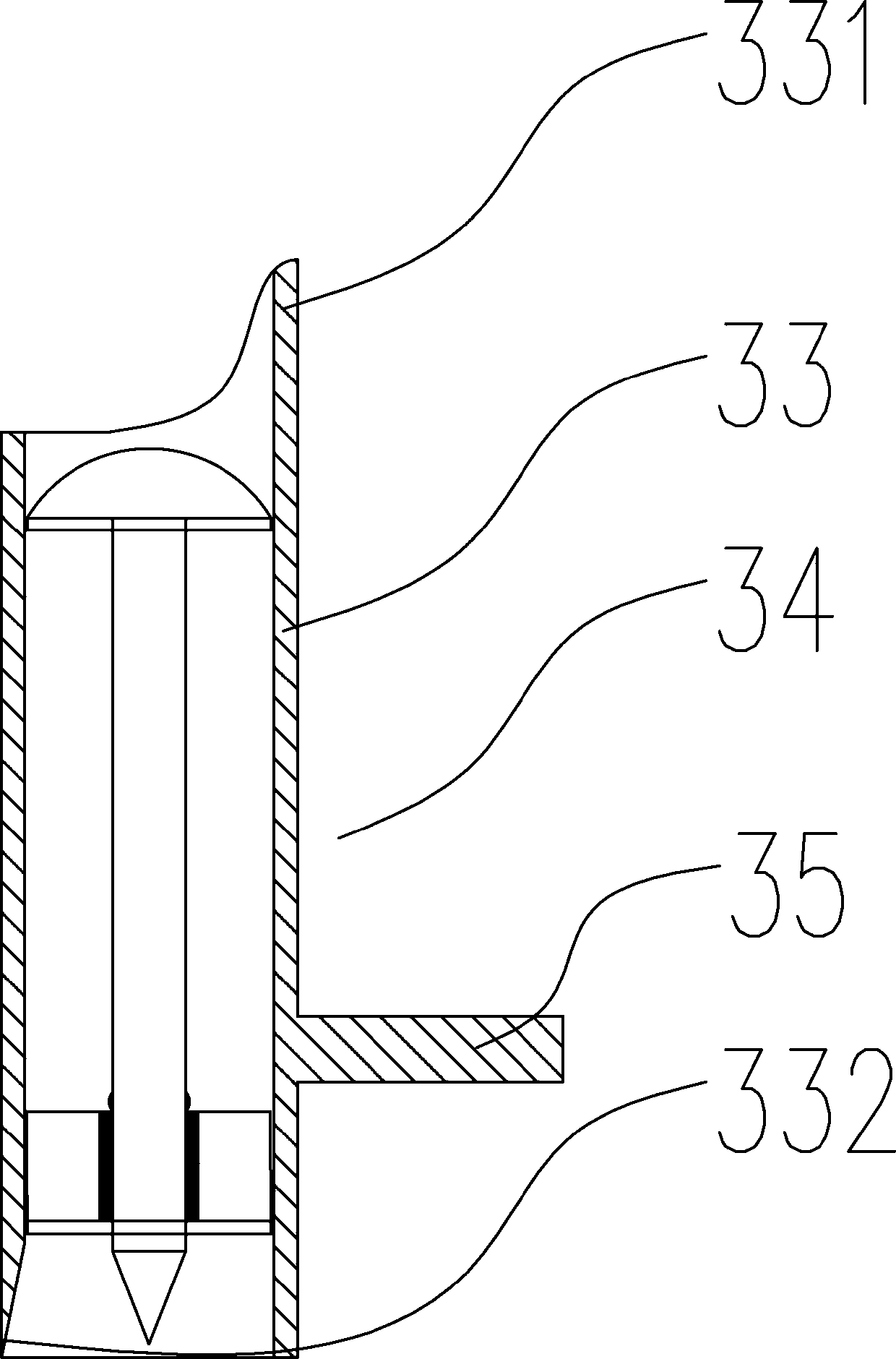

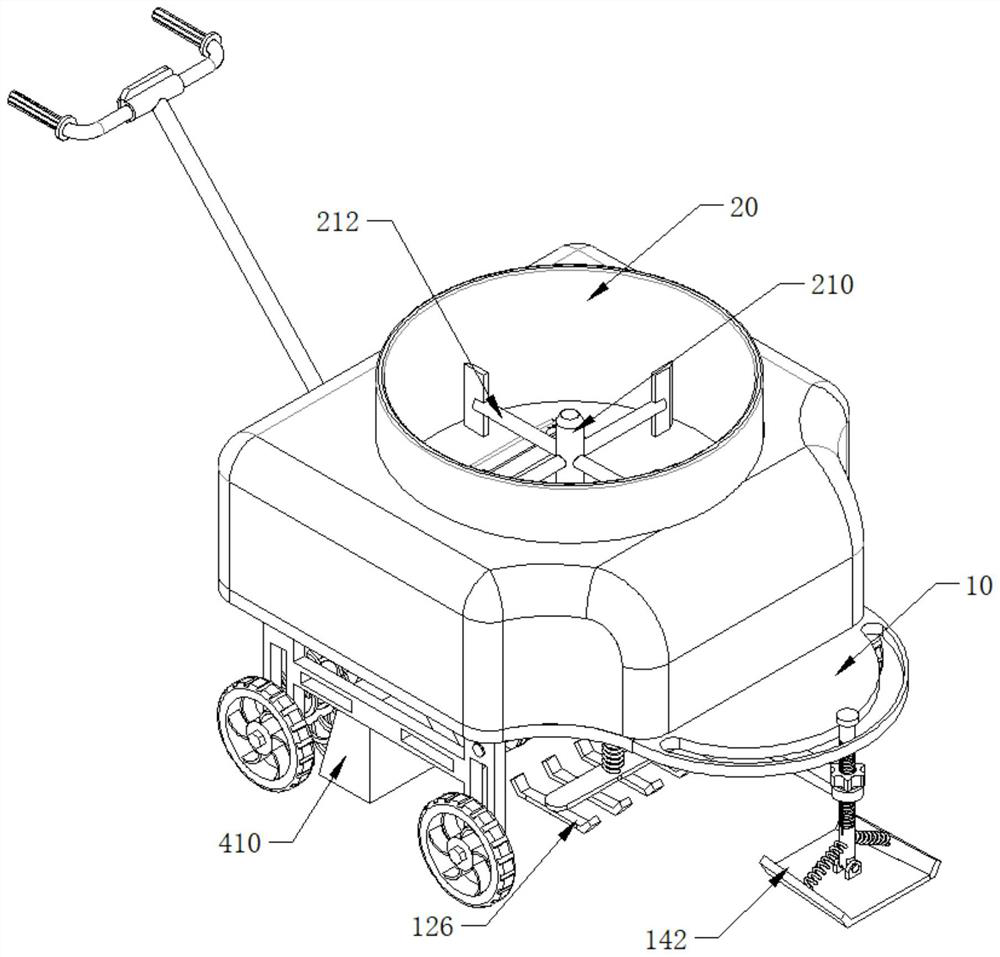

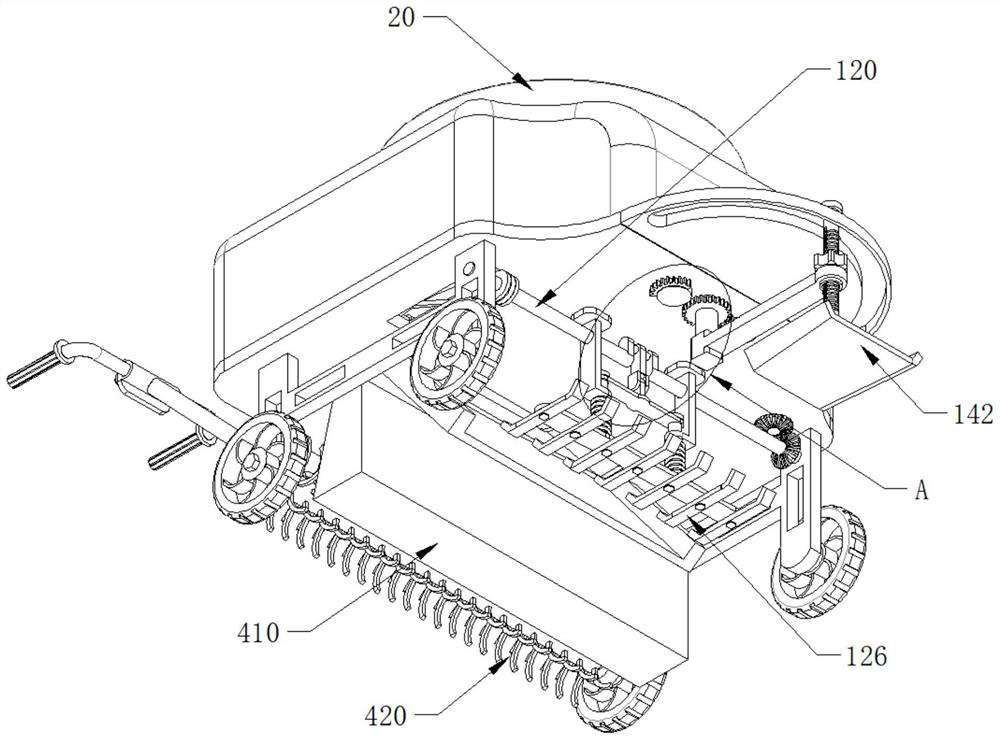

Light concrete cast-in-place robot

ActiveCN112267683APrecise Control of ElevationPrecise control angleBuilding material handlingControl systemClassical mechanics

The invention relates to a light concrete cast-in-place robot, the cast-in-place robot comprises a vehicle body, a motion system, a discharging system, a vibrating system, a plastering system and a control system electrically connected with the motion system, the discharging system, the vibrating system and the plastering system, the motion system is arranged at the bottom of the vehicle body, thedischarging system, the vibrating system and the plastering system are all arranged on the vehicle body, the discharging system comprises a discharging cylinder internally provided with a concrete channel, the bottom of the discharging cylinder is provided with a concrete discharging port with an opening towards the rear portion of the vehicle body, the vibrating system comprises a vibrating rodwhich can ascend and descend and is located on the rear portion of the vehicle body, the plastering system comprises a plastering device with multiple degrees of freedom, and the plastering device islocated on one side of the vehicle body. Compared with the prior art, the light concrete cast-in-place robot has the advantages that concrete discharging, vibrating and plastering can be conducted atthe same time, light weight and flexibility are achieved, traditional manual labor is replaced, and the construction mechanization degree is improved.

Owner:TONGJI UNIV

Rapid wall face decoration plate construction device

ActiveCN108547841APrevent falling offImprove construction efficiencyCovering/liningsStaplesExtreme positionEngineering

The invention provides a rapid wall face decoration plate construction device. The rapid wall face decoration plate construction device comprises nails and a nail gun. In each nail, a nail head is arranged at one end of a nail column of each nail, wherein the end away from the nail head is provided with a sleeve capable of sliding, and the outer wall of the sleeve is provided with a wing plate corresponding to a decoration plate spliced gap. In the nail gun, an outer sleeve and an inner sleeve are fixedly connected, a nail inlet is formed in one side of the outer sleeve, and a sliding groove is further formed in the outer wall of the outer sleeve. A sliding sleeve is arranged on the outer sleeve in a sliding manner, the nail inlet and the sliding groove are sealed at the extreme position of the sliding sleeve, the nail inlet is completely opened at the other extreme position of the sliding sleeve, and a connecting rod penetrates the sliding groove and is fixedly connected with the sliding sleeve. The outer sleeve is connected with a high-pressure air pipe or a compression gas bottle through a valve. According to the rapid wall face decoration plate construction device, the high-pressure air can be conveniently utilized, nails are shot into a wall face, the corners of the decoration plate are limited through the nail heads and the wing plates, and accordingly decoration plate disengaging is prevented.

Owner:HUBEI PEI HAN CONSTR CO LTD

Cement mortar masonry building system based on BIM building model and working method of cement mortar masonry building system

InactiveCN109797977AHigh dimensional accuracyAvoid wastingBuilding material handlingSpecial data processing applicationsNumerical controlCement mortar

The invention discloses a cement mortar masonry building system based on a BIM building model and a working method of the cement mortar masonry building system. The system comprises a BIM design unit,a numerical control unit, an intelligent feeding unit, a masonry unit, a display unit, a monitoring unit and a detection and alarm unit.

