Patents

Literature

124 results about "Nanocrystalline diamond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boron-doped nanocrystalline diamond

InactiveUS20050110024A1Simple methodDiamondSemiconductor/solid-state device manufacturingCharge carrierRedox

A conductive boron doped nanocrystalline diamond is described. The boron doped diamond has a conductivity which uses the boron in the crystals as a charge carrier. The diamond is particularly useful for electrochemical electrodes in oxidation-reduction reactions and decontamination of aqueous solutions.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

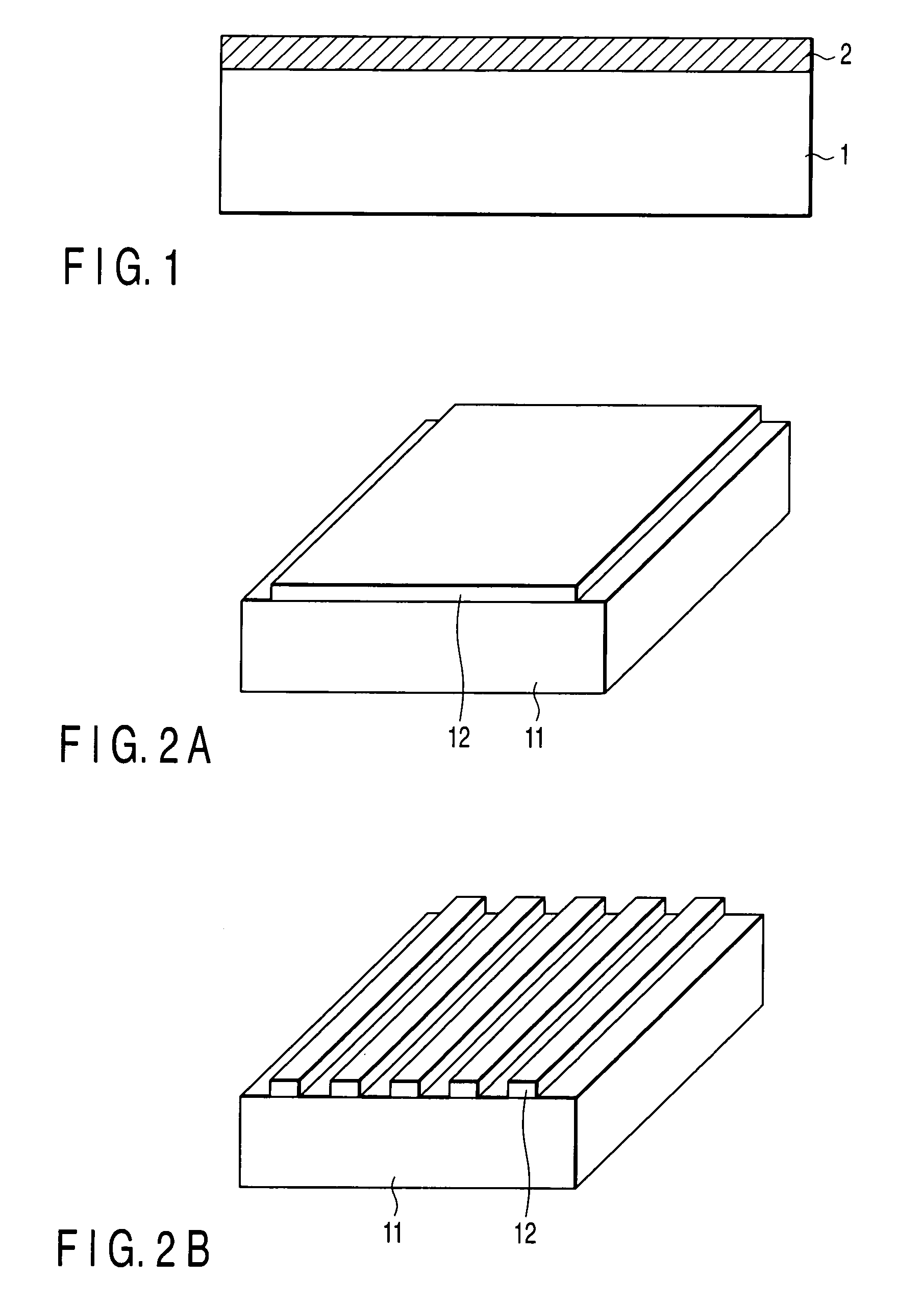

Nano-crystal diamond film, manufacturing method thereof, and device using nano-crystal diamond film

A nano-crystal diamond film synthesized on a substrate and containing, as a major component, nano-crystal diamond having a grain diameter from 1 nm to less than 1000 nm. This nano-crystal diamond film can be formed on a substrate by means of a plasma CVD method using a raw material gas containing a hydrocarbon and hydrogen, allowing the formation of the nano-crystal diamond film to take place outside the plasma region. This nano-crystal diamond film is applicable to the manufacture of an electrochemical device, an electrochemical electrode, a DNA chip, an organic electroluminescent device, an organic photoelectric receiving device, an organic thin film transistor, a cold electron-emission device, a fuel cell and a catalyst.

Owner:TOPPAN PRINTING CO LTD +1

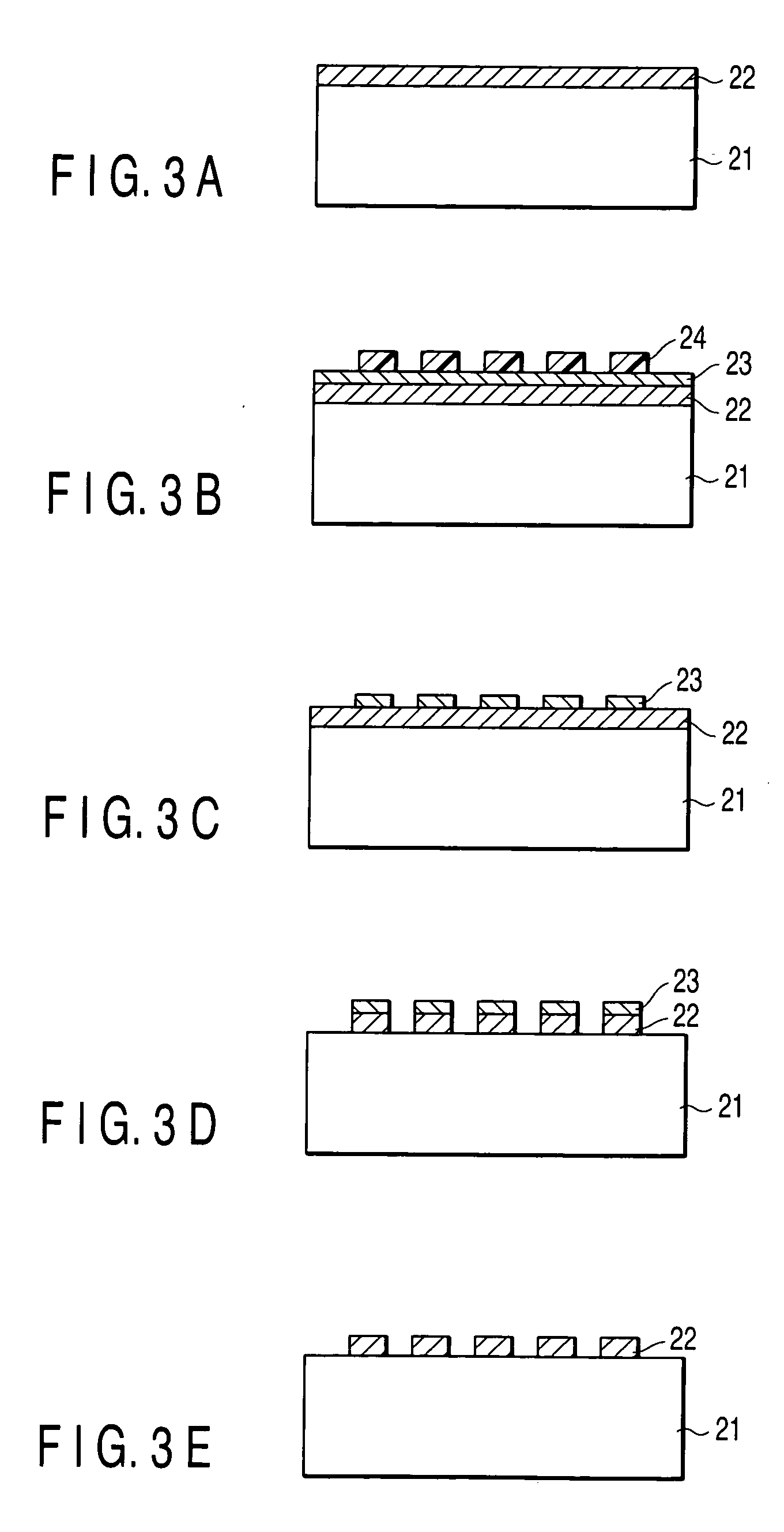

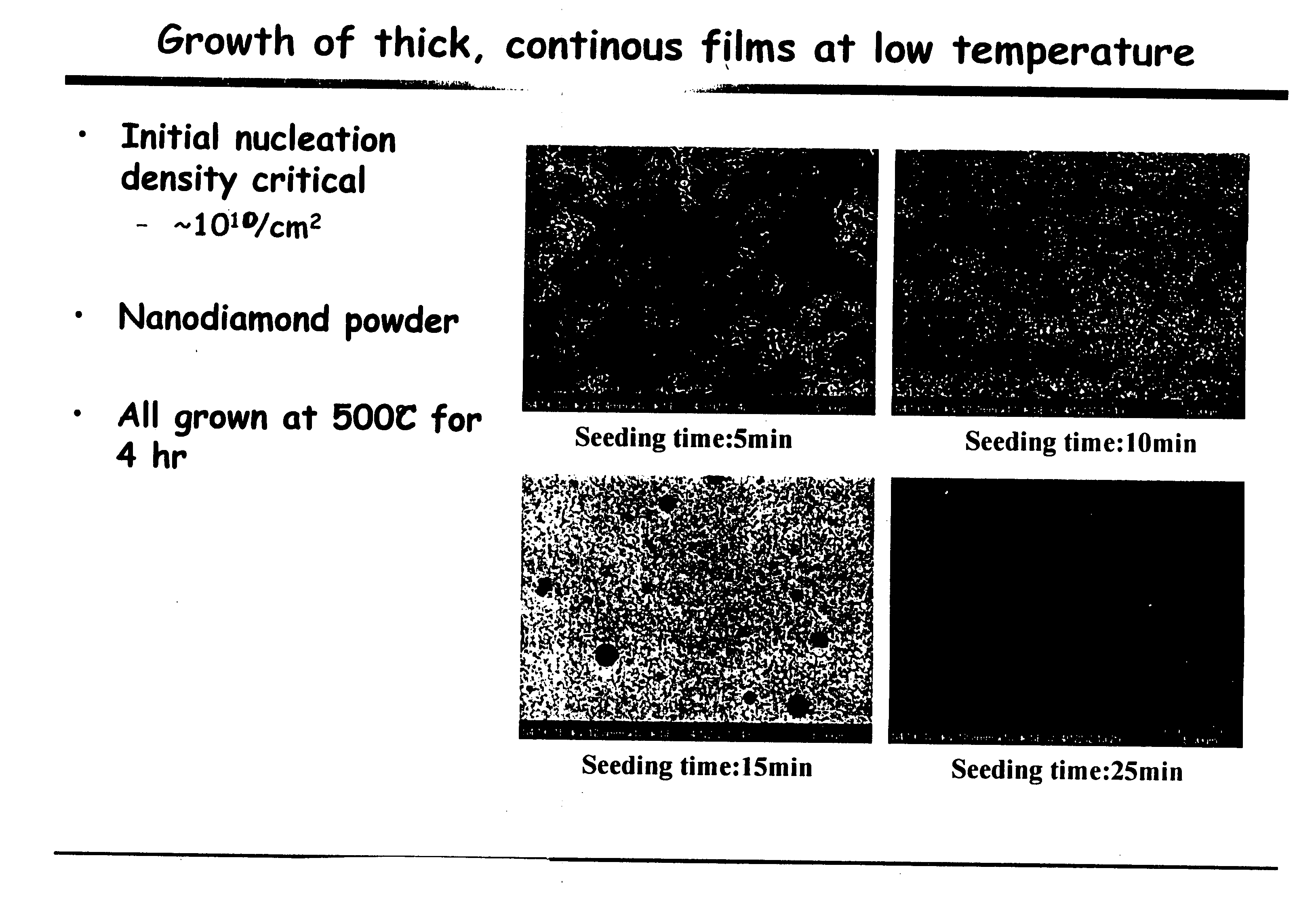

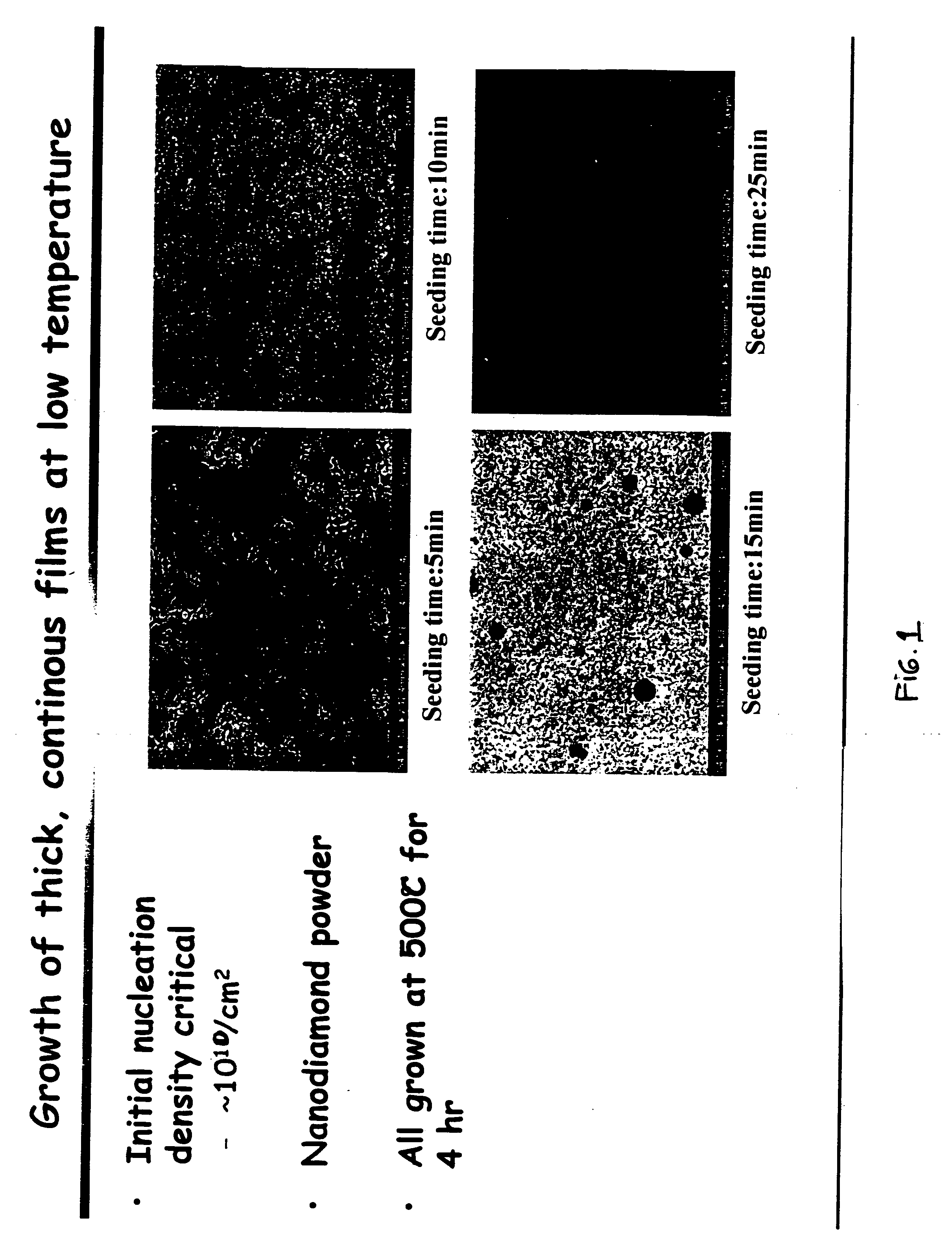

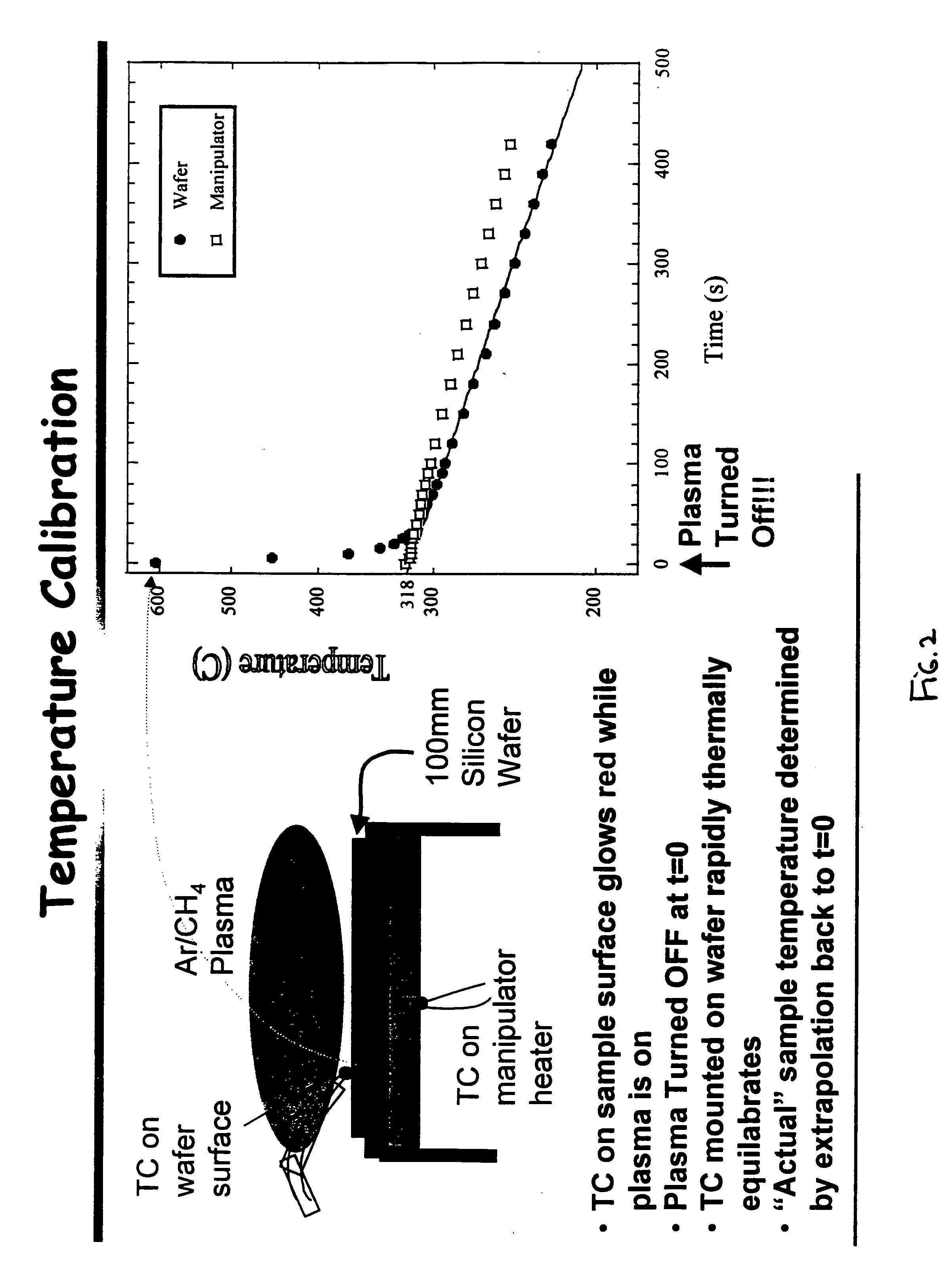

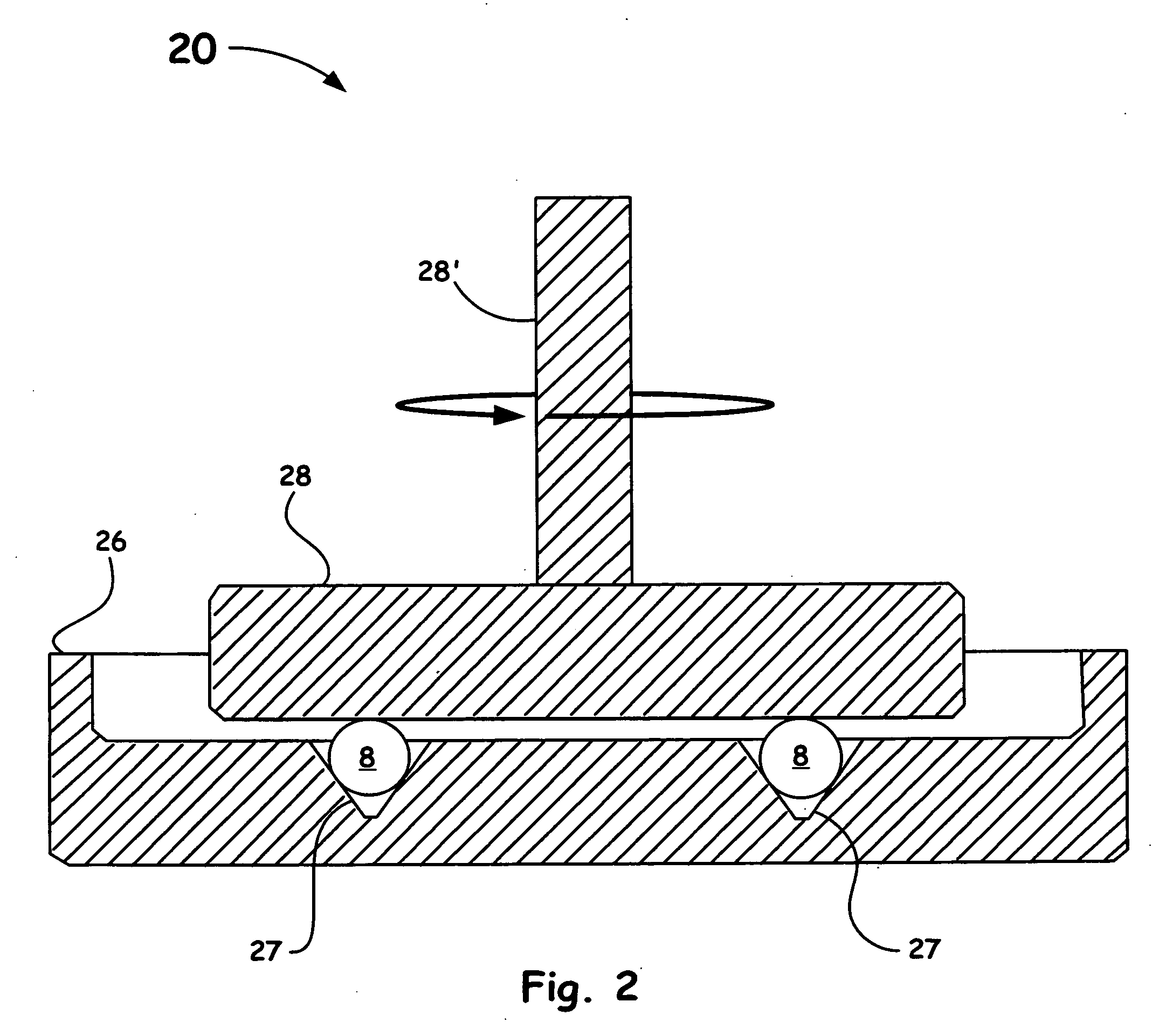

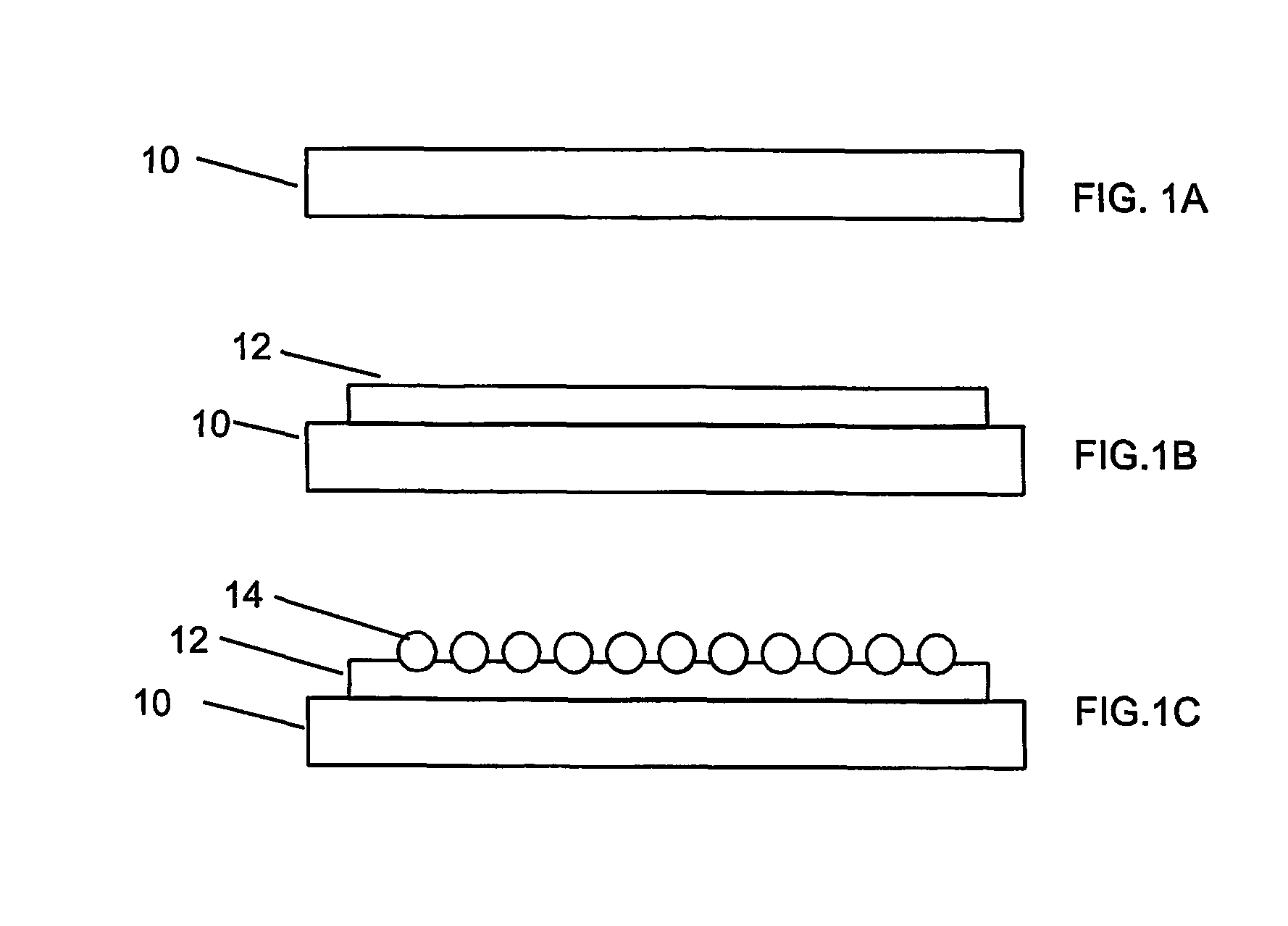

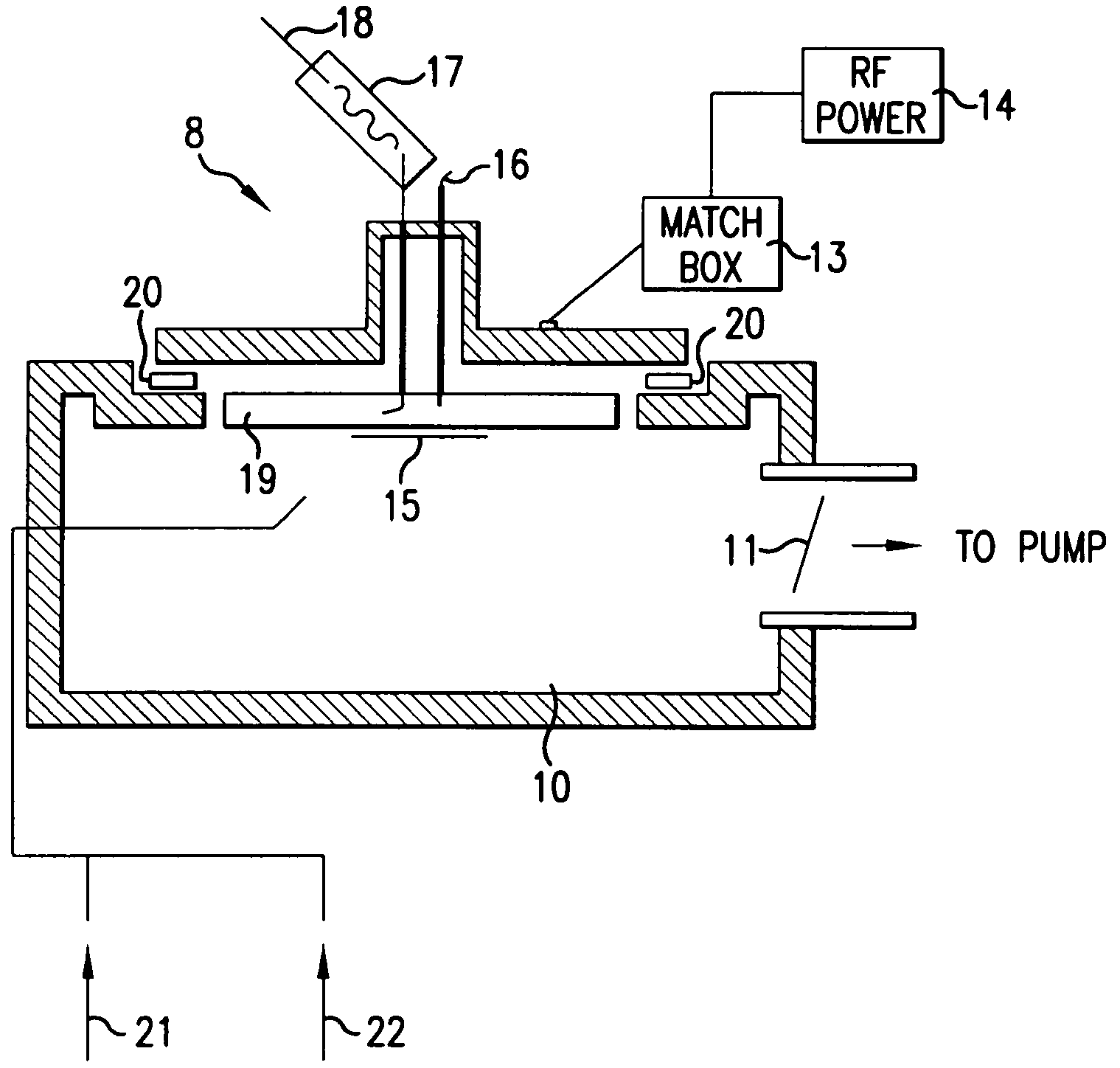

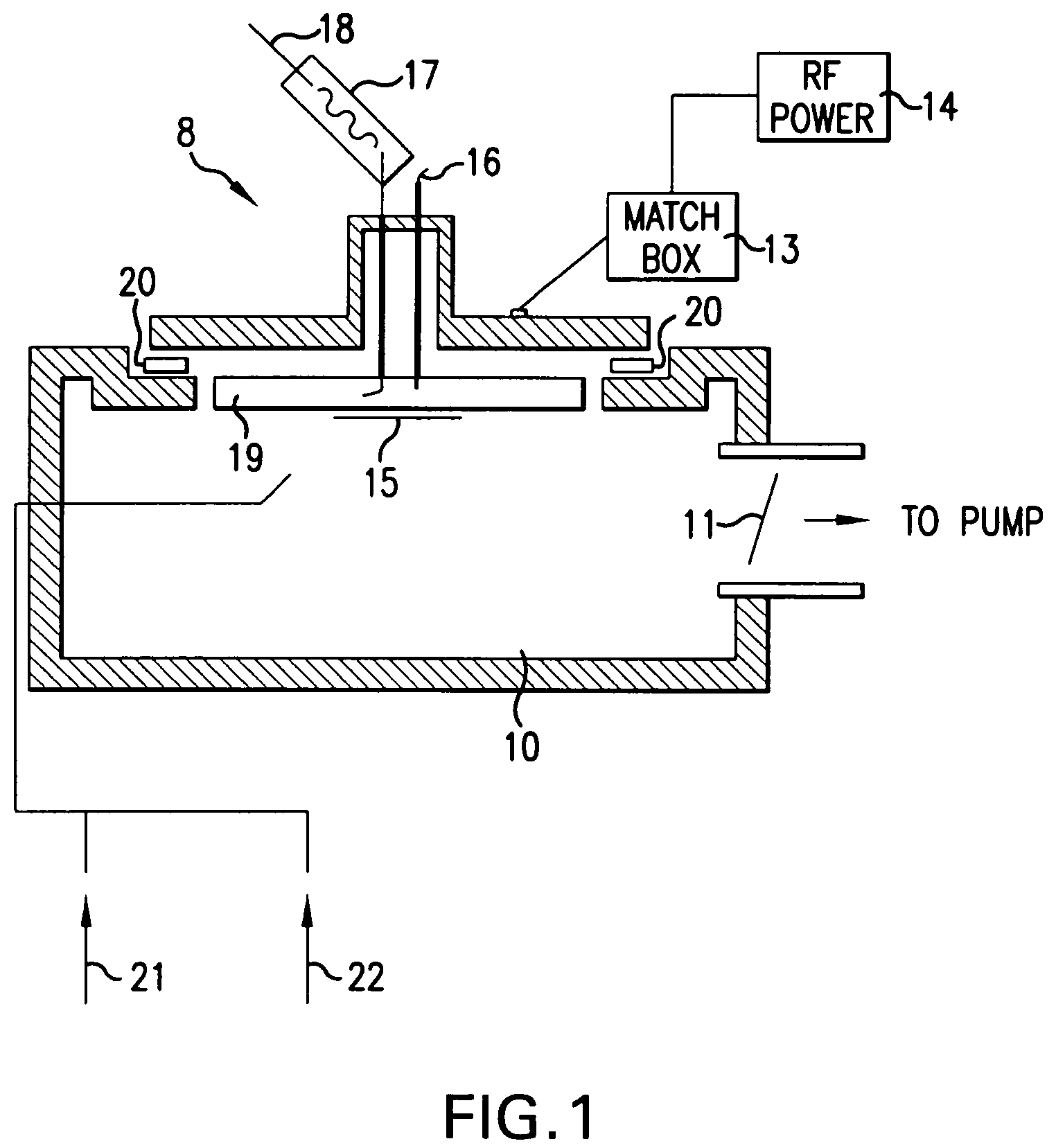

Method to grow pure nanocrystalline diamond films at low temperatures and high deposition rates

ActiveUS20050031785A1Increase deposition rateEnhanced vapor depositionLayered productsSemiconductor/solid-state device manufacturingMetallurgyVolumetric Mass Density

A method of depositing nanocrystalline diamond film on a substrate at a rate of not less than about 0.2 microns / hour at a substrate temperature less than about 500° C. The method includes seeding the substrate surface with nanocrystalline diamond powder to an areal density of not less than about 1010sites / cm2, and contacting the seeded substrate surface with a gas of about 99% by volume of an inert gas other than helium and about 1% by volume of methane or hydrogen and one or more of acetylene, fullerene and anthracene in the presence of a microwave induced plasma while maintaining the substrate temperature less than about 500° C. to deposit nanocrystalline diamond on the seeded substrate surface at a rate not less than about 0.2 microns / hour. Coatings of nanocrystalline diamond with average particle diameters of less than about 20 nanometers can be deposited with thermal budgets of 500° C.-4 hours or less onto a variety of substrates such as MEMS devices.

