Hinge-connected multi-pallet turning mechanism for accumulation and release type conveying

A technology of hinge connection and overturning mechanism, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of limited length and size of pallet trolley, cannot adapt to large components, etc., and achieves the advantages of improving equipment utilization, simple structure, and reducing equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

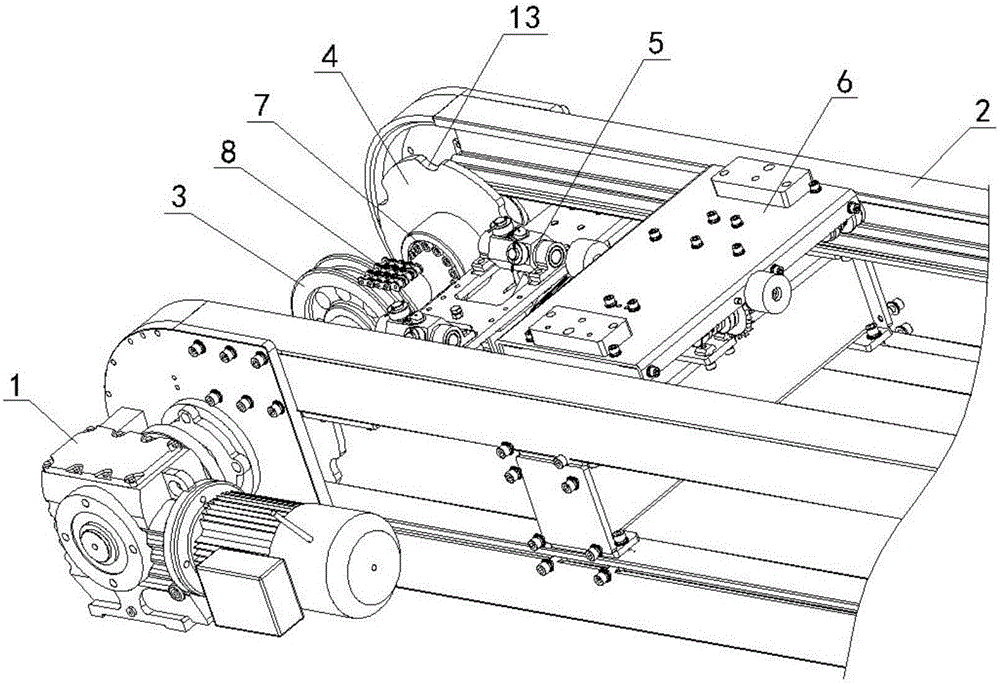

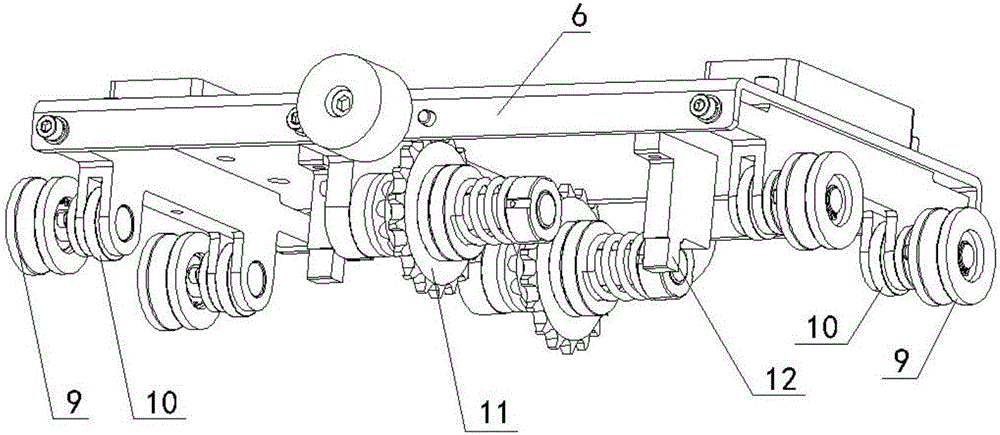

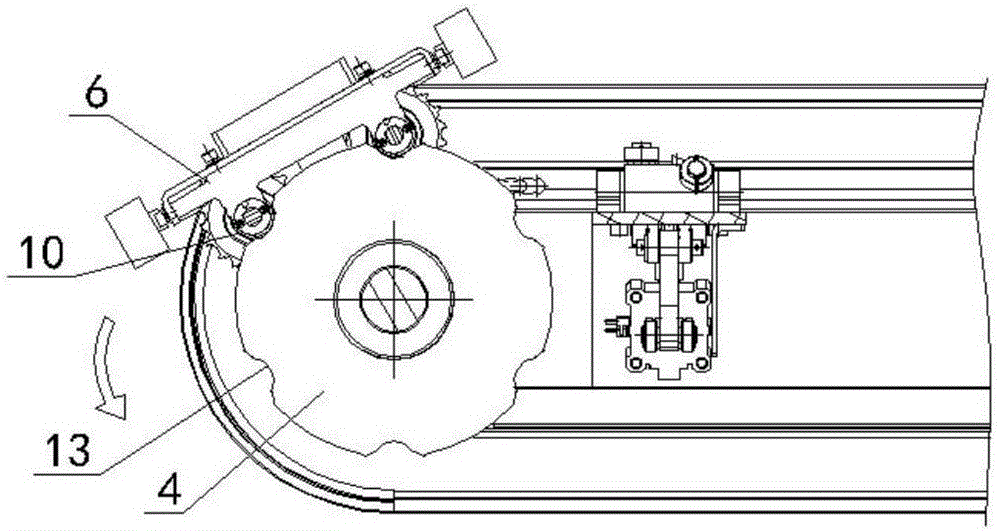

[0024] see figure 1 , figure 2 with image 3 , the present embodiment adopts the accumulative-and-free conveying mechanism with the publication number CN106144528A, which is to set a large sprocket 3 driven by the motor 1 through the motor transmission shaft at the end of the track bed 2, and the pallet trolley 6 is placed on the track In the bed 2, the chain 8 used to drive the pallet trolley 6 to move horizontally is meshed with the large sprocket 3; on both sides of the pallet trolley 6, two rollers 9 in front and one behind are respectively installed through their respective roller shafts. The wheel 9 is cooperatingly arranged in the side track of the track bed 2 to form support and guidance; at the end of the motor drive shaft, on the inner side of the track bed 2, a turning disc 4 is provided through the expansion sleeve 7, and the turning disc 4 Through the expansion sleeve 7 rotating with the motor transmission shaft, six arc-shaped grooves 13 are evenly distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com