Patents

Literature

31results about How to "Easy connection and construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

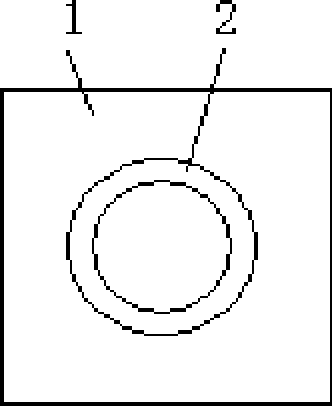

High-density polyethylene steel reinforced winded pipe spigot-and-socket connector

InactiveCN1614286ASolve the problem that the socket connection cannot be usedWith deflection anglePipe connection arrangementsLow-density polyethyleneHigh density

A plug-socket connector for the steel wire reinforced high-density polyethene pipes is composed of plug-type connection pipe welded to the end of one steel wire reinforced high-density polyethene pipe, a sealing ring for said plug-type connection pipe, a socket-type connection pipe welded to the end of another polyethene pipe, and a reinforcing sleeve pipe for said socket-type connection pipe. Its advantages are high connection strength and high sealing effect.

Owner:HANGZHOU YISHIDA IND

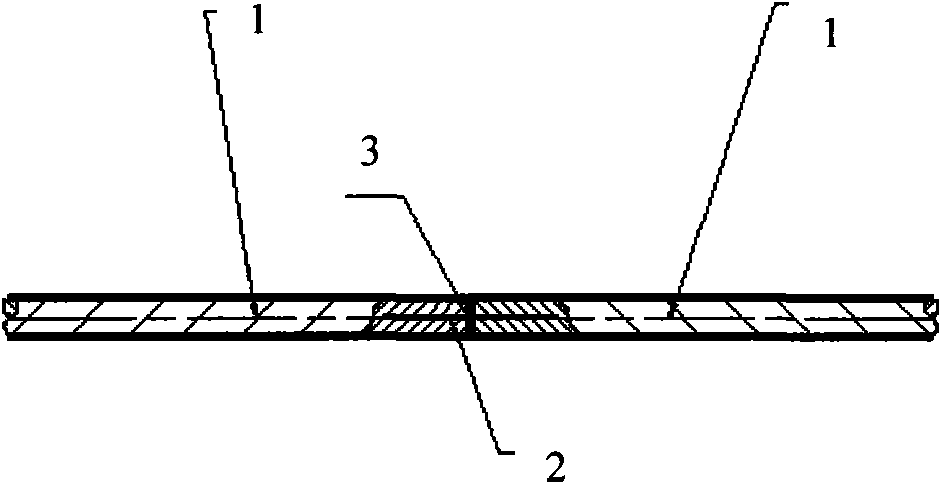

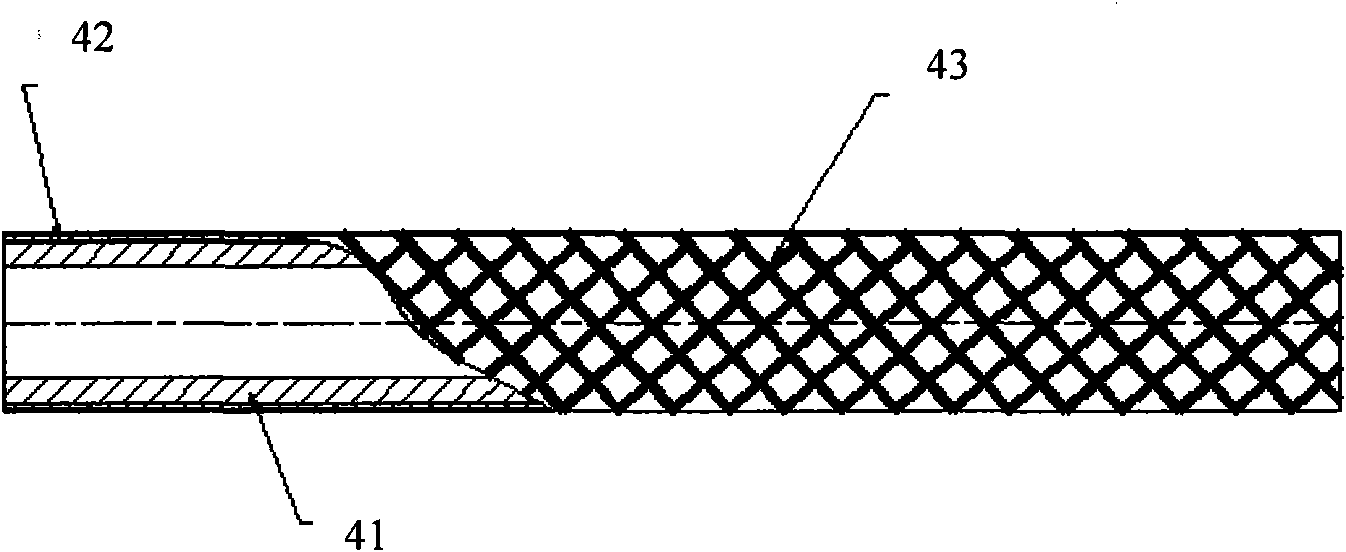

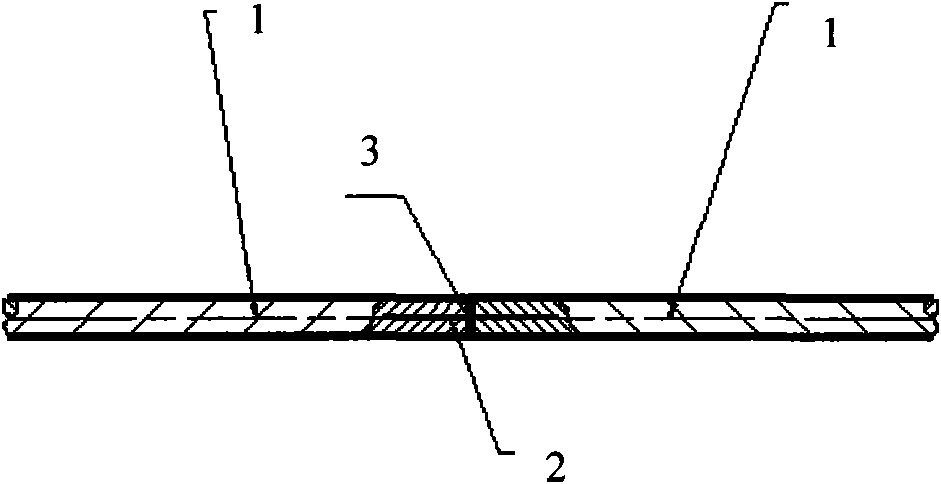

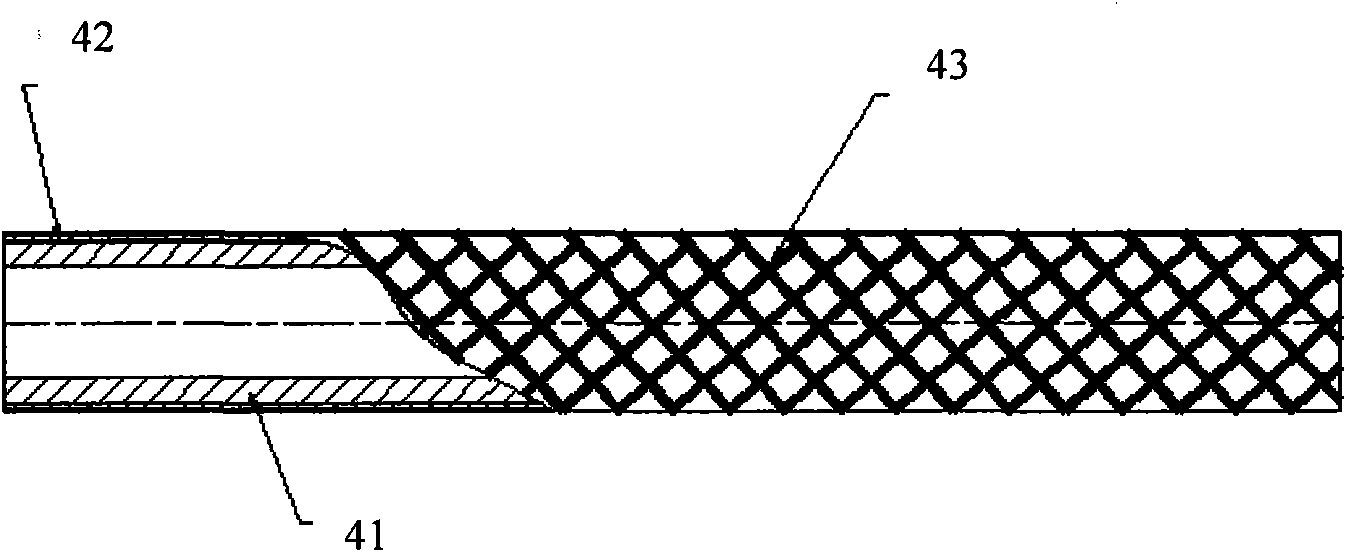

Method for coaxially connecting FRP reinforcements by FRP connecting pipe and expansive cement

The invention provides a method for coaxially connecting two FRP reinforcements by an FRP connecting pipe and an expansive cement, comprising the following steps of respectively perforating two reinforcements to be connected with coaxial holes, coaxially connecting and positioning the two reinforcements by an FRP extruding / pulling rod or a wire rope, sheathing a section of FRP connecting pipe at the joint of the reinforcements; carrying out coaxial positioning by a positioning ring at two ends of the connecting pipe; arranging a pouring opening / air outlet on the positioning ring during horizontal pouring process and injecting expansive cement solution between the reinforcements and the connecting pipe by the pouring opening; needing not to arrange the pouring opening / air outlet on the positioning ring during vertical pouring process, firstly installing and then sealing the lower positioning ring; putting the upper sealing ring in place after completing pouring the cement solution to be expanded from the upper opening along the wall of the FRP connecting pipe, thus ensuring the coaxiality of the reinforcements and the sheathed pipes. The hardening time of the expansive cement is 6-12 hours generally. The FRP pipe can be prefabricated, the quality thereof is easy to be controlled, the cost of the expansive cement is low, the connection construction is simple and convenient, and the connecting part prepared by the expansive cement has light weight, high strength and corrosion resistance and can be used for structures with demagnetization requirements.