Owner:UCHICAGO ARGONNE LLC

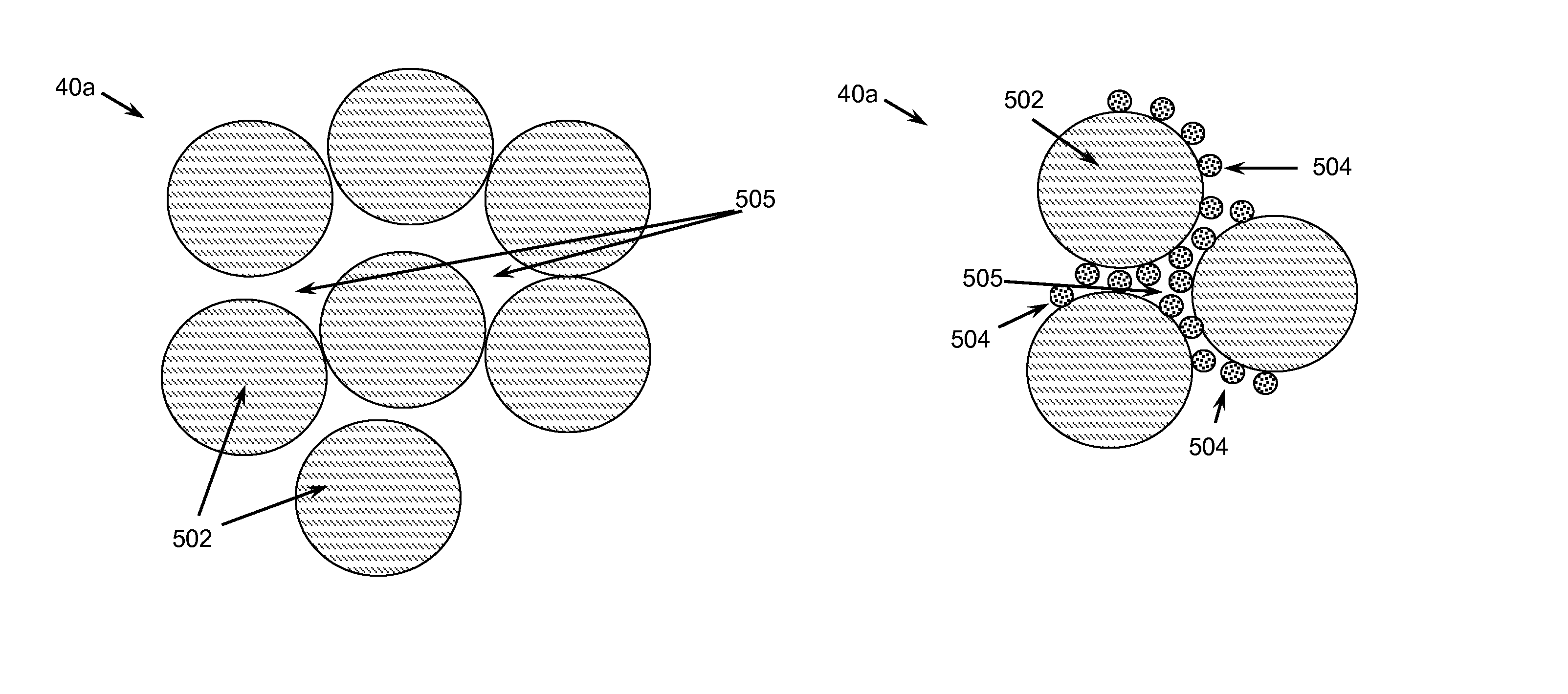

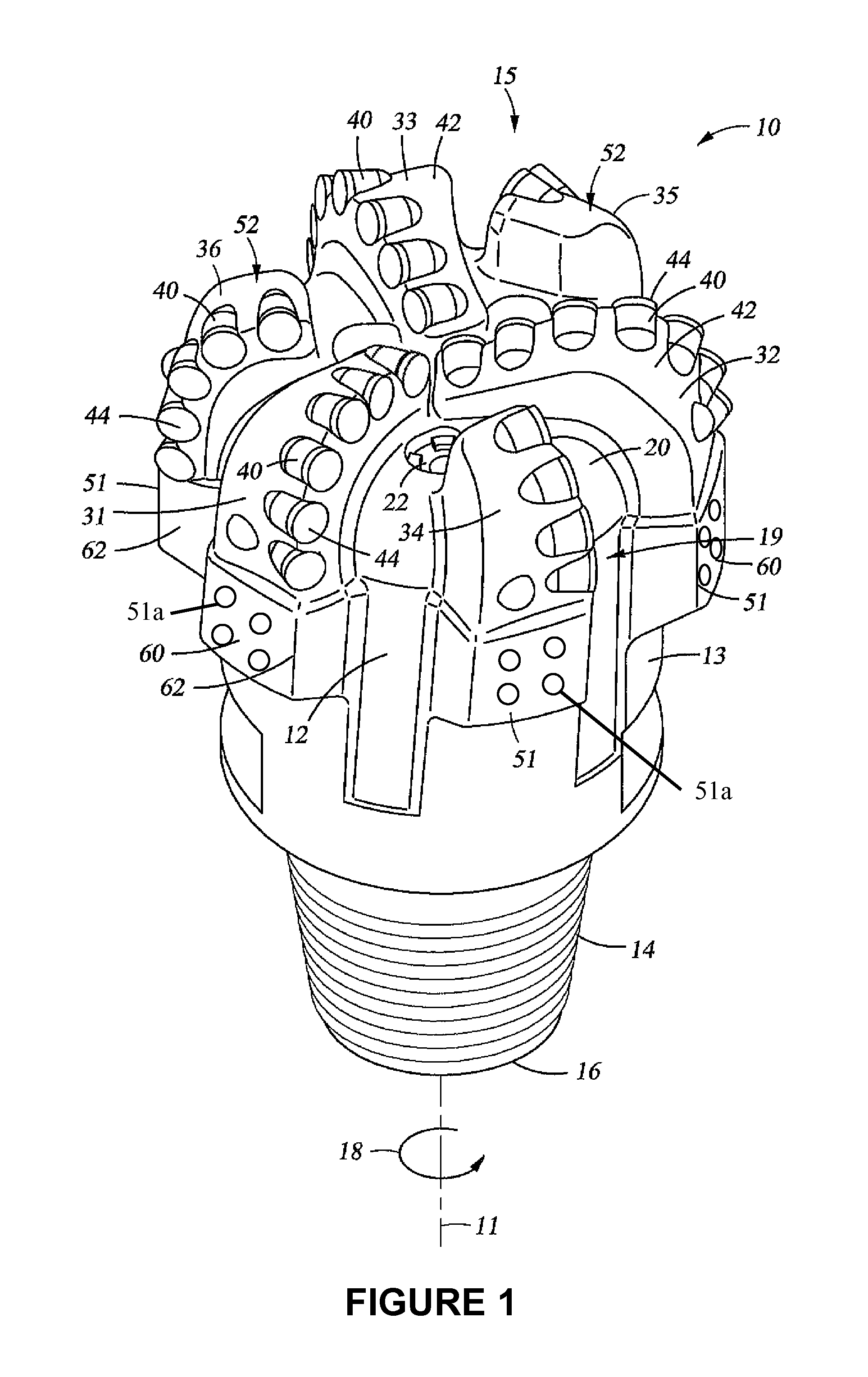

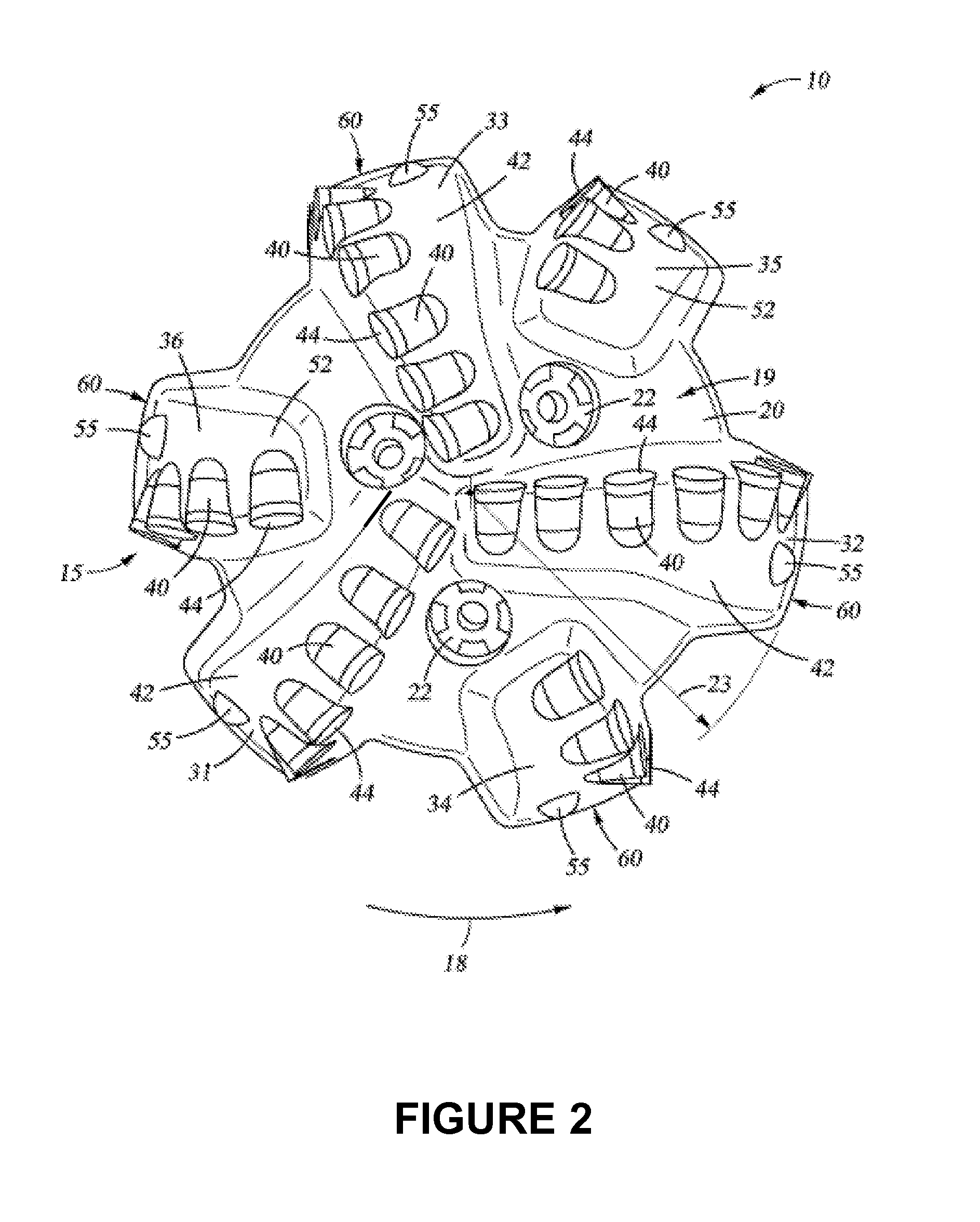

Preparation of Nanocrystalline Diamond Coated Diamond Particles and Applications Thereof

ActiveUS20130180181A1Pigmenting treatmentMaterial nanotechnologyPolycrystalline diamondHigh pressure

A method of making a polycrystalline diamond cutter element includes forming a blend, comprising a first particle size of polycrystalline diamond particles and a second particle size of polycrystalline diamond particles; forming a suspension of nanocrystalline diamond particles suspended in a solvent; and mixing the blend into the suspension to form a polycrystalline diamond mixture comprising nanocrystalline diamond coated polycrystalline diamond particles. The mixture is sintered with a substrate at high temperature and high pressure to form the polycrystalline diamond cutter element.

Owner:NAT OILWELL DHT

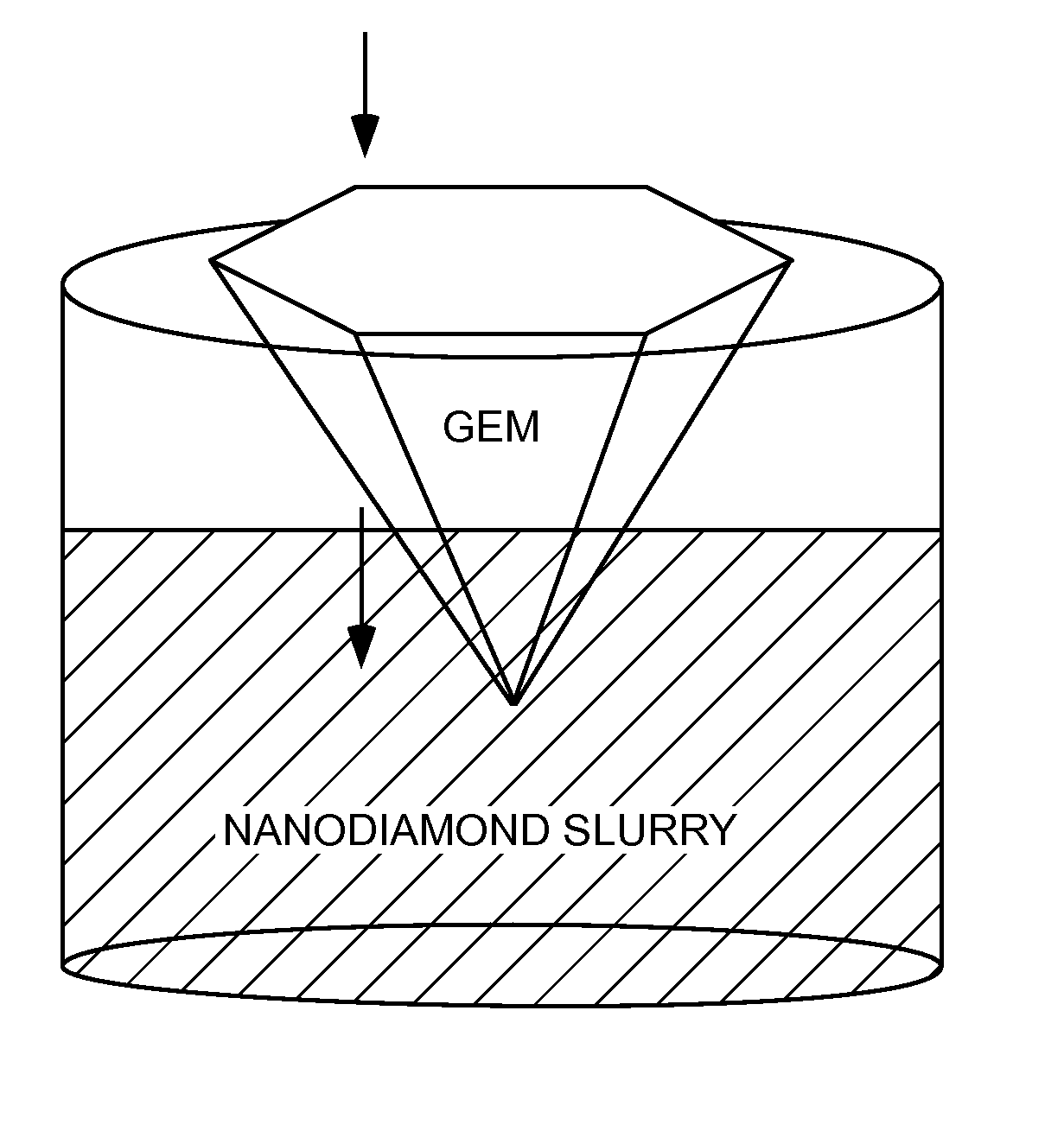

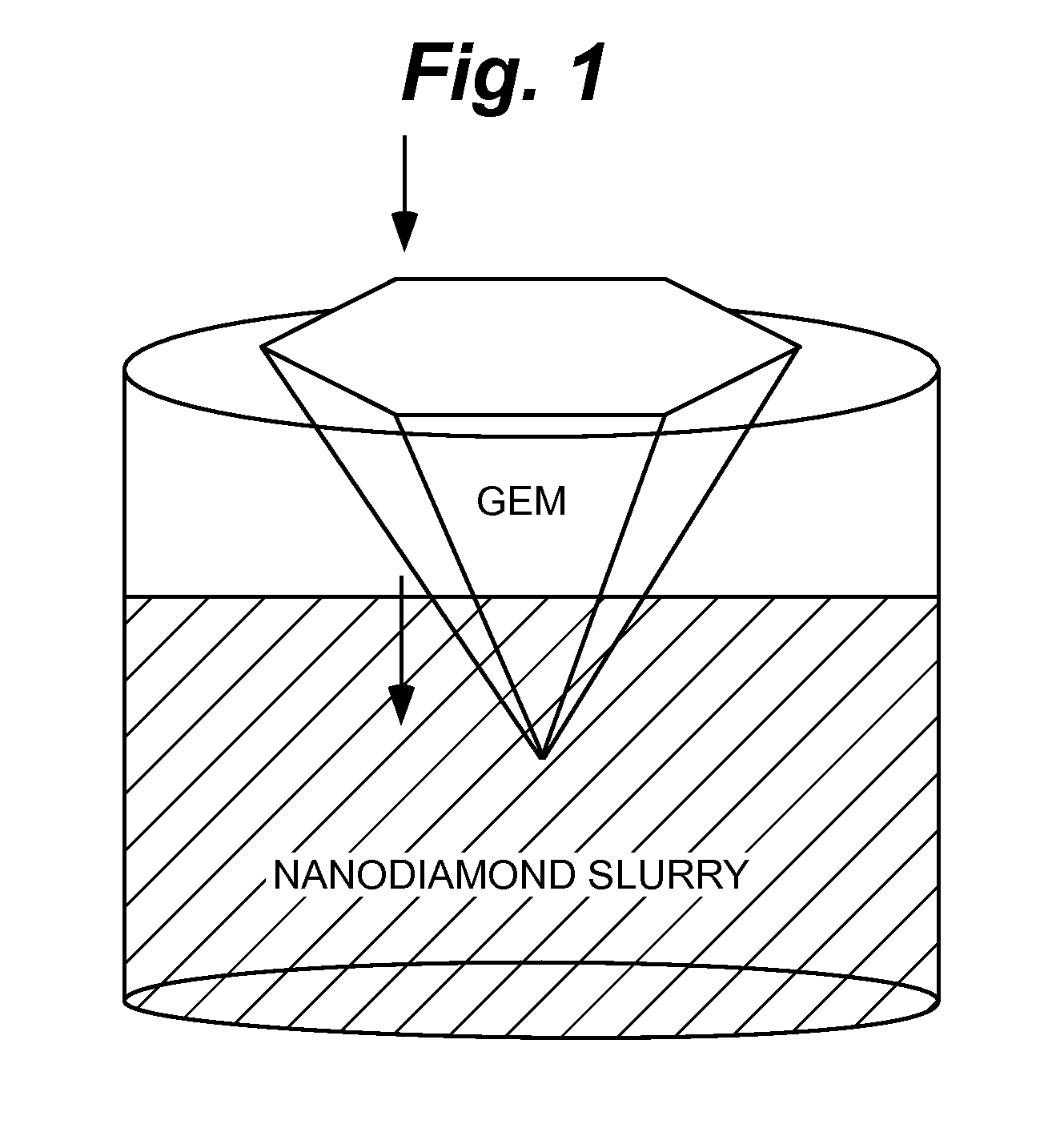

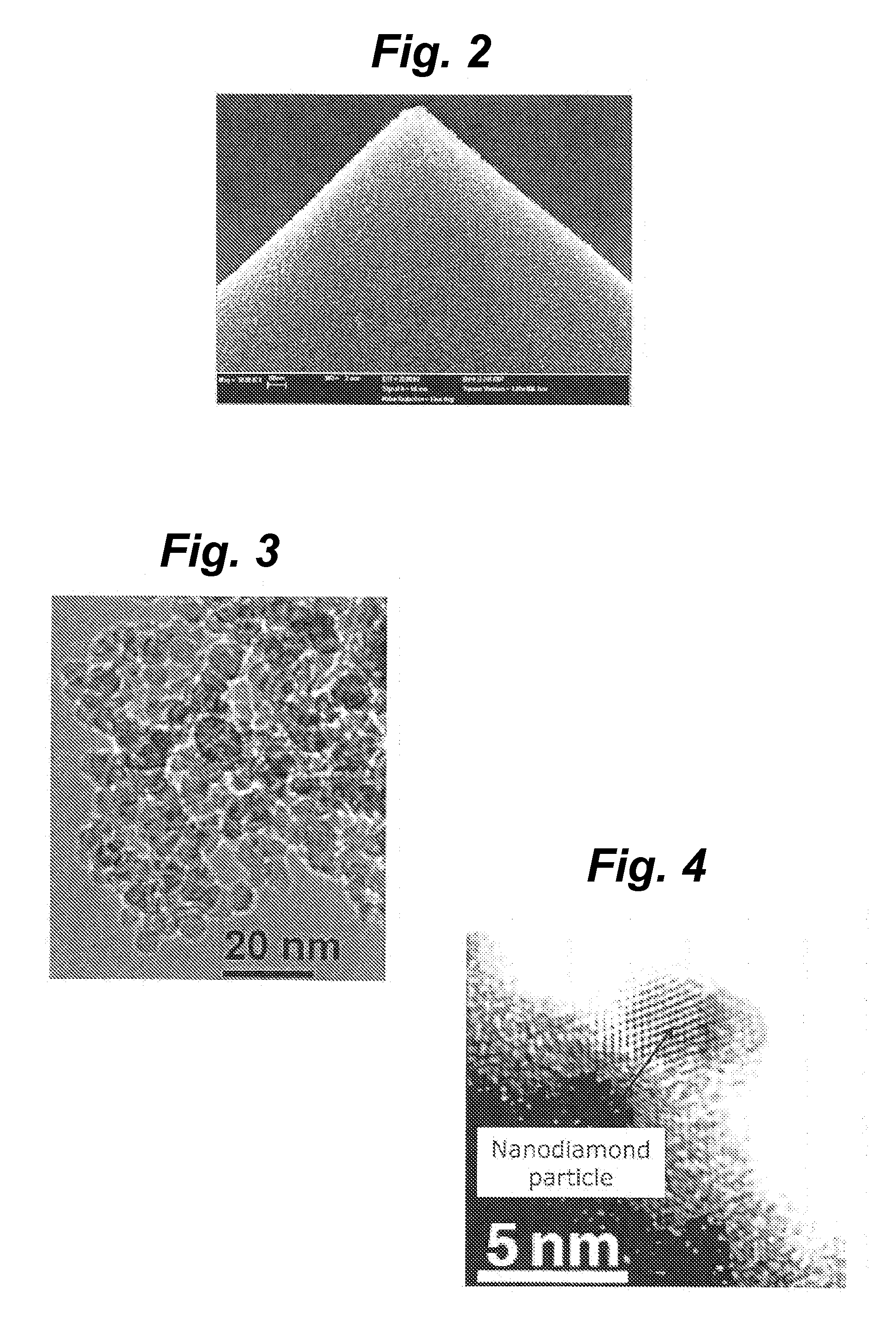

Method for producing nanocrystalline diamond coatings on gemstones and other substrates

ActiveUS20100068503A1Reduce usageEasy to storeElectric discharge heatingLayered productsGemstoneSlurry

A method to apply nano-crystalline diamond onto a selected substrate, including preparing Nanodiamond slurry of nanodiamond particles dispersed in a medium. The medium may include a liquid or a sol-gel. The selected substrate is immersed in the Nanodiamond slurry for a predetermined period of time. Then the substrate is removed from the slurry. The substrate is then dried with a flow of inert gas. The substrate is left coated with a coating of the nanodiamond particles that are highly adherently held by van der Waals forces.

Owner:ARYAMOND SINGAPORE PTE LTD

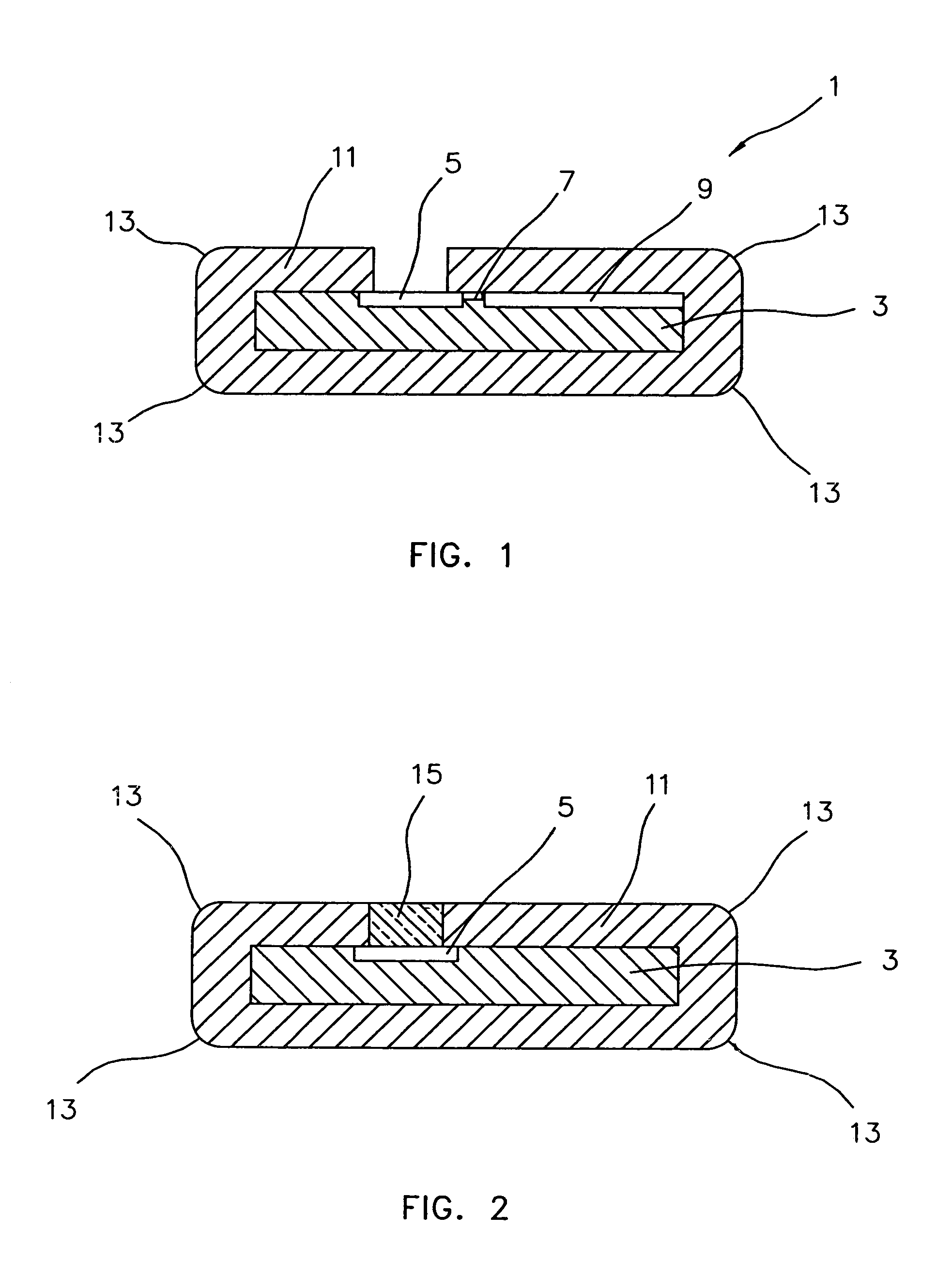

Implantable device using ultra-nanocrystalline diamond

An implantable biocompatible device, that may be either a sensor or stimulator, having electronic circuitry and electrodes formed on a substrate, is uniformly covered with a coating approximately one-micron thick of ultra-nanocrystalline diamond, hermetically sealing the electronic circuitry. Selected electrodes are either left uncovered during coating or uncovered by conventional patterning techniques, allowing the electrodes to be exposed to living tissue and fluids. The ultra-nanocrystalline diamond coating may be doped to create electrically conductive electrodes. These approaches eliminate the need for a hermetically sealed lid or cover to protect hybrid electronic circuitry, and thus allow the device to be thinner than otherwise possible. The conformal ultra-nanocrystalline diamond coating uniformly covers the device, providing relief from sharp edges and producing a strong, uniformly thick hermetic coating around sharp edges and on high aspect-ratio parts.

Owner:SECOND SIGHT MEDICAL PRODS

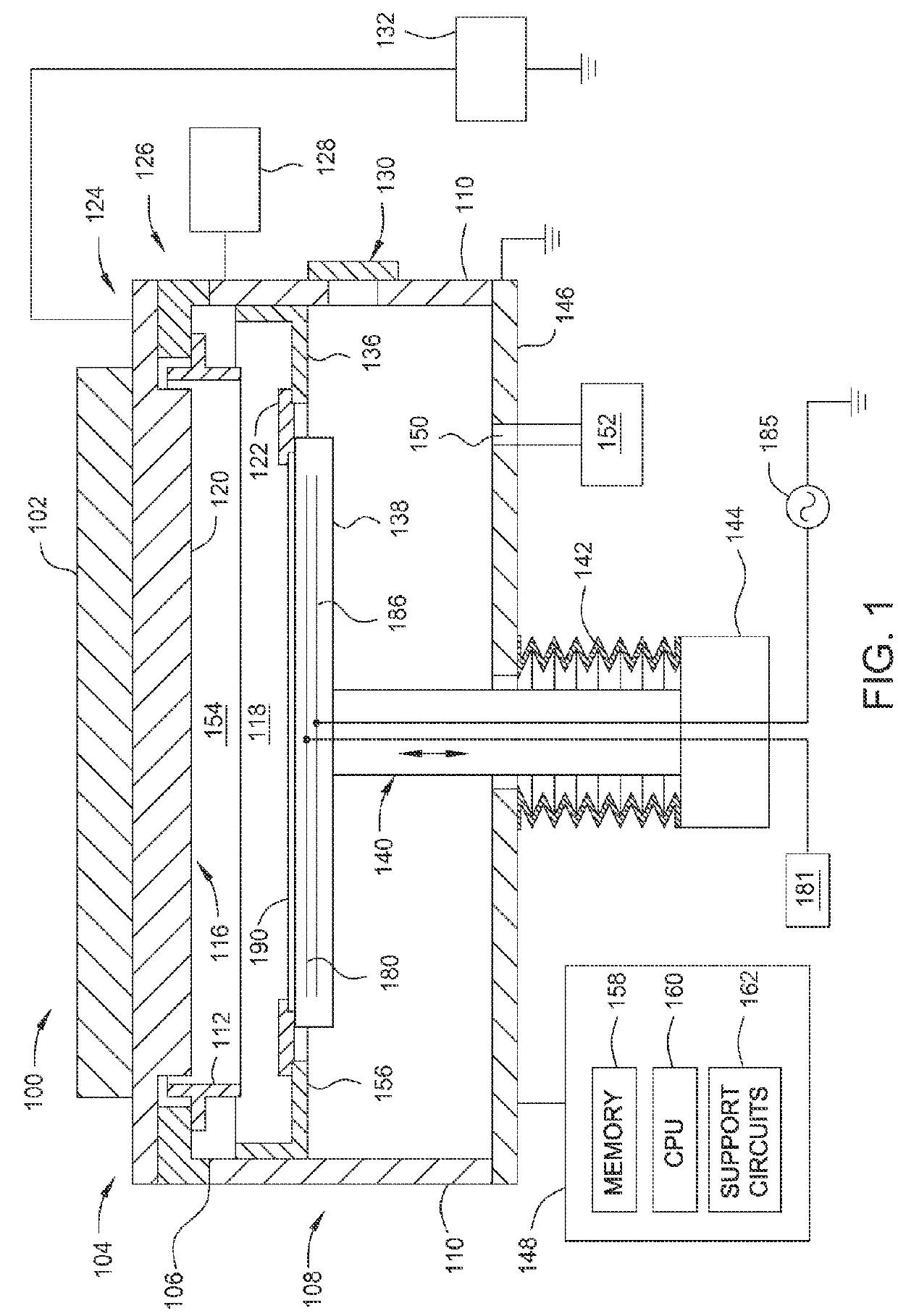

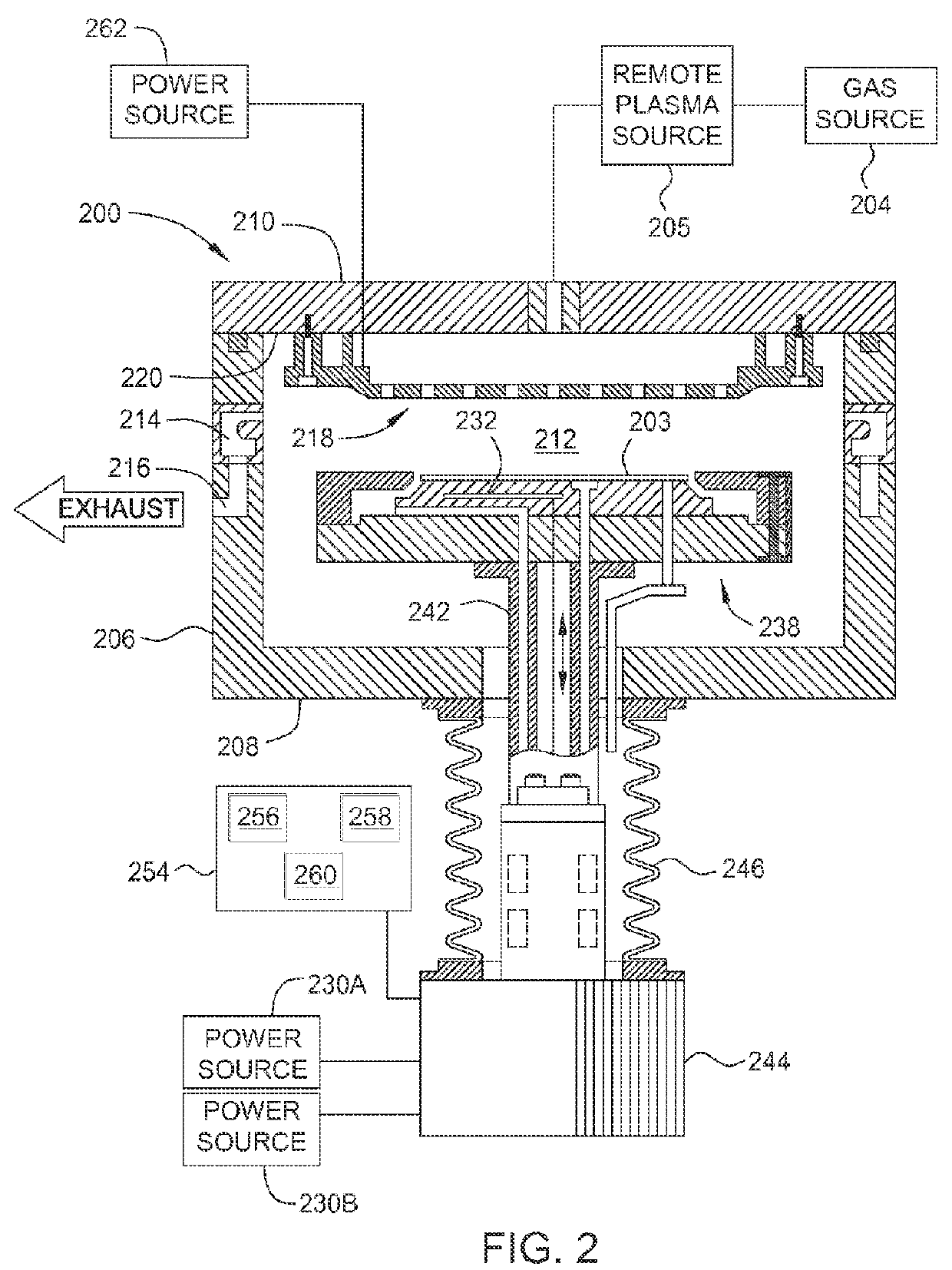

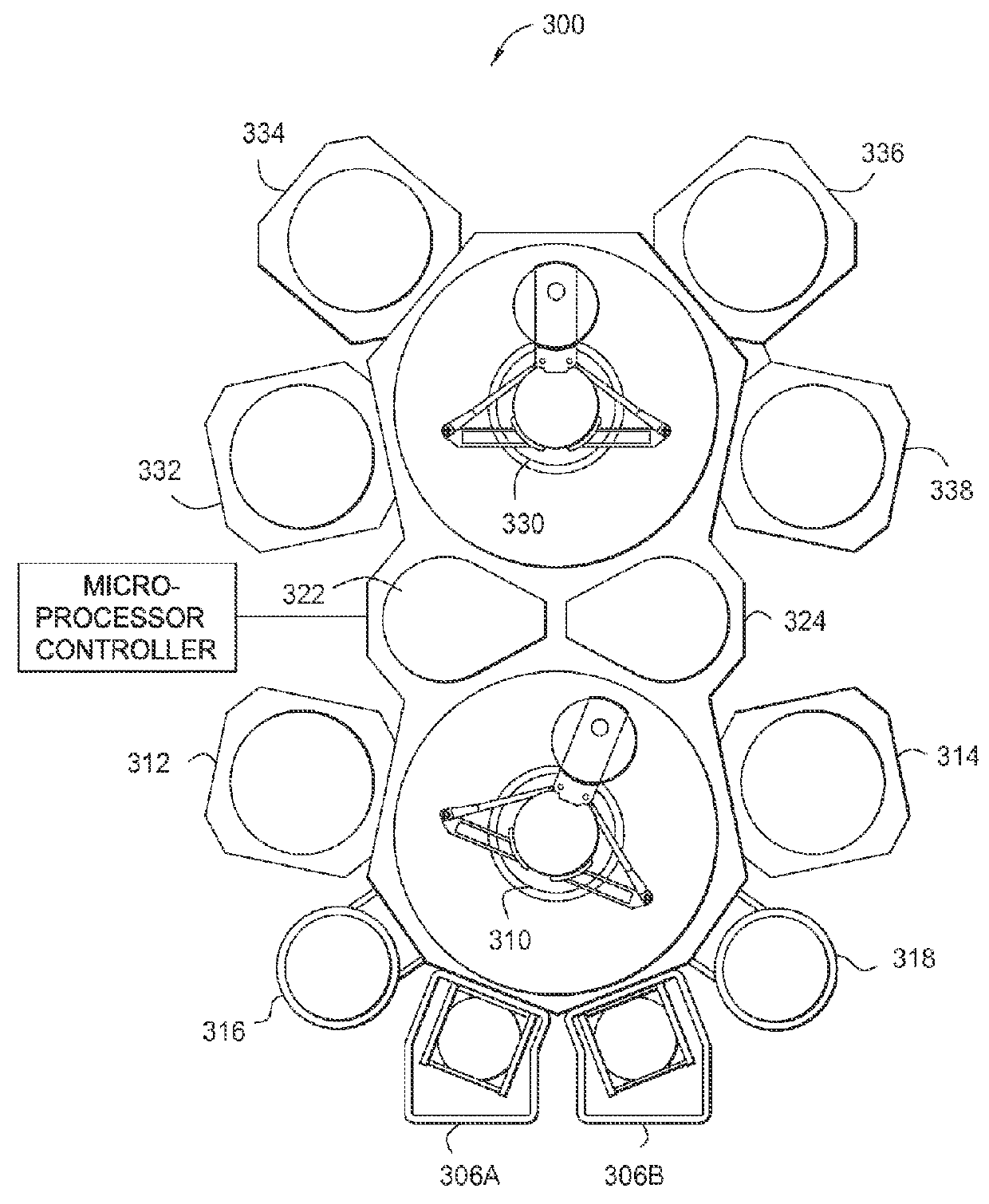

High power impulse magnetron sputtering process to achieve a high density high sp3 containing layer

