A long-distance high-energy plasma igniter with jet arc ignition

A plasma and long-distance technology, applied in the field of plasma, can solve the problems of low efficiency and too small distance between spark plug and nozzle electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

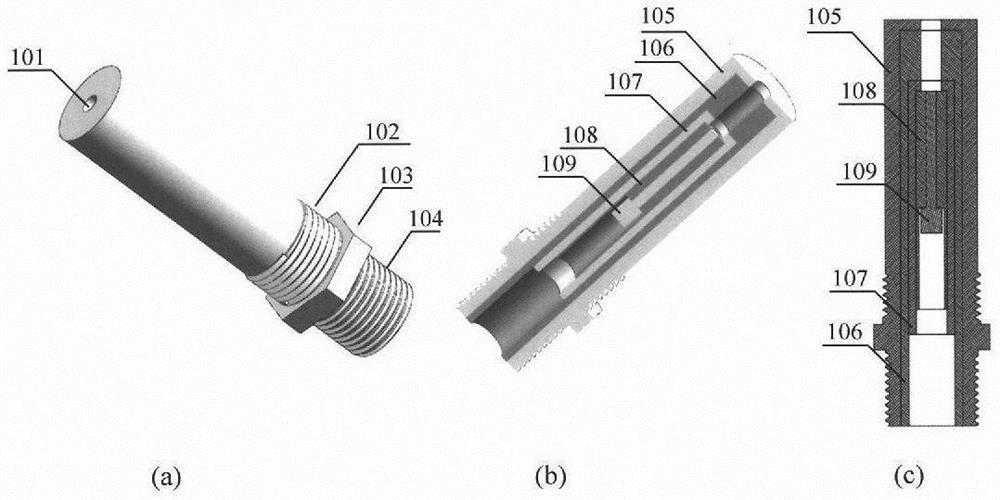

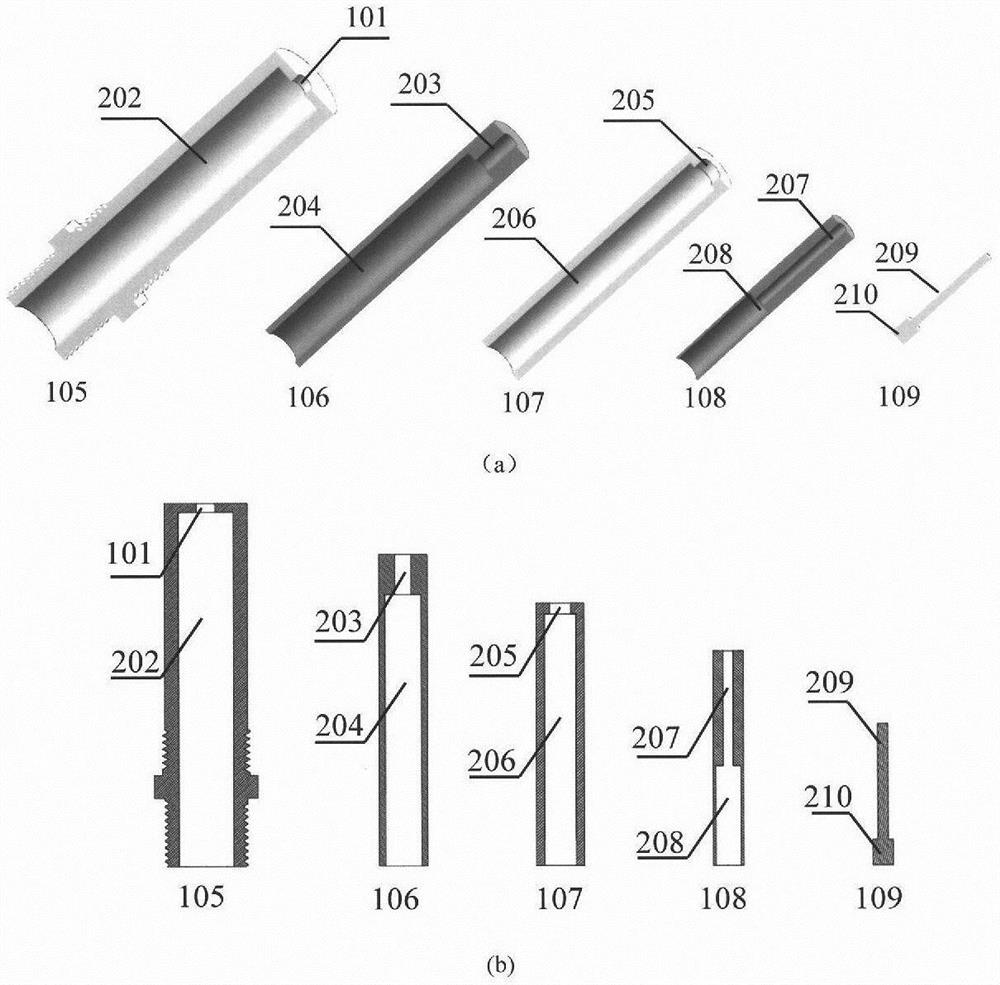

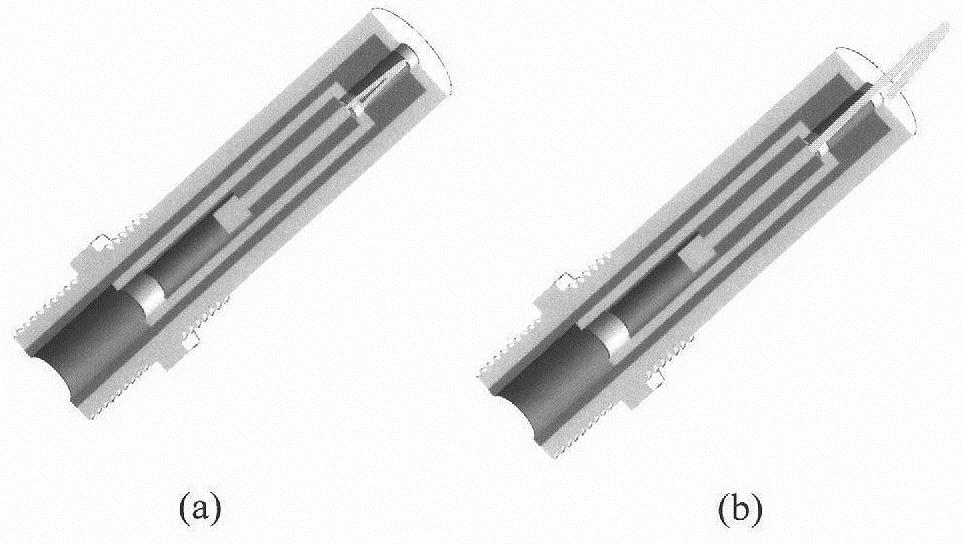

[0036] see Figures 1 to 3 The jet arc-striking long-spacing high-energy plasma igniter of the present invention is mainly composed of an anode 109, an inner insulating member 108, an intermediate arc-striking electrode 107, an outer insulating member 106, and a cathode 105. These components are nested and installed sequentially from the inside to the outside, and finally form the overall structure of the igniter. The cathode 105 is made of nickel-based superalloy, the whole is like a flashlight, the diameter of the head is 16mm, the external processing of the combustion chamber installation thread 102, the ignition cable installation thread 104 and the positioning step 103, the wall thickness is 2mm; the head of the cathode 105 is processed The jet hole 101 has a hole diameter of 4 mm; the cathode 105 has a hollow structure inside, and the inner hole 202 is used to embed other components with a diameter of 12 mm. The size of the mounting thread 102 is M18, and the size of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com