Owner:TONGJI UNIV +1

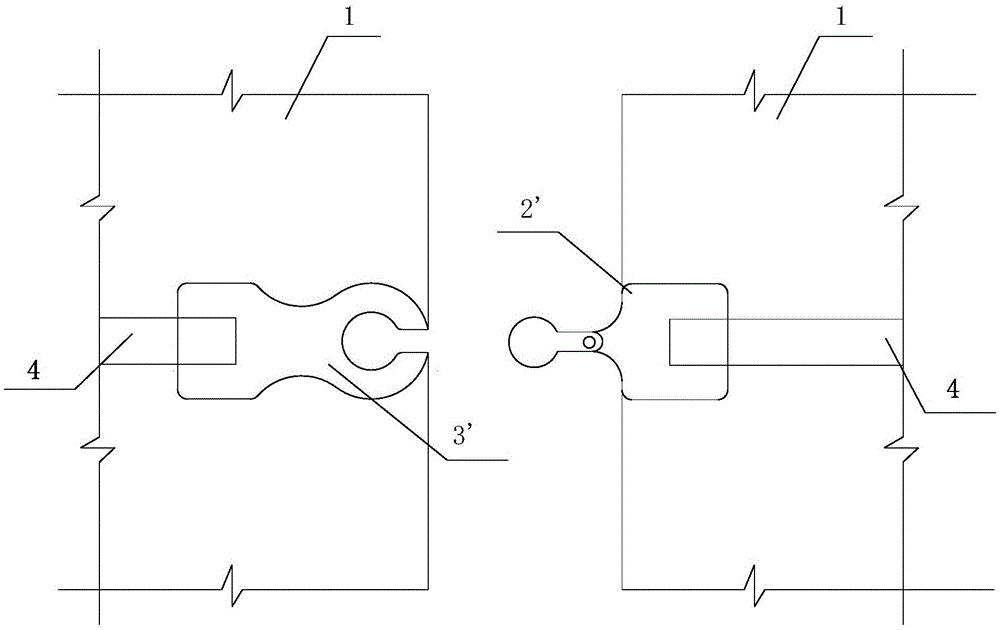

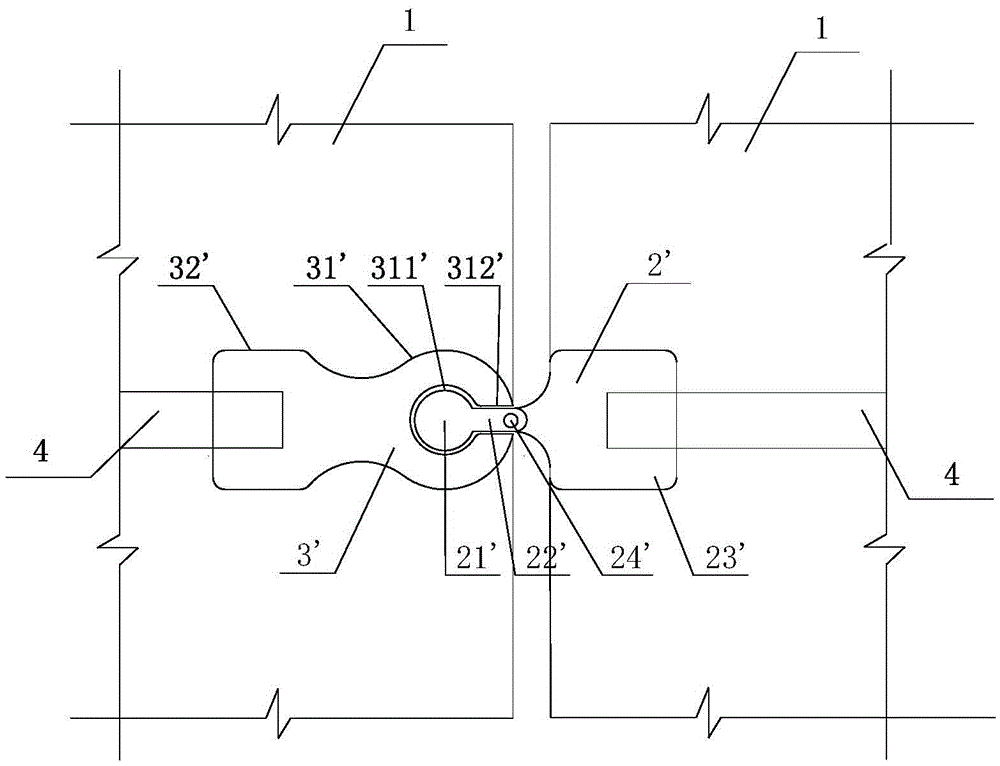

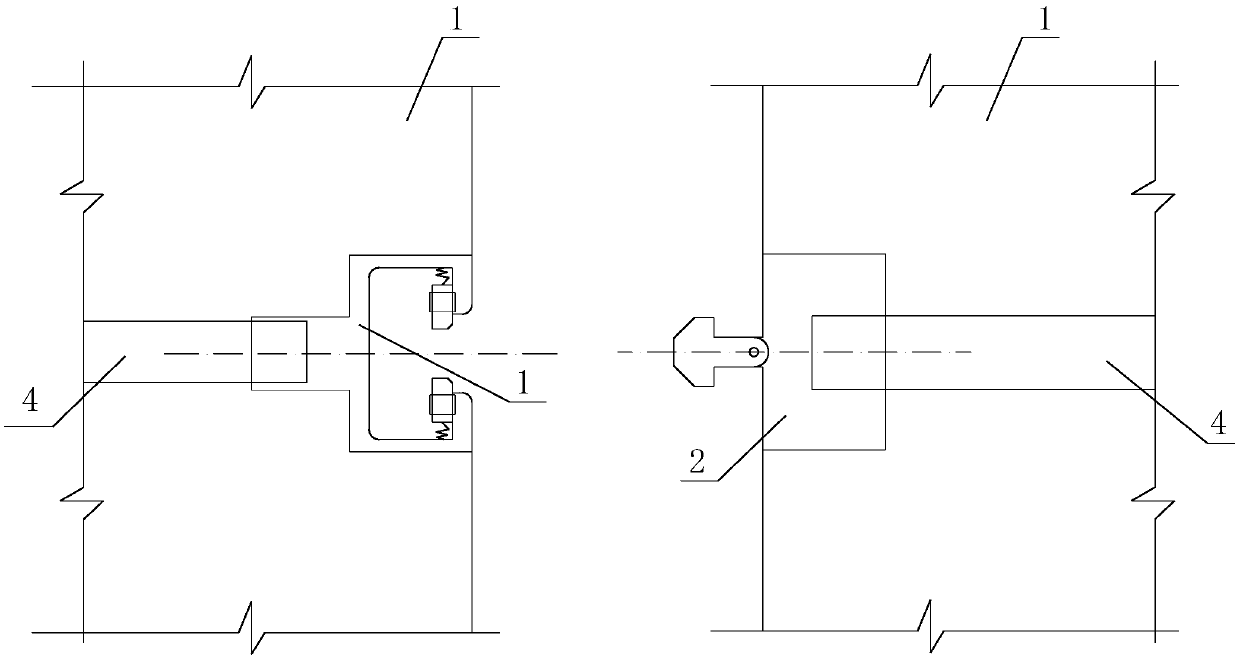

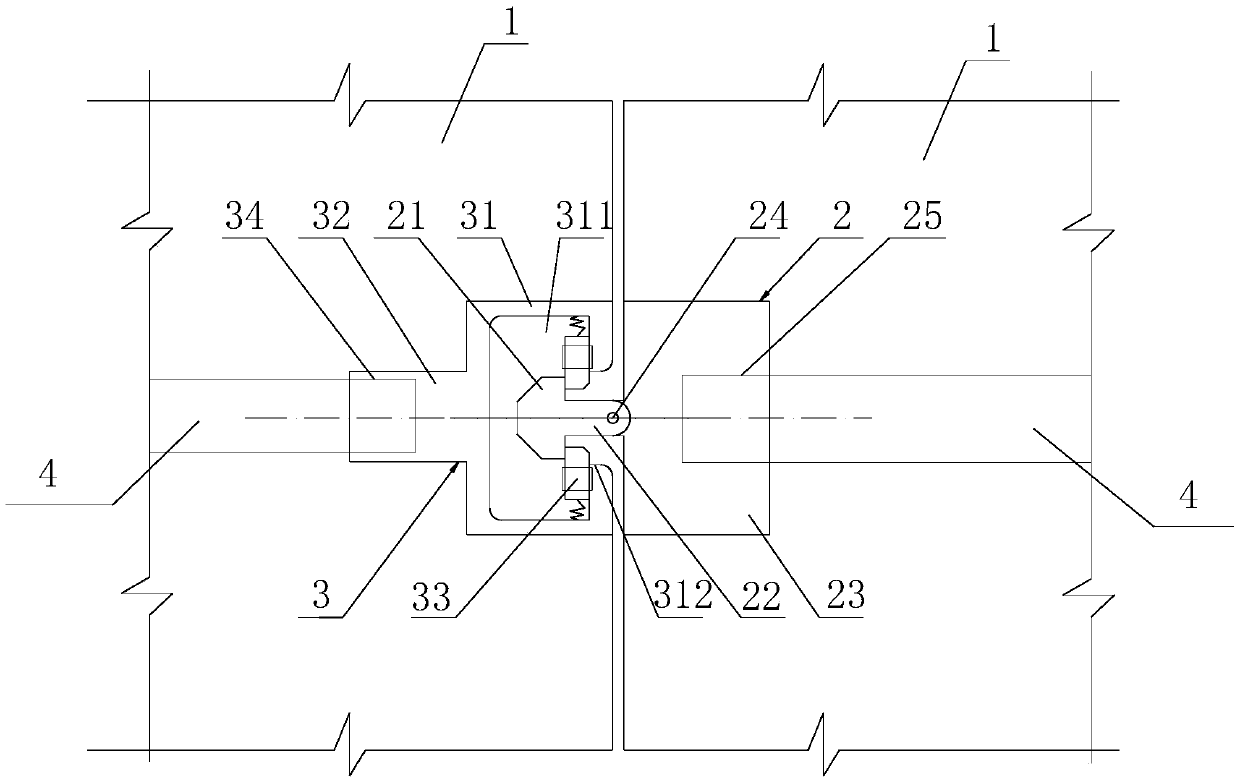

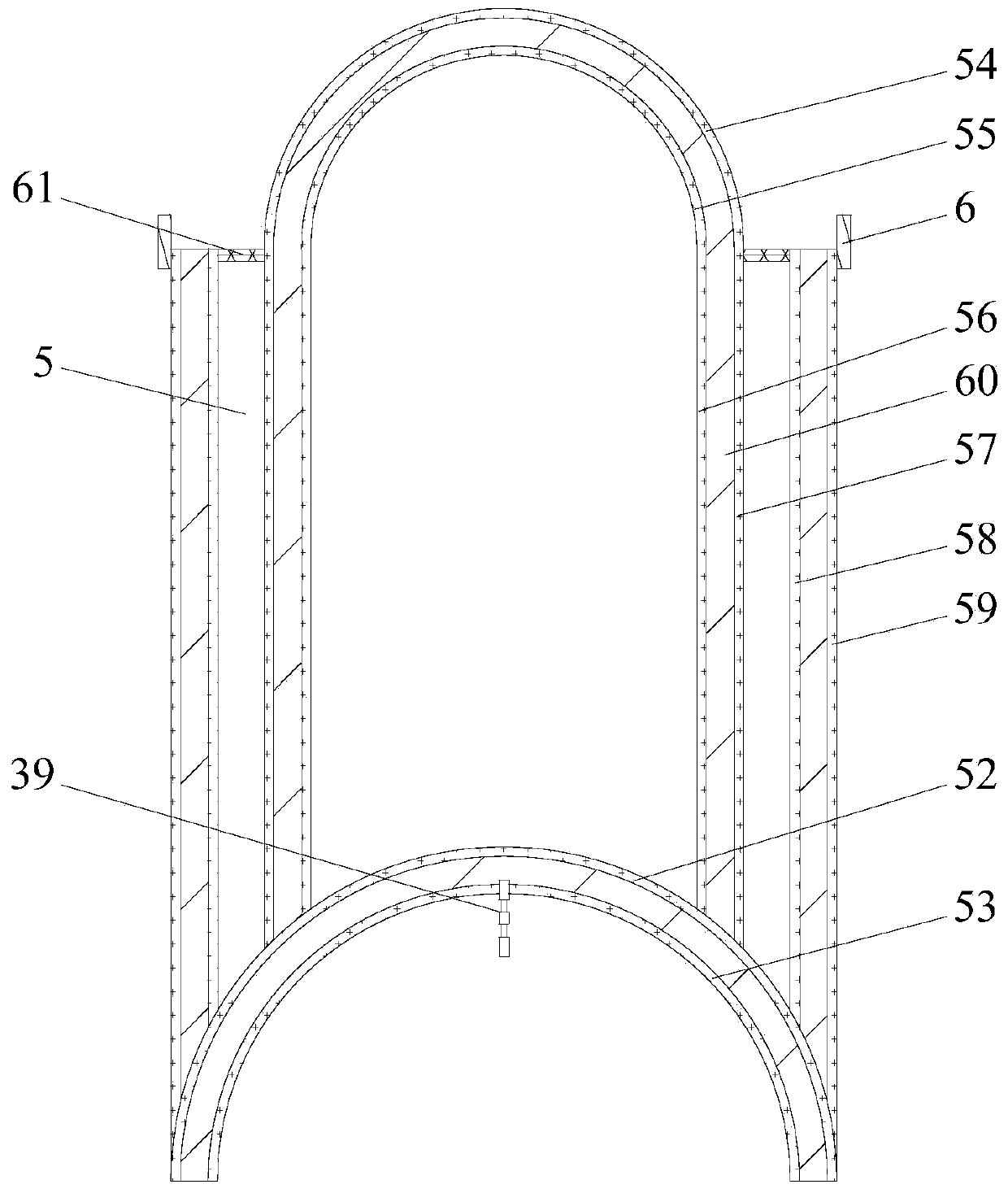

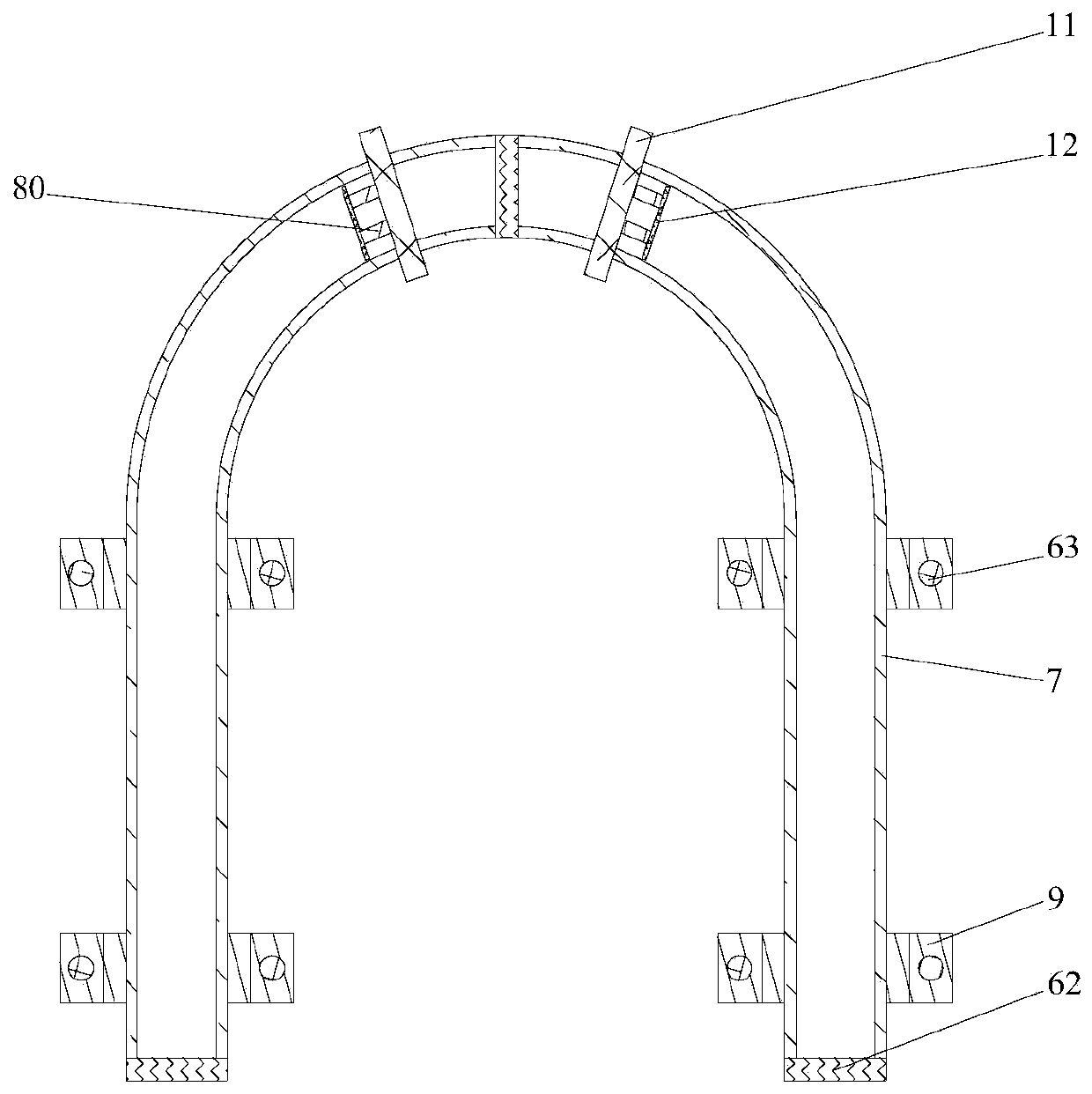

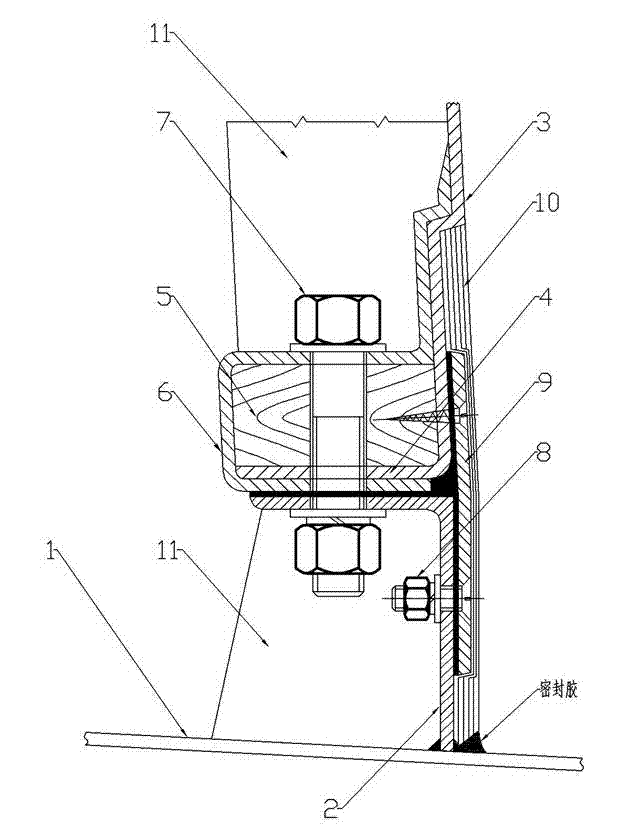

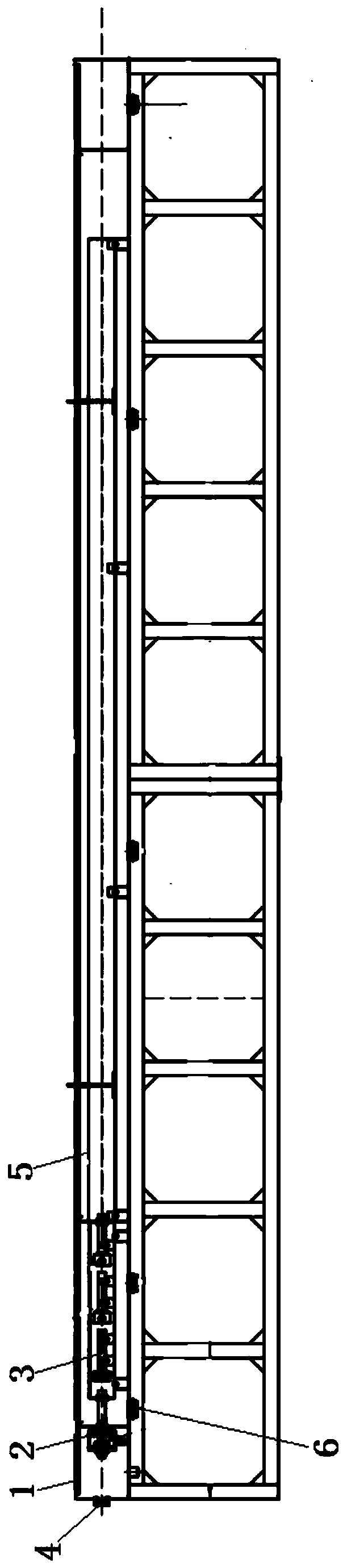

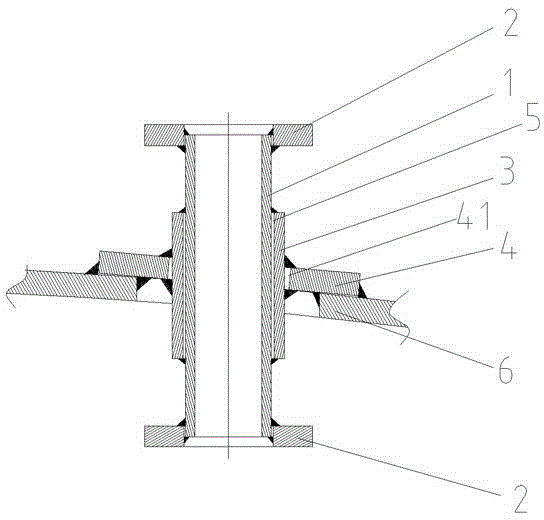

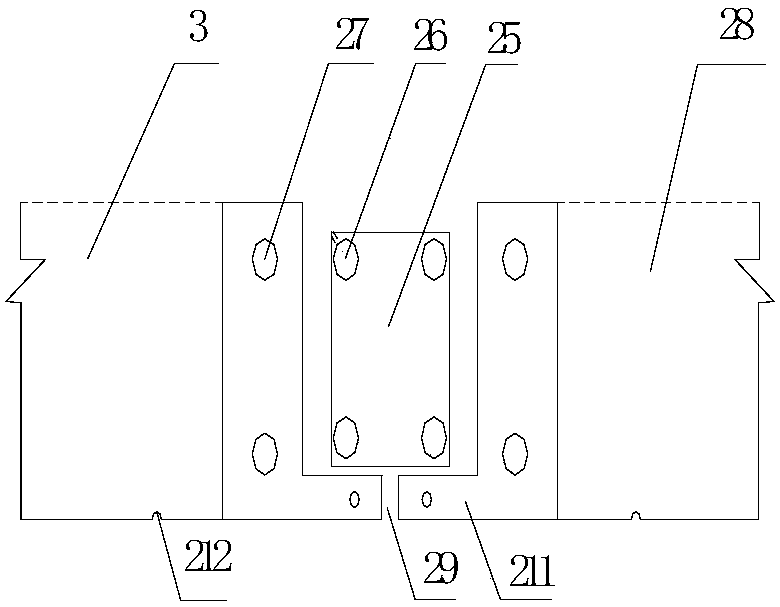

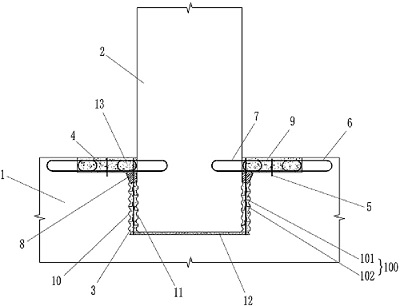

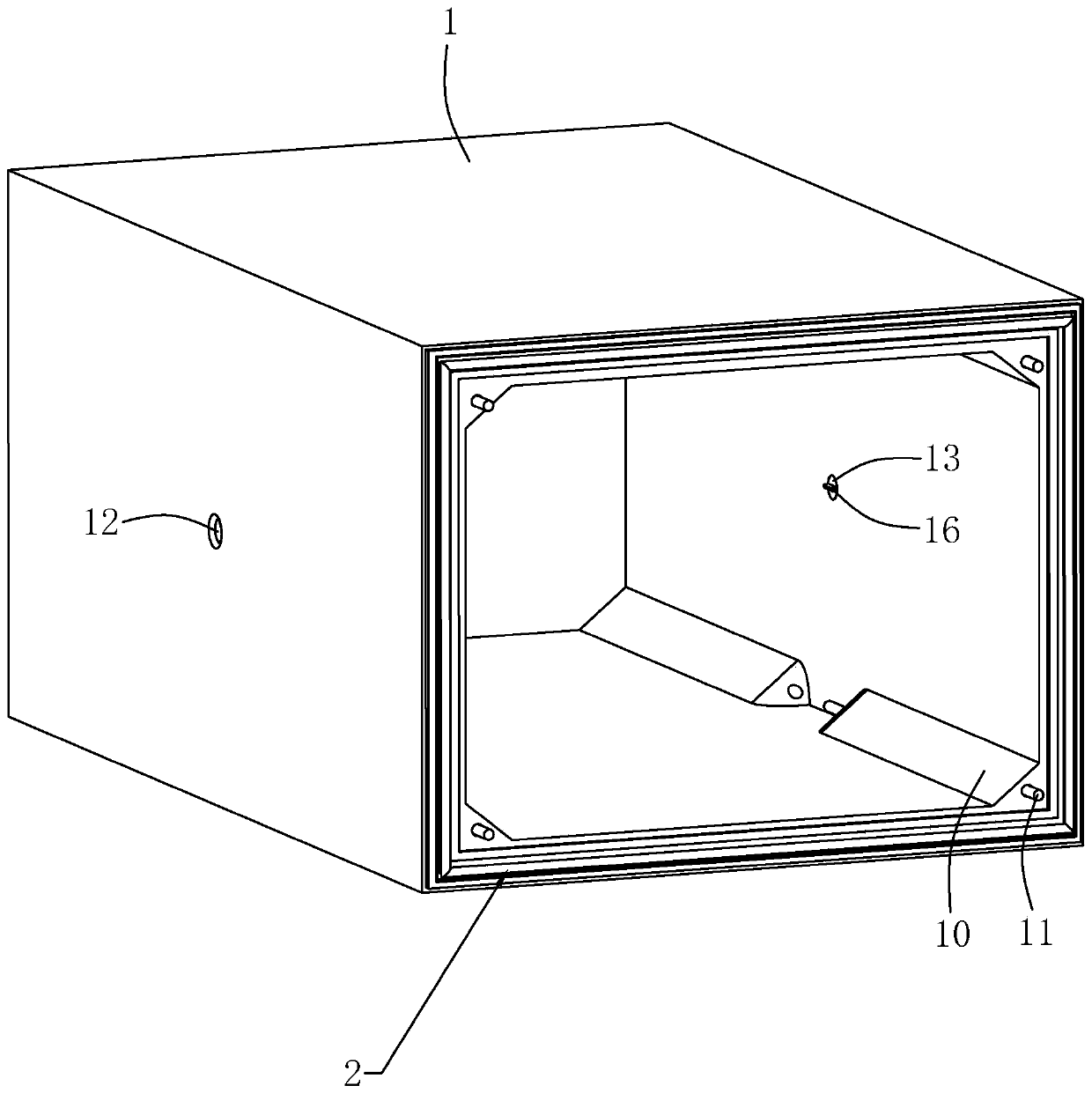

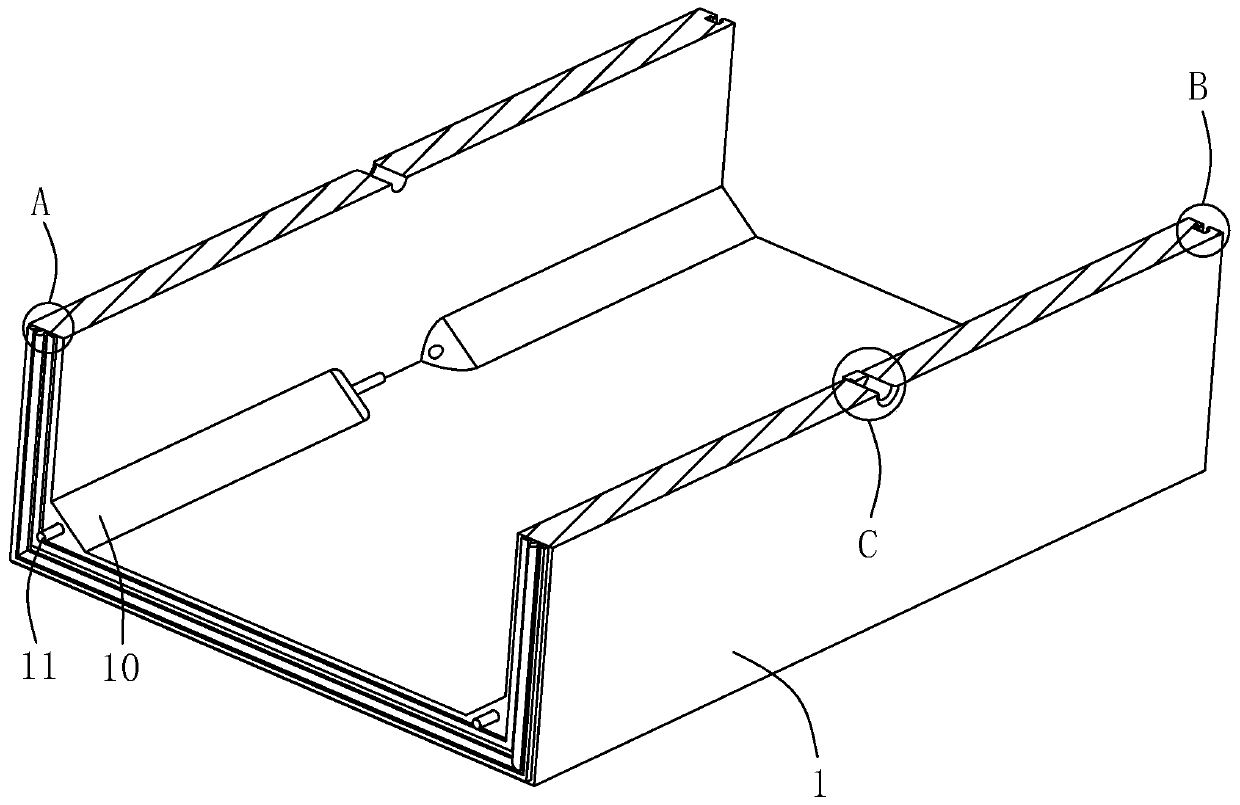

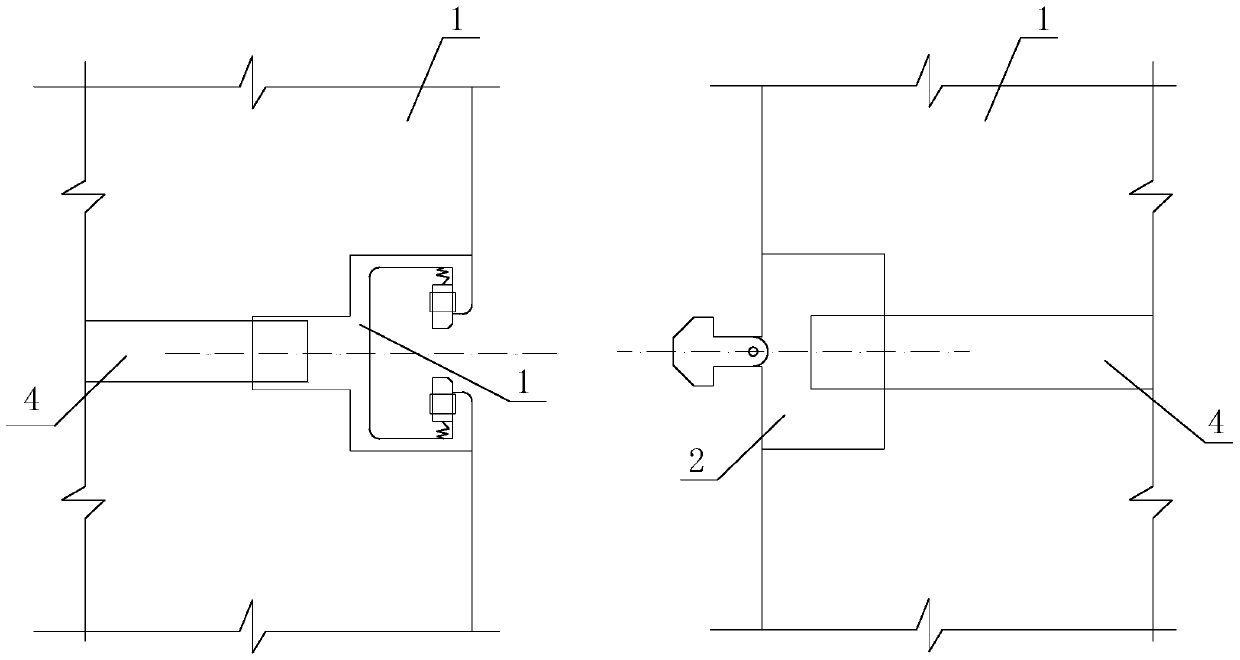

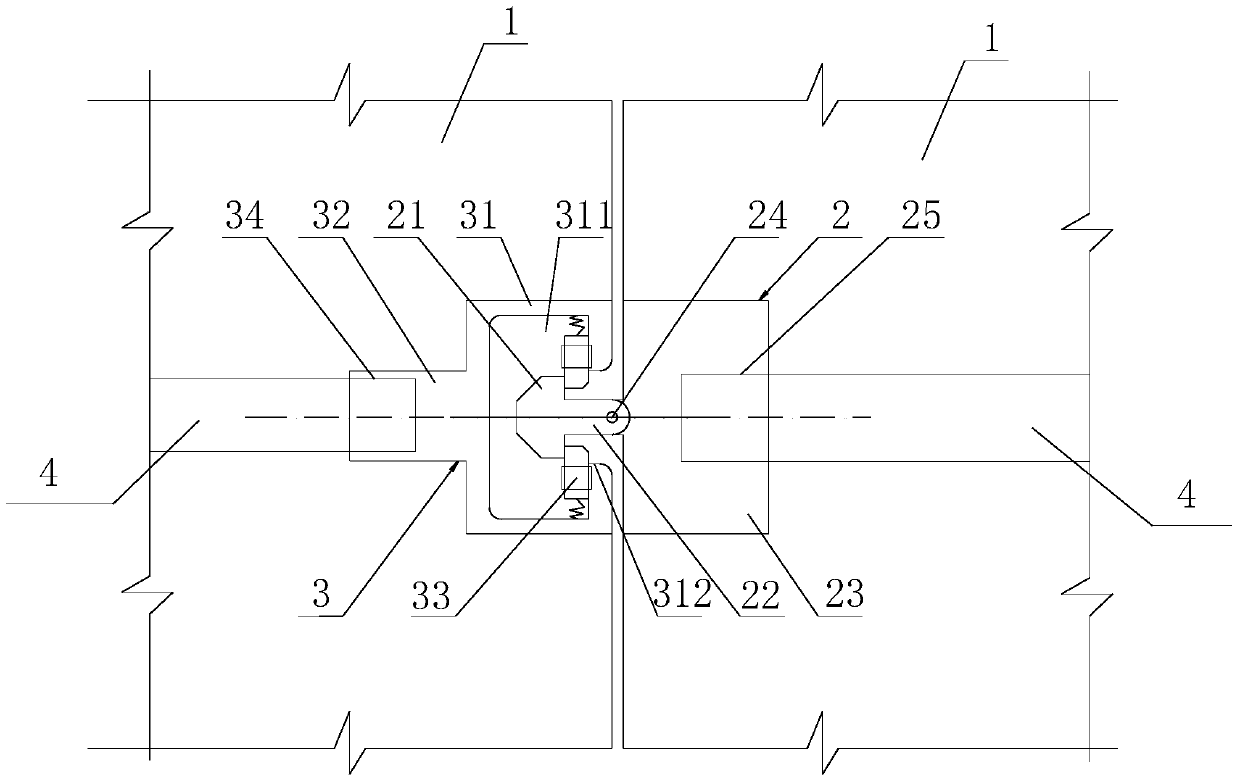

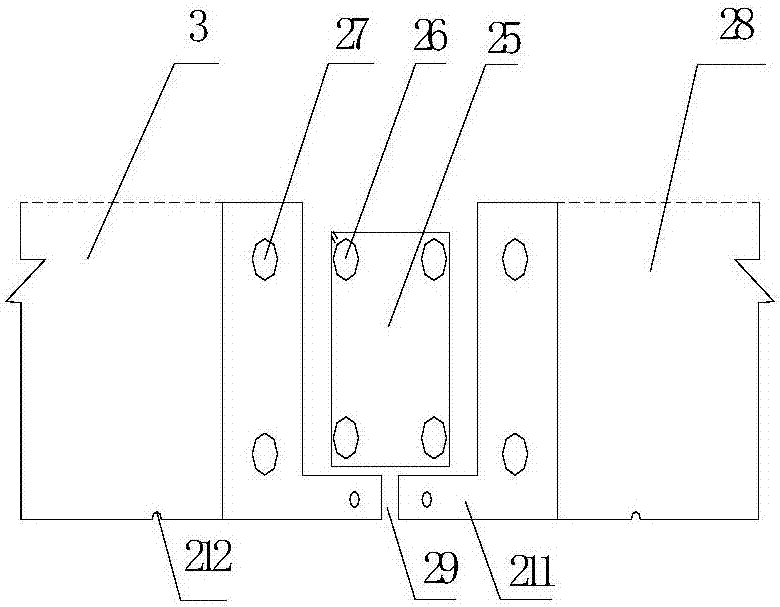

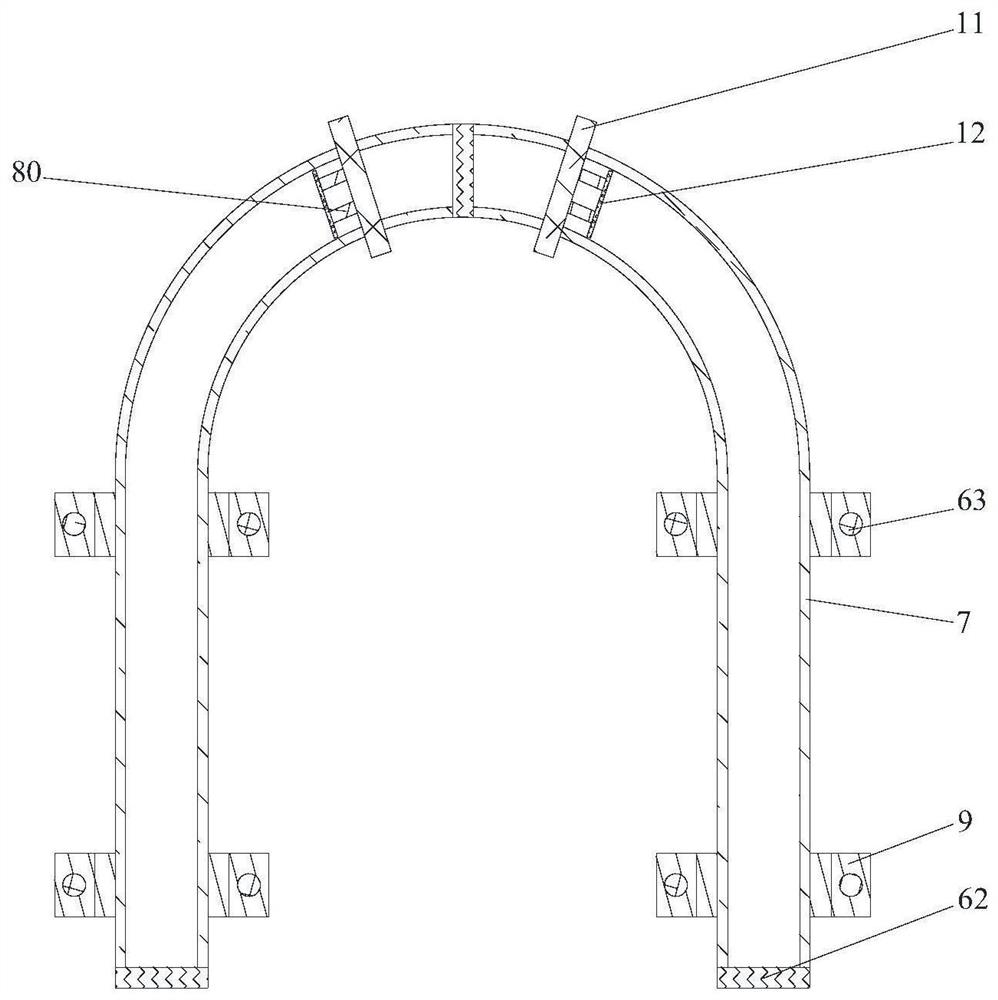

Segment longitudinal seam connecting assembly, tunnel segment structure and construction method

ActiveCN105484764ACapable of toleranceEasy connection and constructionUnderground chambersTunnel liningButt jointEngineering