ActiveUS20160053366A1Reduce the temperatureVacuum evaporation coatingSputtering coatingSputteringHigh density

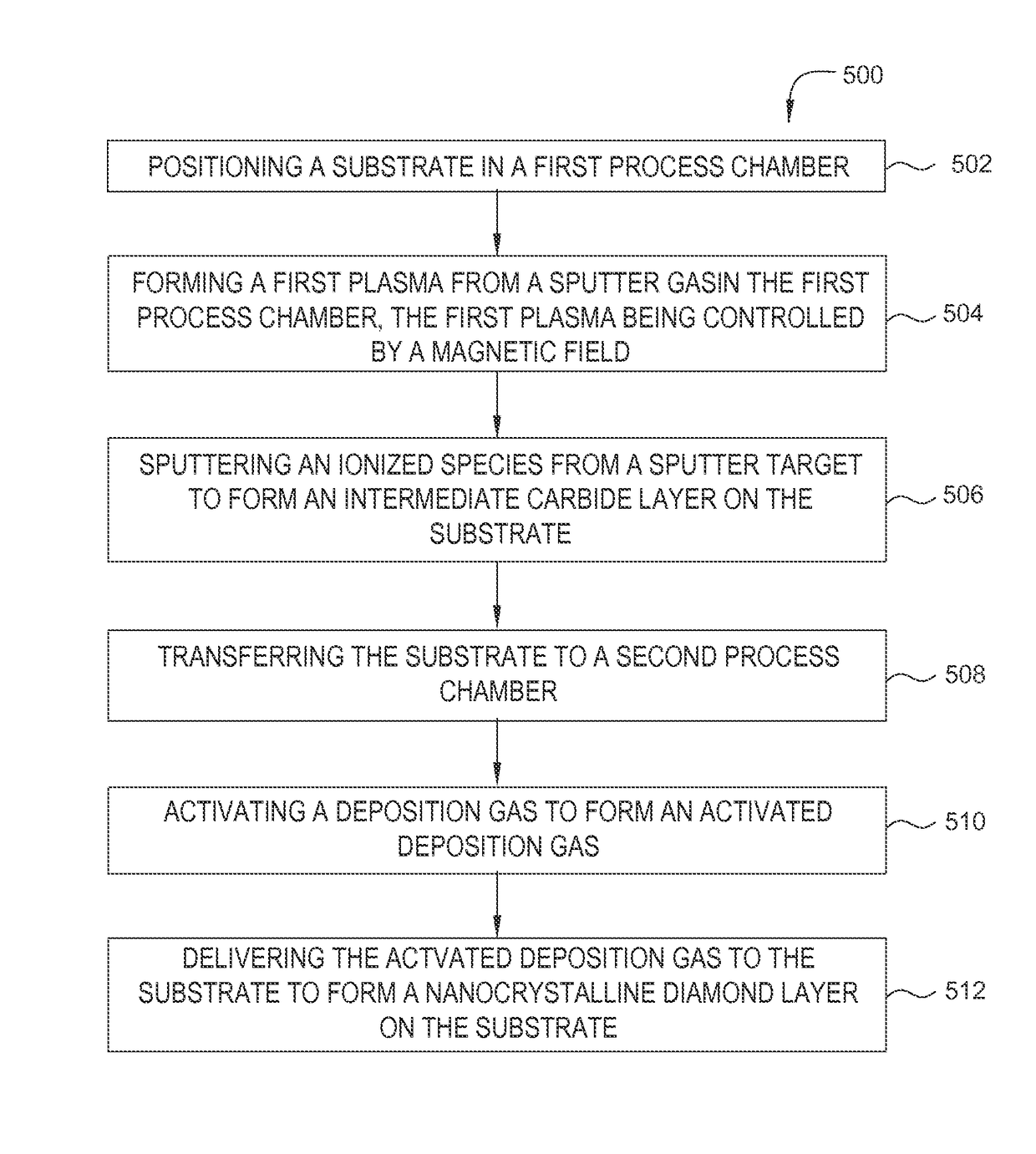

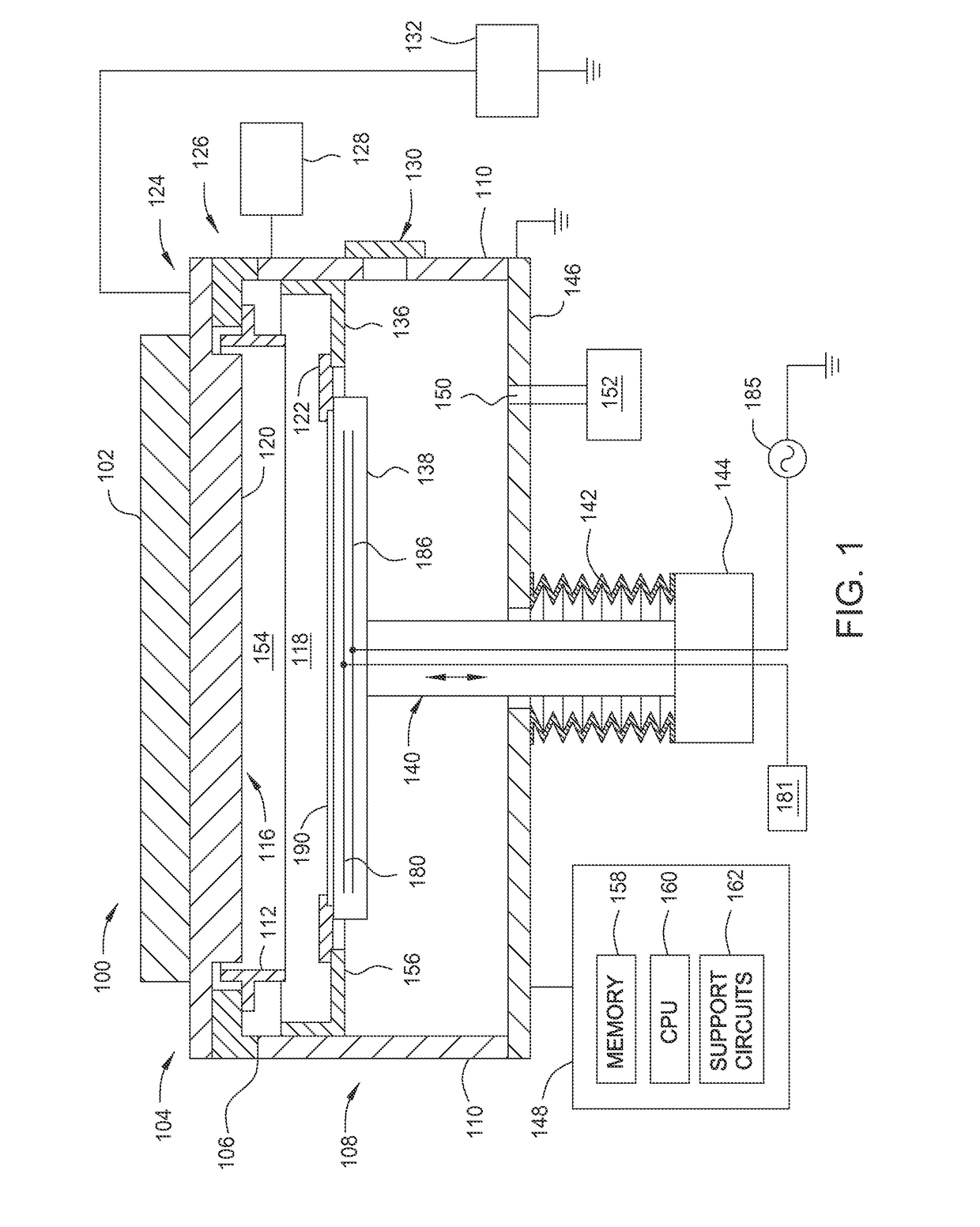

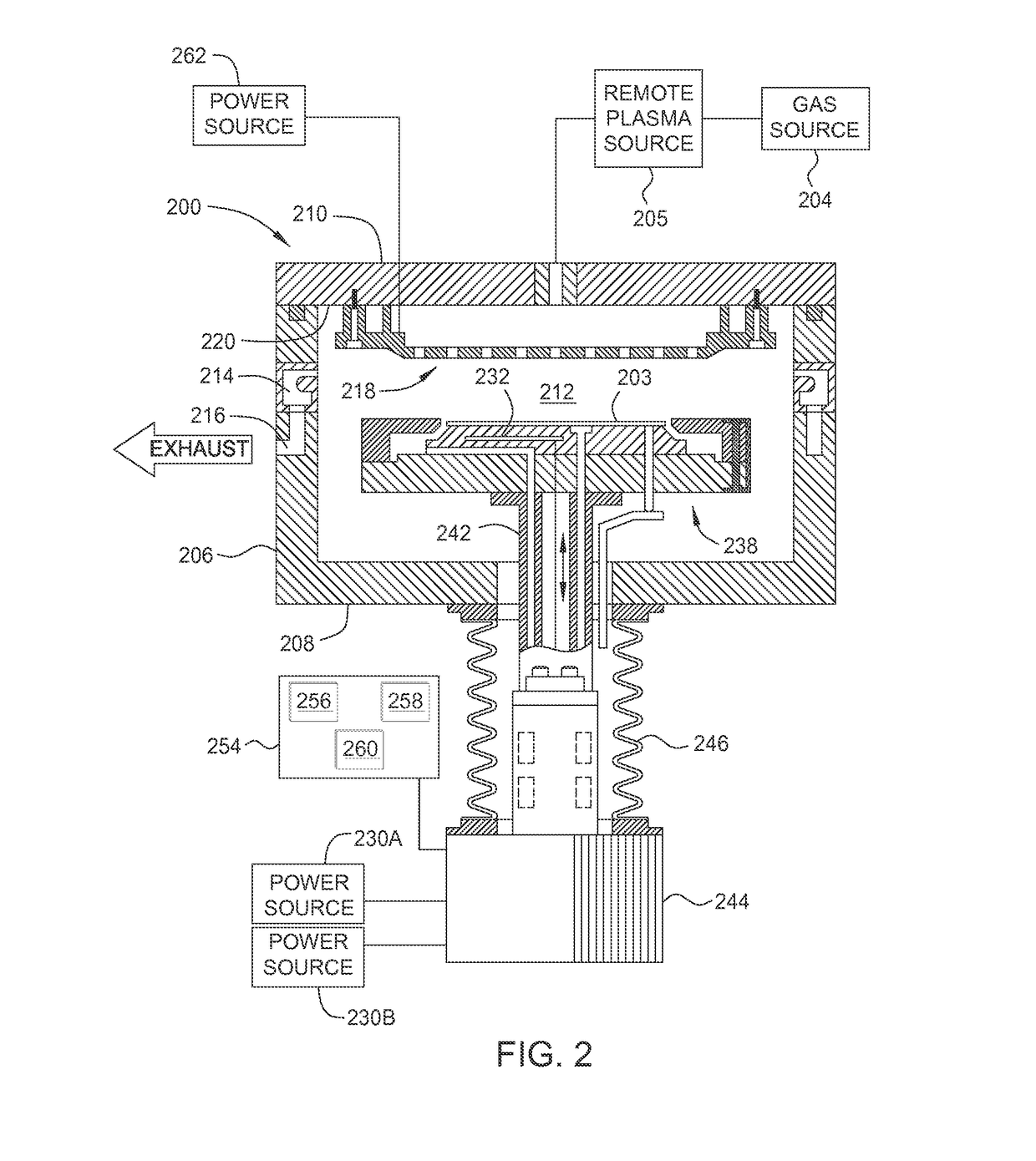

Methods for depositing a nanocrystalline diamond layer are disclosed herein. The method can include delivering a sputter gas to a substrate positioned in a processing region of a first process chamber, the first process chamber having a carbon-containing sputter target, delivering an energy pulse to the sputter gas to create a sputtering plasma, the sputtering plasma having a sputtering duration, the energy pulse having an average power between 1 W / cm2 and 10 W / cm2 and a pulse width which is less than 100 μs and greater than 30 μs, the sputtering plasma being controlled by a magnetic field, the magnetic field being less than 300. Gauss, and delivering the sputtering plasma to the sputter target to form an ionized species, the ionized species forming a crystalline carbon-containing layer on the substrate.

Owner:APPLIED MATERIALS INC

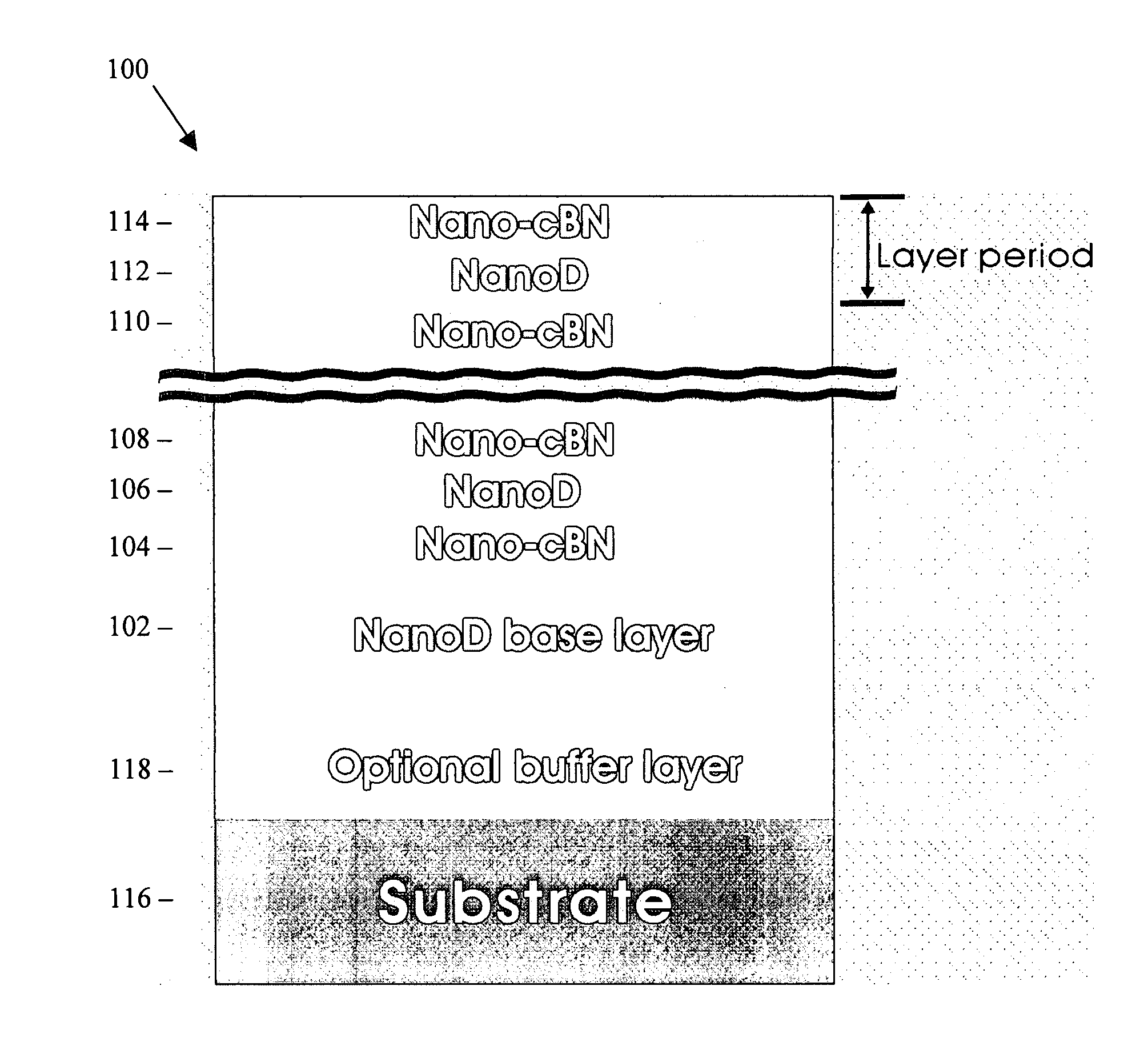

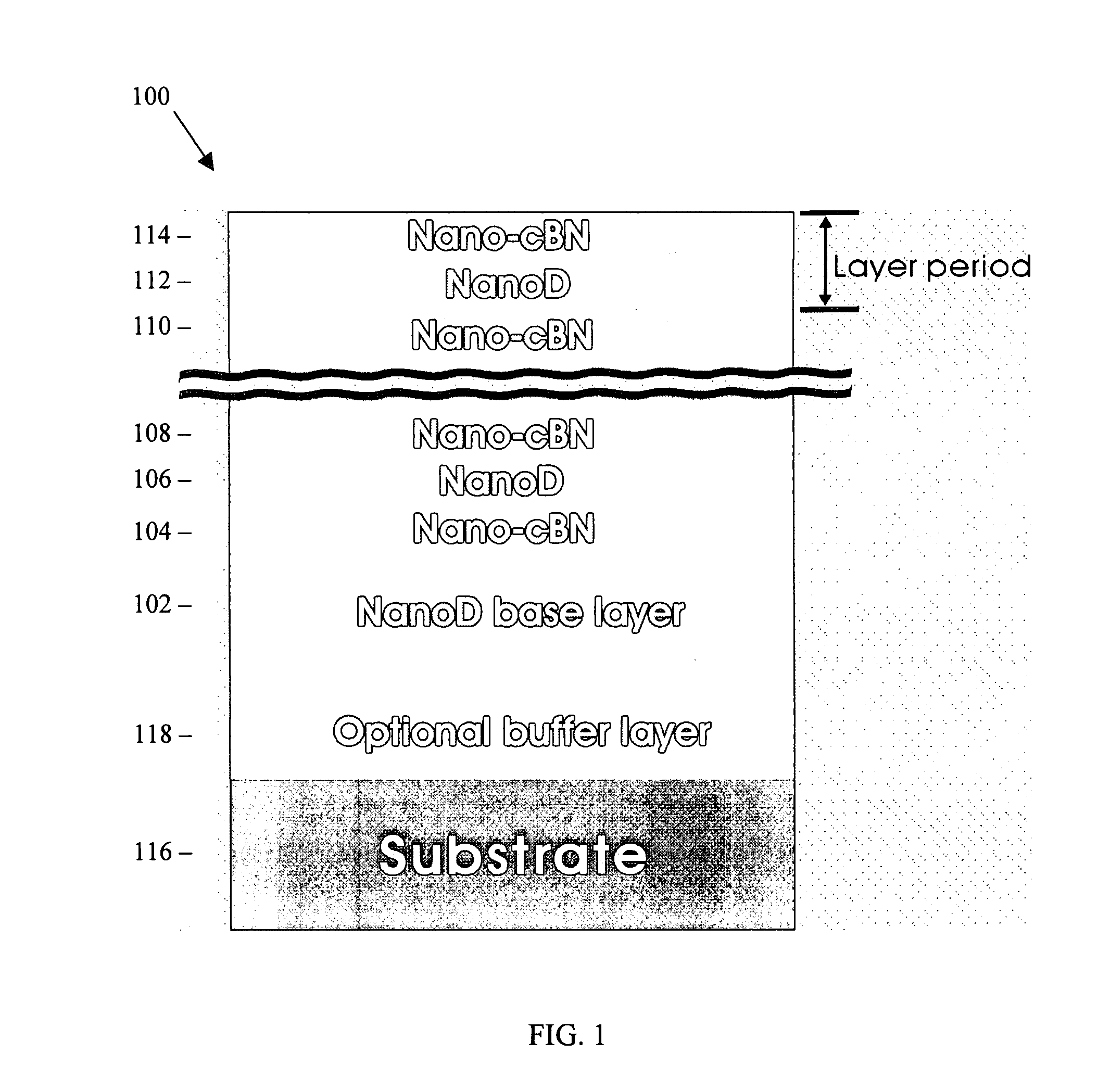

Ultrahard multilayer coating comprising nanocrystalline diamond and nanocrystalline cubic boron nitride

A multilayer coating (MLC) is composed of two chemically different layered nanocrystalline materials, nanodiamond (nanoD) and nano-cubic boron nitride (nono-cBN). The structure of the MLC and fabrication sequence of layered structure are disclosed. The base layer is preferably nanoD and is the first deposited layer serving as an accommodation layer on a pretreated substrate. It can be designed with a larger thickness whereas subsequent alternate nano-cBN and nanoD layers are typically prepared with a thickness of 2 to 100 nm. The thickness of these layers can be engineered for a specific use. The deposition of the nanoD layer, by either cold or thermal plasma CVD, is preceded by diamond nucleation on a pretreated and / or precoated substrate, which has the capacity to accommodate the MLC and provides excellent adhesion. Nano-cBN layers are directly grown on nanodiamond crystallites using ion-assisted physical vapor deposition (PVD) and ion-assisted plasma enhanced chemical vapor deposition (PECVD), again followed by nanodiamond deposition using CVD methods in cycles until the intended number of layers of the MLC is obtained.

Owner:CITY UNIVERSITY OF HONG KONG

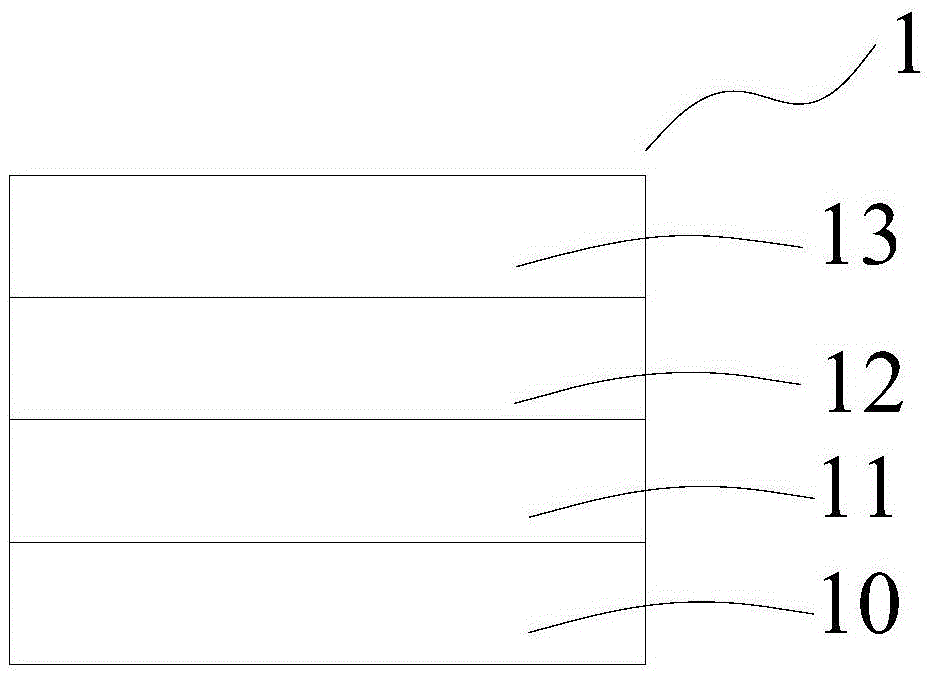

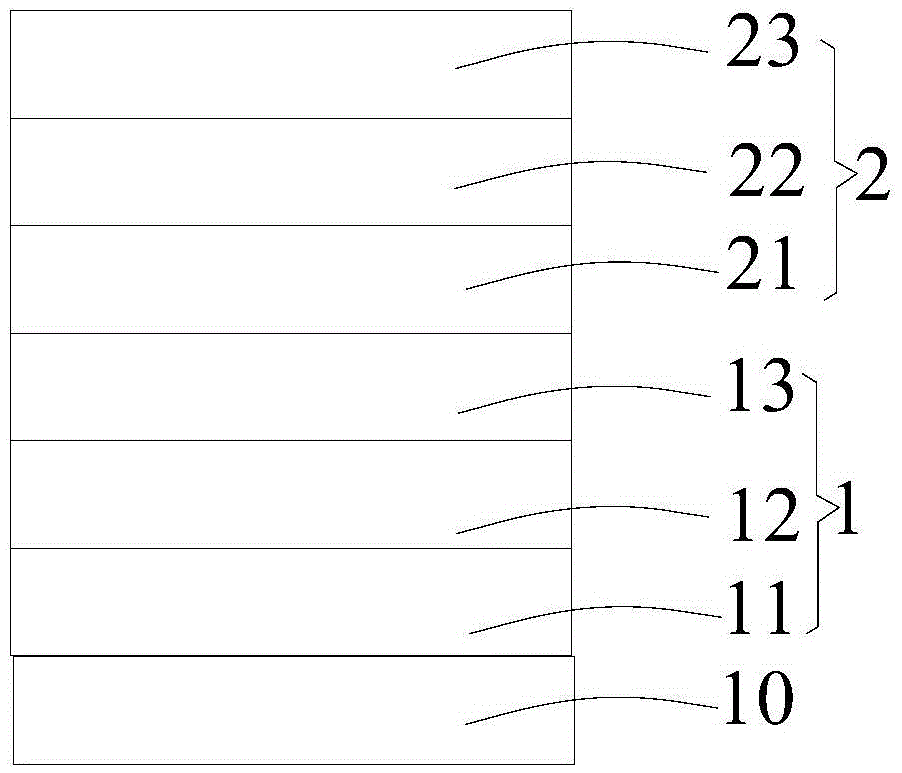

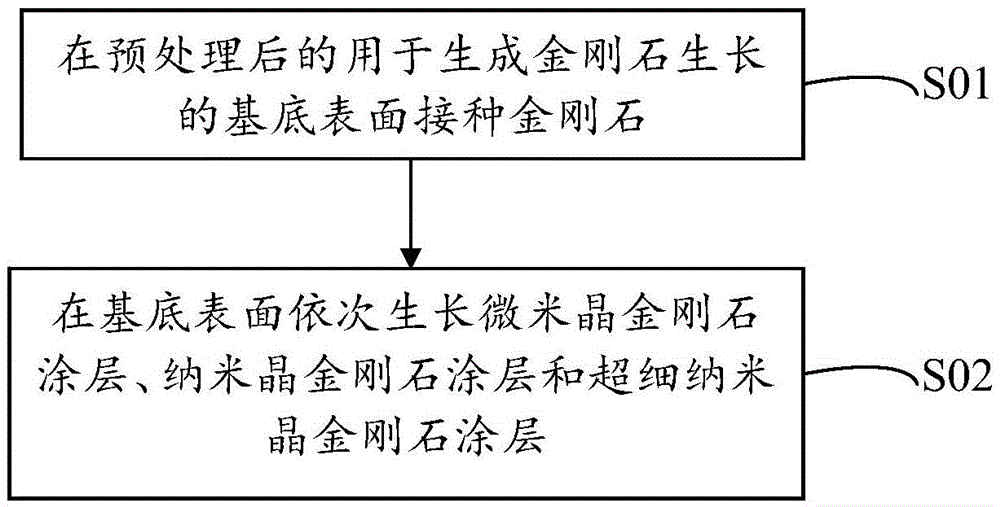

Multilayer diamond coating, manufacturing method thereof and coating tool

InactiveCN105483644AHigh hardnessImprove wear resistanceChemical vapor deposition coatingSuperimposed coating processMicrometerSurface roughness

The invention discloses a multilayer diamond coating, a manufacturing method thereof and a coating tool. The multilayer diamond coating comprises at least one composite diamond coating structure unit. Each composite diamond coating structure unit comprises a micrometer-grain diamond coating body, a nanocrystalline diamond coating body and a superfine nanocrystalline diamond coating body, wherein the nanocrystalline diamond coating body and the superfine nanocrystalline diamond coating body sequentially grow on the surface of the micrometer-grain diamond coating body. The multilayer diamond coating is high in hardness, abrasion resistance and tenacity and low in surface roughness, friction coefficient and coating stress. The coating tool comprises a tool body and the multilayer diamond coating combined to the surface of the tool body. Meanwhile, the coating tool is high in hardness, good in abrasion resistance and long in service life. The multilayer diamond coating is firmly combined with the tool body, precise machining is further facilitated, machining cost is reduced, and production efficiency is improved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Fabrication of diamond shells

ActiveUS20070104399A1Good chemical stabilityAbsorb large mechanical stressPaper/cardboard articlesTransportation and packagingInfraredInfra-red color

A novel method for fabricating diamond shells is introduced. The fabrication of such shells is a multi-step process, which involves diamond chemical vapor deposition on predetermined mandrels followed by polishing, microfabrication of holes, and removal of the mandrel by an etch process. The resultant shells of the present invention can be configured with a surface roughness at the nanometer level (e.g., on the order of down to about 10 nm RMS) on a mm length scale, and exhibit excellent hardness / strength, and good transparency in the both the infra-red and visible. Specifically, a novel process is disclosed herein, which allows coating of spherical substrates with optical-quality diamond films or nanocrystalline diamond films.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Boron-doped nanocrystalline diamond

A conductive boron doped nanocrystalline diamond is described. The boron doped diamond has a conductivity which uses the boron in the crystals as a charge carrier. The diamond is particularly useful for electrochemical electrodes in oxidation-reduction reactions and decontamination of aqueous solutions.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

