Patents

Literature

35 results about "Long spacing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

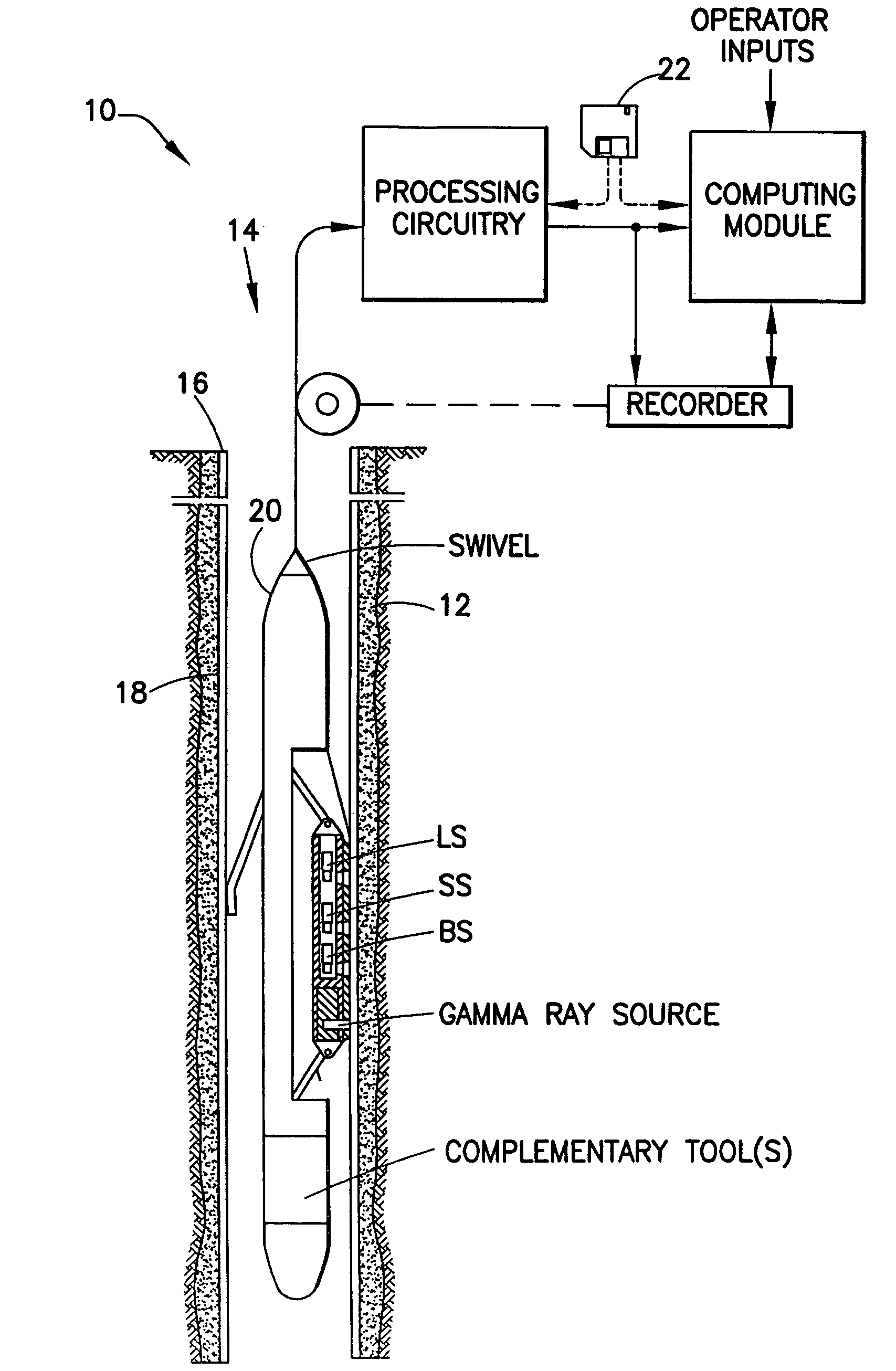

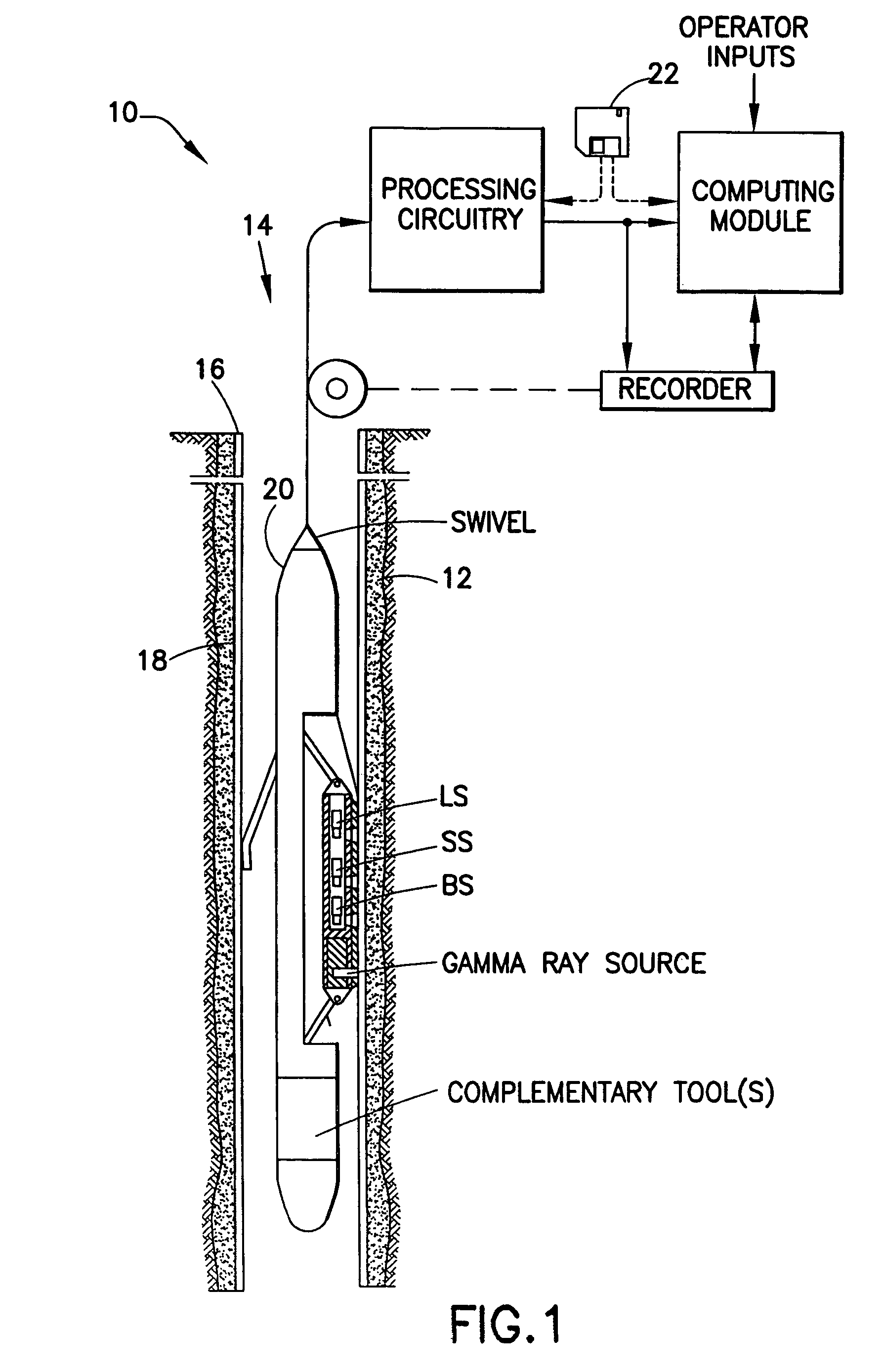

Measuring formation density through casing

ActiveUS7292942B2Electric/magnetic detection for well-loggingSeismology for water-loggingLong spacingWell logging

A method of determining formation density in a cased hole environment using a logging tool having a gamma ray source, a long spacing detector, and a short spacing detector that includes developing one or more cased hole calibration relationships that utilize differences between scattered gamma rays observed by short spacing detectors and scattered gamma rays observed by long spacing detectors to determine corrected formation density values, and using the cased hole calibration relationships and scattered gamma ray measurements obtained by the long spacing detector and the short spacing detector to determine the formation density. An associated article of manufacture and computerized well logging system are also described.

Owner:SCHLUMBERGER TECH CORP

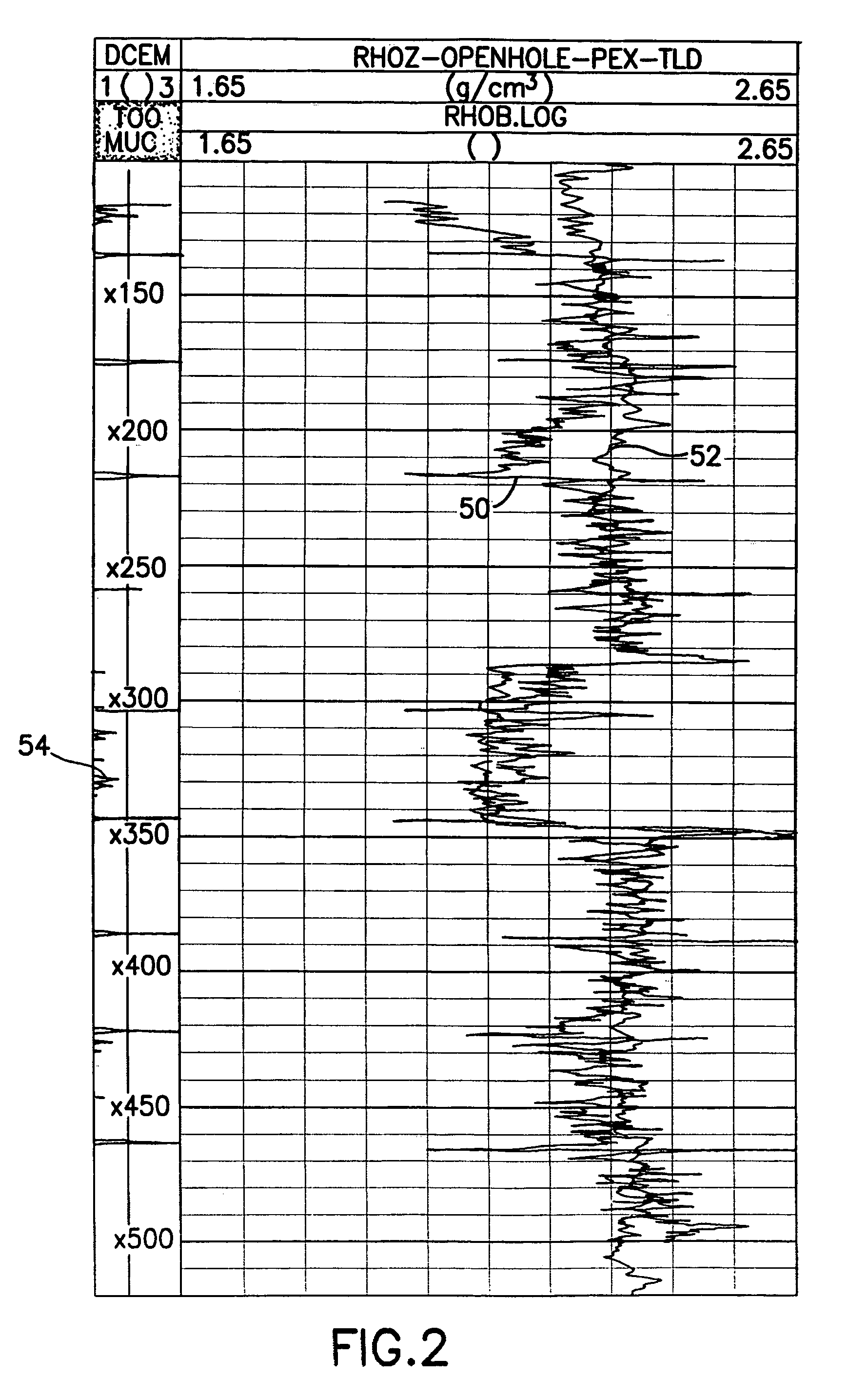

Compensating neutron well logging instrument

InactiveCN1793607AImprove detection efficiencyHighly integratedBorehole/well accessoriesLong spacingPorosity

Owner:中国石化集团胜利石油管理局测井公司

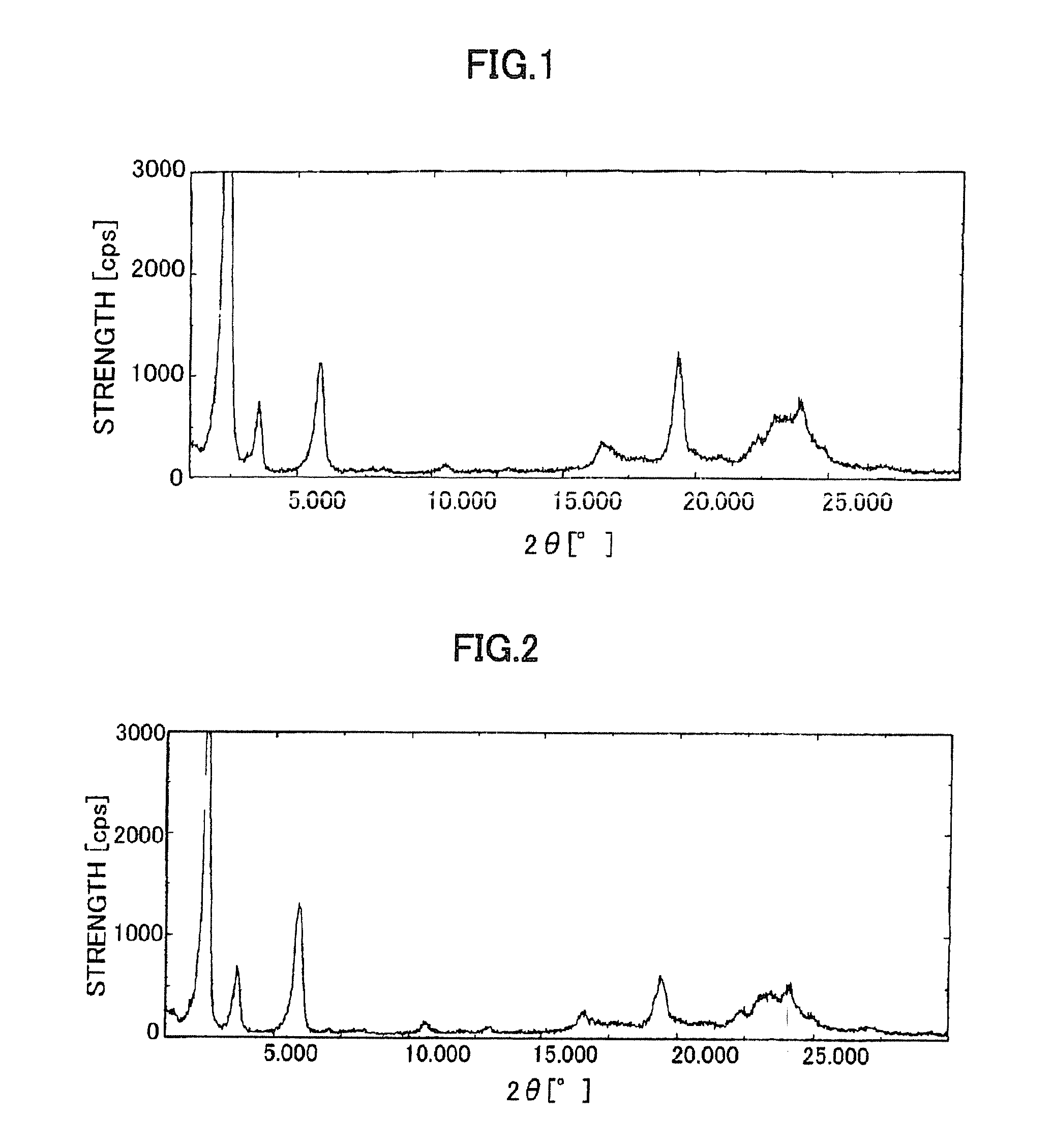

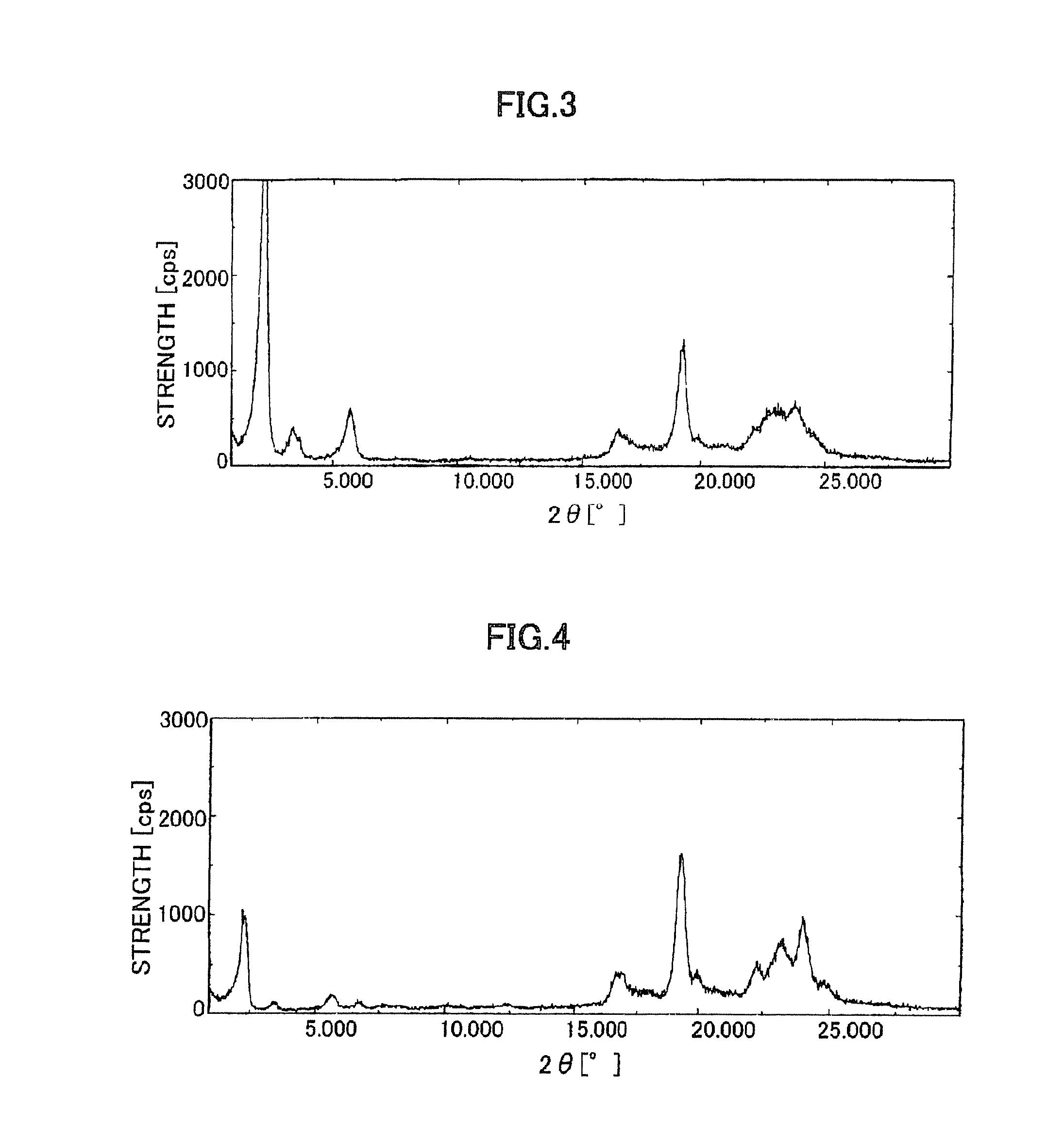

Edible fat powders

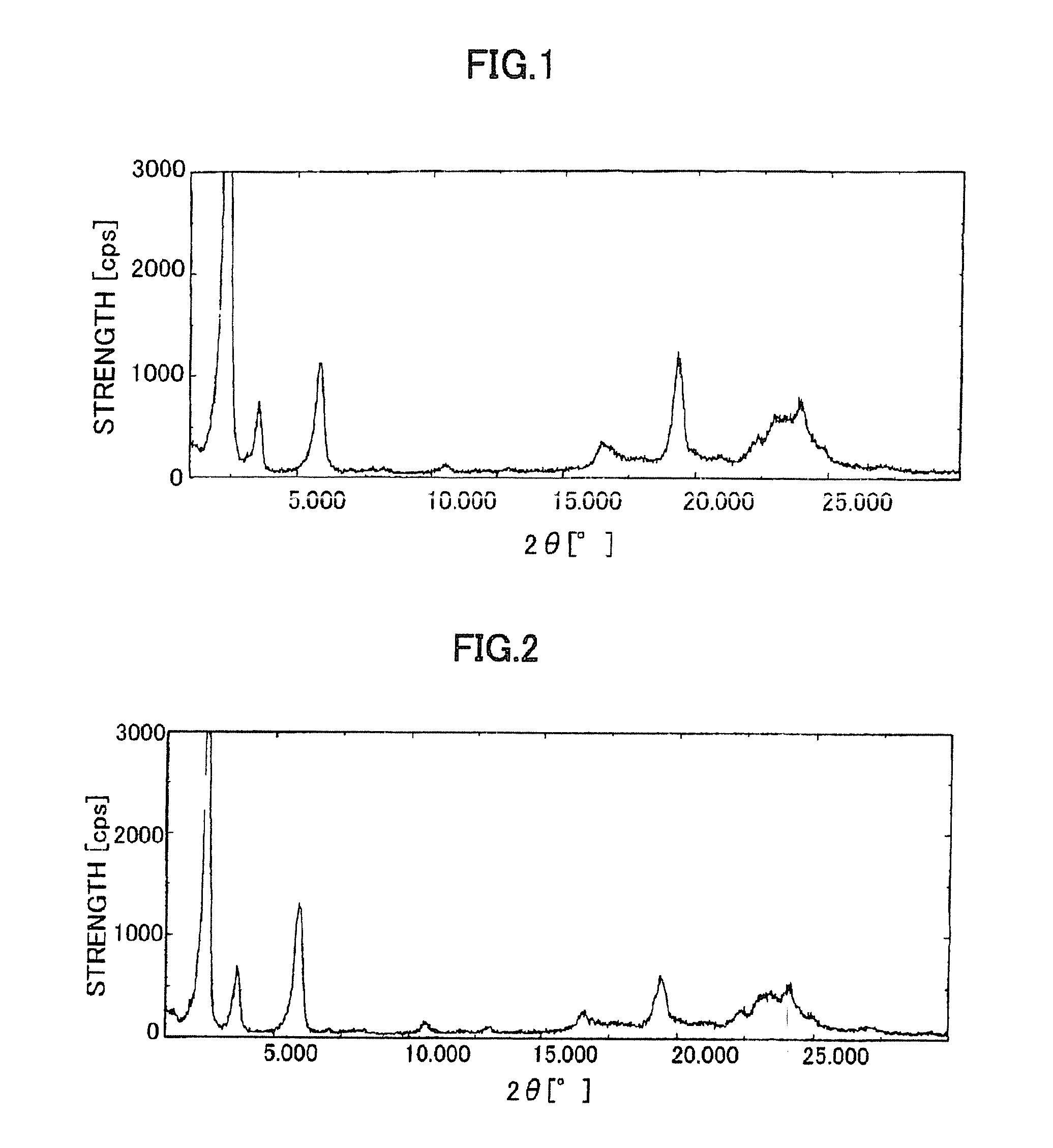

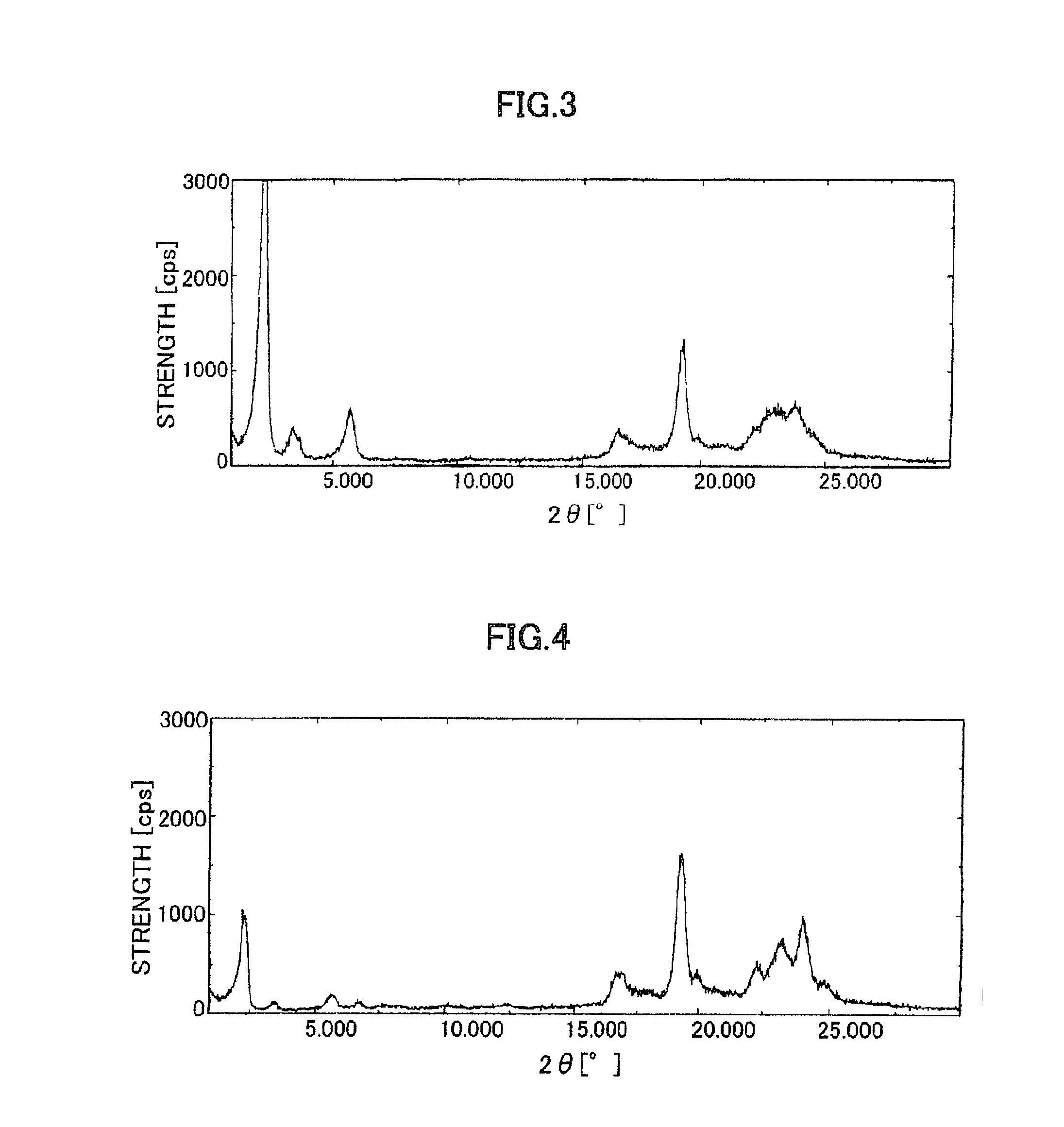

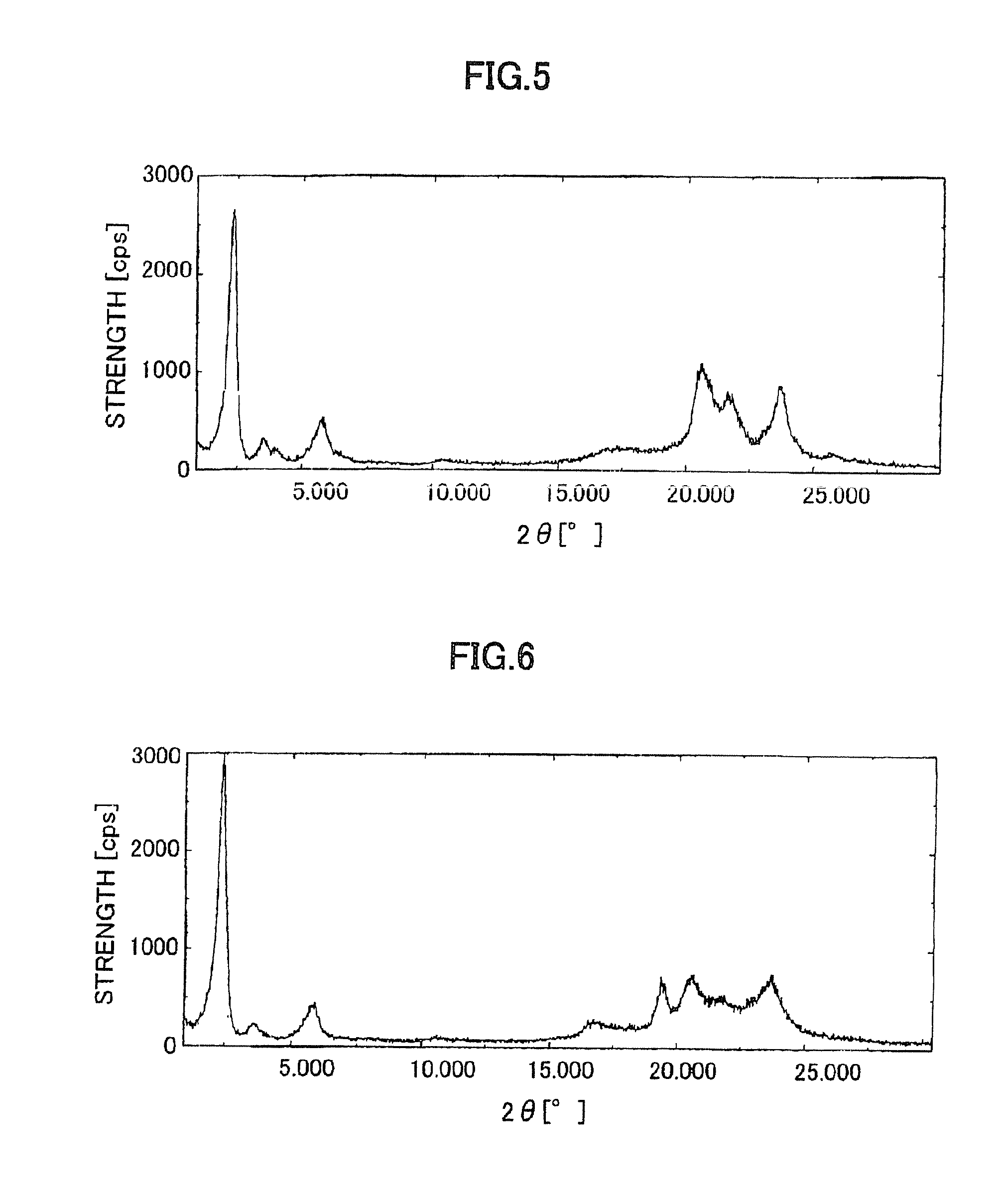

ActiveUS20110244111A1Simple structureSpread compositionsAlcoholic beverage preparationLong spacingFull width at half maximum

The invention relates to edible fat powders having a full width at half maximum of the first order long spacing X-ray diffraction peak of 0.17 to 0.80 degrees and a free flowing density of 10 to 350 g / l; with the proviso that when the free flowing density is equal to or greater than C, the full width at half maximum is equal to or greater than ((A*free flowing density)+B), wherein A is 0.0005625, B is 0.213 degrees and C is 90 g / l. The invention further relates to a method of preparing a fat continuous spread comprising the use of such edible fat powder.