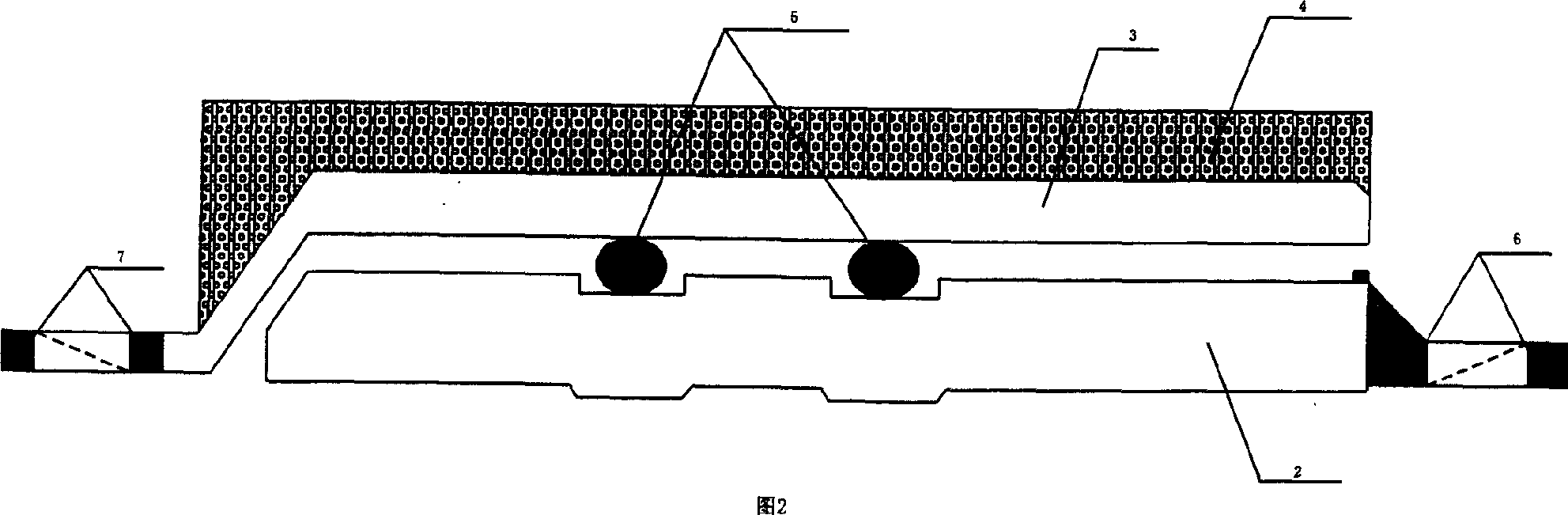

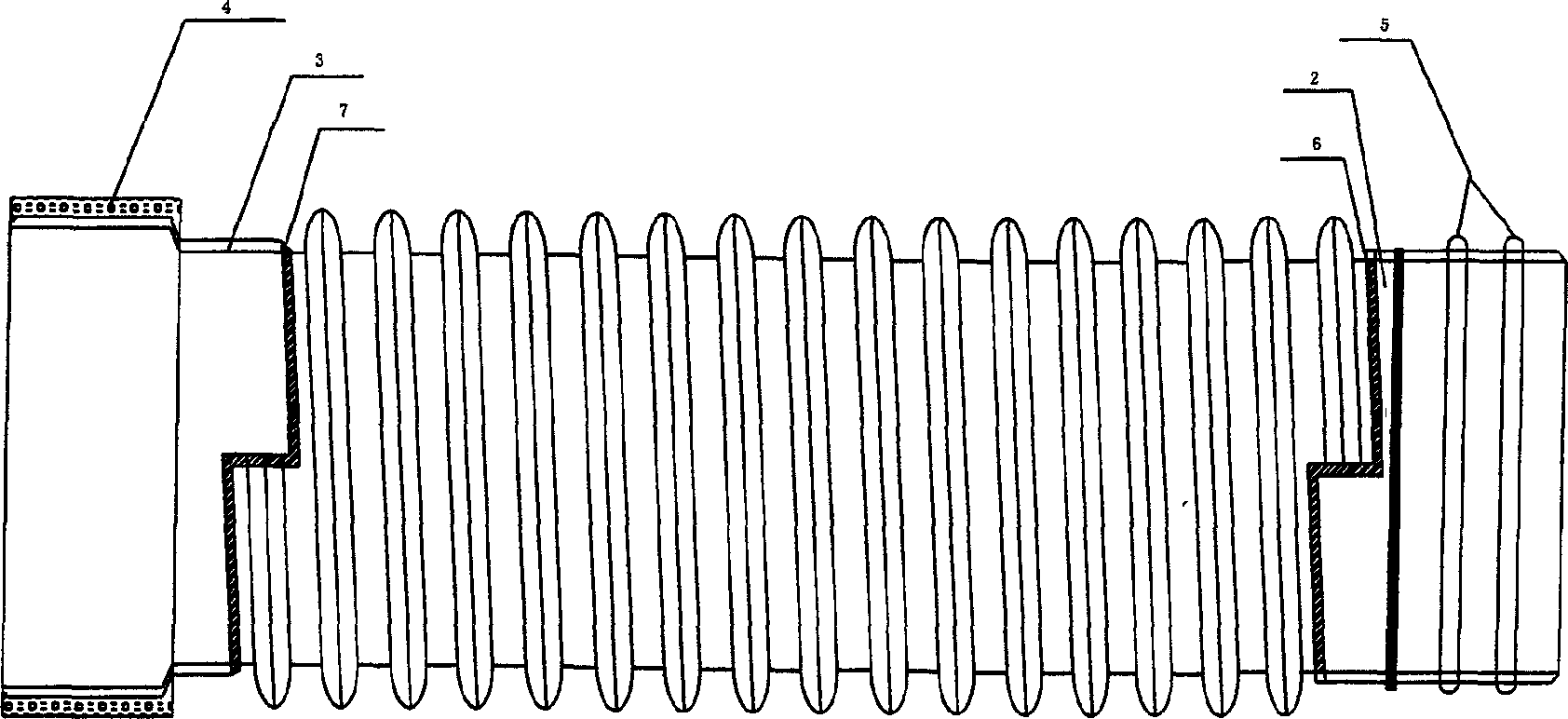

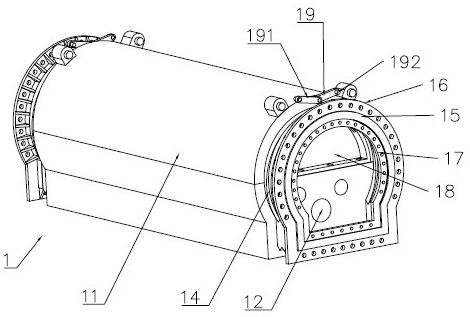

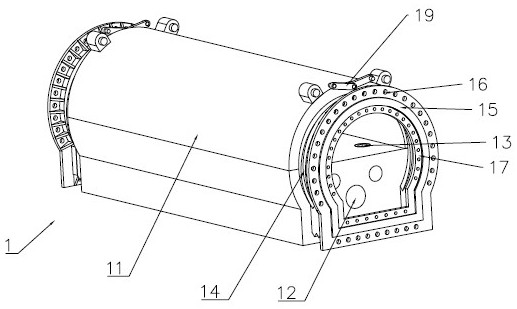

The invention discloses a segment longitudinal seam connecting assembly, a tunnel segment structure and a construction method. The segment longitudinal seam connecting assembly comprises a longitudinal seam male part and a longitudinal seam female part, wherein the longitudinal seam male part comprises a gradient section cylinder, a connecting plate and a base, one end of the connecting plate is fixedly connected to the side face of the gradient section cylinder, and the other end of the connecting plate is connected with the base; the longitudinal seam female part comprises a front section and a rear section, a gradient section cylindrical cavity matched with the gradient section cylinder is formed in the front section, a through hole matched with the connecting plate in shape and size and communicated with the gradient section cylindrical cavity is formed in one end, away from the rear section, of the front section, the longitudinal seam female part is wholly pre-buried into a segment, a groove capable of containing the longitudinal seam male part is formed in the segment, and the longitudinal seam female part is located at one side of the groove. The tunnel segment structure has certain tolerance capacity, is adaptive to construction environment and capable of achieving simultaneous butt joint of segments in the longitudinal and circumferential directions, and has the advantages of being fast and convenient to construct and easy to construct automatically.

Owner:SHANGHAI CONSTRUCTION GROUP

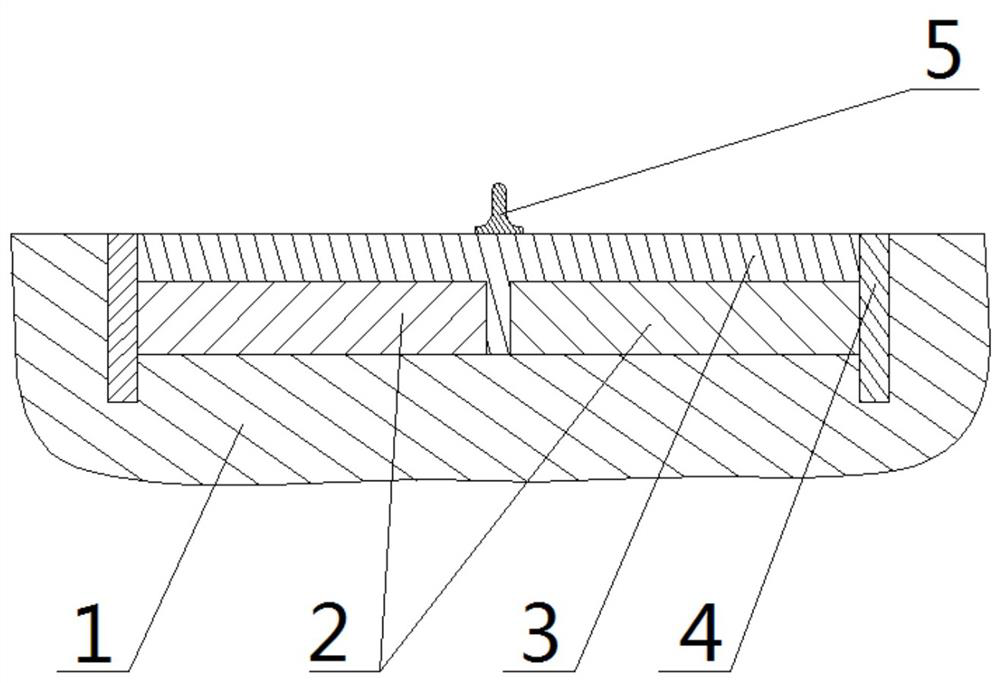

Deck penetration piece for ship pipe and penetration method

InactiveCN102720894ASimple structureEasy to manufactureThermal insulationPipesMarine engineeringNonferrous metal

The invention discloses a deck penetration piece for a ship pipe, which includes a penetration steel pipe, a flange, a sleeve and a web, wherein the sleeve is mounted and fixed on the penetration steel pipe in a sleeving manner, an air thermal insulation layer with uniform thickness is arranged between the sleeve and the penetration steel pipe, and the deck penetration piece is plated with corrosion-resisting nonferrous metal. The invention provides a penetration method of the deck penetration piece for the ship pipe, and the method comprises the steps as follows: (1) the deck penetration piece is manufactured, the sleeve is arranged at the middle part of the penetration steel pipe in a sleeving manner and is positioned through spot welding, the flange is welded, and the deck penetration piece is wholly plated with corrosion-resisting nonferrous metal; and (2) the deck penetration piece is mounted, a line is drawn on a deck and a hole is formed, the axis of the deck penetration piece is perpendicular to a corresponding hull reference plane, the deck penetration piece is completely welded with upper and lower sides of the web firstly, and then the web is completely welded with the hole formed on the deck. According to the invention, the deck penetration piece is provided with a simple structure and is convenient to manufacture. The penetration method provided by the invention does not damage the plating layer on the inner wall of the penetration steel pipe, and the attractive effect of horizontal-vertical connection between the deck penetration piece and the ship pipe can be achieved.