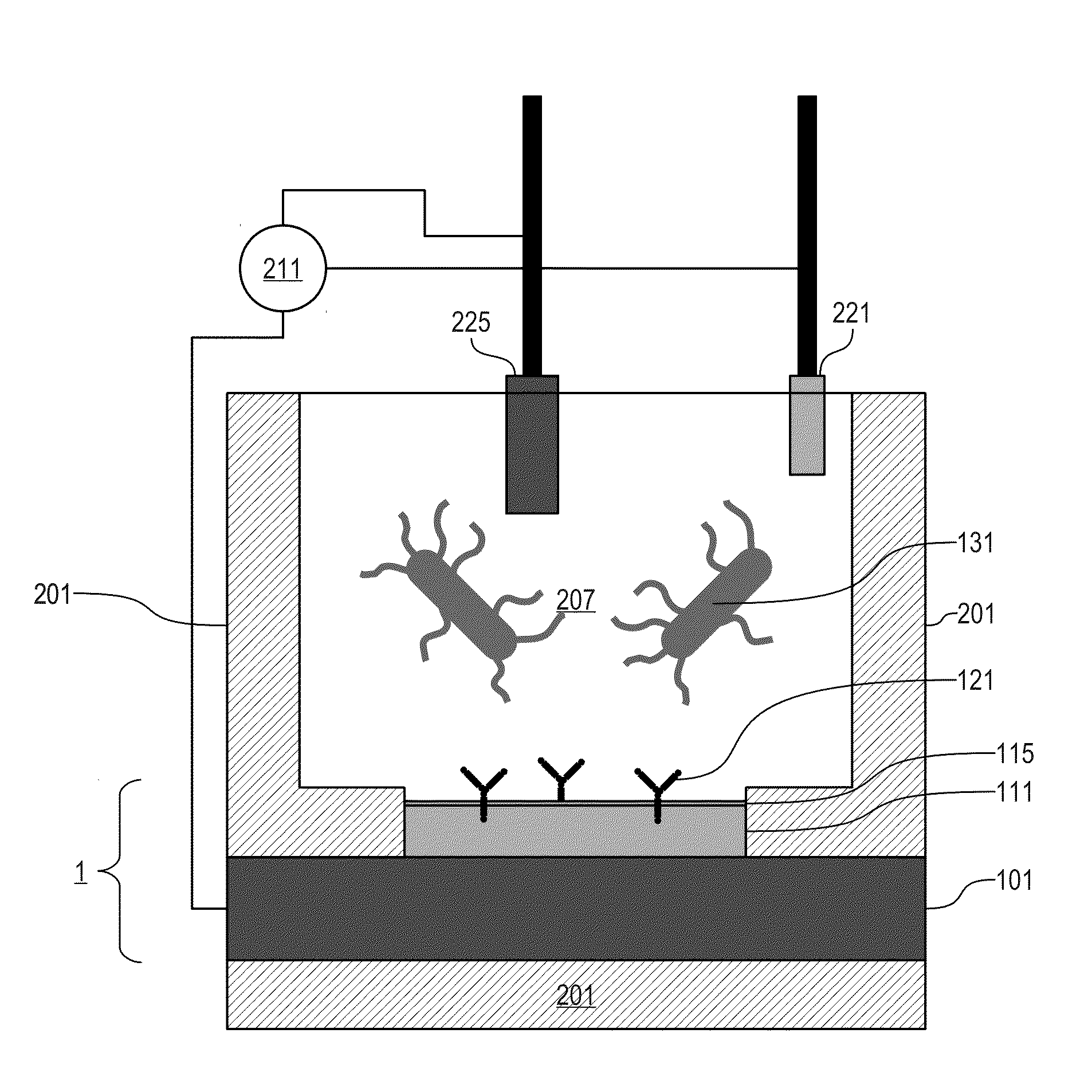

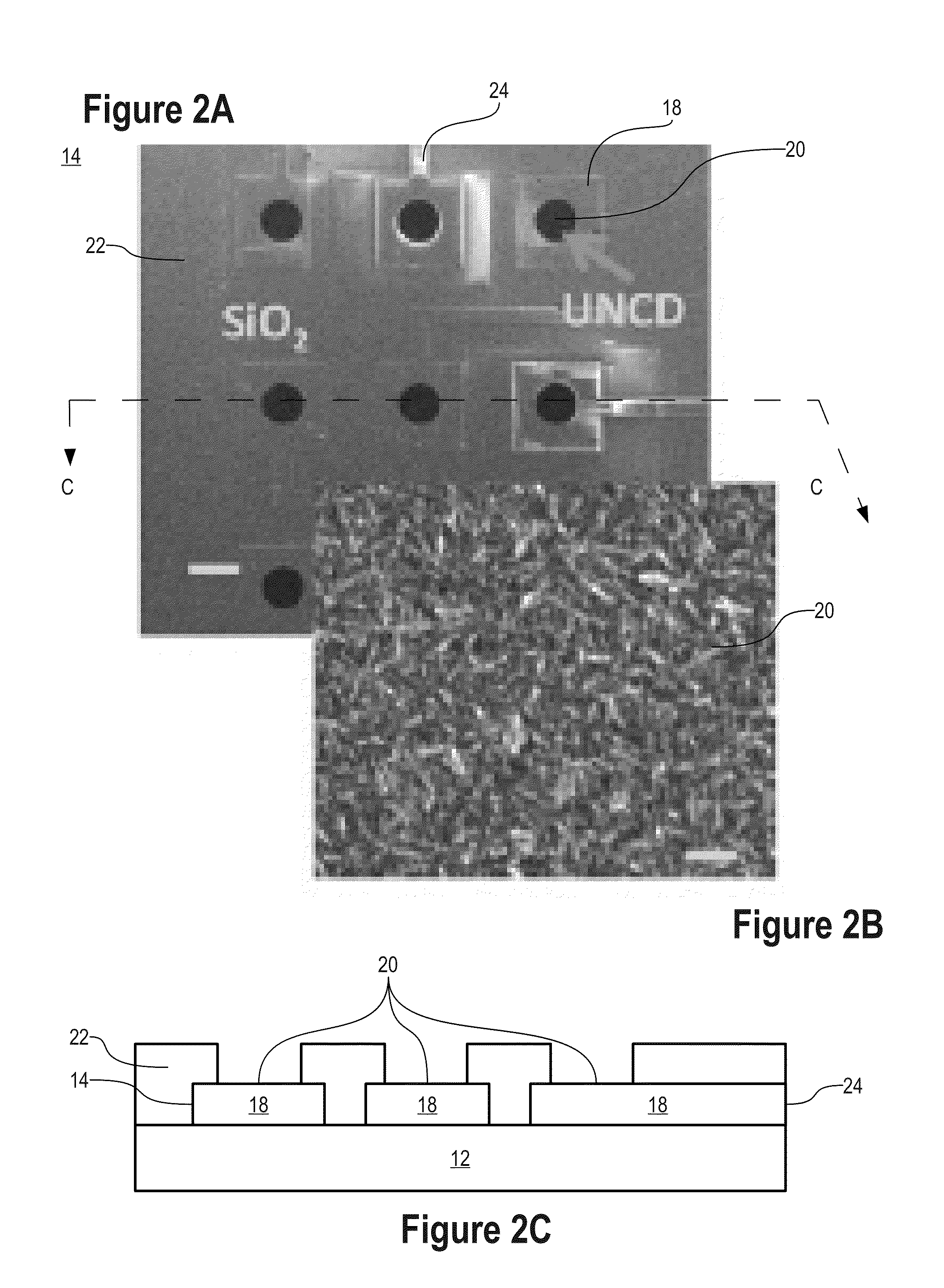

Electroanalytical sensor based on nanocrystalline diamond electrodes and microelectrode arrays

ActiveUS20130213823A1Addressing Insufficient SensitivityHigh signal voltageImmobilised enzymesBioreactor/fermenter combinationsDiamond electrodesSpectroscopy

A diamond electrode and a diamond microelectrode array for biosensors and electroanalytical applications, such as electrochemical impedance spectroscopy (EIS), are disclosed. The electrode comprises a layer of ultra-smooth conductive nanocrystalline diamond (NCD) having a resistivity of >0.05 Ωcm and a surface roughness of <20 nm Ra. Preferably, the diamond layer comprises boron or nitrogen-doped ultrananocrystalline diamond (UNCD) having an average grain size <10 nm and a surface roughness <10 nm Ra. It may be patterned to define a microelectrode array with a plurality of individually addressable electrodes, each having a diameter in the range from 100 nm to 100 μm. The surface of each microelectrode is hydrogen-terminated before bio-functionalization, i.e. modifying with sensing molecules for detection of a specific biological or chemical target and coating with a blocker for reducing non-specific binding. These diamond electrodes exhibited substantial increases in sensitivity, selectivity and signal reproducibility, e.g. for detection of E. coli K12 using EIS.

Owner:JOHN CRANE INC

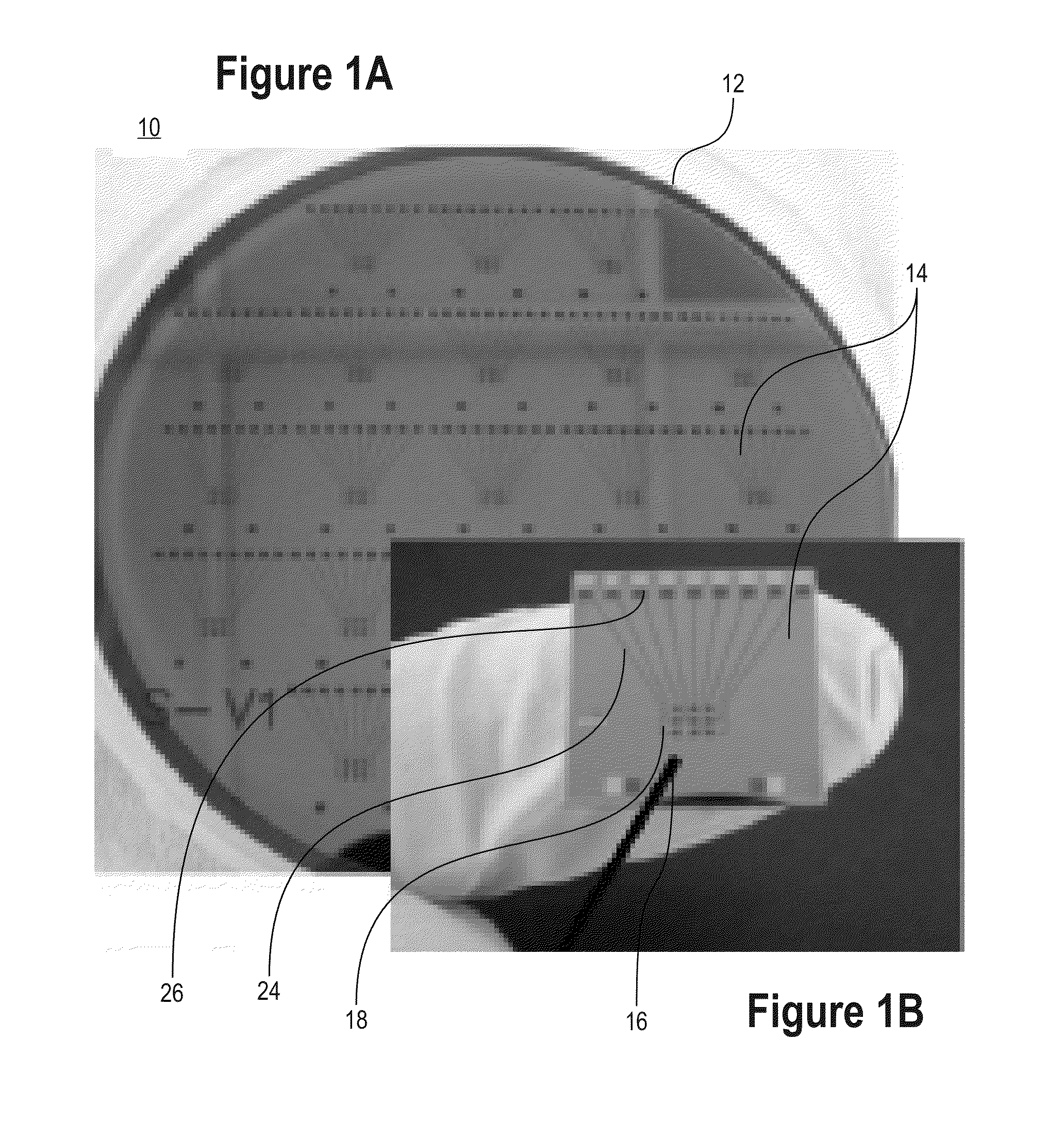

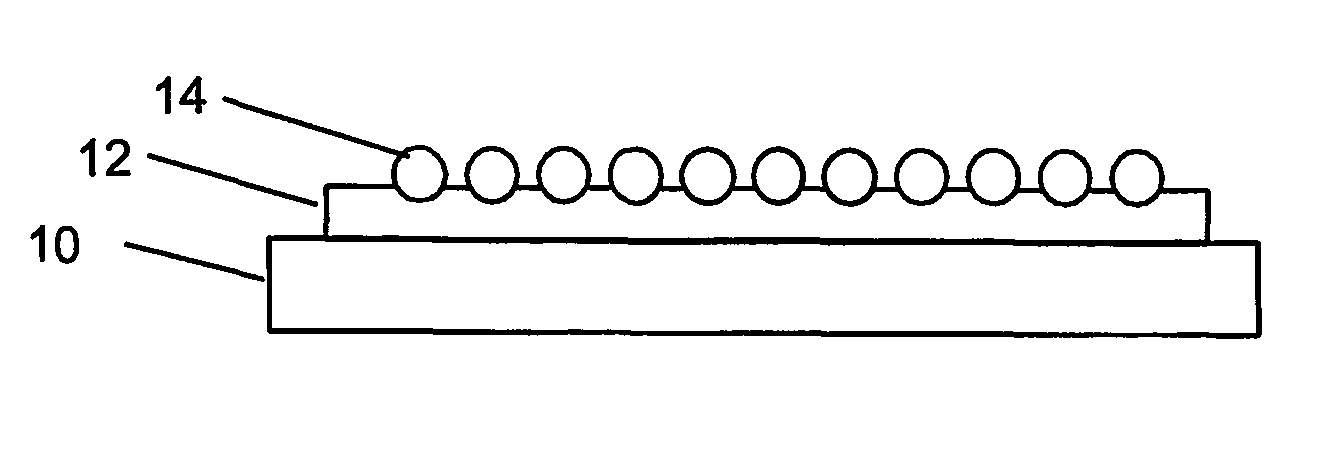

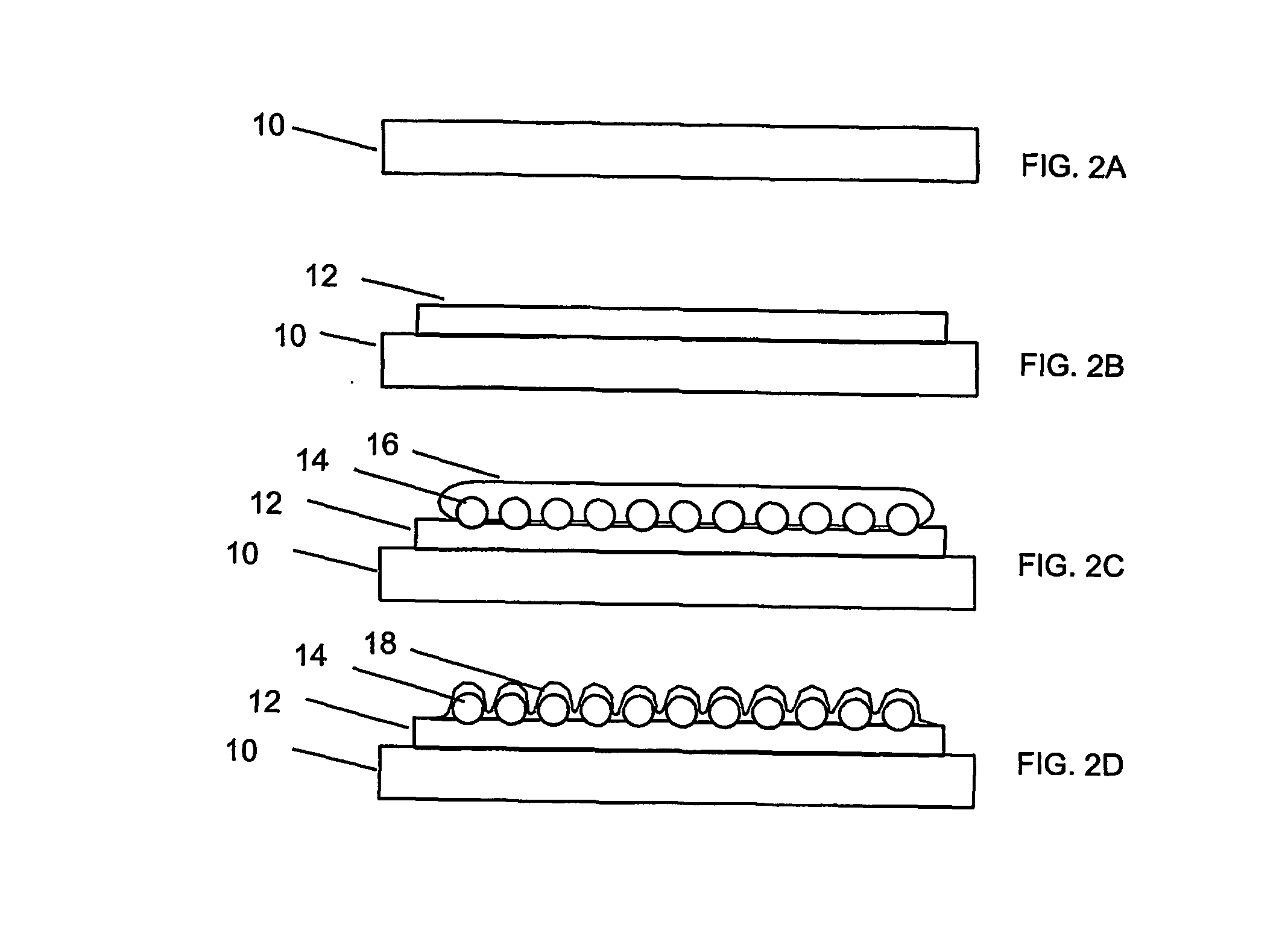

Field emitter device

InactiveUS20060261719A1Improve conductivityHigh electron affinityThermionic cathodesDischarge tube main electrodesNanometreNanocrystalline diamond

An electron emitter including a high work function metal 18 encapsulating a metal-doped, nanocrystalline diamond particle layer 14 in contact with a planar surface of a low workfunction metal cathode 12, and a method of fabrication of the same is disclosed. The method may include formulating the conductive nanodiamond powder with a metallic solution, containing the high workfunction metal, and disposing it on the metal cathode 12 to form a composite material layer containing surface areas exhibiting low electron affinity. The resulting cold cathode structure has a low extraction field needed for efficient emission, a means to limit the emission current per unit area, and a reduced emission sensitivity to surface adsorption / desorption effects.

Owner:UNIVERSITY OF BRISTOL

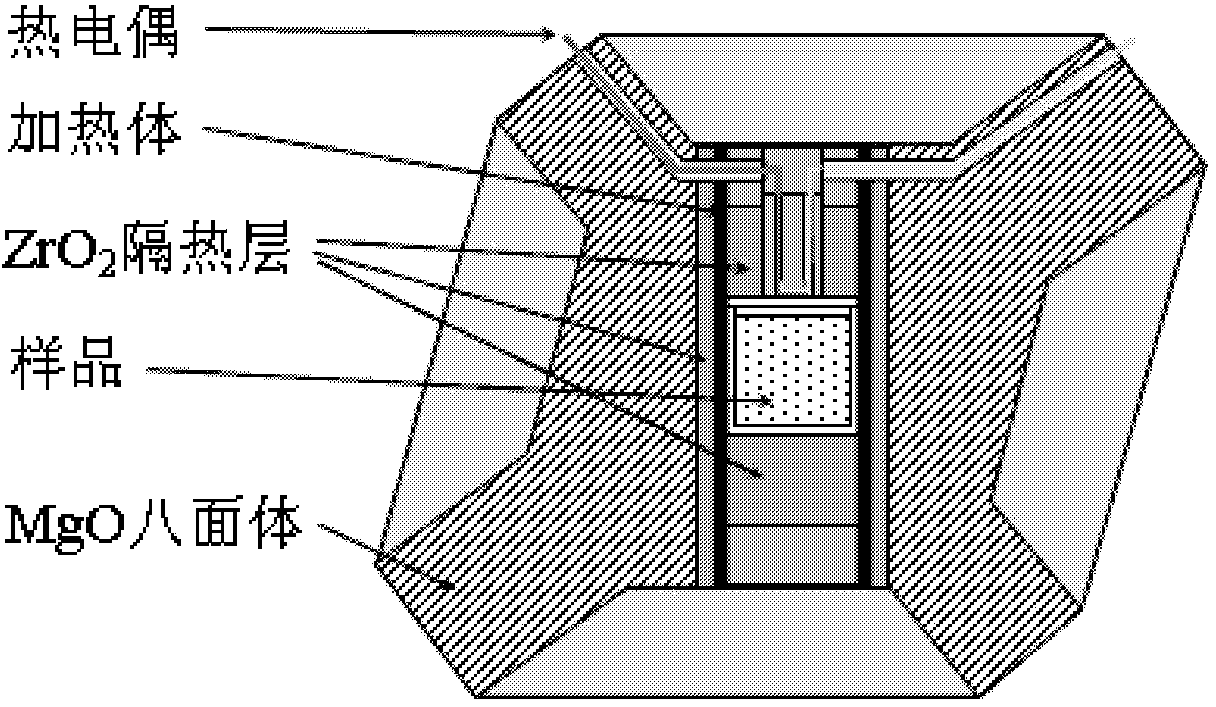

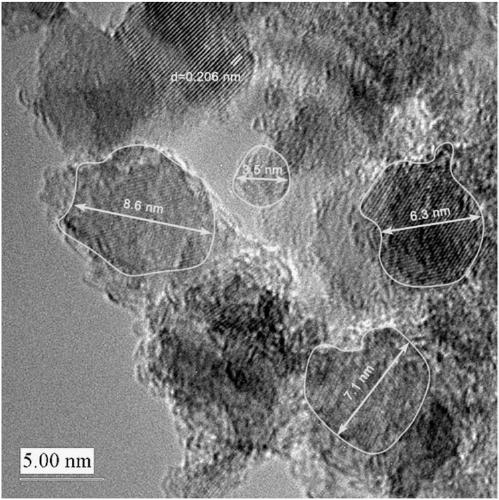

Ultrahigh hard nano twin diamond block material and preparation method thereof

ActiveCN104209062ASimple processHigh pressure synthesis parameters are easy to controlUltra-high pressure processesPhysical chemistryPolycrystalline diamond

The invention relates to an ultrahigh hard nano twin diamond block material and a preparation method thereof, and specifically discloses a nanocrystalline diamond block material containing high density twin crystals and a synthesis method thereof. Particles of nano spherical carbon without a diamond core (carbon with an onion structure is named as coreless onion carbon for short) are taken as the raw materials and then subjected to synthesis under a high pressure at a high temperature to obtain nano twin diamond blocks. The volume of obtained nano twin diamond block is 1-2000 mm3; the Vickers hardness is 155-350 GPa, the Knoop hardness is 140-240 GPa, and the twin width is 1-15 nm. Compared to the prior art, the hardness of the obtained nano twin diamond blocks is far higher than the hardness of diamond mono-crystal and ultrahigh hard polycrystalline diamond, wherein the Vickers hardness of diamond mono-crystal is just around 100 GPa, the highest Knoop hardness of ultrahigh polycrystalline diamond is 140 GPa, while the highest Vickers hardness of the nano twin diamond blocks can reach 350 GPa, and the highest Knoop hardness of the nano twin diamond blocks can reach 240 GPa. The nano twin diamond block has a wide application prospect in the machinery processing field such as geological drilling, high speed cutting, ultra precision processing, and the like, the grinding material and grinding tool field, the wire-drawing die field, and the special optical element field.