Owner:UPFIELD EURO BV

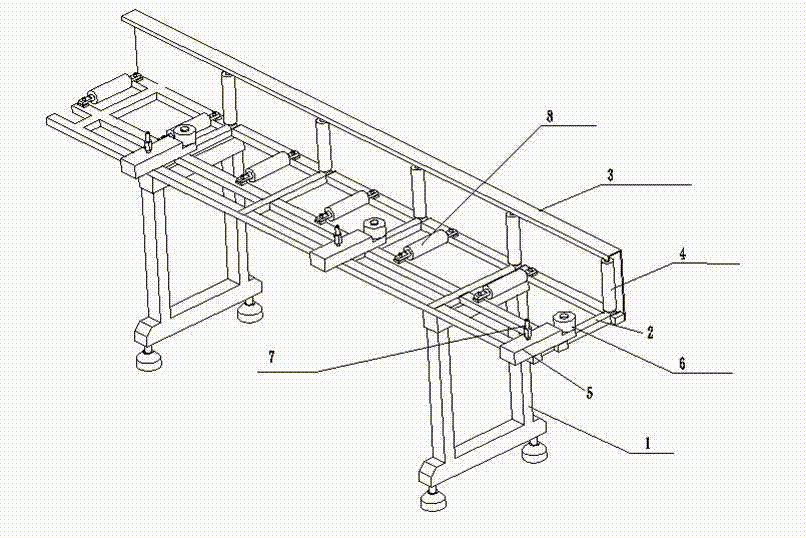

Glass conveying device with adjustable width

InactiveCN102785936AEasy to operateEasy to processCharge manipulationConveyor partsLong spacingPulp and paper industry

The invention discloses a glass conveying device with an adjustable width, which comprises a column (1) and a bracket (2) fixed on the column (1); a supporting roller (8) is arranged in the middle of the bracket (2); a roller bracket (3) for limiting the position of a long roller is fixedly arranged at one end of the bracket (2); a long spacing roller (4) is mounted on the roller bracket (3); a movable roller frame (5) is mounted on one side, opposite to the fixed side of the roller bracket (3), of the bracket (2); a short spacing roller (6) is arranged at the inner side end of the movable roller frame (5); and the horizontal position of the movable roller frame (5) is adjusted through an adjusting screw rod (7).

Owner:WUHU YAOHUA GLASS HORTICULTURE

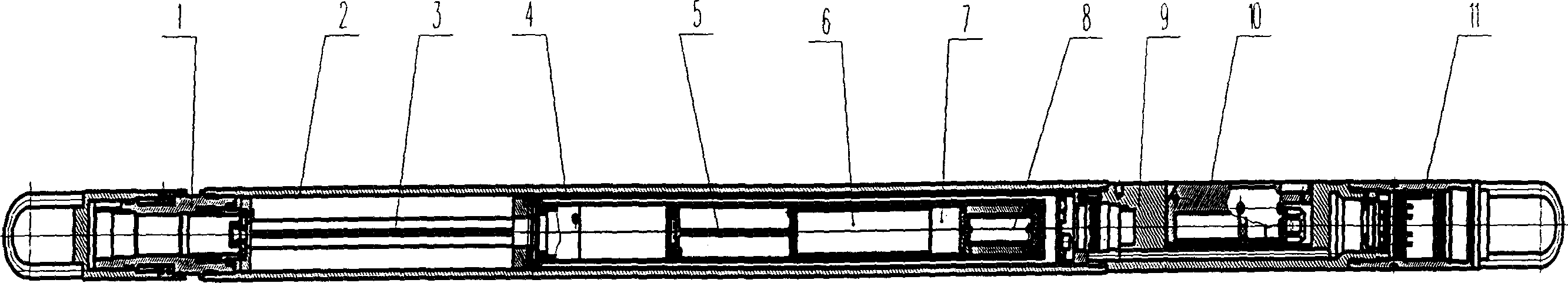

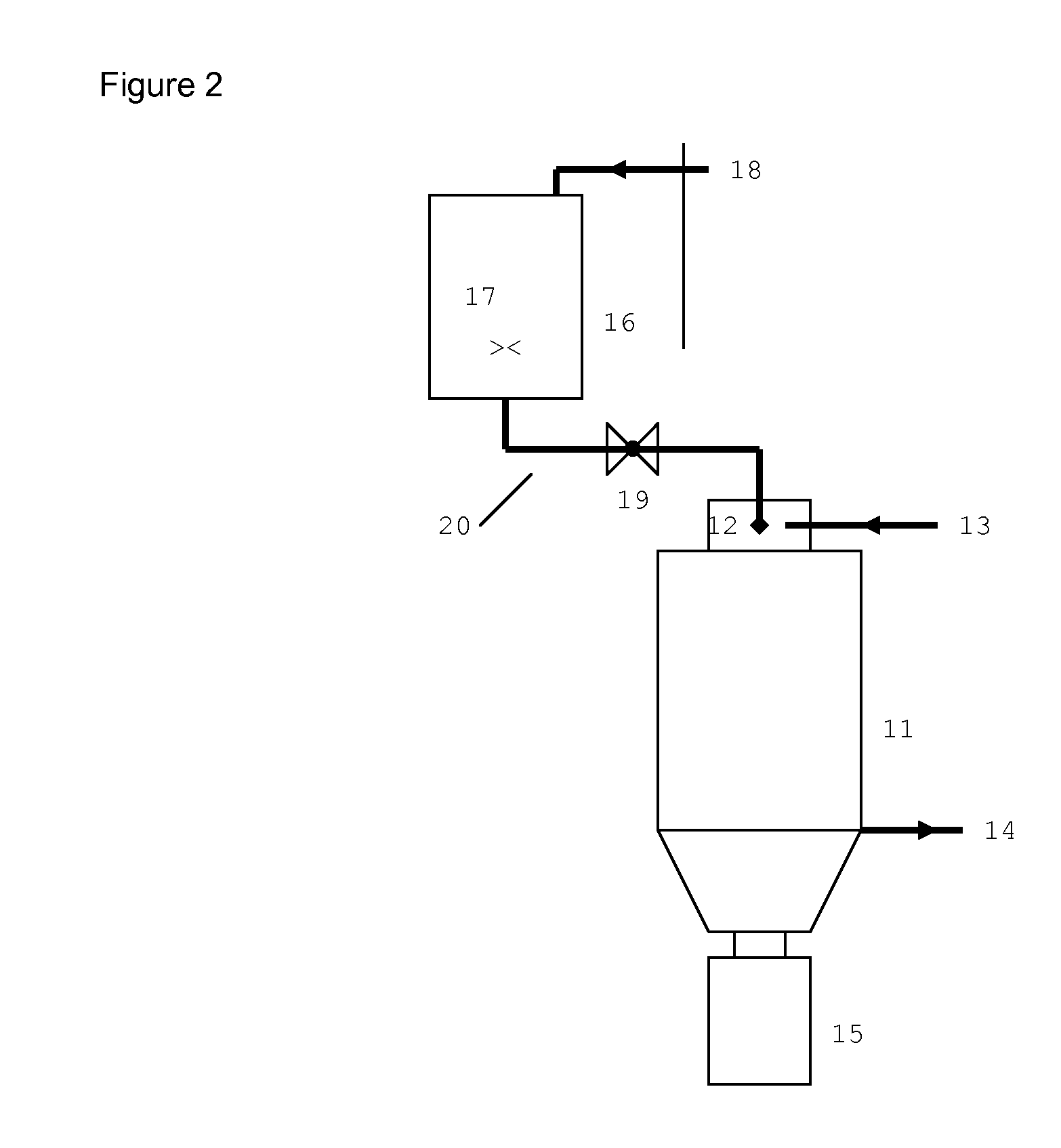

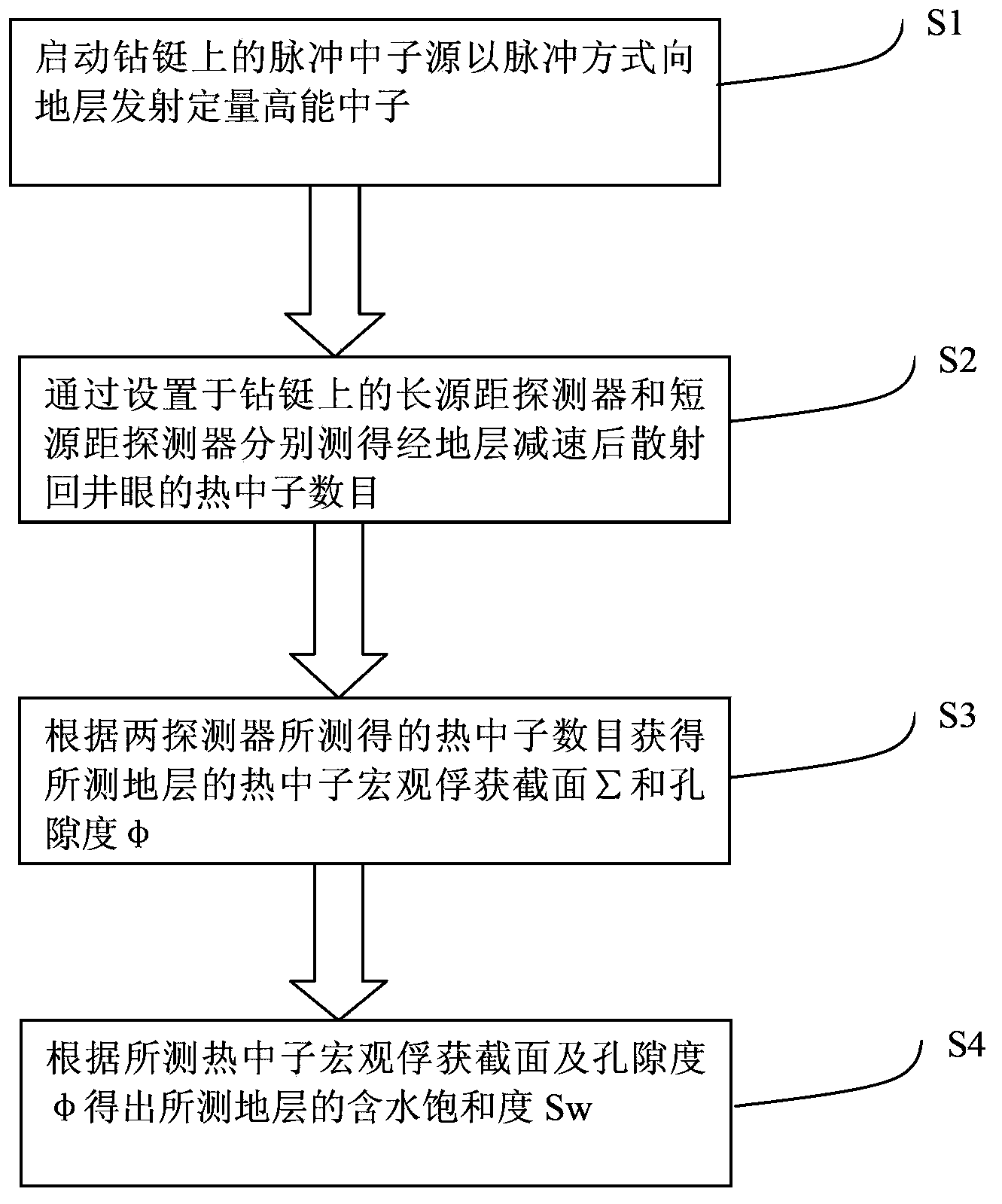

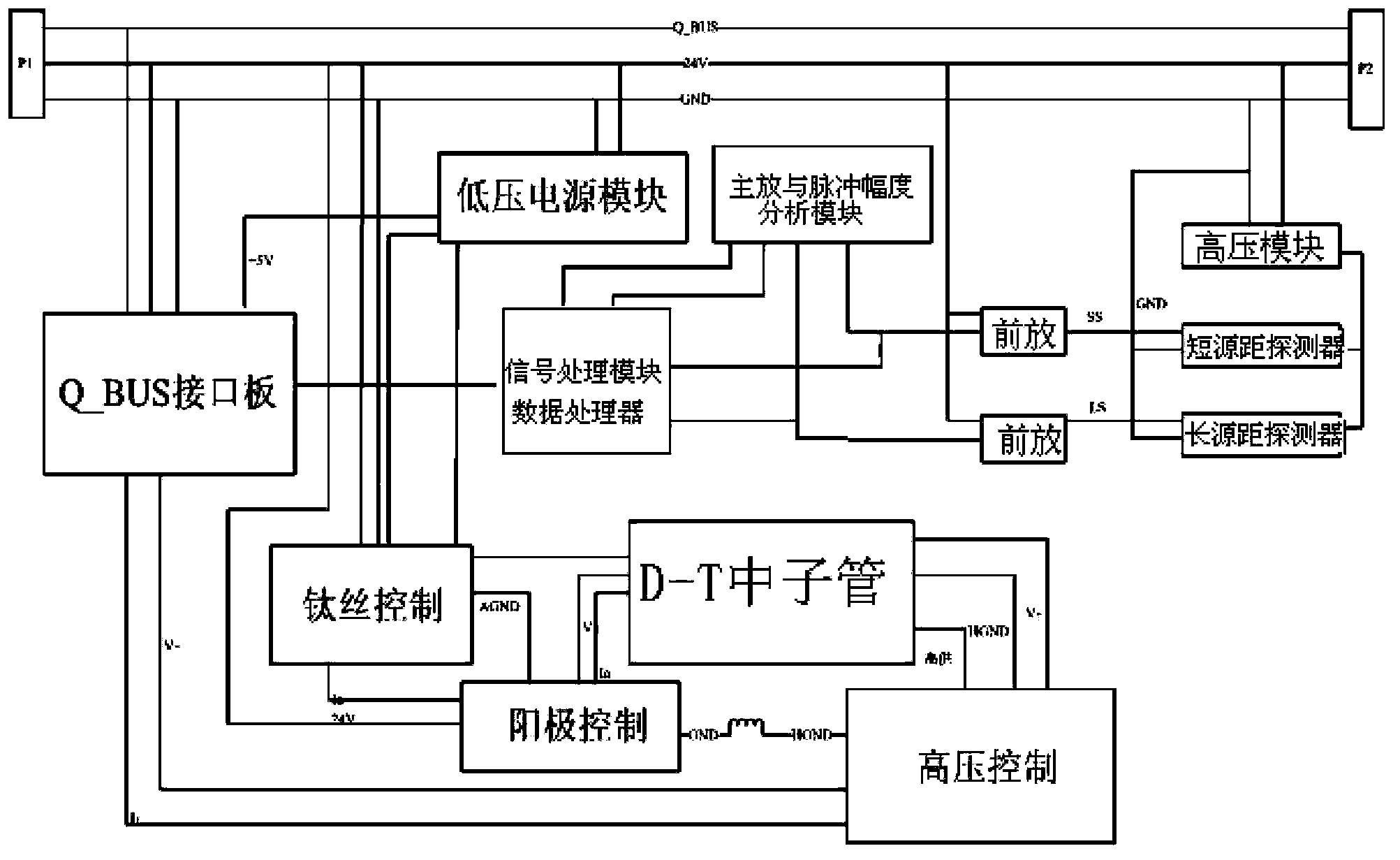

Method and instrument for controllable source neutron logging during drilling

ActiveCN103527181AReduce the numberIncrease count rateDrilling rodsDrilling casingsLong spacingHigh energy

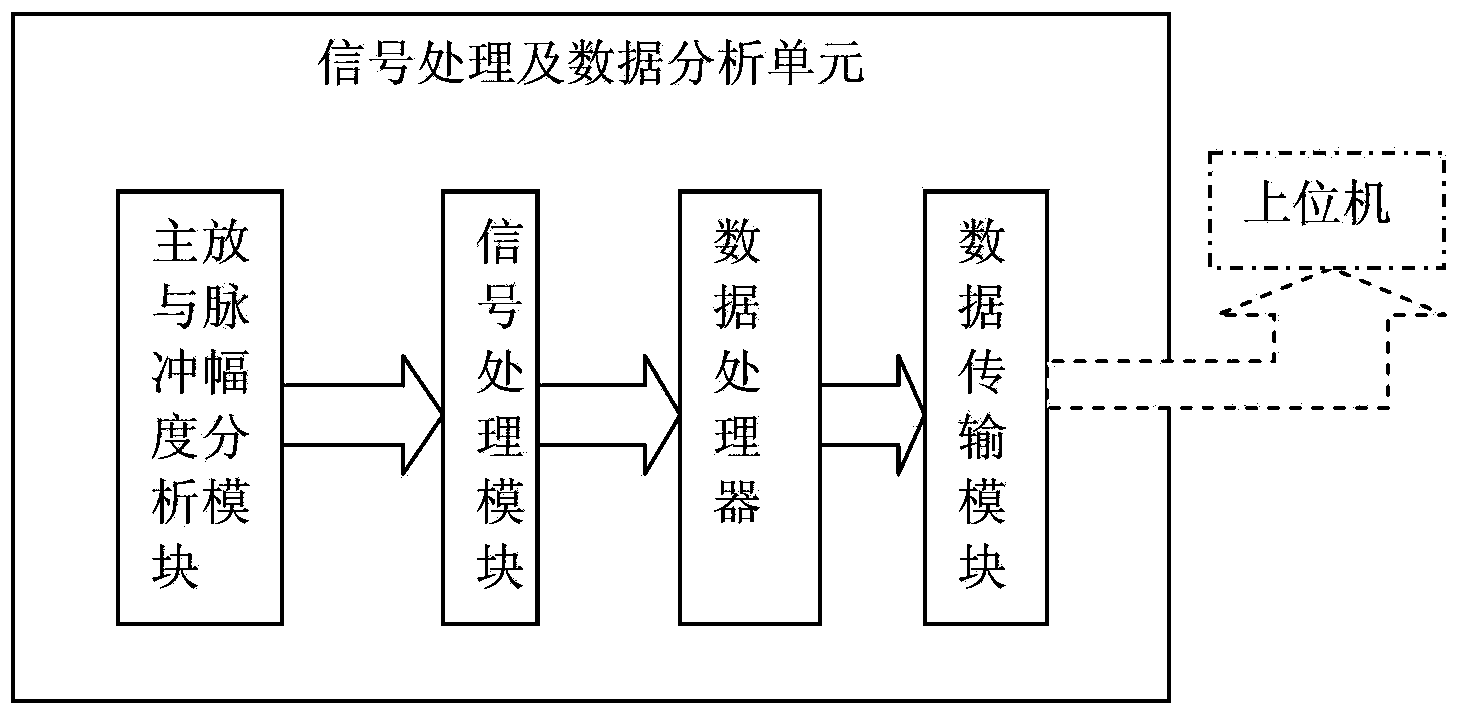

The invention discloses a method and instrument for controllable source neutron logging during drilling. The method comprises the steps that a pulse neutron source on a drill collar is started and quantitative high-energy neutrons are emitted to a stratum in a pulse mode; the number of thermal neutrons with the speed reduced by the stratum is measured through a long spacing detector and a short spacing detector which are arranged on the drill collar respectively, wherein the thermal neutrons are scattered back to a well hole; according to the number, measured through the two spacing detectors, of the thermal neutrons, the macroscopic capture cross section sigma of the thermal neutrons and the porosity phi of the stratum are obtained; the stratum water saturation Sw is obtained according to the macroscopic capture cross section of the thermal neutrons and the porosity phi. The instrument comprises the pulse neutron source, a detection unit, a signal processing and data analyzing unit and a power module used for supplying power for the detection unit and the signal processing and data analyzing unit. The thermal neutrons are detected through the long spacing <3>He thermal neutron detector and the short spacing <3>He thermal neutron detector, two sets of parameters including the porosity and the macroscopic capture cross section of the thermal neutrons and are obtained, and therefore the measurement of the water saturation and the porosity of the stratum with a relatively low degree of mineralization is achieved. Due to the use of the pulse neutron source, damage, caused by a radioactive source, to human and the environment is eliminated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for setting inter-station unidirectional sectioned green wave signals for long-spacing buses

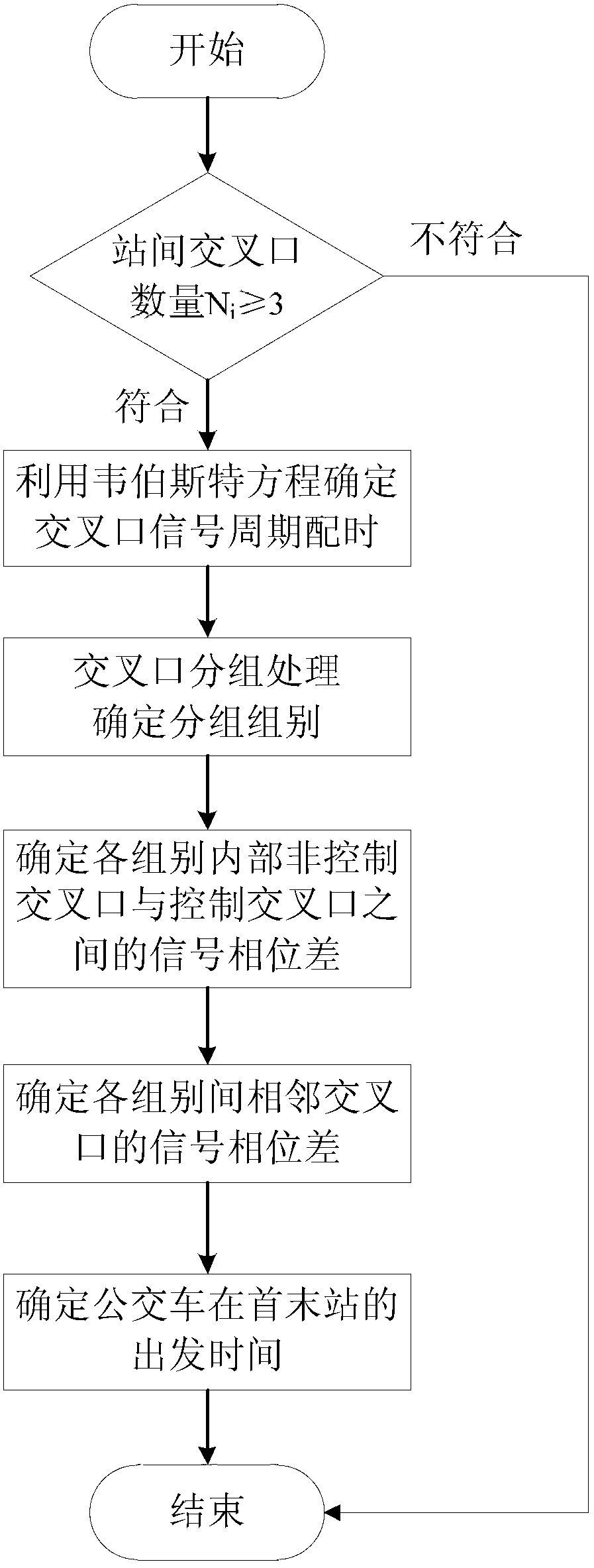

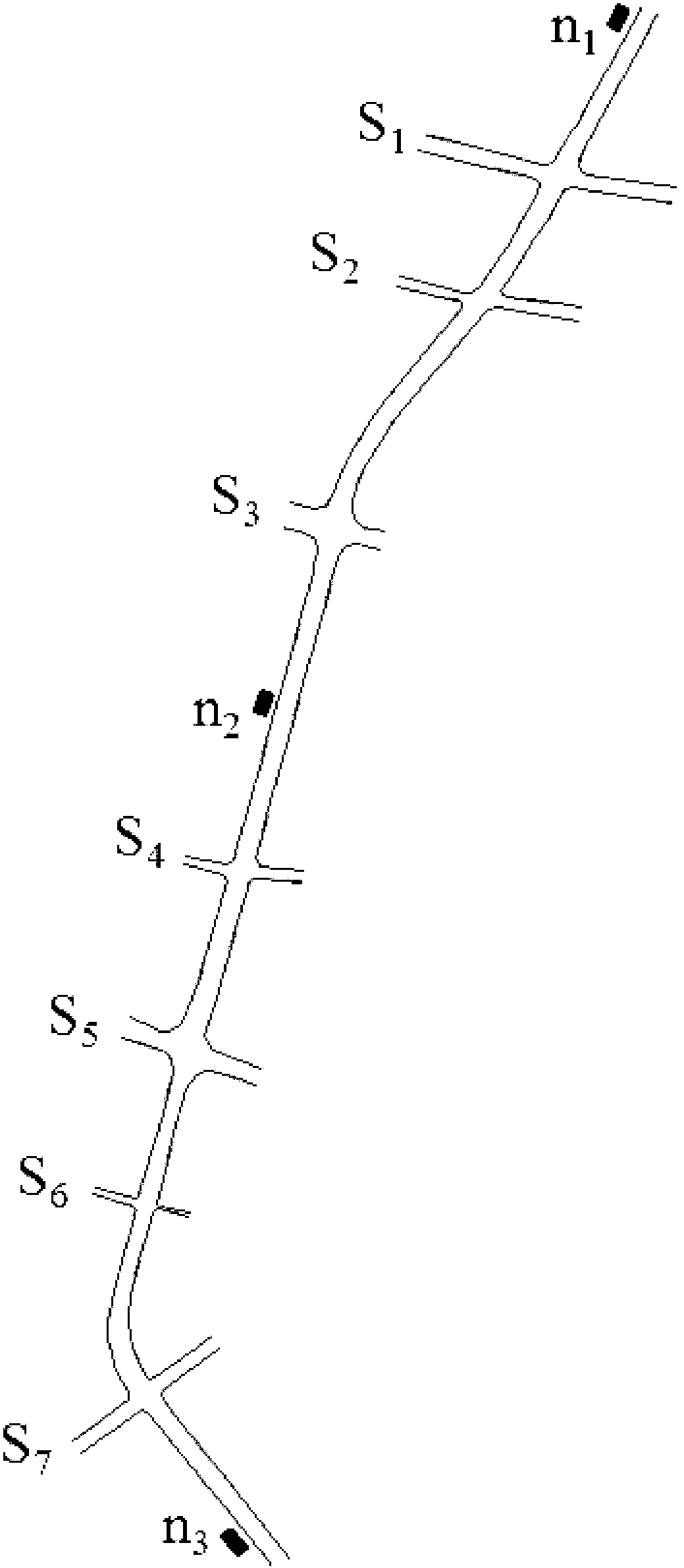

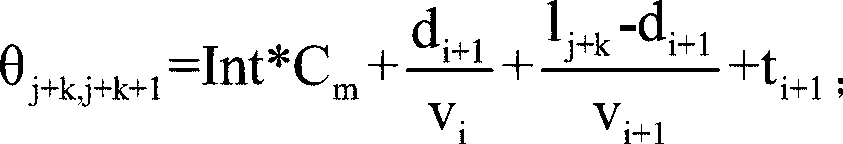

ActiveCN103021194AAlleviate needsReduce congestionRoad vehicles traffic controlLong spacingPhase difference

The invention discloses a method for setting inter-station unidirectional sectioned green wave signals for long-spacing buses. The method is specifically implemented for long-spacing bus stations containing a plurality of intersections among the stations, the inter-station intersections are grouped on the basis of unified signal periods and unified timing, signal phase differences of the intra-group intersections are set, signal phase differences of the inter-group intersections are coordinated with one another, and inter-station unidirectional sectioned green waves are set by means of adjusting departure moments of the buses. The method has the advantages that problems of fast rising demands on unidirectional buses and congestion caused by 'tidal traffic' are mainly relieved, fast and efficient running of the buses is guaranteed by means of setting the inter-station unidirectional sectioned green waves, the bus service level and the travel efficiency of passengers are improved simultaneously, attraction power of the buses is strengthened, and road congestion is relieved.