Owner:JIANGSU ZHENJIANG SHIPYARD GROUP

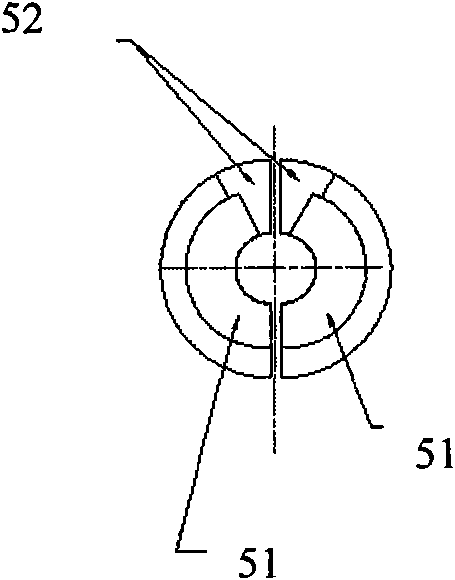

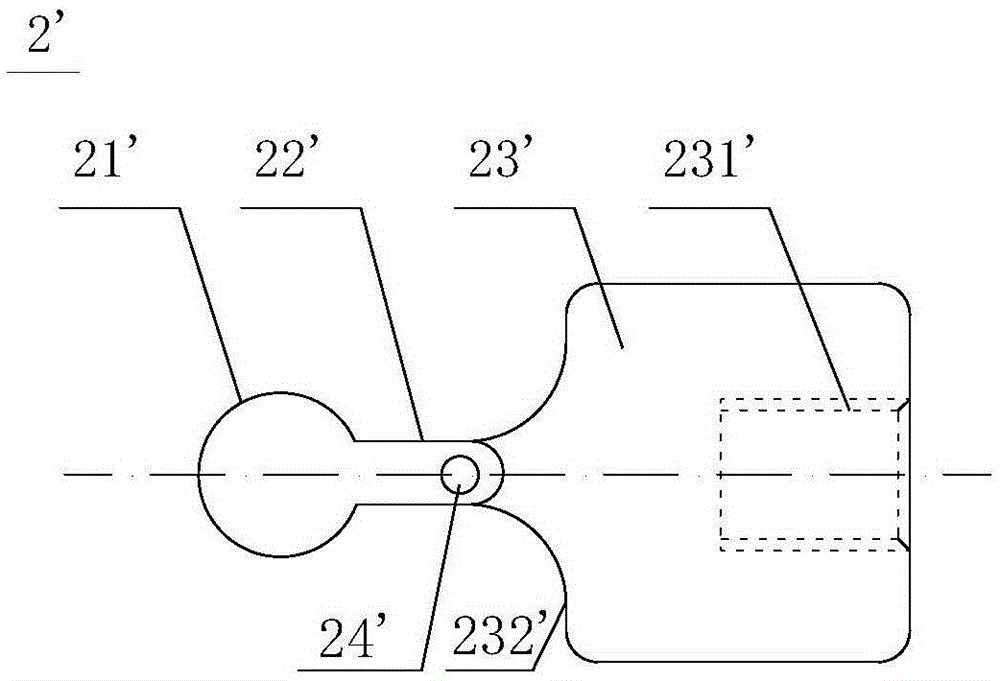

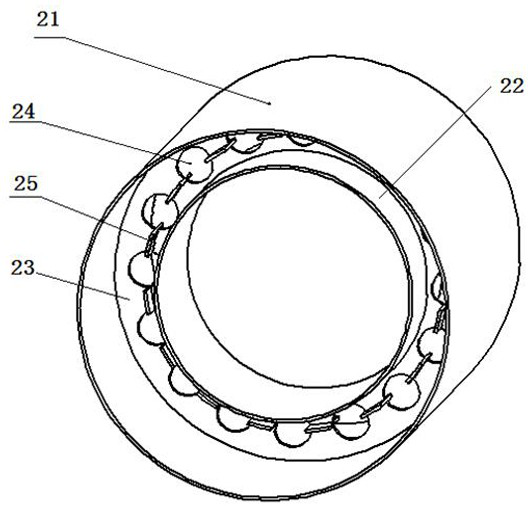

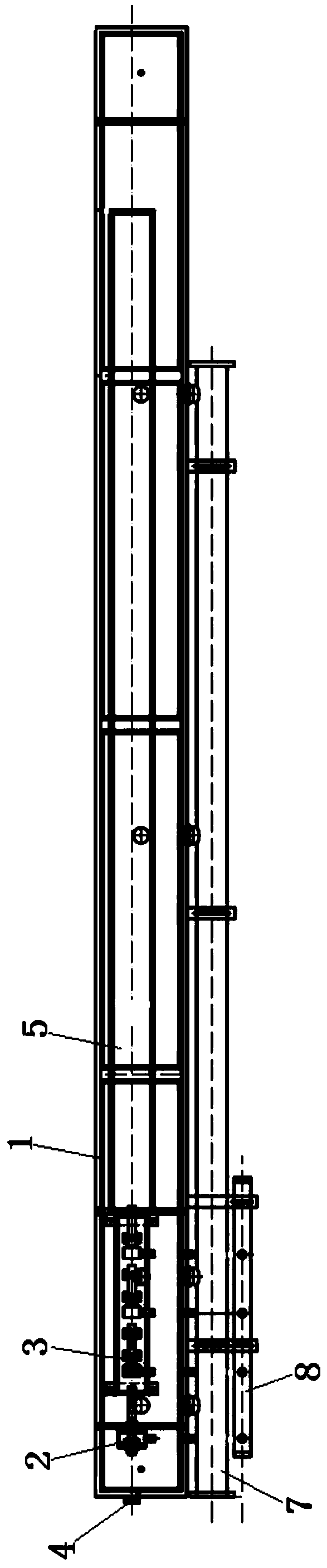

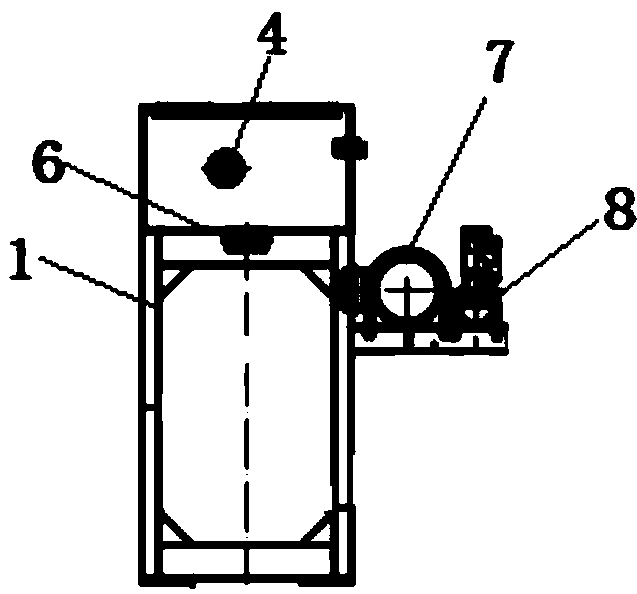

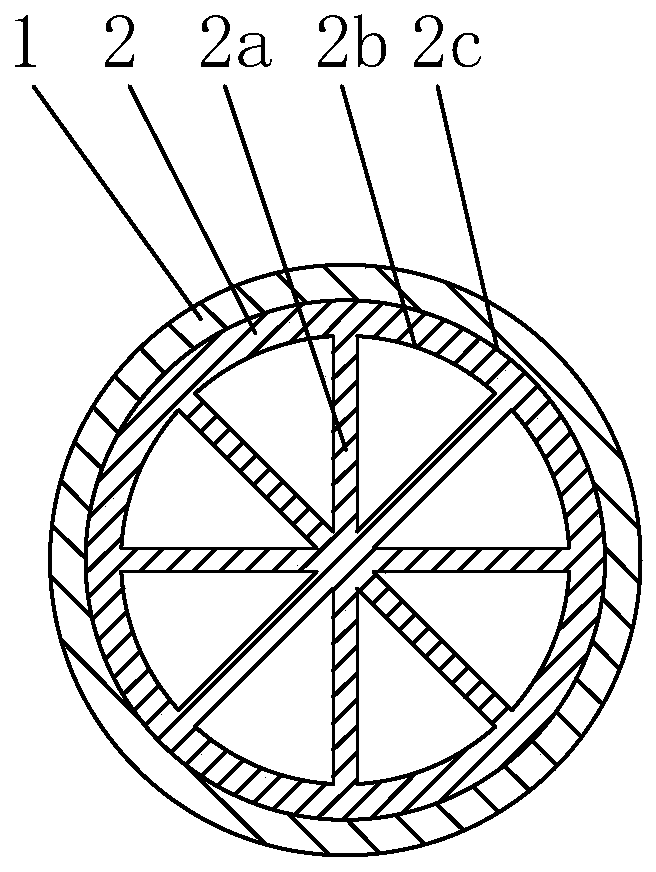

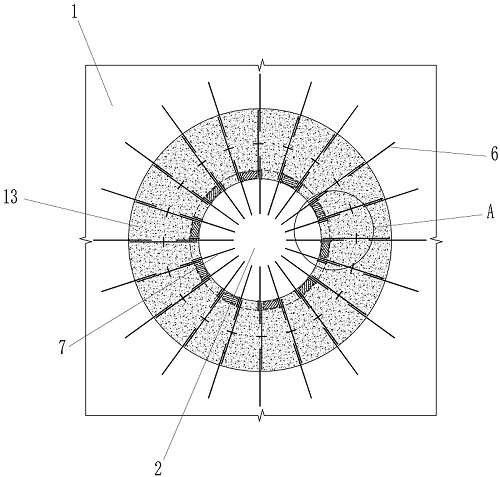

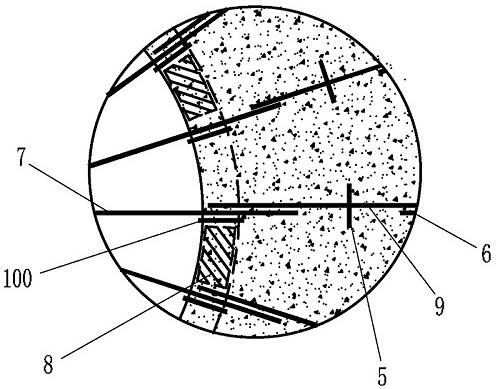

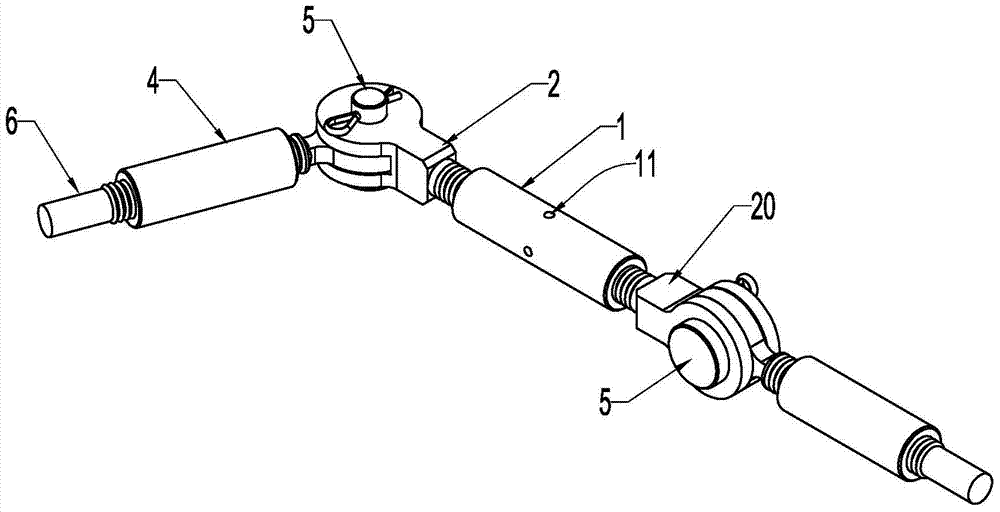

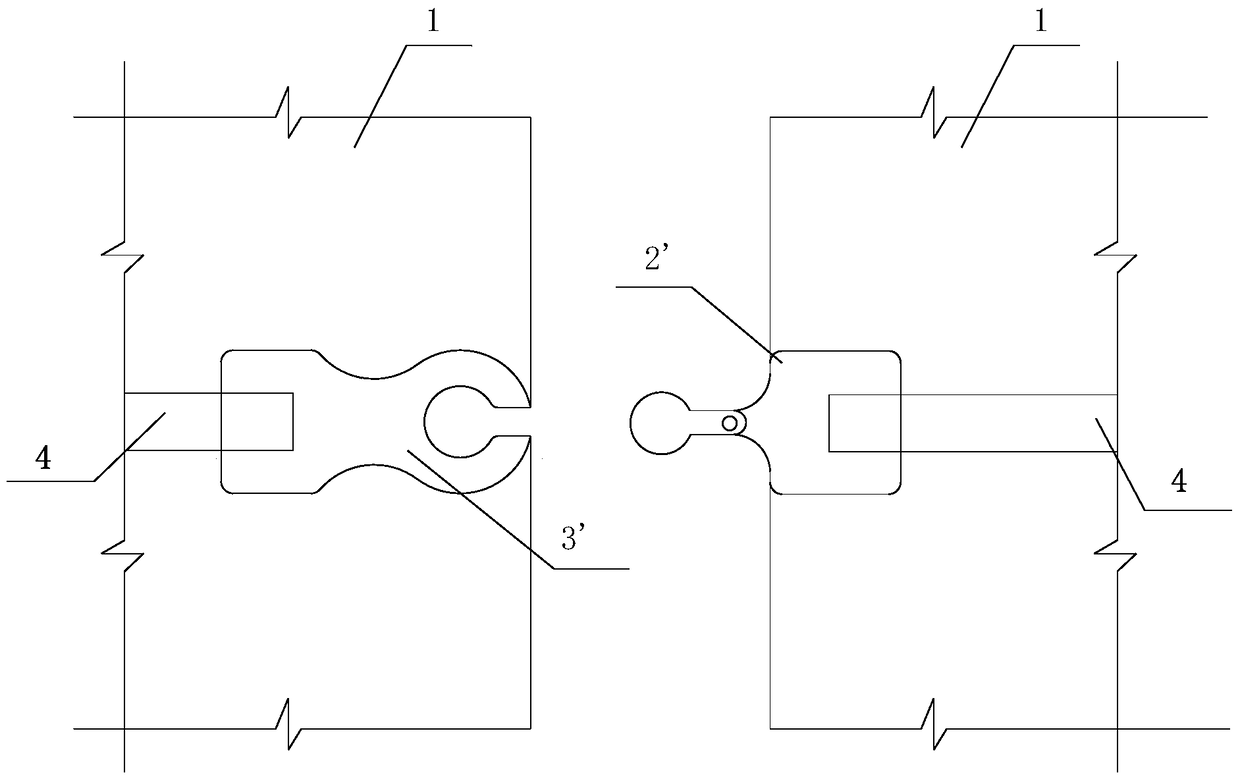

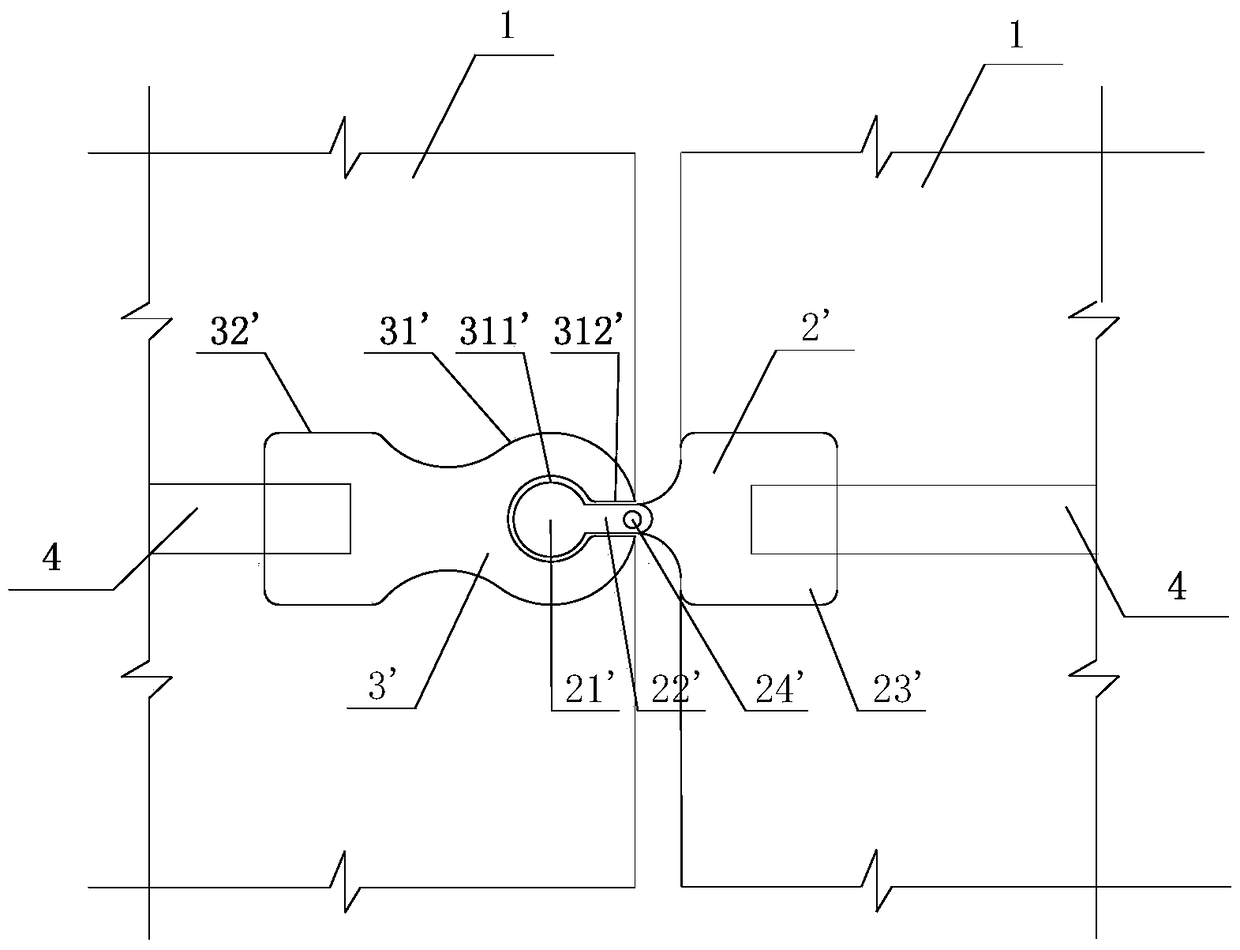

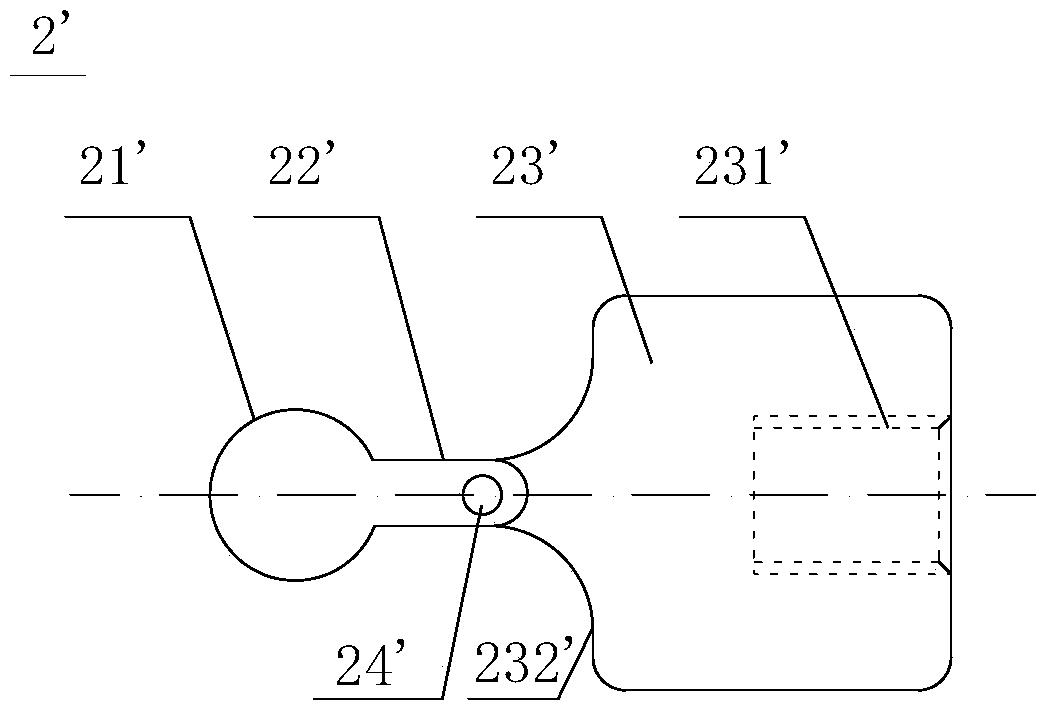

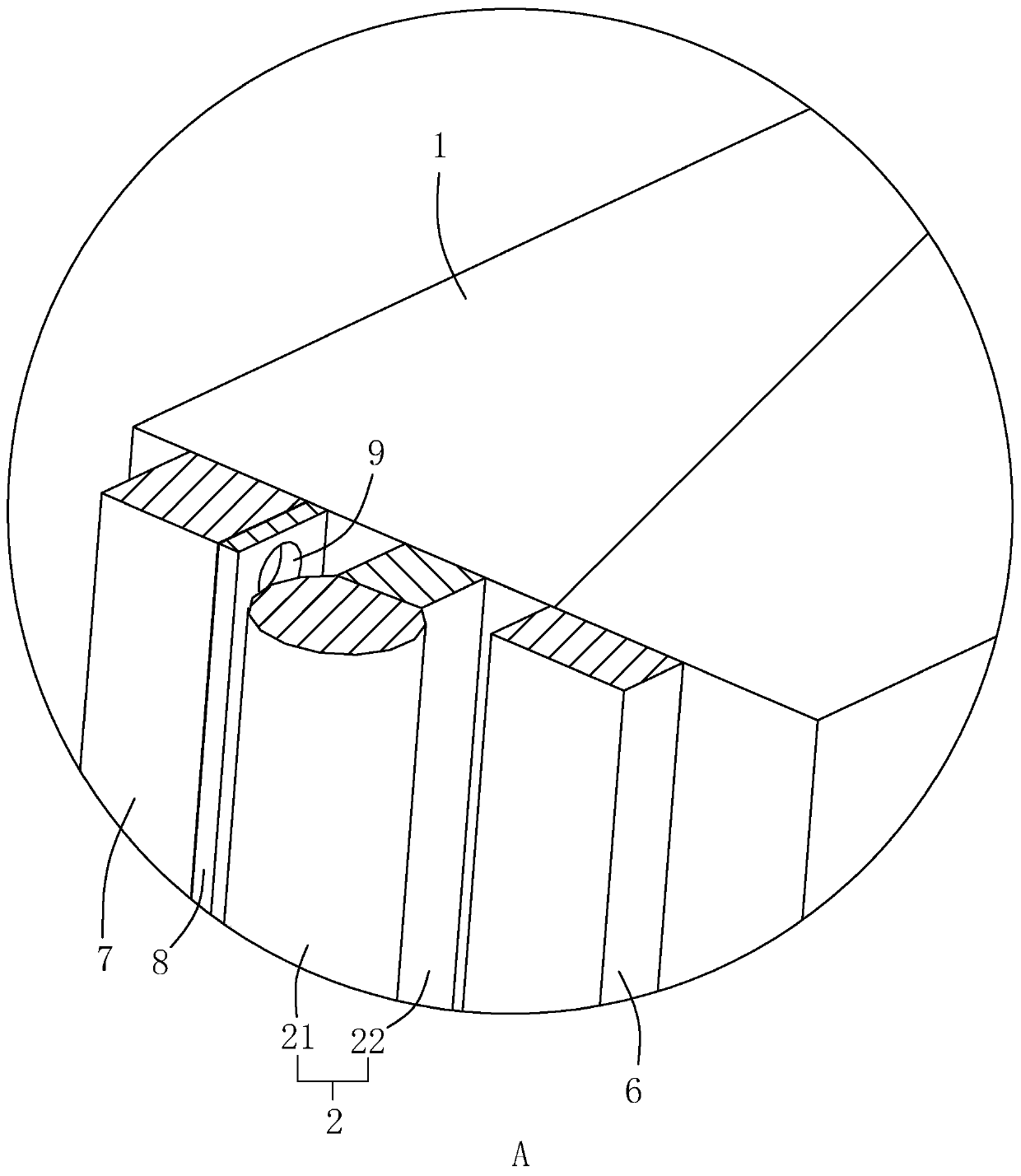

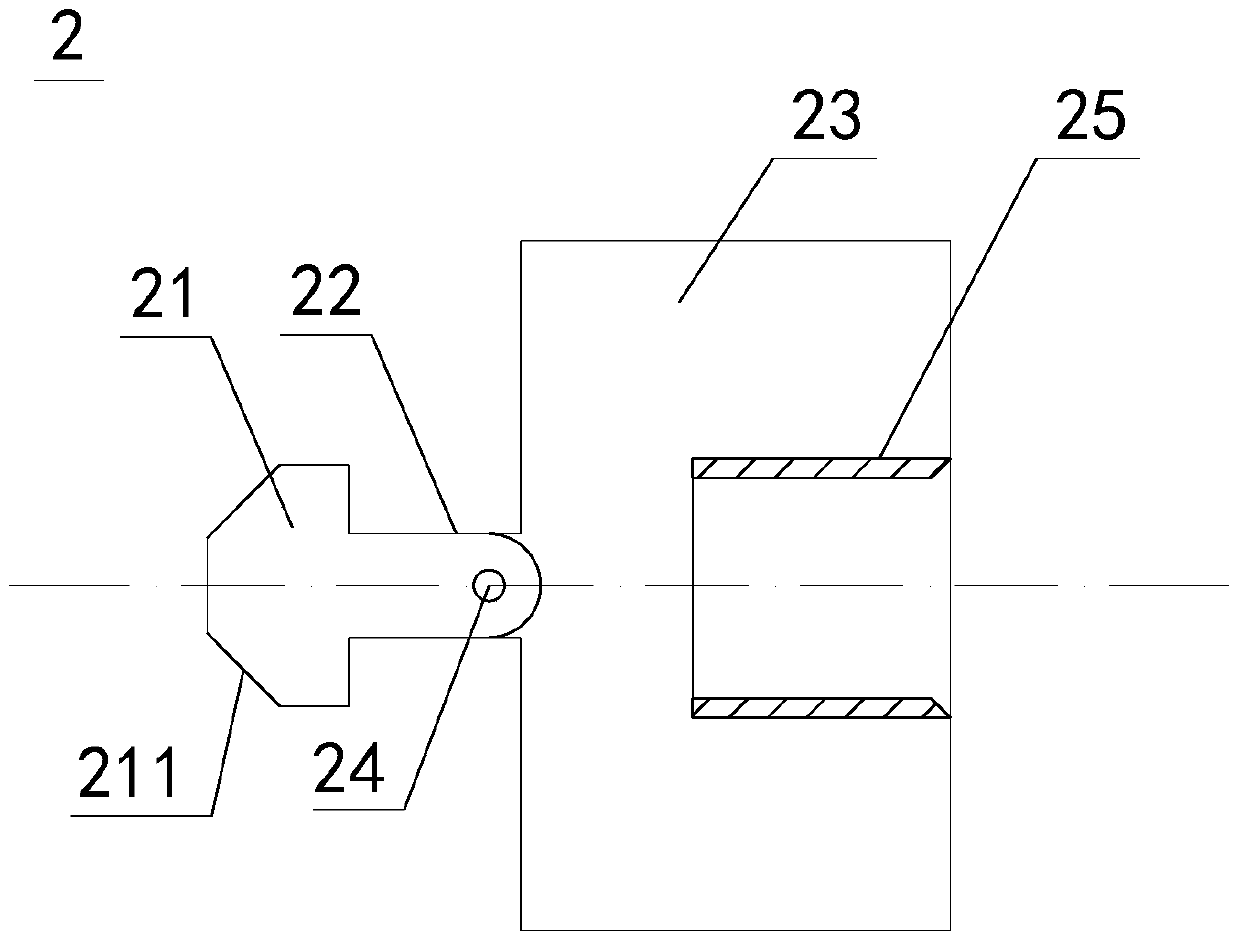

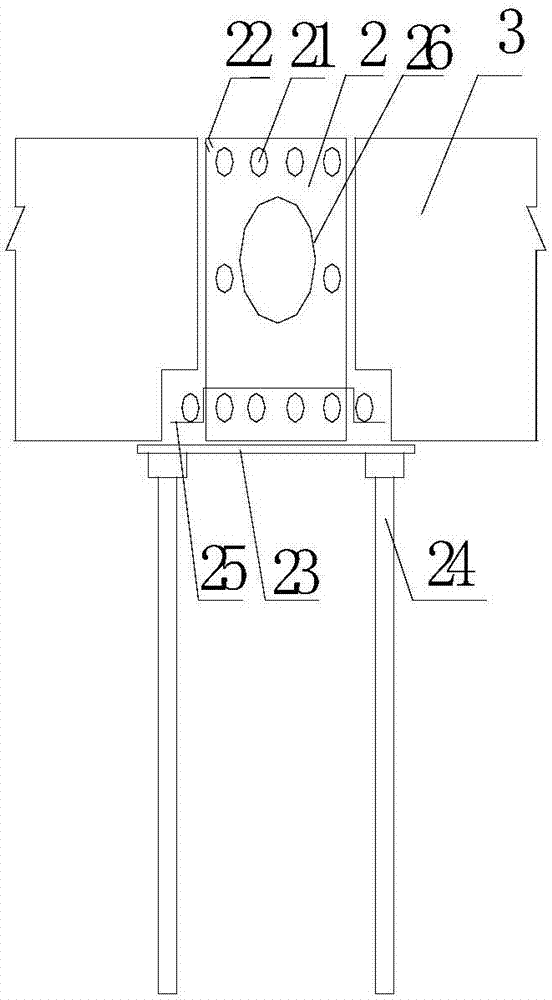

Segment circular seam connection component, tunnel segment structure and construction method

ActiveCN105507924AImprove toleranceFirmly connectedUnderground chambersTunnel liningUniversal jointButt joint

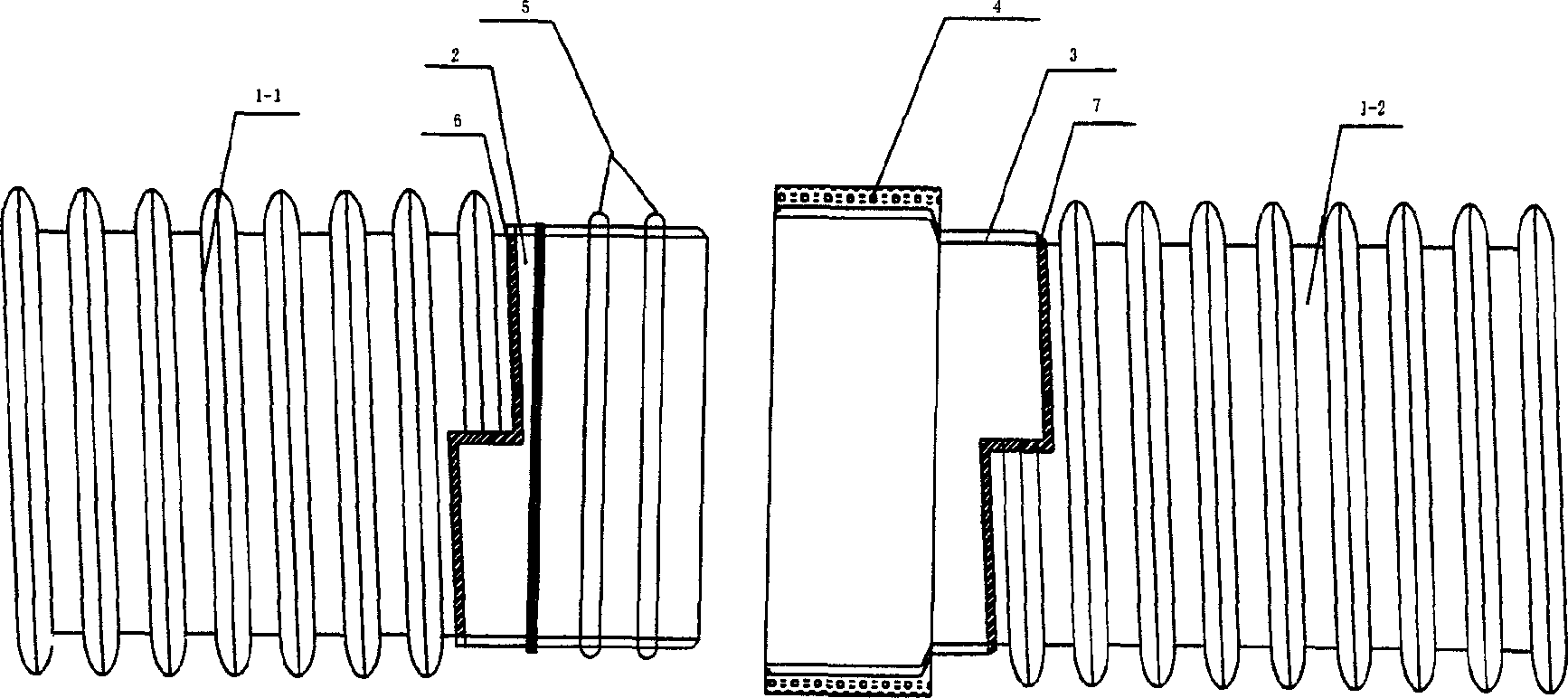

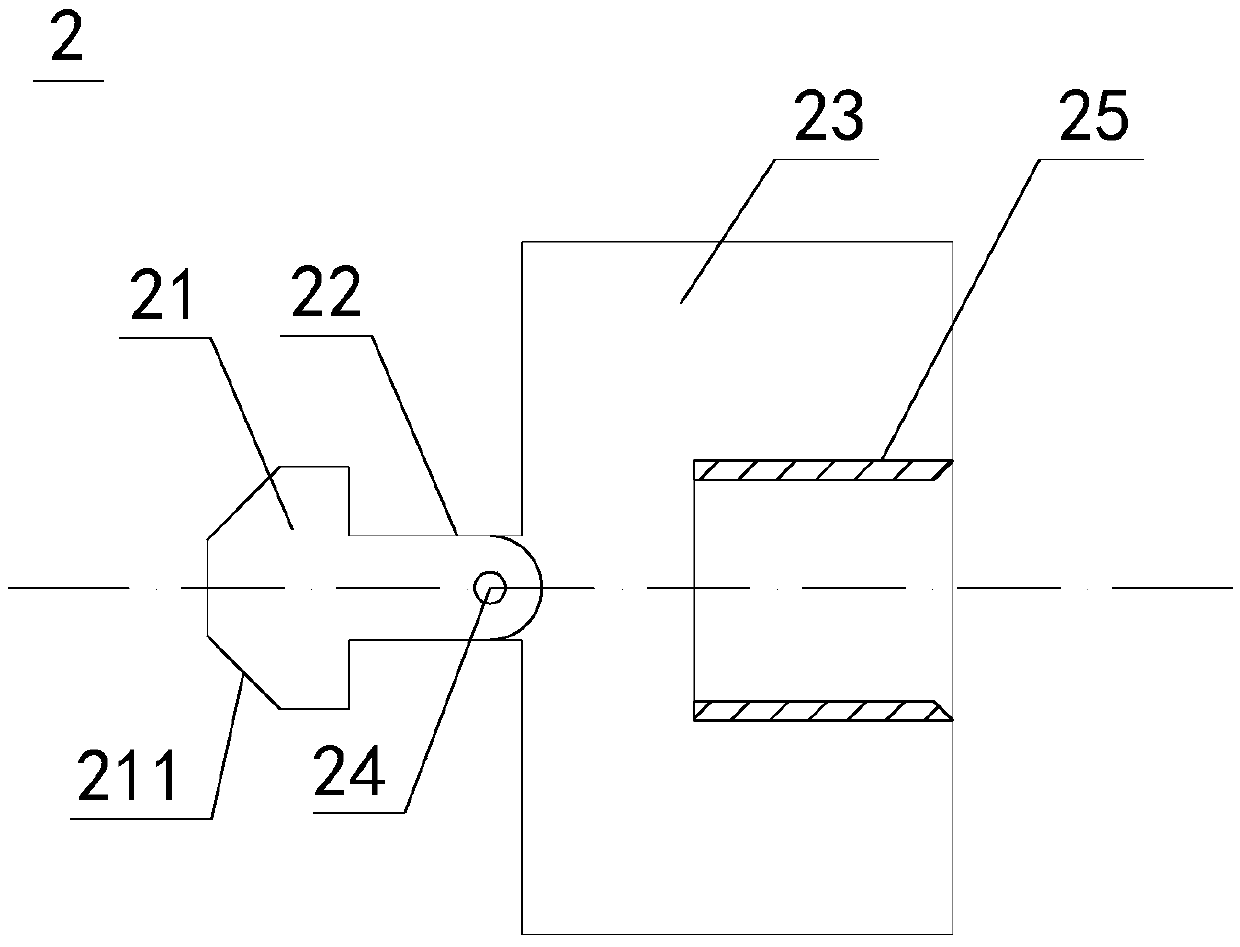

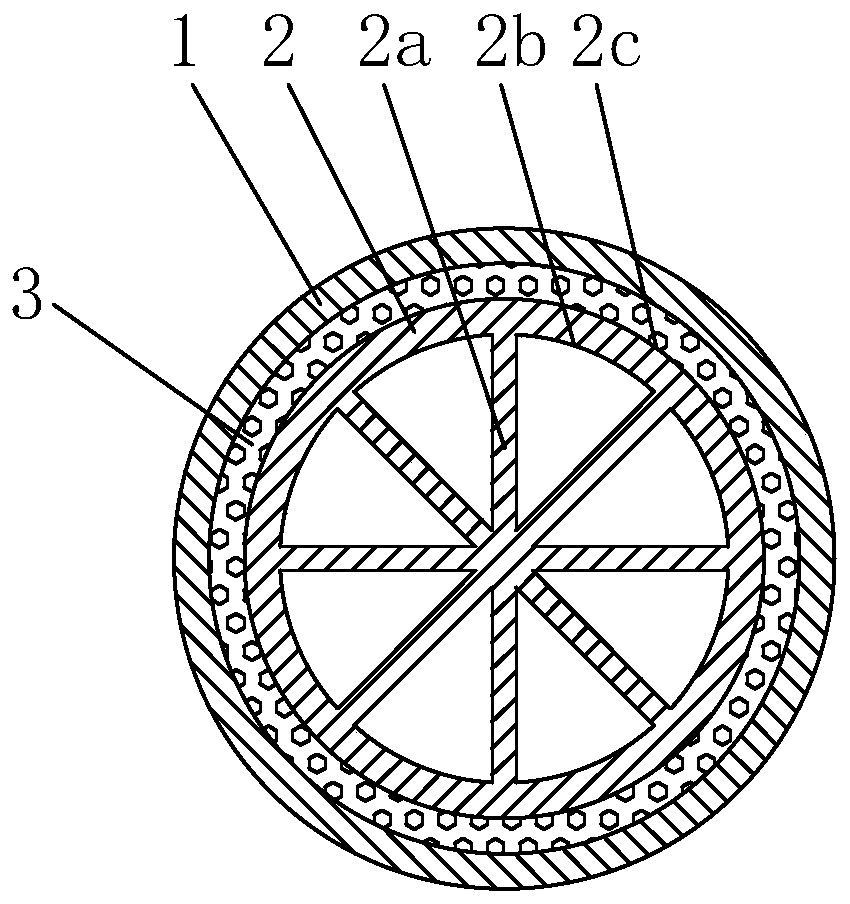

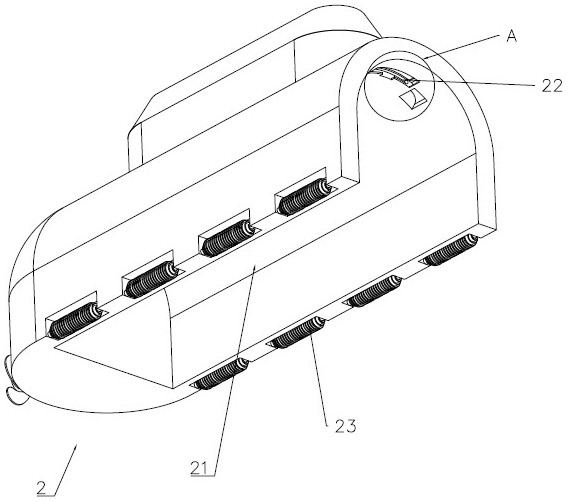

The invention discloses a segment circular seam connection component, a tunnel segment structure and a construction method. The segment circular seam connection component comprises a circular seam convex part and a circular seam concave part, and the circular seam convex part and the circular seam concave part are pre-embedded in two segments requiring circular butt joint. The circular seam convex part comprises a head portion, a neck portion and a tail portion in sequential connection, an outer diameter of the head portion is larger than that of the neck portion, and the neck portion is connected with the tail portion through a universal joint. The circular seam concave part comprises a front portion and a rear portion, the front portion and the rear portion are connected with each other, the front portion is internally provided with an inner cavity, one end, away from the rear portion, of the front portion is provided with an opening communicated with the inner cavity, a plurality of slider mechanisms are arranged around the opening of the front portion, and an inner diameter of the opening is larger than an outer diameter of the head portion. The segment circular seam connection component has an allowance performance and is adaptive to construction environments and capable of meeting the requirements on stress, deformation and water resistance in construction and use of lining segments 1. In addition, simultaneity in longitudinal and circular butt joint of the segments can be realized, and quickness and convenience in construction, easiness for mechanization and automation in construction are achieved.

