Process and apparatus for the modification of surfaces

A technology for equipment and substrates, applied in mechanical equipment, transportation and packaging, ion implantation and plating, etc., can solve problems such as reduction in mechanical properties, and achieve the effect of preventing crack propagation

Inactive Publication Date: 2009-08-05

CREEPSERVICE R L

View PDF7 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

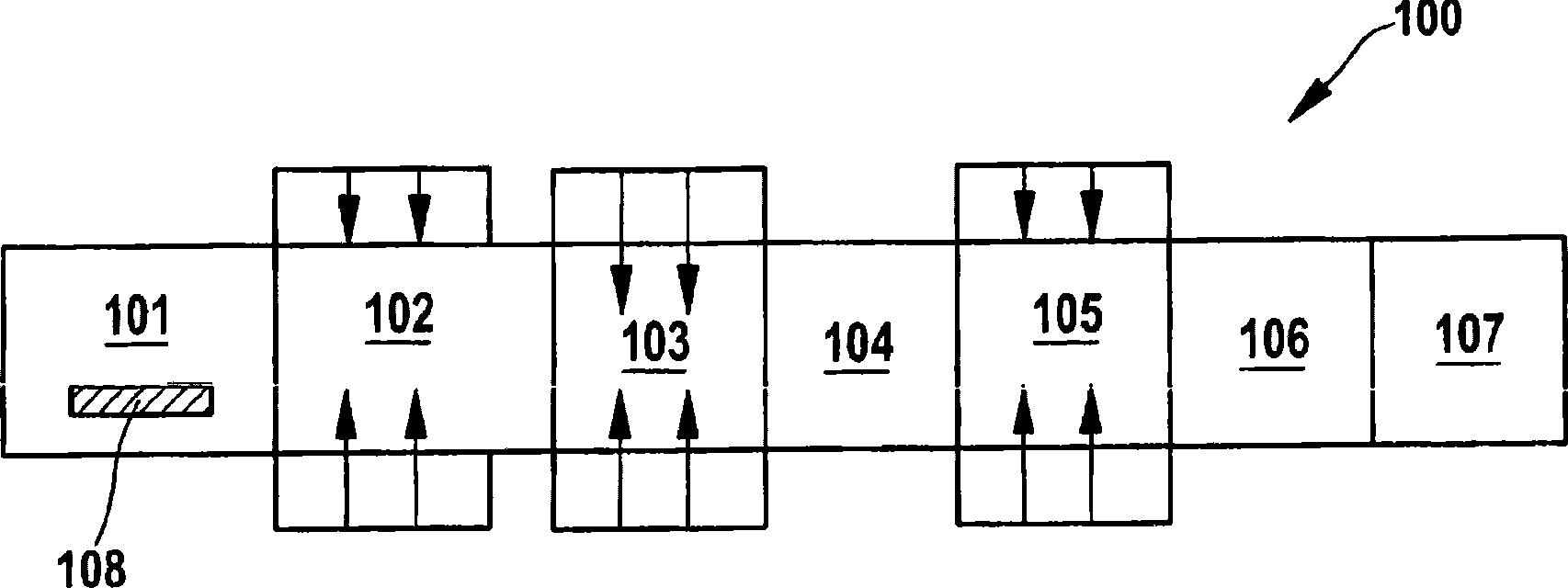

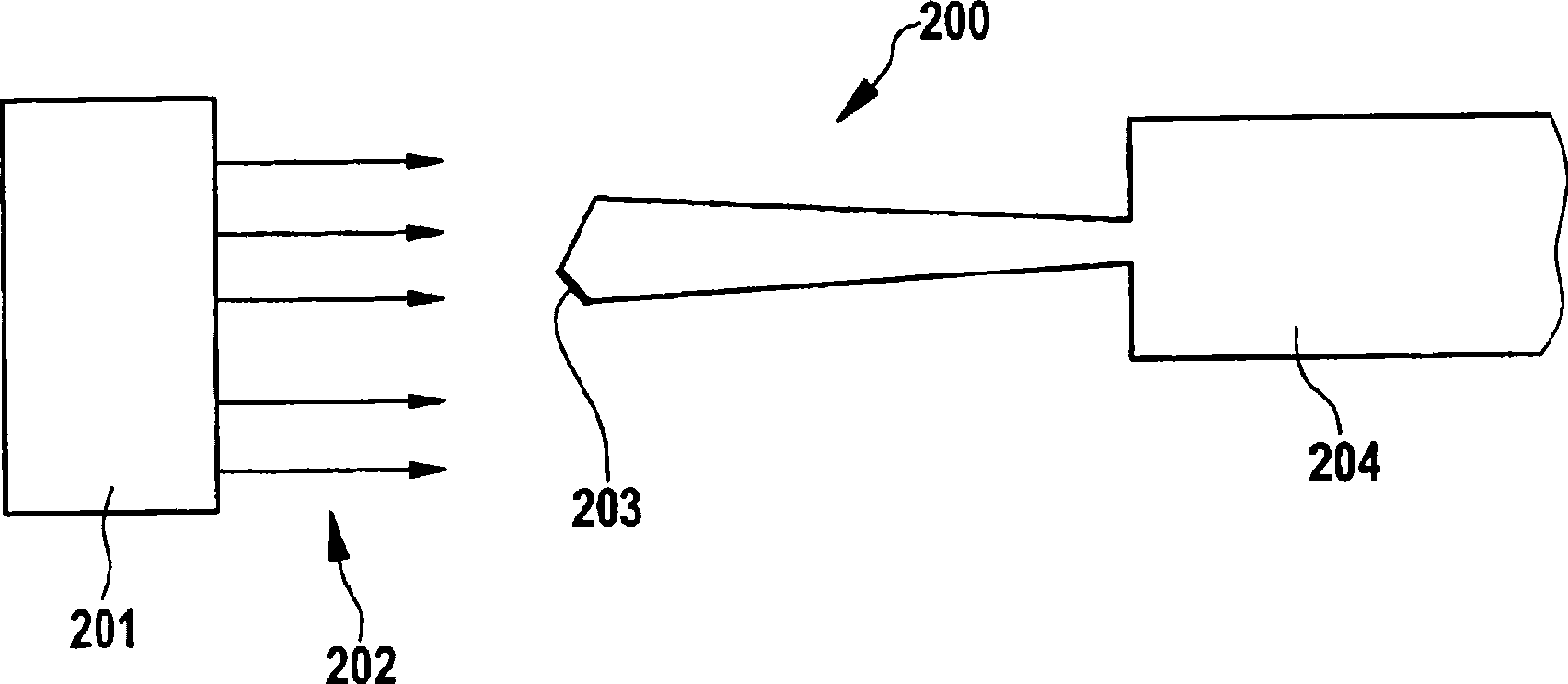

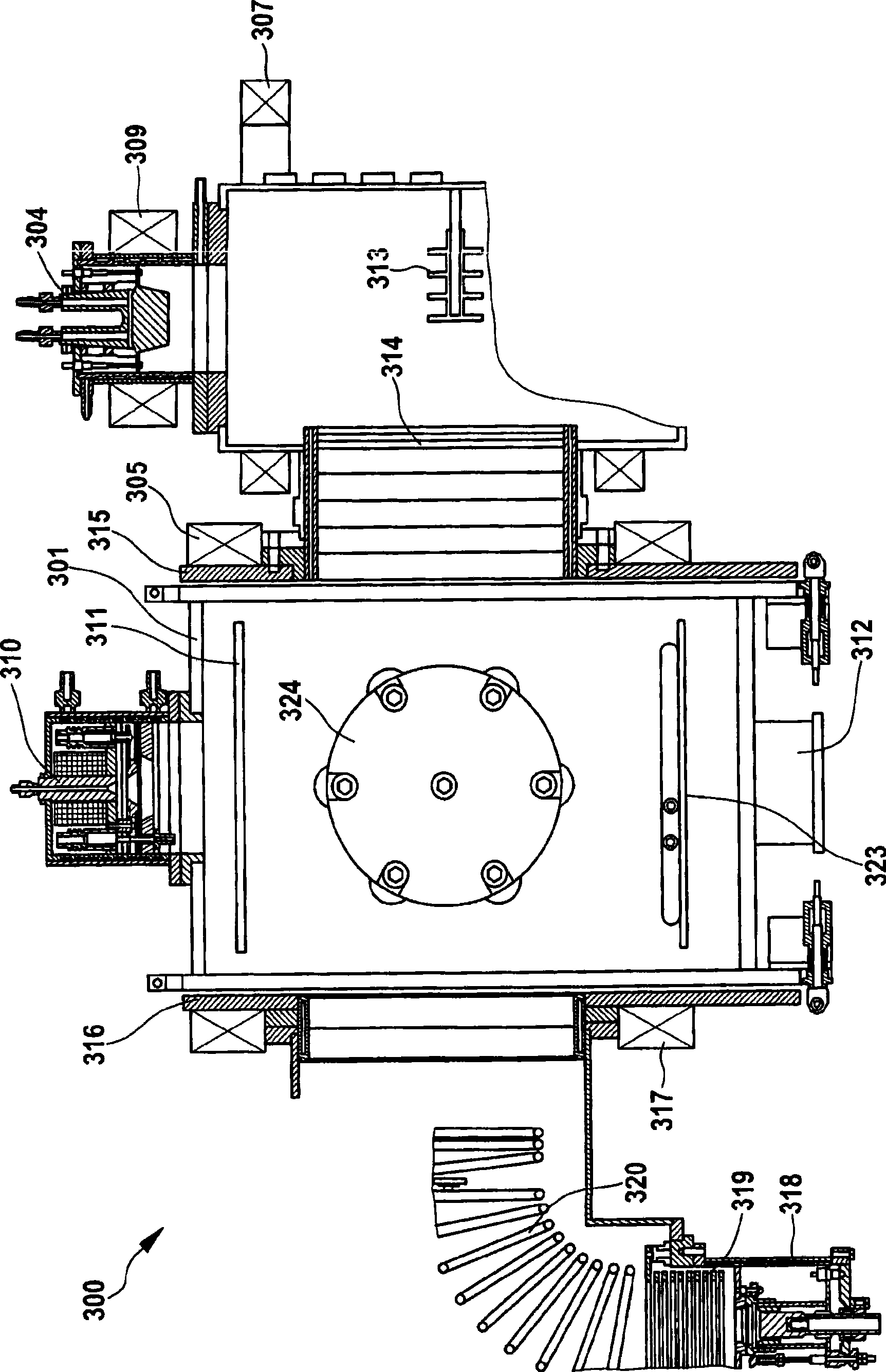

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0117] According to the method of the invention, a drill bit (diameter 0.1 mm) comprising a tungsten carbide-based alloy containing approximately 5% cobalt is coated with a titanium / DLC layer (Ti: 0.1 μm, DLC: 0.6 μm) .