Owner:SOUTHEAST UNIV

Intermolecular compounds of fatty acid triglycerides

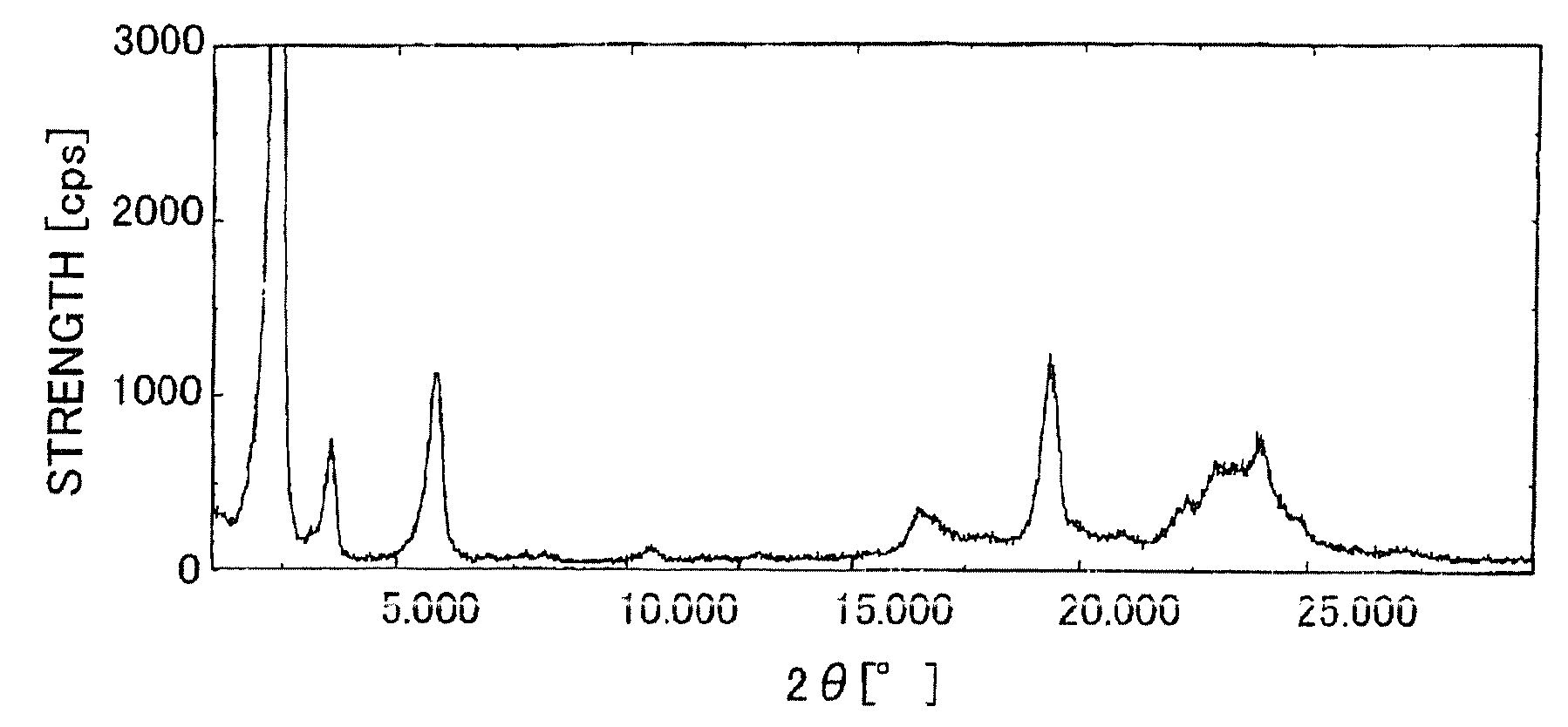

ActiveUS20080260931A1Fatty acid chemical modificationOrganic chemistryLong spacingLong chain fatty acid

There are provided an intermolecular compound of (a) di-saturated medium chain fatty acids mono-saturated long chain fatty acid triglyceride and (b) 1,3-di-saturated long chain fatty acids 2-mono-unsaturated long chain fatty acid triglyceride, of which a long spacing value by X-ray diffraction is 65 Å or more, and foods containing the intermolecular compound. The intermolecular compound can be used as a part of fats and oils that constitute foods. Due to formation of the intermolecular compound, the fats and oils containing large amounts of symmetric triglycerides such as cocoa butter and those containing medium chain fatty acids do not form separate crystals and, therefore, can keep smooth texture and prevent blooming.

Owner:THE NISSHIN OILLIO GRP LTD

Edible fat powders

InactiveUS20110256300A1Simple structureSpread compositionsFatty-oils/fats/waxes solidificationLong spacingMedicine

The invention relates to edible fat powders having a full width at half maximum of the first order long spacing X-ray diffraction peak of 0.17 to 0.80 degrees and a gel strength of 5 to 3500 Pa. The invention further relates to a method of preparing a fat continuous spread comprising the use of such edible fat powder.

Owner:CONOPCO INC D B A UNILEVER

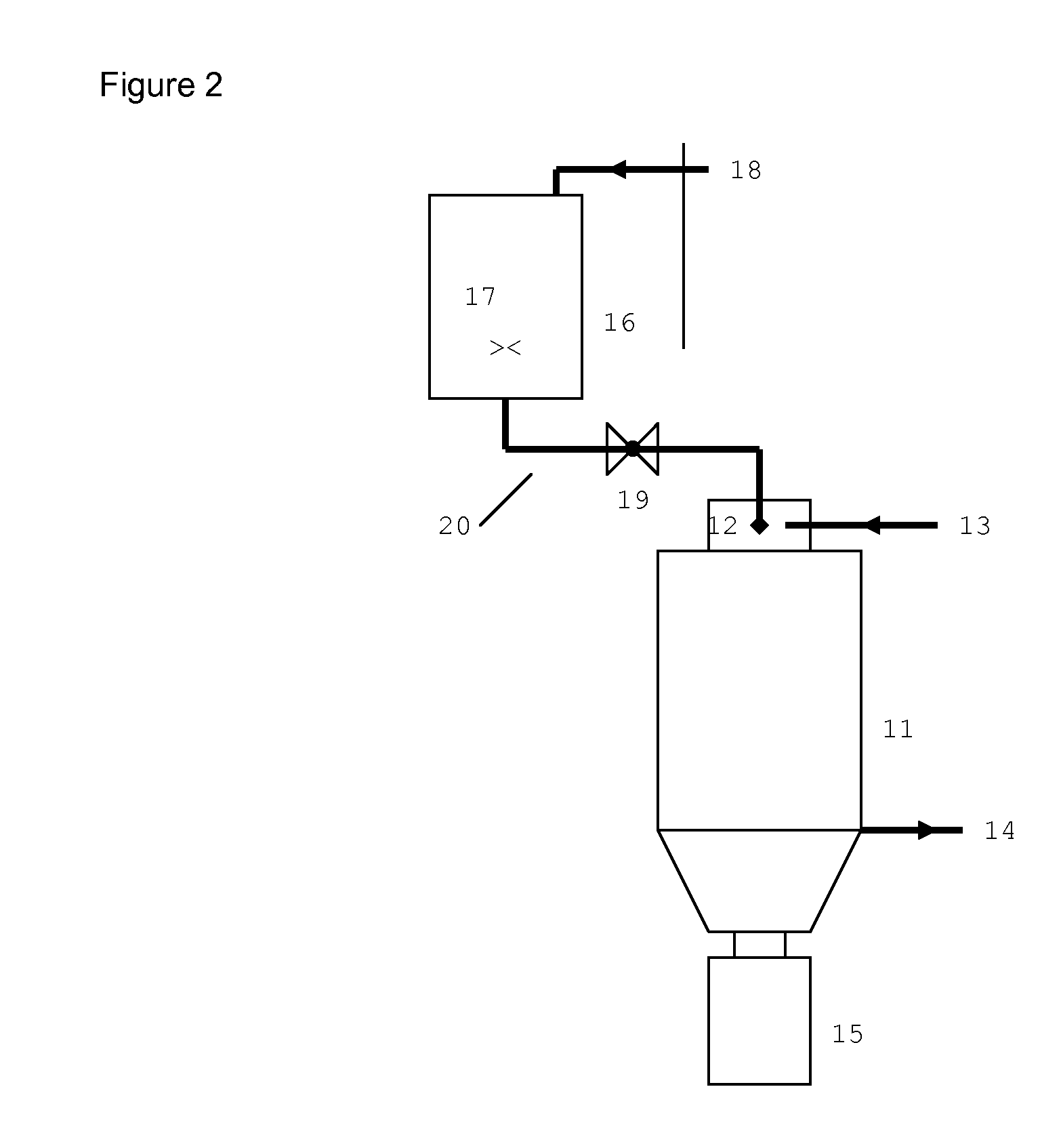

Novel pipeline blocking device and pipeline leaking blocking and isolation repairing method

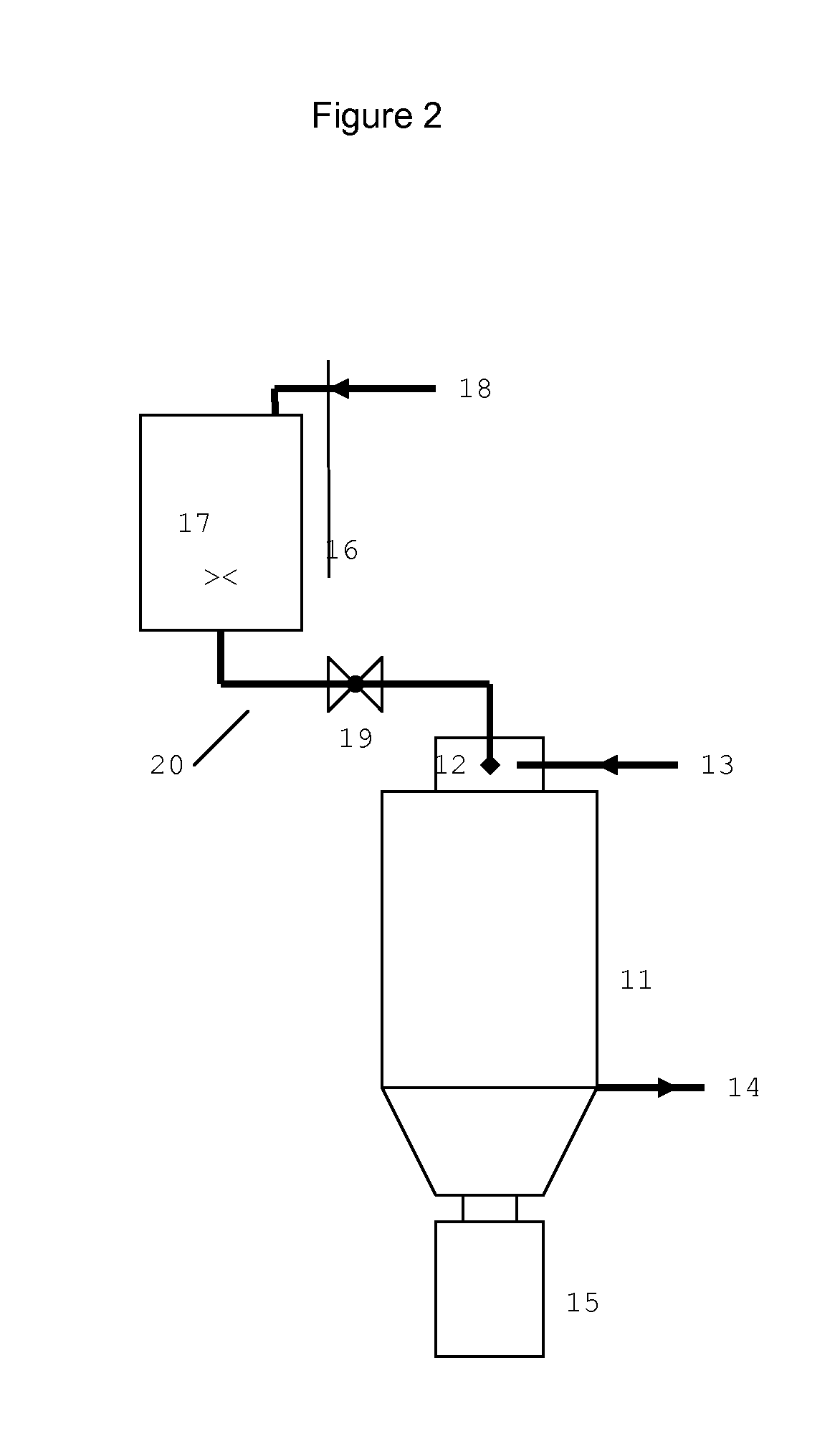

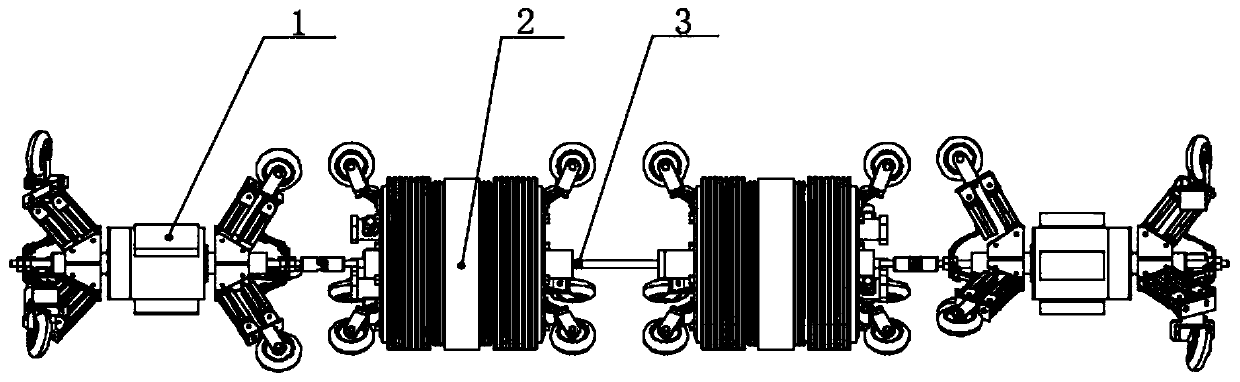

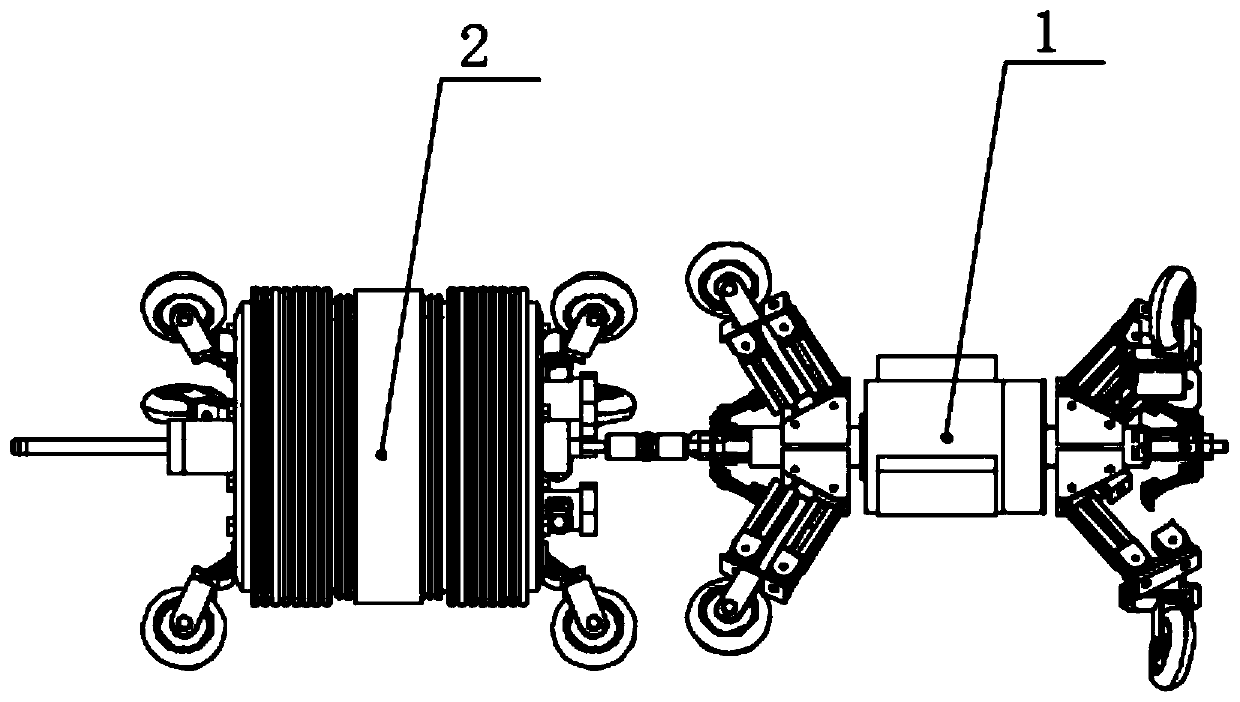

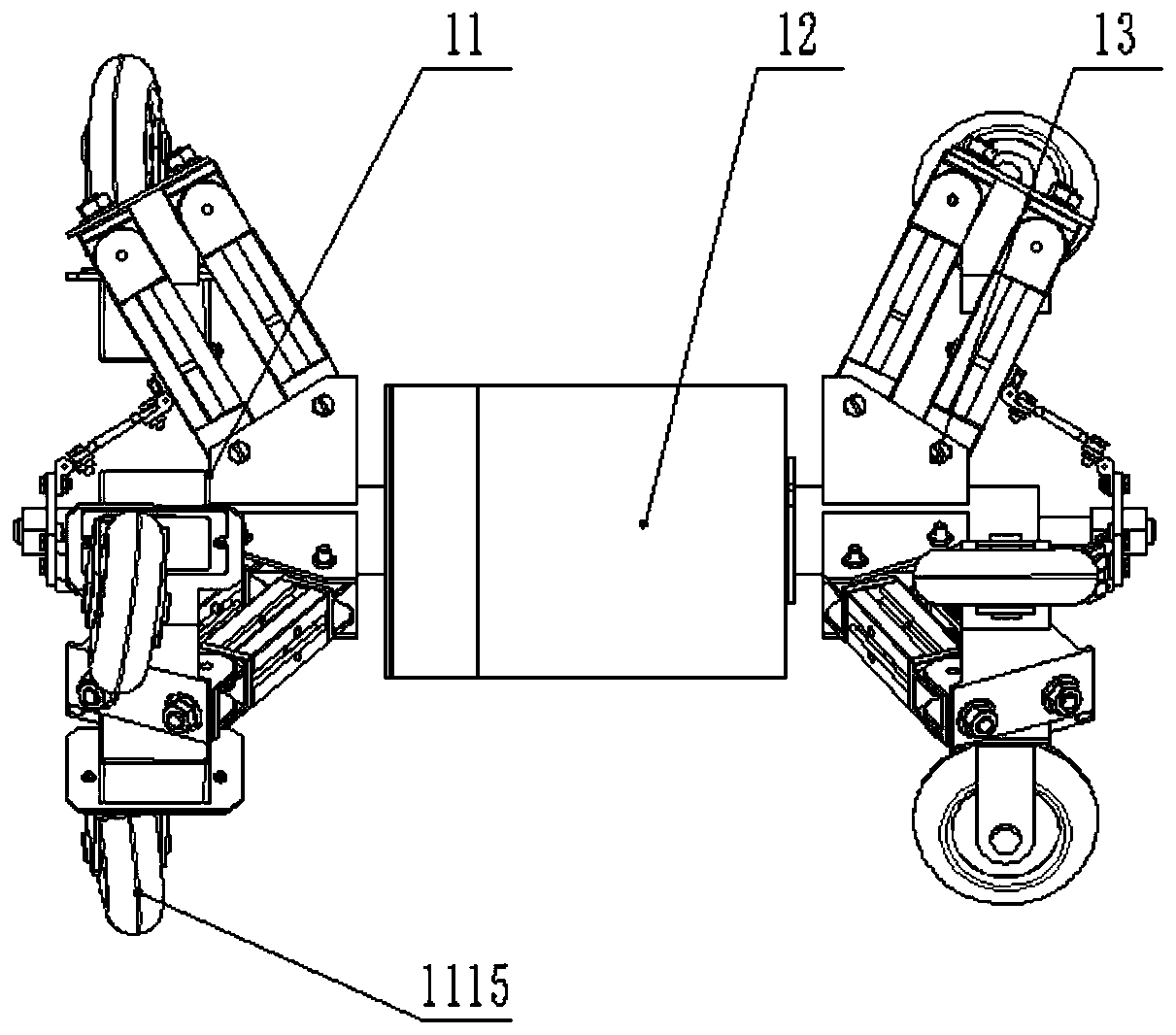

ActiveCN110260090ABlockage repair is effectiveEase of external repairPigs/molesMetal coatingSupporting system

The invention discloses a pipeline leaking blocking and isolation repairing method. The method is carried out on the basis of a novel blocking device, wherein the blocking device mainly comprises two spiral driving units and two blocking repairing units, wherein one spiral driving unit and one blocking repairing unit form a blocking repairing system set; each blocking repairing unit comprises a supporting frame, a blocking air bag, a repairing air bag and a metal coating layer; and the spiral driving units comprise front driving systems, outer rotor motors and rear supporting systems. In case of leaking accident of a pipeline, three conditions, including a single-point leaking condition, a short-spacing multi-point area leaking condition and a multi-point long-spacing dispersing section leaking condition based on the pipeline leaking condition. According to the method, the blocking repairing units are dragged into a leaking area through the spiral driving units; and the pipeline leakage is subjected to emergency treatment by blocking and isolation mending repairing and blocking and isolation replacing repairing based on the leaking condition.

Owner:ZHONGBEI UNIV

Edible fat powders

ActiveUS8865245B2Simple structureEdible oils/fats ingredientsSpread compositionsLong spacingFull width at half maximum

The invention relates to edible fat powders having a full width at half maximum of the first order long spacing X-ray diffraction peak of 0.17 to 0.80 degrees and a free flowing density of 10 to 350 g / l; with the proviso that when the free flowing density is equal to or greater than C, the full width at half maximum is equal to or greater than ((A*free flowing density)+B), wherein A is 0.0005625, B is 0.213 degrees and C is 90 g / l. The invention further relates to a method of preparing a fat continuous spread comprising the use of such edible fat powder.

Owner:UPFIELD EURO BV

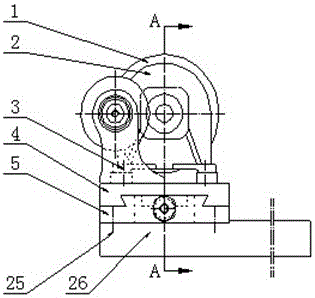

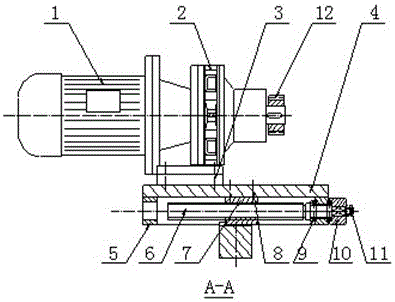

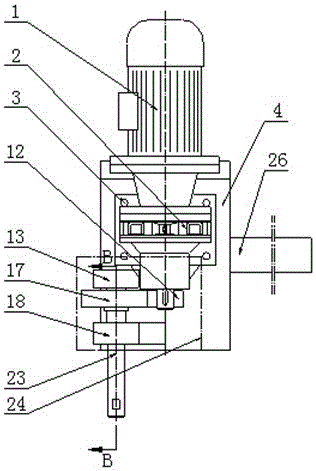

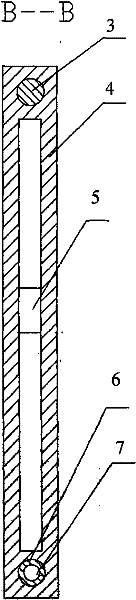

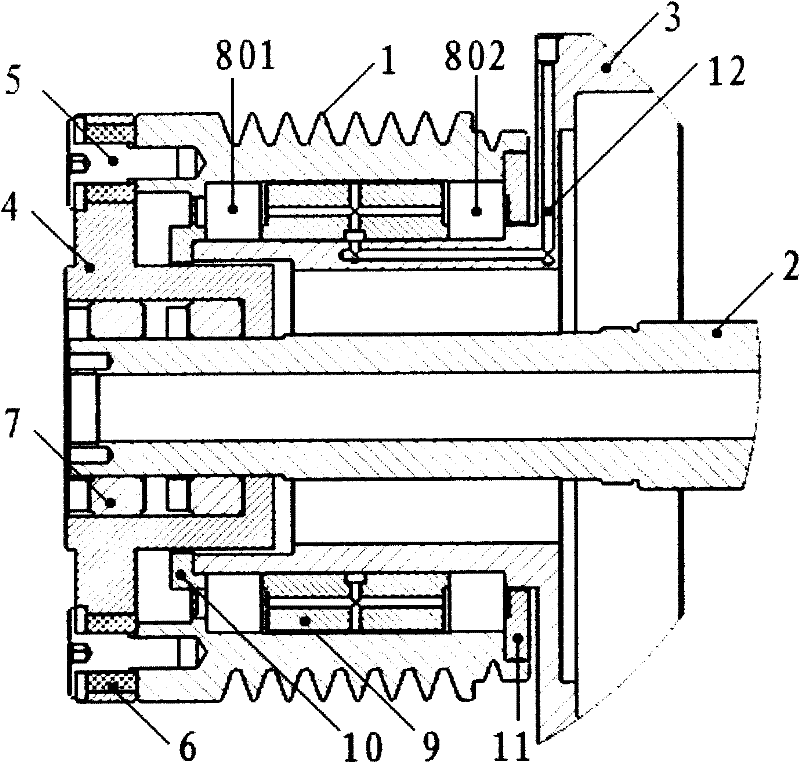

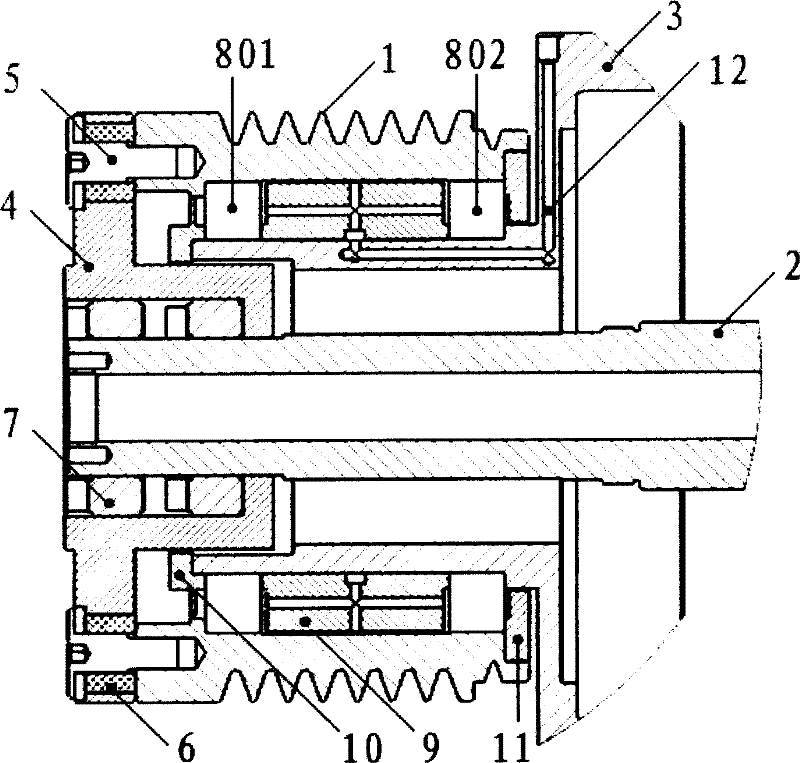

Boring device for multiple sets of long-spacing coaxial holes

ActiveCN105728791ASolve the problem that long-distance processing cannot be realizedMeet the design requirementsFeeding apparatusDriving apparatusLong spacingGear wheel

The invention relates to a boring device for multiple sets of long-spacing coaxial holes. The boring device for multiple sets of long-spacing coaxial holes comprises a three-phase asynchronous motor, a cycloidal-pin wheel speed reducer, a movable carriage, a fixed carriage, a T-shaped screw rod, a T-shaped copper nut, an axial thrust bearing, a longitudinal movable adjusting nut, a boring rod fixing base A, a boring rod fixing base B, a thrust bearing ,a small gear, a large gear, a radial bearing, a boring rod, a boring machine fixing rod and the like. The boring device fixing rod is pressed on a tool rest on any side of a double housing planer, the tool rest can move horizontally and vertically, the moving distance is accurately determined through a dial indicator, and the boring coaxiality is high; coaxiality and roundness tolerance of holes can meet design requirements; and the boring device is suitable for machining holes with various types of spacing and with the high requirement for coaxiality.