Owner:ZHEJIANG GUANGSHA COLLEGE OF APPLIED CONSTRTECH

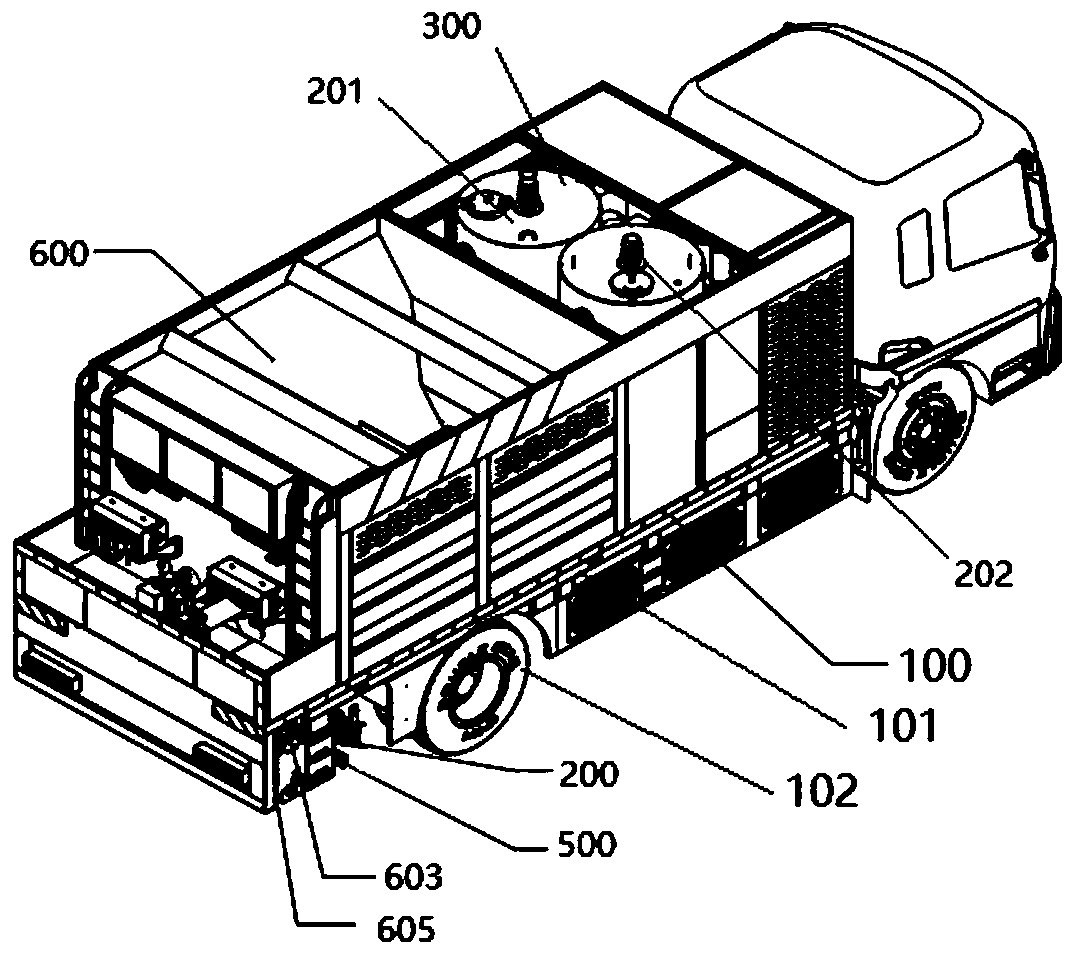

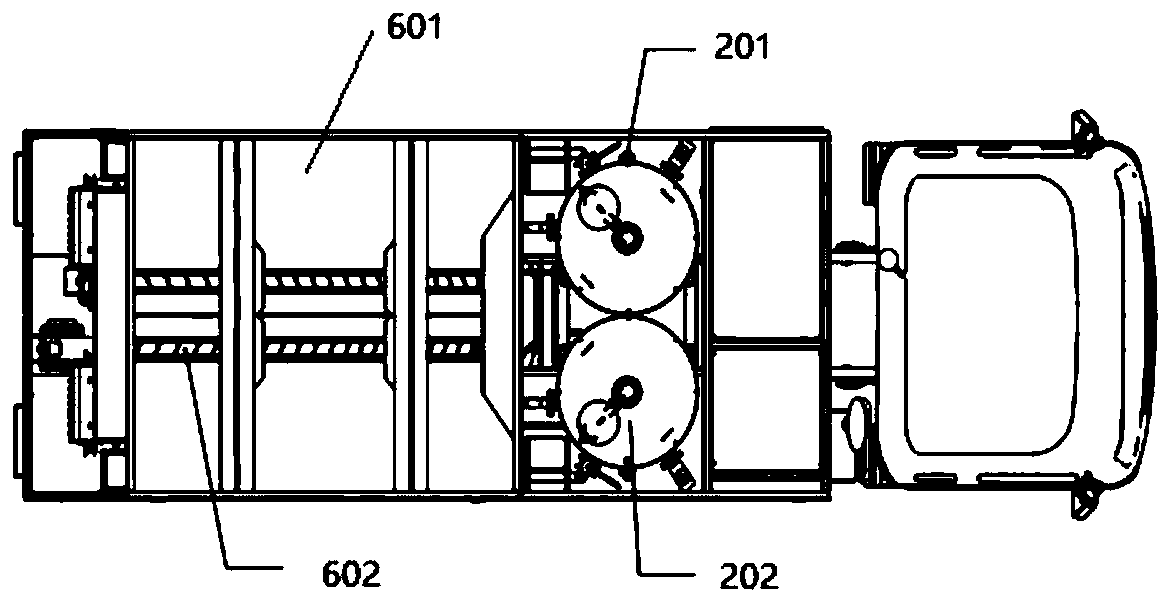

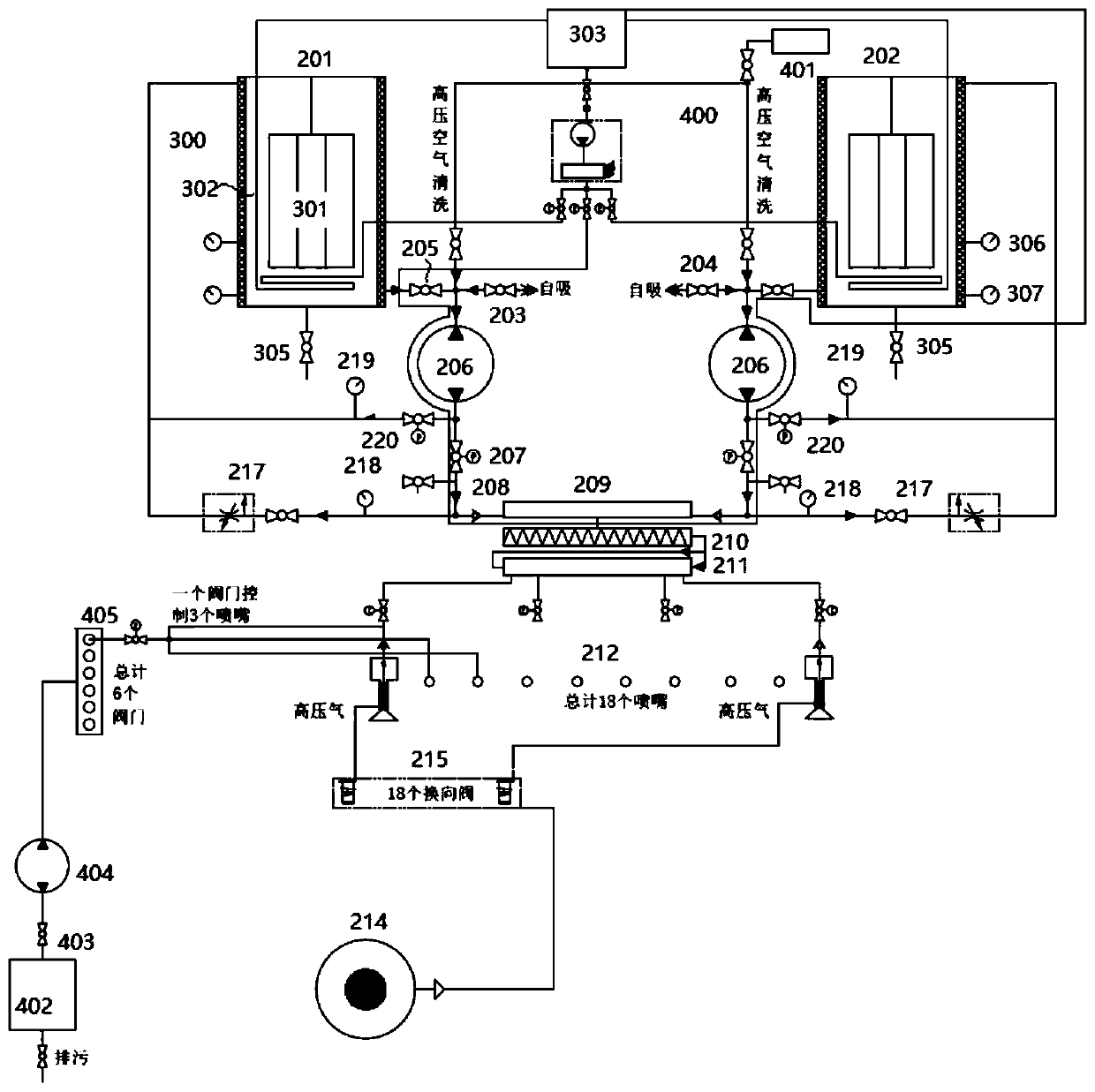

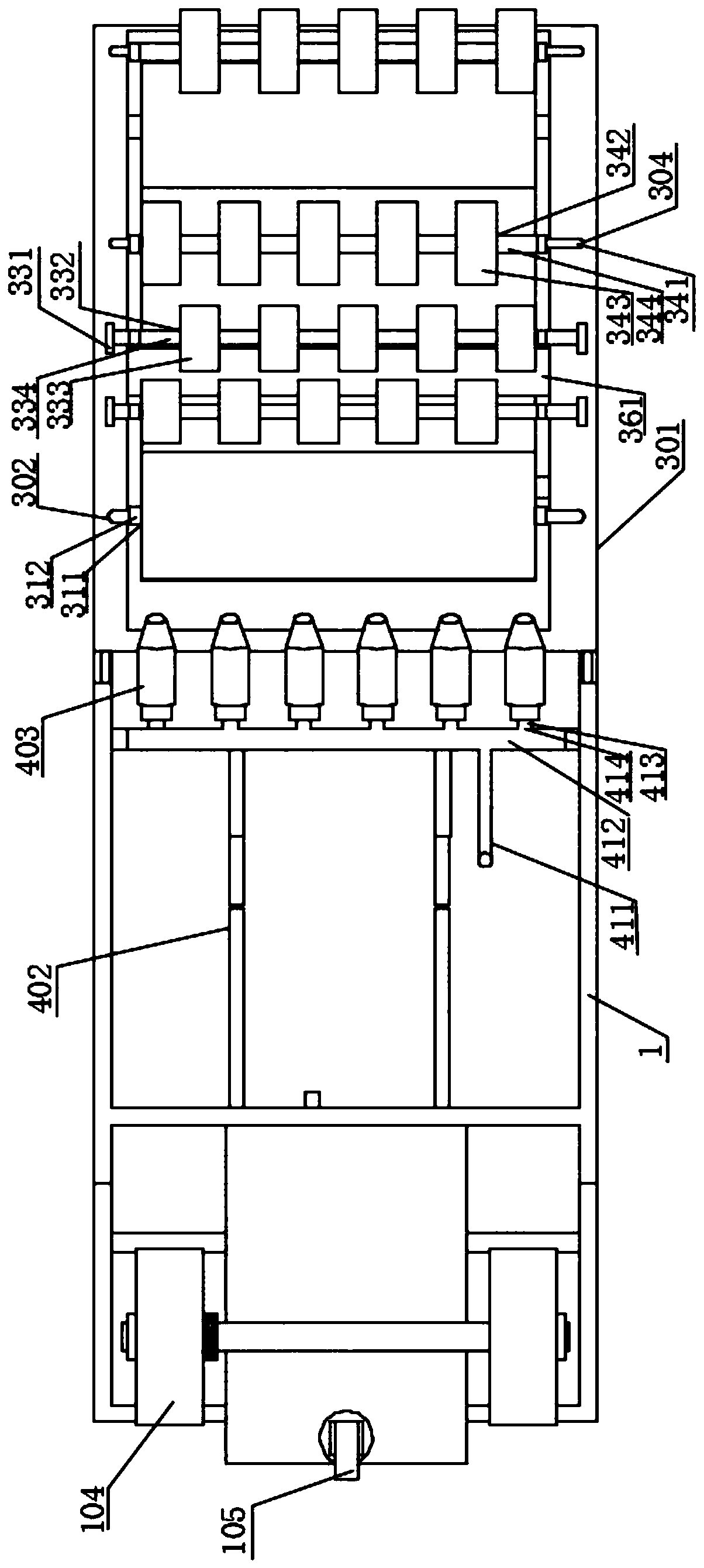

Integrated intelligent construction vehicle of bi-component equal-volume-ratio pavement material

The invention discloses an integrated intelligent construction vehicle of a bi-component equal-volume-ratio pavement material. The construction vehicle comprises a walking system, the walking system comprises a chassis, the chassis comprises a frame and a walking device located at the bottom of the frame, and the front part of the chassis is also provided with an operating system; and a spraying system, an auxiliary spraying system, a heating and heat preserving system, a cleaning system and a stone spreading system are arranged on the chassis. Spraying of a mixed coating and spreading of stones are completed in the one-way one-time form process of the construction vehicle, the construction efficiency of a colored thin anti-skid layer pavement is improved, the construction precision is high, coating and stone waste is greatly reduced, a construction area can be rapidly opened, and traffic jam is reduced.

