Intelligent disc-loading seeder hole pressing device

A seeder and tray loading technology is applied in the field of seedling raising machinery, which can solve the problems of easily damaged seedling trays, poor universality of the seedling trays, and inability to adapt to the seedling trays, and achieves the effect of increasing the versatility and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

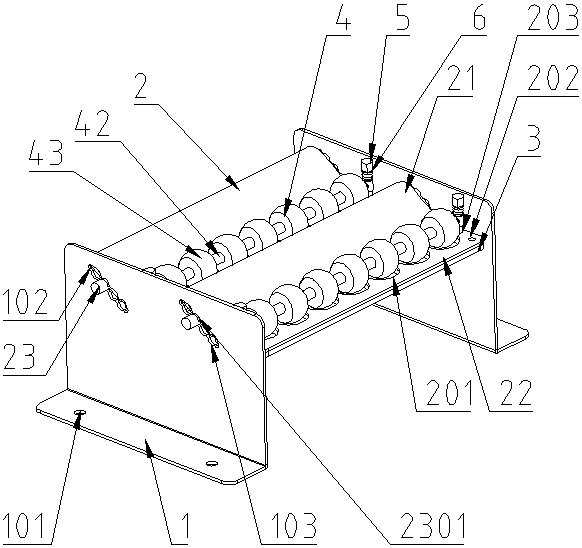

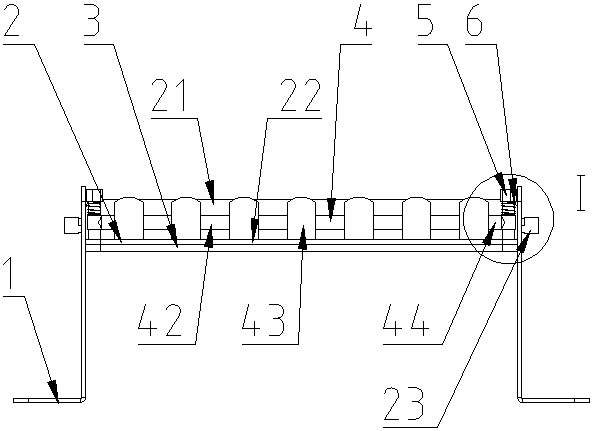

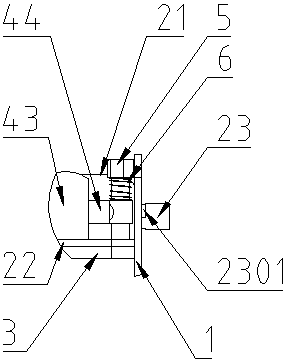

[0020] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

[0021] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a kind of hole-pressing device of an intelligent disc planter includes a frame body 1, a scraper board 2, a friction plate 3 and a final shaft assembly 4, the frame body 1 is a sheet metal structural part, and the frame body 1 is in the shape of " L" type, two installation holes 101 are arranged on the horizontal surface of the frame body 1, and the installation holes 101 are used to fix the present invention on the seedling raising machine, and two inclined holes are arranged on the vertical surface of the frame body 1. The fixed slot 102, the fixed slot 102 is evenly provided with a plurality of circular holes 103, the diameter of the circular hole 103 is larger than the diameter of the fixed slot 102, the fixed slot 102 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com