Owner:SINOHYDRO BUREAU 14 CO LTD

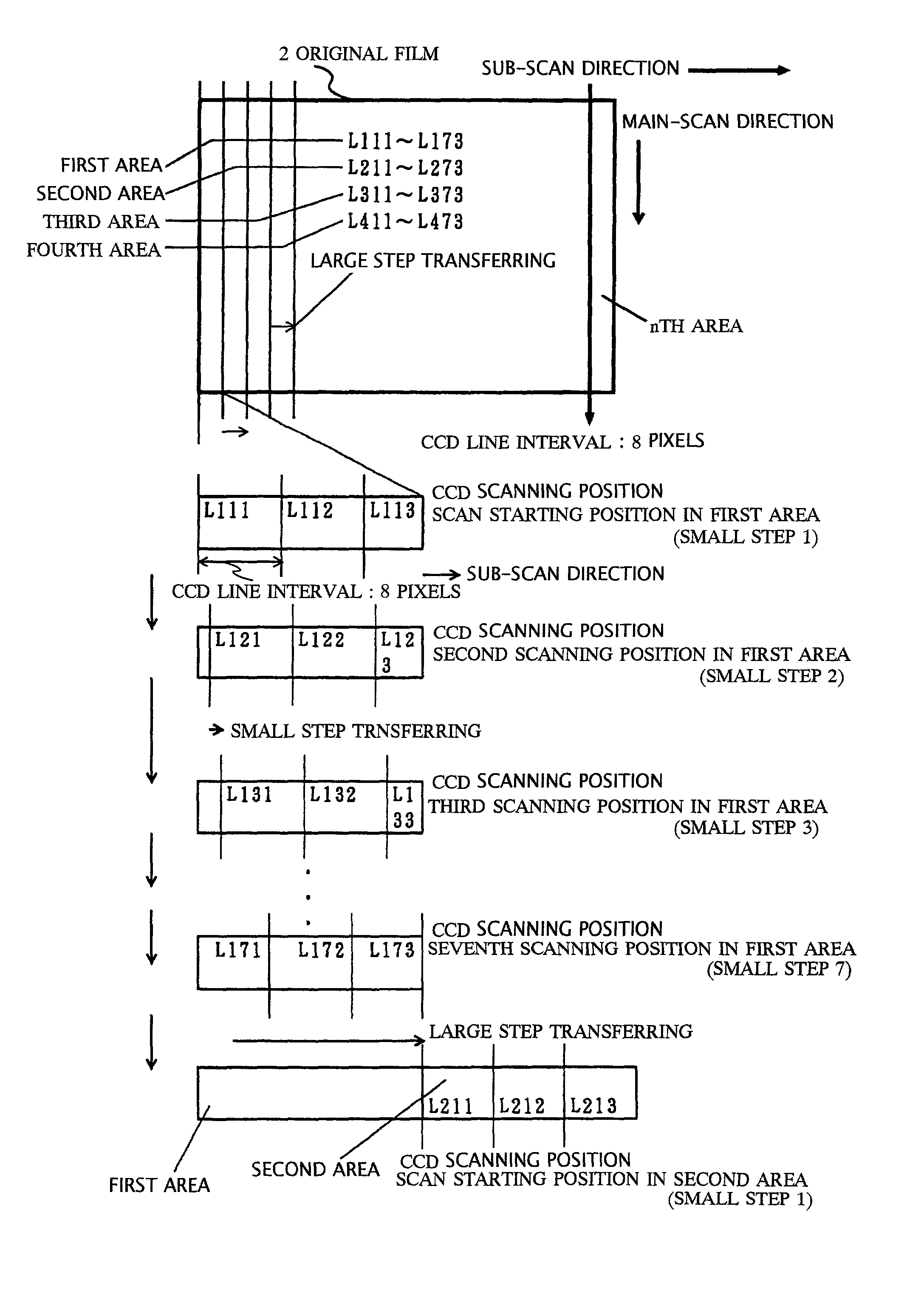

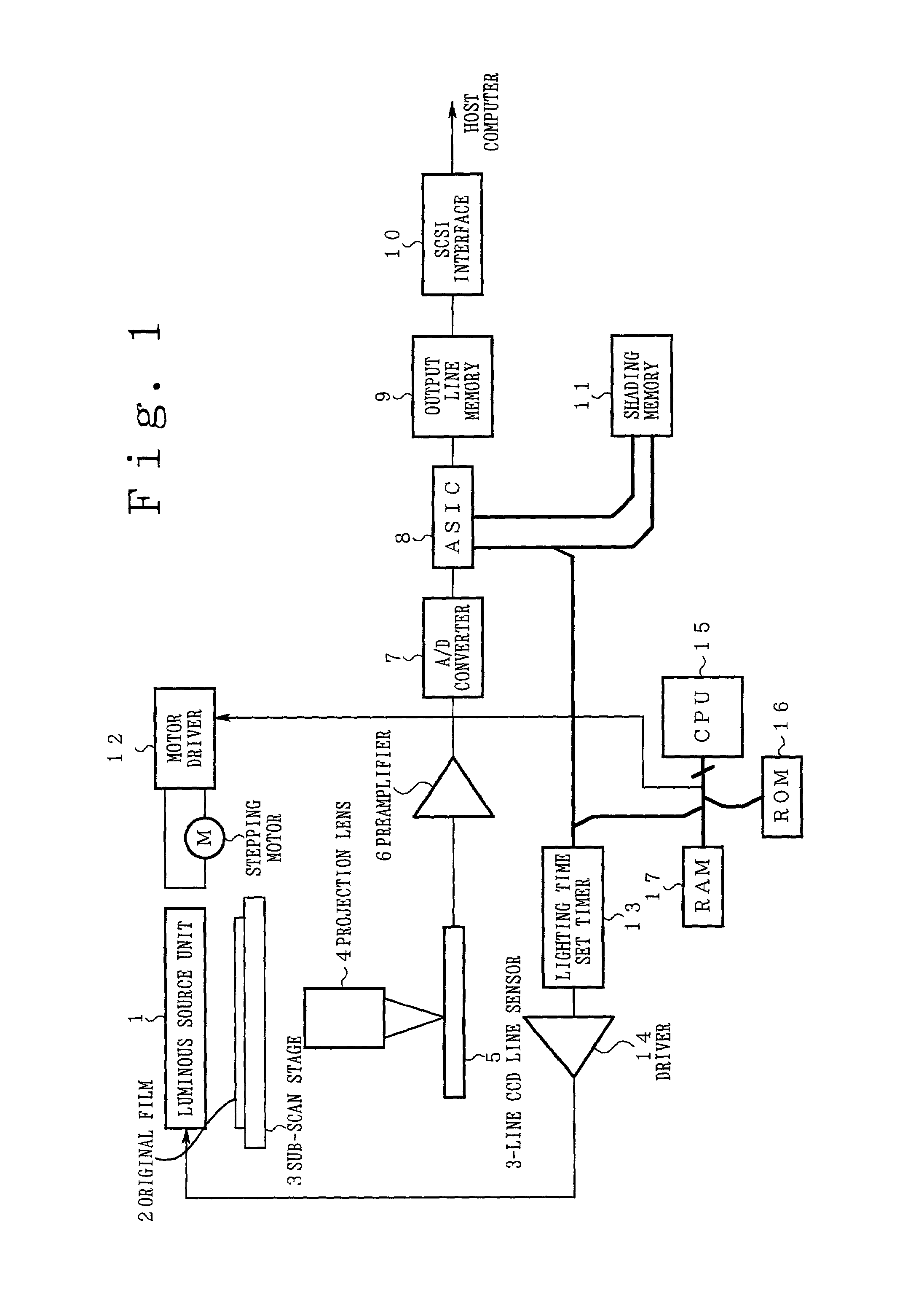

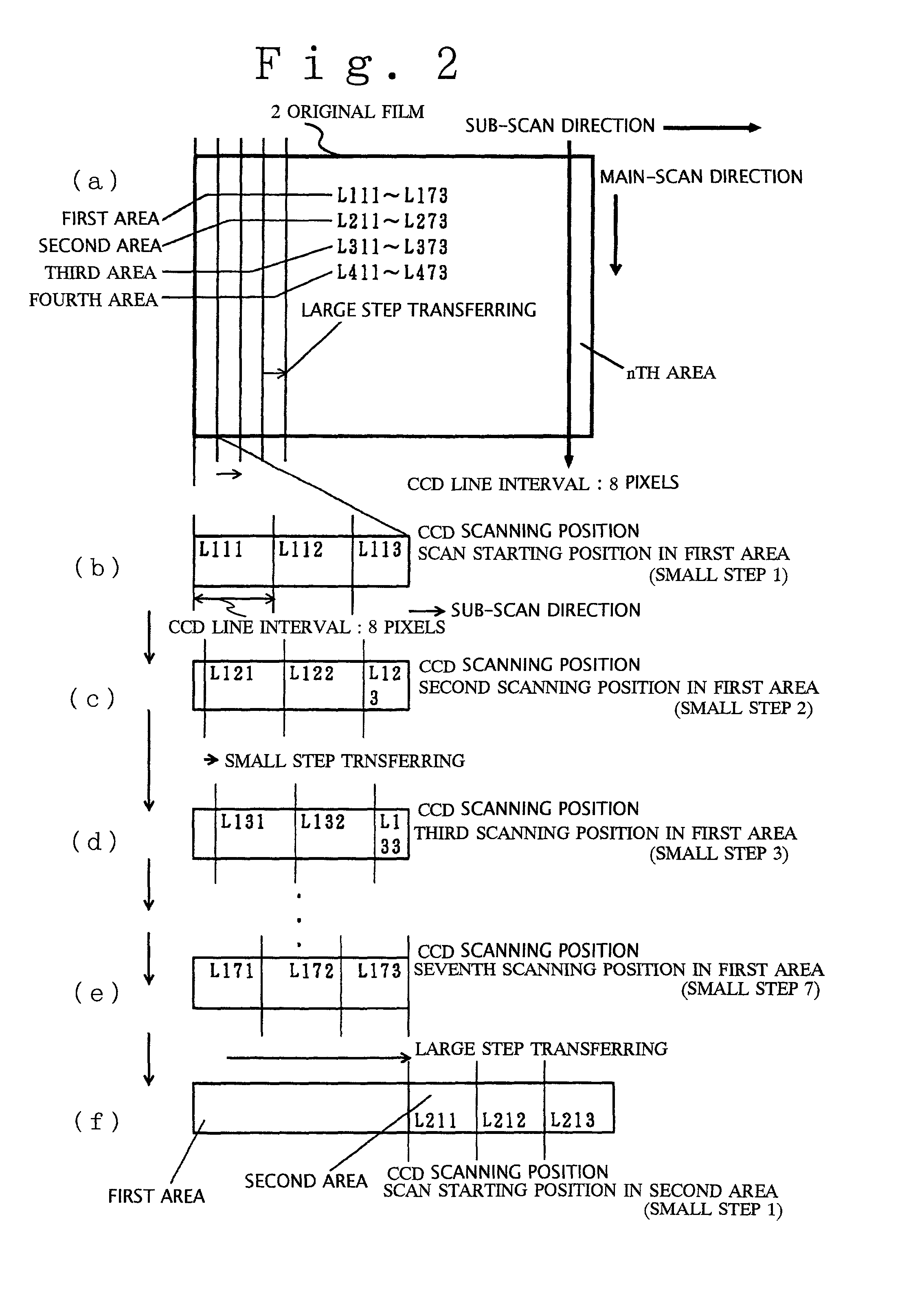

Image scanning apparatus, storage medium for storing controlling procedure of image scanning apparatus, and control program for image scanning apparatus

ActiveUS7023591B2High coloring rateCorrection coefficientDigitally marking record carriersDigital computer detailsLong spacingComputer science

It is assumed that there are a plurality of areas where a transfer is to be performed at a long pitch, in an original film, and a plurality of areas where a transfer is to be performed at a short pitch in each of the areas where a transfer is to be performed at a long pitch. On a sub-scan stage the original document is sub-scanned in the area where a transfer is to be performed at a short pitch, by performing at least one small step transferring, which is a transfer performed at a short pitch. Thereafter, a large step transferring which is a transfer performed at a long pitch, is performed on the sub-scan stage. The sub-scanning is repeated by performing the large step transferring and the small step transferring.