Owner:YANSHAN UNIV

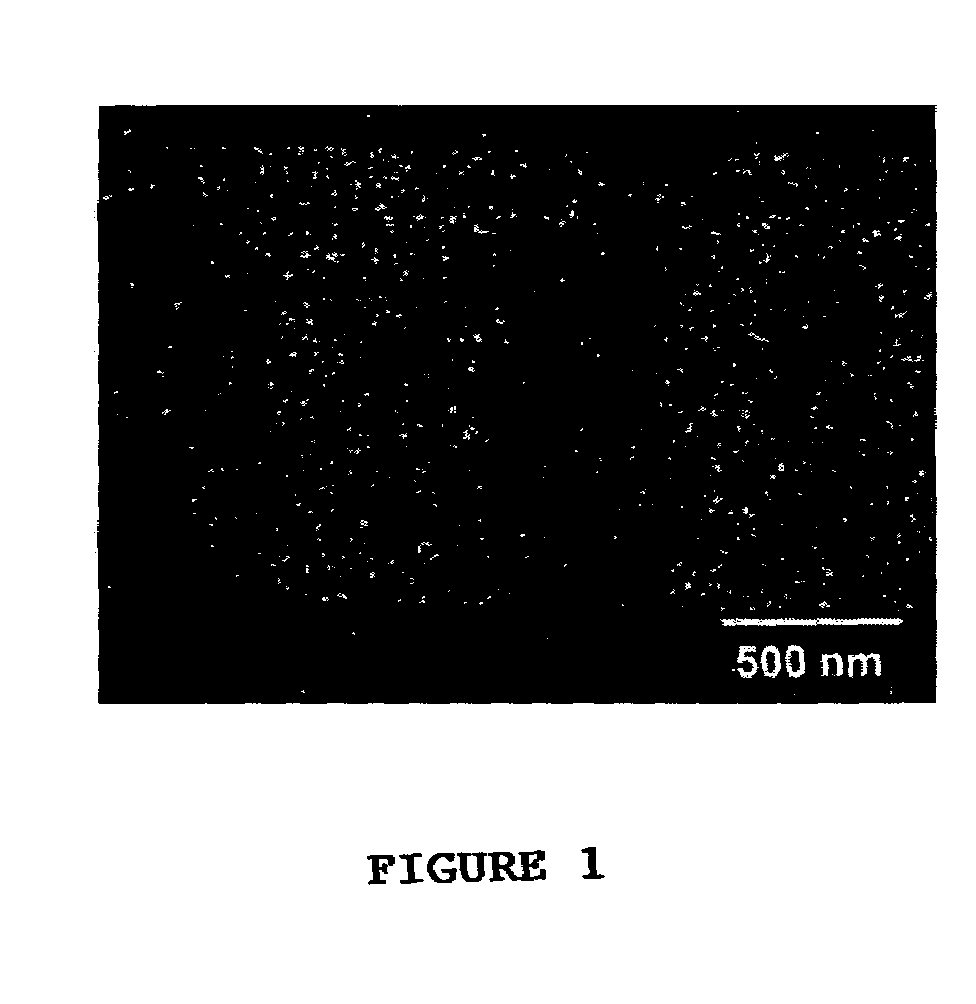

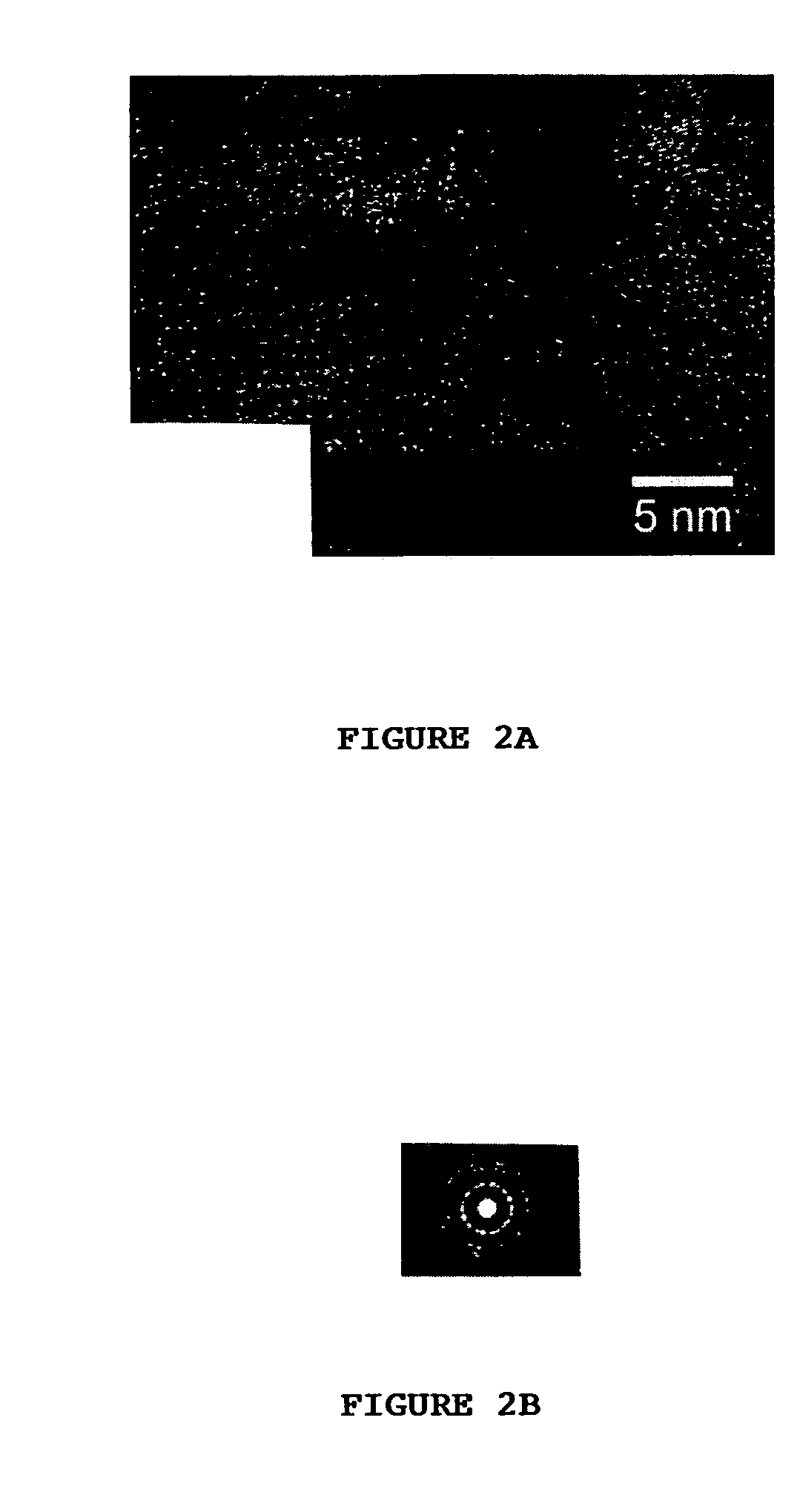

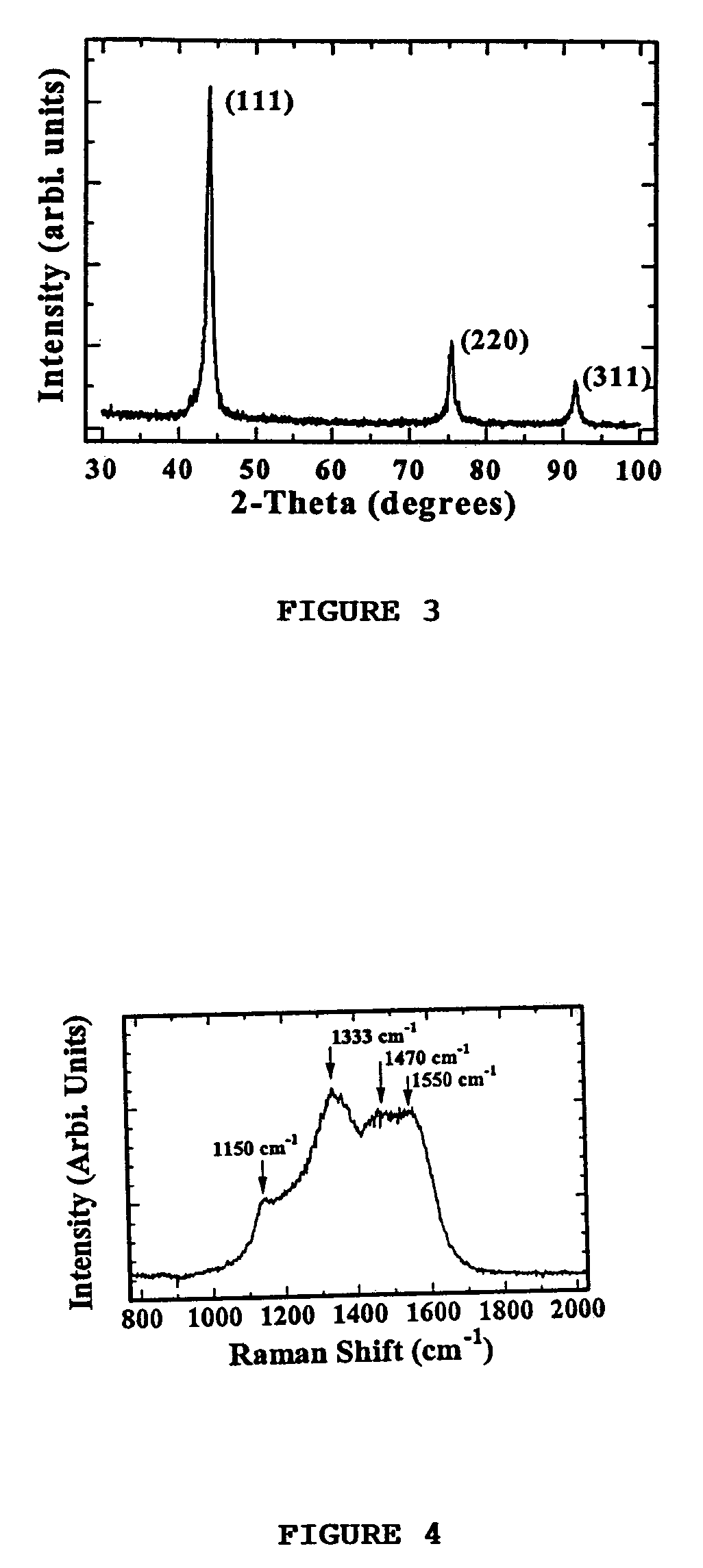

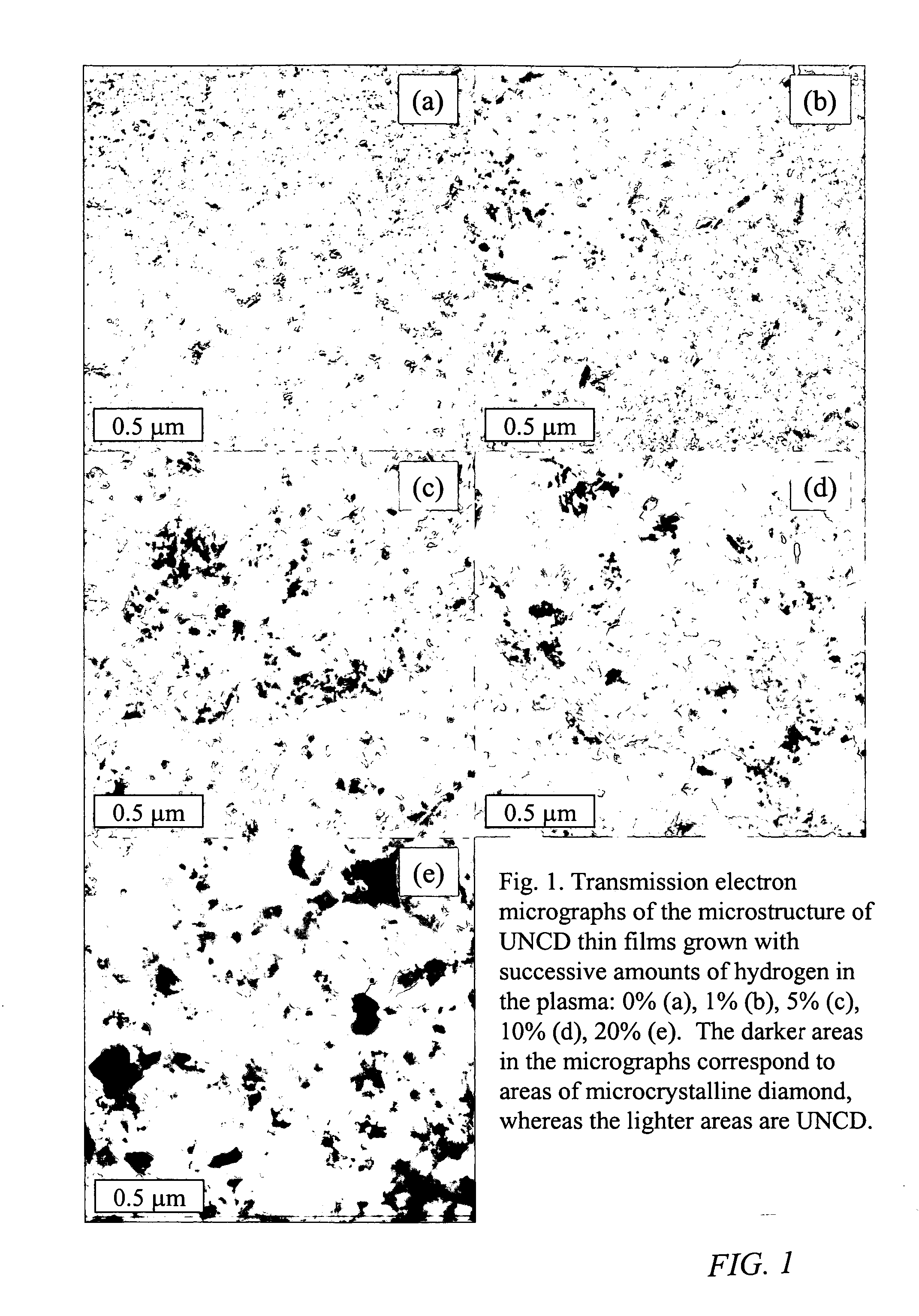

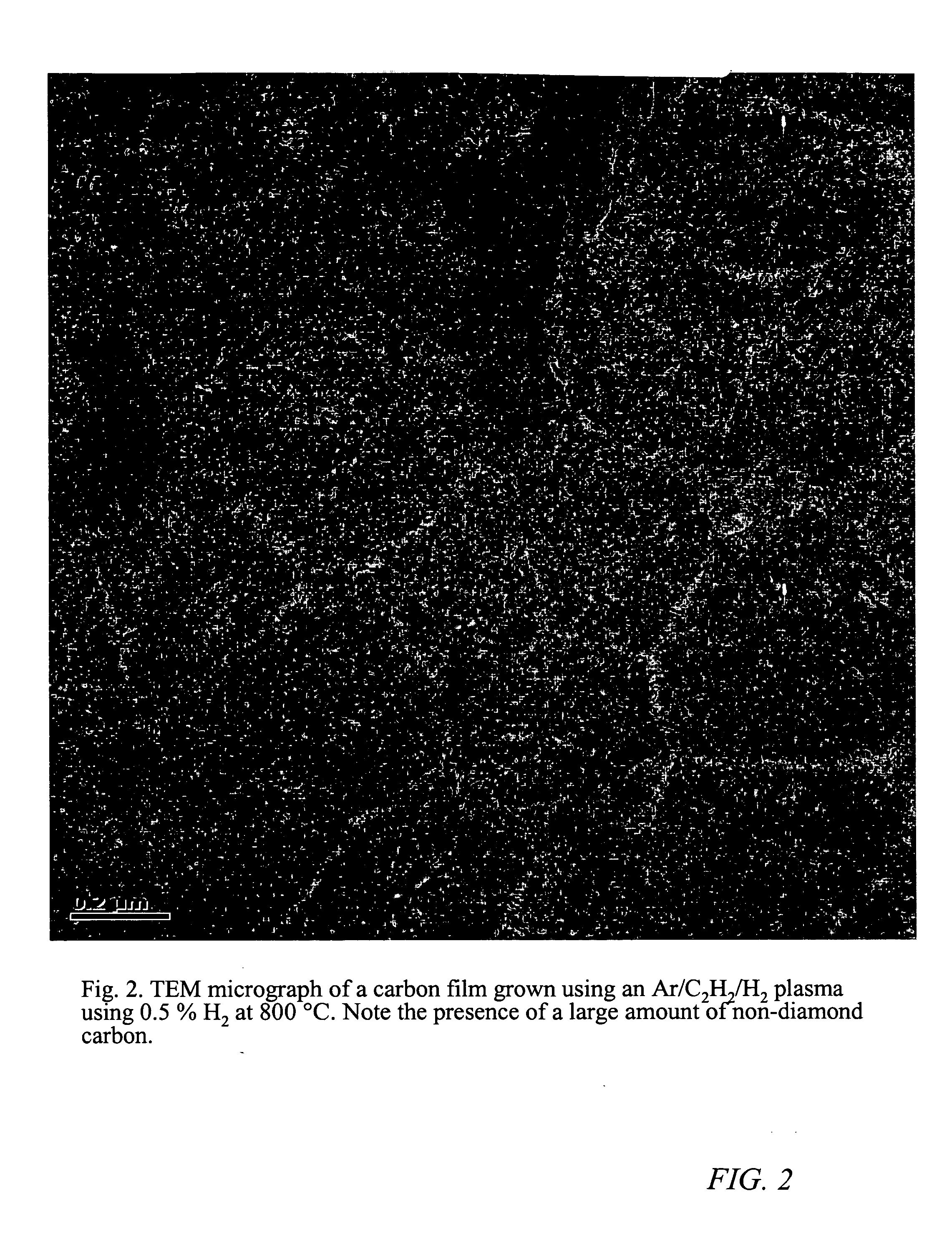

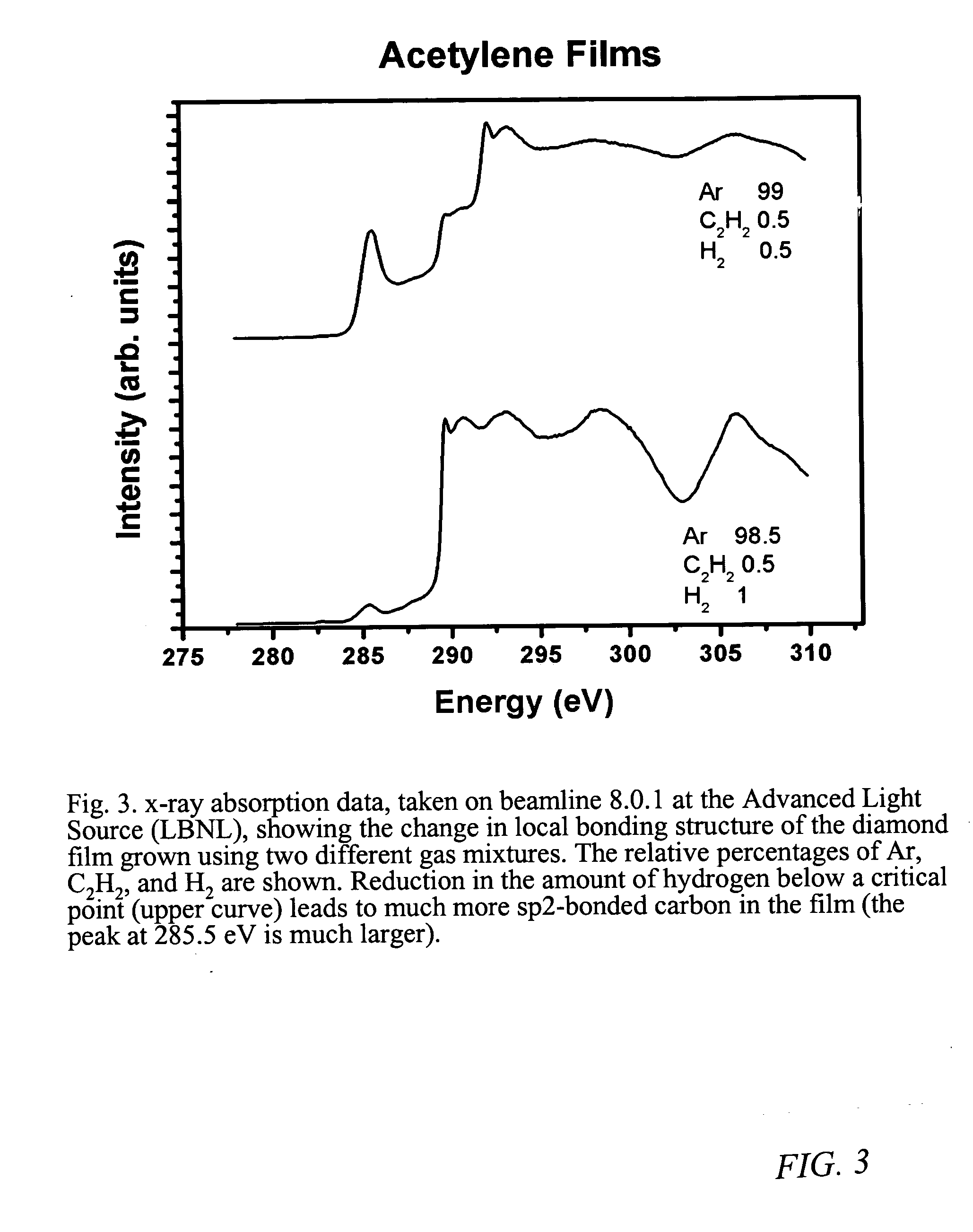

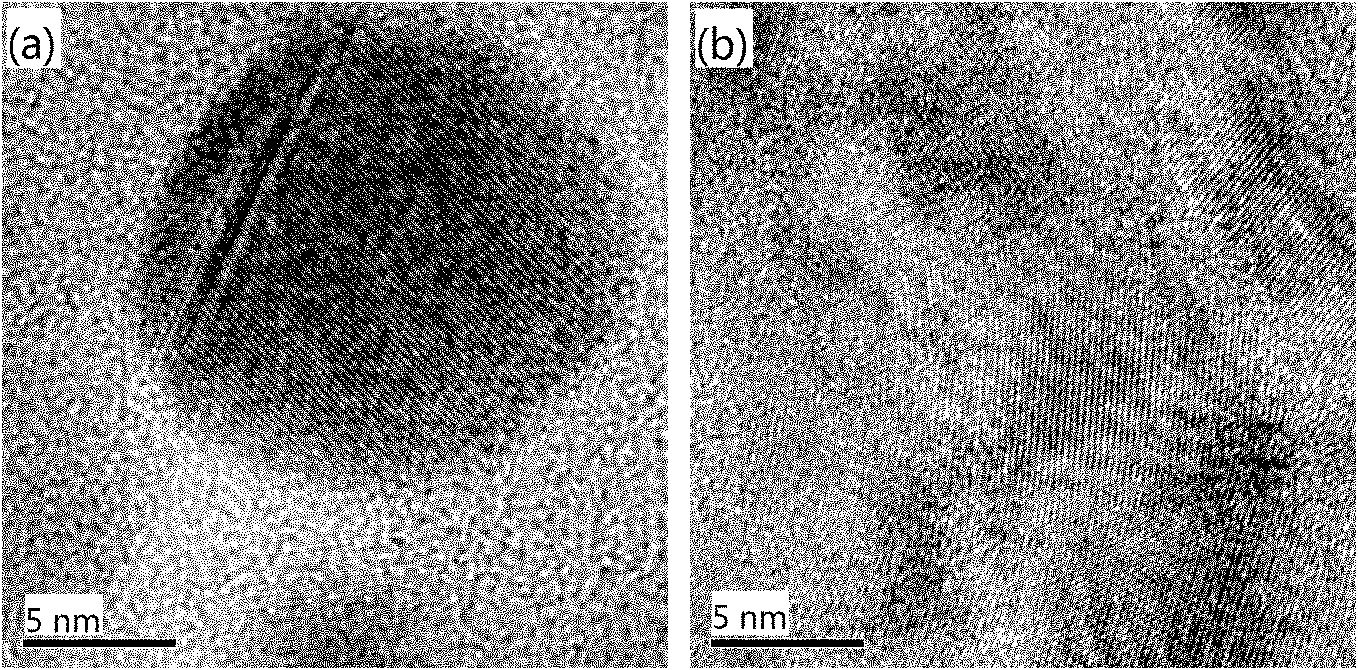

Method to grow carbon thin films consisting entirely of diamond grains 3-5 nm in size and high-energy grain boundaries

ActiveUS20050042161A1Polycrystalline material growthUltra-high pressure processesHydrogenHigh energy

An ultrananocrystalline diamond (UNCD) having an average grain size between 3 and 5 nanometers (nm) with not more than about 8% by volume diamond having an average grain size larger than 10 nm. A method of manufacturing UNCD film is also disclosed in which a vapor of acetylene and hydrogen in an inert gas other than He wherein the volume ratio of acetylene to hydrogen is greater than 0.35 and less than 0.85, with the balance being an inert gas, is subjected to a suitable amount of energy to fragment at least some of the acetylene to form a UNCD film having an average grain size of 3 to 5 nm with not more than about 8% by volume diamond having an average grain size larger than 10 nm.

Owner:UCHICAGO ARGONNE LLC

Diamond films and methods of making diamond films

InactiveUS7306778B2Performance advantageUltra-high pressure processesLayered productsGraphiteNanocrystal

The present invention provides films and substrates coated with films that comprise a nano-crystalline diamond matrix that is substantially free of graphite inclusions. The present invention also provides a method of chemical vapor deposition to prepare the films. The method of chemical vapor deposition operates at a DC bias voltage that substantially precludes the formation of a plasma ion capable of causing a region of a nano-crystalline diamond matrix within a forming film to allotrope when the plasma ion collides with the film.

Owner:NANOTECH

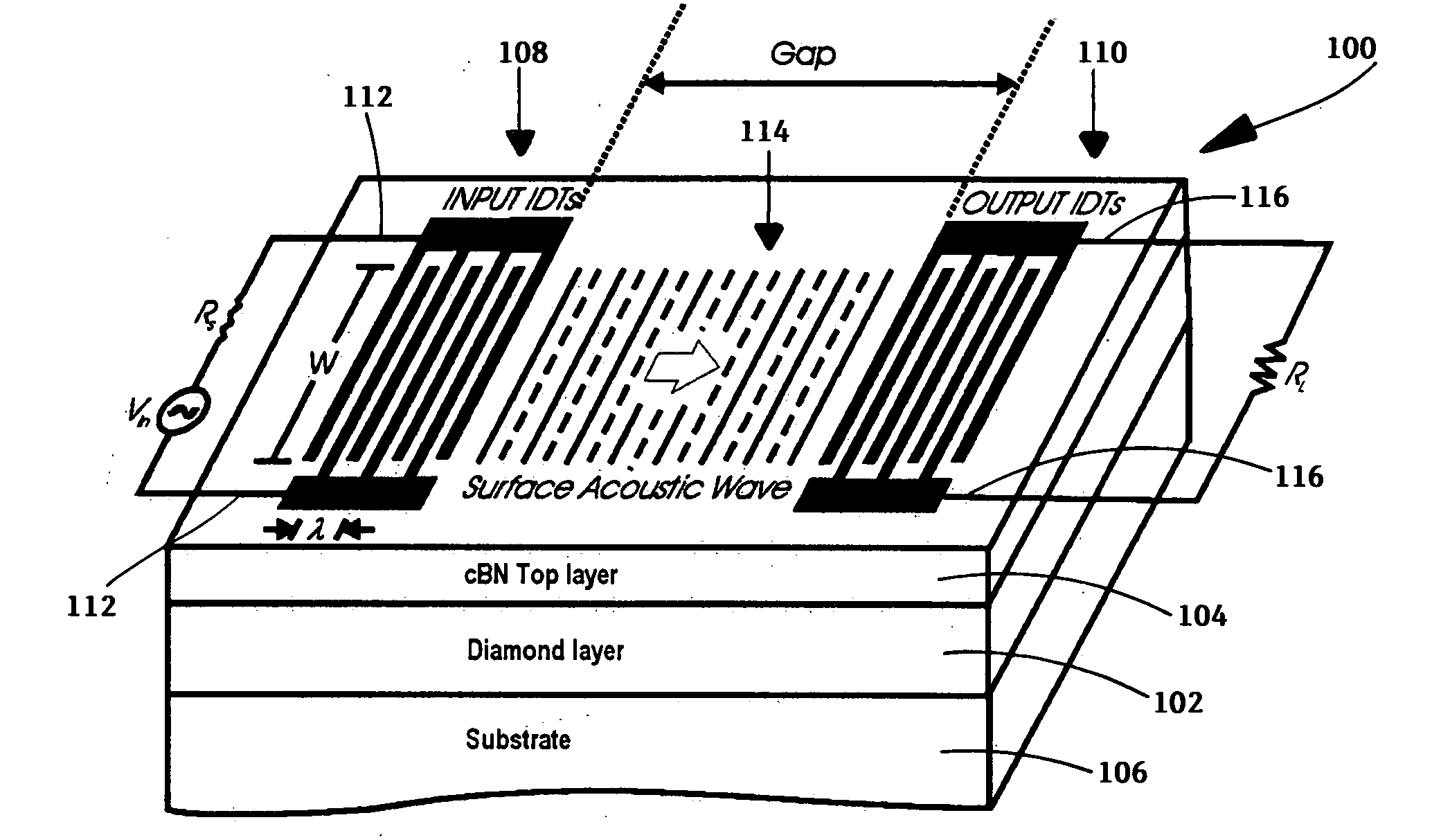

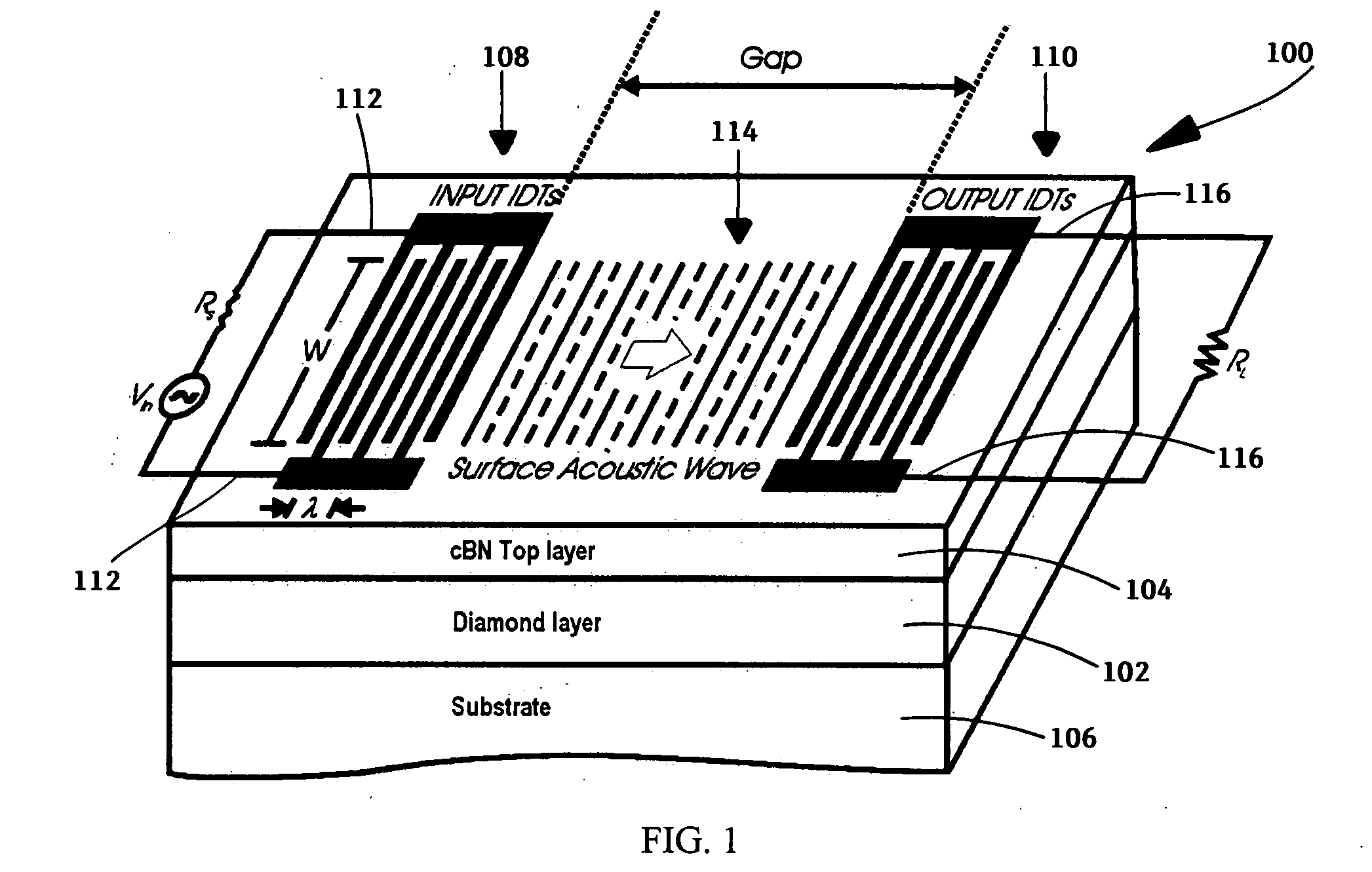

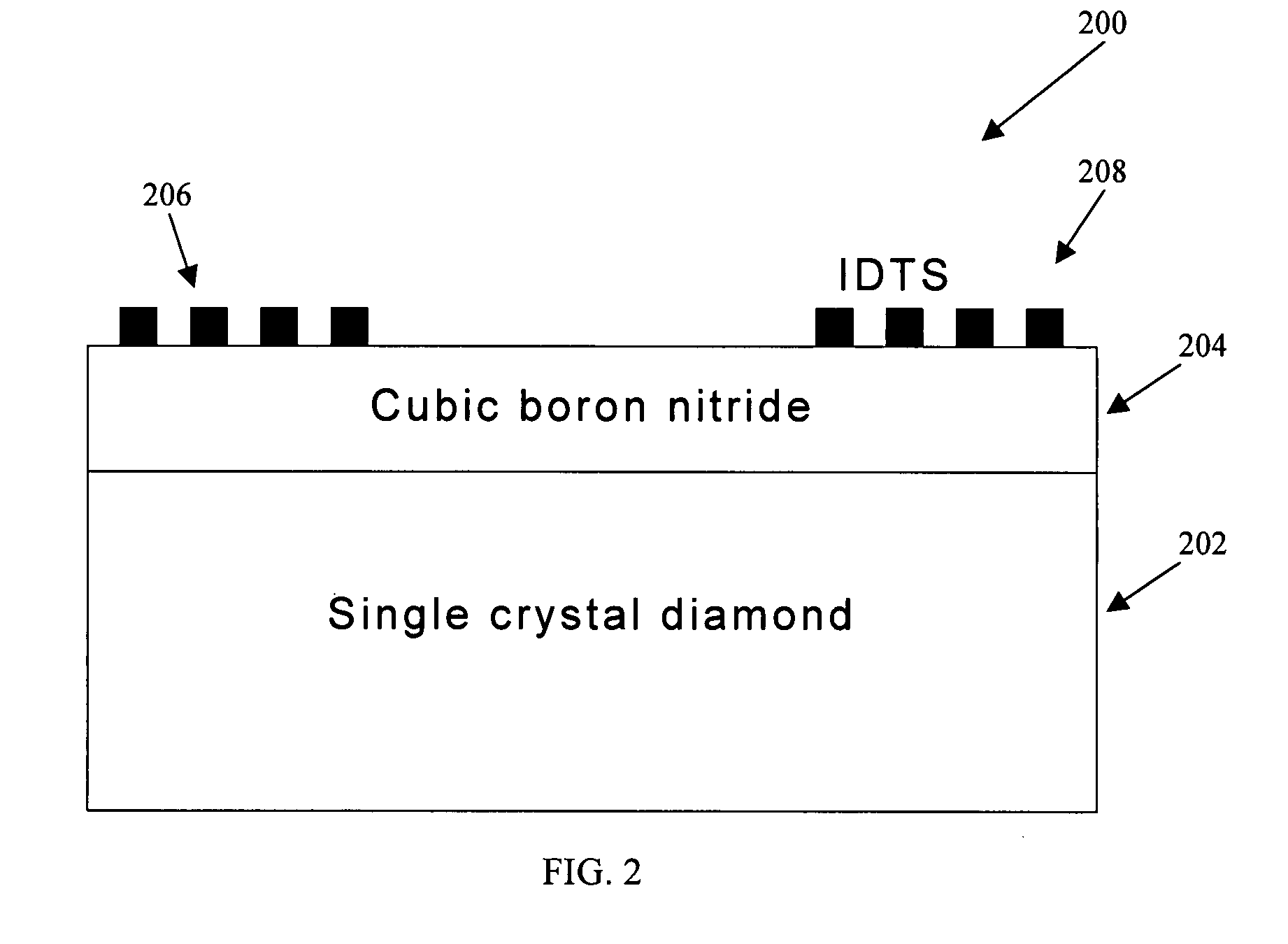

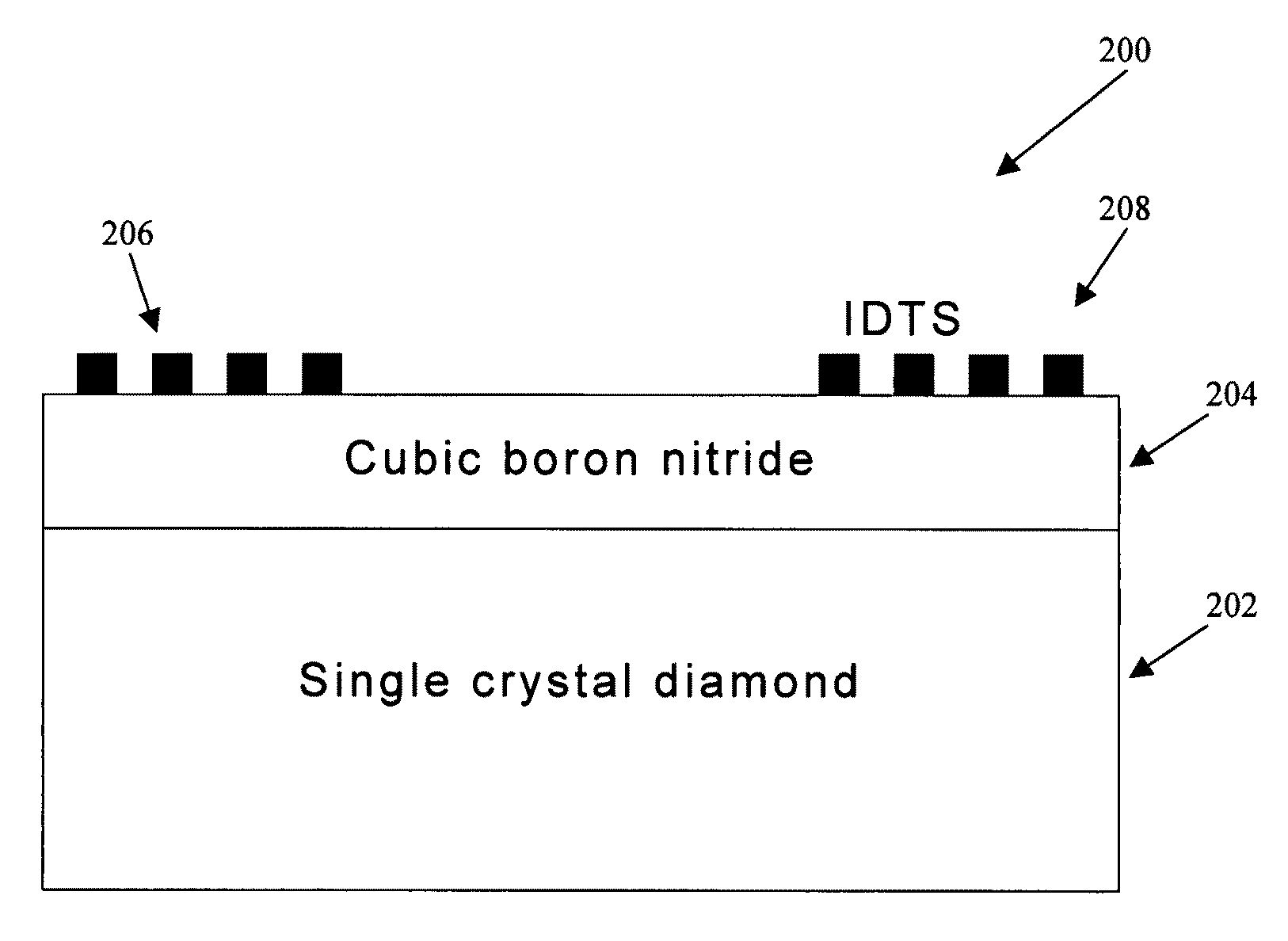

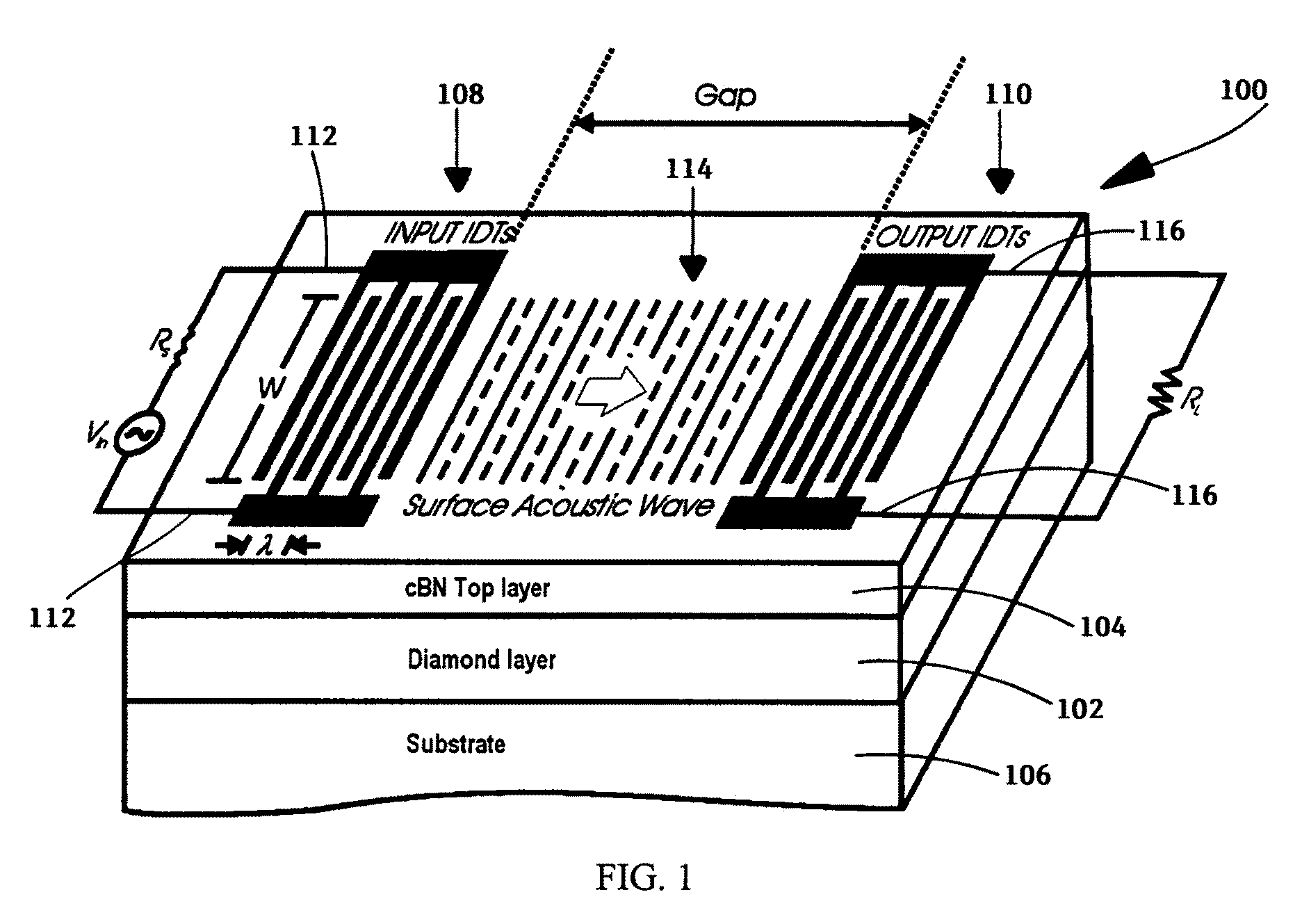

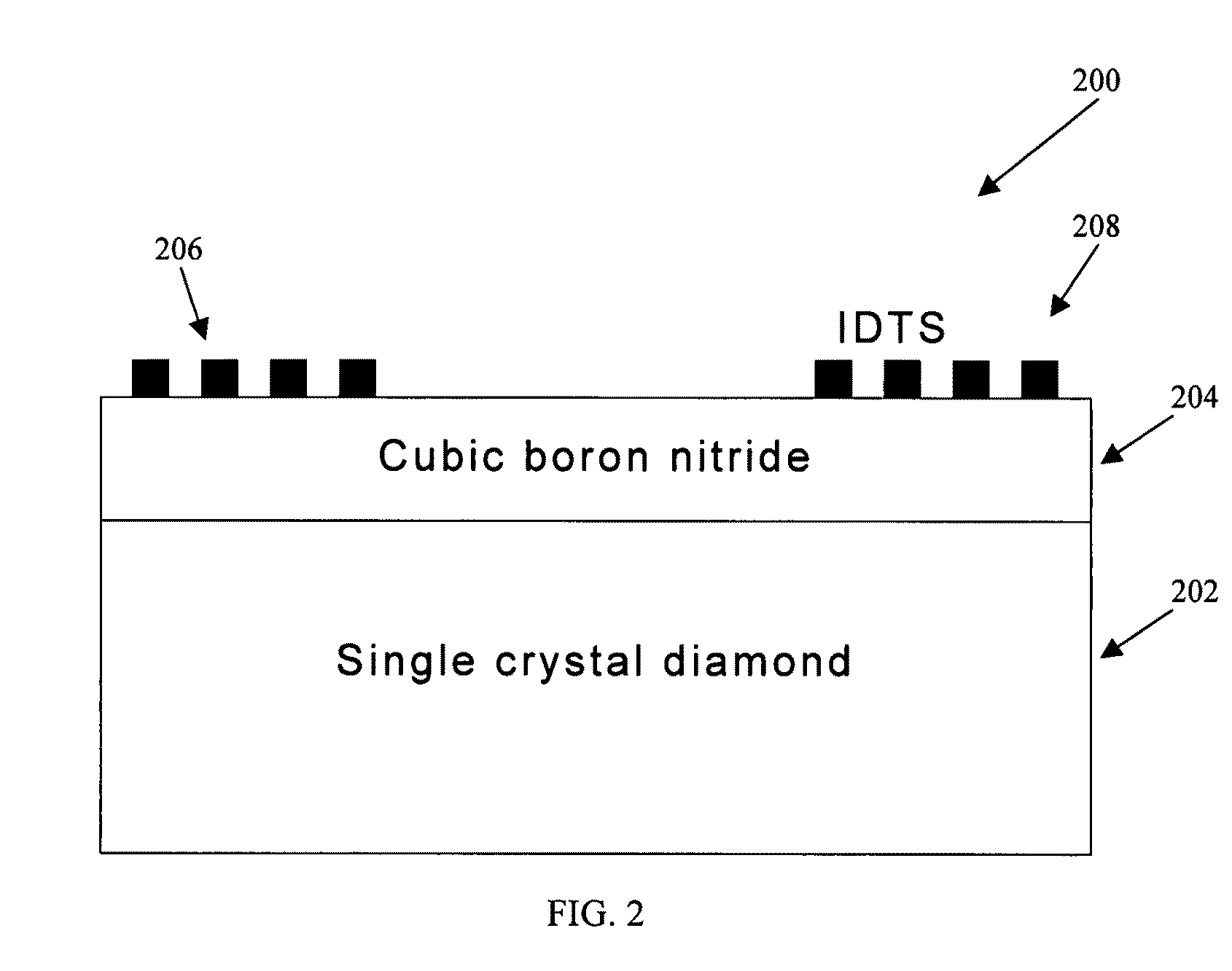

Surface acoustic wave (SAW) devices based on cubic boron nitride/diamond composite structures

ActiveUS20080303378A1Reduce surface roughnessAvoid distractionImpedence networksPiezoelectric/electrostriction/magnetostriction machinesLow speedPolycrystalline diamond

A surface acoustic wave (SAW) device which is made of cBN / diamond composite structures and the fabrication method are disclosed. In the SAW device based on cubic boron nitride and diamond composite structures, the diamond hard layer includes randomly-oriented polycrystalline diamond (poly-D), oriented (heteroepitaxial) diamond, single-crystal diamond wafers and nanocrystalline diamond (nano-D) films. The cBN film with a sound velocity close to that of diamond serves as the piezoelectric layer, which was directly deposited on diamond hard layer without any soft sp2-BN incubation layer by ion assisted physical vapor deposition (PVD) and plasma-enhanced (or ion assisted) chemical vapor deposition (PECVD). Due to the high sound velocity and the low velocity dispersion between the cBN and diamond layered materials, the present SAW device based on cubic boron nitride and diamond composite structures can improve the device performance and operate at ultra-high frequency range.