Owner:重庆市智翔铺道技术工程有限公司

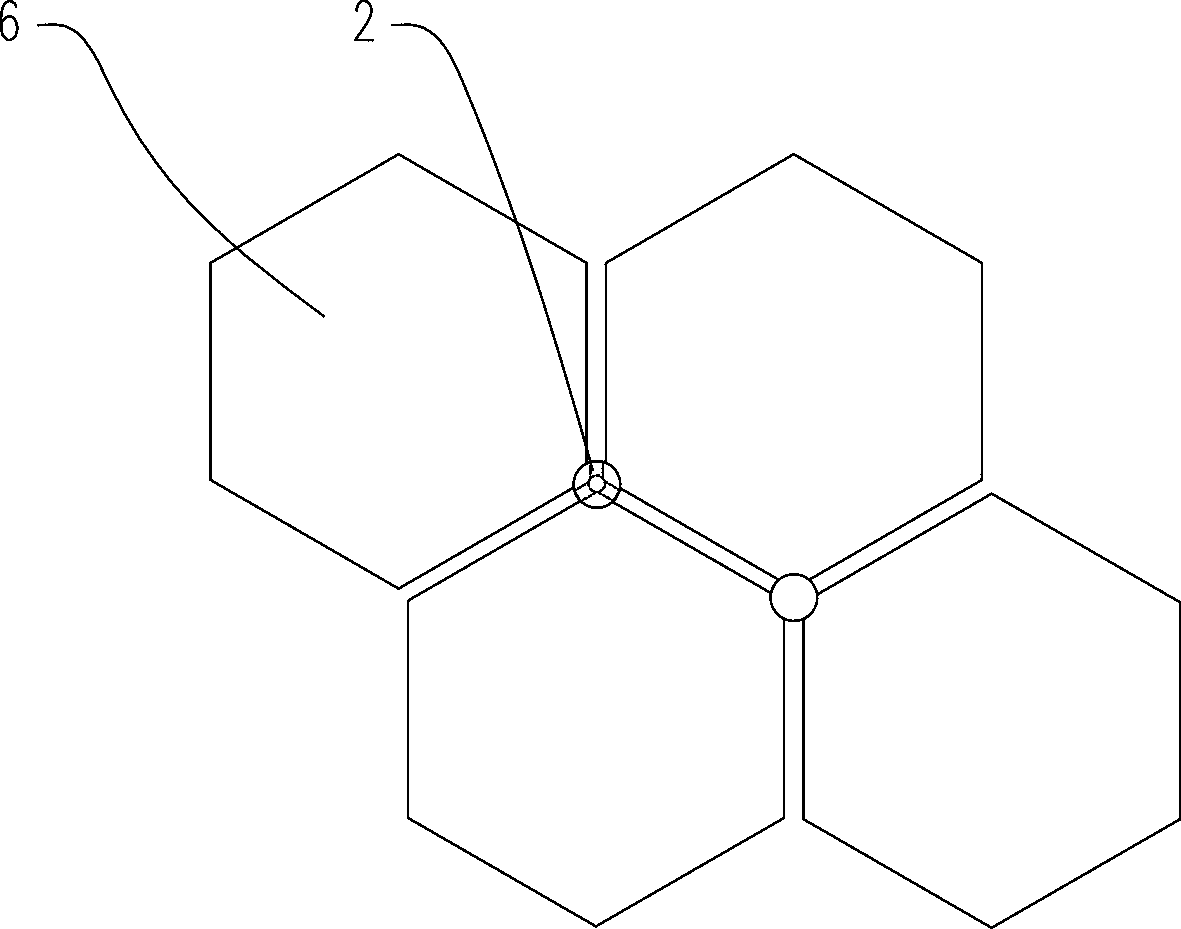

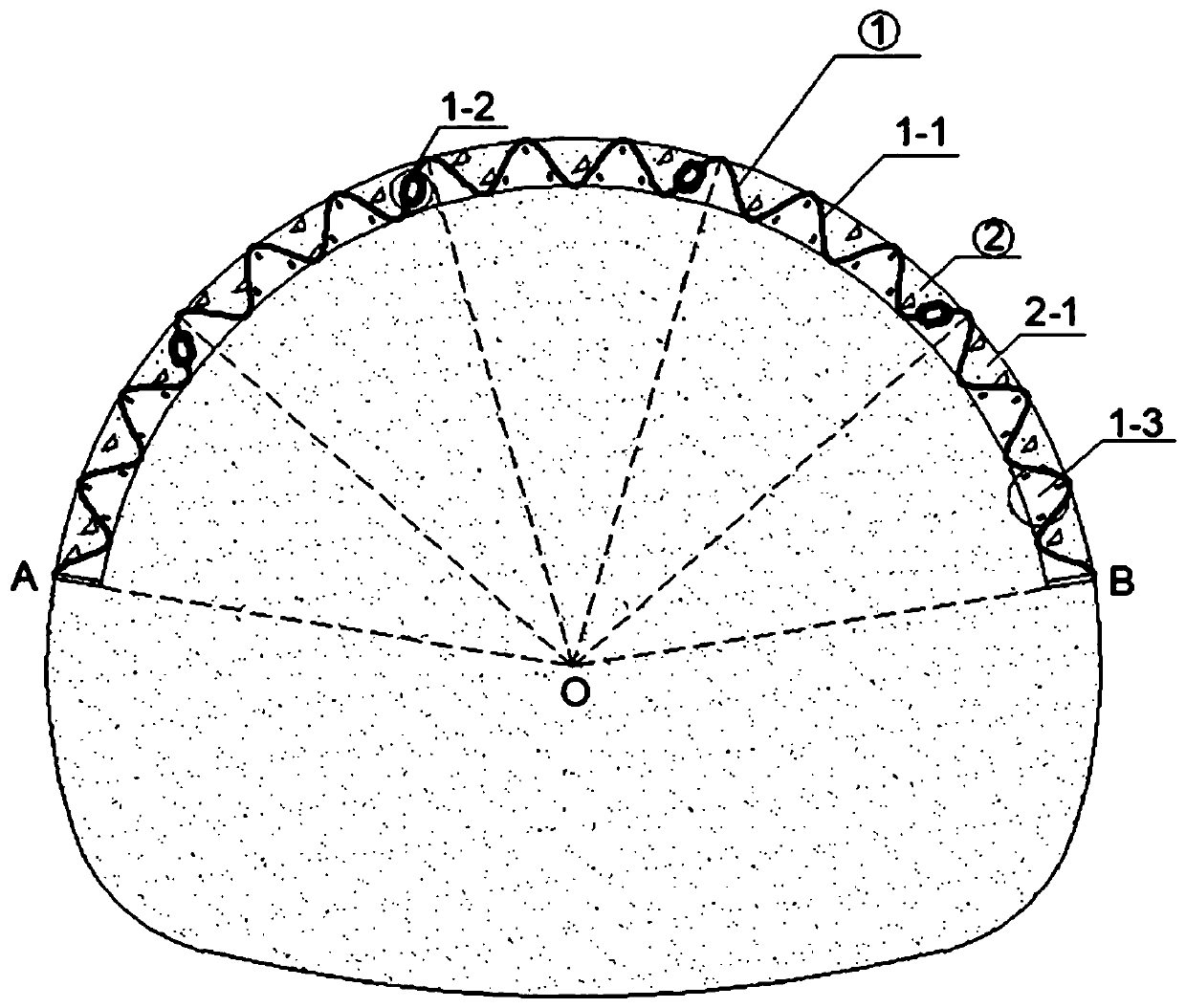

Advanced supporting structure spliced by adopting corrugated steel pipe sheets and advanced supporting method

PendingCN110924990AIncreased moment of inertiaHigh strengthUnderground chambersTunnel liningClassical mechanicsUltimate tensile strength

The invention relates to an advanced supporting structure spliced by adopting corrugated steel pipe sheets and an advanced supporting method. According to the structure and the method, the stability of an excavation working surface of the tunnel project can be guaranteed. The structure comprises a plurality of corrugated steel splicing modules and grout, wherein the corrugated steel splicing modules are mutually overlapped and fixed in the longitudinal direction of a tunnel, and the grout is used for filling the spaces between the corrugated steel splicing modules and a tunnel surrounding rockthrough injection; and each corrugated steel splicing module is composed of a plurality of corrugated steel pipe sheets, wherein the corrugated steel pipe sheets are assembled and formed by clampingin the circumferential direction through annular joints and fixedly connecting in the longitudinal direction through longitudinal joints. Compared with the prior art, the structure and the method havethe advantages that modular splicing is adopted, the construction efficiency is high, the structural strength is high, the structure can be used as an initial supporting structure, and intelligence,automatic construction and the like are facilitated.