Owner:NIKON CORP

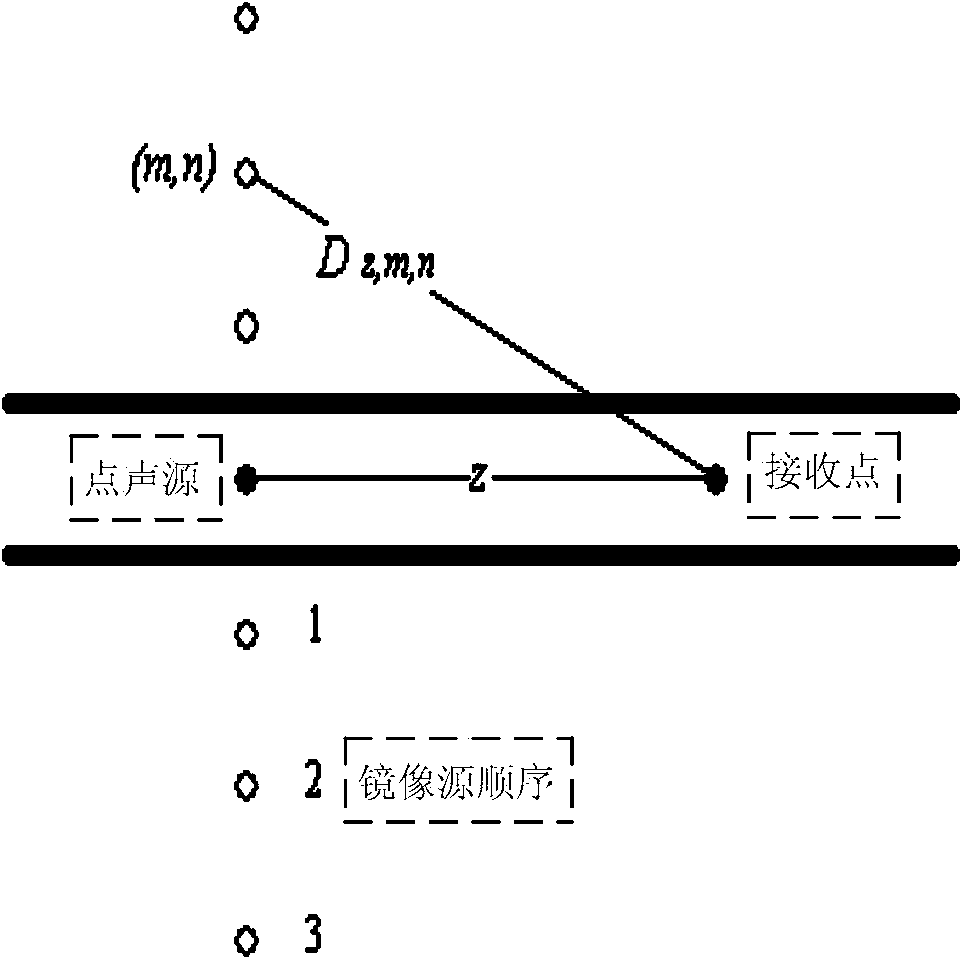

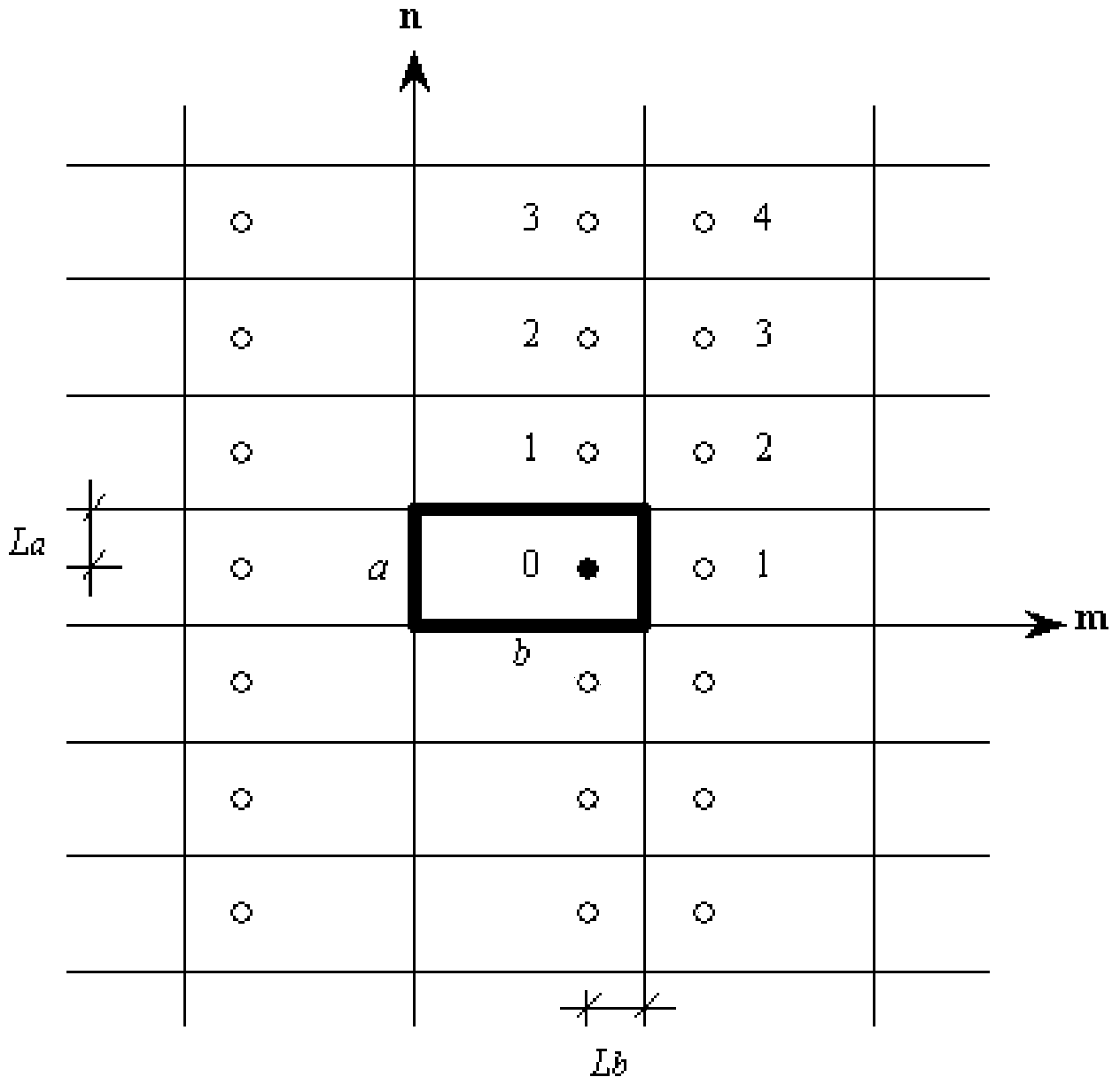

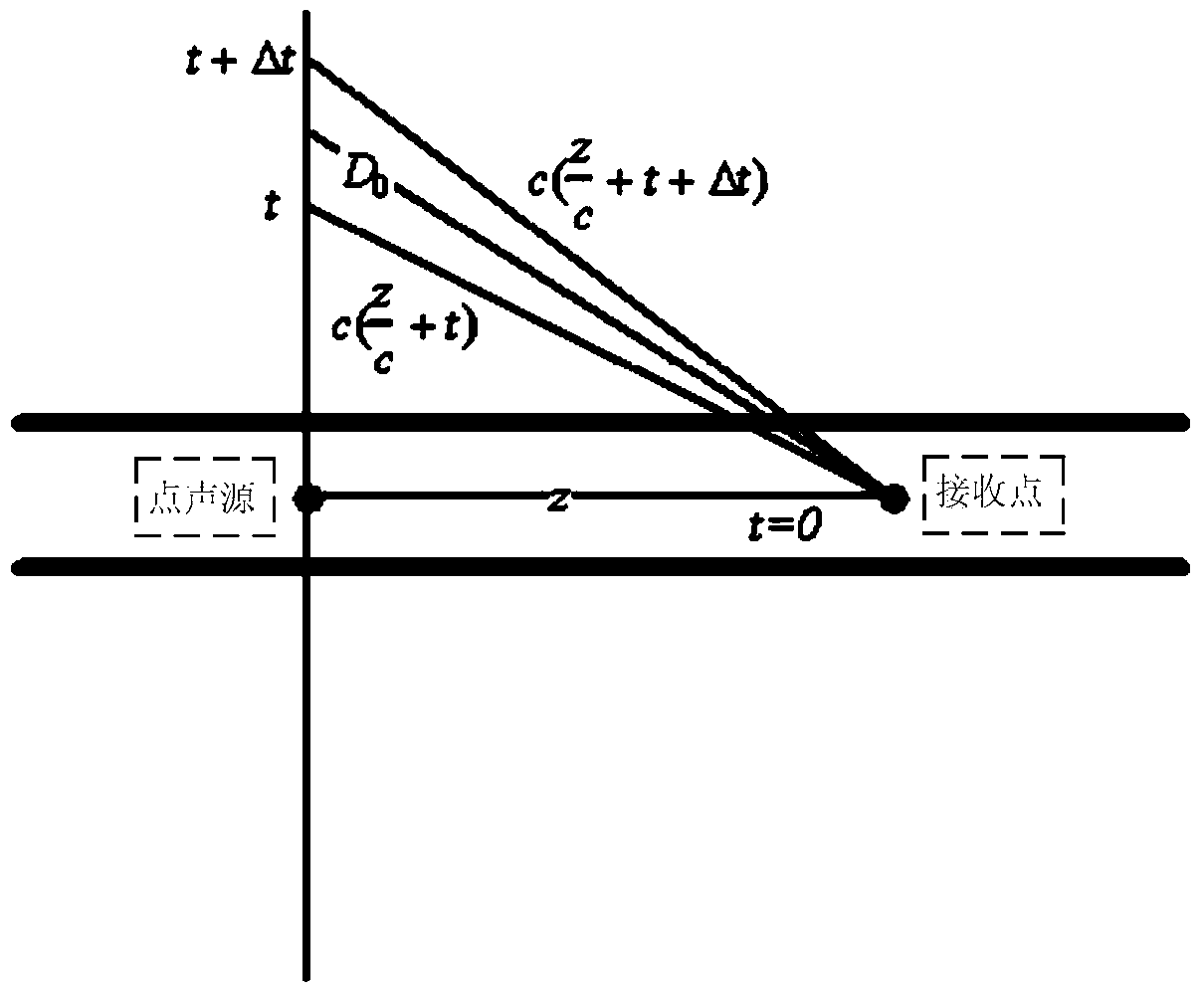

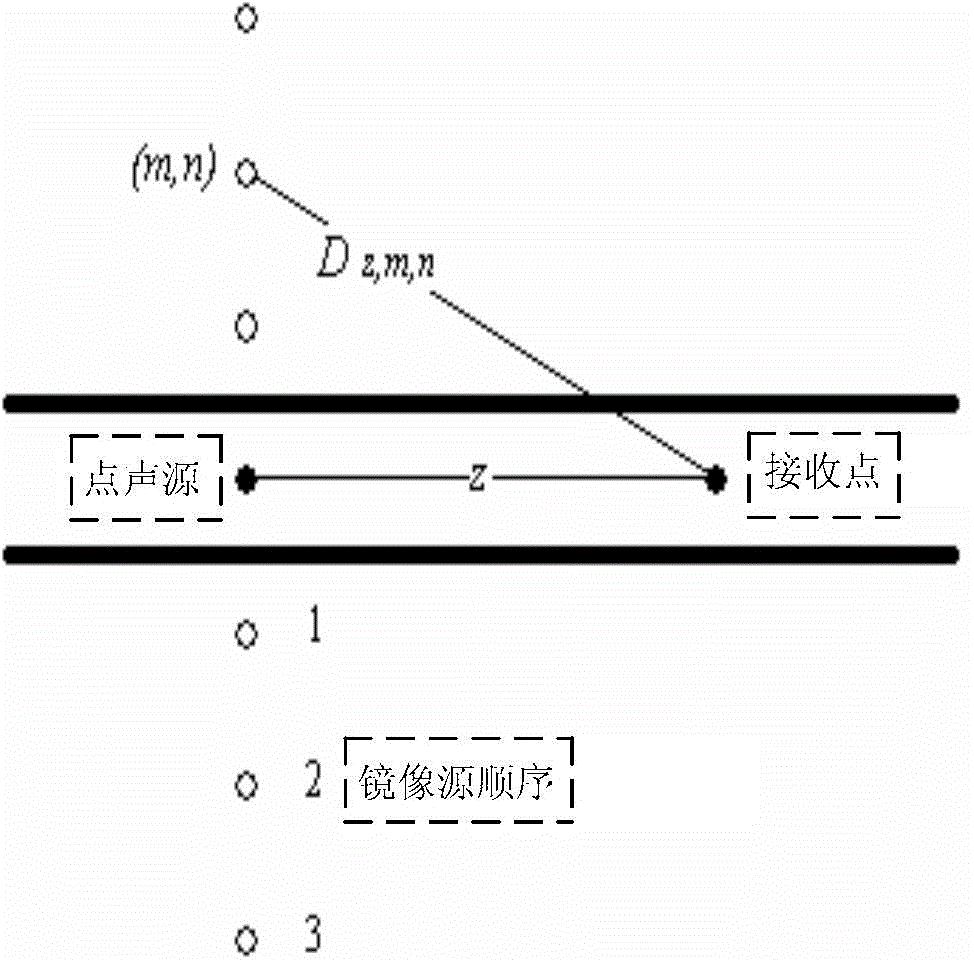

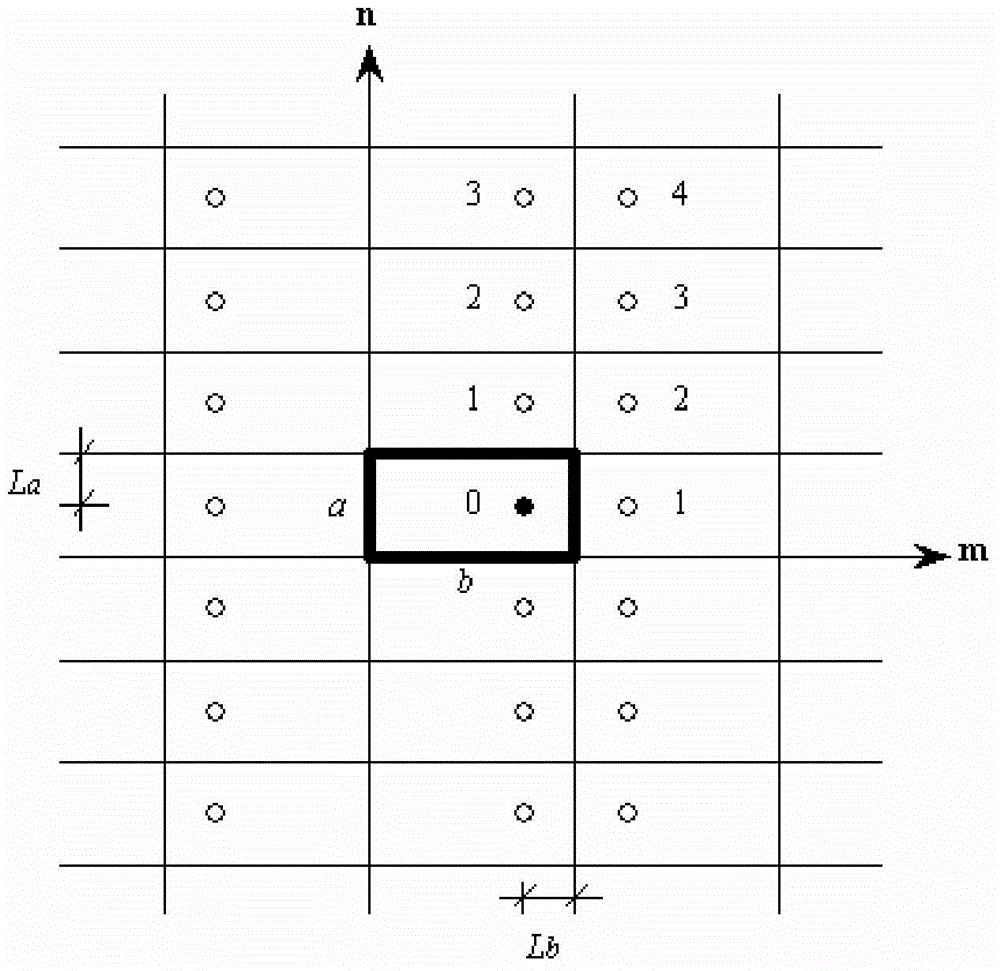

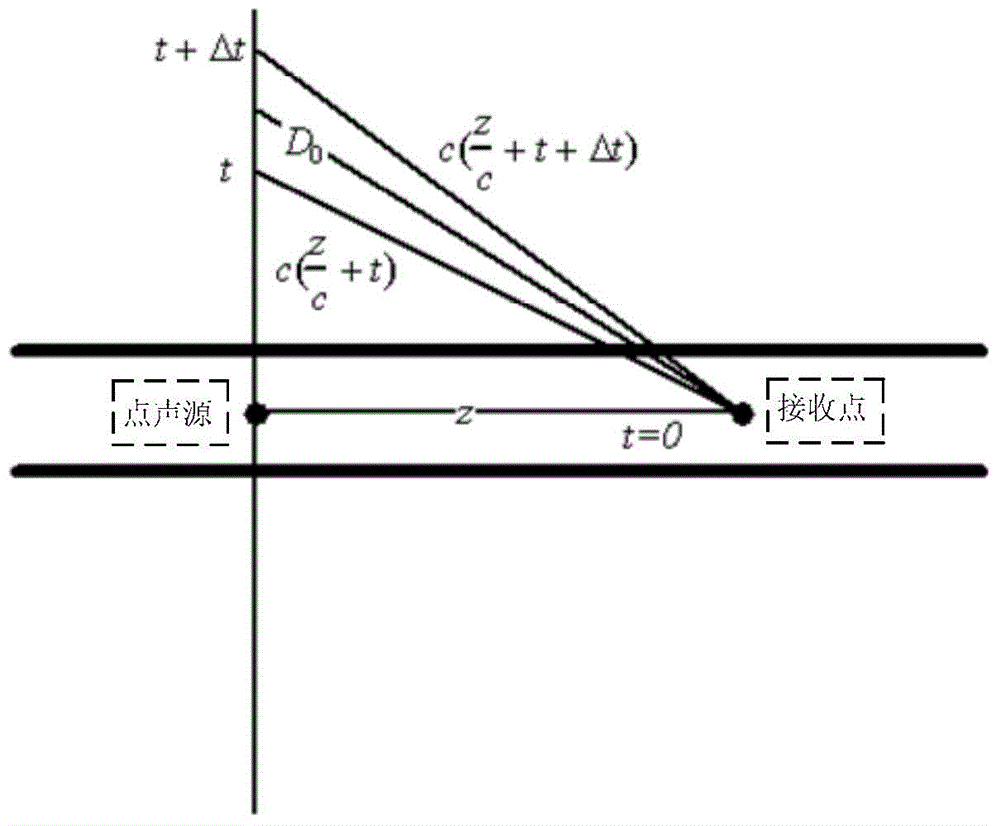

Mirror image source method based long spacing reverberation time obtaining method

The invention relates to a long spacing reverberation time obtaining method, particularly relates to a mirror image source method based long spacing reverberation time obtaining method, and aims to solve the problem of big errors of existing methods for obtaining long spacing reverberation. The long spacing reverberation time obtaining method includes arranging a point acoustic source (m, n) and a receiving point at the position which is z from the mirror image acoustic source in long spacing with a geometric reflection boundary, and subsequently performing calculation according to acoustic energy and the distance between the point acoustic source (m, n) and the receiving point to finally obtain long spacing reverberation time. The mirror image source method based long spacing reverberation time obtaining method is applicable to obtaining long spacing acoustic reverberation time of subway stations, passages and the like.

Owner:HARBIN INST OF TECH

Intermolecular compounds of fatty acid triglycerides

There are provided an intermolecular compound of (a) di-saturated medium chain fatty acids mono-saturated long chain fatty acid triglyceride and (b) 1,3-di-saturated long chain fatty acids 2-mono-unsaturated long chain fatty acid triglyceride, of which a long spacing value by X-ray diffraction is 65 Å or more, and foods containing the intermolecular compound. The intermolecular compound can be used as a part of fats and oils that constitute foods. Due to formation of the intermolecular compound, the fats and oils containing large amounts of symmetric triglycerides such as cocoa butter and those containing medium chain fatty acids do not form separate crystals and, therefore, can keep smooth texture and prevent blooming.

Owner:THE NISSHIN OILLIO GRP LTD

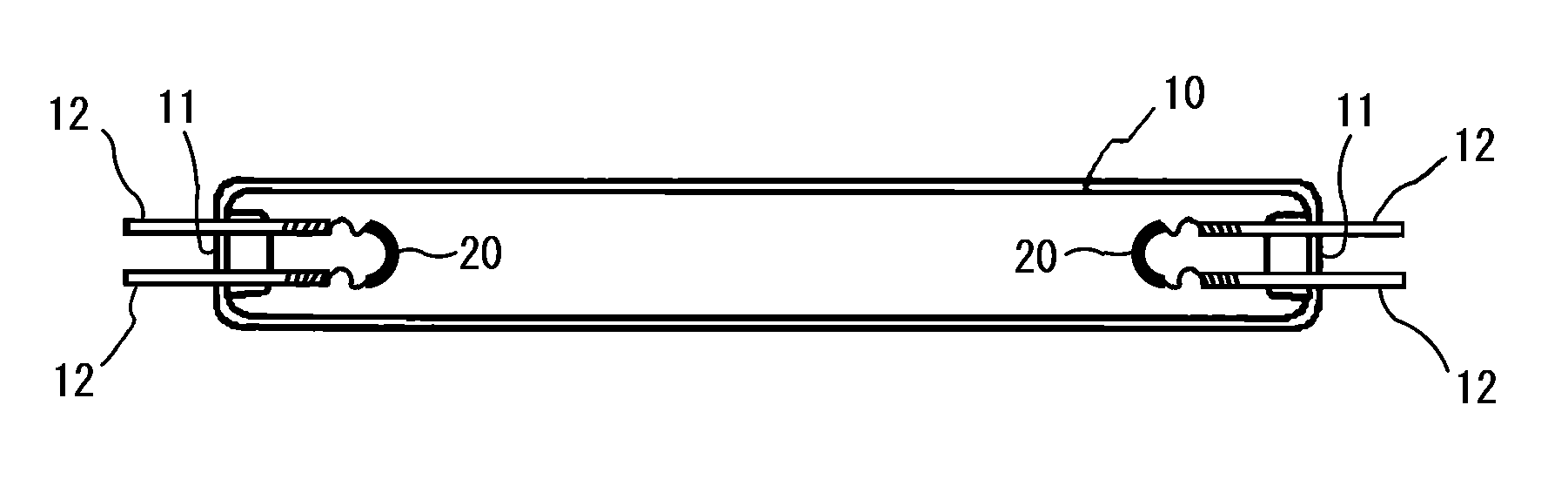

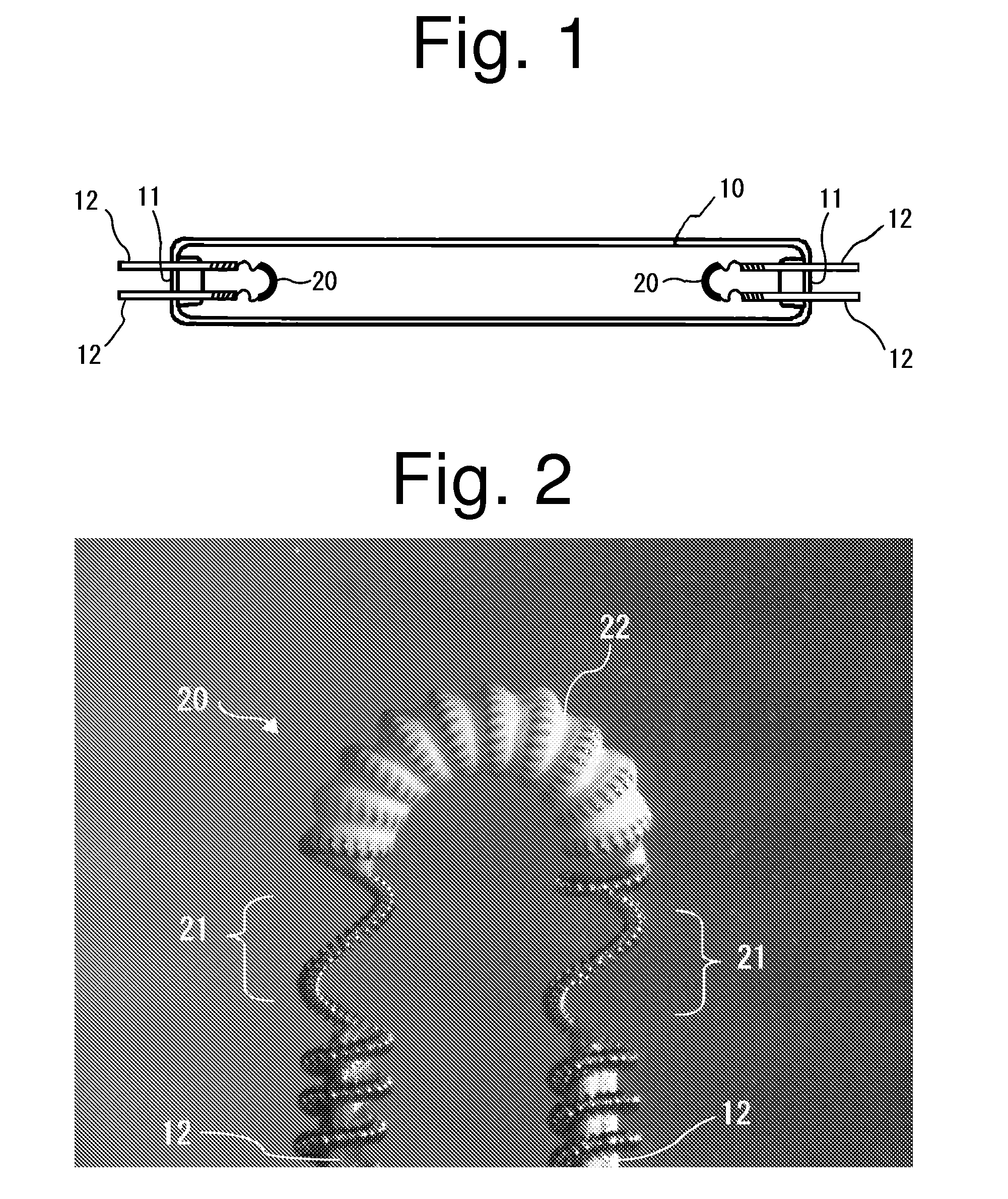

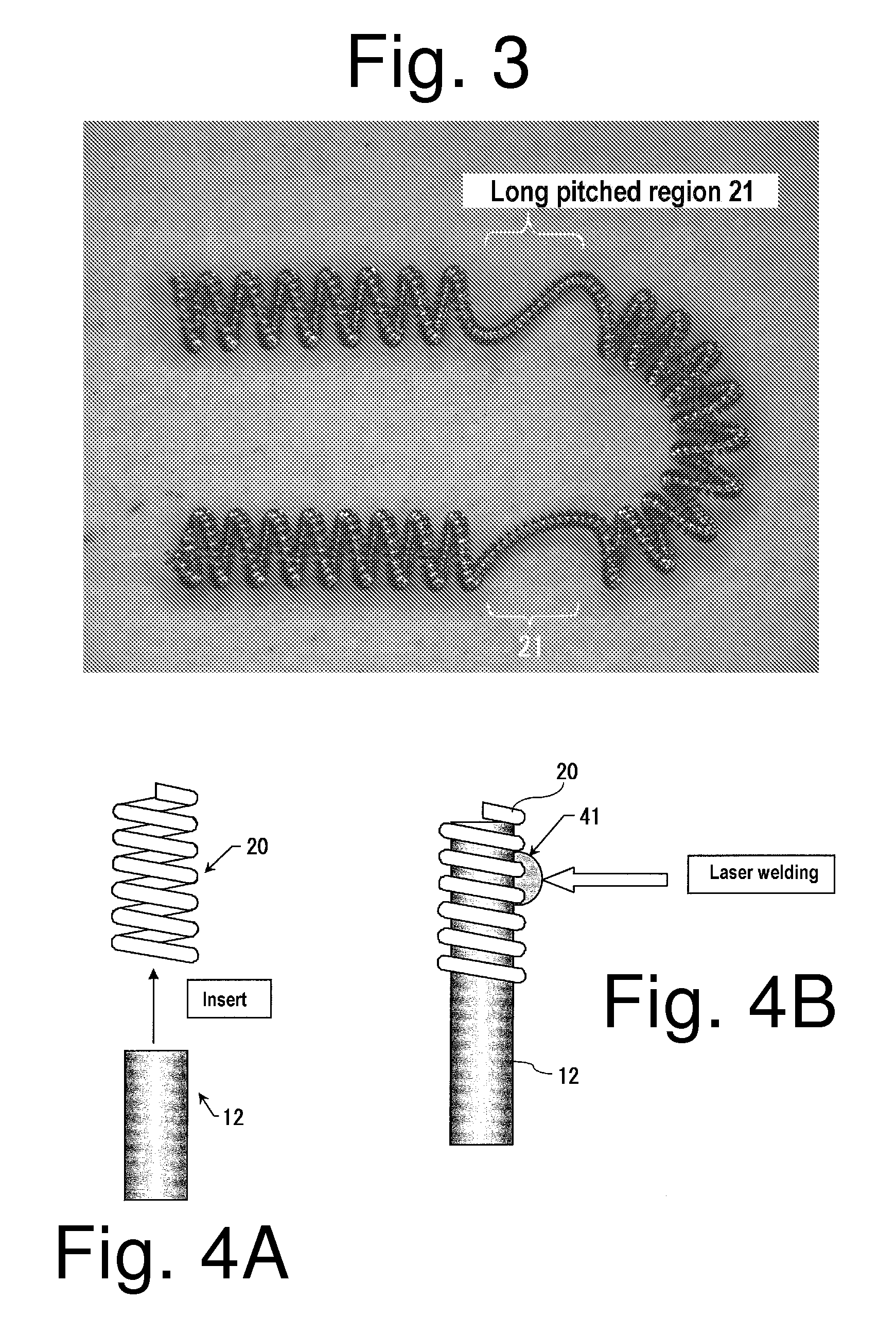

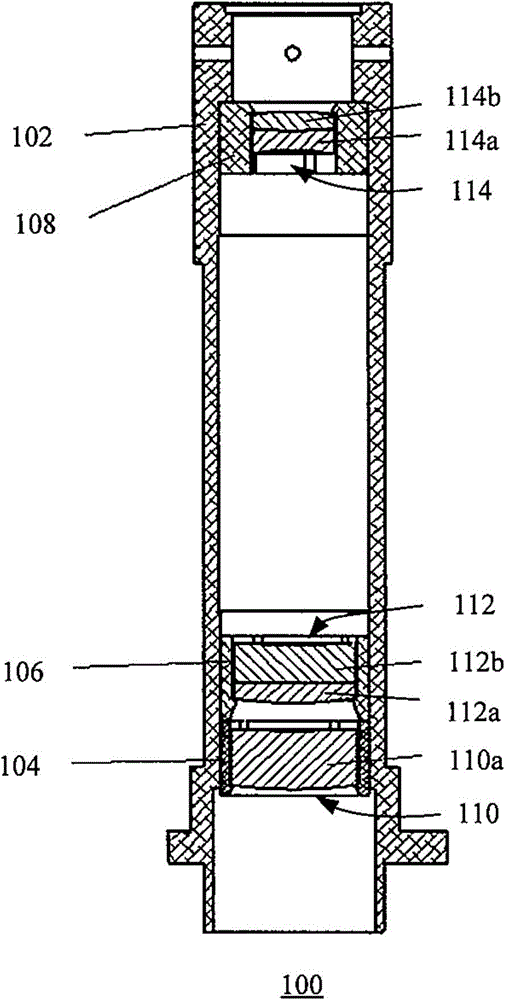

Hot cathode fluorescent lamp and electrode for fluorescent lamp

InactiveUS20100244660A1Solution to short lifeLuminous stabilityDischarge tube luminescnet screensLamp incadescent bodiesLong spacingEngineering

A long-life hot cathode fluorescent lamp can include a pair of parallel lead wires that can be arranged at each end of a tube. A coiled filament can be connected at its opposite end portions to the lead wires. The coiled filament can have two long pitched regions in which a coil pitch is longer than regions outside of the long pitched regions. Emitter can be located in a region defined between the two long pitched regions. Shape characteristics and intensive current flow obtained by the presence of the long pitched regions can form the origins of discharge near the boundaries between long and short pitched regions. Accordingly, stable discharge can be achieved with the origins of discharge located at ends of the emitter. As a result, the hot cathode fluorescent lamp is allowed to have a long life and stable light emission characteristics.

Owner:STANLEY ELECTRIC CO LTD

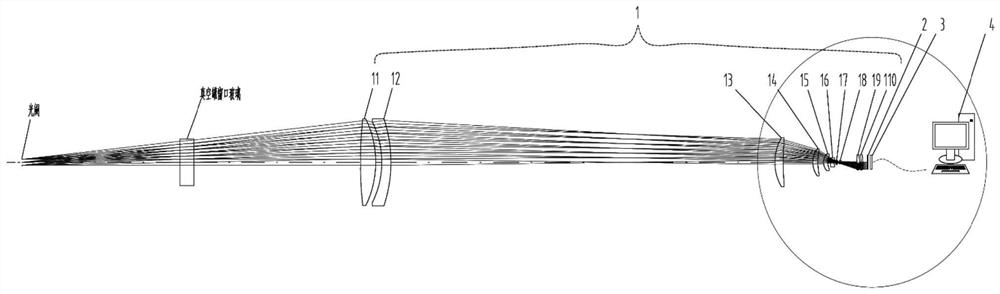

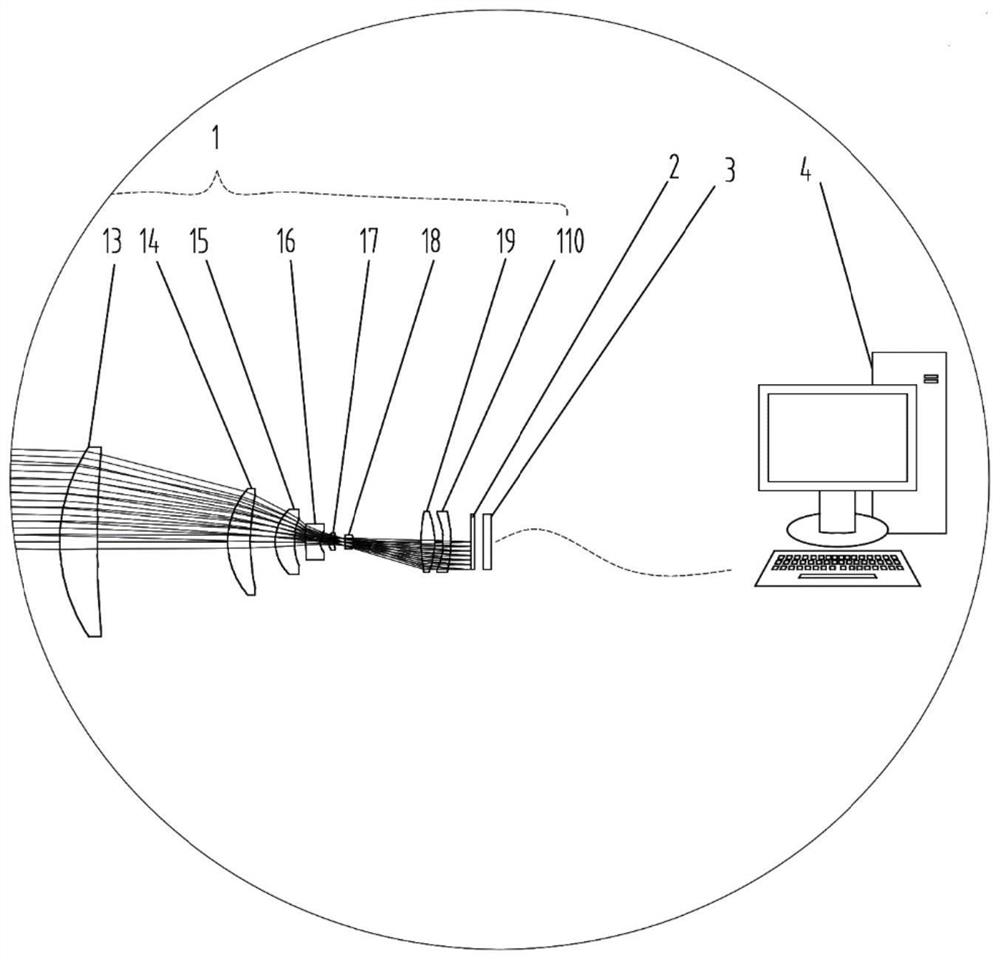

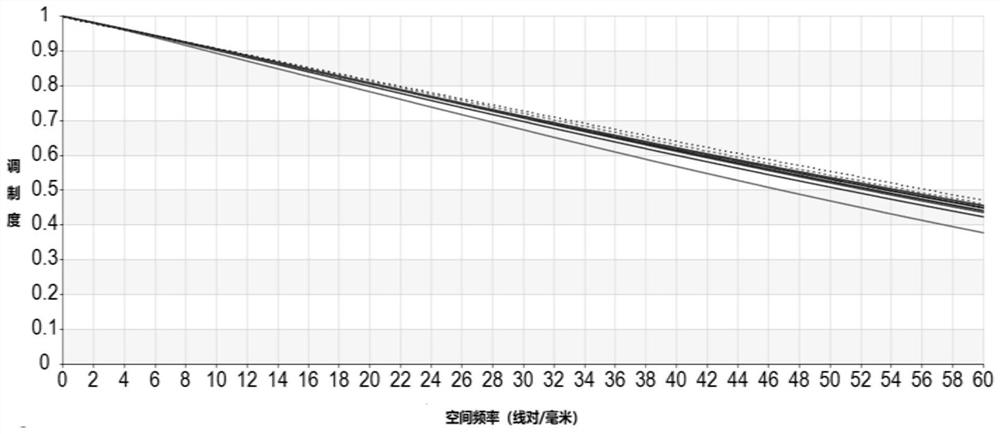

Tubular lens of image recognition system and image recognition system employing tubular lens

The invention discloses a tubular lens of an image recognition system. The tubular lens is used for cooperating with an object lens; the focal distance of the tubular lens is f; the tubular lens comprises a first lens group, a second lens group and a third lens group; a diaphragm can be flexibly arranged; the focal distance of the first lens group f1 is greater than 0.7f, but smaller than 1.2f, and the effective clear aperture of the first lens group is greater than 0.1f; the focal distance of the second lens group f2 is greater than 0, but smaller than 0.2f; the focal distance of the third lens group f3 is greater than -5f, but smaller than -2f; an interval between the first lens group and the second lens group on an optical axis is smaller than 0.05f; an interval between the second lens group and the third lens group on the optical axis is greater than 0.25f. According to the tubular lens, the first lens group adopts a lens made of a material with large clear aperture and high refractivity as a light beam constraining lens, so that a large-visual field light beam under a large interval can be effectively constrained; furthermore, the second lens group and the third lens group can compensate and optimize light rays, so that aberration is corrected and an image space visual field is controlled, and thus the requirement of high-quality imaging, in which the interval can be increased and the lens can be varied, is ultimately met.

Owner:RAINTREE SCI INSTR SHANGHAI

Combined Long Distance Shaft Sleeve Coaxiality Detector

ActiveCN104197818BAvoid damageIngenious ideaMechanical measuring arrangementsLong spacingDesign standard

The invention provides a coaxiality detector for a combined long-spaced shaft sleeve. The coaxiality detector comprises sliding end shafts, a reference rod and detection sliding sleeves, wherein two sliding end shafts are provided; the sliding end shafts comprise chamfered fitting portions and sliding pin portions; the two ends of the reference rod are provided with end stepped holes; two detection sliding sleeves are provided; the detection sliding sleeves have tubular structures provided with through holes; the through holes are sliding sleeve sliding holes; the sliding sleeve sliding holes are in clearance fit with the sliding pin portions of the sliding end shafts; the difference between the inner diameter of the shaft sleeve and the outer diameter of each detection sliding sleeve is smaller than a preset coaxiality standard value of the shaft sleeve. In the detector, the sliding end shafts and the reference rod are combined into a public axis, and inspection on whether the coaxiality between shaft sleeves at the two ends of a rear axle and the public axis meets a design standard or not is performed by detecting whether the sliding sleeves can be inserted into the gaps between the sliding pin portions of the sliding end shafts and the shaft sleeves. The coaxiality detector is skillful in design, and is rapid and convenient to operate and use.