Owner:CITY UNIVERSITY OF HONG KONG

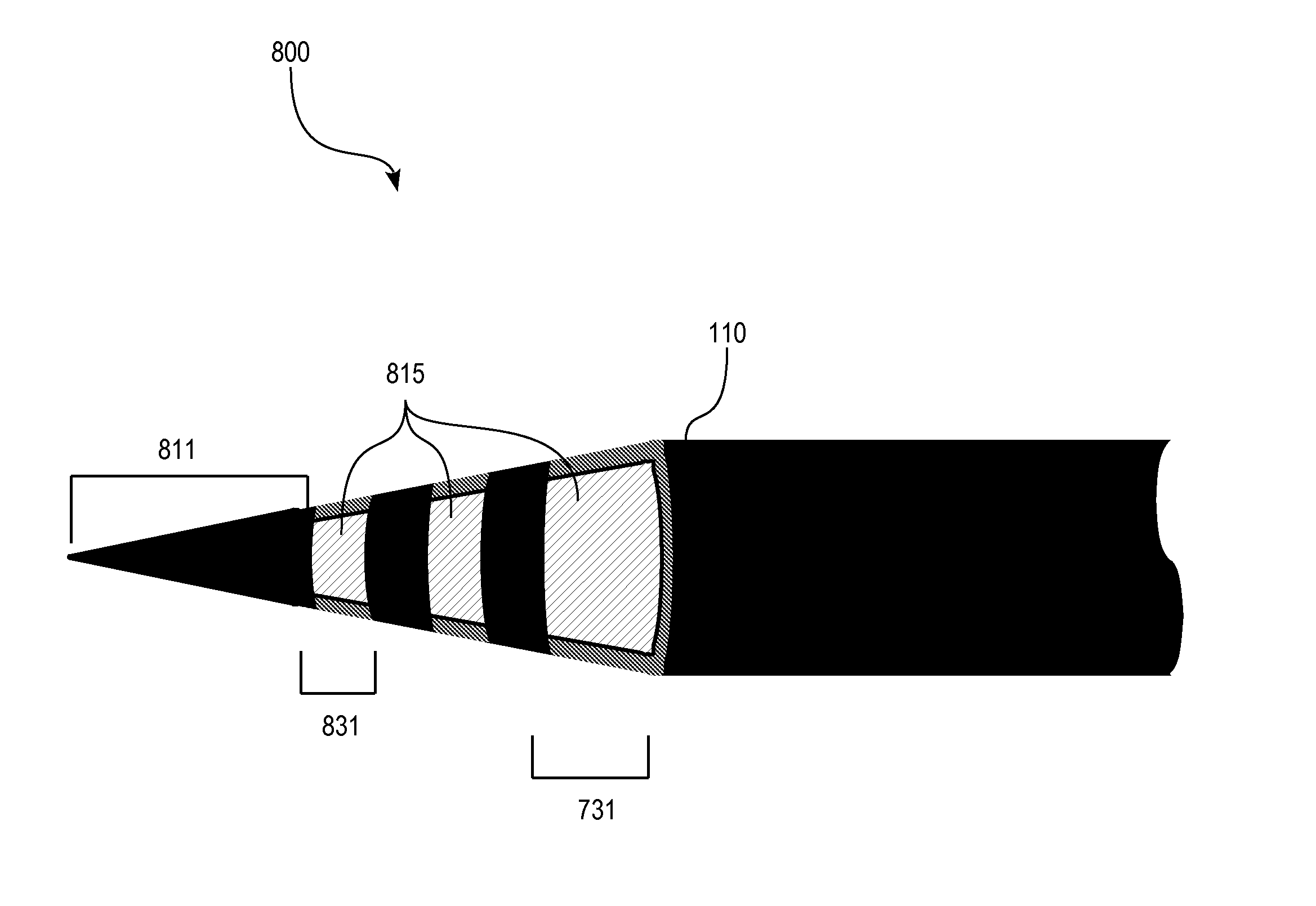

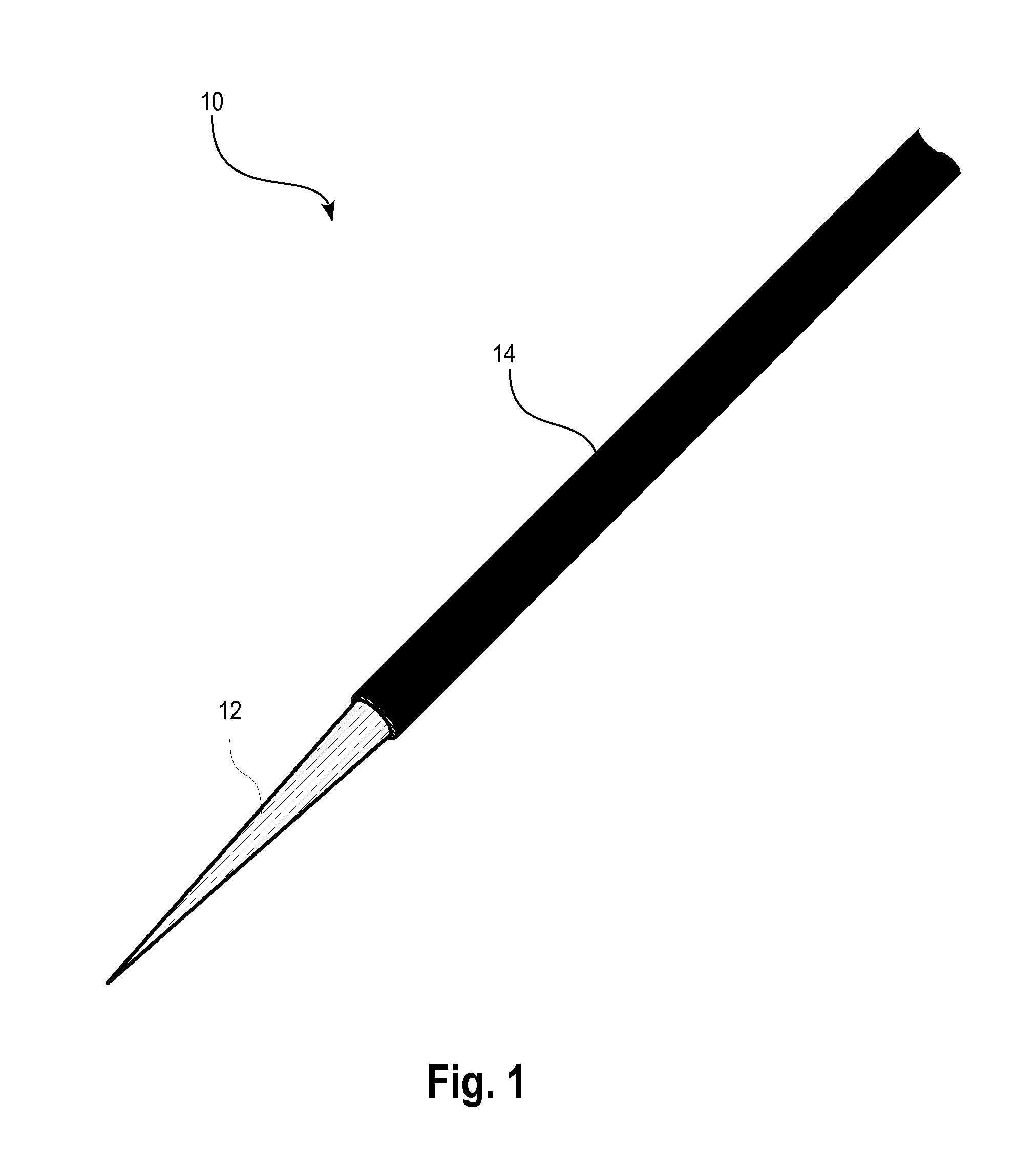

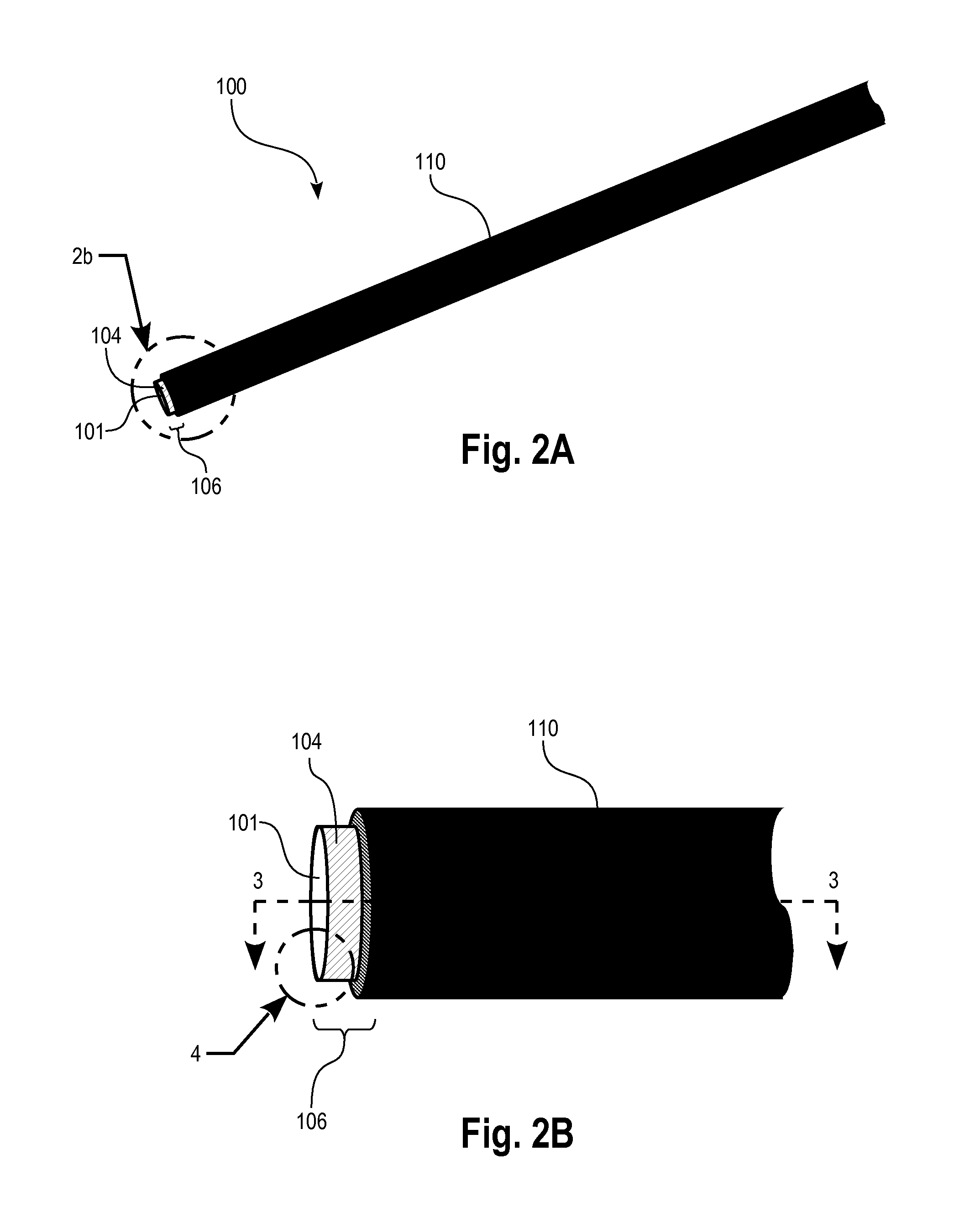

Conductive nanocrystalline diamond micro-electrode sensors and arrays for in-vivo chemical sensing of neurotransmitters and neuroactive substances and method of fabrication thereof

InactiveUS20150250421A1High selectivityHigh sensitivityDecorative surface effectsPreparing sample for investigationSensor arrayNeuroactive substances

Conductive diamond micro-electrode sensors and sensor arrays are disclosed for in vivo chemical sensing. Also provided is a method of fabrication of individual sensors and sensor arrays. Reliable, sensitive and selective chemical micro-sensors may be constructed for real-time, continuous monitoring of neurotransmitters and neuro-active substances in vivo. Each sensor comprises a conductive microwire, having a distal end comprising a tip, coated with nanocrystalline or ultrananocrystalline conductive diamond, and an overlying insulating layer. Active sensor areas of the conductive diamond layer are defined by openings in the insulating layer at the distal end. Multiple sensor areas may be defined by a 2 or 3 dimensional pattern of openings near the tip. This structure limits interference from surrounding areas for improved signal to noise ratio, sensitivity and selectivity. Using fast-scan cyclic voltammetry and high speed multiplexers, multiple sensors can be arrayed to provide 3-D spatial, and near real-time monitoring.

Owner:JOHN CRANE INC

High power impulse magnetron sputtering process to achieve a high density high SP3 containing layer

Methods for depositing a nanocrystalline diamond layer are disclosed herein. The method can include delivering a sputter gas to a substrate positioned in a processing region of a first process chamber, the first process chamber having a carbon-containing sputter target, delivering an energy pulse to the sputter gas to create a sputtering plasma, the sputtering plasma having a sputtering duration, the energy pulse having an average power between 1 W / cm2 and 10 W / cm2 and a pulse width which is less than 100 μs and greater than 30 μs, the sputtering plasma being controlled by a magnetic field, the magnetic field being less than 300. Gauss, and delivering the sputtering plasma to the sputter target to form an ionized species, the ionized species forming a crystalline carbon-containing layer on the substrate.

Owner:APPLIED MATERIALS INC

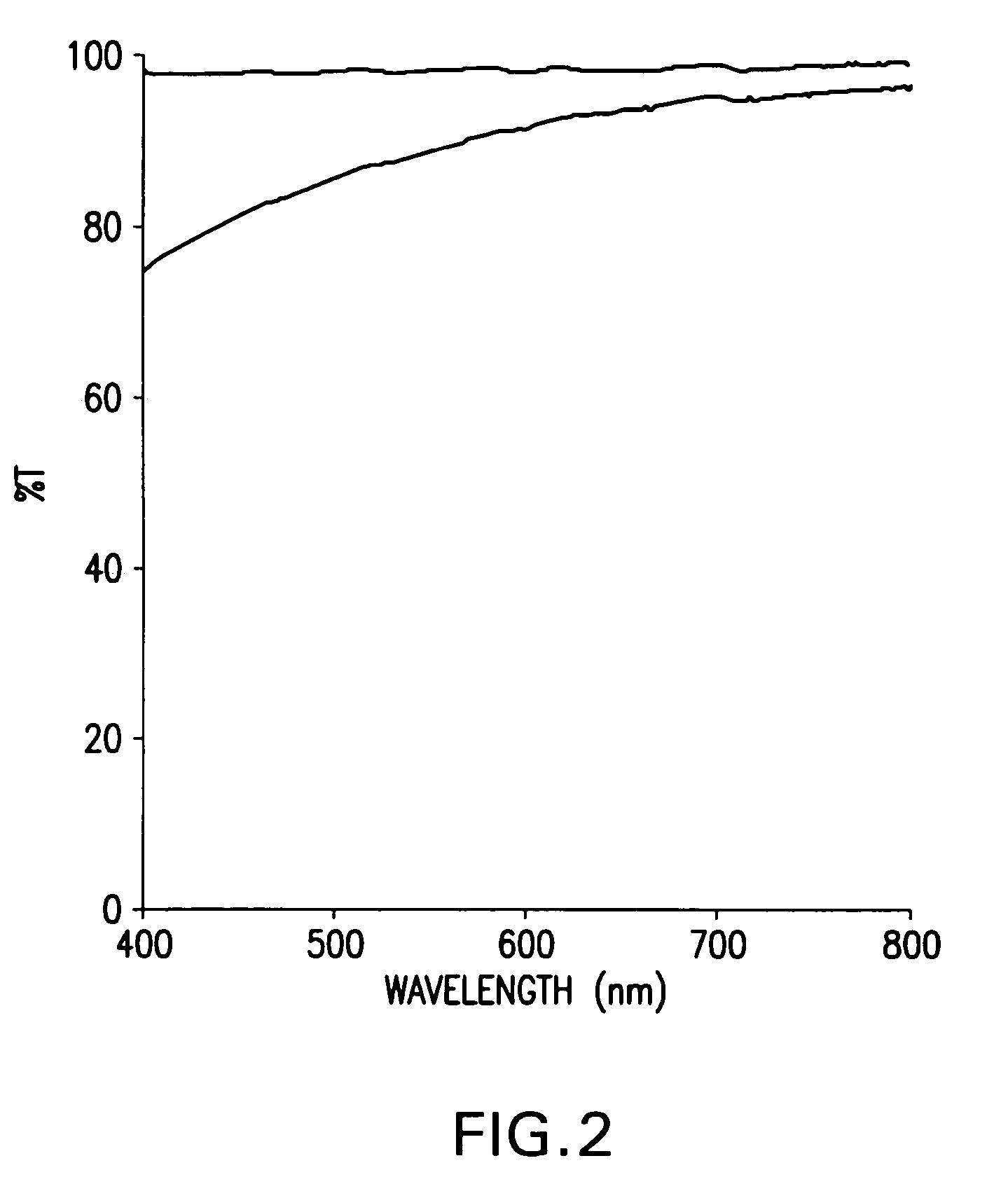

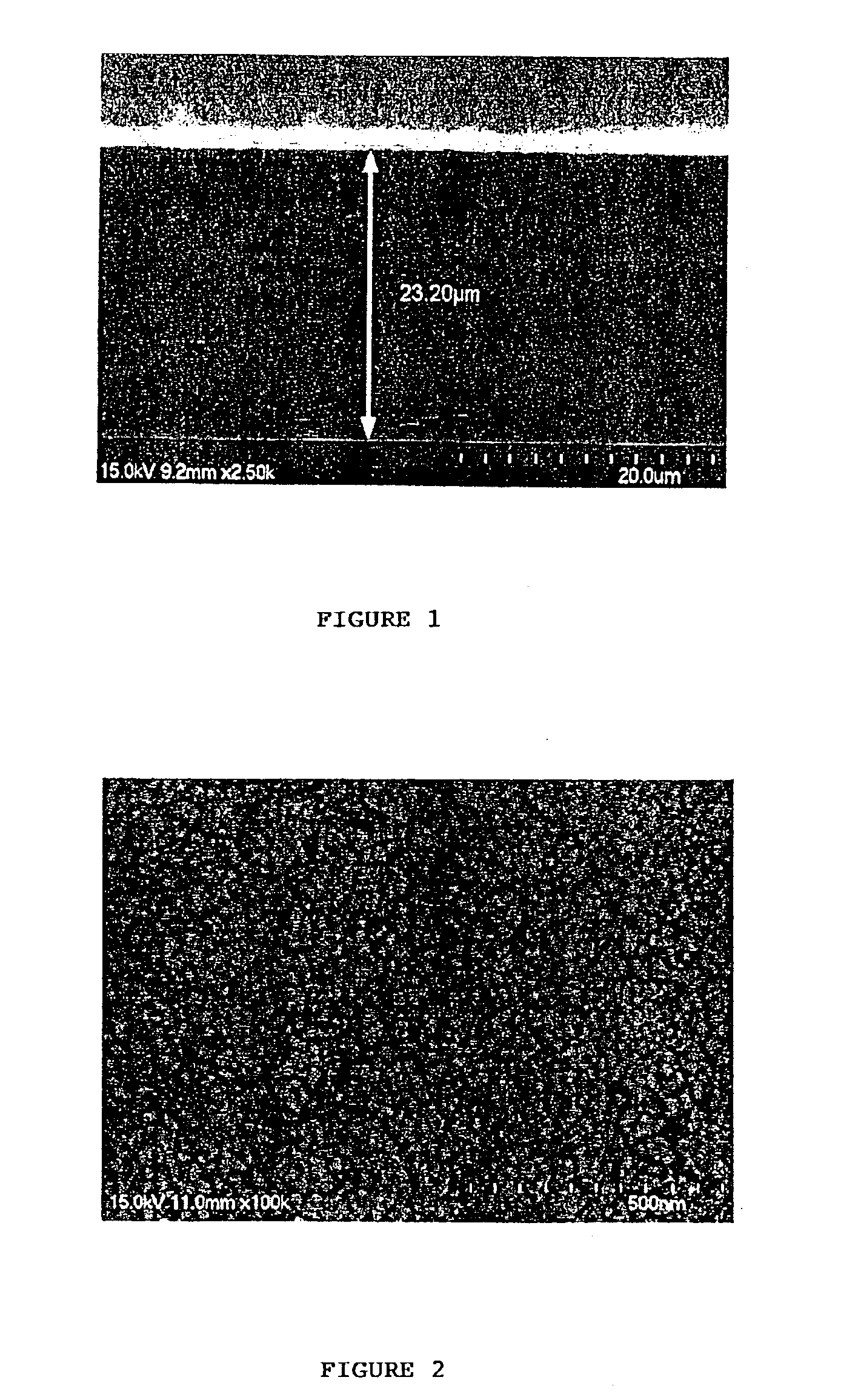

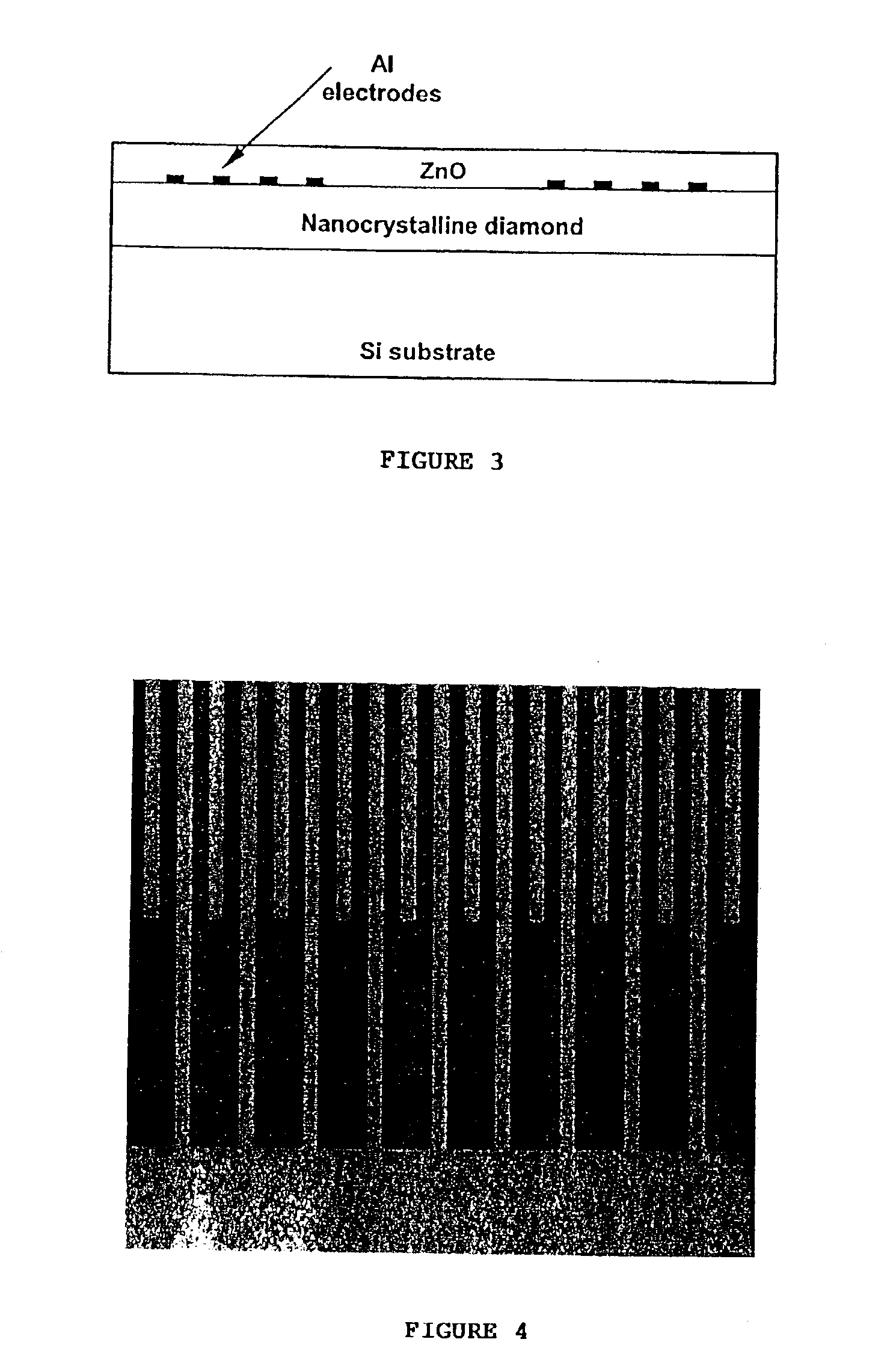

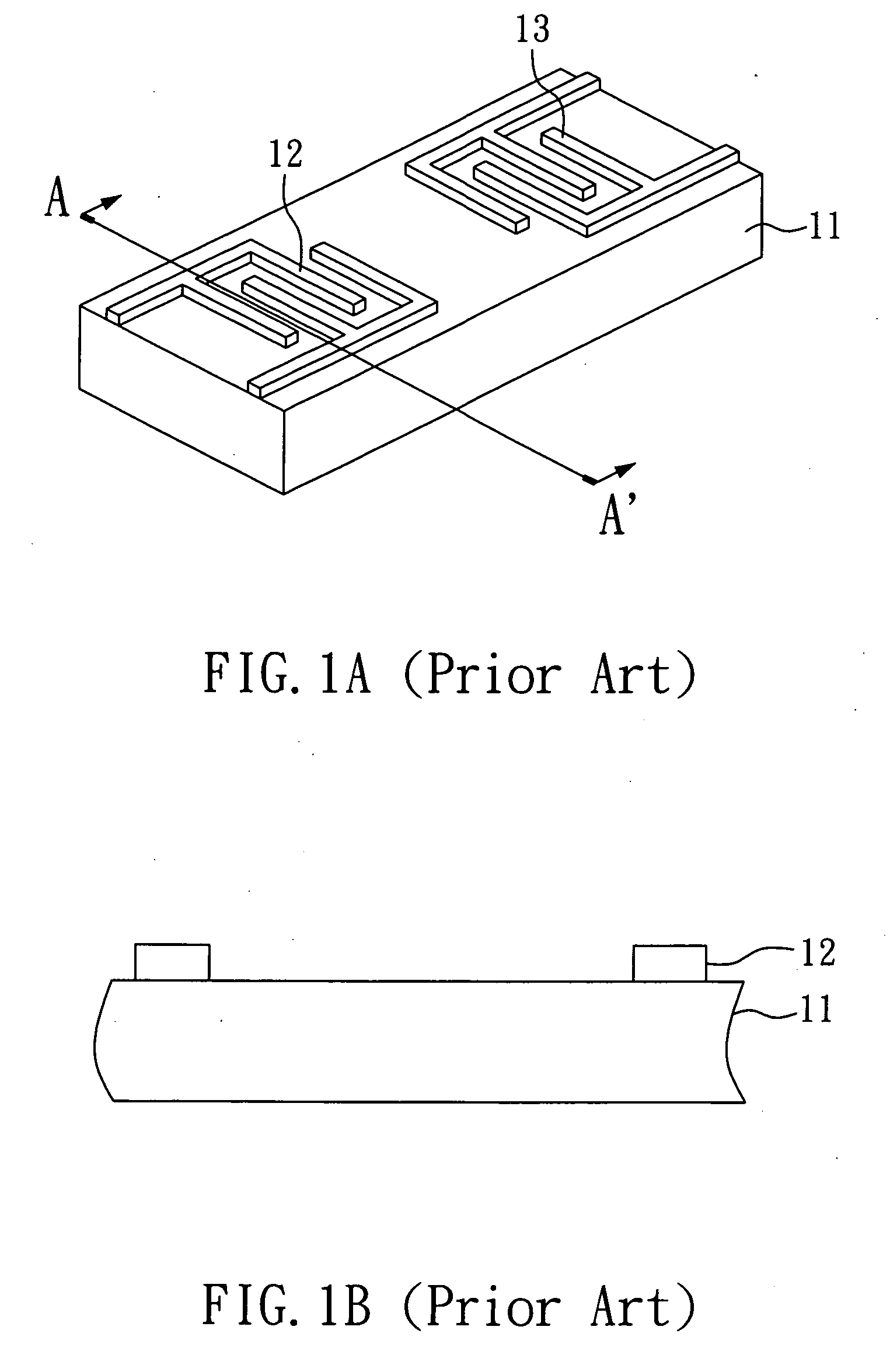

Surface acoustic wave devices based on unpolished nanocrystalline diamond

InactiveUS6858969B2Piezoelectric/electrostriction/magnetostriction machinesImpedence networksAcoustic waveSurface acoustic wave

Owner:MICHIGAN STATE UNIV BOARD OF TRUSTEES OPERATING

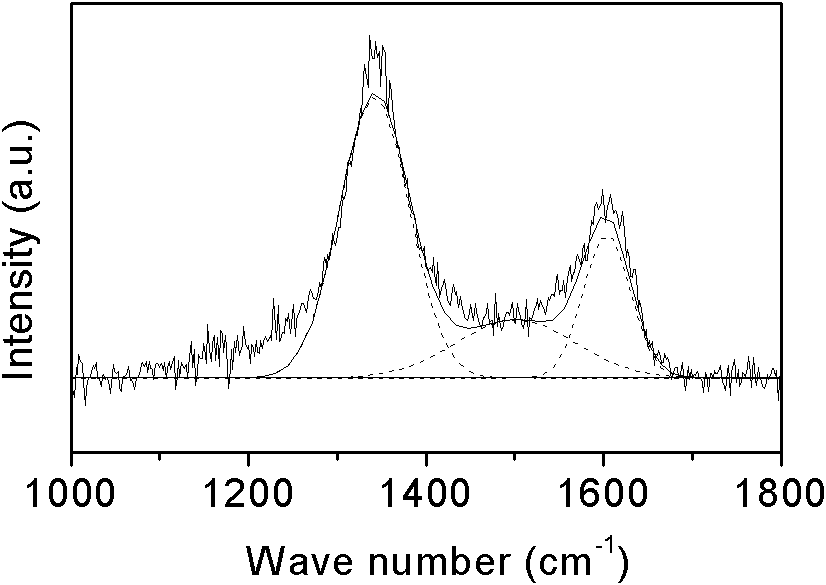

Boron-doped nanocrystalline diamond film and preparation method thereof

InactiveCN101956178AImprove electrochemical performanceImprove conductivityChemical vapor deposition coatingBoron atomElectrochemistry

The invention provides a boron-doped nanocrystalline diamond film. The boron-doped nanocrystalline diamond film is prepared by using the following steps of: preparing a boron-doped nanocrystalline diamond film on a monocrystalline silicon substrate by adopting a CVD (Chemical Vapor Deposition) method and annealing the film in vacuum at 800-1200 DEG C for 30-60 min to obtain the boron-doped nanocrystalline diamond film. By using the vacuum annealing method, the invention ensure that boron atoms aggregated on a grain boundary of the nanocrystalline diamond film are dispersed into nanocrystalline diamond grains and the amount of trans-polyacetylene on the grain boundary is greatly reduced, thereby effectively improving the p-type conductive performance and the electrochemical performance of the boron-doped nanocrystalline diamond film. The invention has very important scientific meaning and engineering values to the application of the boron-doped nanocrystalline diamond film in nano-electronic devices and the electrochemical field, such as water treatment, heavy metal detection, and the like.