Owner:SHANGHAI CONSTRUCTION GROUP

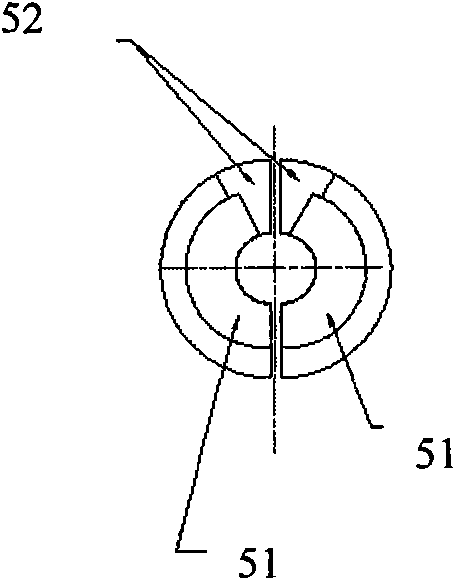

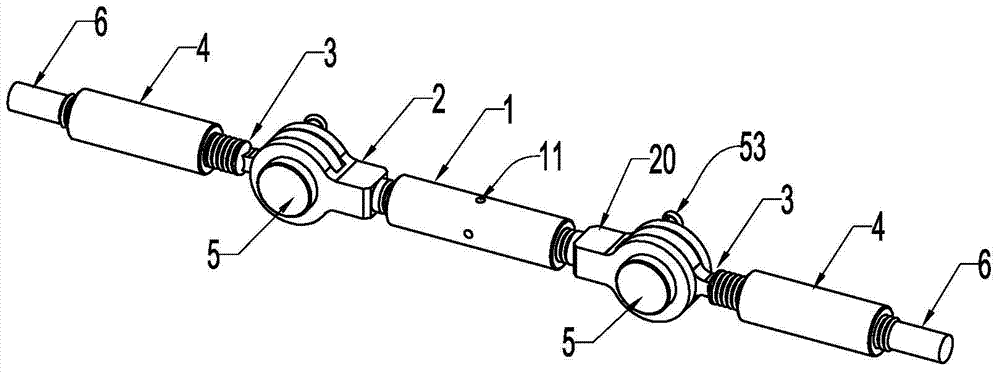

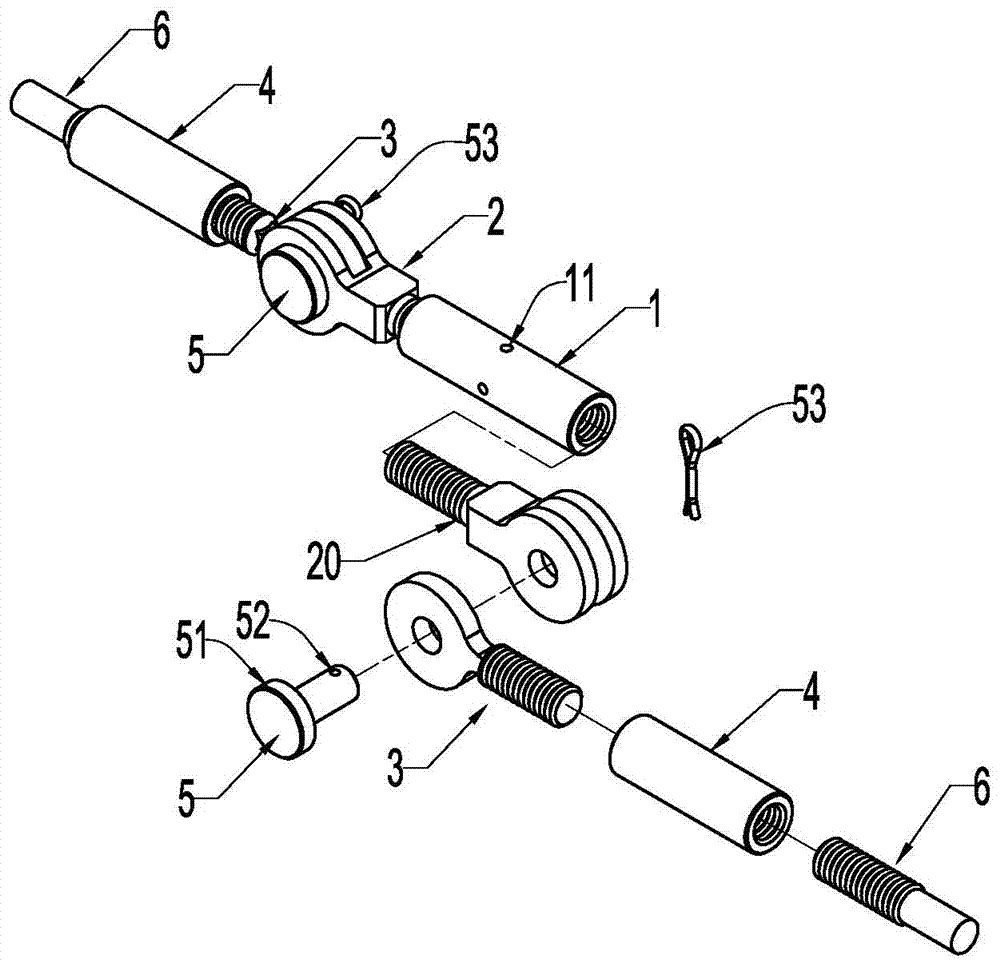

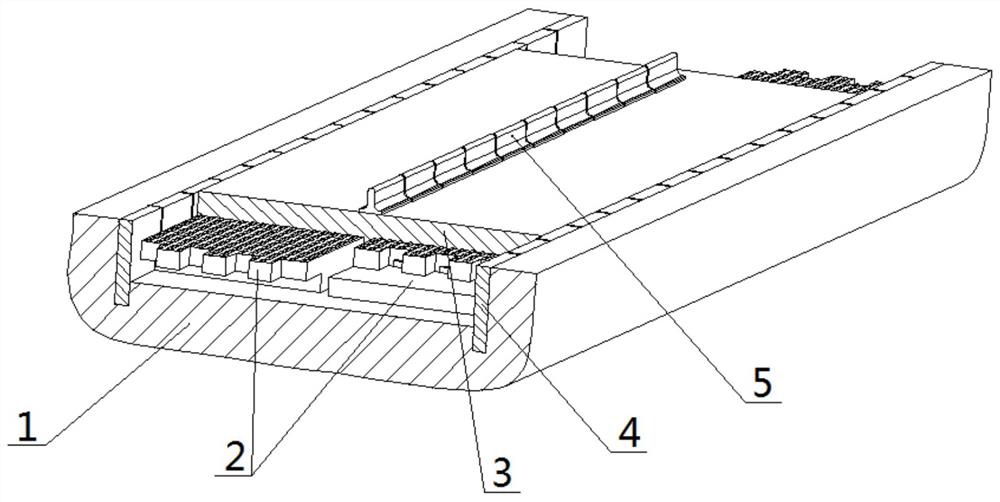

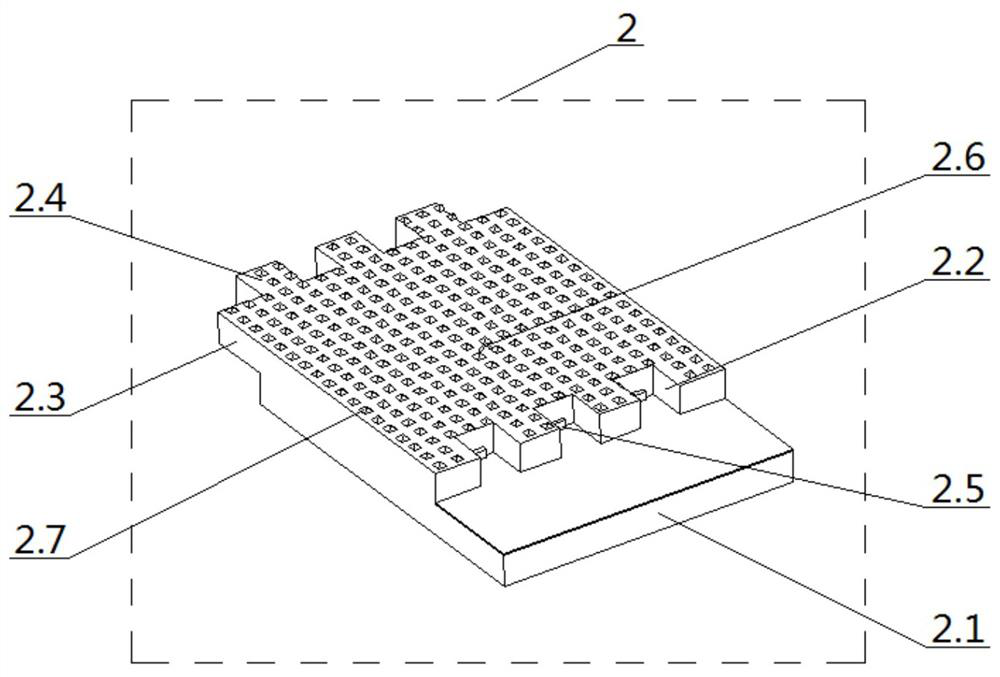

Telescopic steel bar connecting external member

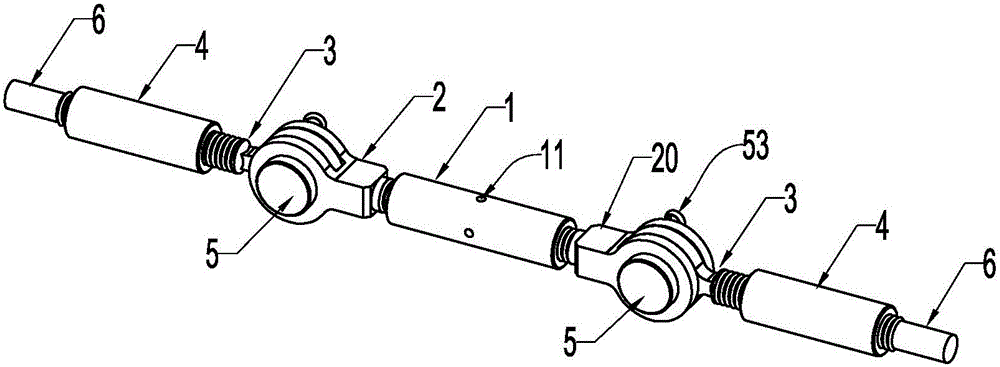

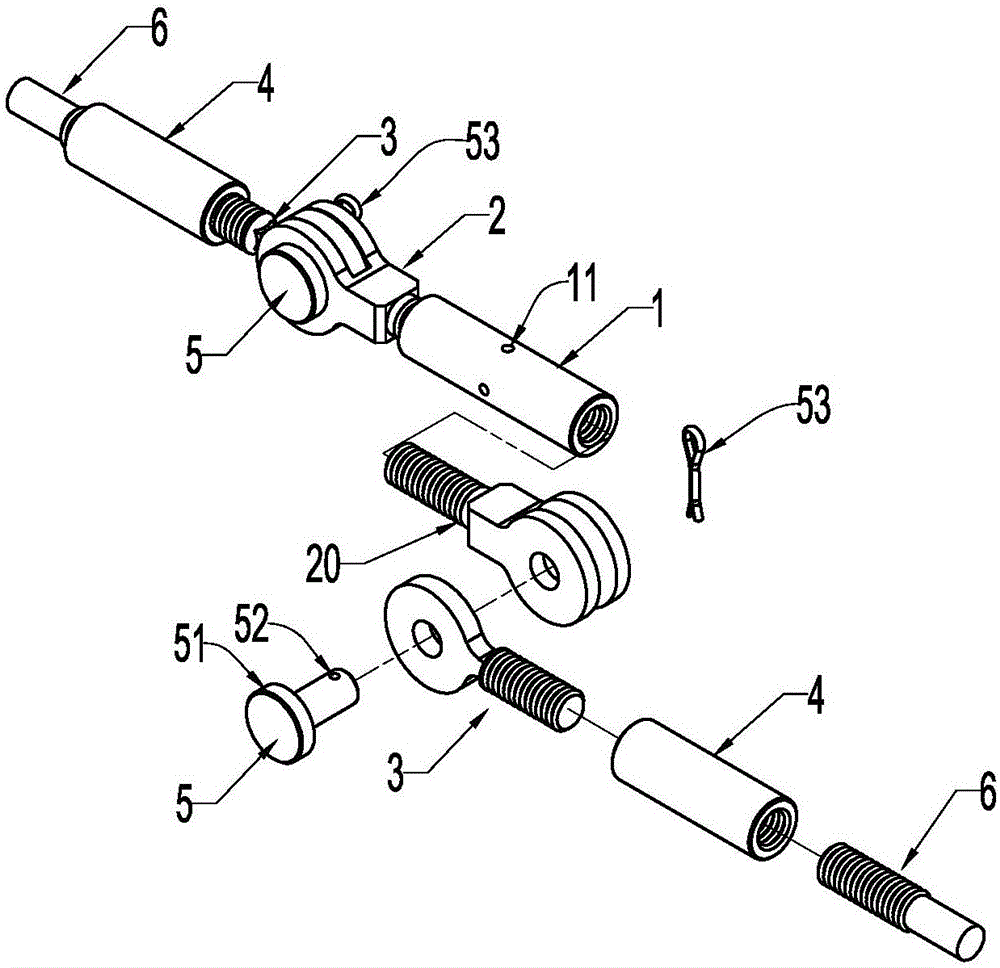

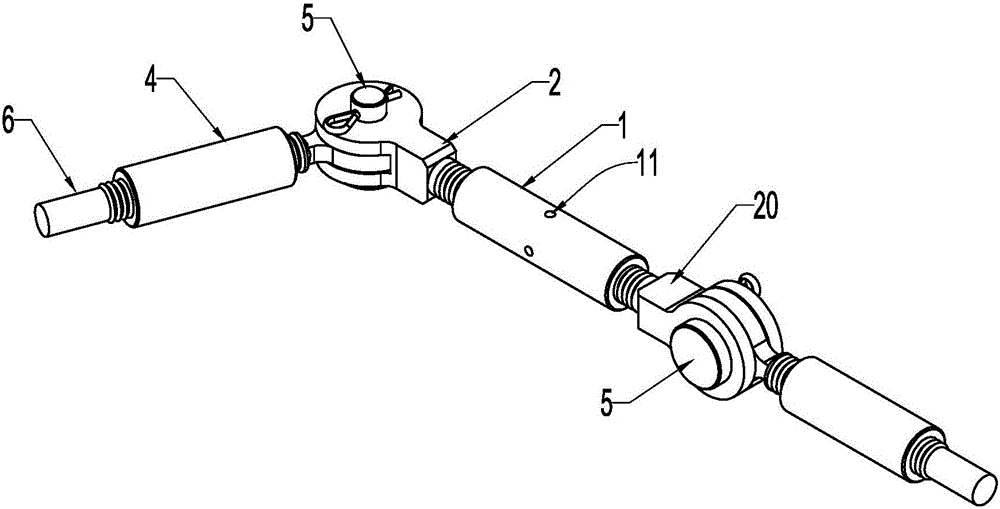

ActiveCN105064622AEasy connection and constructionReduce short-distance connectionsBuilding reinforcementsButt jointShortest distance

The invention relates to a telescopic steel bar connecting external member. An external member body comprises a bidirectional thread sleeve, a forward spinning screw rod seat, a reverse spinning screw rod seat, screw connectors, one-way thread sleeves and pin shafts. An internal thread at one end of the bidirectional thread sleeve is consistent with internal threads of the one-way thread sleeves, and the forward spinning screw rod seat, the screw connectors and external threads headed and turned by steel bar heads are consistent. All the components in the external member can be organically combined, for example, the components are increased or reduced, two steel bar heads with different intervals are in butt joint, and the external member for connection of the steel bar heads on a construction site is provided. The telescopic steel bar connecting external member has the advantages that the combining mode is flexible, according to the needs for steel bar intervals, short-distance connection can be achieved by reducing the components, the needs for long-distance connection can be met by adding the components connected in series, and connecting clearances are tightened and eliminated through the bidirectional thread sleeve; connection is reliable, no deformation exists, the requirement for stress design can be met, the telescopic steel bar connecting external member meets the connection needs of two staggered steel bar heads with different included angles, and connection construction of the steel bars is greatly facilitated.

Owner:裴敏雅

Electric melting pipe fitting with barrier function and manufacturing method thereof

ActiveCN113864559AHigh strengthImprove pressure resistanceCoatingsPipe connection arrangementsCopper wirePipe fitting

The invention discloses an electric melting pipe fitting with a barrier function. The electric melting pipe fitting comprises a pipe fitting body, a copper insert, a copper wire, an EVOH barrier layer and binding posts, the pipe fitting body comprises a plastic outer layer and a plastic inner layer, the copper insert is embedded in the pipe fitting body, the EVOH barrier layer is arranged in the middle of the pipe fitting body and between the plastic outer layer and the plastic inner layer, the copper wire is arranged on the inner surface of the plastic outer layer by adopting a front wiring process, the number of the binding posts is two, the binding posts are arranged at two ends of the outer surface of the plastic outer layer correspondingly, the copper wire serves as a resistance wire, the two ends of the copper wire are connected with the two binding posts correspondingly, the binding posts are connected with an external welding machine and are used for heating the resistance wire, and therefore the inner wall of the electric melting pipe fitting body is heated, and the electric melting pipe fitting body and two to-be-connected pipes are fused and connected. The invention further provides a preparation method of the electric melting pipe fitting. According to the technical scheme, the problems that a barrier type nonmetal composite pipe is poor in connection, and the barrier function cannot be achieved at the connecting position are solved, and the pipe fitting is convenient to connect and construct and suitable for being popularized.

Owner:LINHAI WEIXING NEW BUILDING MATERIALS CO LTD

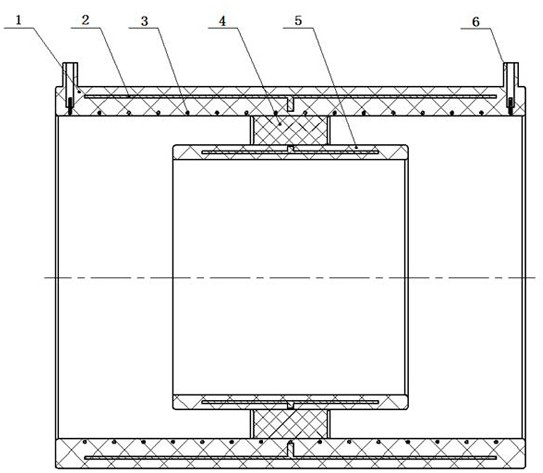

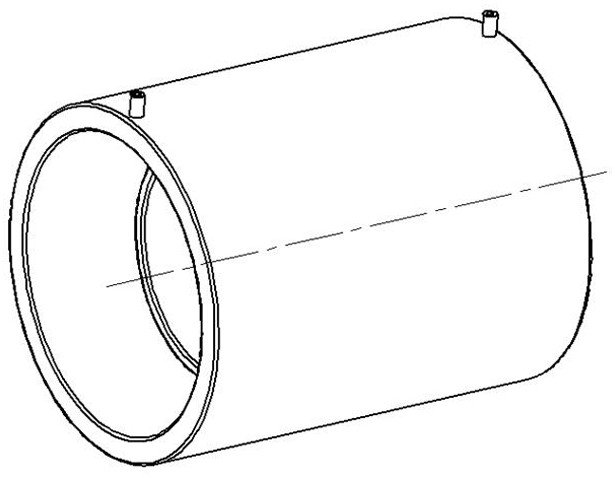

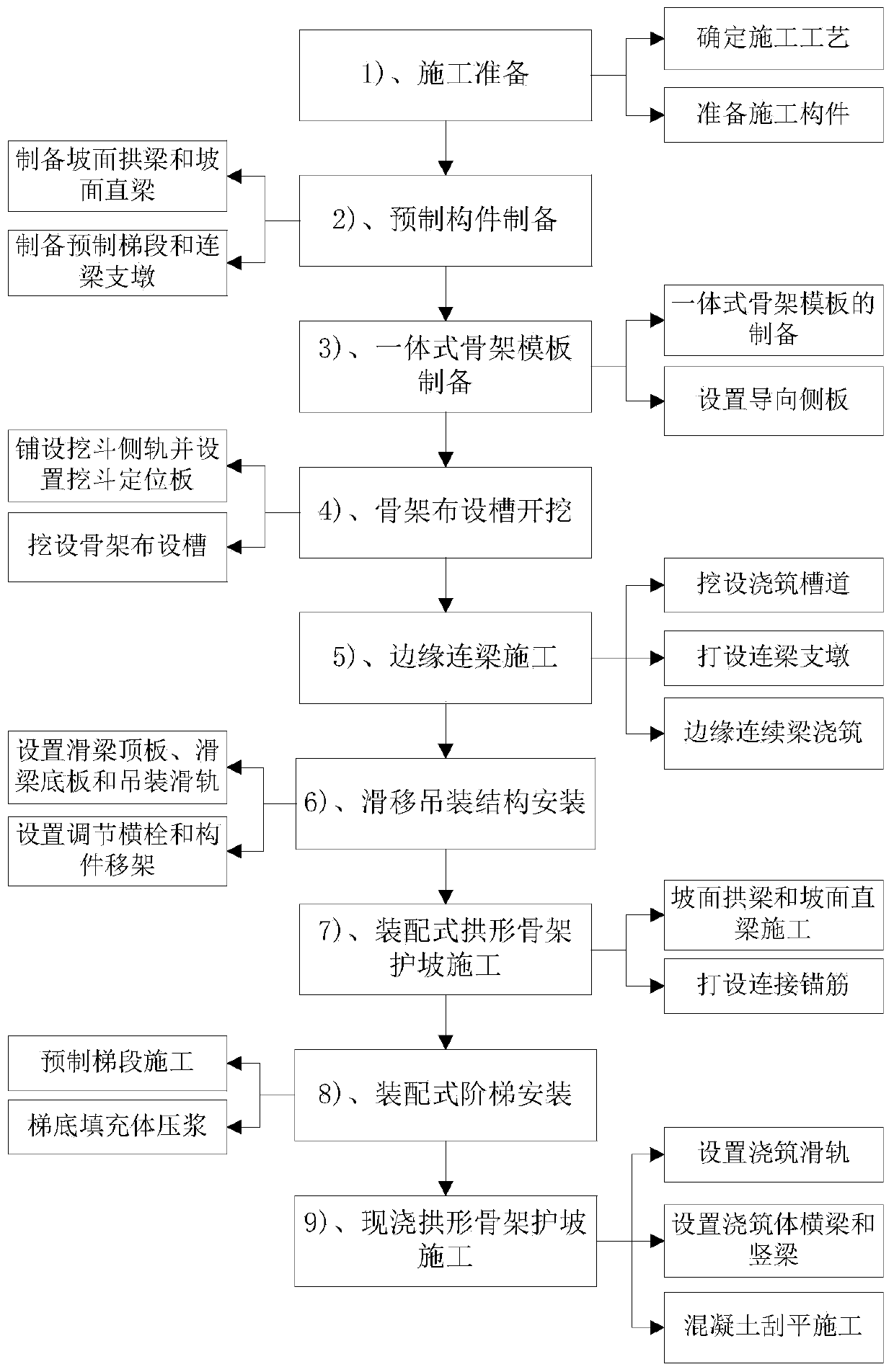

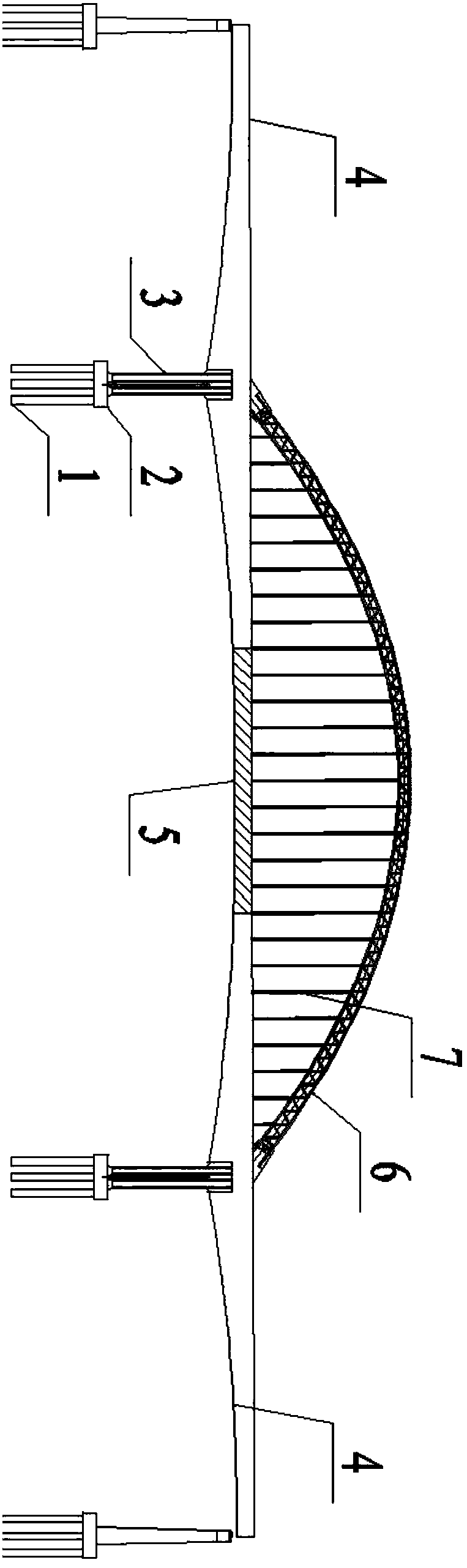

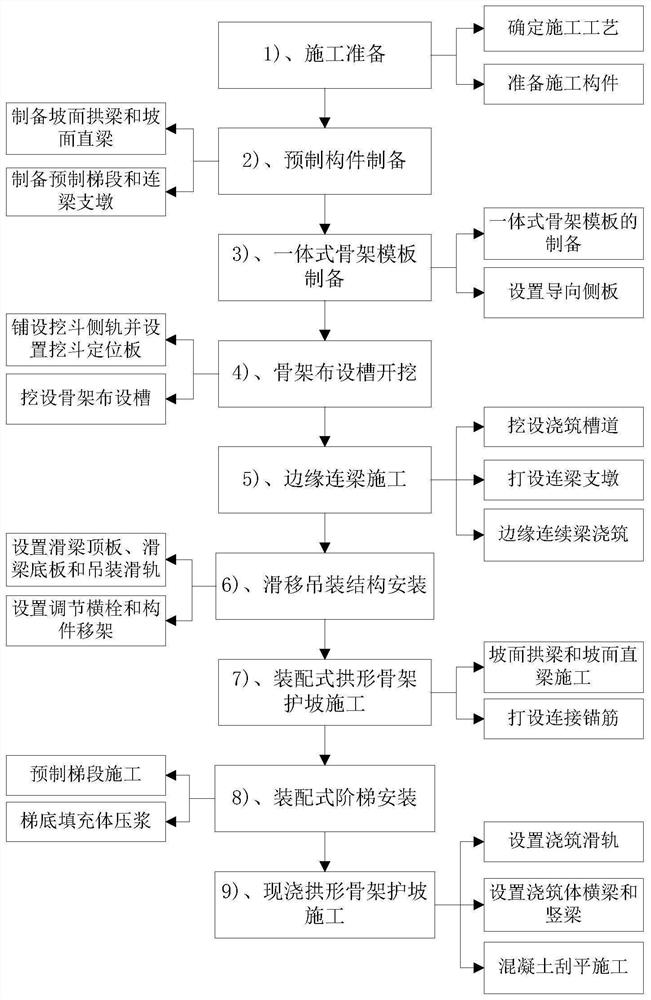

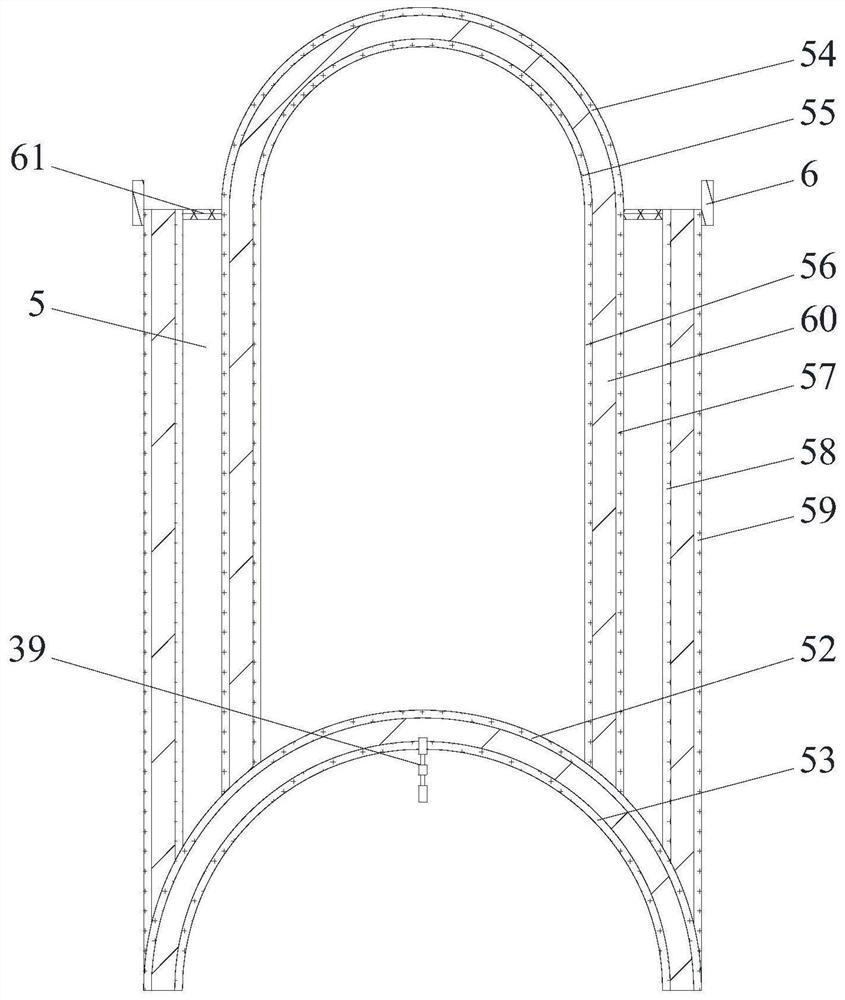

Construction method of concrete arch-shaped framework revetment

ActiveCN111119204AReduce difficultyImprove carrying capacityExcavationsArchitectural engineeringStructural engineering