Owner:GREAT WALL MOTOR CO LTD

A tube mirror of an image recognition system and an image recognition system with the tube mirror

ActiveCN104570276BHigh quality imagingAberration correctionOptical elementsLong spacingVisual field loss

The invention discloses a tubular lens of an image recognition system. The tubular lens is used for cooperating with an object lens; the focal distance of the tubular lens is f; the tubular lens comprises a first lens group, a second lens group and a third lens group; a diaphragm can be flexibly arranged; the focal distance of the first lens group f1 is greater than 0.7f, but smaller than 1.2f, and the effective clear aperture of the first lens group is greater than 0.1f; the focal distance of the second lens group f2 is greater than 0, but smaller than 0.2f; the focal distance of the third lens group f3 is greater than -5f, but smaller than -2f; an interval between the first lens group and the second lens group on an optical axis is smaller than 0.05f; an interval between the second lens group and the third lens group on the optical axis is greater than 0.25f. According to the tubular lens, the first lens group adopts a lens made of a material with large clear aperture and high refractivity as a light beam constraining lens, so that a large-visual field light beam under a large interval can be effectively constrained; furthermore, the second lens group and the third lens group can compensate and optimize light rays, so that aberration is corrected and an image space visual field is controlled, and thus the requirement of high-quality imaging, in which the interval can be increased and the lens can be varied, is ultimately met.

Owner:RAINTREE SCI INSTR SHANGHAI

A Super-Long Exit Pupil Distance Multi-Star Simulator for Thermal Vacuum Testing

ActiveCN112067018BEliminate the effects ofExcellent relative illuminationMeasurement devicesLong spacingExit pupil

The invention discloses a super-long exit pupil distance multi-star simulator for thermal vacuum testing, which comprises a diaphragm, an optical collimation module, and a star point plate arranged coaxially along the incident direction of light, and is the star point The board provides a light source for illumination, and a control system for controlling the light source; wherein, the optical alignment module includes lens one, lens two, lens three, lens four, lens five, lens six, lens seven, lens eight, lens nine, and Lens ten. The invention is placed outside the thermal vacuum tank, and can perform attitude calibration on the star sensor in the thermal vacuum test.

Owner:西安中科微星光电科技有限公司

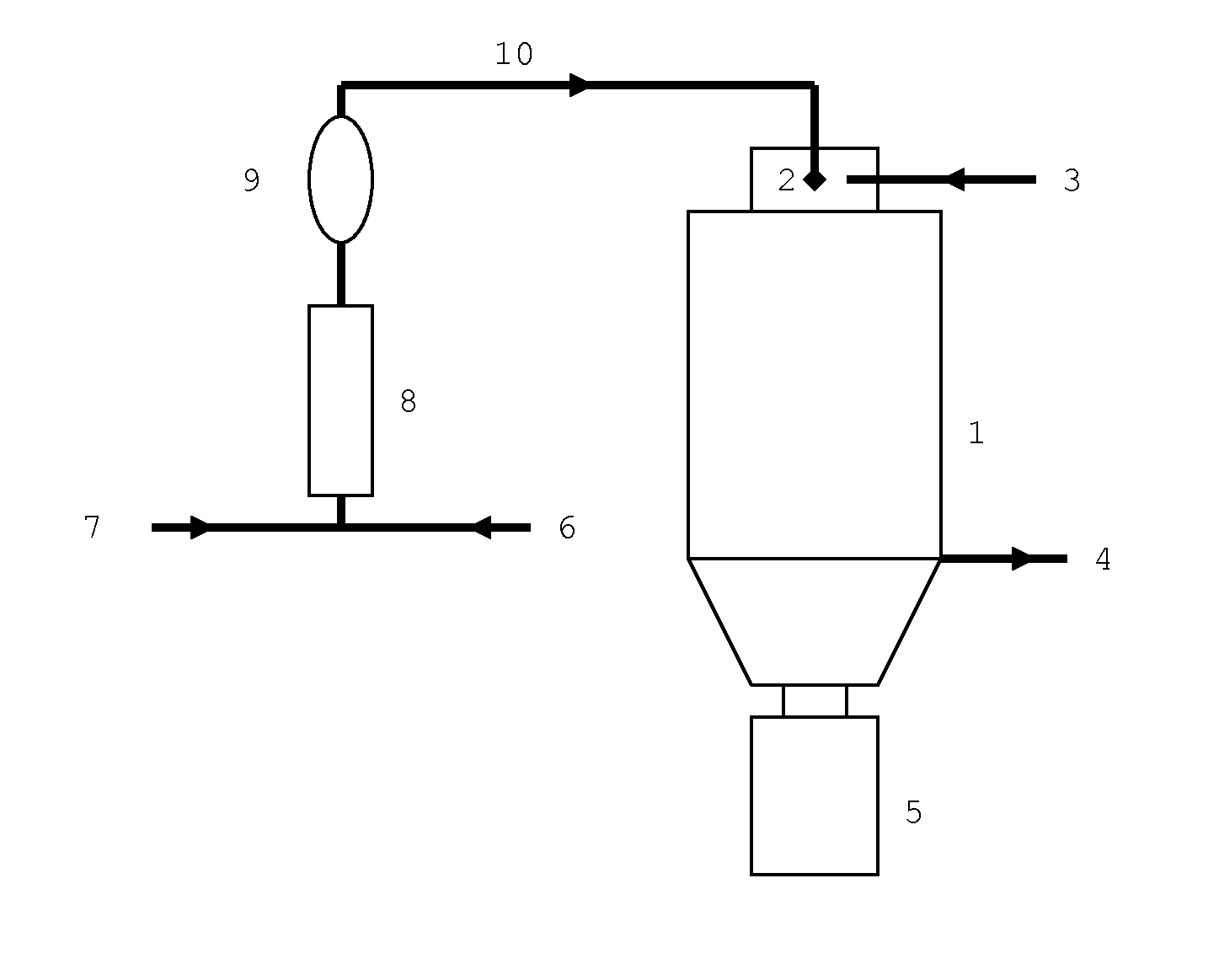

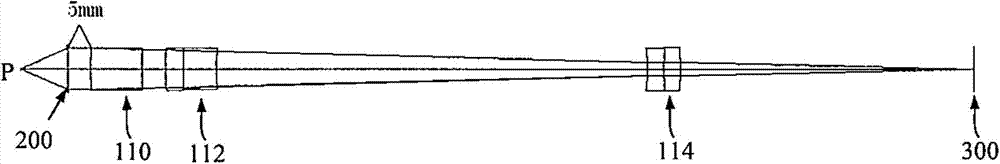

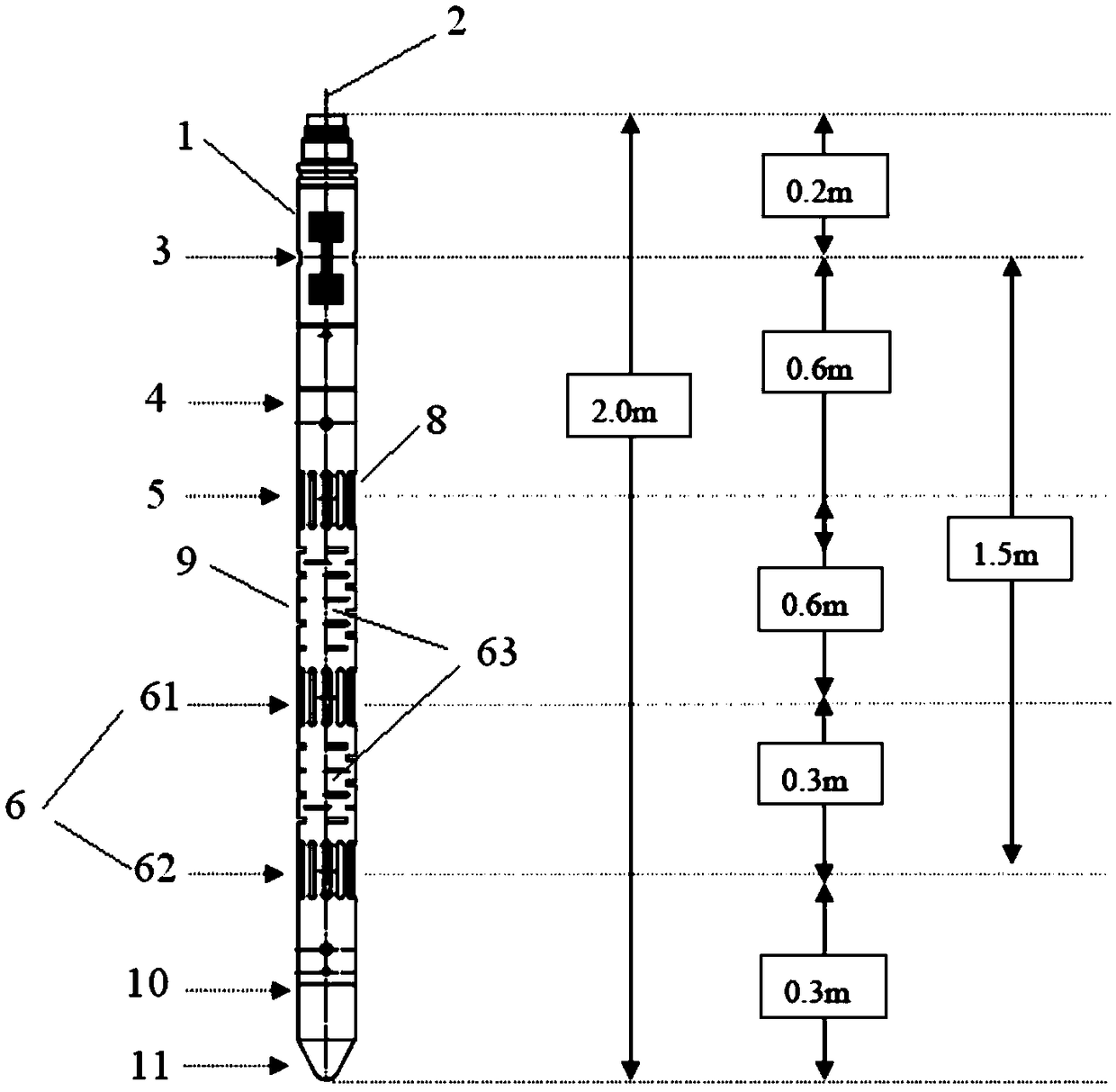

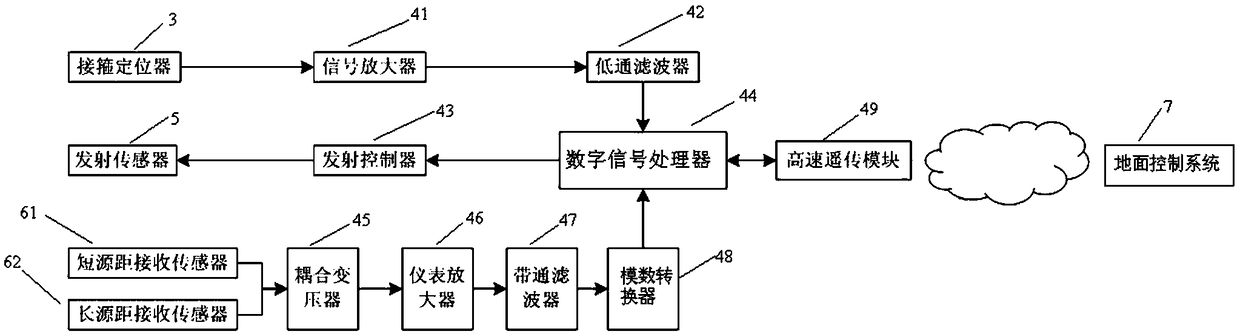

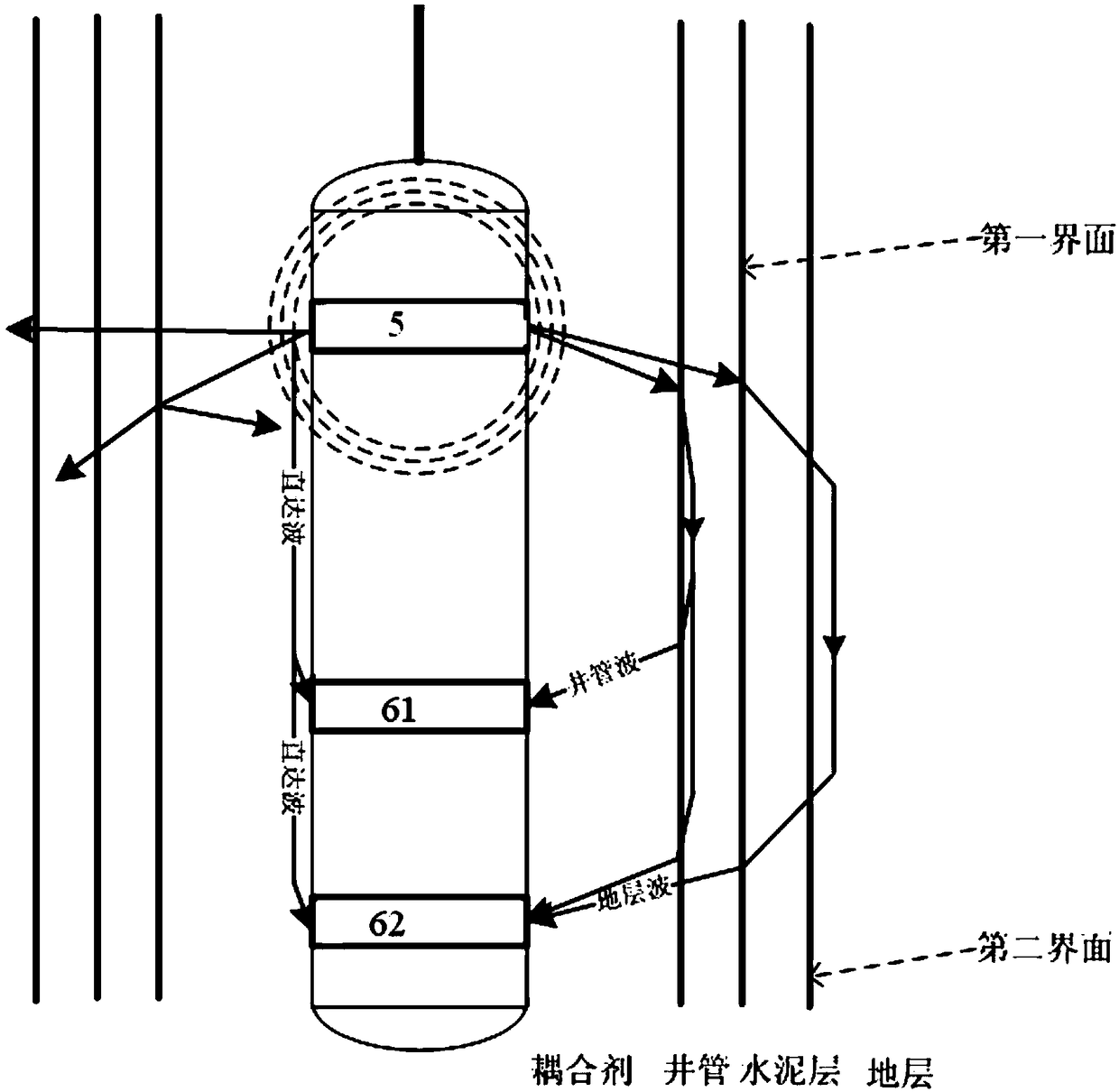

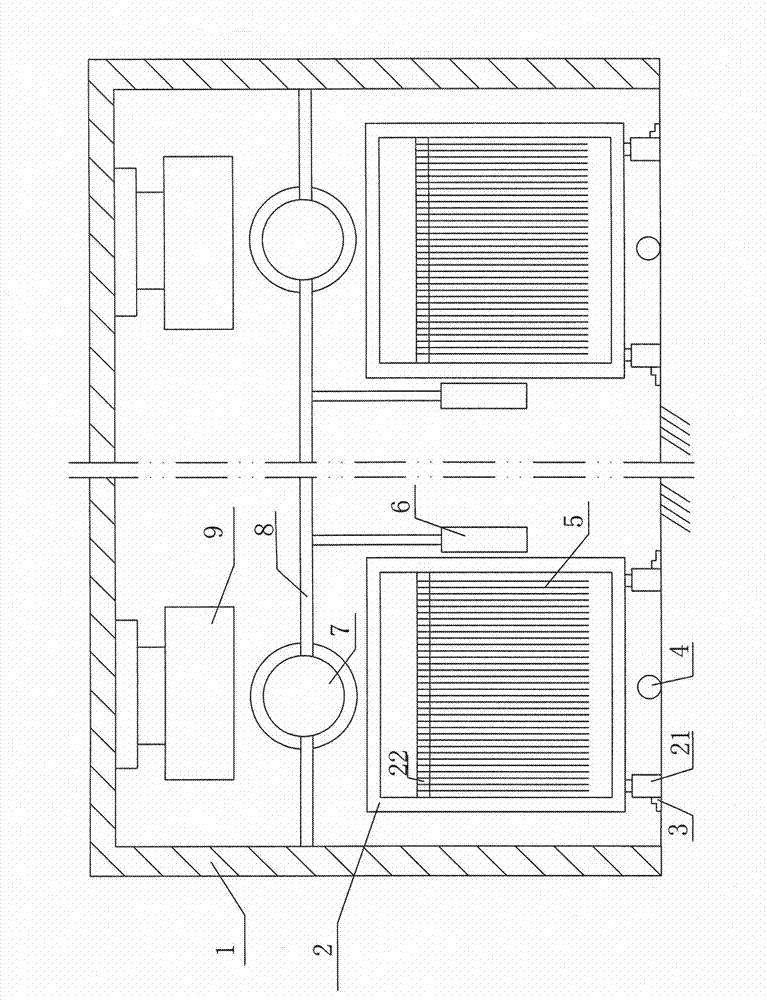

Acoustic wave detection equipment for detecting cementation quality of cement protection layer of gas storage well

ActiveCN109507298AQuick checkSonic detection of detection fastAnalysing solids using sonic/ultrasonic/infrasonic wavesLong spacingInstrumentation amplifier

The invention discloses acoustic wave detection equipment for detecting cementation quality of a cement protection layer of a gas storage well, and the acoustic wave detection equipment is used for detecting the cementation quality of the cement protection layer of an outer layer of the gas storage well. The acoustic wave detection equipment comprises a housing, a multi-core armor cable, a collarlocator fixed inside the housing, an electronic circuit structure, a transmitting sensor; a receiving sensor, and a ground control system, wherein the electronic circuit structure is fixed to a lowerpart of the collar locator and comprises a signal amplifier, a low pass filter, a transmission controller, a digital signal processor, a coupling transformer, an instrumentation amplifier, a band passfilter, an analog-to-digital converter and a high-speed remote transmission module; the receiving sensor comprises a short spacing receiving sensor and a long spacing receiving sensor fixed to the lower part of the transmitting sensor, the short spacing receiving sensor is 1.4 m away from the top of the housing, the long spacing receiving sensor is located at the bottom of the housing, and soundinsulating materials are filled between the transmitting sensor and the short spacing receiving sensor and between the short spacing receiving sensor and the long spacing receiving sensor.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST +1

Temperature control grate cast by embedding stainless steel capillary and control method thereof

InactiveCN101703371BImprove mechanical propertiesAvoid breakingFoundry mouldsRoasting apparatusLong spacingMedical product

Owner:刘中国

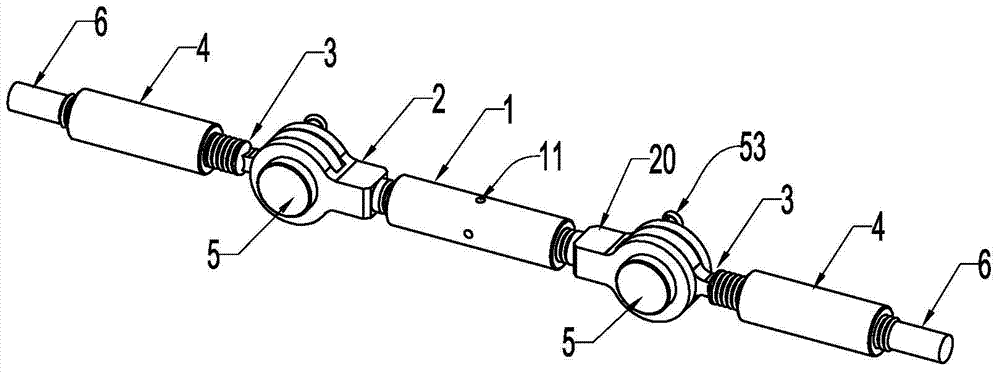

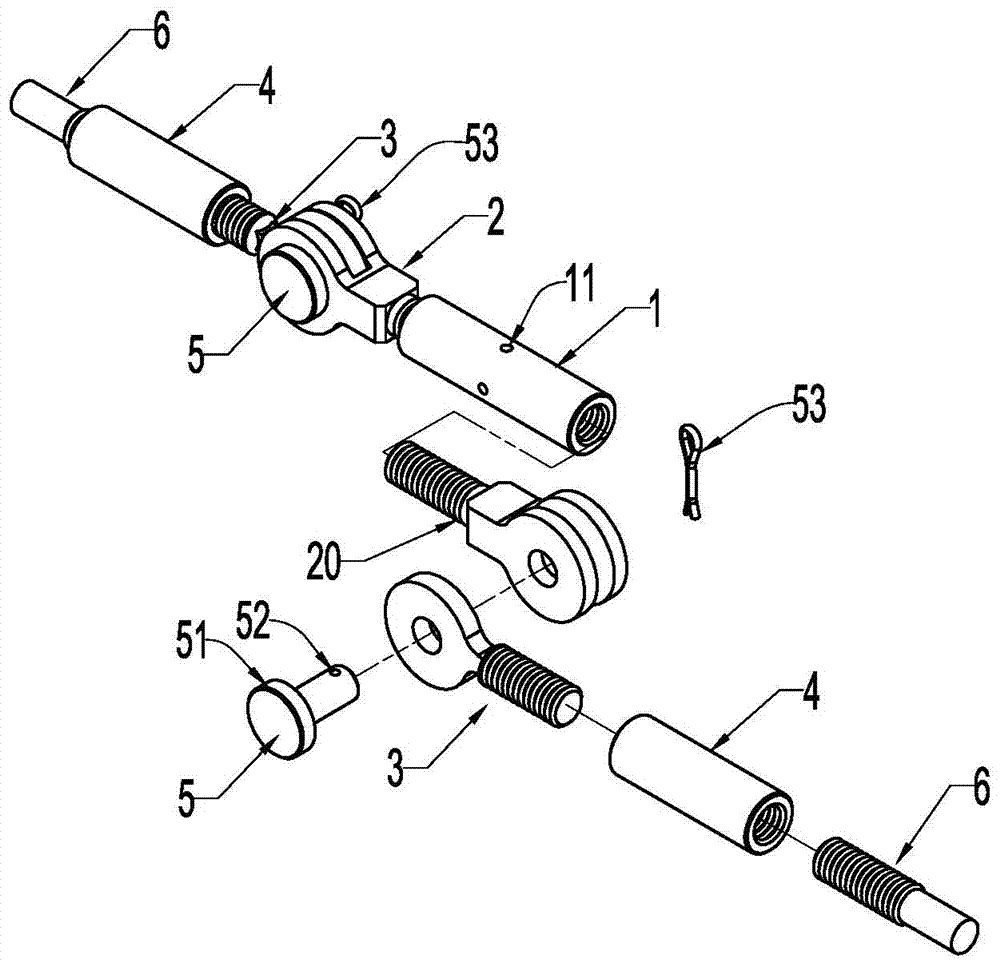

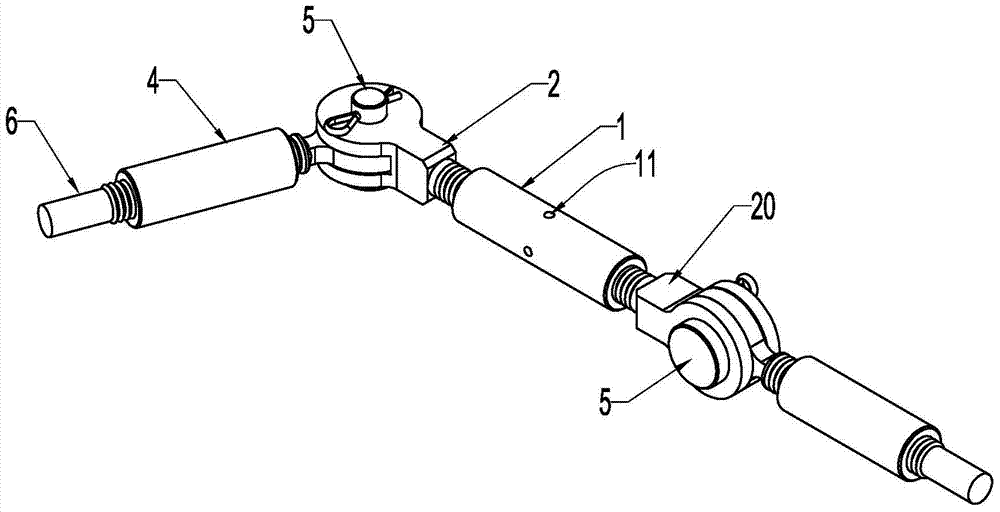

Telescopic Rebar Splice Kit

ActiveCN105064622BEasy connection and constructionReduce short-distance connectionsBuilding reinforcementsLong spacingArchitectural engineering

The invention relates to a telescopic steel bar connection kit, the main body of which includes a two-way screw sleeve, a forward screw seat, a reverse screw seat, a screw joint, a one-way screw sleeve and a pin shaft; one end of the two-way screw sleeve The inner thread of the thread is consistent with the inner thread of the one-way thread sleeve, and the outer thread of the forward screw seat, screw joint and steel head pier is consistent; each part in the kit can be organically combined, such as adding or subtracting Parts, for the butt connection of two steel bar heads with different spacing, and provide a kit for the connection of steel bar heads at the construction site. The combination method is flexible. According to the requirements of the steel bar spacing, it can reduce the number of parts to form a short-distance connection, and can also increase the number of parts in series to meet the needs of long-distance connections. With the help of two-way threaded sleeves, it can achieve tension and eliminate connection gaps; the connection is reliable, no The amount of deformation can meet the stress design requirements, and it is suitable for the connection of two steel bar heads with dislocation and different angles, which greatly facilitates the construction of steel bar connection.