Owner:TONGJI UNIV

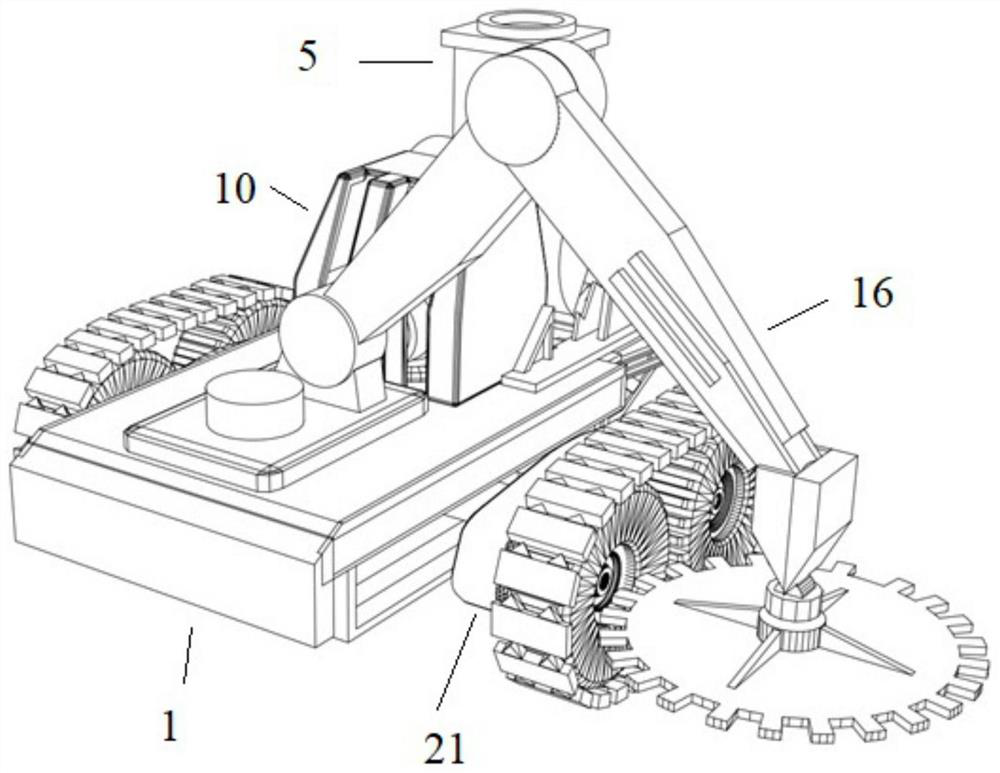

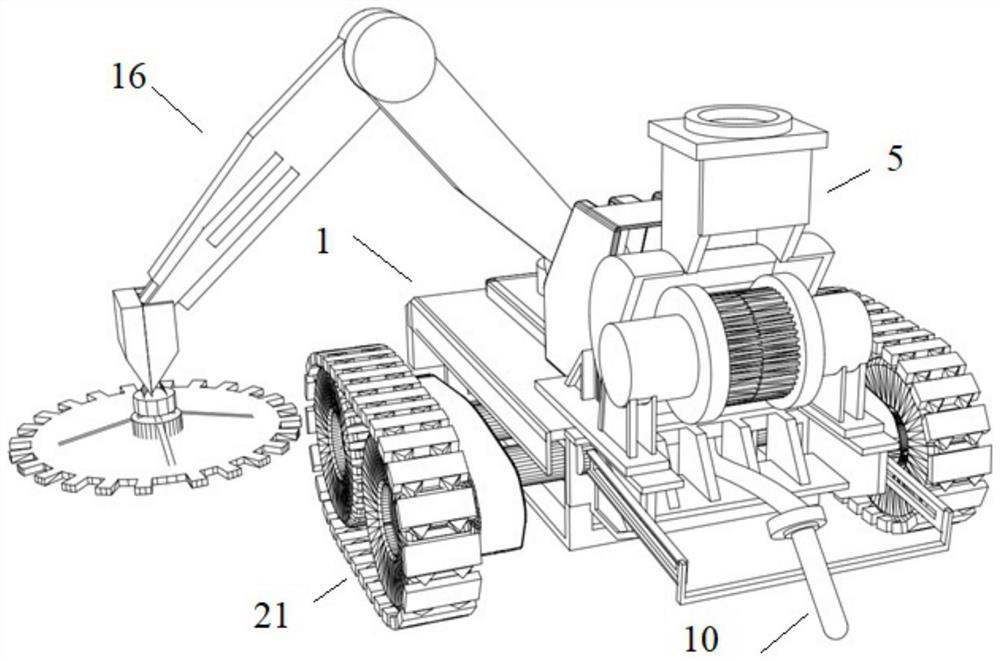

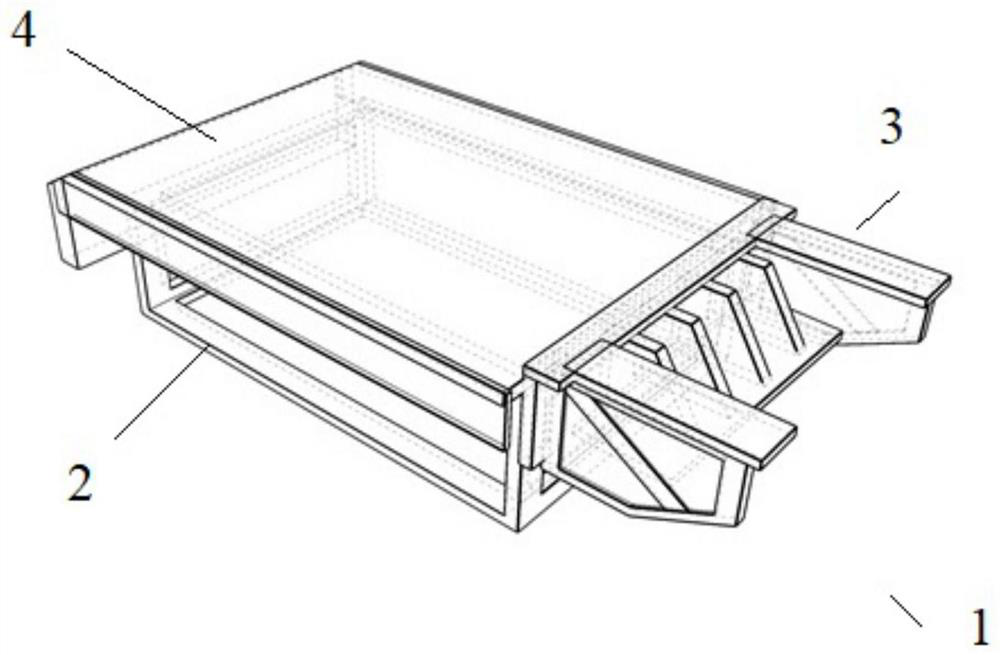

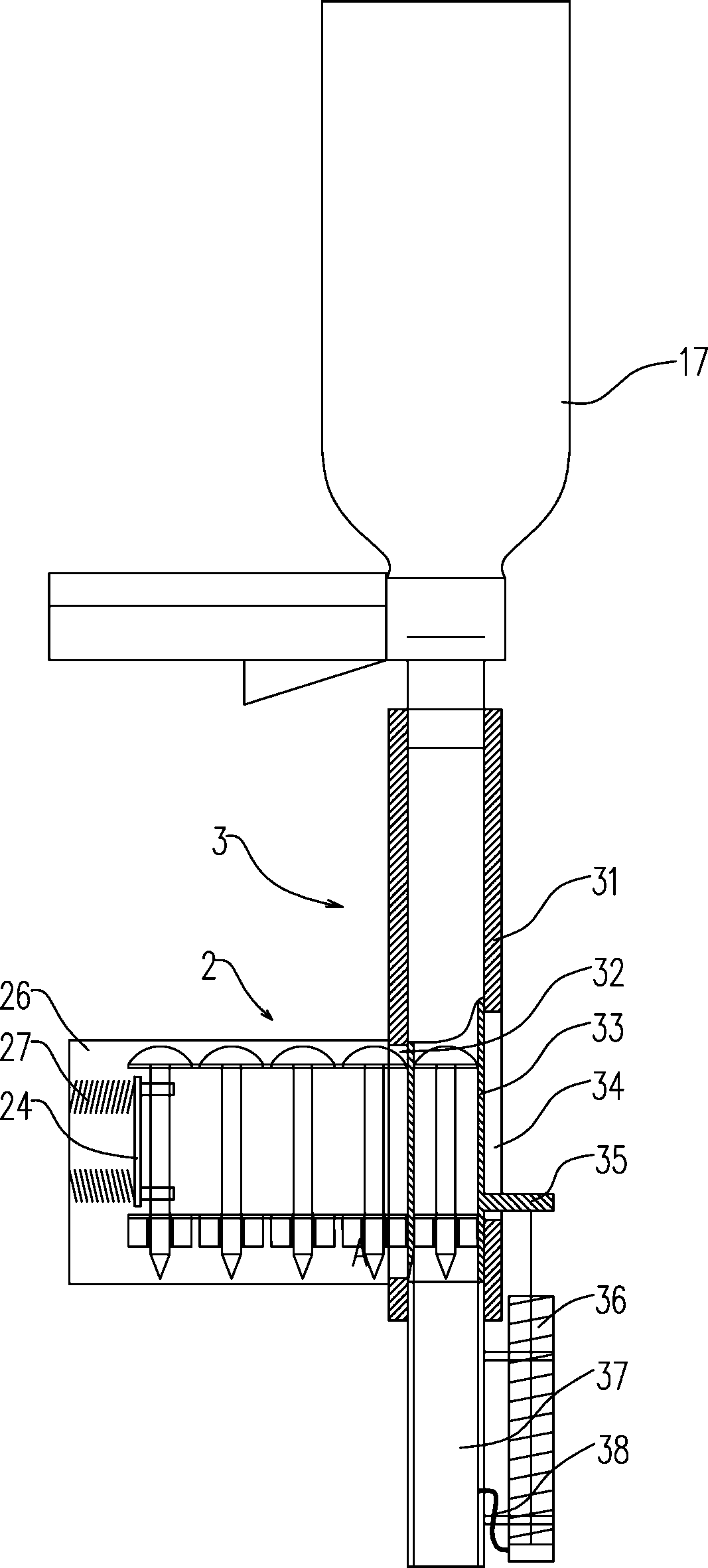

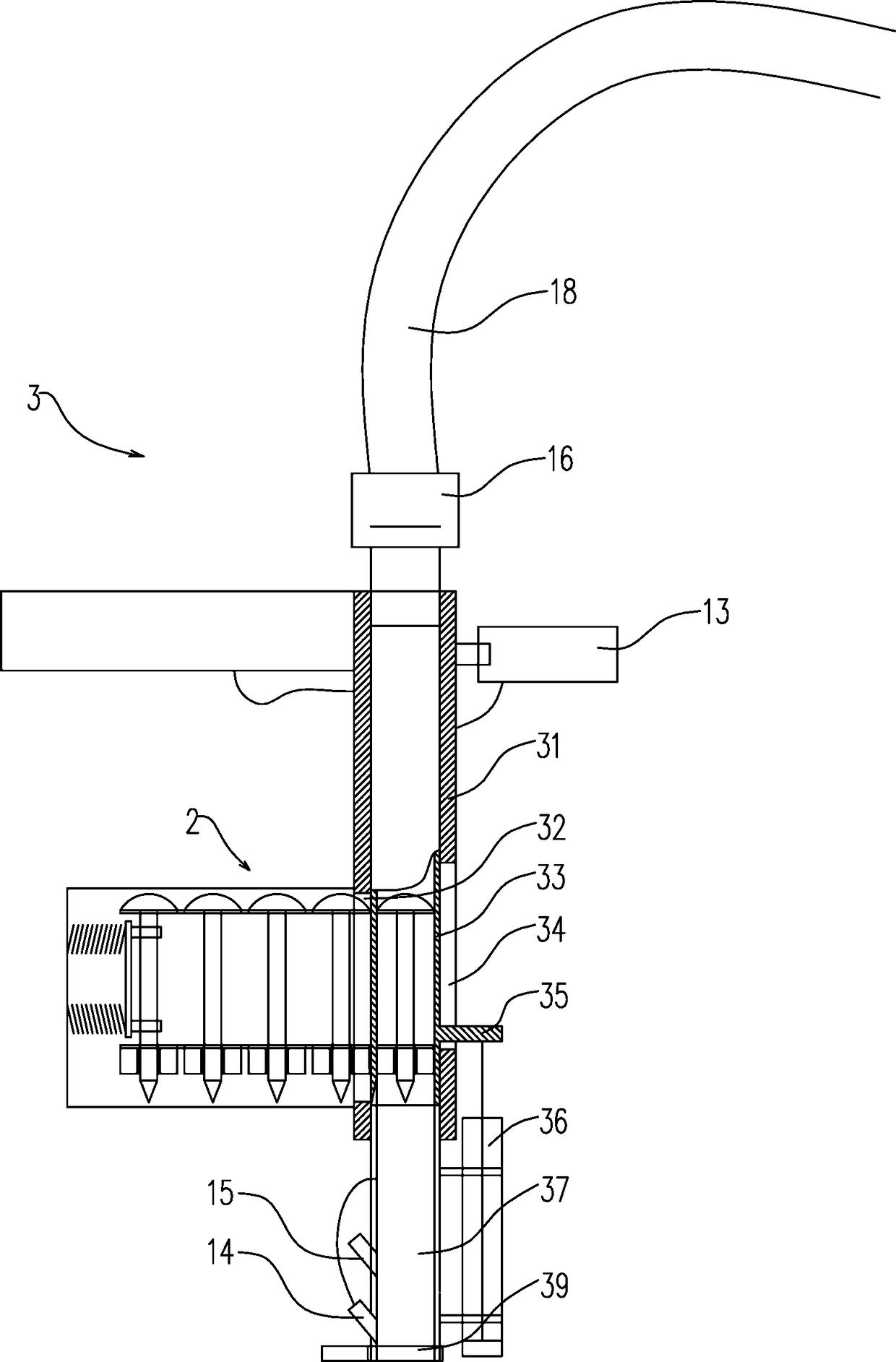

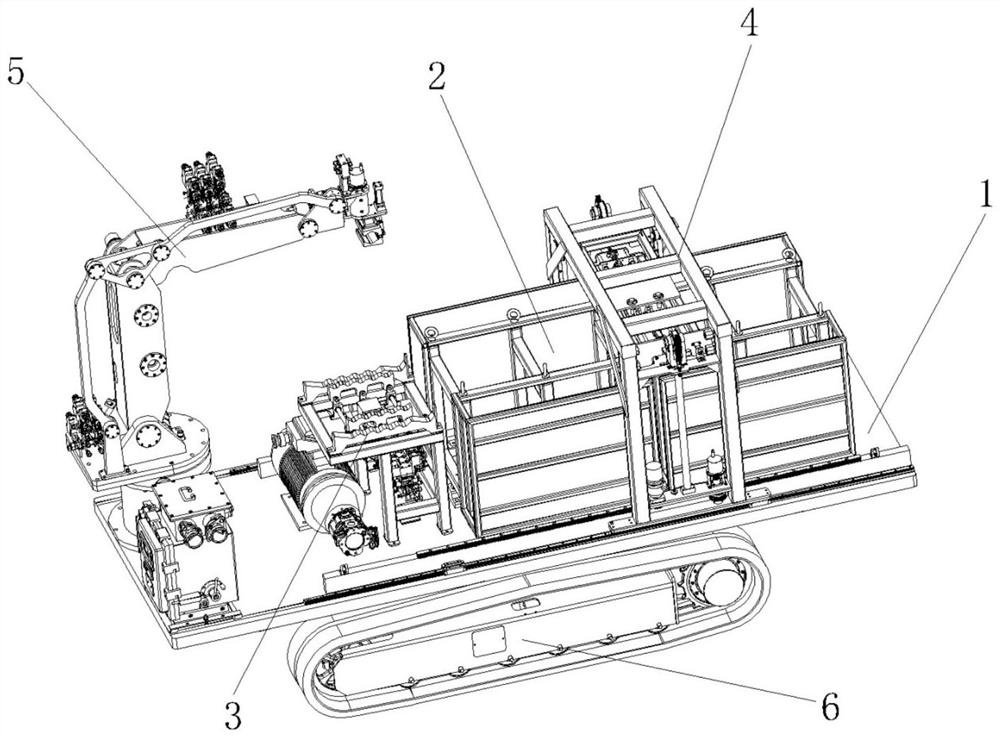

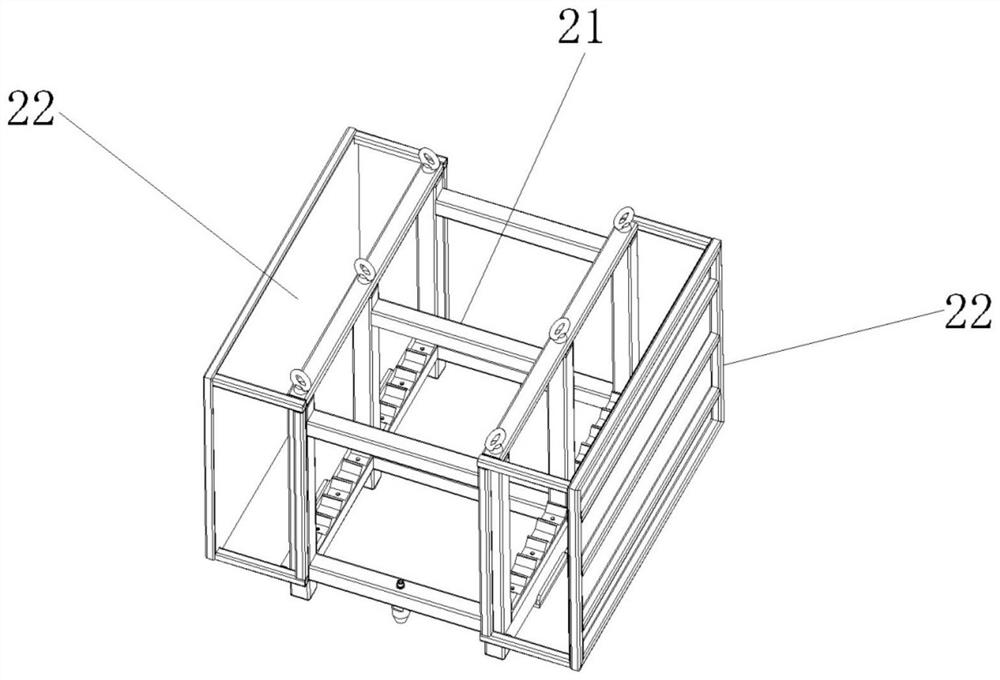

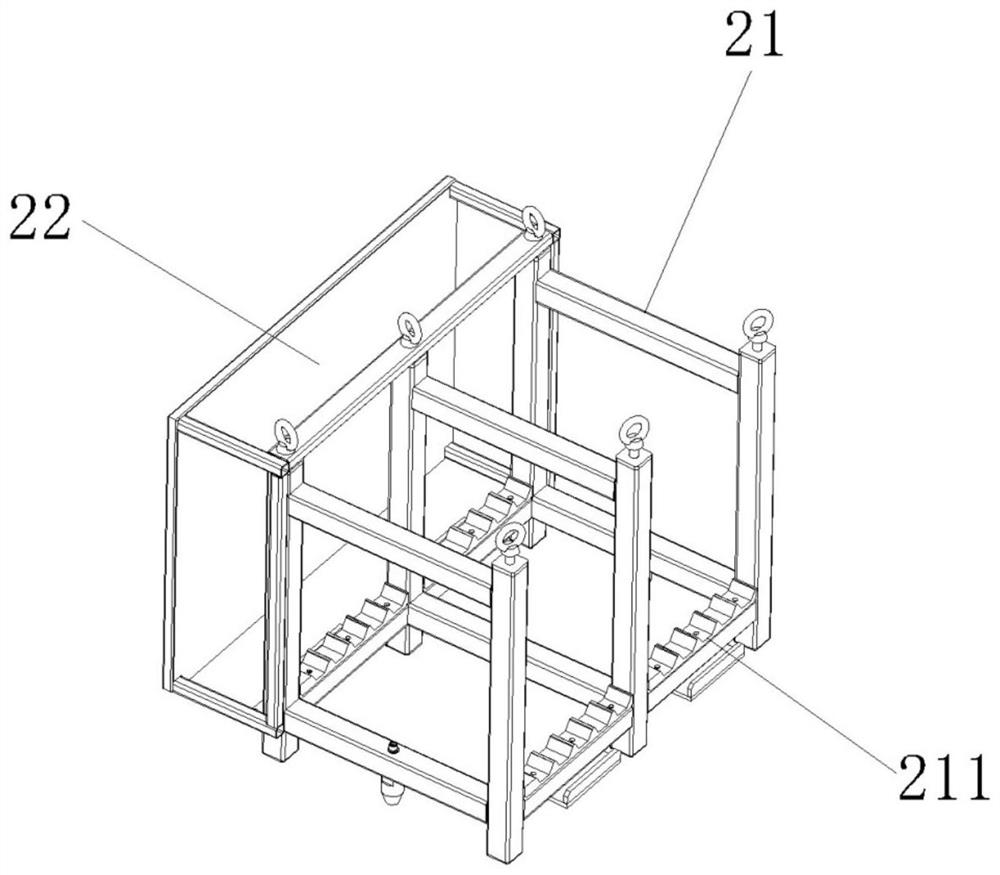

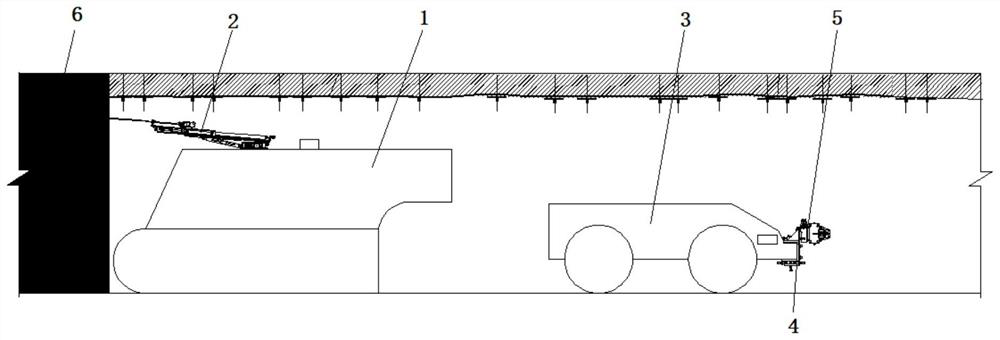

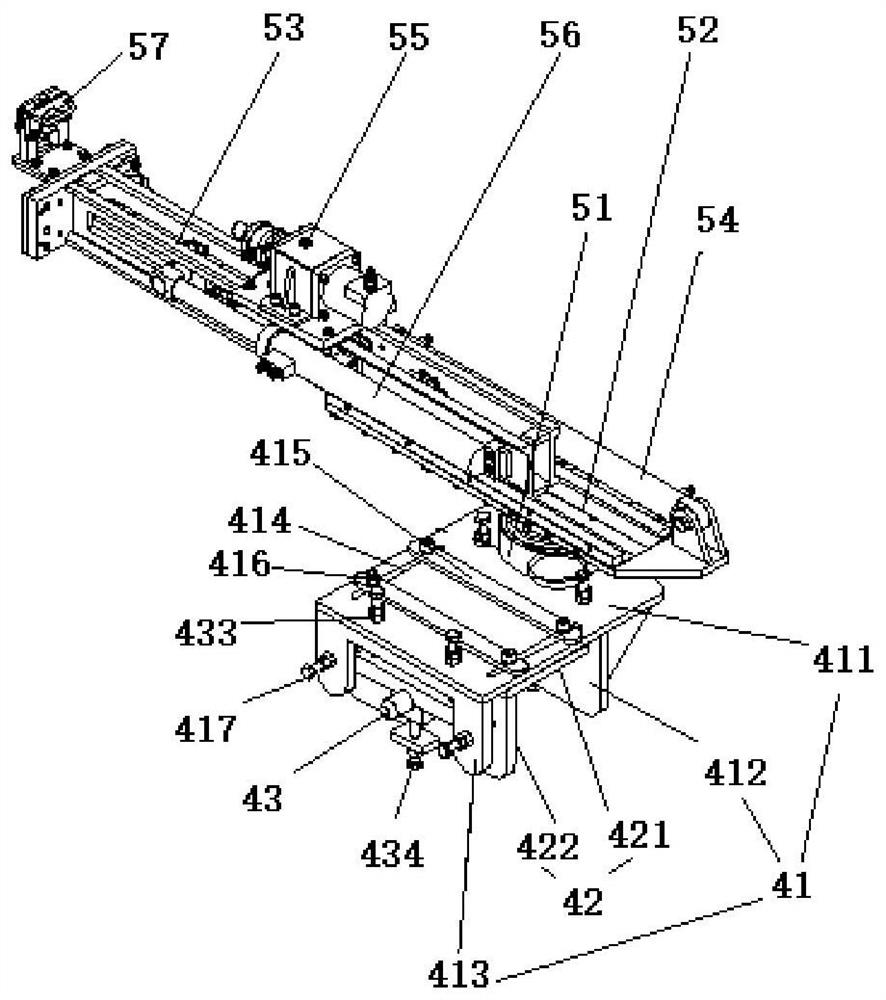

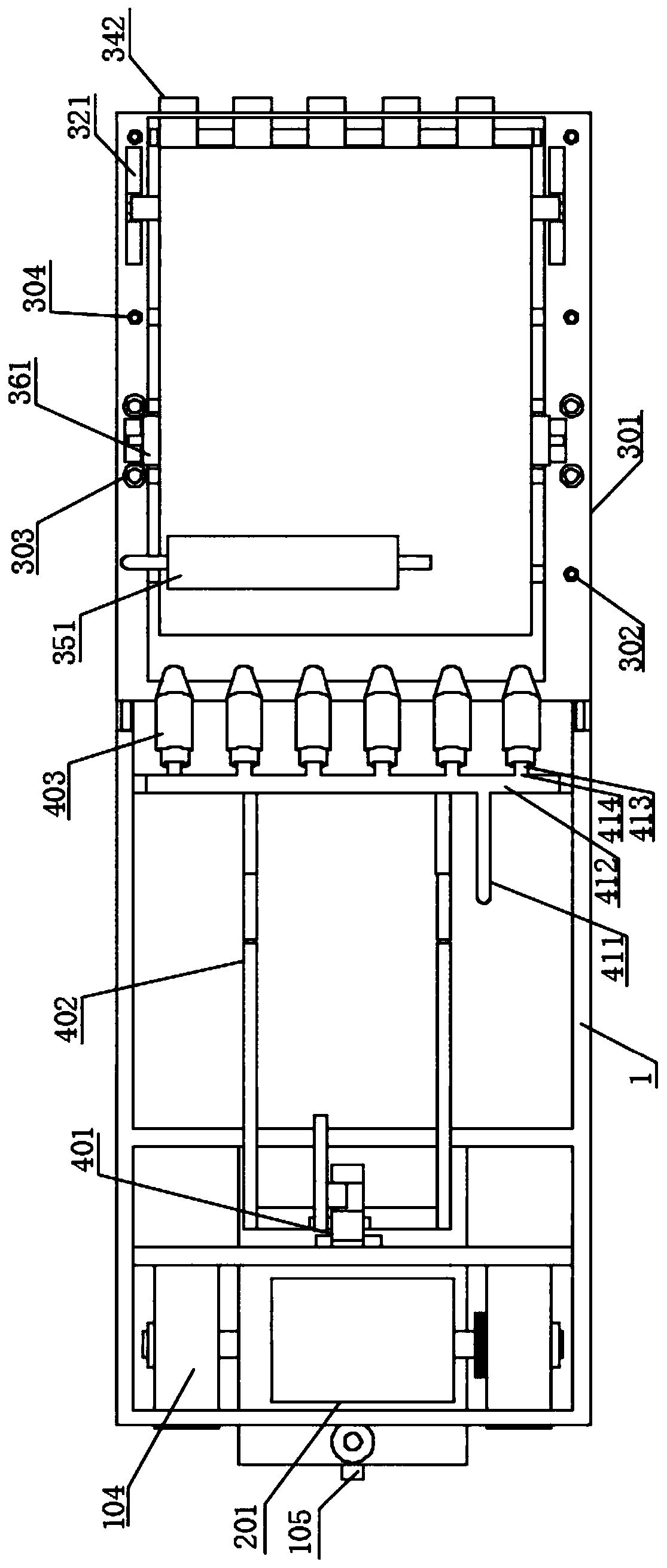

Automatic drill rod loading and unloading equipment

PendingCN114278238AGuaranteed normal transmissionAutomate operationDrilling rodsEndless track vehiclesEngineeringStructural engineering

The invention relates to the technical field of drill rod conveying, and discloses automatic drill rod loading and unloading equipment which comprises a rack, a stock bin, a drill rod transfer platform, a drill rod carrying device, a drill rod grabbing mechanical arm and a walking device, and the stock bin, the drill rod transfer platform, the drill rod carrying device, the drill rod grabbing mechanical arm and the walking device are arranged on the rack. The drill rod carrying device moves back and forth between the drill rod transfer platform and the stock bin, used drill rods are put into the stock bin, to-be-used drill rods in the stock bin are conveyed to the drill rod transfer platform, the drill rod grabbing mechanical arm is responsible for grabbing the drill rods, and the walking device is responsible for driving the whole rack to move. Compared with the prior art, the automatic drill rod loading and unloading equipment can achieve automatic operation of drill rod loading and unloading, manual operation is avoided, the construction efficiency is effectively improved, the good construction effect can be achieved for part of dangerous areas with large depth, and the using effect is excellent.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP +1

Rapid construction system and method for anchor rod holes on side wall of tunneling working face and advance borehole

