Boring device for multiple sets of long-spacing coaxial holes

A distance and coaxial technology, used in feeding devices, driving devices, drilling/drilling equipment, etc., can solve the problems of machining accuracy and tolerance of multiple groups of long-distance coaxial holes, and achieve high processing efficiency, stable performance, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

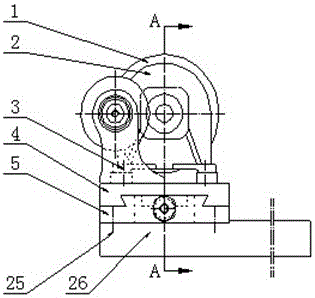

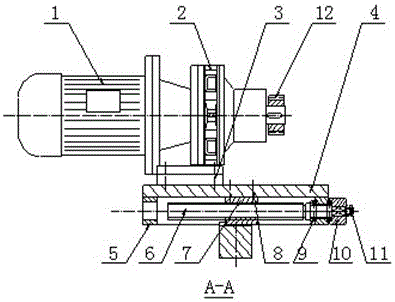

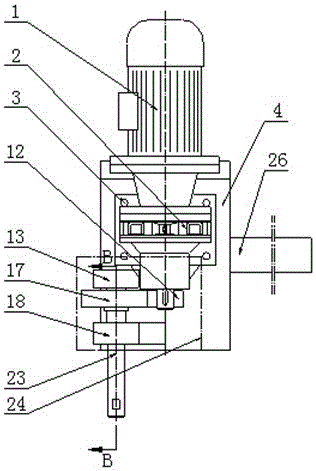

[0014] The multi-group long-distance coaxial boring device of the present invention is mainly composed of a three-phase asynchronous motor 1, a cycloidal pin wheel reducer 2, a moving carriage 4, a fixed carriage 5, a T-shaped screw rod 6, a T-shaped copper nut 7, a shaft Consists of axial thrust bearing 9, longitudinal movement adjustment nut 10, boring bar fixing seat A13, boring bar fixing seat B18, thrust bearing 14, pinion gear 12, large gear 17, radial bearing 19, boring bar 23, boring machine fixing bar 26, etc. . The three-phase asynchronous motor 1 and the cycloid reducer 2 are connected as a whole, and the output shaft has a flat key for connecting the pinion 12. There are four holes on the base of the cycloid reducer 2, through which the bolts A is pressed on the movable pallet 4, the boring bar holder A and the boring bar holder B are welded on the movable pallet 4, the boring bar holder A is equipped with a thrust bearing 14, and the boring bar holder B is equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com