Owner:裴敏雅

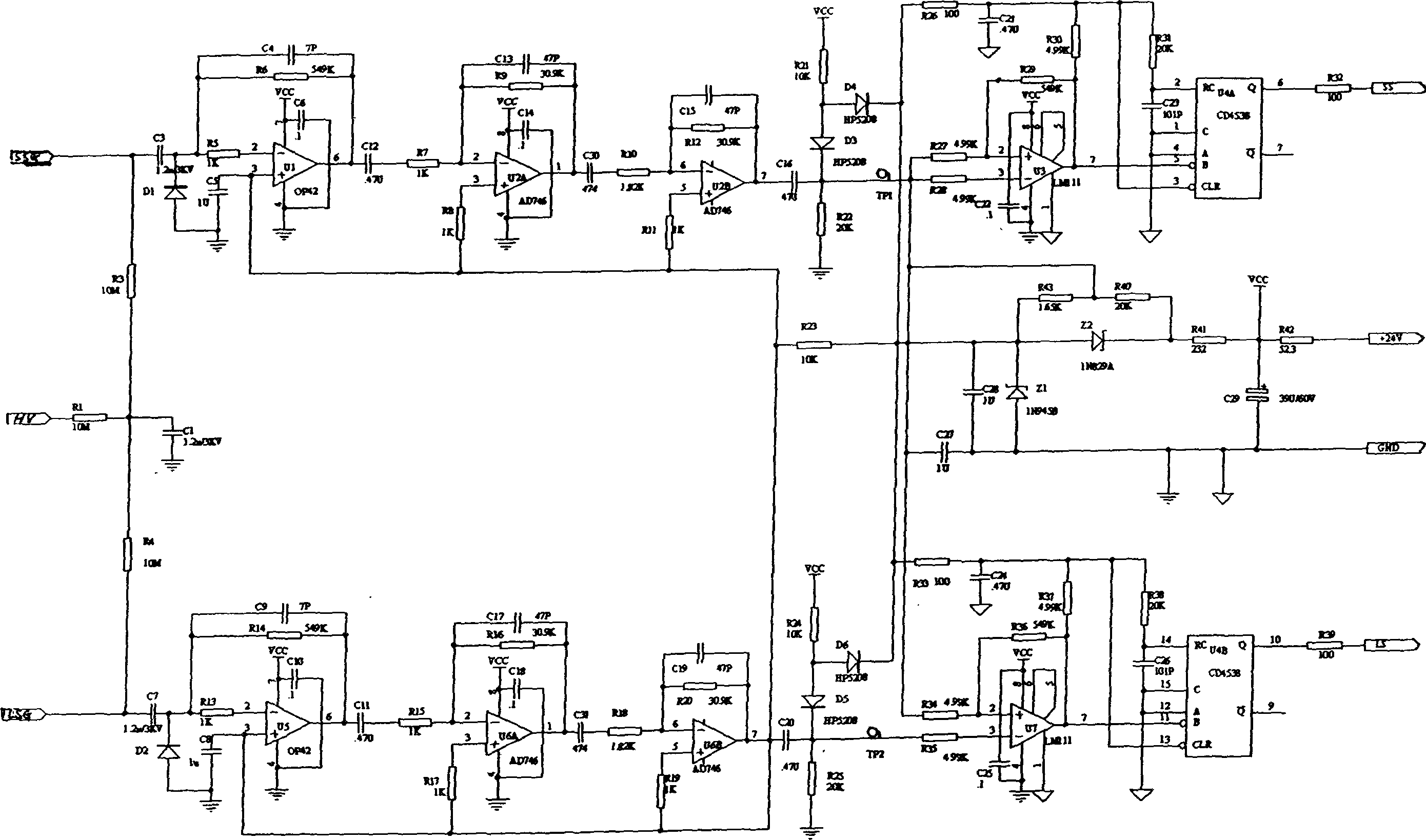

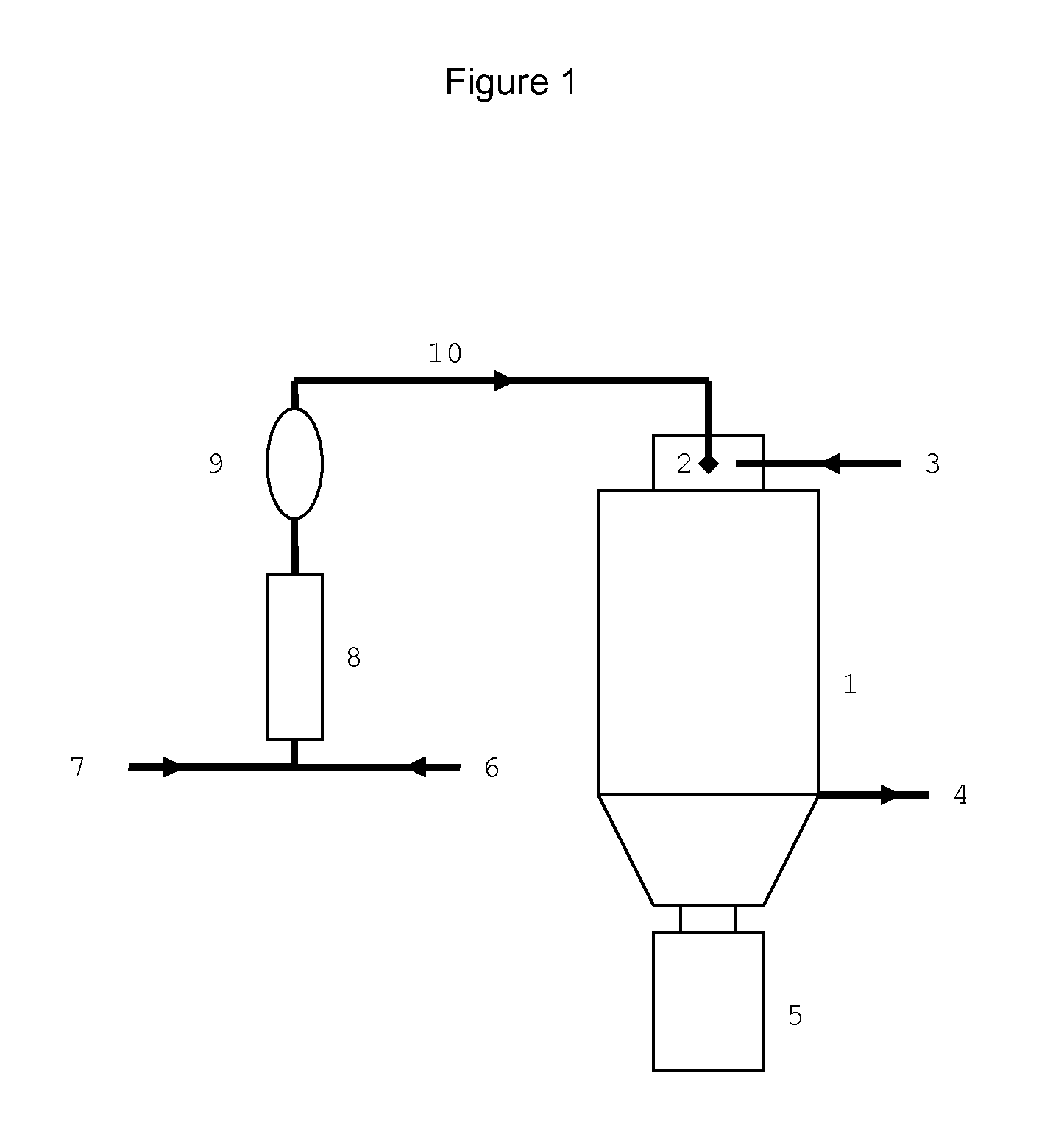

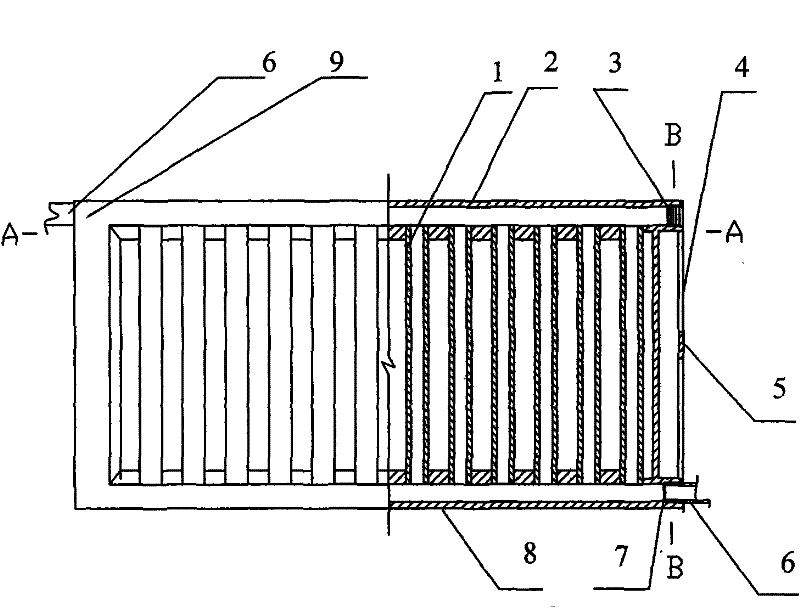

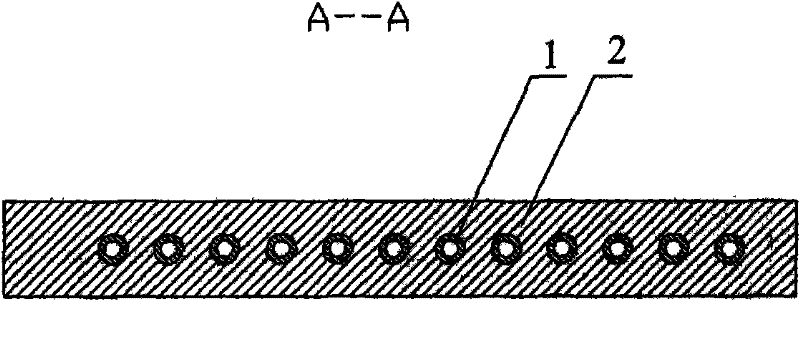

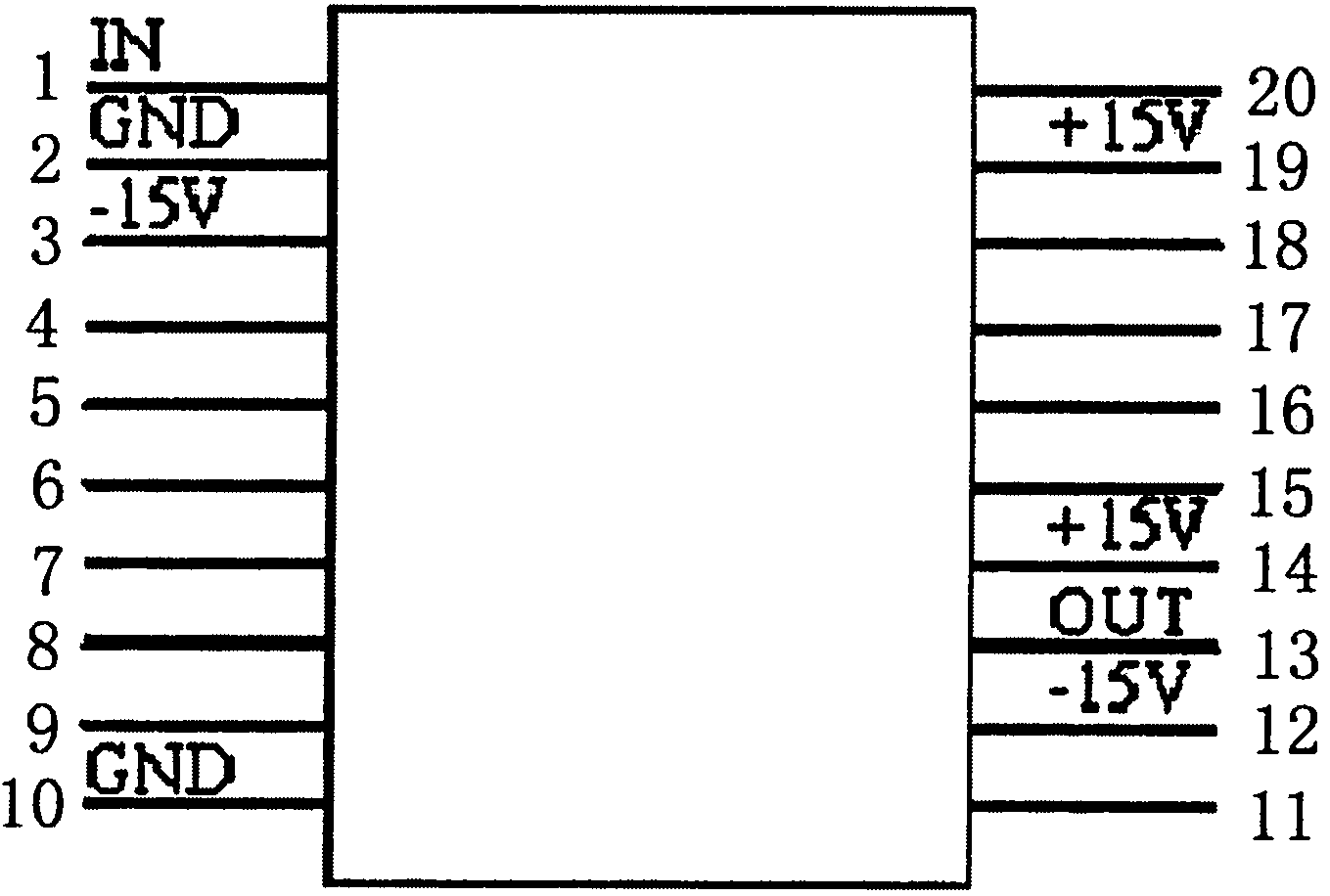

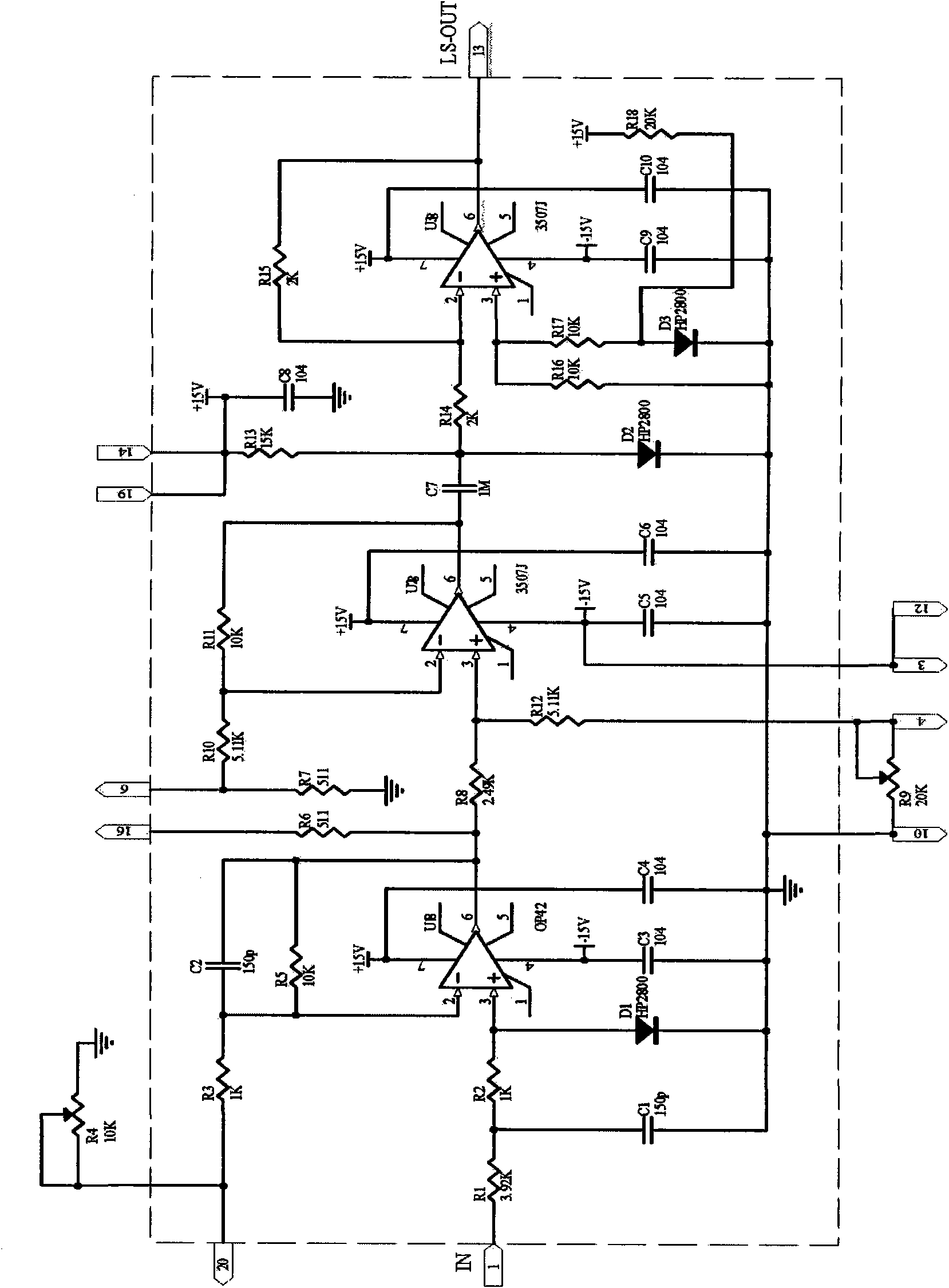

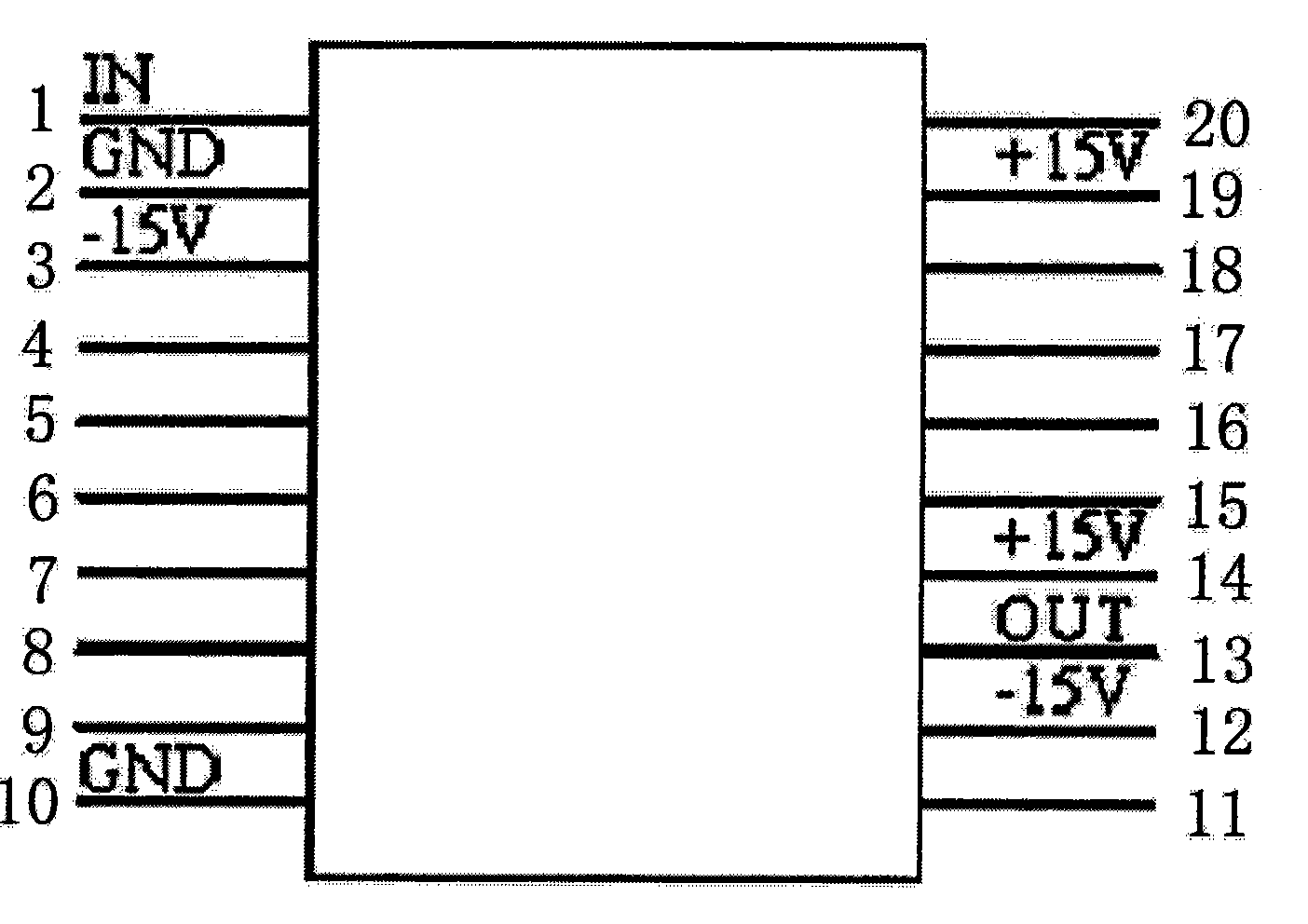

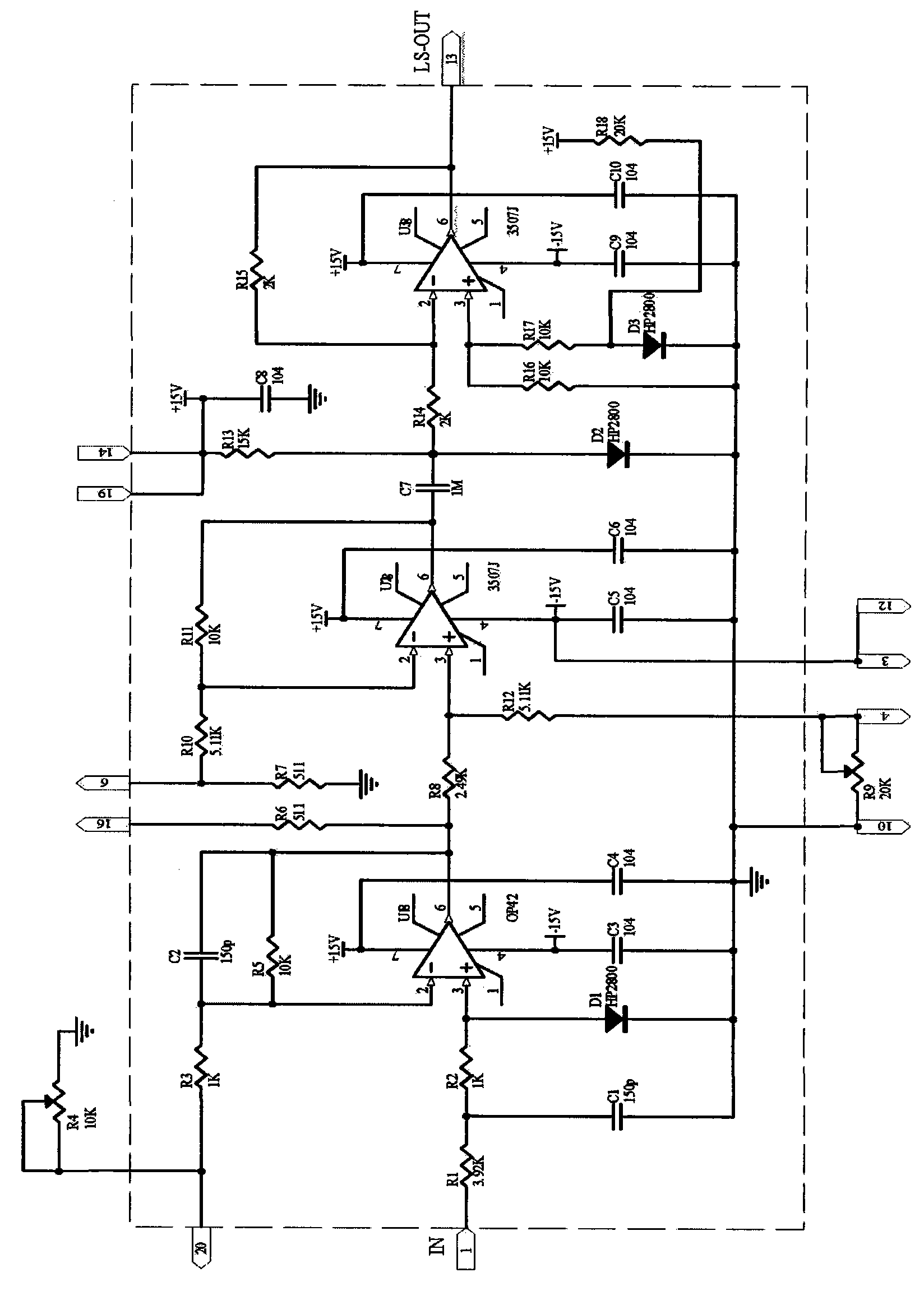

Lithologic density long-spacing data acquisition and processing thick film circuit

InactiveCN102042007ASmall temperature driftEasy maintenanceBorehole/well accessoriesElectrical resistance and conductanceLong spacing

The invention relates to a long-spacing signal processing thick film circuit. Most of long-spacing signal processing circuits used at present comprise discrete components, and when a set of components are damaged, the maintenance is always comparatively difficult. The long-spacing signal processing thick film circuit is a rectangular thick film block and comprises 20 acicular pins, which are arrayed in two rows at both sides of the thick film circuit, and a built-in long-spacing signal processing circuit, wherein a long-spacing signal input end is the pin 1 of a thick film; one end of a variable resistor R4 is grounded, and the other end of the variable resistor R4 is connected with the pin 20 of the thick film, together with a sliding end; one end of a variable resistor R9 is connected with the pin 4 of the thick film, together with the sliding end, and the other end of the variable resistor R9 is connected with a pin 10; the pins 14 and 19 of the thick film are connected with a +15V power supply; the pins 3 and 12 of the thick film are connected with a -15V power supply; and the pin 13 of the thick film is the OUT output end of a long spacing signal. The packaged thick film circuit disclosed by the invention has relatively low temperature drift, is easy to maintain and is more suitable for debugging the signal in the actual use.