Owner:ZHEJIANG UNIV OF TECH

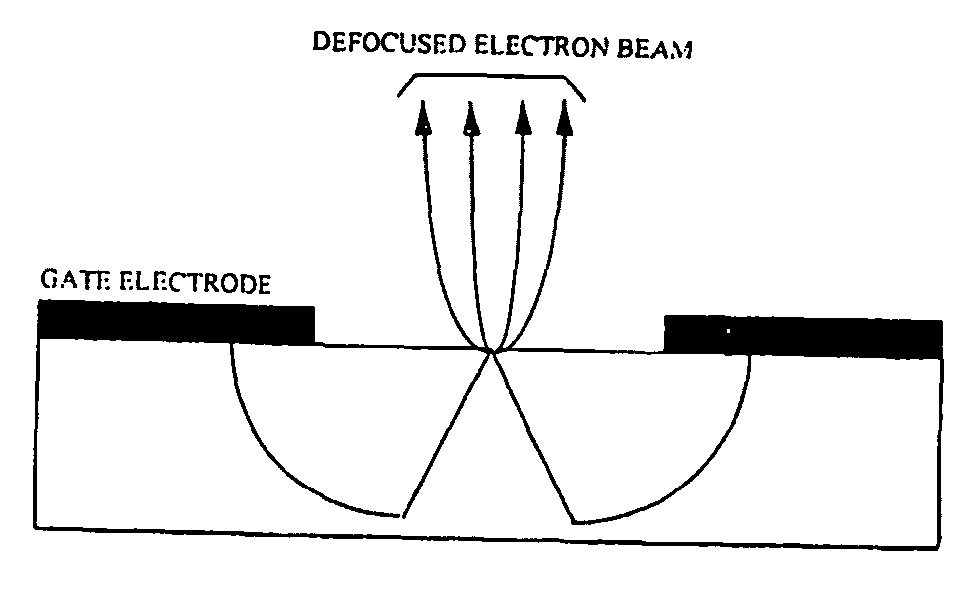

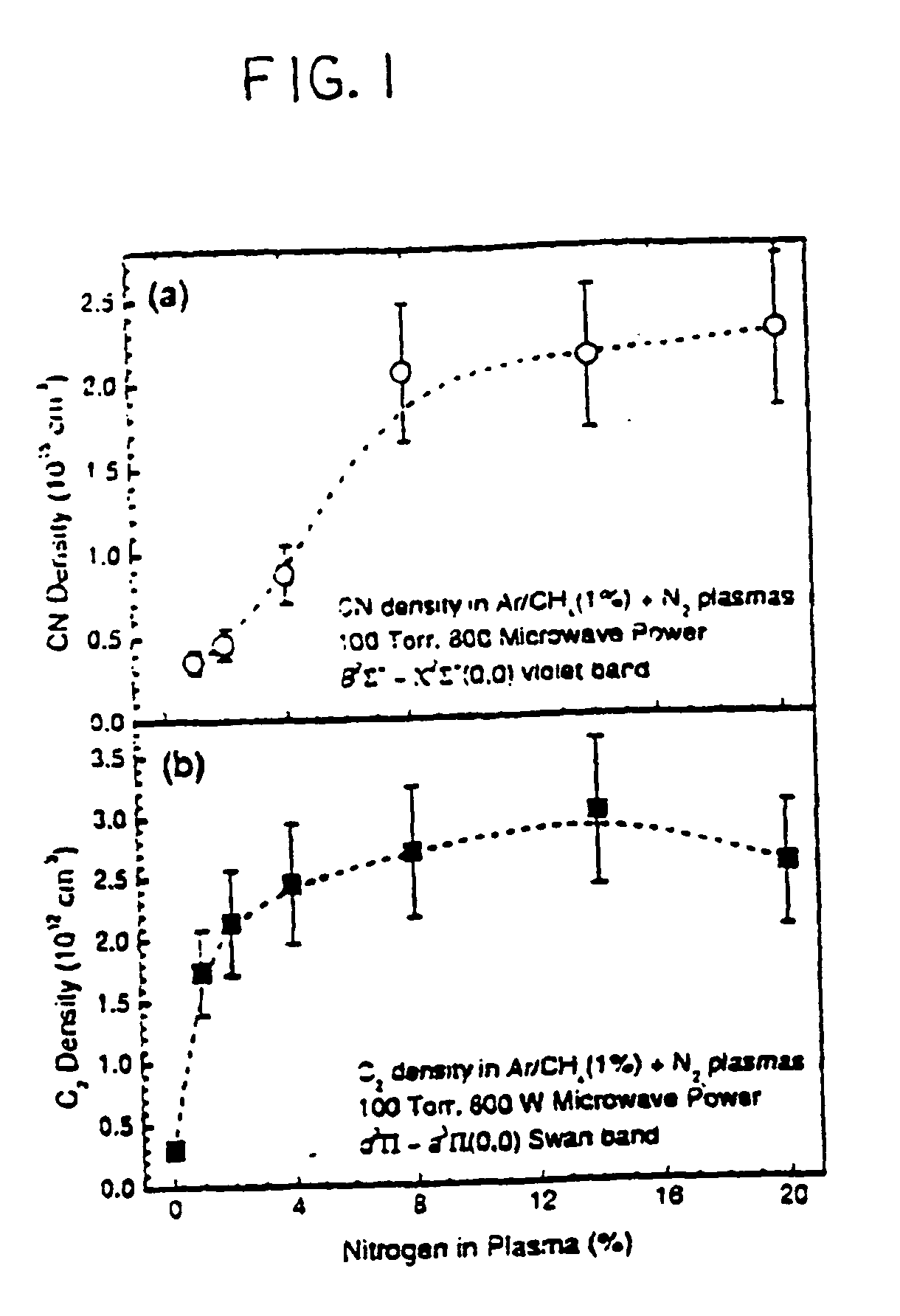

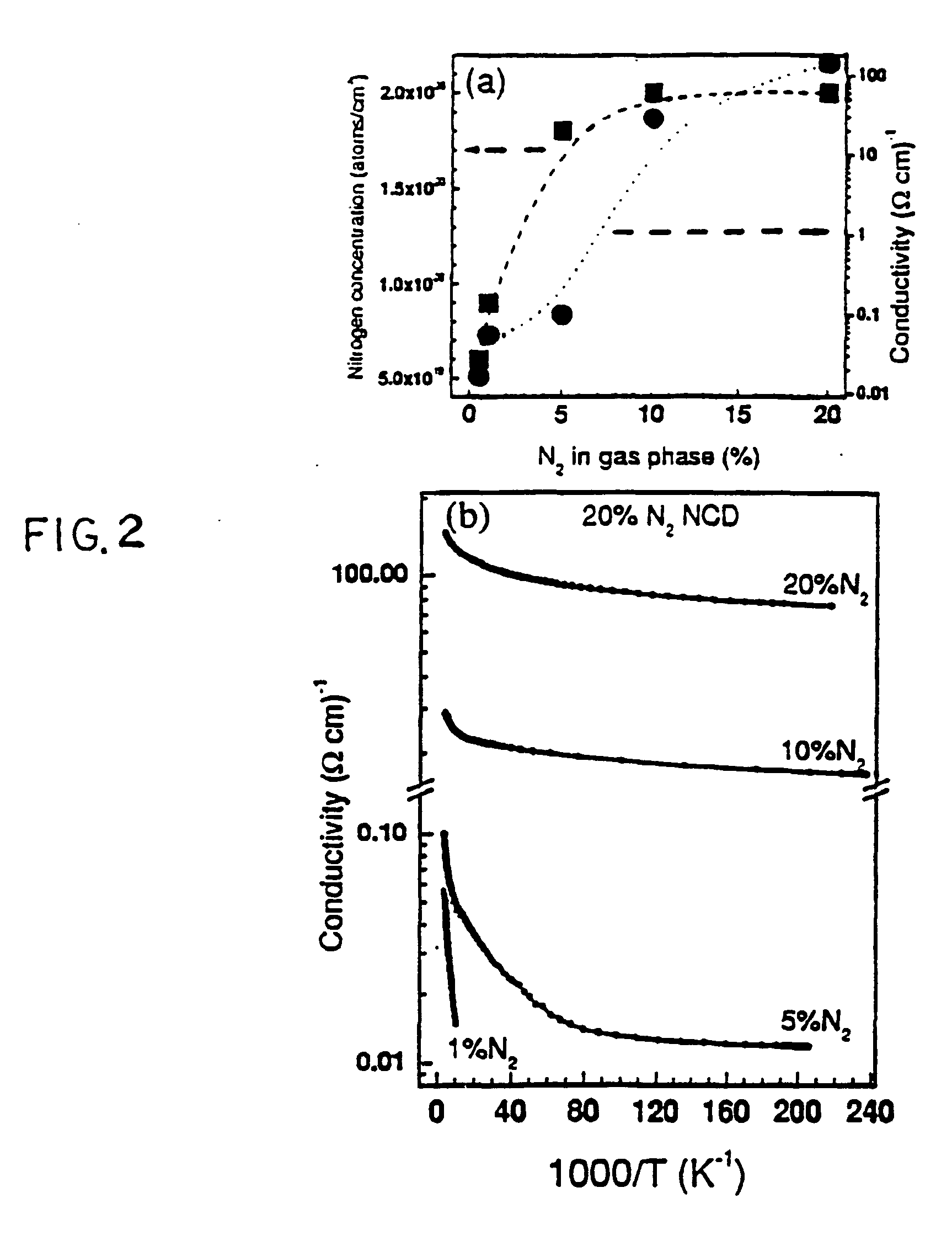

Electrode and electron emission applications for n-type doped nanocrystalline materials

InactiveUS20060131588A1Improve conductivityLarge grainCathode ray tubes/electron beam tubesDischarge tube/lamp detailsNitrogenToxic material

An electrode having a surface of an electrically conducting ultrananocrystalline diamond having not less than 1019 atoms / cm3 nitrogen with an electrical conductivity at ambient temperature of not less than about 0.1 (Ω·cm)−1 is disclosed as is a method of remediating toxic materials with the electrode. An electron emission device incorporating an electrically conducting ultrananocrystalline diamond having not less that 1019 atoms / cm3 nitrogen with an electrical conductivity at ambient temperature of not less than about 0.1 (Ω·cm)−1 is disclosed.

Owner:UCHICAGO ARGONNE LLC

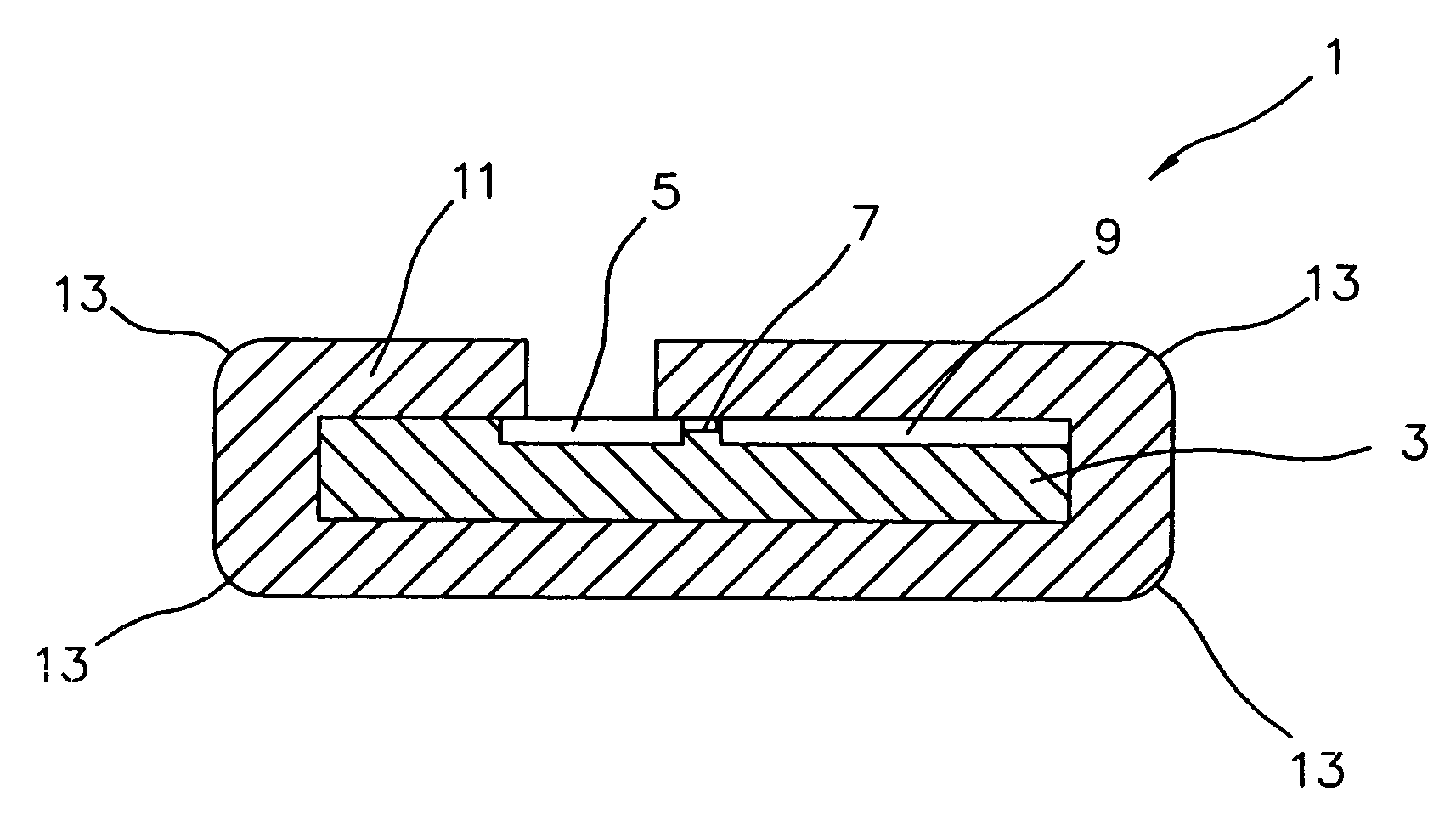

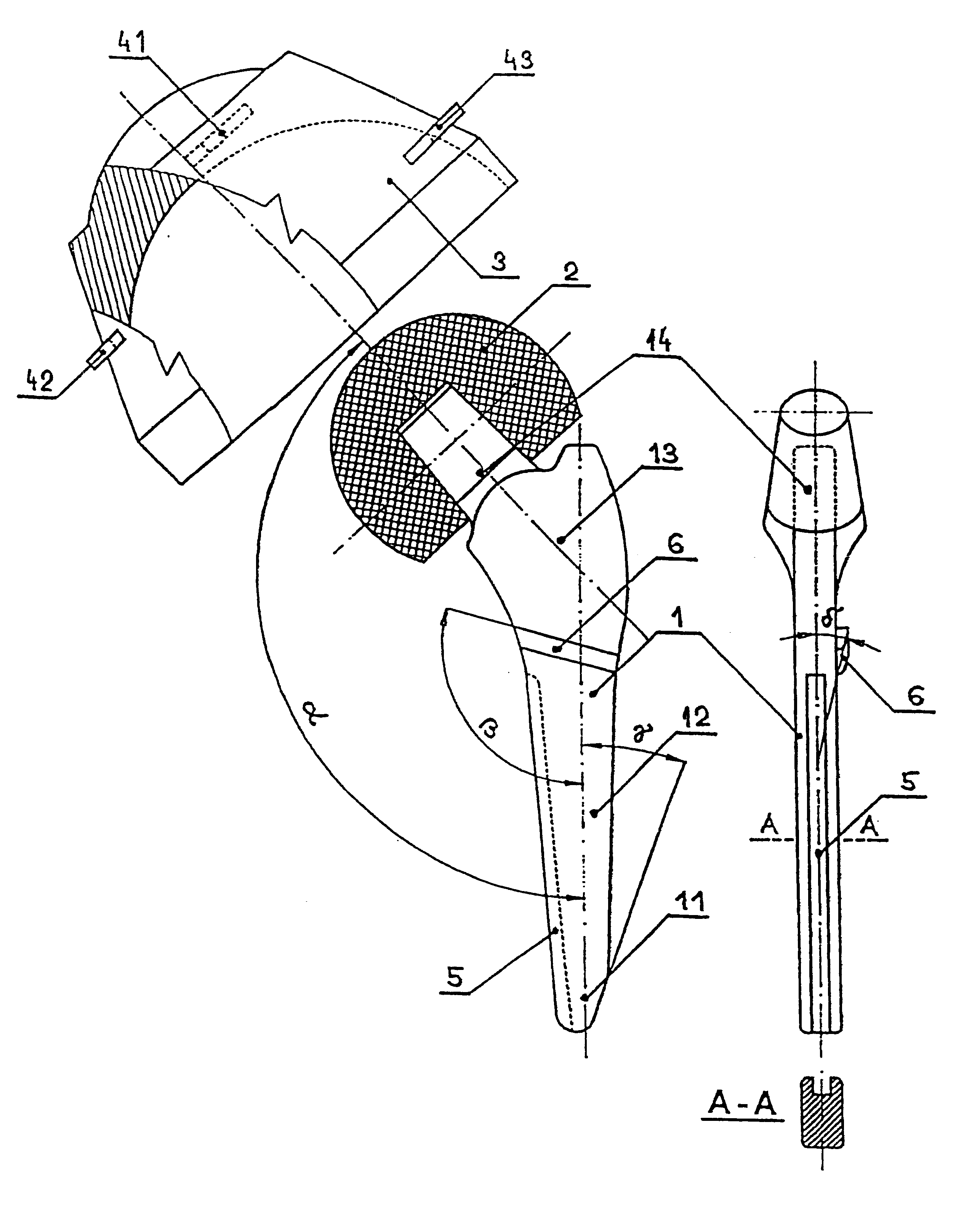

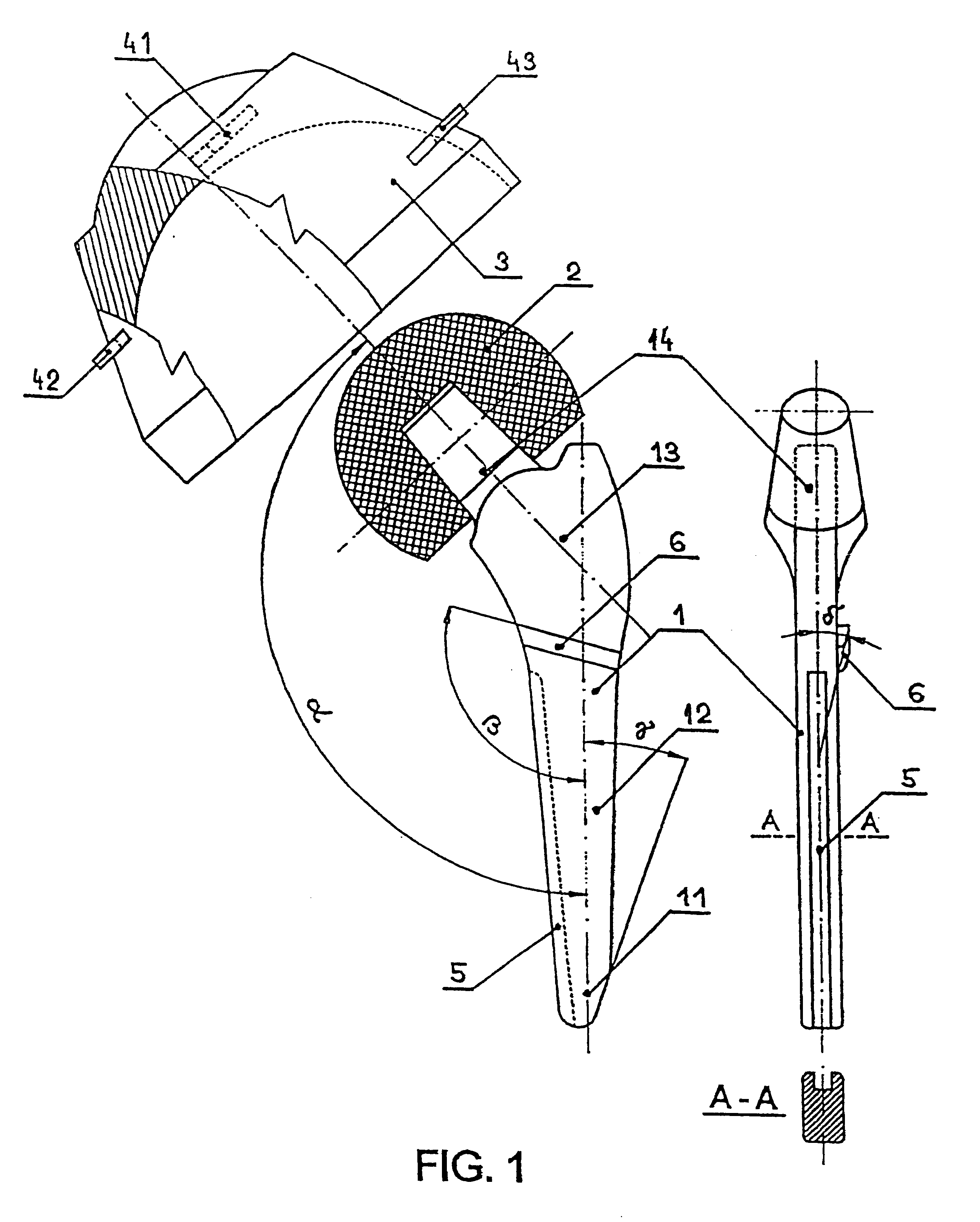

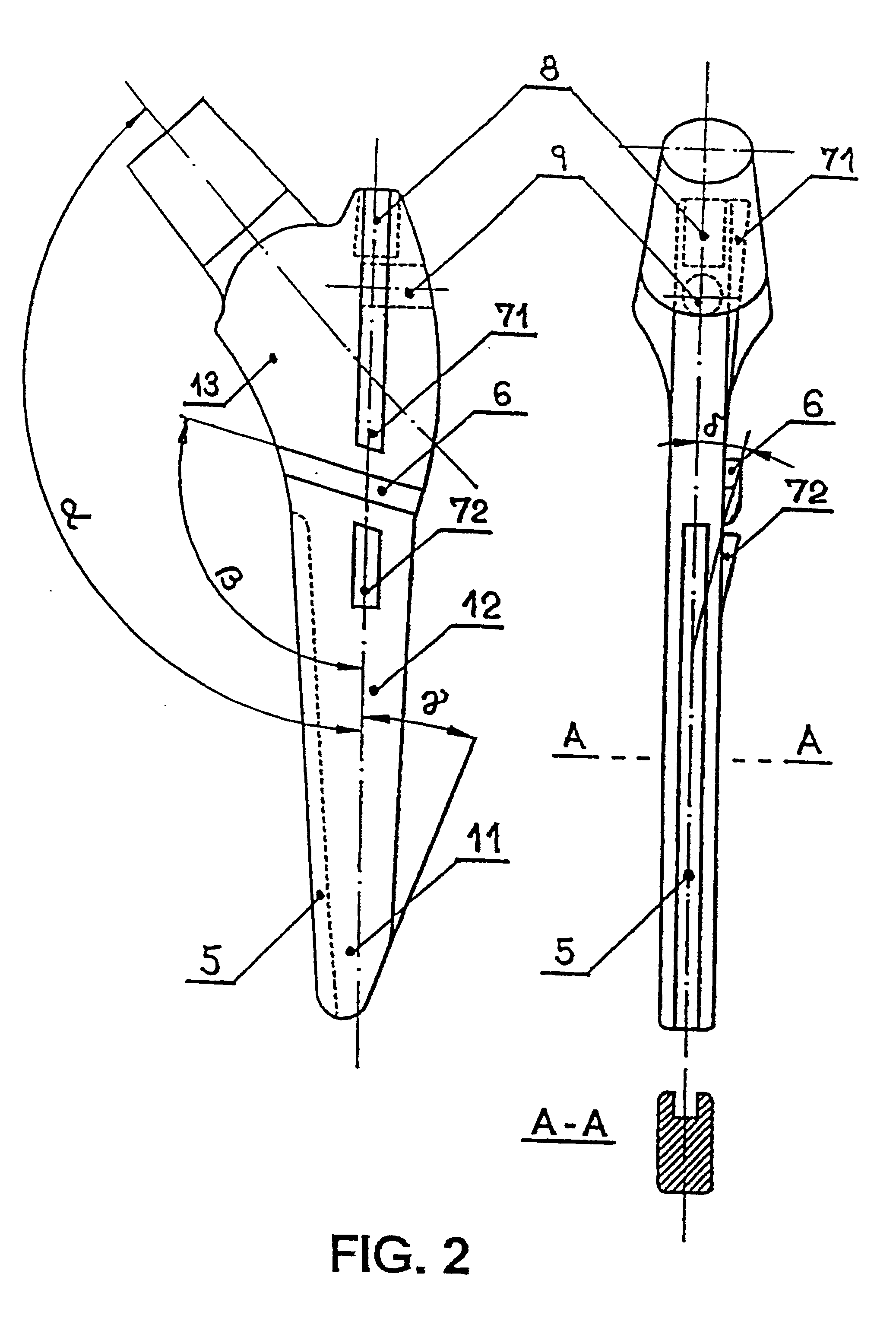

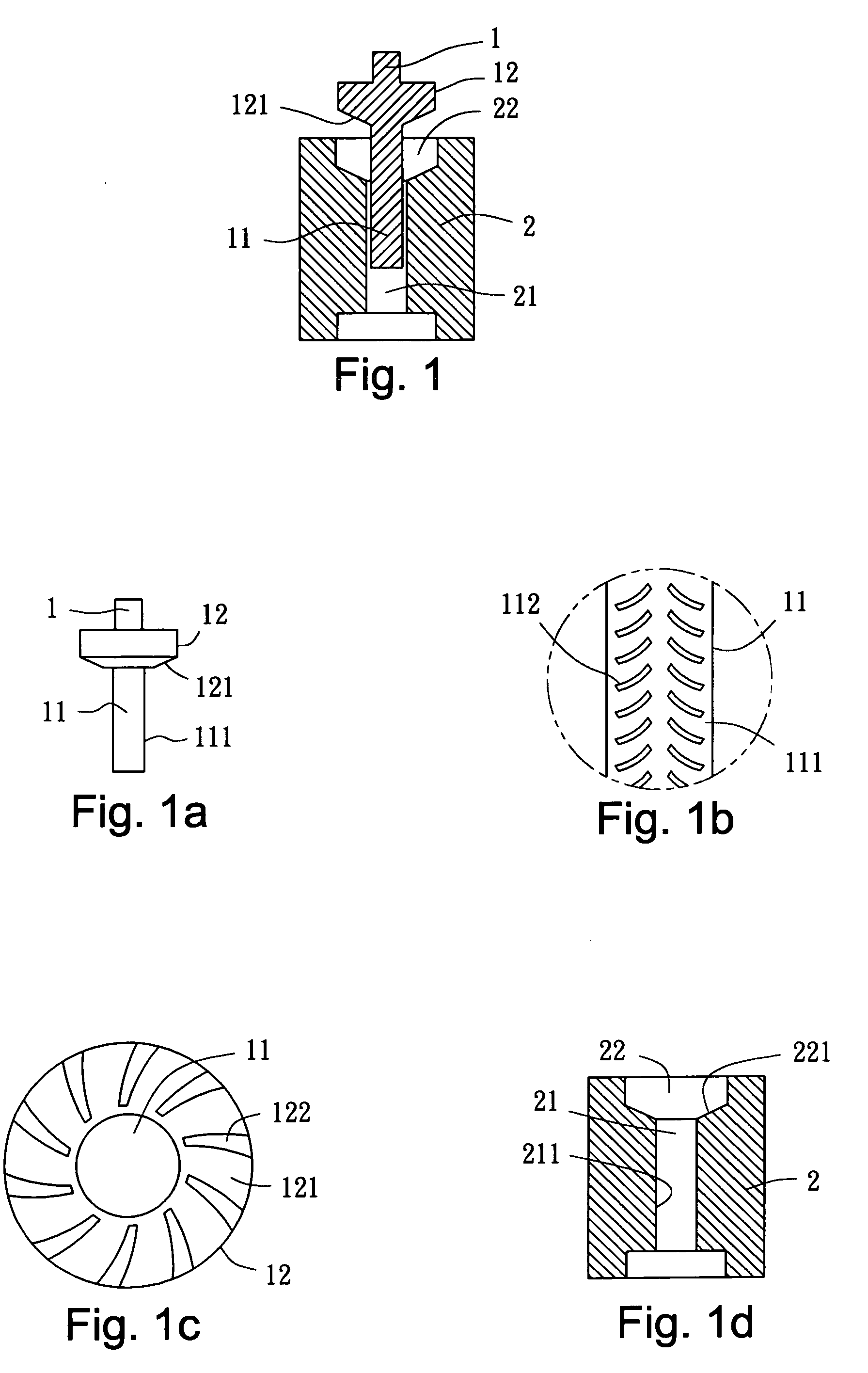

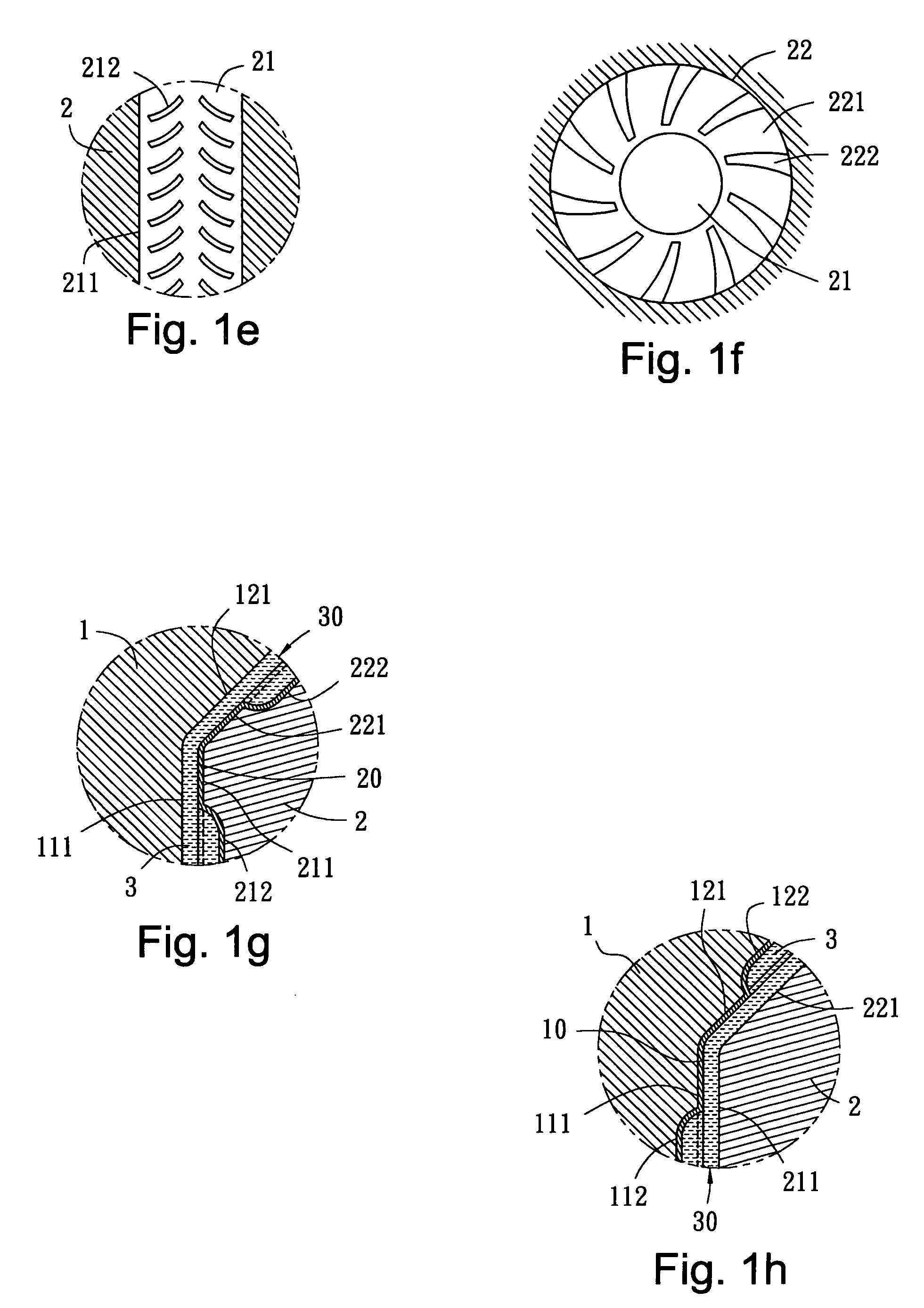

Cementless total replacement of the human hip joint

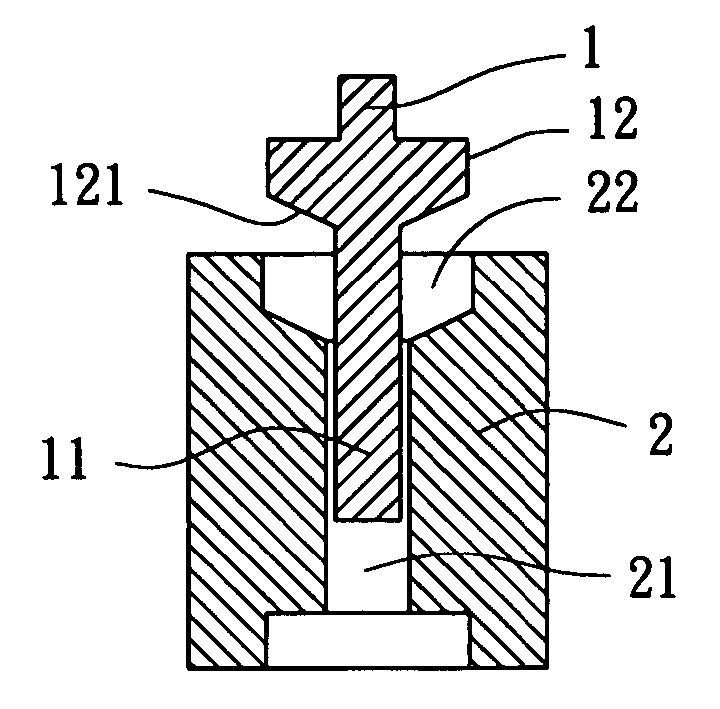

The solution is based on the fact, that on the surface of the acetabulum (3) there is a self-drilling thread, containing at least three independent teeth (41, 42 and 43) which advantageously have a concave shape of the cutting edge and a truncated pike, whereas the planes of their upper edges lie on a spherical surface. The femoral component (1) has on outer side of its lower part (11) an asymmetric tapering under the angle gamma=20° to 70° and on the upper part (13) a convexly widened outer side. Minimally on the lower part (11) and middle part (12) of the inner side of the femoral component (1) at least one longitudinal groove (5) is provided, and minimally on one side plane of the middle part (12) and / or of the upper part (13) there, is provided at least one transversal rib (6), forming with the axis of the wedge an angle beta=70° to 110°. At least on a part of the outer surface of the acetabulum (3) a nanocrystalline diamond or hydroxyapatite layer is preferably created and at least on a part of the outer surface of the femoral component (1) a nanocrystalline diamond and / or hydroxyapatite layer is provided.

