Tunnel slag tapping, sand and gravel processing and concrete processing and conveying integrated equipment and process

A technology for tunnel construction and tunneling, which is applied in tunnels, mining equipment, clay preparation devices, etc. It can solve the problems that the normal maintenance of concrete cannot be guaranteed, the equipment can only move forward but not backward, and the construction method is limited by rocks, so as to achieve the realization of waste recycling, Improve construction efficiency and construction quality, low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention:

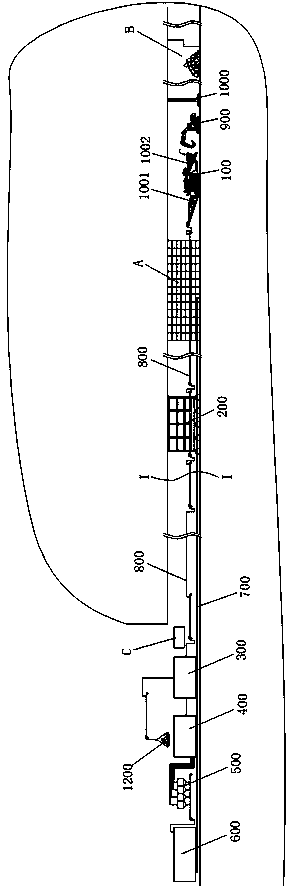

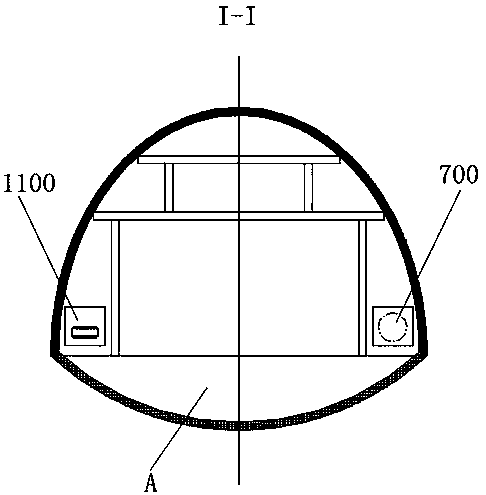

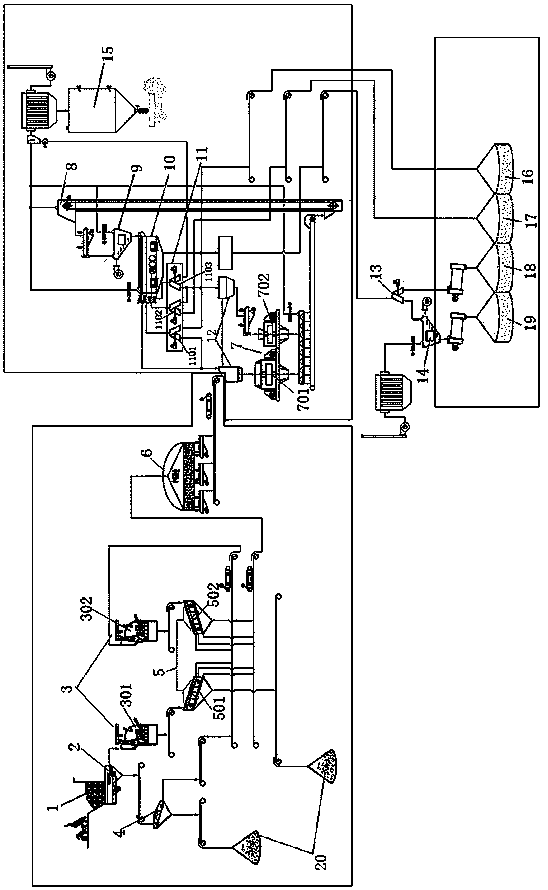

[0036] Such as figure 1 and figure 2 As shown, an integrated process of tunnel slag discharge, sand processing and concrete processing and transportation, which specifically includes the following steps:

[0037] s1. Transport the materials in the blasting area B of the tunnel to the mobile crushing equipment 100 for preliminary crushing into coarse aggregates, so as to facilitate the transportation to the outside of the tunnel through the telescopic conveyor belt set 800 for aggregate processing;

[0038] The materials in the tunnel blasting area B are obtained from tunnel excavation through mining blasting technology; and are crushed by mobile crushing equipment 100 to coarsely crushed aggregates with a particle size of 150 mm or less;

[0039] The material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com