The invention relates to a construction method of a concrete arch-shaped framework revetment. The construction method comprises the following steps of 1) construction preparation; 2) preparation of aprefabricated member; 3) preparation of an integrated framework template; 4) excavation of a framework arranging slot; 5) construction of an edge coupling beam; 6) mounting of a slip hoisting structure; 7) construction of an assembled arch-shaped framework revetment; 8) mounting of an assembled step; and 9) construction of a cast-in-situ arch-shaped framework revetment. The construction method hasthe beneficial effects that mold top cover plates are separately arranged between a first straight mold and a second straight mold, a third straight mold and a fourth straight mold, a first arc-shaped mold and a second arc-shaped mold and a third arc-shaped mold and a fourth arc-shaped mold of the integrated framework template, so that effects of concrete spouting and integrated framework template enhancing can be met synchronously; and guiding side plates are separately arranged on two sides of the fourth straight mold of the integrated framework template, so that the mounting and positioning difficulty of the integrated framework template can be reduced.

Owner:中国路桥集团西安实业发展有限公司

Construction process for closed connection of aluminum alloy/steel-glass fiber reinforced plastic composite ship

The invention discloses a construction process for closed connection of an aluminum alloy / steel-glass fiber reinforced plastic composite ship, and aims to provide the construction process for the closed connection of the aluminum alloy / steel-glass fiber reinforced plastic composite ship, which has the advantages of simple process, convenience in construction, reliability in connection and good effect. The construction process comprises the following steps: vertically welding one edge of angle aluminum / angle steel on an aluminum alloy / steel deck; grinding a contact surface of the angle aluminum / angle steel; mounting a vertical bolt; connecting with the outer side of the angle aluminum / angle steel through a glass fiber reinforced plastic plate on the outer side of a glass fiber reinforced plastic side wall; wrapping outer glass fiber reinforced plastic on the outer sides of the glass fiber reinforced plastic side wall, the angle aluminum / angle steel and the glass fiber reinforced plastic plate; filling with hair to block a gap of the glass fiber reinforced plastic and the contact surface of the angle aluminum / angle steel; grinding to form a gap in a corner joint part of the bottom of the outer glass fiber reinforced plastic and the aluminum alloy / steel deck; then blocking with a sealant and leveling. The construction process is applied to the technical field of the closed connection construction of the composite ship.

Owner:JIANGLONG BOAT TECH

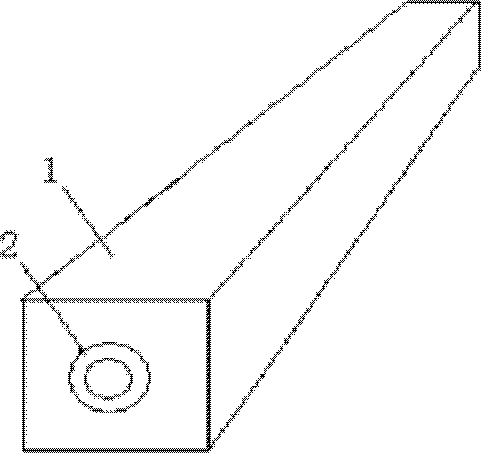

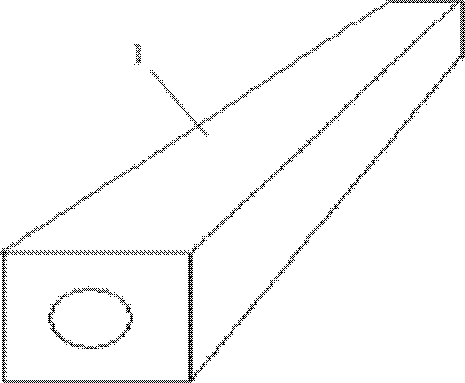

Composite stringer

InactiveCN102359271AEasy to installEasy connection and constructionAuxillary members of forms/shuttering/falseworksFloor slabMaterials science

The invention relates to the field of building equipment and discloses a composite stringer. The composite stringer comprises a rigid material and a nailing material coated on the external side of the rigid material. Because the composite stringer disclosed by the invention is provided with the rigid material in the interior, the rigidity of the composite stringer satisfies the construction requirement; meanwhile, because the nailing material is coated outside the composite stringer, convenience in mounting the composite stringer and connecting the composite stringer with the floor slab template is obtained. Meanwhile, the embodiment of the invention also provides multiple stringer standardized dimensions so that the dimension of the composite stringer is simple to adjust, the construction time is saved and the building and construction cost is reduced.

Owner:杨元东

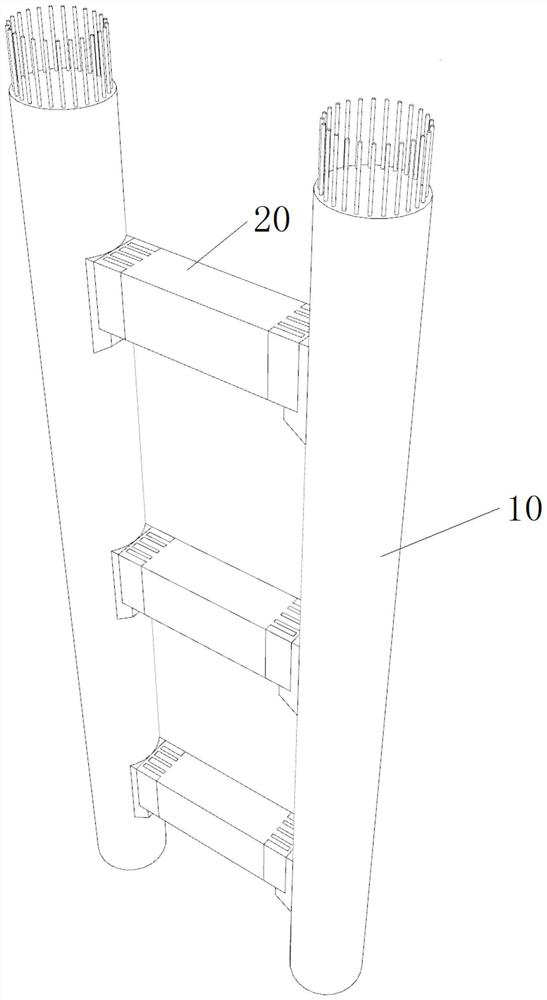

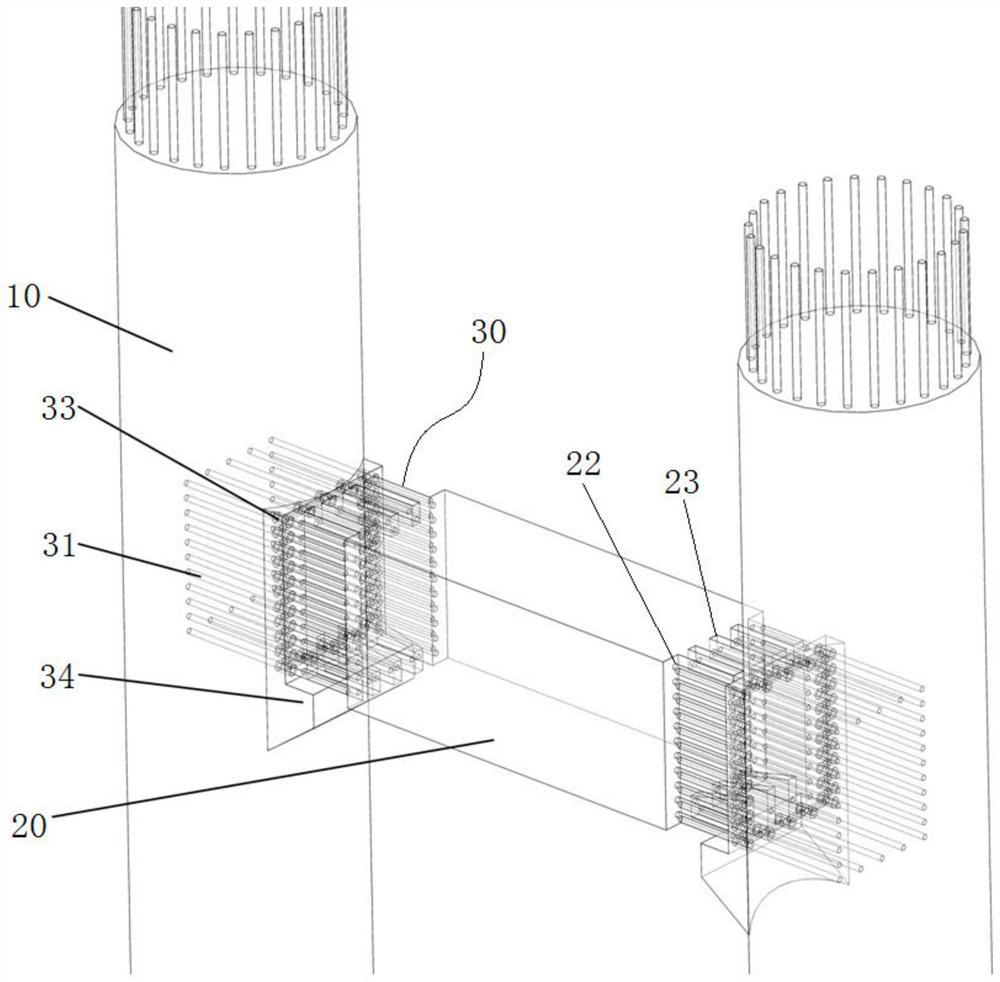

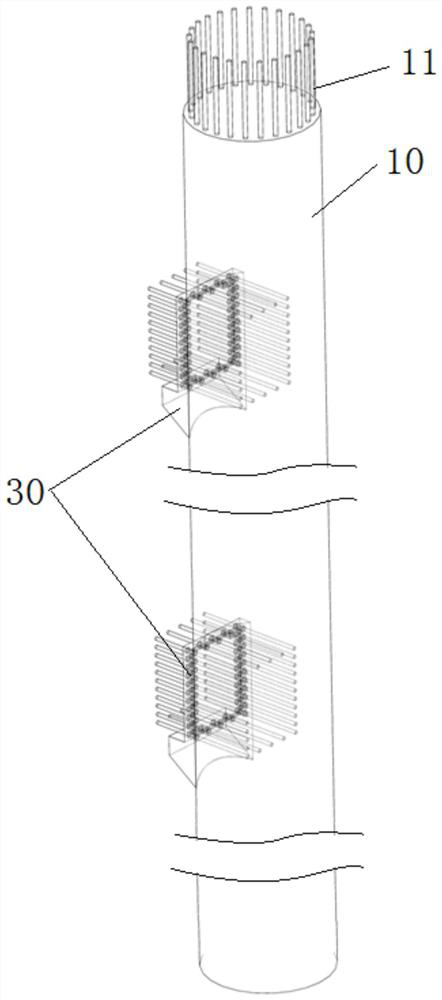

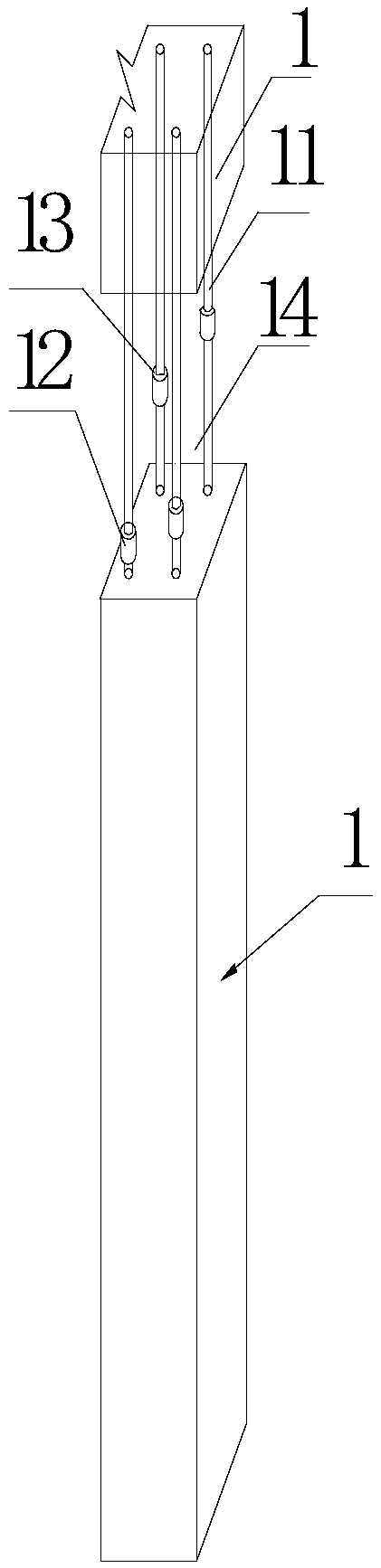

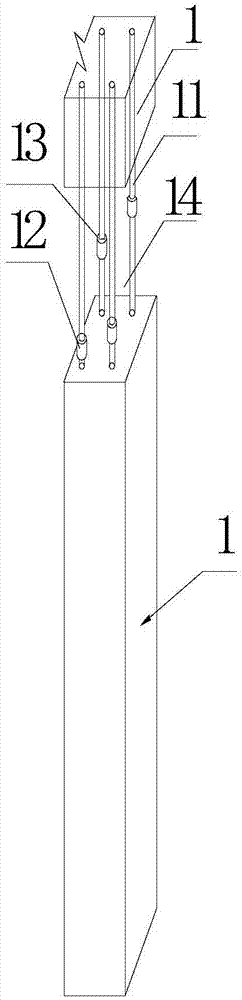

Prefabricated bridge pier and construction method thereof

PendingCN113668370AShort construction periodImprove structural strengthBridge structural detailsBridge erection/assemblyPierColumn structure

The invention relates to the field of buildings, and provides a prefabricated assembly type pier and a construction method thereof. The pier comprises a plurality of pier columns arranged at intervals in the first direction; prefabricated straining beams arranged between two adjacent pier columns in the plurality of pier columns; and connecting pieces arranged at the joints of the pier columns and the prefabricated straining beams; wherein at least part of the connecting pieces and the pier columns are integrally formed in a pouring mode, the prefabricated straining beams are provided with assembling ends, and the assembling ends are fixedly connected with the connecting pieces. The prefabricated assembly type pier has the advantages that the connecting pieces and the pier columns are integrally formed in a pouring mode, then the connecting pieces are connected with the prefabricated straining beams, and the assembling of the prefabricated straining beams and the pier columns is achieved. In the construction process, the pier columns can be continuously constructed, the construction period is short, the pier columns are not provided with splicing sections, and the pier column structure strength is high.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

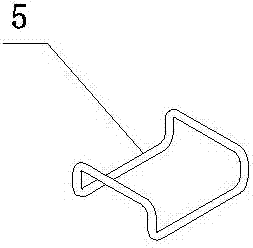

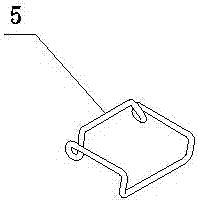

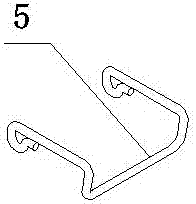

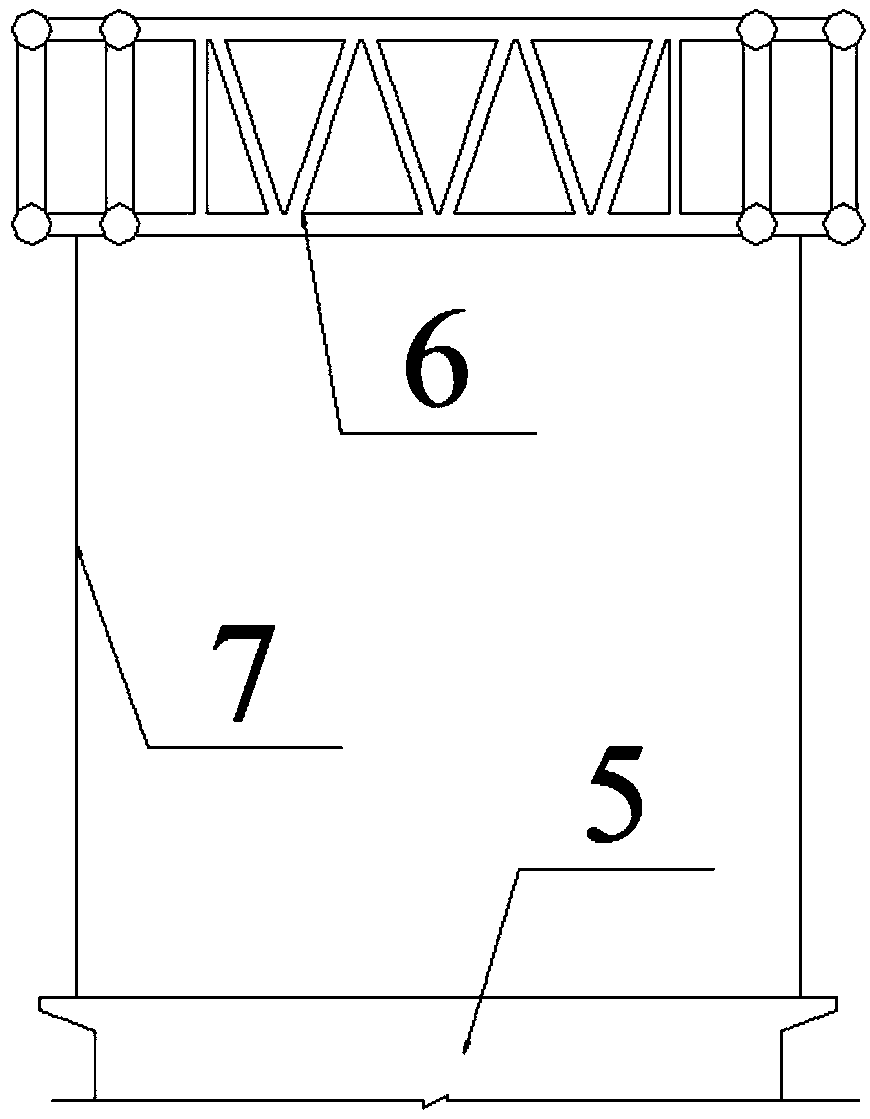

Laminated slab type concrete shear wall steel bar snap-fit connecting joint and construction method

PendingCN107165313AAvoid the disadvantages of indirect force transmissionEasy connection and constructionWallsBuilding reinforcementsThin slabRebar

The invention discloses a laminated slab type concrete shear wall steel bar snap-fit connecting joint and a construction method. The connecting mode commonly adopts that steel bars are anchored into cast-in-situ concrete in a wall cavity, structural steel bars are forced to be disconnected, force cannot be directly transmitted, structural safety stock is lowered, the overall stiffness of a wall body is weakened, and the anti-shearing capacity of the wall body is lowered. The laminated slab type concrete shear wall steel bar snap-fit connecting joint comprises a laminated slab type concrete shear wall (1), snap-fit steel bars (5) and spring bars (6). The laminated slab type concrete shear wall is composed of two layers of concrete thin plates which form a whole through lattice steel bars (2), and the laminated slab type concrete shear wall comprises longitudinal steel bars (3) and transverse steel bars (4); and the snap-fit steel bars are set up at the short edges of the transverse steel bars, are arranged at the short edges of the transverse steel bars in advance according to the different modes and additionally provided with the spring bars according to the specific modes of the snap-fit steel bars.

Owner:姜雯雯

Oil quenching spring steel wire heat treatment spray quenching device and process thereof

PendingCN108823389ACool evenlyReduce consumptionFurnace typesHeat treatment furnacesSpring steelOil temperature

The invention relates to the technical field of oil quenching spring steel wires, in particular to an oil quenching spring steel wire heat treatment spray quenching device and a process thereof. The device comprises a worktable, a main spray quenching device and an auxiliary spray quenching device; a guide device is arranged at one end of the worktable; the main spray quenching device and the auxiliary spray quenching device are arranged on the worktable in sequence; an inner oil tank is formed in the worktable; multiple oil return ports are formed in the lower end of the worktable; the oil return ports communicate with the inner oil tank; an oil return pipe and a main oil inlet pipe are arranged beside the worktable; and the oil return pipe communicates with the oil return ports through pipes. The device has the following beneficial effects: the oil temperature can be lowered after quenching, so that the lampblack generation is reduced, and the consumption of quenching oil is reduced;and the advantages of convenience to operate and adjust, simple process control, energy conservation and environmental protection are achieved.

Owner:无锡正太金属制品有限公司

Deck penetration piece for ship pipe and penetration method

InactiveCN102720894BSimple structureEasy to manufactureThermal insulationPipesThermal insulationNonferrous metal

Owner:JIANGSU ZHENJIANG SHIPYARD GROUP

Section assembly type pier column structure connection section and design method and construction method thereof

PendingCN110258312ANo shear failureHigh degree of standardizationBridge structural detailsBridge erection/assemblyEngineeringDesign methods

The invention discloses a section assembly type pier column structure connection section and a design method and a construction method thereof. The structure connecting section comprises a male section and a female section, wherein the male section comprises a first body, a first splicing end and a second splicing end are arranged on the first body, a plurality of first longitudinal ribs are further arranged in the first body, each first longitudinal rib penetrates through the first body and extends out from the first splicing end and the second splicing end correspondingly, the female section comprises a second body, a third splicing end and a fourth splicing end are arranged on the second body, the height of the second body is greater than or equal to the sum of the lengths of the portions, extending out of the first splicing end and the second splicing end, of each first longitudinal rib, a plurality of through holes are further formed in the second body, the number, the position and the cross section size of the through holes are matched with those of the first longitudinal ribs, shear keys A are arranged at the first splicing end and the third splicing end, shear keys B are arranged at the second splicing end and the fourth splicing end, the shear keys A and the shear keys B are matched, and grooves with the same shape and size are formed in all splicing ends.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Fabricated steel bar-concrete combined frame structure with column caps

The invention provides a fabricated steel bar-concrete combined frame structure with column caps. The fabricated steel bar-concrete combined frame structure comprises prefabricated columns, frame beams, cavity plate components, longitudinal combined ribbed beams, reclaimed transverse rib steel bars and combined seams. The fabricated steel bar-concrete combined frame structure is characterized in that stress steel bars are reserved at the two ends of the prefabricated columns; the column caps are formed on the peripheries of the connecting points of the prefabricated columns; the frame beams are post-poured beams or prefabricated beams; frame beam steel bars penetrate through the stress steel bars reserved at the two ends of the connecting positions of the prefabricated columns so as to form a steel bar-concrete combined frame; the cavity plate components are composed of longitudinal steel bar concrete ribbed beams, transverse steel bar concrete ribbed beams, cavity bodies and lower flange plates; the cavity plate components are mounted at the edges of the frame beams; ribbed beam steel bars of the cavity plate components extend into supporting seats of the frame beams; and the cavity plate component combined seams do not penetrate through floor slabs.

