Temperature control grate cast by embedding stainless steel capillary and control method thereof

A technology of capillary and stainless steel, which is applied in the field of stainless steel capillary buried pipe casting temperature control grate and its manufacture, which can solve the problems of blocked pipeline, large flow resistance in the pipe, welding deformation, etc., to ensure the use needs and safety, and overcome the nozzle The effect of reduced inner diameter and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

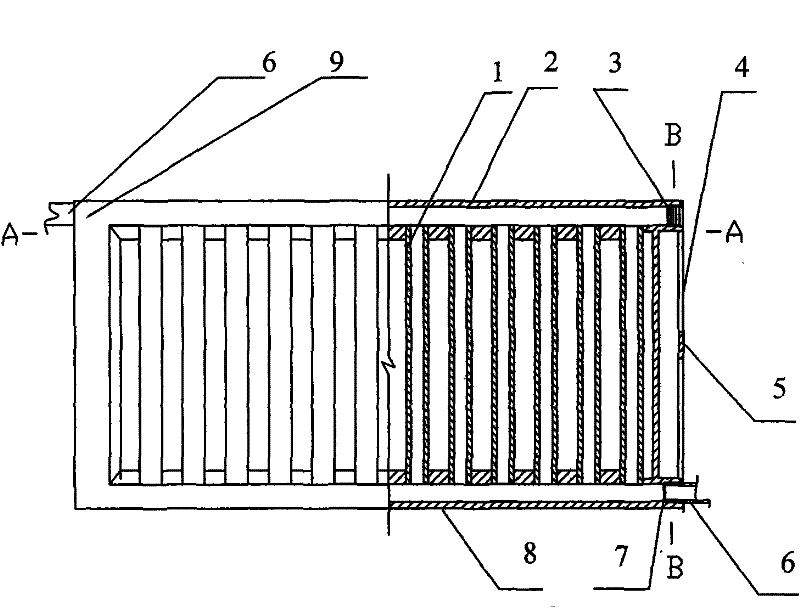

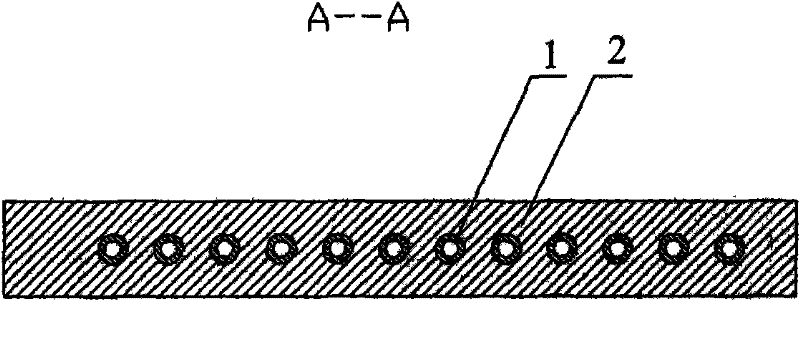

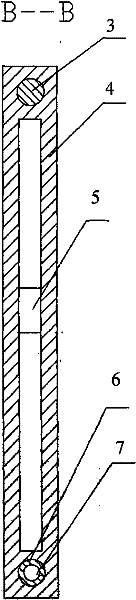

[0039] Such as Figure 1 ~ Figure 3 As shown, the stainless steel capillary buried pipe casting temperature control grate of the present invention has an upper water distribution pipe 2 and a lower water distribution pipe 8, one end of the lower water distribution pipe 8 is a water inlet 7, and the other end is equipped with a plug 3, and one end of the upper water distribution pipe 2 is Water outlet 9, the other end installs plug 3, the water inlet 7 of lower water distribution pipe 8 and the water outlet 9 of upper water distribution pipe 2 are respectively connected with quick-connect fittings 6, and a direct connection between upper water distribution pipe 2 and lower water distribution pipe 8 is provided. Row-type stainless steel capillary tube type grate 1, the two ends of the straight row type stainless steel capillary tube type grate 1 are buried in the tube walls of the upper water distribution pipe 2 and the lower water distribution pipe 8, and are cast and The upper...

Embodiment approach 2

[0041] Such as Figure 4 , Figure 5 As shown, the stainless steel capillary buried pipe casting temperature control grate of the present invention has an upper water distribution pipe 2 and a lower water distribution pipe 8, one end of the lower water distribution pipe 8 is a water inlet 7, and the other end is equipped with a plug 3, and one end of the upper water distribution pipe 2 is The water outlet 9, the other end is equipped with a plug 3, the water inlet 7 of the lower water distribution pipe 8 and the water outlet 9 of the upper water distribution pipe 2 are respectively connected with the quick-connect fittings 6, and a water wave is provided between the upper water distribution pipe 2 and the lower water distribution pipe 8. type stainless steel capillary tube type grate 1, the two ends of the water wave type stainless steel capillary tube type grate 1 are buried in the upper water distribution pipe 2 and the lower water distribution pipe 8 pipe walls and fixed, a...

Embodiment approach 3

[0043] Such as Figure 6 , Figure 7 As shown, the stainless steel capillary buried pipe casting temperature control grate of the present invention has an upper water distribution pipe 2 and a lower water distribution pipe 8, one end of the lower water distribution pipe 8 is a water inlet 7, and the other end is equipped with a plug 3, and one end of the upper water distribution pipe 2 is The water outlet 9, the other end is installed with a plug 3, the water inlet of the lower water distribution pipe 8 and the water outlet of the upper water distribution pipe 2 are respectively connected with the quick-connect fittings 6, and a grid-shaped Stainless steel capillary tubular grate 1, the preparation method of the grid-type stainless steel capillary tubular grate 1 is: first, a stainless steel capillary is bent and formed, and then a plurality of single formed stainless steel capillary is butt-welded in pairs to form Grid type, and then the two ends of the grid-type stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com