ActiveCN112627725AEfficient productionSafe and efficient productionDerricks/mastsAnchoring boltsAutomatic controlDrill hole

The invention discloses a rapid construction system and a method for anchor rod holes on the side wall of a tunneling working face and an advance borehole. The rapid construction system comprises an upper machine-mounted drilling machine, a lower machine-mounted drilling machine and a control system, the upper machine-mounted drilling machine is installed on a top platform of a tunneling and anchoring machine and used for construction of upper row anchor rod holes in two walls of a tunneling working face roadway and the advance borehole, the advance borehole comprises a tunneling working face water exploring and discharging hole, a region verification hole and a coal seam water injection hole, so that multi-purpose efficient utilization of the upper machine-mounted drilling machine is achieved, the lower machine-mounted drilling machine is mounted at the tail joint of a shuttle car and used for constructing lower row anchor rod holes in the two walls of the roadway, and the control system comprises a drill jamming control module, an automatic drilling module and a mode selection module and is used for automatic control over drilling construction of the drilling machine. According to the rapid construction system and the method for the anchor rod holes on the side wall of the tunneling working face and the advance borehole, comprehensive construction of tunneling, supporting, water exploring and discharging, region verification and water injection and dust reduction is achieved, the side wall anchor rod supporting efficiency is improved, the construction safety of a tunneling working face is guaranteed, dust on the tunneling working face is reduced, and the system and the method have great significance in efficient, safe and environment-friendly underground mining.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP +1