Owner:HUNAN BDF ENERGY SAVING TECH +1

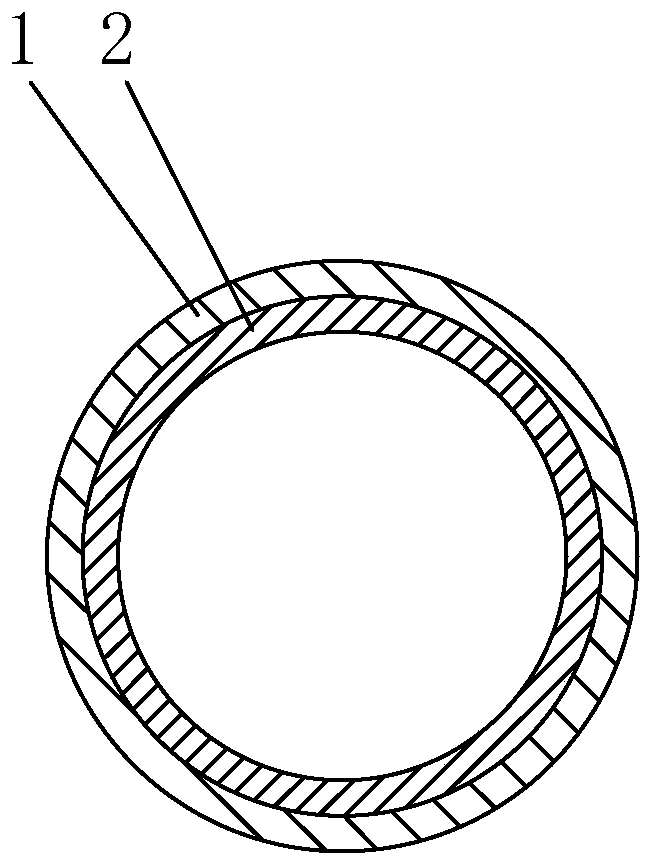

Novel drinking water pipe, cold and hot water two-way pipe and connector of novel drinking water pipe

InactiveCN111503387AExtended service lifeHigh strengthThermal insulationElectrical apparatusThermal insulationHazardous substance

The invention relates to the technical field of water pipes, and discloses a novel drinking water pipe, a cold and hot water two-way pipe and a connector of the novel drinking water pipe. The novel drinking water pipe comprises an inner pipe and an outer pipe, wherein the outer pipe is a plastic pipe, the inner pipe is made of a silicate material, the silicate material is one of enamel, cement andglass, and a layer of thermal insulation pipe is arranged between the inner pipe and the outer pipe. The cold and hot water two-way pipe comprises an outer plastic pipe and three pipes wrapped in a thermal insulation material, wherein the three pipes refer to a water inlet pipe used for cold water, a water outlet pipe used for hot water and a control pipe used for electric wires. The connector comprises a straight connector body, an elbow and a three-way connector body and consists of an outer plastic pipe and an inner glass pipe. The connector is welded with the plastic outer pipe of the water pipe through the outer plastic pipe so as to achieve connection with the drinking water pipe. A metal pipe with internal threads is arranged in the connector to achieve connection with a faucet. After drinking water passes through the water pipe, the drinking water only contacts with the silicate material, does not dissolve toxic and harmful substances, and has the advantages of corrosion resistance, no toxicity, sanitation and convenient installation.

Owner:海宁萃智智能机器人有限公司

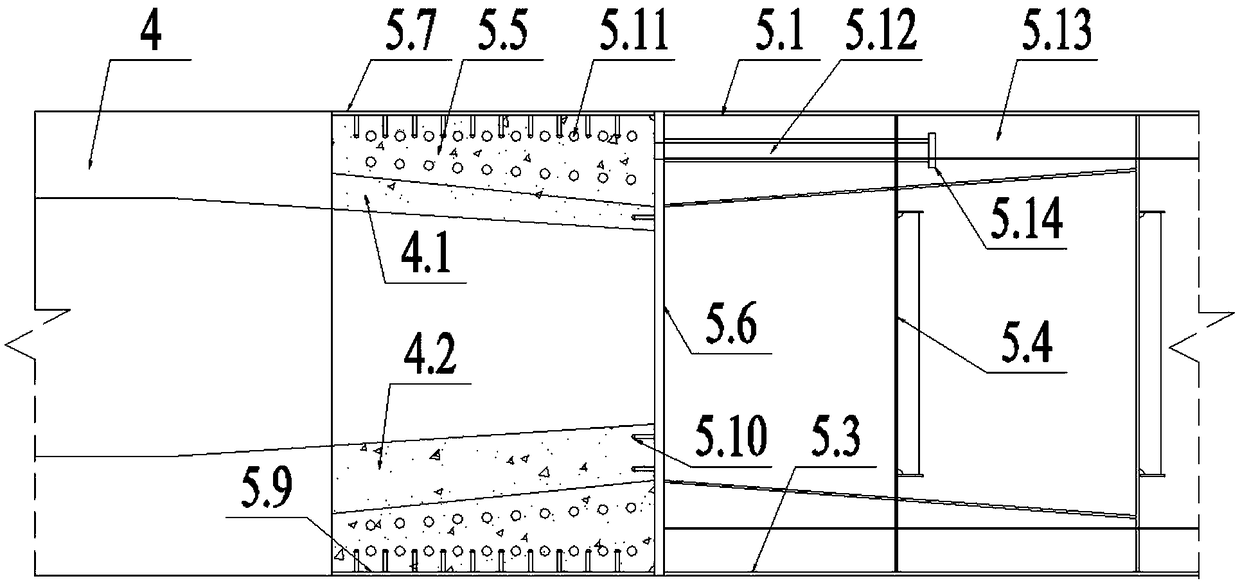

A kind of subsea tunnel construction method

ActiveCN109537632BEasy connection and constructionReduce construction difficultyArtificial islandsUnderwater structuresArchitectural engineeringSubmarine

The invention discloses a construction method for a subsea tunnel. The construction method is characterized in that several horizontally arranged water draining pipelines and a vertically arranged connecting column are preinstalled on a base of a tunnel body, floating rings are arranged at the front and back ends of the tunnel body, and sealing rings are formed on the end portions of the floatingrings; outer connecting rings are annularly arranged on the outer portions of the sealing rings, inner connecting rings are arranged annularly in the sealing rings, and several uniformly distributed bolt holes are formed in the outer connecting ring and the inner connecting ring; sealing walls used for sealing the tunnel body are further arranged at the two ends of the tunnel body and are detachably connected with the tunnel body. The construction method has the advantages that under the sealing effect of the sealing wall, in the process of laying the tunnel, in order to avoid that sea water is poured into the tunnel, when each tunnel prefabricated piece is laid, construction for the inside of the tunnel can be directly conducted in the tunnel, laying and construction are conducted synchronously, parts of the tunnel can also be pre-arranged in advance and then subjected to sinking laying, and the work efficiency of construction is greatly improved.

Owner:黄仕

A socket-type connection structure based on T-slots and its construction method

ActiveCN113089500BEasy connection and constructionLittle impact on construction progressBridge structural detailsBridge erection/assemblyEarthquake resistanceArchitectural engineering

The invention discloses a T-shaped groove-based socket connection structure and a construction method thereof, wherein the construction method includes the steps of: a. cast-in-place or prefabricated caps, so that the upper port of the caps forms a T-shaped longitudinal section; For the notch, the first shear reinforcement protruding upward is pre-embedded on the bottom wall of the cap corresponding to the large opening, and the first tensile steel bar protruding toward the center of the large opening is pre-embedded on the side wall of the cap corresponding to the large opening, prefabricated for inserting For the pier column installed in the notch, the second tensile steel bar protruding to the outside of the pier column is pre-embedded on the side of the pier column; b. Lay a grouting material leveling layer on the bottom wall of the cap corresponding to the small opening, insert the pier column Erection in the notch; c, adjust the plane coordinates, elevation and verticality of the pier column; d, connect the first tensile steel bar and the second tensile steel bar through the tensile connecting steel bar; e, pour concrete in the notch, which is based on The T-slot socket connection structure and its construction method aim to solve the technical problems of the existing socket connection structure with poor durability and anti-seismic performance.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

Method for coaxially connecting FRP reinforcements by FRP connecting pipe and expansive cement

The invention provides a method for coaxially connecting two FRP reinforcements by an FRP connecting pipe and an expansive cement, comprising the following steps of respectively perforating two reinforcements to be connected with coaxial holes, coaxially connecting and positioning the two reinforcements by an FRP extruding / pulling rod or a wire rope, sheathing a section of FRP connecting pipe at the joint of the reinforcements; carrying out coaxial positioning by a positioning ring at two ends of the connecting pipe; arranging a pouring opening or an air outlet on the positioning ring during horizontal pouring process and injecting expansive cement solution between the reinforcements and the connecting pipe by the pouring opening; needing not to arrange the pouring opening or the air outlet on the positioning ring during vertical pouring process, firstly installing and then sealing the lower positioning ring; putting the upper sealing ring in place after completing pouring the cement solution to beexpanded from the upper opening along the wall of the FRP connecting pipe, thus ensuring the coaxiality of the reinforcements and the sheathed pipes. The hardening time of the expansive cement is 6-12 hours generally. The FRP pipe can be prefabricated, the quality thereof is easy to be controlled, the cost of the expansive cement is low, the connection construction is simple and convenient, and the connecting part prepared by the expansive cement has light weight, high strength and corrosion resistance and can be used for structures with demagnetization requirements.

Owner:TONGJI UNIV +1

Telescopic Rebar Splice Kit

ActiveCN105064622BEasy connection and constructionReduce short-distance connectionsBuilding reinforcementsLong spacingArchitectural engineering

The invention relates to a telescopic steel bar connection kit, the main body of which includes a two-way screw sleeve, a forward screw seat, a reverse screw seat, a screw joint, a one-way screw sleeve and a pin shaft; one end of the two-way screw sleeve The inner thread of the thread is consistent with the inner thread of the one-way thread sleeve, and the outer thread of the forward screw seat, screw joint and steel head pier is consistent; each part in the kit can be organically combined, such as adding or subtracting Parts, for the butt connection of two steel bar heads with different spacing, and provide a kit for the connection of steel bar heads at the construction site. The combination method is flexible. According to the requirements of the steel bar spacing, it can reduce the number of parts to form a short-distance connection, and can also increase the number of parts in series to meet the needs of long-distance connections. With the help of two-way threaded sleeves, it can achieve tension and eliminate connection gaps; the connection is reliable, no The amount of deformation can meet the stress design requirements, and it is suitable for the connection of two steel bar heads with dislocation and different angles, which greatly facilitates the construction of steel bar connection.

Owner:裴敏雅

Segment longitudinal seam connection assembly, tunnel segment structure and construction method

ActiveCN105484764BCapable of toleranceEasy connection and constructionUnderground chambersTunnel liningButt jointSegment structure

The invention discloses a segment longitudinal seam connecting assembly, a tunnel segment structure and a construction method. The segment longitudinal seam connecting assembly comprises a longitudinal seam male part and a longitudinal seam female part, wherein the longitudinal seam male part comprises a gradient section cylinder, a connecting plate and a base, one end of the connecting plate is fixedly connected to the side face of the gradient section cylinder, and the other end of the connecting plate is connected with the base; the longitudinal seam female part comprises a front section and a rear section, a gradient section cylindrical cavity matched with the gradient section cylinder is formed in the front section, a through hole matched with the connecting plate in shape and size and communicated with the gradient section cylindrical cavity is formed in one end, away from the rear section, of the front section, the longitudinal seam female part is wholly pre-buried into a segment, a groove capable of containing the longitudinal seam male part is formed in the segment, and the longitudinal seam female part is located at one side of the groove. The tunnel segment structure has certain tolerance capacity, is adaptive to construction environment and capable of achieving simultaneous butt joint of segments in the longitudinal and circumferential directions, and has the advantages of being fast and convenient to construct and easy to construct automatically.

Owner:SHANGHAI CONSTRUCTION GROUP

Prefabricated single-compartment municipal utility tunnel

InactiveCN109706962AFirmly connectedImprove waterproof performanceArtificial islandsUnderwater structuresUtility tunnelSingle compartment

The invention relates to a prefabricated single-compartment municipal utility tunnel. The prefabricated single-compartment municipal utility tunnel comprises a plurality of prefabricated duct pieces arranged on a concrete cushion layer, wherein longitudinal male rings and longitudinal female grooves are correspondingly and fixedly connected to the two end surfaces of the prefabricated duct pieces,and the longitudinal male rings and the longitudinal female grooves of adjacent prefabricated duct pieces mesh with each other; the longitudinal male rings comprise connecting rings and cylinders with circular cross sections, wherein one ends of the connecting rings are fixedly connected to the side surfaces of the cylinders, the other ends of the connecting rings are fixedly connected to the endsurfaces of the prefabricated duct pieces, and the thickness of the connecting rings is smaller than the diameter of the cylinders; and the longitudinal female grooves comprise cylindrical cavities accommodating the cylinders and connecting holes in which the connecting rings are inserted, the connecting holes communicate with the cylindrical cavities, elastic water stop strips are arranged on the two inner walls of the connecting holes, and the distance between the two water stop strips is smaller than the thickness of the connecting rings. The cylinders are connected into inner cavities ofthe longitudinal female grooves in a clamped mode to improve the connection convenience and adaptability of the longitudinal male rings and the longitudinal female grooves; and the water stop strips abut against the surfaces of the connecting rings in a pressing mode, and the waterproof effect between the adjacent prefabricated duct pieces can be enhanced.

Owner:四川荣晨建设工程有限公司

Heavy-load long-service-life highway structure and construction method

ActiveCN112281561ASolve the problem of alternating up and down dislocation changesAvoid Alternating Shear Stress ChangesIn situ pavingsClimate change adaptationArchitectural engineeringCement board

The invention discloses a heavy-load long-service-life highway structure and a construction method. The heavy-load long-service-life highway structure comprises a roadbed, a base plate and an asphaltpavement layer, wherein the substrate is a prefabricated part and is fixedly arranged at the upper part of the roadbed; the asphalt pavement layer is laid on the substrate; the substrate is plate-shaped, the lower side of the end part of one side of the substrate is provided with a substrate lower crimping plate, and the upper side of the end part of the other side of the substrate is provided with a substrate upper crimping plate; when the substrate is arranged on a roadbed, the base plate upper crimping plate of the previous substrate is arranged at the upper part of the base plate lower crimping plate of the next substrate along the driving direction of a vehicle, so that a plurality of substrates are connected into a whole, and the problem when the heavy-load vehicle passes, the expansion and shrinkage joints of the adjacent cement plates are alternately staggered up and down is solved, so that the problem that reflective cracks are generated on the asphalt pavement layer is solved; the heavy-load long-service-life highway structure has the advantages of being simple in structure, simple and convenient in construction process and short in construction period, the bearing capacity of a highway is greatly improved, and the service life of the highway is greatly prolonged.

Owner:河南璟信工程管理咨询有限公司

A steel-concrete beam rigid-frame arch bridge

The invention relates to the technical field of bridge structure, in particular to a steel reinforced concrete beam rigid framework bridge. The bride comprises a pile foundation, bearing platforms grouted on the foundation, bridge piers supported by the bearing platforms and beam bodies supported by the bridge piers. The beam bodies comprise two concrete beams and steel box beams located between two concrete beams. Two concrete beams are fixed on the upper end of the bridge section, and are erected in the bridge sidespan section and partial midspan section along the positive direction of the bridge. The steel box beams are the steel beams erected in the midspan section along the bridge positive direction. Two ends of the steel box beams in the bridge positive direction are fixed to the ends of two concrete beams respectively. Reinforcing structures providing vertically upward forces to the box beams are arranged on the box beams. The steel reinforced concrete beam rigid framework bridge has the advantages is simple in structure. The spanning capability of the midspan section can be effectively elevated by the arrangement of the steel box beam structures. The negative effects brought by the concrete beam contraction and creeping can be relieved. The construction schedule is shortened. The steel reinforced concrete beam rigid framework bridge has a big promotion value.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

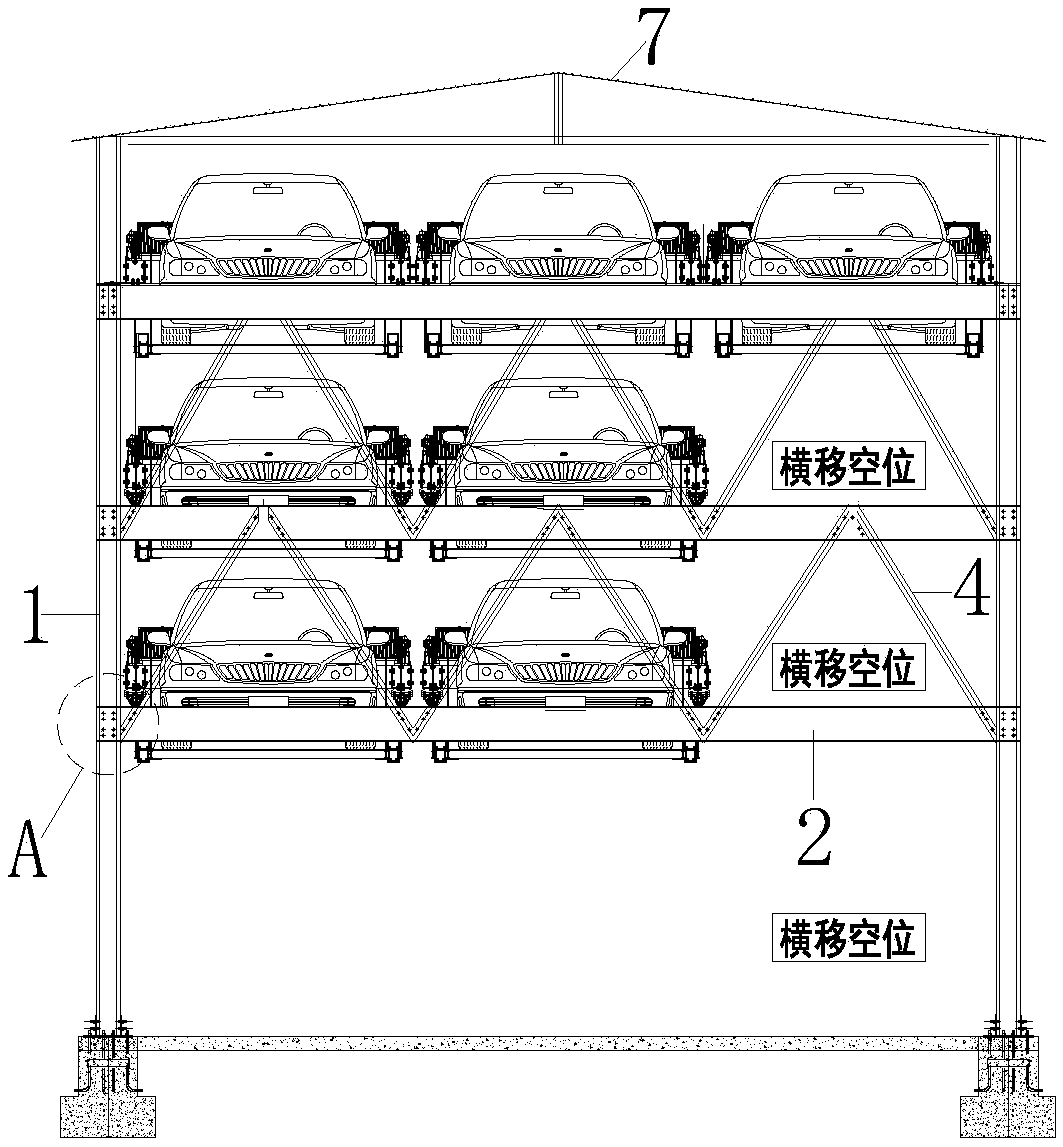

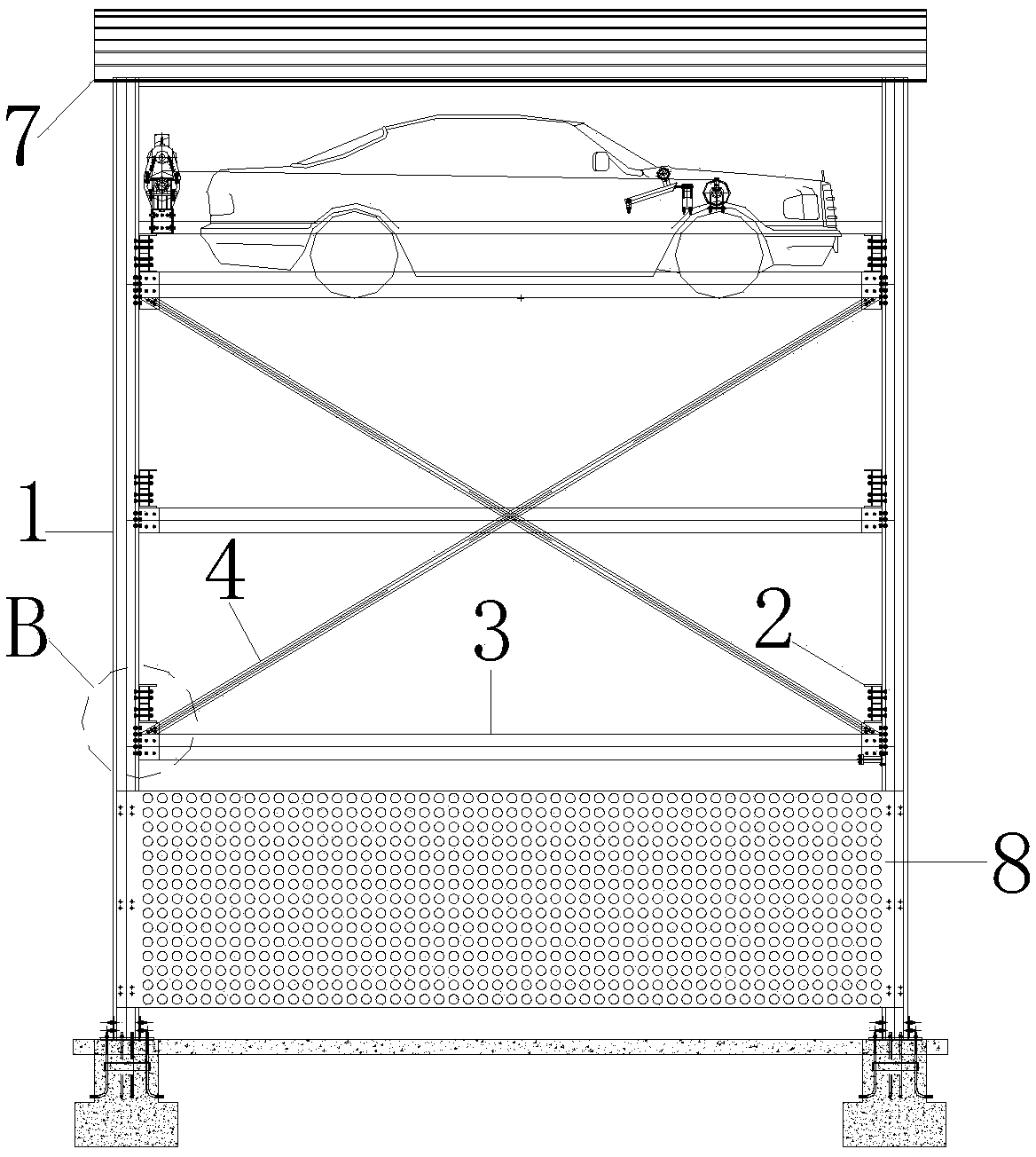

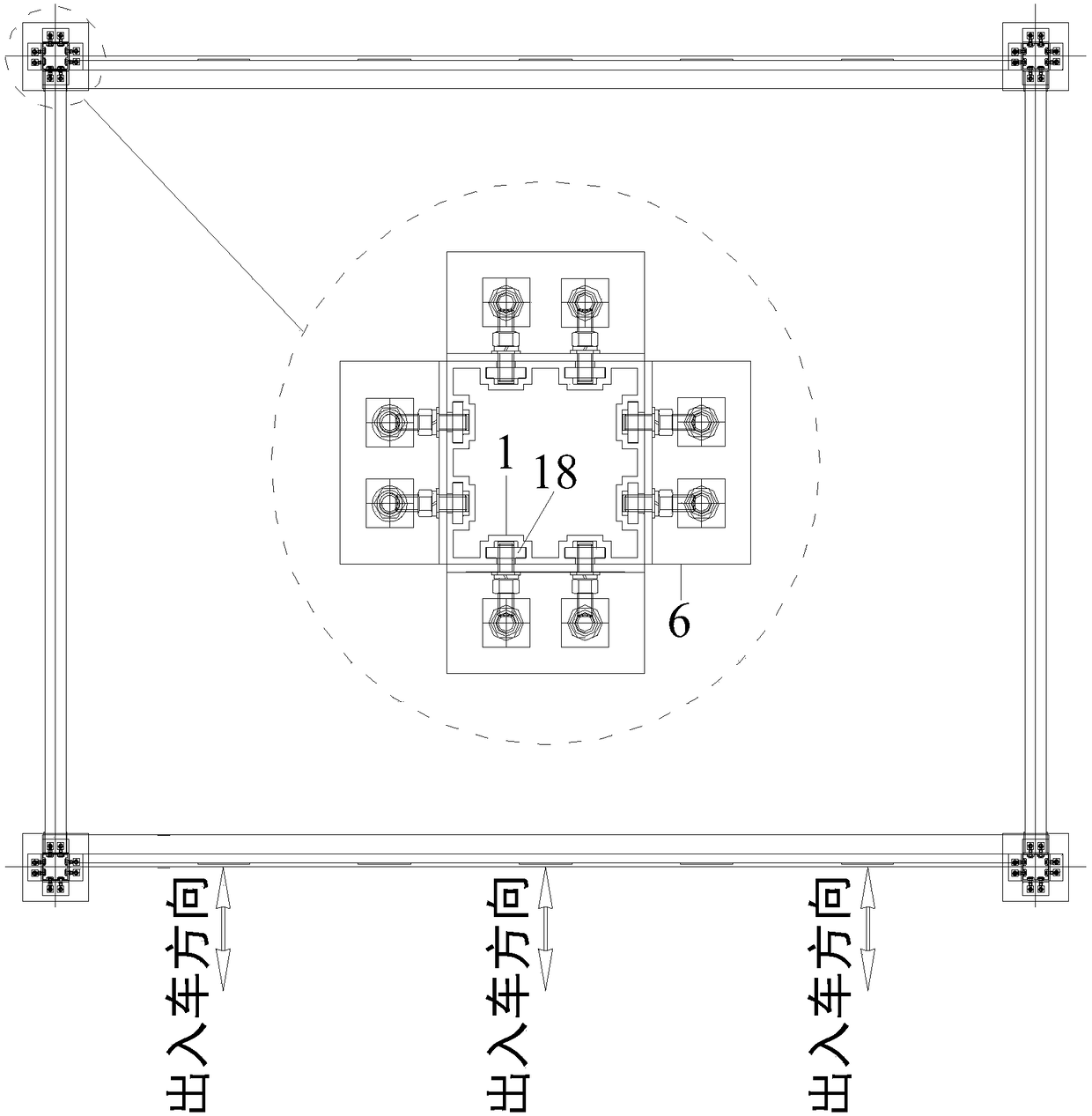

Multilayered stereo park with detachable movable aluminium alloy frame

InactiveCN108590287AEasy to disassembleImprove anti-corrosion performanceParkingsMaterials scienceCorrosion

The invention discloses a multilayered stereo park with a detachable movable aluminium alloy frame. The multilayered stereo park includes a frame structure produced by aluminium alloy squeezing profiles; the frame structure is internally divided into at least three layers in the vertical direction and the width of each layer can accommodate at least three vehicle carrying units; the number of thevehicle carrying units arranged in other layers except the top layer is at least one less than the maximum accommodating number of the corresponding layer; the vehicle carrying units can freely translate in the horizontal direction and vehicle bearing plates are hung below the vehicle carrying units; and the vehicle bearing plates can rise or decline relative to the vehicle carrying units. The defects of corrosion and poor durability and weather fastness of steel of a traditional steel structure park, troublesome maintaining during use and high cost of the traditional steel structure park in the prior art are overcome; the technical problems that the top layer and the bottom layer of the existing steel structure stereo park are non-protective, disassembly is not convenient and recycle of materials is not achieved are solved; and vehicles can directly achieve the parking or taking of the vehicles by combining of horizontal moving and vertical moving.