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a process for coating a substrate with a wear resistant layer on the basis of carbon comprising the steps of: i) providing a substrate containing a material which has an affinity for carbon, ii) cleaning a surface of the substrate, iii) deposition of a metal containing layer on the surface, iv) ion-bombarding the coated surface, v) deposition of a carbon layer on the surface. Further, the present invention relates to a substrate with a diamond-like carbon coating on the surface of the substrate and an apparatus for carrying out the process according to the invention.

Description

technical field [0001] This invention relates to the application of coatings in a vacuum, and more particularly to devices for generating plasmas of electrically conductive materials. The apparatus is used to practice a method of providing a substrate with a diamond-like carbon coating, wherein the carbon coating improves the hardness, machinability and wear resistance of the substrate. In addition, the present invention also relates to a drilling device for performing processing such as routing, slitting, drilling, etc. on a printed circuit board and for machining of non-ferrous metal materials such as Al, Cu, and the like. Background technique [0002] Coating with diamond-like carbon is well known in the art. [0003] WO 2004 / 083484 A1 describes the possibility of depositing nanocrystalline diamond-like materials on substrate surfaces by means of CVD (Chemical Vapor Deposition) techniques, in particular for obtaining these standard carbon-like materials on the surface of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01J37/32C23C14/22B23B51/02

CPCH01J2237/022C23C14/027C23C14/025B05B1/1609B05B7/0408F16K3/32C23C14/0605F16K3/085H01J37/32055E03C1/0409Y10T428/24752C23C16/27H01J37/32

Inventor 安娜·安德烈亚娜·希利克阿列克谢·赛尔吉耶维奇·米哈伊洛夫赛尔古耶·米哈伊洛夫

Owner CREEPSERVICE R L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com