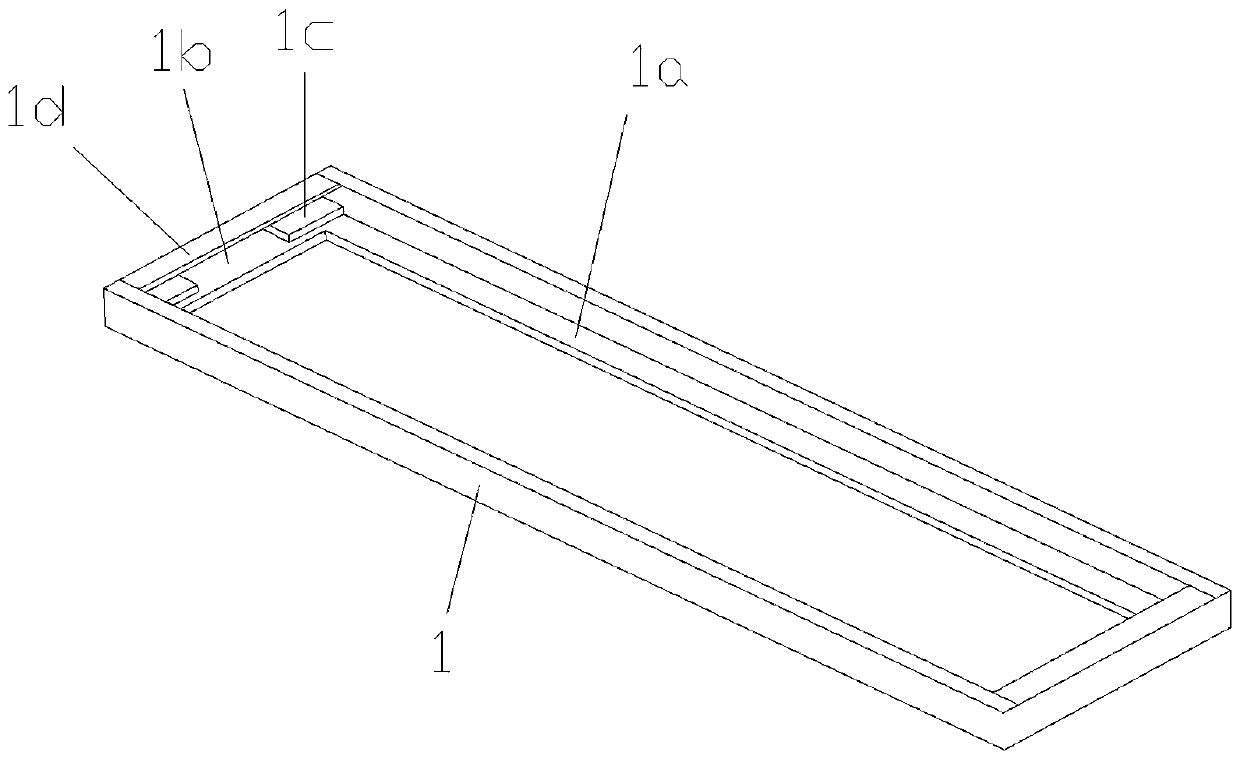

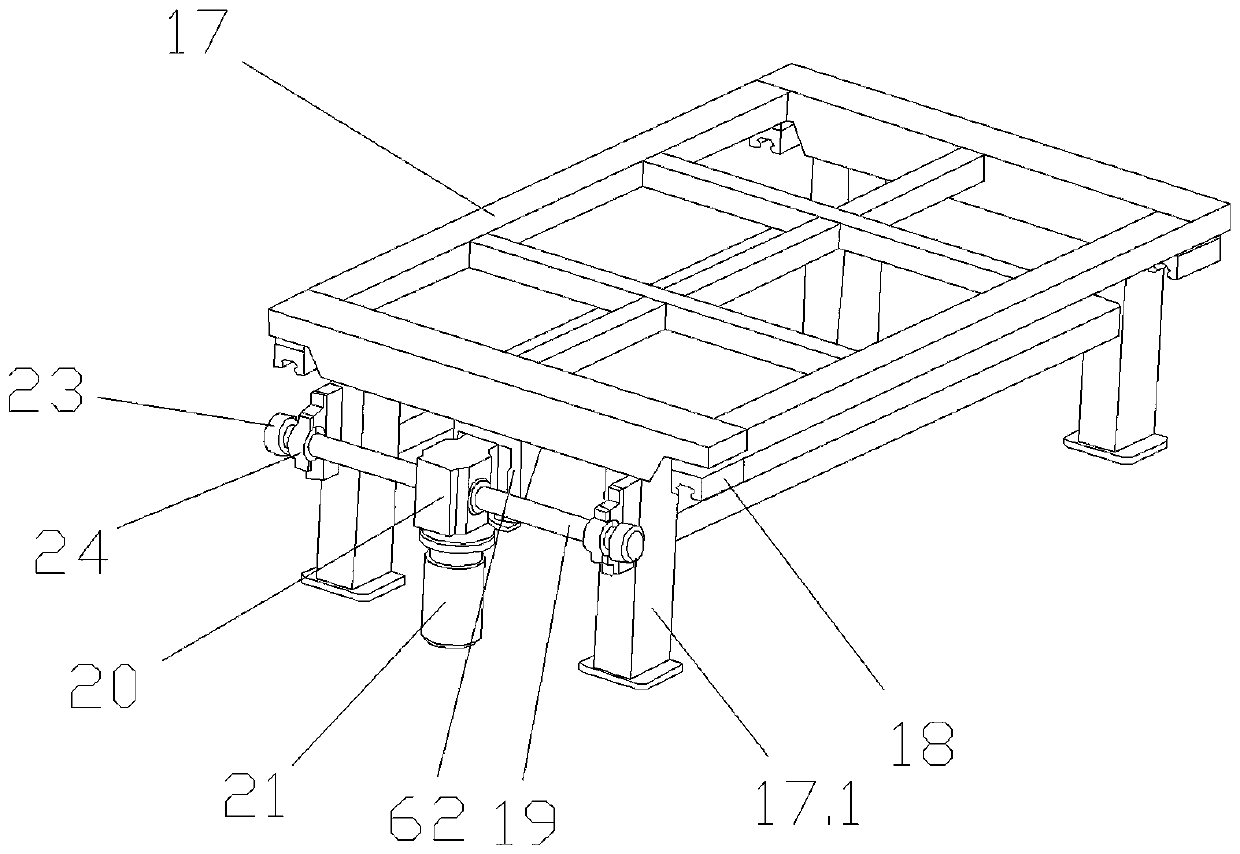

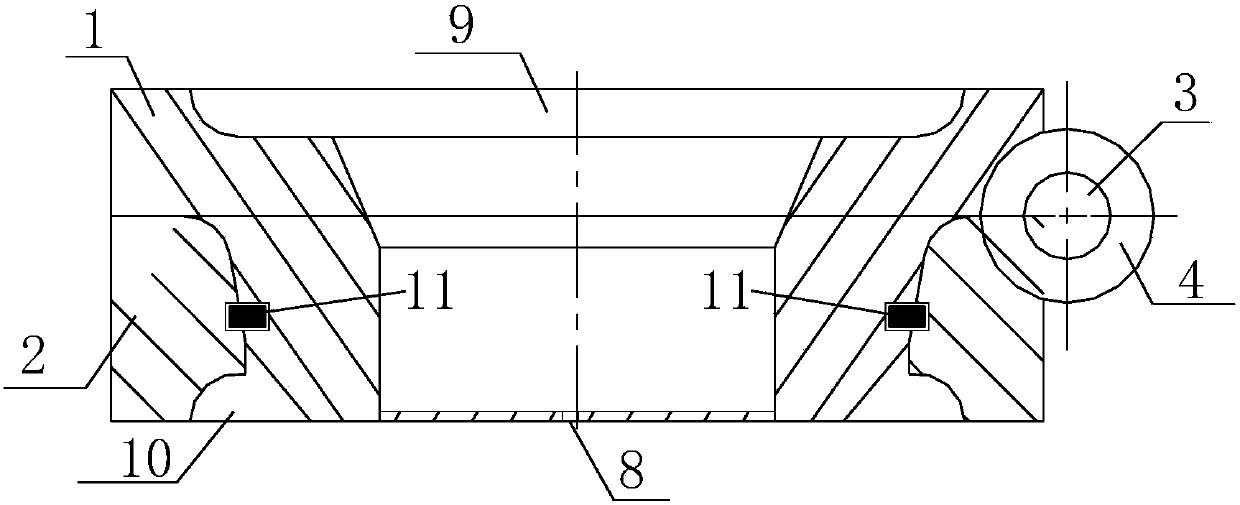

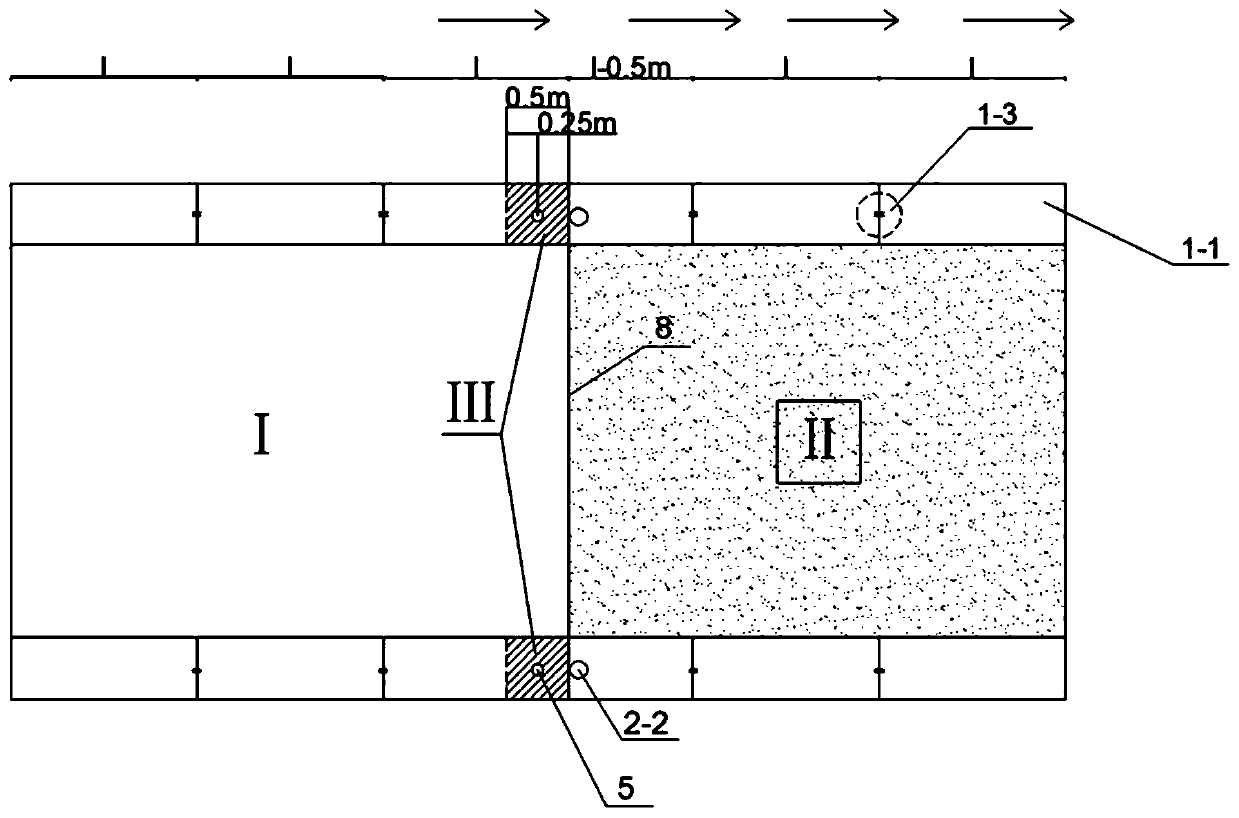

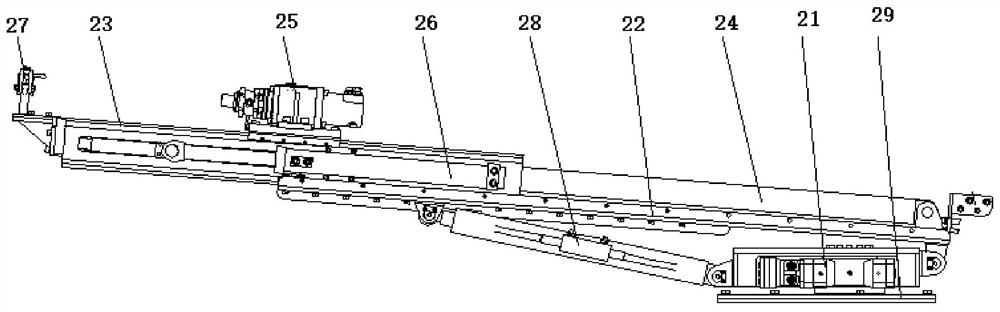

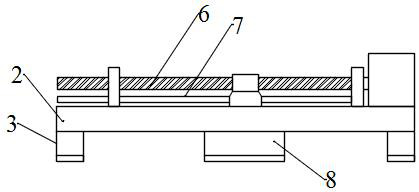

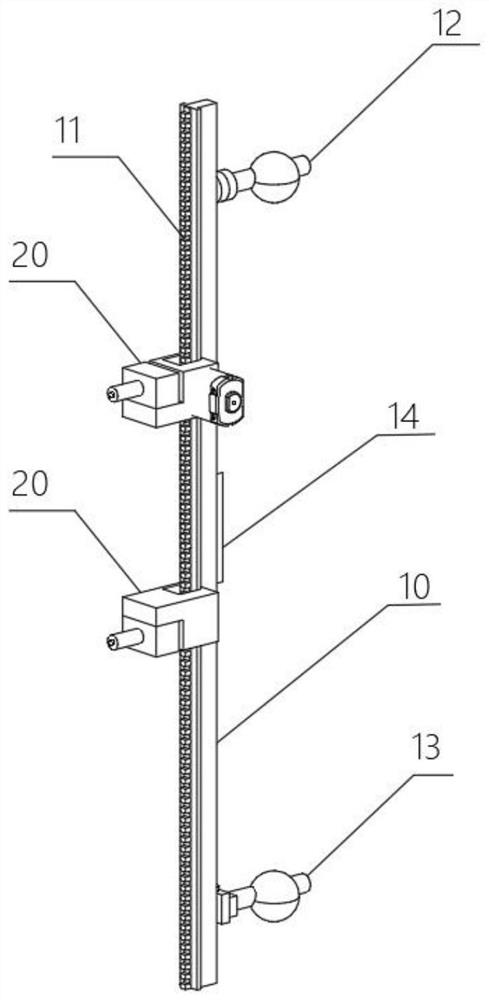

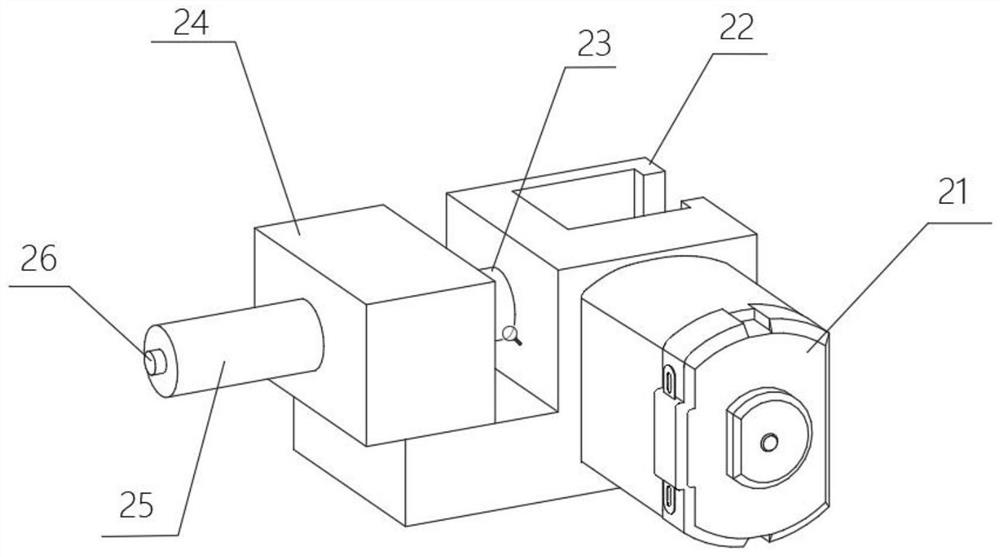

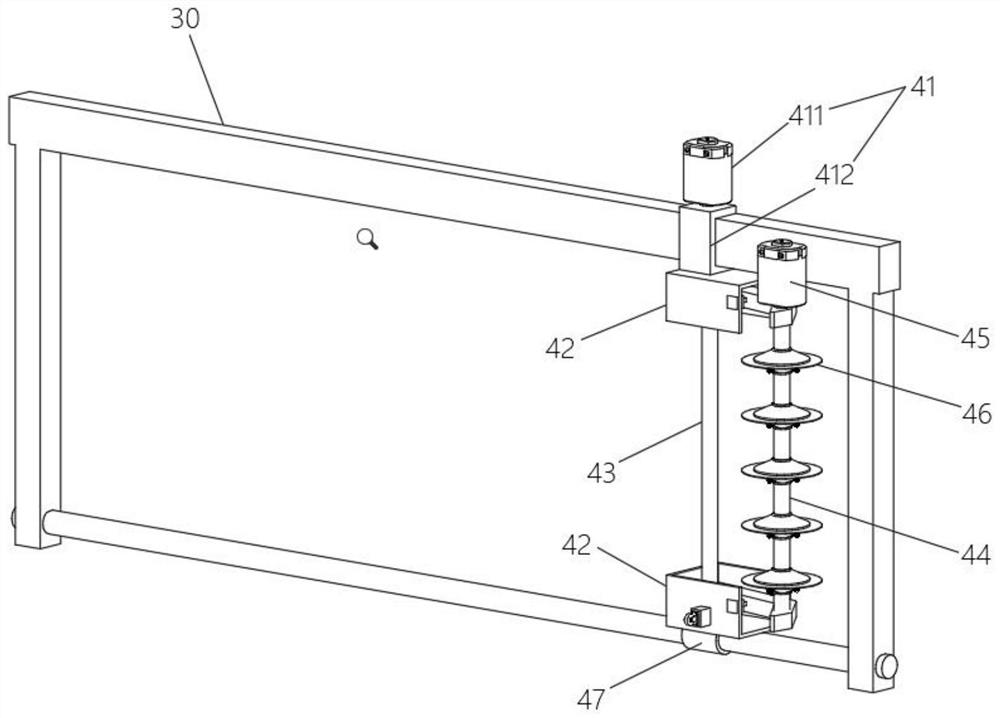

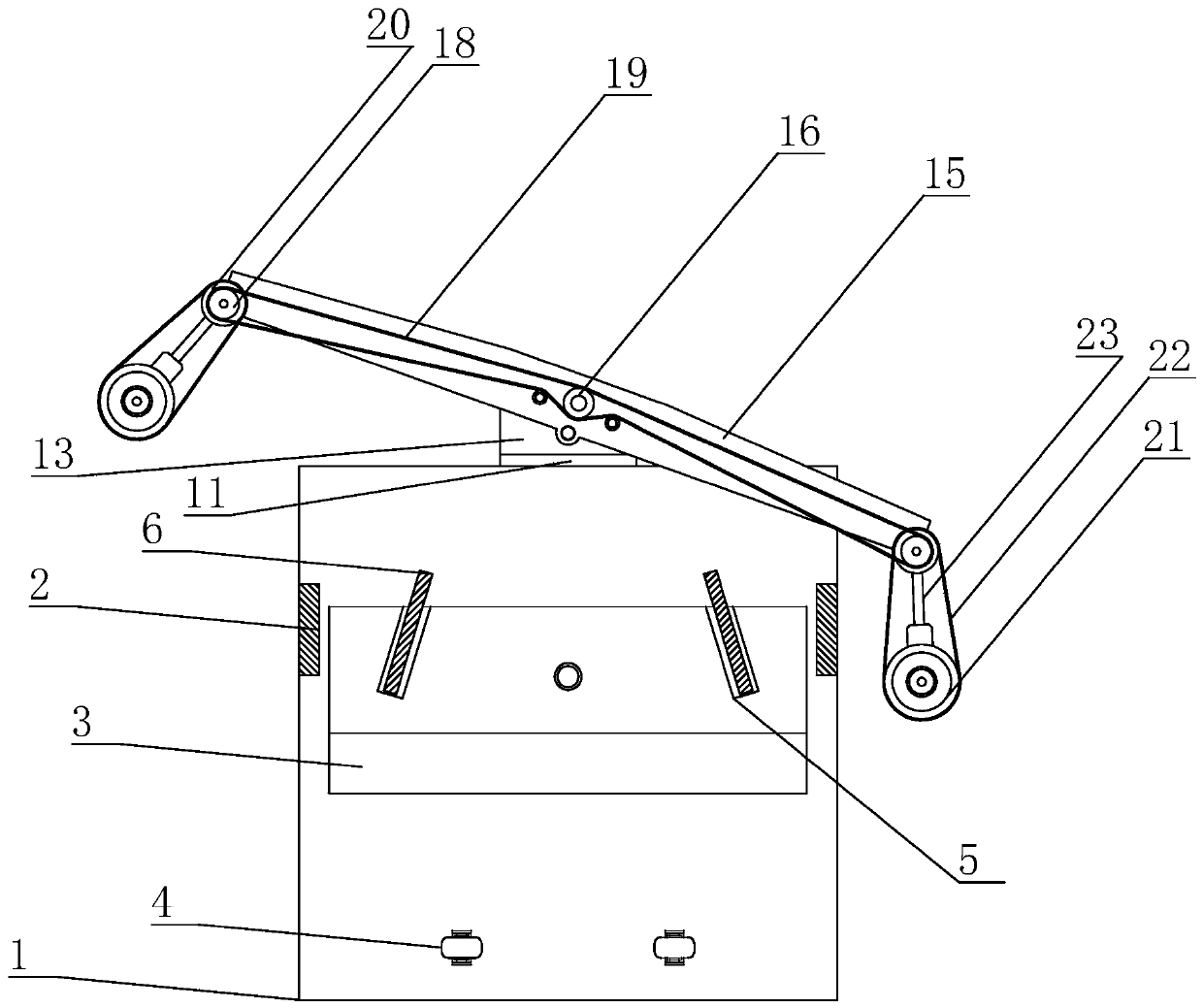

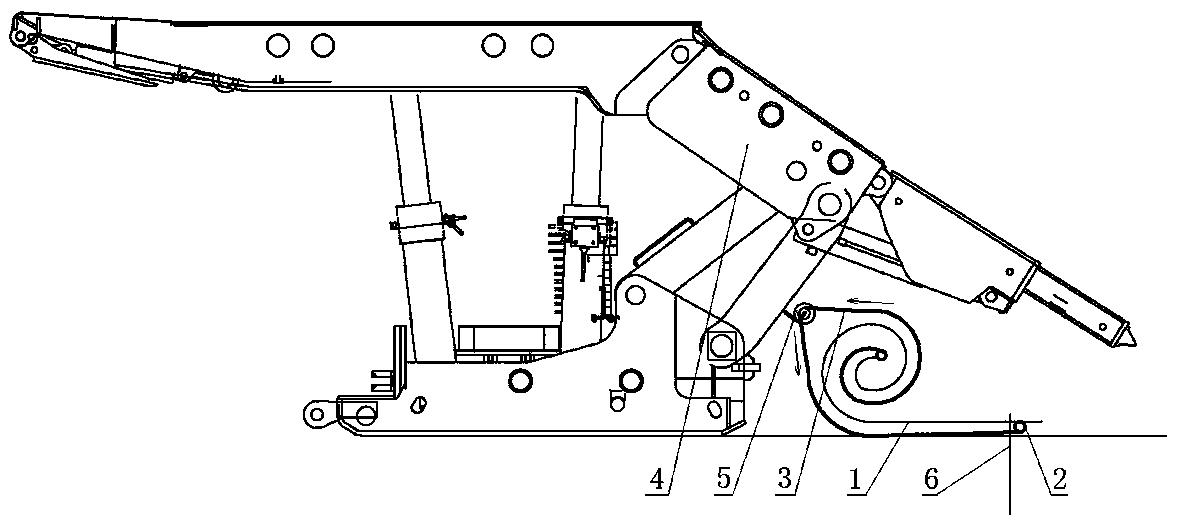

Spreading device for trackless intelligent spreading device

ActiveCN107513908ARealize automated constructionGood construction performanceClimate change adaptationRailway track constructionGear wheelTrackway

The invention relates to a spreading device for a trackless intelligent spreading device. The spreading device comprises an adjusting frame (1), wherein a spreading vehicle (10) is connected to the adjusting frame (1); racks (11) are fixedly connected with the adjusting frame; the spreading vehicle comprises a walking frame (17); a walking motor (21) is mounted on one side of the walking frame; the walking motor is connected with a rotating shaft (19), gears (23) which are respectively meshed with the racks are connected to the rotating shaft; a spreading wagon (15) is mounted on the walking frame (17); the spreading wagon (15) comprises a spreading frame (25); a soil spreading hopper (27), a vibrating device (28), a material distributing device (29), a vibrating roller device (30) and a leveling roller device (31) are sequentially mounted on the spreading frame (25) in the moving direction from front to rear. The spreading device disclosed by the invention has the advantages that the spreading device is used for the spreading of cement concrete of track in a tunnel; automated construction can be realized by the equipment, and spreading, vibrating, compacting and leveling are completed at a time; and the spreading device is good in constructing effect and high in operating efficiency.

Owner:ANHUI XINGYU TRACK EQUIP

Rapid construction device for wall decorative panels

InactiveCN108547841BInhibit sheddingEasy to installCovering/liningsStaplesGas cylinderExtreme position