Owner:CHINA UNIV OF MINING & TECH

Segment circular joint connection assembly, tunnel segment structure and construction method

ActiveCN105507924BImprove convenienceImprove adaptabilityUnderground chambersTunnel liningUniversal jointButt joint

The invention discloses a segment circular seam connection component, a tunnel segment structure and a construction method. The segment circular seam connection component comprises a circular seam convex part and a circular seam concave part, and the circular seam convex part and the circular seam concave part are pre-embedded in two segments requiring circular butt joint. The circular seam convex part comprises a head portion, a neck portion and a tail portion in sequential connection, an outer diameter of the head portion is larger than that of the neck portion, and the neck portion is connected with the tail portion through a universal joint. The circular seam concave part comprises a front portion and a rear portion, the front portion and the rear portion are connected with each other, the front portion is internally provided with an inner cavity, one end, away from the rear portion, of the front portion is provided with an opening communicated with the inner cavity, a plurality of slider mechanisms are arranged around the opening of the front portion, and an inner diameter of the opening is larger than an outer diameter of the head portion. The segment circular seam connection component has an allowance performance and is adaptive to construction environments and capable of meeting the requirements on stress, deformation and water resistance in construction and use of lining segments 1. In addition, simultaneity in longitudinal and circular butt joint of the segments can be realized, and quickness and convenience in construction, easiness for mechanization and automation in construction are achieved.

Owner:SHANGHAI CONSTRUCTION GROUP

Assembly type long-span building with combined frame structure

The invention provides an assembly type long-span building with combined frame structure. The building includes a prefabricated column, a prefabricated convex main beam, a cavity plate member, a longitudinal combined rib beam, a regenerated transverse rib rebar and a combination seam. The building is characterized in that rebars are arranged at the two ends of the prefabricated column in advance;rebars are arranged at the two ends of the prefabricated convex main beam in advance; the reserved rebars pass through a support base formed through connection of the reserved rebars at the two ends of the prefabricated column to form a reinforced concrete combined frame structure. The cavity plate member is composed of a longitudinal reinforced concrete ribbed beam, a transversal reinforced concrete ribbed beam, an empty cavity and a lower flange plate. The cavity plate member is installed on the edge of the prefabricated convex main beam, the combination seam of the cavity plate member doesnot penetrate through a floorslab, and the depth of the combination seam is less than or equal to 50 mm.

Owner:HUNAN BDF ENERGY SAVING TECH +1

Construction method of concrete arched skeleton slope protection

ActiveCN111119204BReduce difficultyImprove carrying capacityExcavationsArchitectural engineeringStairs

Owner:中国路桥集团西安实业发展有限公司

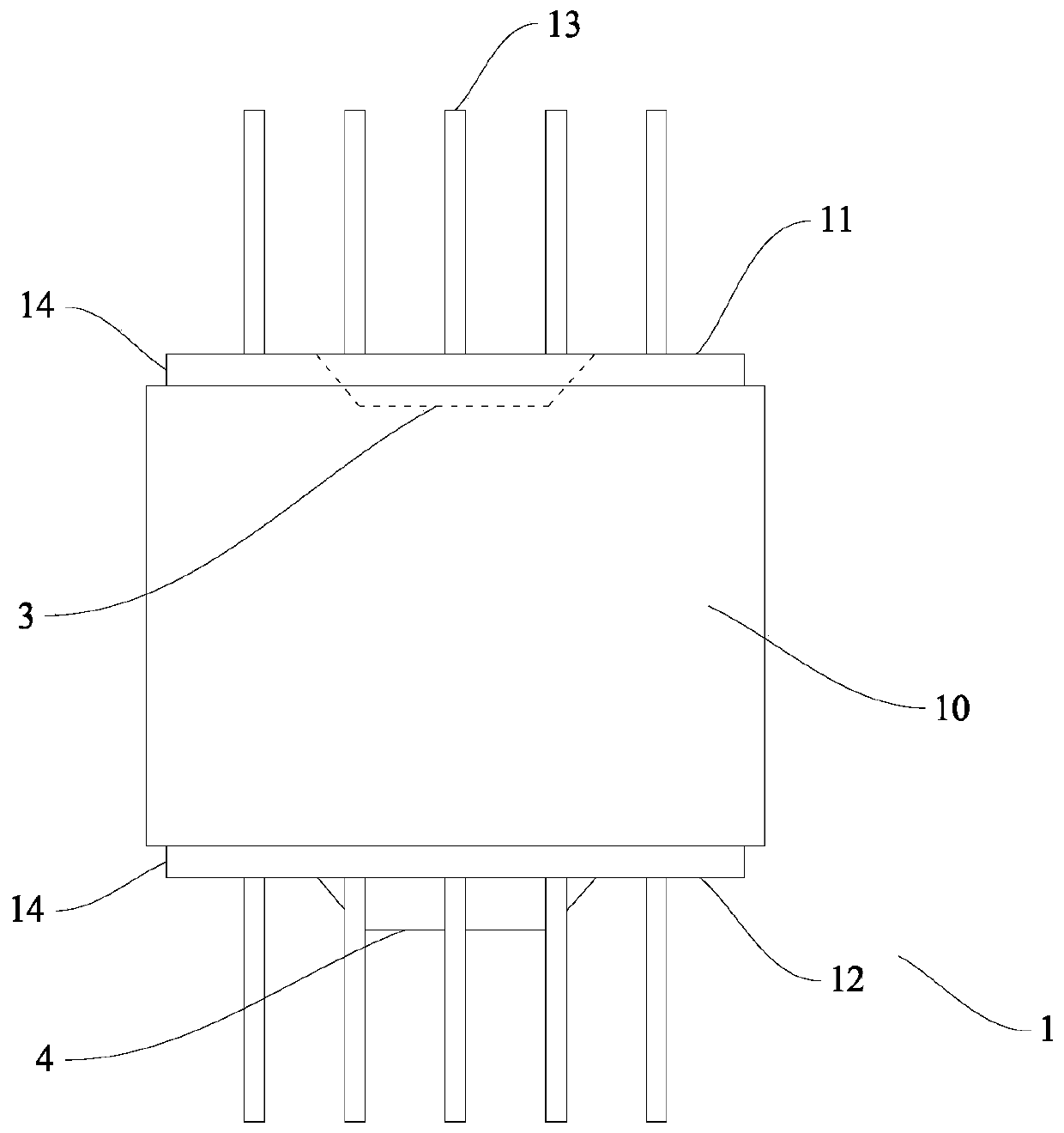

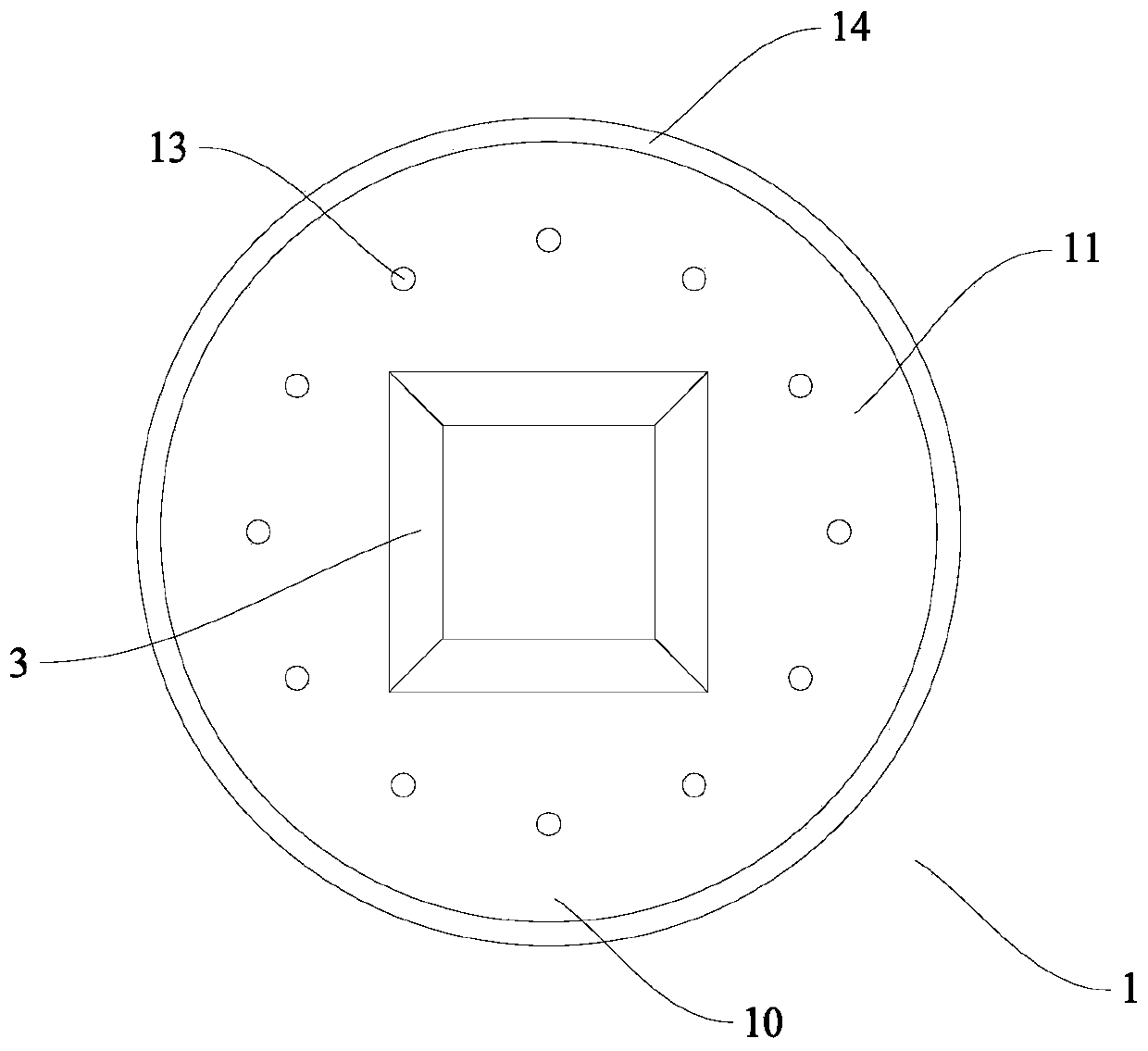

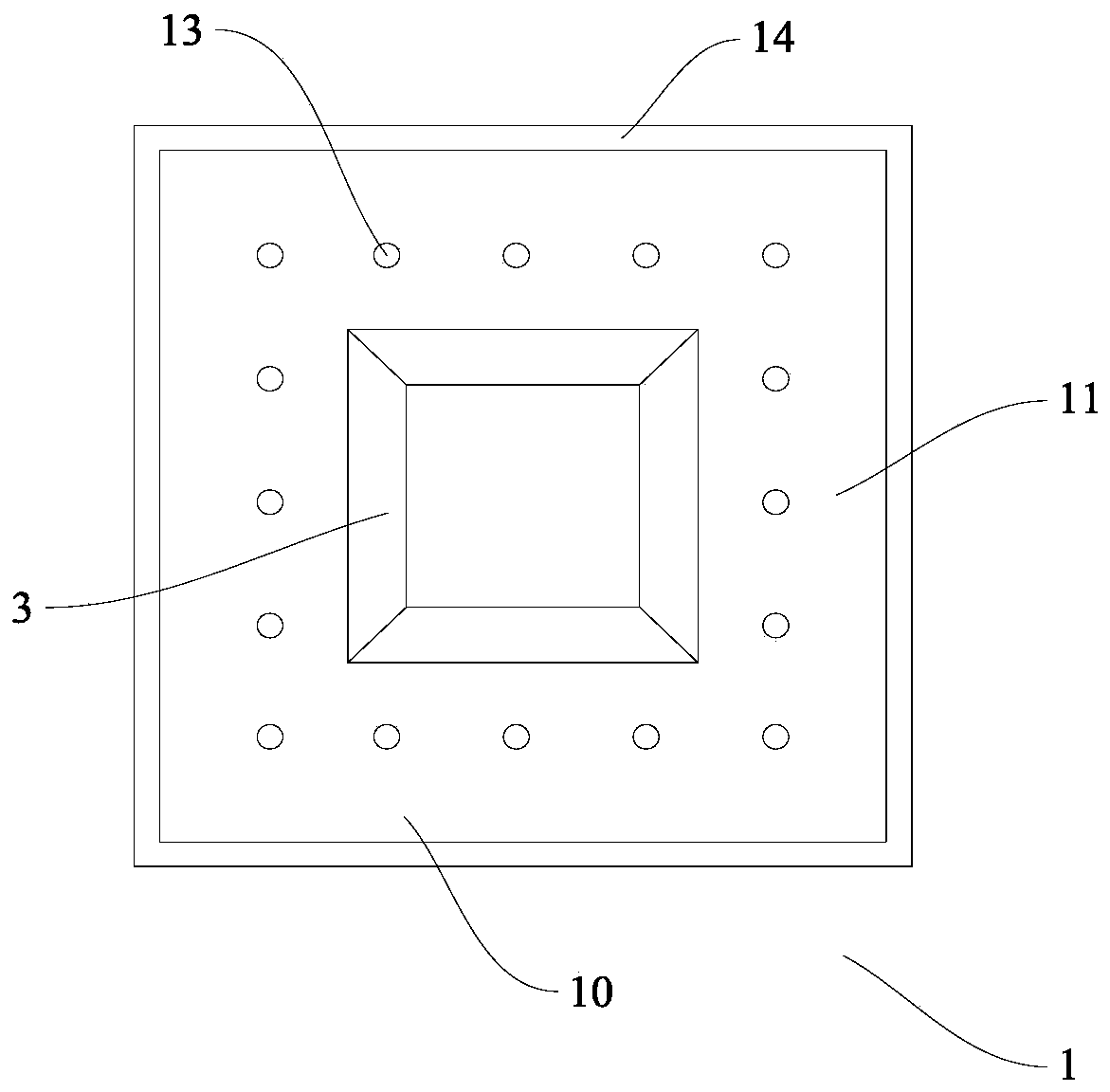

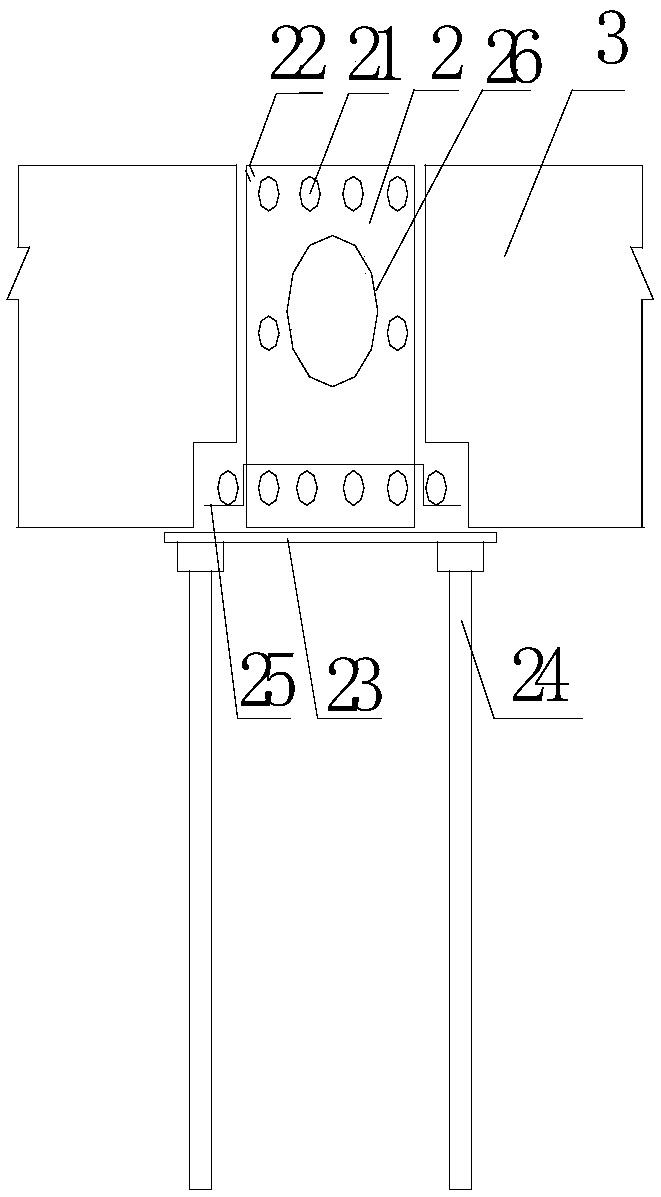

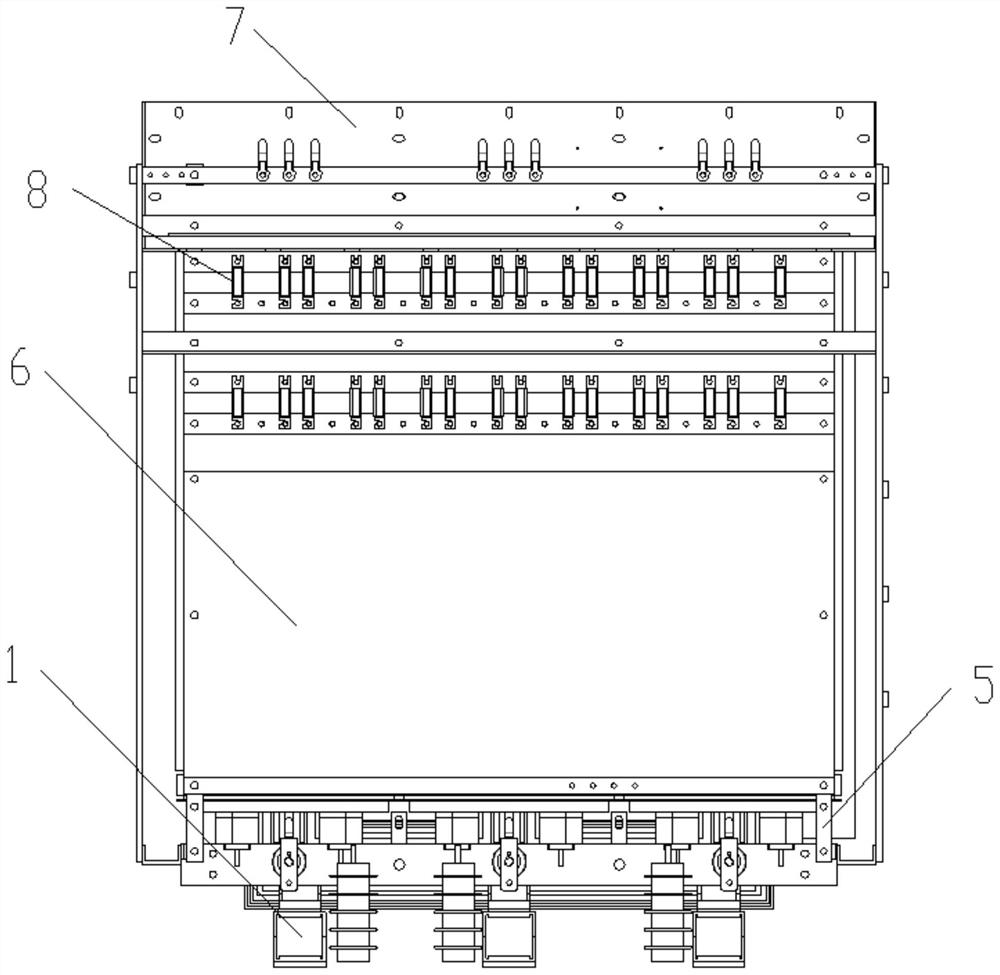

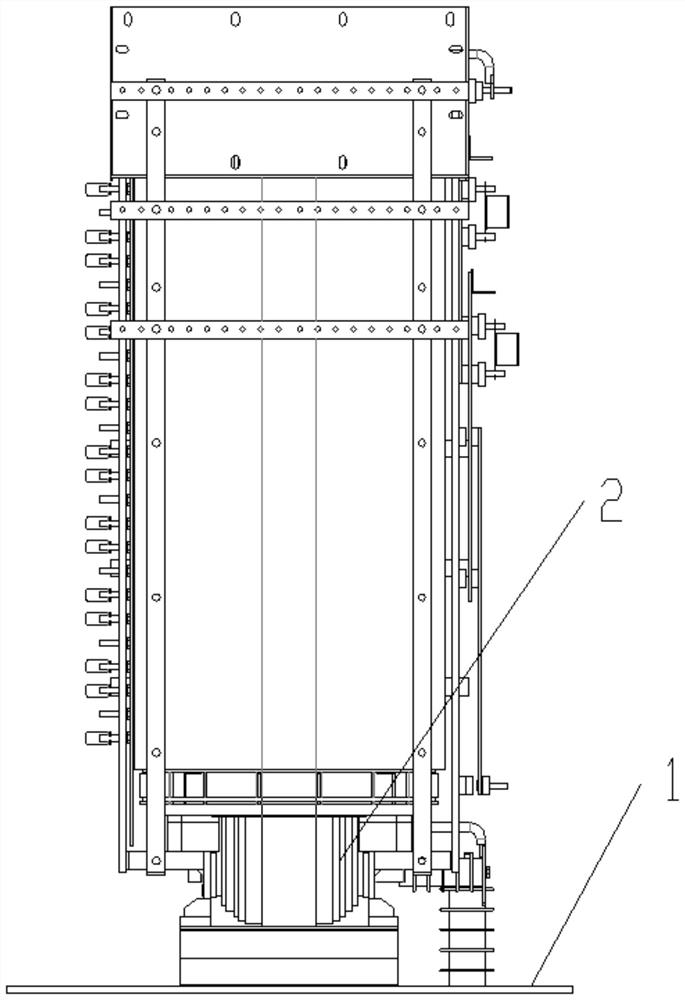

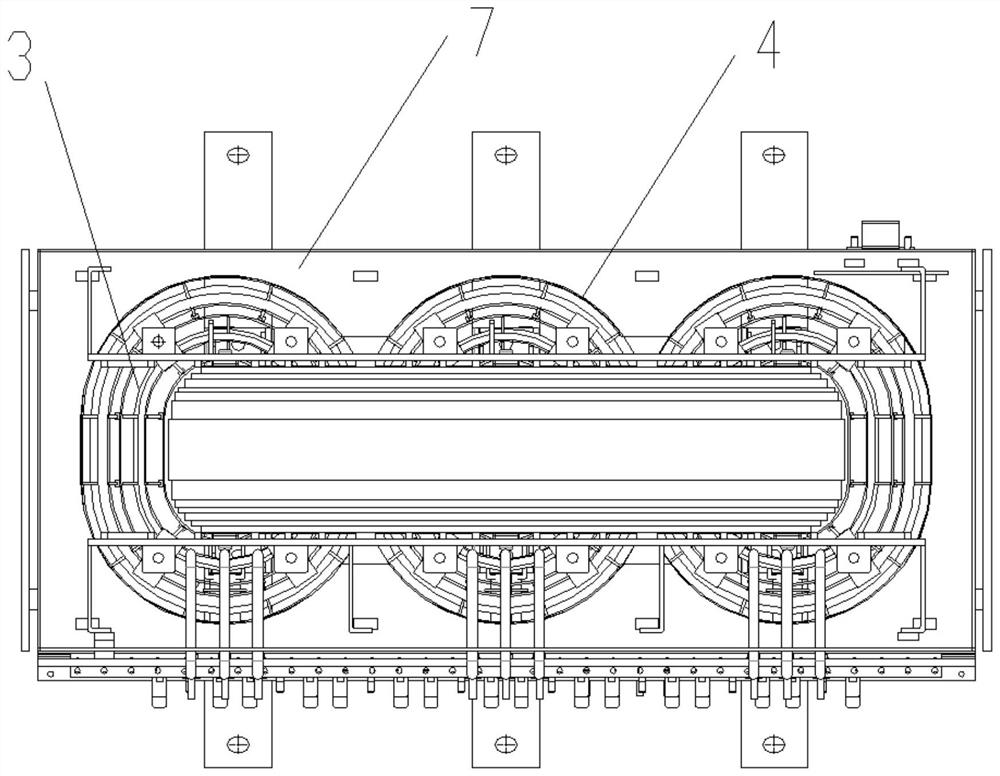

Transformer convenient for external connection of cable

PendingCN112599331AShorten the lengthReduce consumptionTransformers/inductances casingsTransformers/inductances coils/windings/connectionsStructural engineeringElectrical and Electronics engineering

The invention discloses a transformer convenient for external connection of a cable, belongs to the technical field of transformers, aims to provide a transformer convenient for external connection ofa cable, and solves the problem that an existing dry-type transformer is inconvenient for external connection of a cable. The transformer comprises a base, wherein a plurality of iron cores are installed on the base, the iron cores are sleeved with coils, the coils are sleeved with insulating cylinders, a connecting frame is installed on the base, an insulating plate is installed on the connecting frame, an insulating air air is further installed above the insulating cylinders, the adjacent insulating cylinders are sealed and fixed through insulating angle steel, and the wiring ports of the coils are close to one side of the insulating air box and are fixed on the insulating plate. The transformer is suitable for being externally connected with a cable conveniently.

Owner:四川特种变压器厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com