Owner:XIAN WELL LOGGING ENERGY TECH

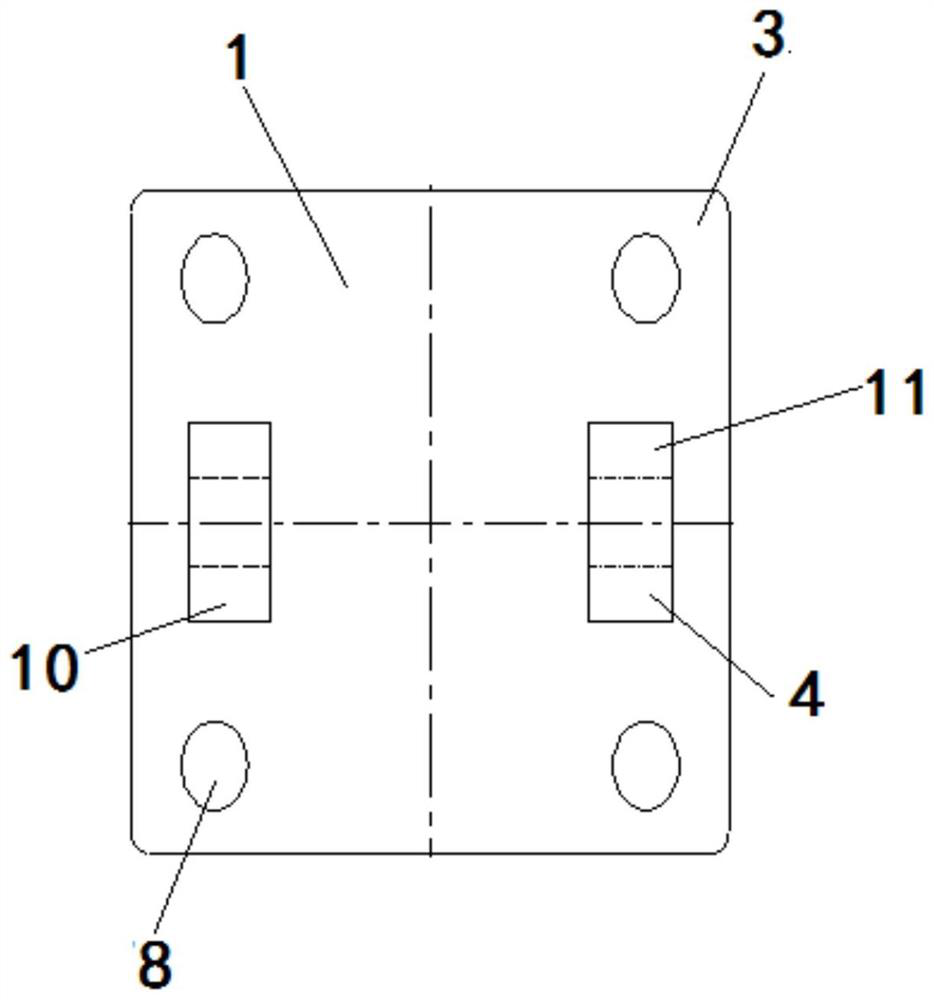

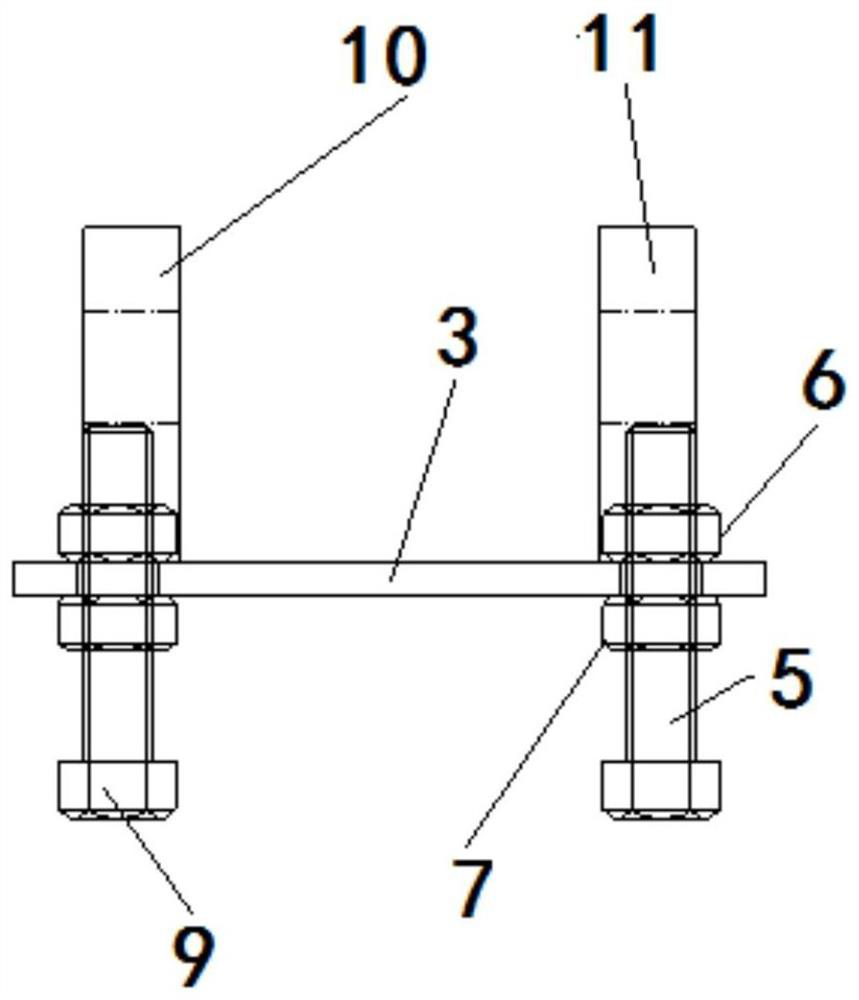

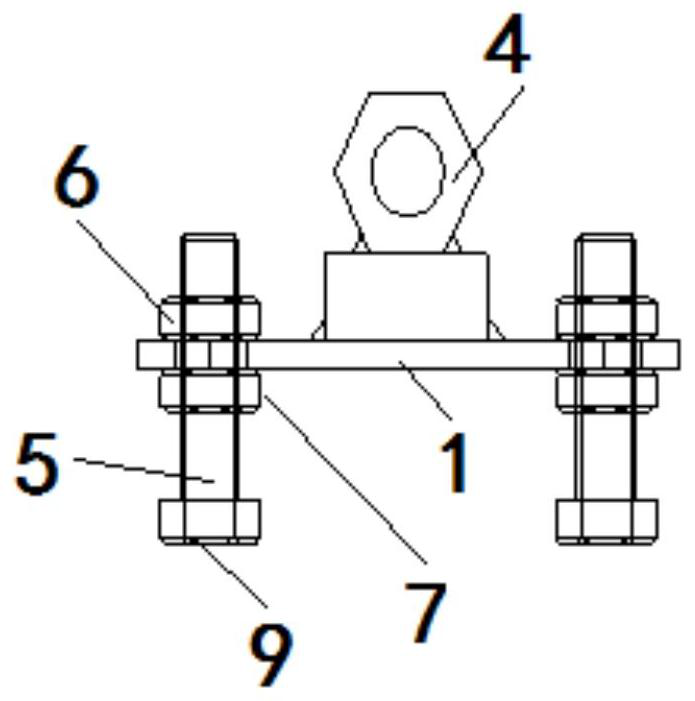

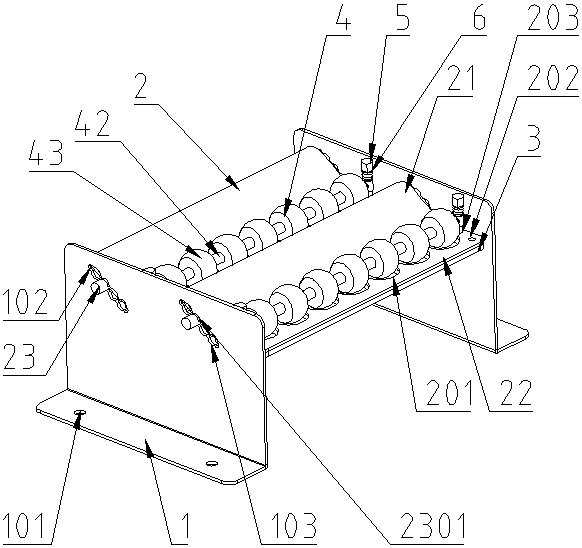

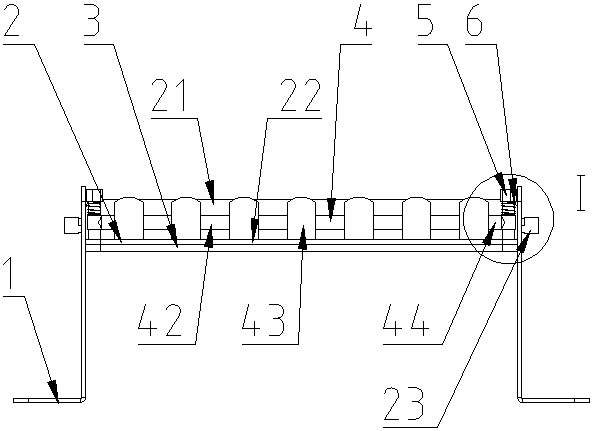

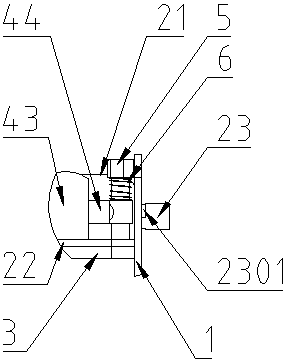

A long-distance hinge seat positioning welding tool and its positioning welding method

ActiveCN112372205BSimple structureEasy to manufactureWelding/cutting auxillary devicesAuxillary welding devicesLong spacingStructural engineering

The invention provides a long-spacing hinge seat positioning welding tool used in the technical field of workpiece / box hinge seats. The present invention also relates to a long-spacing hinge seat positioning welding method. Each of the long-spacing hinge seat positioning welding tooling has The positioning assemblies (1) respectively include a base (3), an ear plate (4), an adjustment bolt (5), an adjustment nut I (6), and an adjustment nut II (7). The base (3) is provided with a plurality of adjustment holes ( 8), an adjusting bolt (5) passes through each adjusting hole (8), the adjusting nut I (6) is screwed on the adjusting bolt (5) above the base (3), and the adjusting nut II (7) is screwed on On the adjusting bolt (5) under the base (3), the above-mentioned tooling and method can conveniently and quickly realize the positioning welding of multiple hinge seats. During positioning welding, the positioning size and the coaxiality requirements of each hinge can be effectively guaranteed, which can be used in subsequent products. The hinge arm no longer deforms or flips stuck when the hinge is flipped.

Owner:WUHU SHIPYARD CO LTD

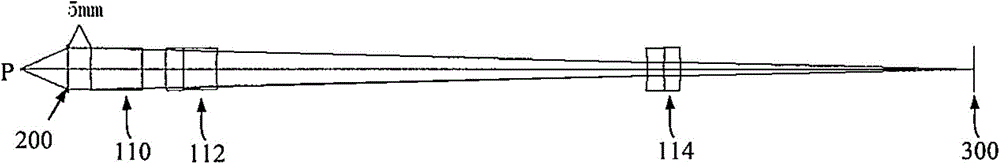

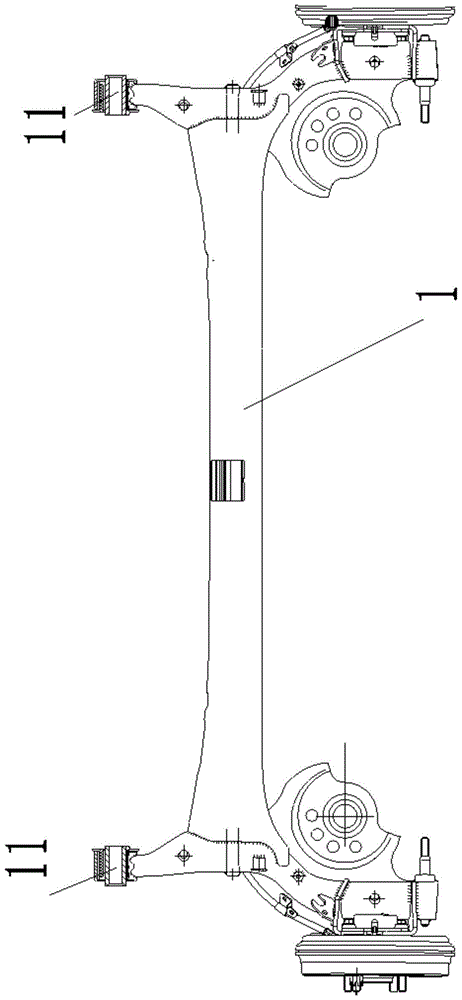

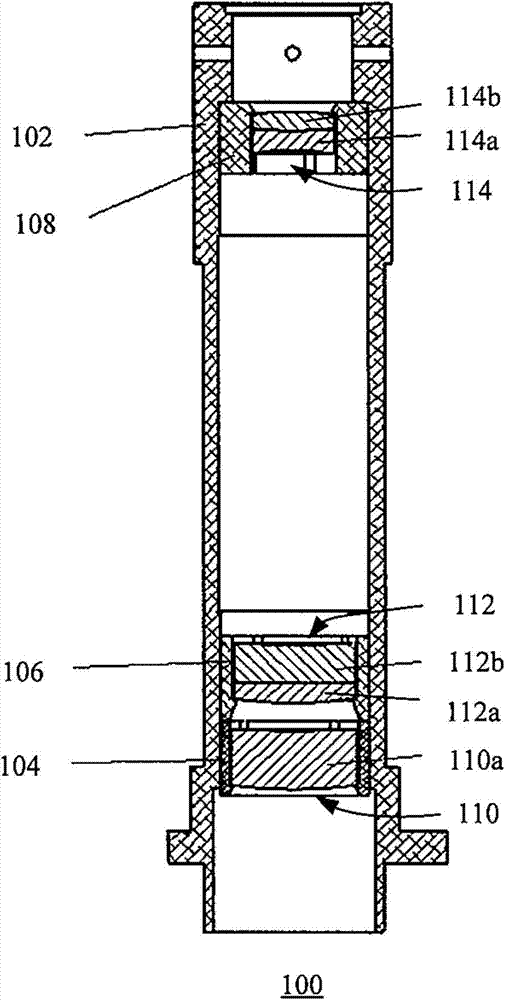

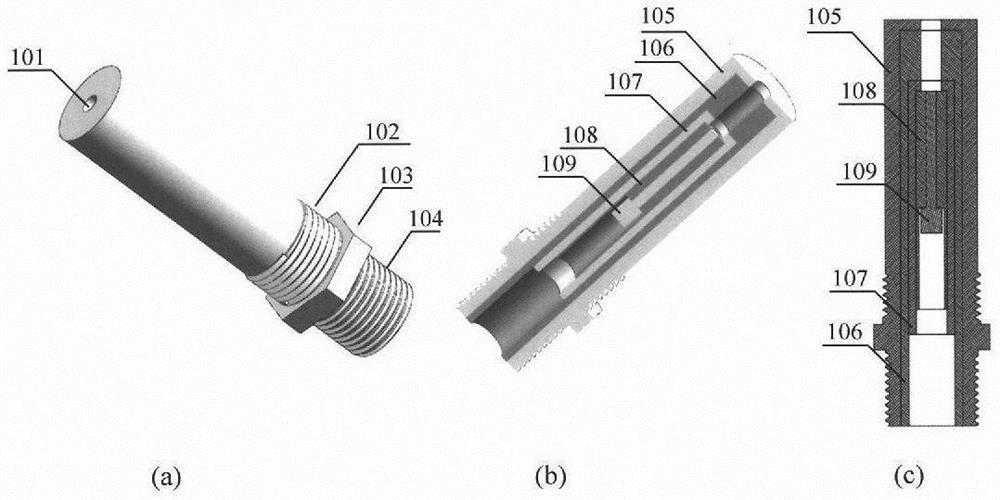

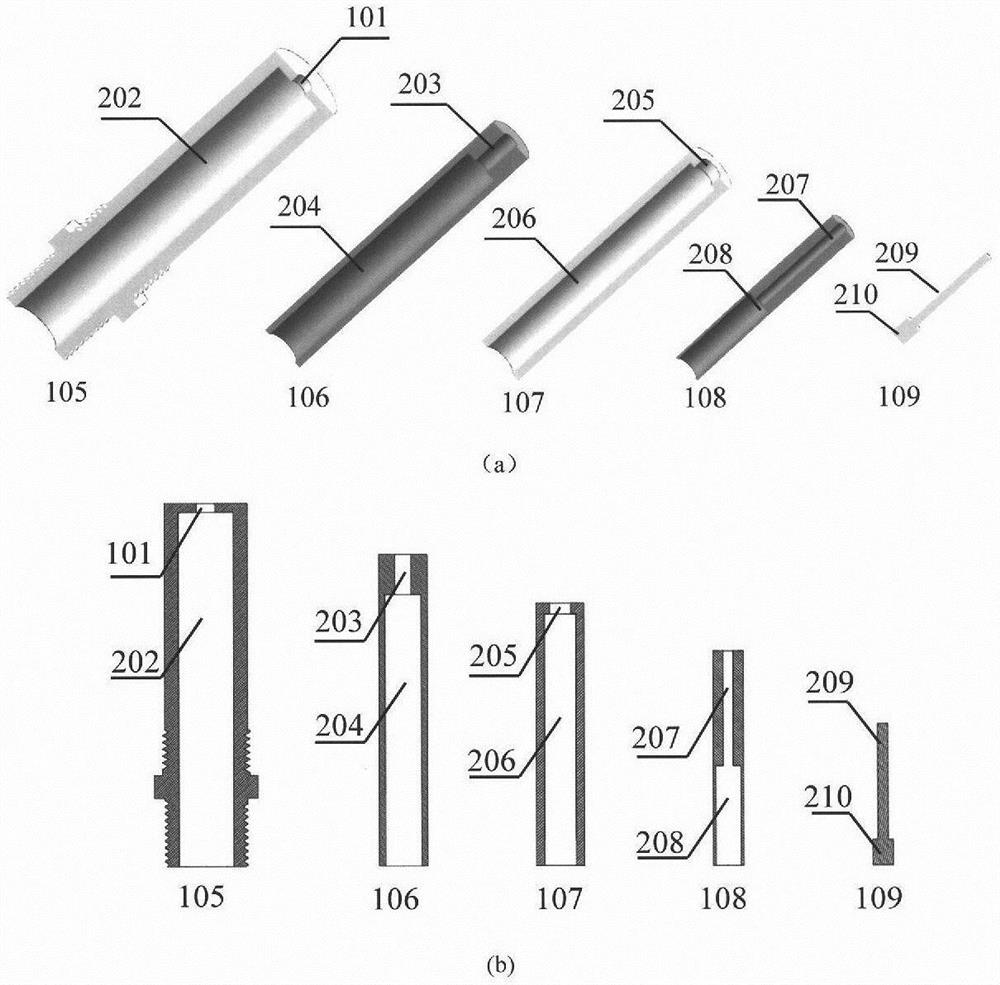

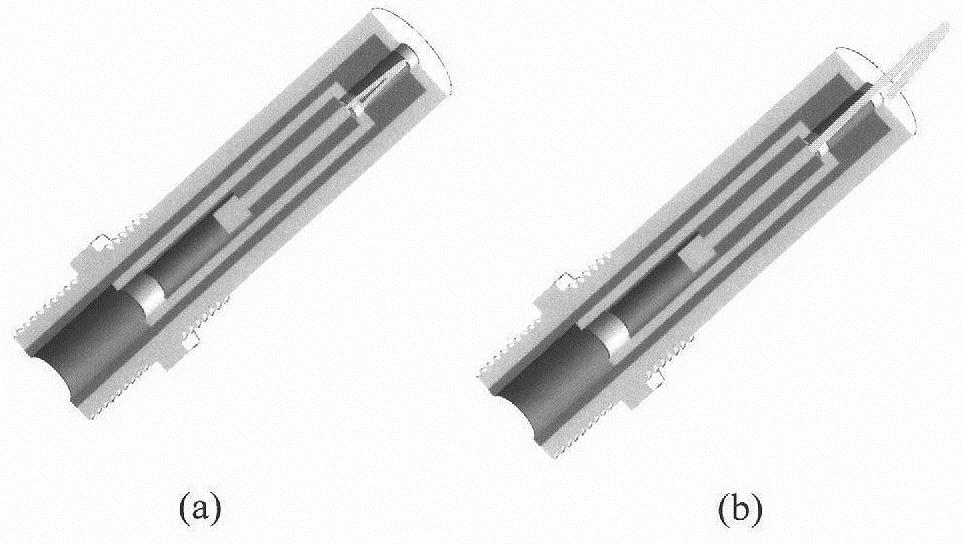

A long-distance high-energy plasma igniter with jet arc ignition

ActiveCN112443401BImprove discharge efficiencyExtended discharge distanceGas turbine plantsJet propulsion plantsPlasma jetLong spacing

A jet arc ignition type long-distance high-energy plasma igniter, which is composed of an anode 109, an inner layer insulator 108, an intermediate arc ignition electrode 107, an outer layer insulator 106, and a cathode 105; these parts are nested and installed from inside to outside in sequence : the anode 109 is embedded in the inner insulating member 108 as a whole and embedded in the middle arc electrode 107; these three parts are embedded in the inner insulating member 106 as a whole, and the above four parts are embedded in the cathode 105 to form the overall structure of the igniter. The plasma jet propagates outward through the designed jet holes, and finally contacts with the external cathode, so that the air between the external cathode 105 and the anode 107 breaks down and conducts, forming a large-space discharge, thereby increasing the discharge distance and improving energy utilization, which can solve the problem of At present, the electric spark igniter has the problems of small spacing and low efficiency, and cannot meet the demand for large energy discharge.

Owner:AIR FORCE UNIV PLA

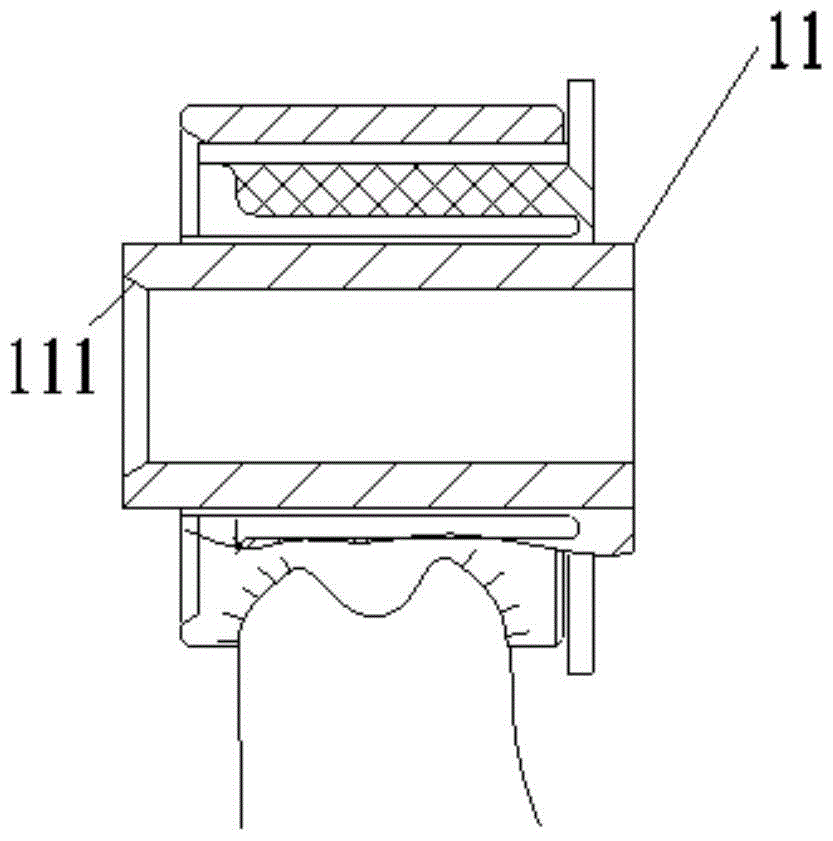

Intelligent disc-loading seeder hole pressing device

PendingCN108575199AImprove versatilityExtended service lifePlantingCultivating equipmentsSeederLong spacing

The invention discloses an intelligent disc-loading seeder hole pressing device. The device comprises frame bodies, soil scraping plates, friction plates and pressing shaft assemblies. Two mounting holes are formed in the horizontal plane of each frame body, two oblique fixing slot holes are formed in the vertical surface of each frame body, the soil scraping plates are arranged in the fixing slotholes and comprise oblique surfaces, horizontal surfaces and fixing shafts, the fixing shafts are fixedly disposed on the two sides of the middle of each oblique surface, multiple circular holes areuniformly formed in the middle of each horizontal surface, and connecting holes are formed in the periphery of each horizontal surface; threaded bottom holes are formed in the centers of the front andrear portions of each horizontal surface respectively, the friction plates are arranged on the lower portions of the soil scraping plates, sliding columns are fixedly arranged in the threaded bottomholes and provided with pressing shaft devices and compression springs from bottom to top in sequence, the pressing shaft devices comprise pressing shafts, long spacing sleeves, hole pressing balls and short spacing sleeves, and the positions of the hole pressing balls correspond to those of the circular holes. The intelligent disc-loading seeder hole pressing device has the advantages of high versatility and a long service life.

Owner:XUCHANG TONGXING MODERN AGRI SCI & TECH

Lithologic density long-spacing data acquisition and processing thick film circuit

InactiveCN102042007BSmall temperature driftEasy maintenanceBorehole/well accessoriesLong spacingSignal processing circuits

Owner:XIAN WELL LOGGING ENERGY TECH

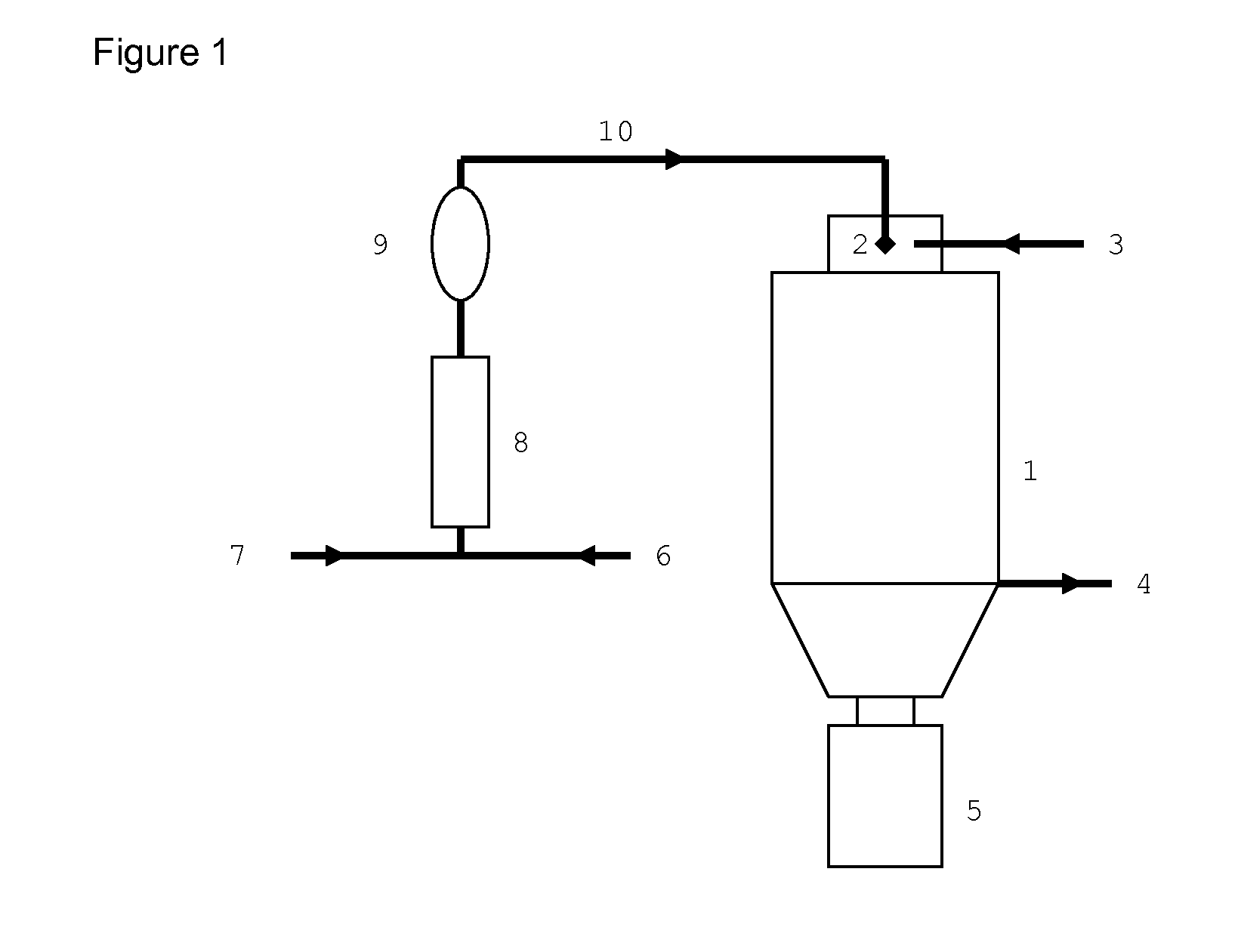

Bean vermicelli drying device

The invention discloses a bean vermicelli drying device, and relates to a bean vermicelli drying device which comprises a box body, a heater, a fan, a mobile bean vermicelli placing trolley, a long spacing guide rail and a steam pipe, wherein the fan is installed on a support at the top of the box body; the long spacing guide rail is installed on the bottom surface of the box body; the heater is an electric heater, and is installed on the support in the box body; the support is also provided with a temperature controller. The bean vermicelli drying device provided by the invention has the advantages of scientific and reasonable structure, appropriate configuration of internal elements, uniformity in bean vermicelli drying, good quality and high efficiency.

Owner:湖南康洁食品科技发展有限公司

A method for obtaining long spatial reverberation time based on image source method

Owner:HARBIN INST OF TECH

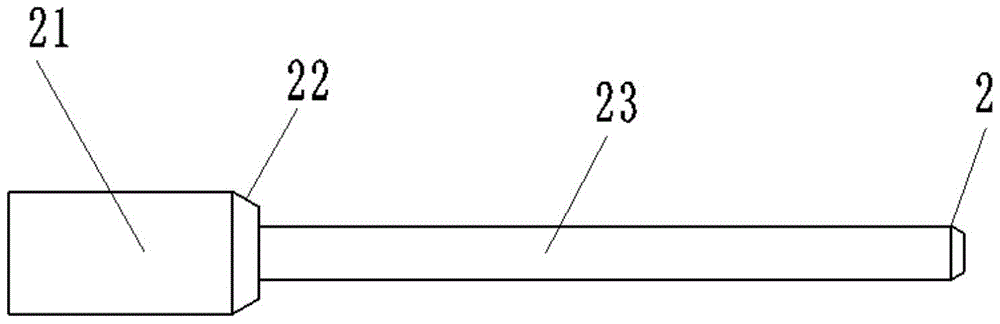

Unloading belt pulley transmission mechanism used for multi-line cutting machine

InactiveCN102678770AImprove running stabilityHigh running precisionCouplings for rigid shaftsLong spacingEngineering

The invention discloses an unloading belt pulley transmission mechanism used for a multi-line cutting machine. The unloading belt pulley transmission mechanism comprises a rack provided with a mandrel, wherein two bearings are arranged on the rack; a belt pulley is supported on the bearing; the bearings consist of a first bearing and a second bearing which are arranged at the two ends of the rack respectively; a long spacing sleeve is arranged between the first bearing and the second bearing; the axial end face of the first bearing is fastened by a gland; the axial end face of the second bearing is fastened by a shielding cover; the rack and the long spacing sleeve are respectively provided with a lubricating oil channel for lubricating the first bearing and the second bearing; the belt pulley is fixedly connected with the mandrel by a connecting plate; and the mandrel is fixedly connected with the connecting plate by a tension sleeve. The transmission mechanism has the advantages that the stability and the processing precision of the apparatus are enhanced, and meanwhile, the failure rate and the repairing difficulty of the apparatus are reduced.

Owner:SUZHOU HRT ELECTRONICS EQUIP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com