The invention provides a rapid wall face decoration plate construction device. The rapid wall face decoration plate construction device comprises nails and a nail gun. In each nail, a nail head is arranged at one end of a nail column of each nail, wherein the end away from the nail head is provided with a sleeve capable of sliding, and the outer wall of the sleeve is provided with a wing plate corresponding to a decoration plate spliced gap. In the nail gun, an outer sleeve and an inner sleeve are fixedly connected, a nail inlet is formed in one side of the outer sleeve, and a sliding groove is further formed in the outer wall of the outer sleeve. A sliding sleeve is arranged on the outer sleeve in a sliding manner, the nail inlet and the sliding groove are sealed at the extreme position of the sliding sleeve, the nail inlet is completely opened at the other extreme position of the sliding sleeve, and a connecting rod penetrates the sliding groove and is fixedly connected with the sliding sleeve. The outer sleeve is connected with a high-pressure air pipe or a compression gas bottle through a valve. According to the rapid wall face decoration plate construction device, the high-pressure air can be conveniently utilized, nails are shot into a wall face, the corners of the decoration plate are limited through the nail heads and the wing plates, and accordingly decoration plate disengaging is prevented.

Owner:HUBEI PEI HAN CONSTR CO LTD

A tunneling and assembly structure of a comprehensive utility gallery and its construction method

ActiveCN104912101BShallow excavation depthSection section is smallArtificial islandsExcavationsPre expansionUtility tunnel

The invention relates to a tunneling and assembling structure of a comprehensive pipe gallery and a construction method thereof. The first end of the foundation pit is provided with shield backing equipment, and the second end is provided with a U-shaped shield machine; the shield backing equipment and U The intermediate parts set between the type shield machines include: an expanded jack or its combination with one or more sections of the prefabricated section of the pipe gallery, or a section of pit or its combination with one or more sections of the prefabricated section of the pipe gallery combination, or one or more prefabricated sections of pipe gallery. The invention effectively improves the efficiency and economy of the construction of the comprehensive pipe gallery.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

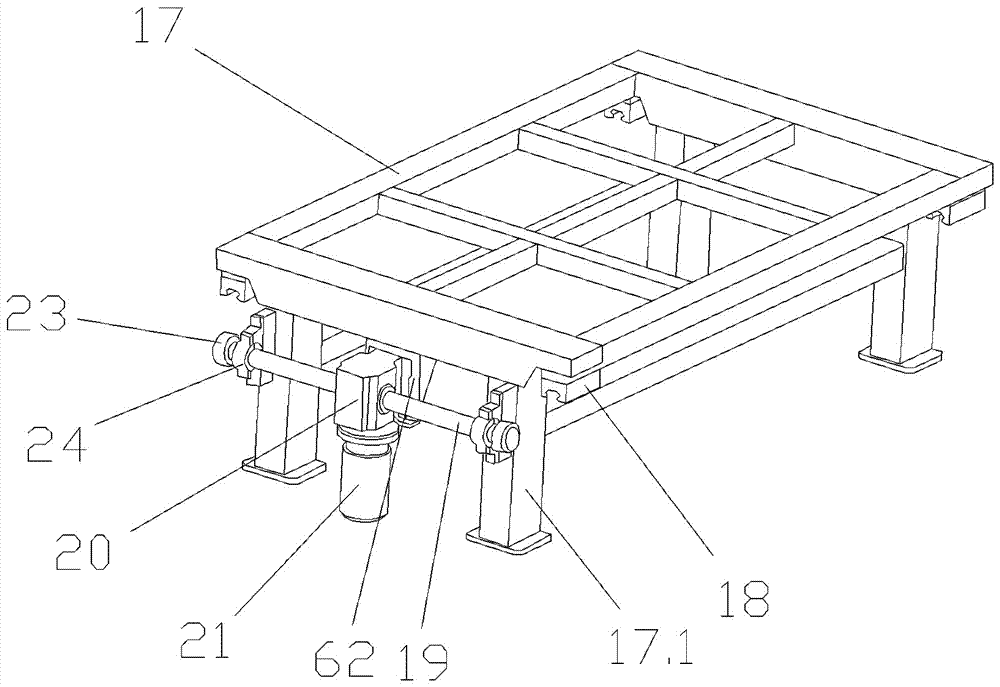

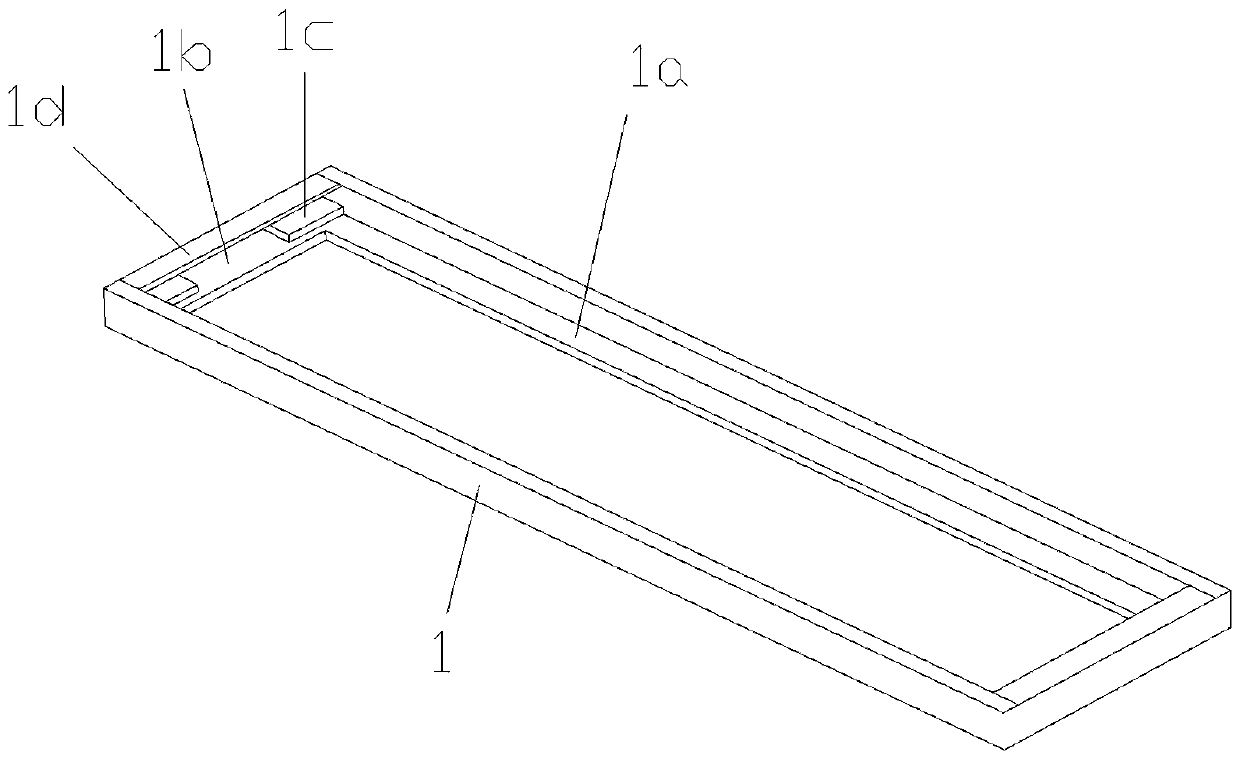

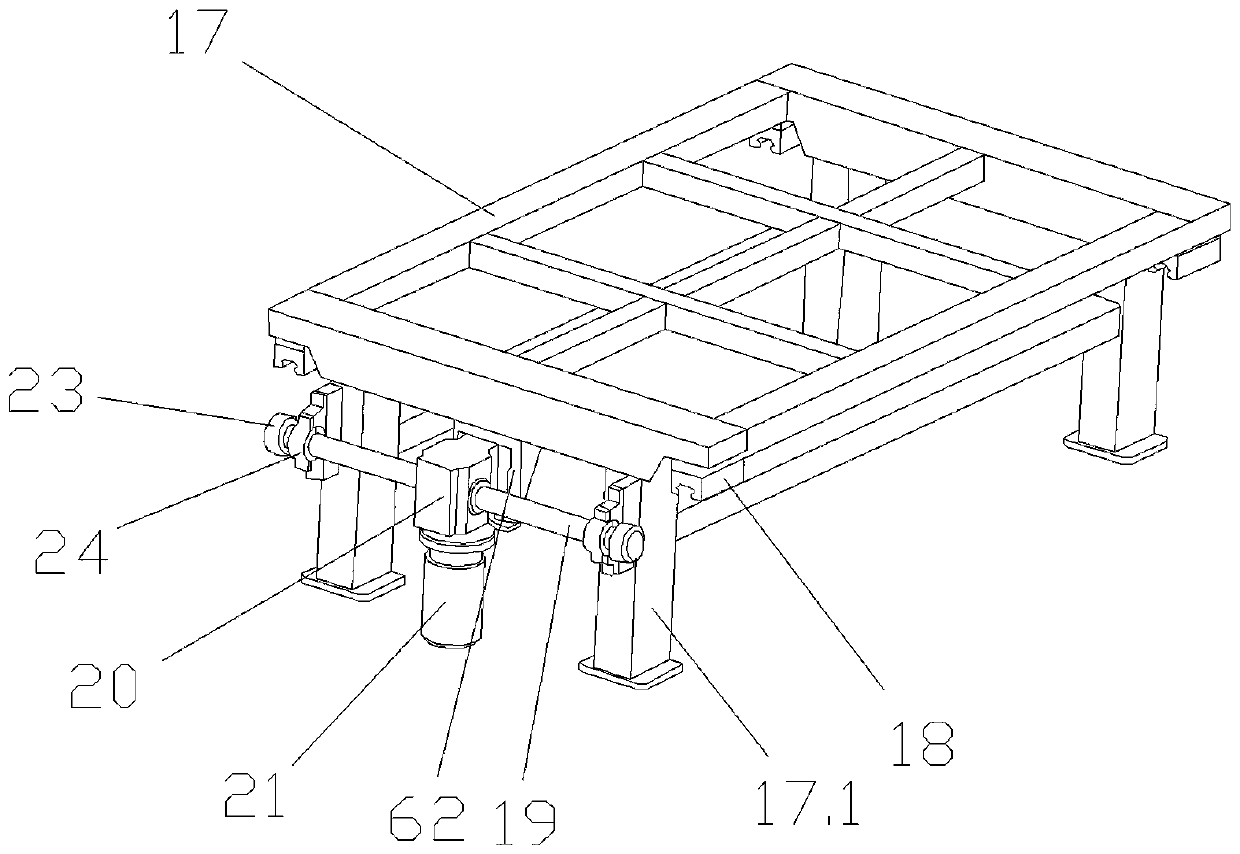

A Beam Segment Sliding Device Applicable to Curved Beams

ActiveCN109594476BSuitable for automatic sliding constructionRealize automated constructionBridge erection/assemblyVertical planeClassical mechanics

The invention relates to a beam segment sliding device suitable for curved beams. The beam segment sliding device comprises an upper bearing platform, a jacking jack, a middle supporting platform anda lower sliding shoe which are successively arranged from top to bottom, the middle supporting platform and the lower sliding shoe are matched through a sphere, and can rotate relatively in the vertical plane, a sliding boot fixing frame capable of rotating in the horizontal plane is further arranged at the rear end of the lower sliding shoe, and the beam segment sliding device further comprises apushing jack and a tail sliding shoe, wherein the sliding boot fixing frame and the tail sliding shoe are rotatably connected to the two ends of the pushing jack correspondingly. Compared with the prior art, according to the beam segment sliding device suitable for the curved beams, through arrangement of two steering regulating mechanisms, the whole beam segment sliding device can be suitable for automatic sliding construction under various working conditions such as the variable beam depth and horizontal curves, and the sliding flexibility and accuracy are improved.

Owner:TONGJI UNIV

Ramp lifting ramp construction device

PendingCN113107149AFlexible constructionImprove construction efficiencyRampsLinear motionDrive by wire

The invention discloses a ramp lifting ramp construction device. The ramp lifting ramp construction device comprises a mechanical arm, a mounting frame body, a linear driving device, a driving seat and a lifting ramp device. The mechanical arm is connected with the mounting frame body, the linear driving device is arranged on the mounting frame body, and the linear driving device drives the driving seat to linearly move in the length direction of the mounting frame body; and a lifting ramp device is arranged at the bottom of the driving seat, a zigzag lifting ramp surface is arranged at the bottom of the lifting ramp device, the driving seat is in sliding connection with the lifting ramp device, and the driving seat and the lifting ramp device are directly provided with a lifting driving device. Overall automatic construction of the mounting frame body is driven by the mechanical arm, and the lifting ramp device performs linear motion type construction in the construction direction through the linear driving device, so that the construction efficiency is improved; and flexible construction of the lifting ramp face of the lifting ramp device is achieved through the lifting driving device, and good practicability is achieved.

Owner:THE THIRD CONSTR & ENG OF CCFED +1

Construction device for slotting transverse seam and vertical seam of wall body

ActiveCN113494193ARealize simultaneous constructionSame distanceGrinding carriagesGrinding drivesPolishingElectric machinery

The invention discloses a construction device for slotting a transverse seam and a vertical seam of a wall. The construction device comprises guide rails, lifting devices, a jig frame, a transverse seam polishing mechanism and a vertical seam polishing mechanism, wherein the lifting devices are arranged on the guide rails, the left end and the right end of the jig frame are fixedly connected with the lifting devices on the two guide rails respectively, the transverse seam polishing mechanism is used for transverse seam construction and comprises a translation mechanism, a limiting device, a movable connecting rod, a transmission rod, a polishing driving motor and a cutter head, and the two ends of the vertical seam polishing mechanism are fixedly connected with the lifting devices on the guide rails and used for vertical seam construction. The construction device can achieve synchronous construction of the transverse seam and the vertical seam, has the advantages of being high in construction efficiency, high in slotting precision and good in construction quality, can achieve mechanical and automatic construction, and greatly reduces the safety risk of construction.

Owner:SHANGHAI NO 4 CONSTR

Wall plaster adjuster

ActiveCN108060783BRealize automated constructionRapid Wall ConstructionBuilding material handlingBrickArchitectural engineering

The invention discloses a wall building plastering regulator, and mainly relates to the field of civil construction facilities. The wall building plastering regulator comprises oppositely arranged positioning plates, and clamping plates and clamping wheels are arranged between the positioning plates from top to bottom; the clamping plates are used for bundling the width of a mortar layer, the clamping wheels are used for clamping a wall face, a travelling frame is hinged to the upper portions of the positioning plates, and the two ends of the travelling frame are provided with track mechanisms; a swinging motor and a travelling motor are mounted on the travelling frame, the swinging motor drives the travelling frame to tilt left and right by a certain angle, and the travelling motor drivesthe track mechanisms to travel; and positive and negative rotation of the travelling motor and swinging of the swinging motor are triggered by sensors arranged at the outer ends of the track mechanisms. The wall building plastering regulator has the beneficial effects that the wall building plastering regulator can realize automation construction of plastering operation, and by cooperating with manual brick stacking, wall building construction can be quickly finished at a high quality.

Owner:DIER GRP CO LTD

A small coil automatic spreading vehicle and a coil spreading method

Owner:东方雨虹民用建材有限责任公司

A trackless intelligent paver

ActiveCN107700320BRealize automated constructionGood construction performanceRoads maintainenceVehicle frameControl room

Owner:ANHUI XINGYU TRACK EQUIP

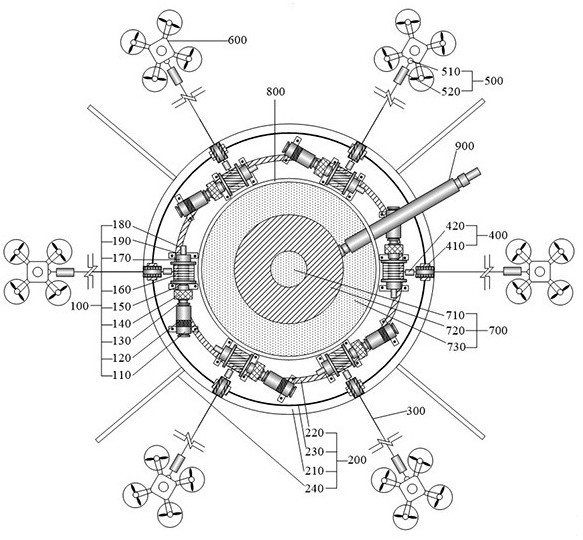

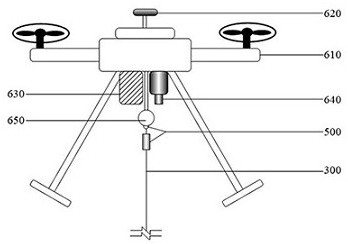

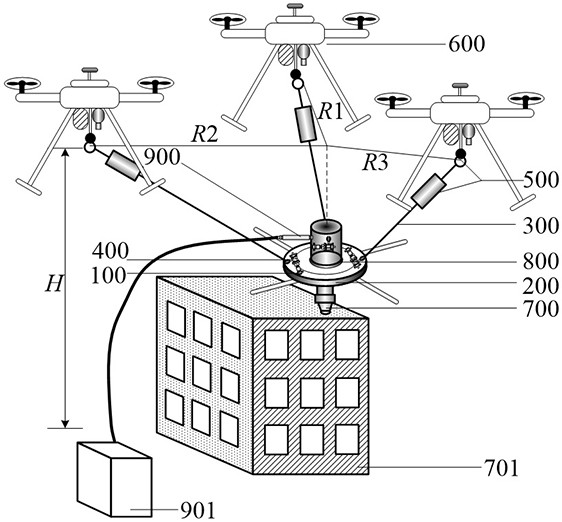

A full-scale 3D printing system and method

ActiveCN111927099BAchieve supportEnable mobilityAdditive manufacturing apparatusBuilding material handlingUncrewed vehicleStructural engineering

The invention provides a full-size 3D printing system and a full-size 3D printing method. A rope driving braking mechanism, a movable platform, a high-strength rope, a rope guiding mechanism, a rope fixing assembly, an unmanned aerial vehicle positioning and lifting system, a printing head mechanism and a printing head connecting mechanism are adopted, one end of the high-strength rope is connected with the rope driving braking mechanism, the other end of the high-strength rope is connected with the unmanned aerial vehicle positioning and lifting system through the rope fixing assembly after being guided by the rope guiding mechanism, the unmanned aerial vehicle positioning and lifting system drives the movable platform to move to achieve the initial positioning and supporting of the printing head mechanism, and the rope driving braking mechanism can accurately locate the printing head mechanism by retracting and releasing a high-strength rope. The full-size 3D printing system and a full-size 3D printing method have the advantages of light weight, small occupied space and portability, solve the problem that the printing operation range of an existing 3D printing device and method is limited by the size of an equipment body, and can achieve the printing of buildings with various volumes in any area.

Owner:SHANGHAI CONSTRUCTION GROUP

Layered opening adopts large-area rapid laying process

The invention relates to a coal mining technology, in particular to a large-area rapid net laying technology for layer mining of a coal mine. The technology is characterized by comprising the steps as follows: net pulling ropes are laid at the bottoms of high-strength polyester fiber nets at certain intervals, net rolls are formed through rolling, are parallel to supports and are placed in space at the back parts of the supports, a fixed pulley is mounted at the back part of each support, the pulleys are sleeved with nylon ropes of the high-strength polyester fiber nets, the supports move forwards to pull the nylon ropes to pass through the pulleys, the nylon ropes drive the net rolls to be spread, and the nets are laid automatically. The technologies for net conveying by workers, net laying, net connection and the like for metal net laying are omitted, the normal advancing speed of the working face is not affected, the security coefficient for layer mining is increased, and the problem about manual net laying behind the supports during layer mining is solved.

Owner:HOCK TECH CO LTD

Building ground construction device and construction technology thereof

ActiveCN114046055AAvoid empty shellsPrevent looseningSolid waste managementDischarging apparatusArchitectural engineeringStructural engineering

The invention provides a building ground construction device and a construction technology thereof. The device comprises a vehicle body and a material guide plate fixedly connected to the bottom wall of the vehicle body, and further comprises a concrete processing assembly connected to the top wall of the vehicle body, wherein a quantitative discharging component is arranged at a discharging opening of the concrete processing assembly, and the quantitative discharging component is matched with the material guide plate; a light receiving assembly, which is connected to the bottom wall of the vehicle body; a vibration assembly, which is connected to the bottom wall of the vehicle body, is connected with a discharging component through a belt and a belt wheel, and is located between the light receiving assembly and the material guide plate; and a cleaning assembly, which comprises a third rotating shaft fixedly connected with a vehicle body hub and a collecting box fixedly connected to the inner wall of the vehicle body, wherein a brush is arranged on the outer wall of the third rotating shaft. By means of automatic construction, labor is saved, meanwhile, the construction efficiency is improved, and the problem that the follow-up construction quality is affected due to the fact that an empty shell appears in cement is avoided.

Owner:吉林省鹏雨建设集团有限公司

A joint hinge device suitable for automatic construction of constrained concrete arch frames

ActiveCN105952481BSimple structureEasy to operateUnderground chambersTunnel liningArchitectural engineeringH shaped

The invention discloses an automatic construction node hinge device suitable for a confined concrete lagging jack. The automatic construction node hinge device comprises a hinge buckle and a hinge groove which are movably connected by virtue of a hinge shaft, wherein the hinge groove is internally hollow, so that the lower end of the hinge buckle is wrapped in the hinge groove; and the lower end of the hinge buckle is provided with a first retainer ring clamping groove, a second retainer ring clamping groove is formed in the corresponding position of the hinge groove, and the hinge buckle and the hinge groove are fixedly buckled. The automatic construction node hinge device is simple in structure and convenient and flexible to install; and the application range is wide, and the node hinge device can be used for different lagging jacks in various shapes, sizes and sectional forms such as a mine U-shaped steel lagging jack, an H-shaped steel lagging jack, and for the confined concrete lagging jacks in various sectional forms and sizes. The node hinge device can be used for connecting nodes of an underground engineering lagging jack and is particularly suitable for connecting confined concrete lagging jacks.

Owner:SHANDONG UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com