Owner:ZITNANSKY MARCEL +2

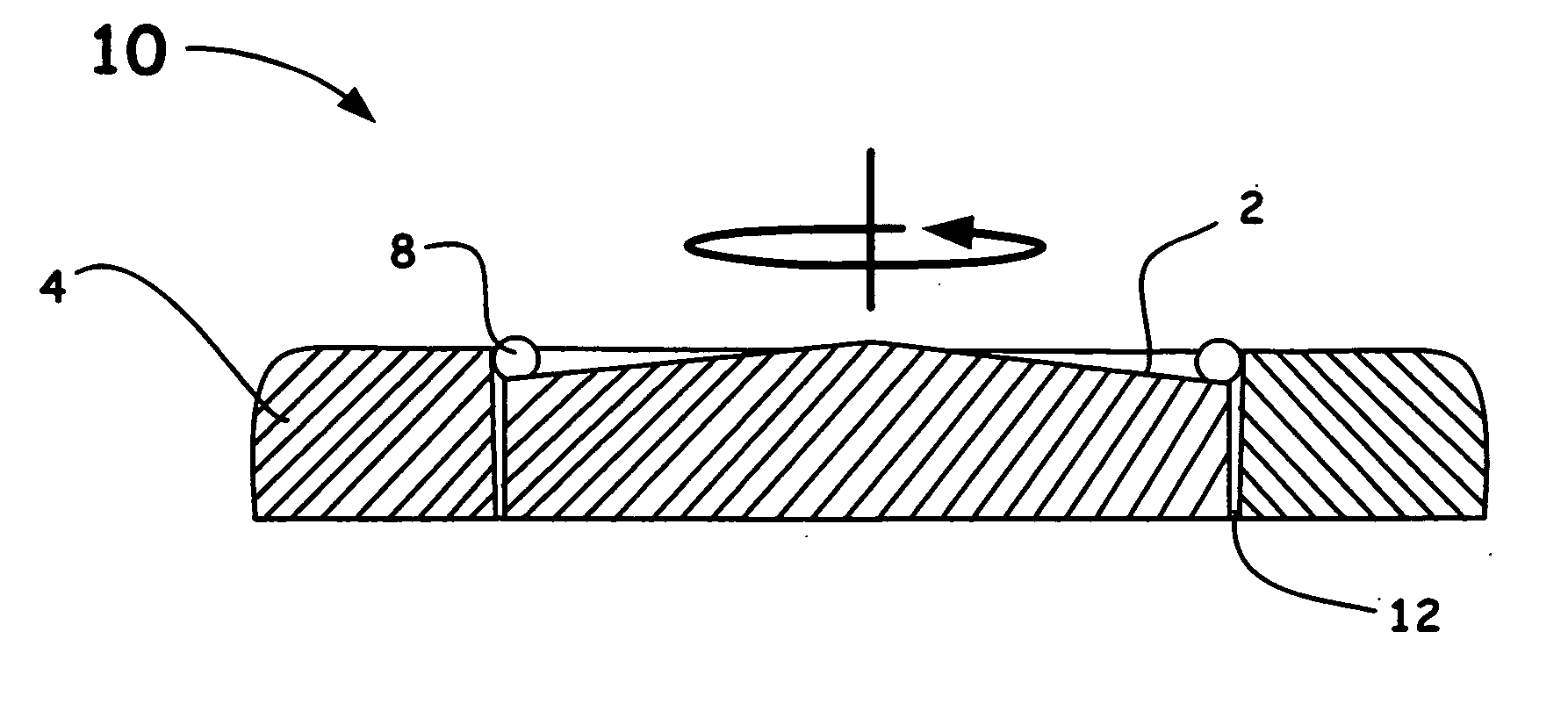

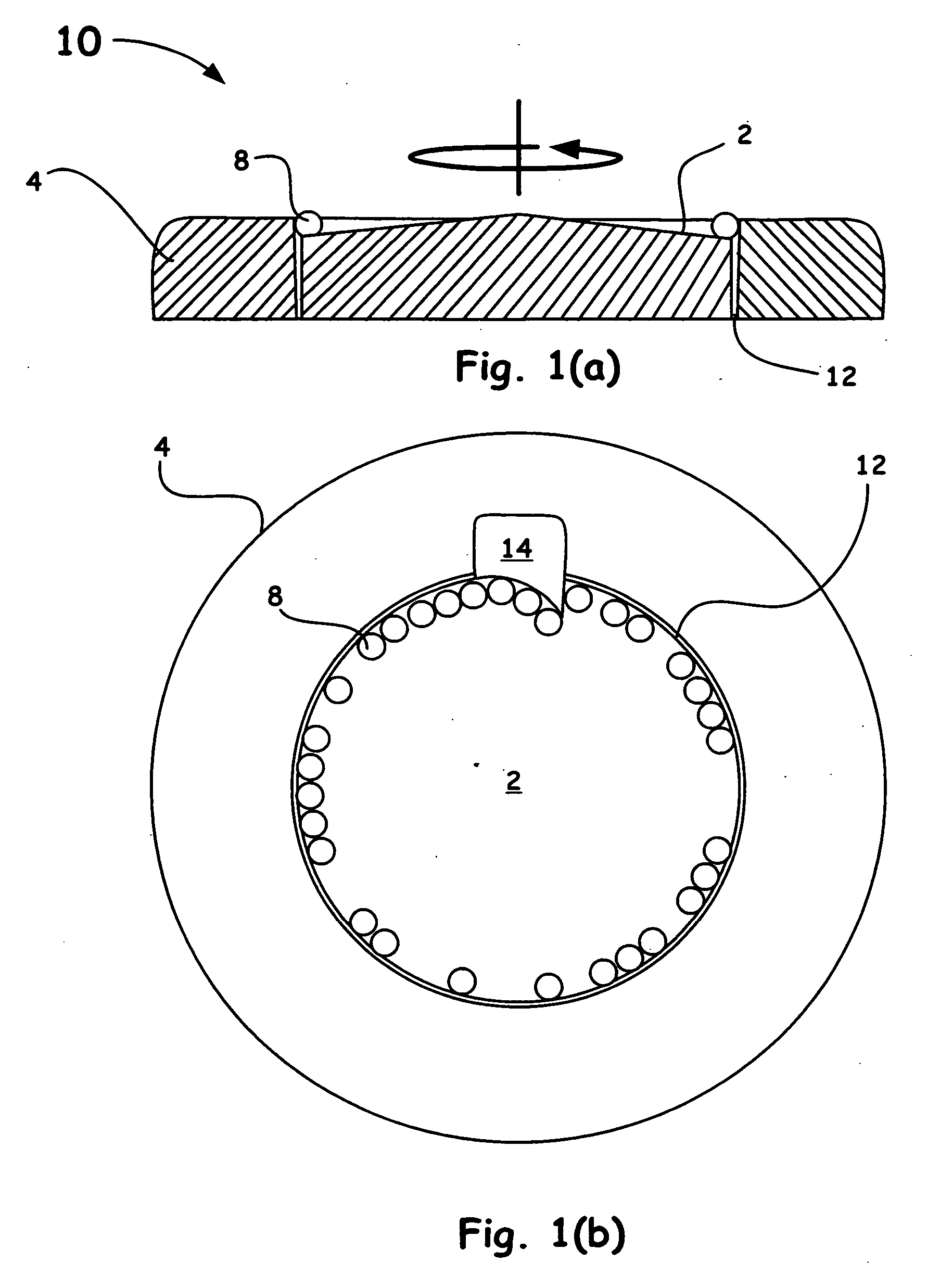

Method for producing a dynamic fluid bearing with high rotation precision and high hardness

InactiveUS20060059688A1High precisionHigh hardnessMetal-working apparatusVacuum evaporation coatingSurface patternGas phase

A method for manufacturing bearing components of high precision and hardness supporting fluid dynamic-pressure comprises the steps of: (1) selecting at least one rotary component provided with a predetermined surface pattern for supporting a distribution of fluid dynamic-pressure; (2) forming an opaque and hard amorphous diamond (DLC, a-D) film (or nano-crystalline diamond film) on the pivotal surface of the component by physical vapor deposition (PVD). Thereby the pivotal surfaces of the rotary component and the pattern thereon can have excellent hardness, wearing resistance, rotational stailbity and durability under repeated urging of dynamic fluid pressure.

Owner:HUNG CHIN CHU +5

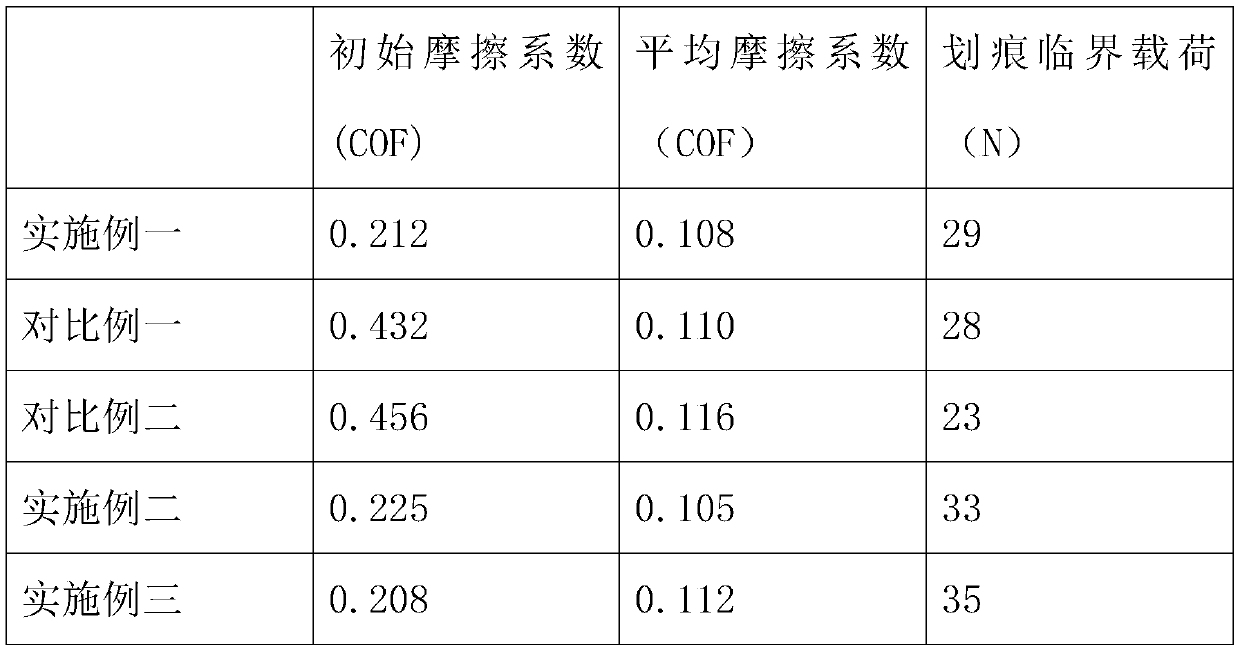

Composite diamond coating hard alloy cutter mold and preparation method thereof

ActiveCN109930129AAvoid it happening againImprove stress distributionChemical vapor deposition coatingMicro nanoEtching

The invention discloses a composite diamond coating hard alloy cutter mold and a preparation method thereof. The surface layer of the hard alloy cutter mold is provided with composite coatings composed of boron-doped or non-boron-doped micron-crystal diamonds and nanocrystalline diamonds which are alternately arranged, and a layer of diamond-like coating DLC is deposited on the surface of each composite diamond coating. The preparation method comprises the steps of oil removal and degreasing, chemical micro-etching, plasma activation, plasma enhanced gaseous boronizing, plasma cleaning, diamond slurry ultrasonic grinding, nano-scale and micron-diamond seed crystal planting, and vapor-phase deposition of the diamond composite coatings. According to the method, boron atoms enter diamond crystal lattices by doping boron in the diamond deposition process, the internal stress of the diamond coatings is adjusted, and the generation of a stress sudden change region is avoided, so that the situation that the stress of each layer is not matched is avoided fundamentally, the stress distribution inside the composite coatings is effectively improved, the integrity of the micro-nano composite coatings is further improved, the substrate-film binding force is improved, and the comprehensive mechanical property of the composite coatings is improved.

Owner:HU-NAN NEW FRONTIER SCI & TECH LTD

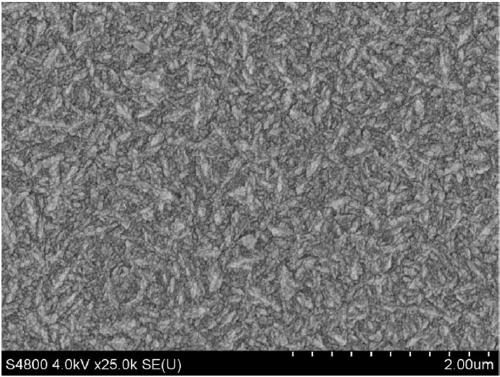

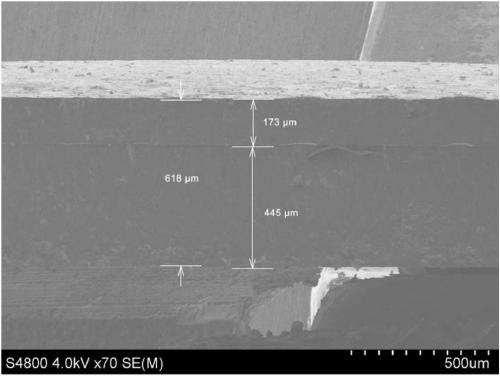

Free-standing ultrafine nanocrystalline diamond thick film

The invention discloses a free-standing ultrafine nanocrystalline diamond thick film. The free-standing ultrafine nanocrystalline diamond thick film is characterized in that the thickness of the thickfilm is 100-3000 micrometers, and the diamond grain size is not less than 1 nanometer and not greater than 20 nanometers. According to the thick film, by employing a chemical vapor deposition method,an ultrafine nanocrystalline diamond is grown on a silicon substrate, and then, the silicon substrate and the diamond are separated to obtain the free-standing ultrafine nanocrystalline diamond thickfilm. The invention provides the simple and effective chemical vapor deposition method, and the free-standing ultrafine nanocrystalline diamond thick film is prepared.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

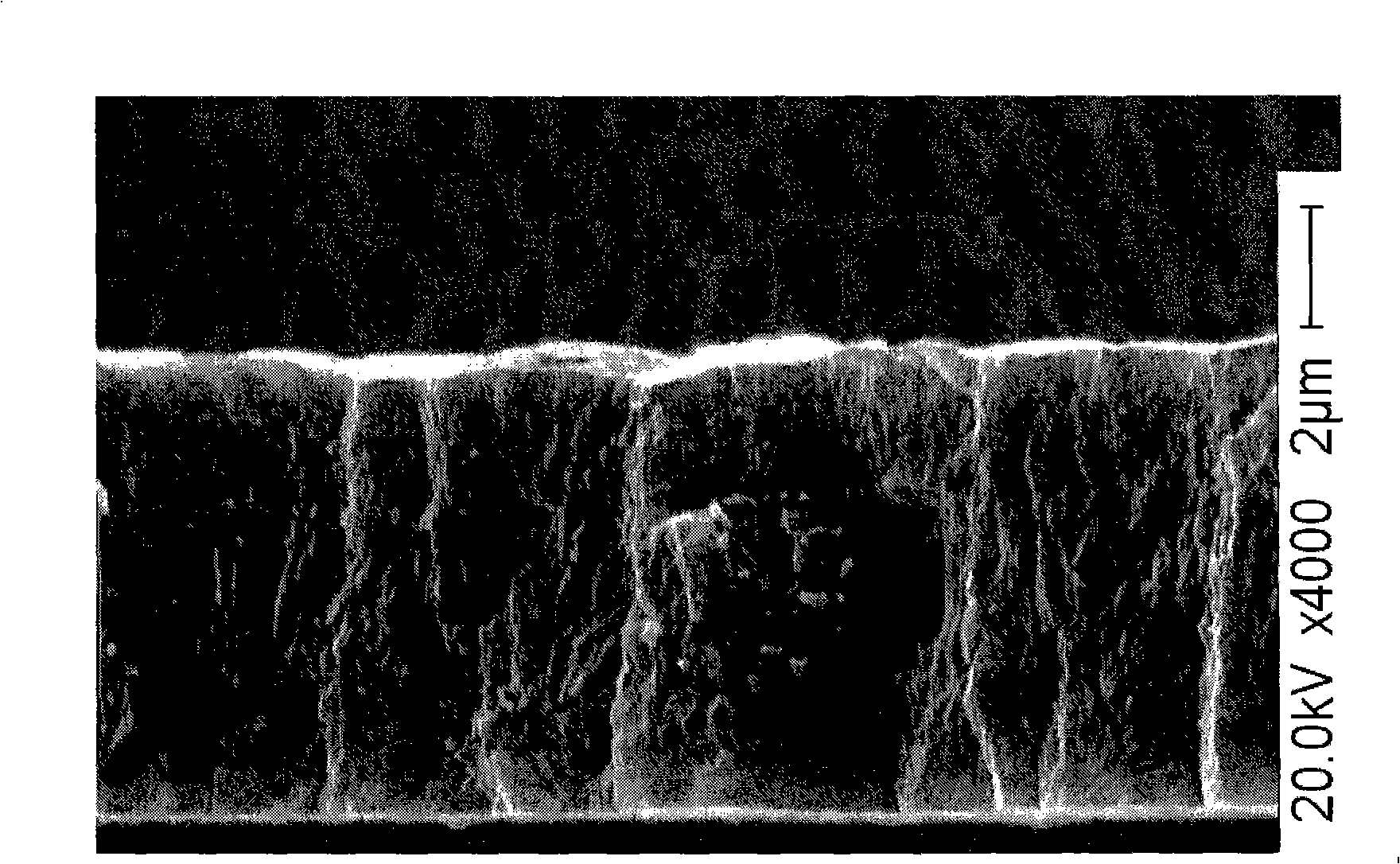

Method for preparing heat sink composite material for semiconductor substrate

InactiveCN101325153AHigh surface flatnessImprove thermal conductivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingComposite filmGas phase

The invention relates to a preparation method of a semiconductor substrate heat sink composite material, which mainly comprises the steps of pre-treating a tantalum wire, pre-treating a silicon substrate, placing a pretreated silicon wafer into a reaction chamber of a hot wire chemical vapor deposition device to be used as a deposition substrate; vacuuming, introducing reactants hydrogen gas and acetone, and allowing nucleation of a microcrystalline diamond film; adjusting the flow rate, temperature and other conditions of the acetone and the hydrogen gas, and allowing growth of the microcrystalline diamond film; allowing growth of a nano-crystal diamond film; and adjusting the flow rate of the acetone and the hydrogen gas, controlling the substrate temperature at 600-650 DEG C, and allowing the film to grow for 3-5 hours to obtain a diamond composite film with a relatively smooth surface, i.e. the semiconductor substrate heat sink composite material. The inventive semiconductor substrate heat sink composite material has the advantages of simple equipment, rapid growth speed, good quality, easy implementation of large area deposition, etc.

Owner:SHANGHAI UNIV

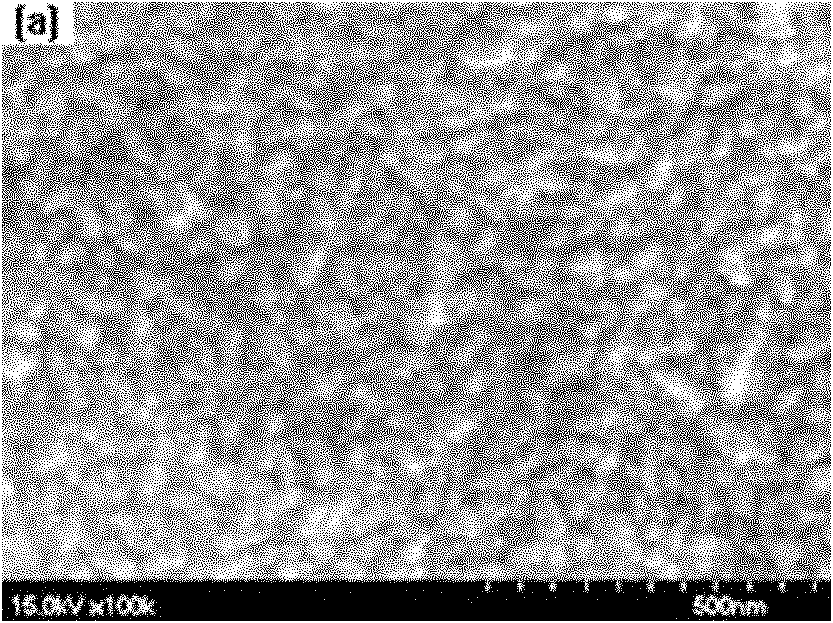

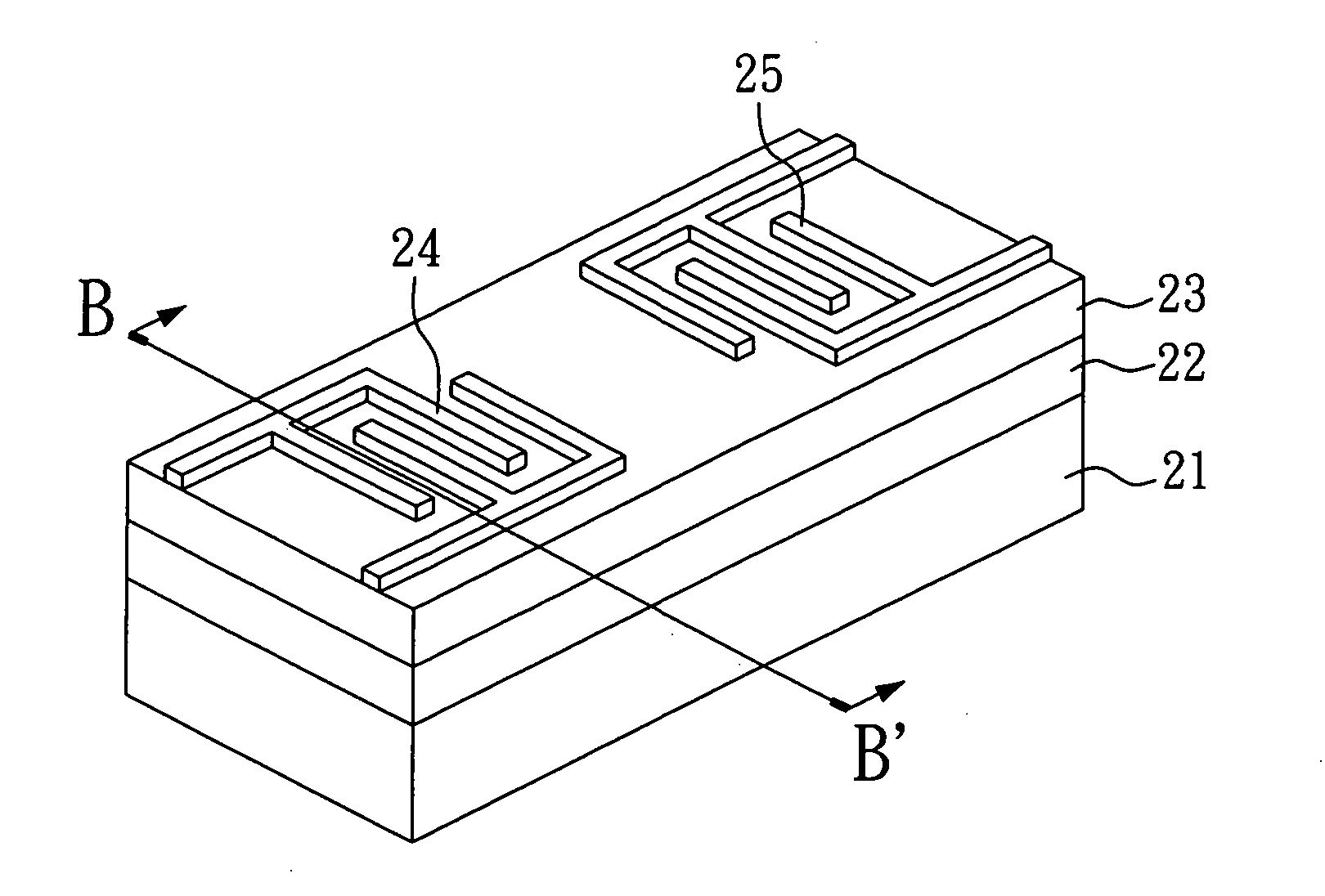

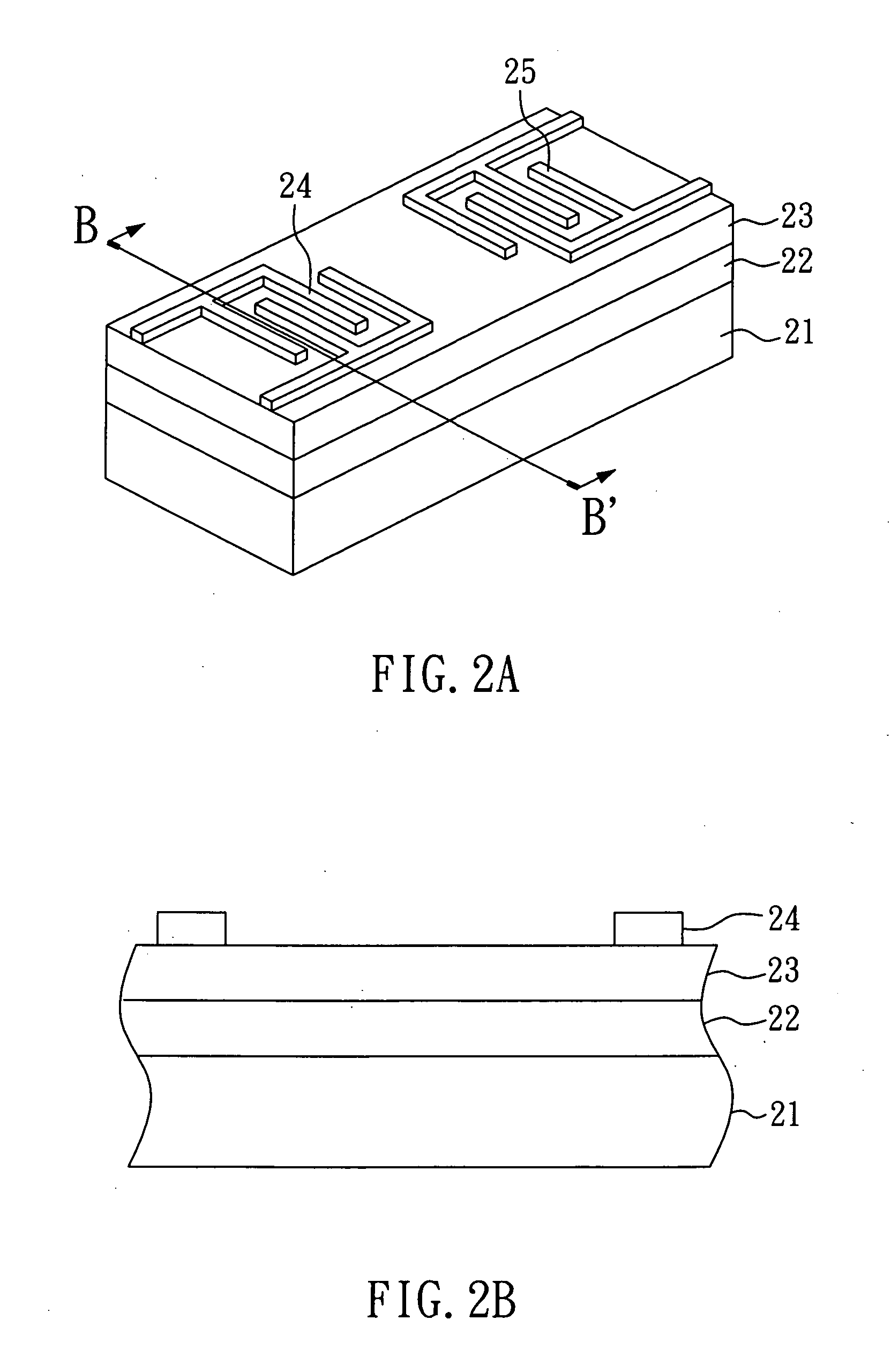

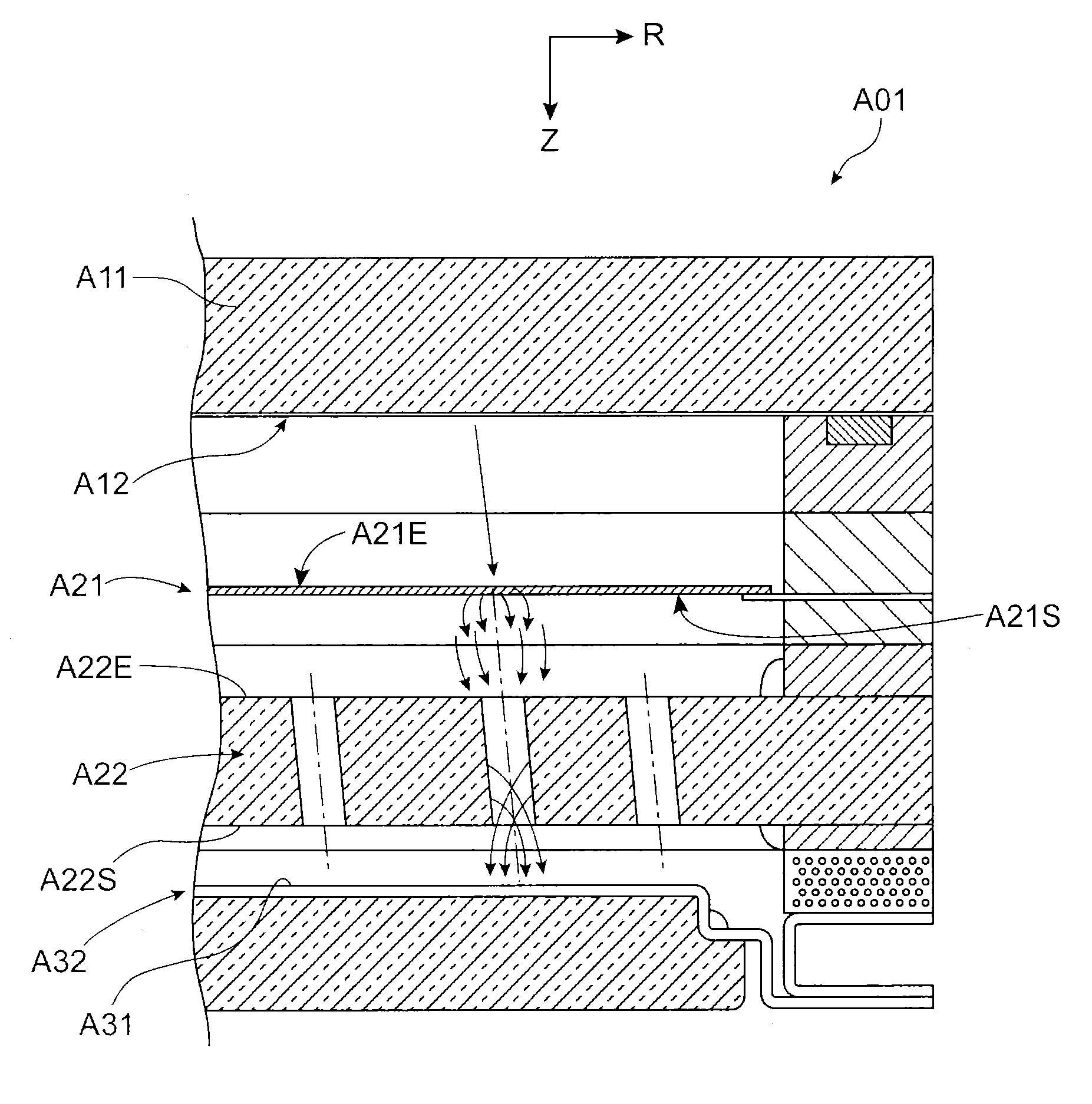

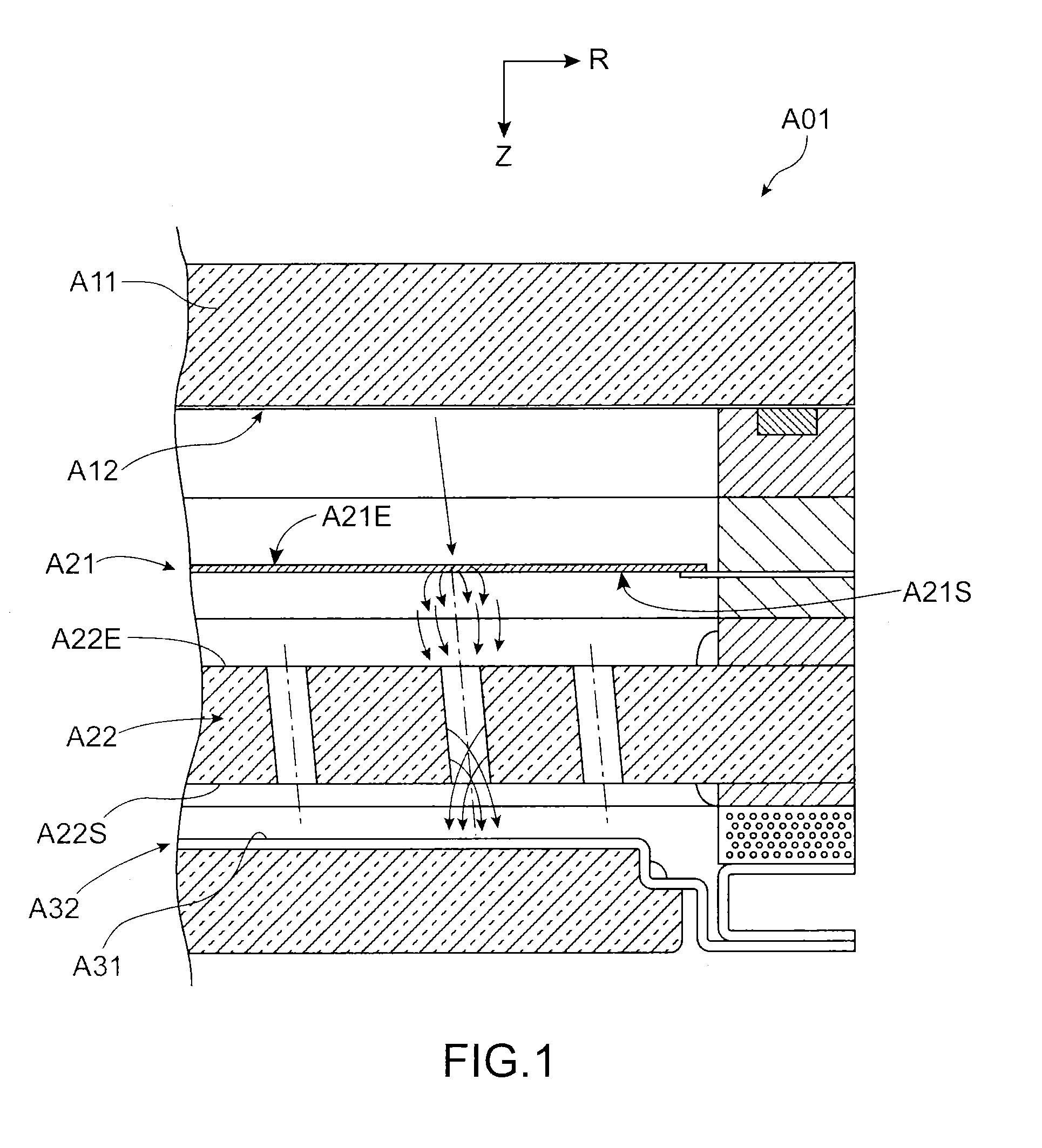

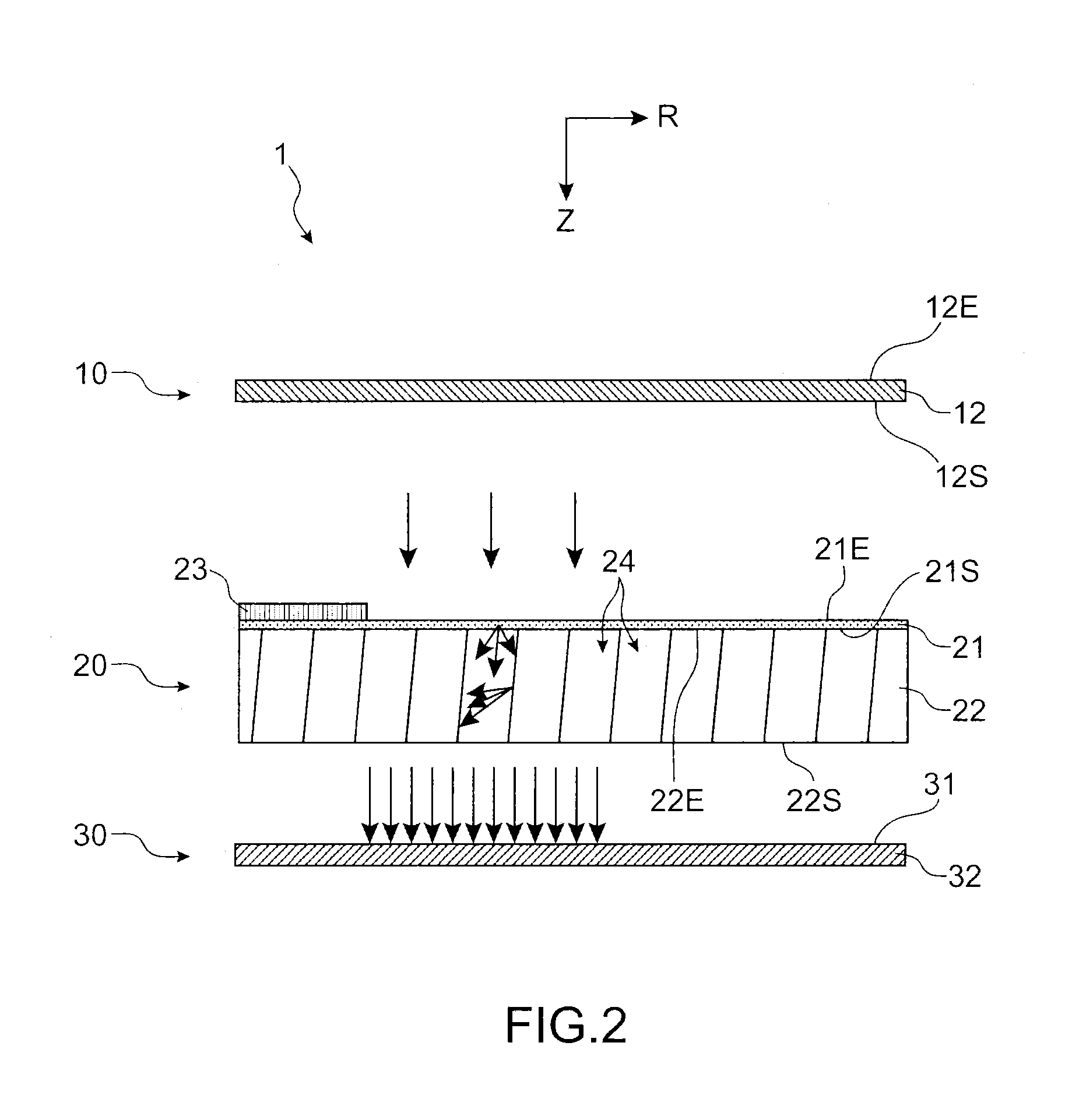

High frequency surface acoustic wave device

InactiveUS20100052471A1Simple processImprove application flexibilityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesAcoustic waveSurface acoustic wave

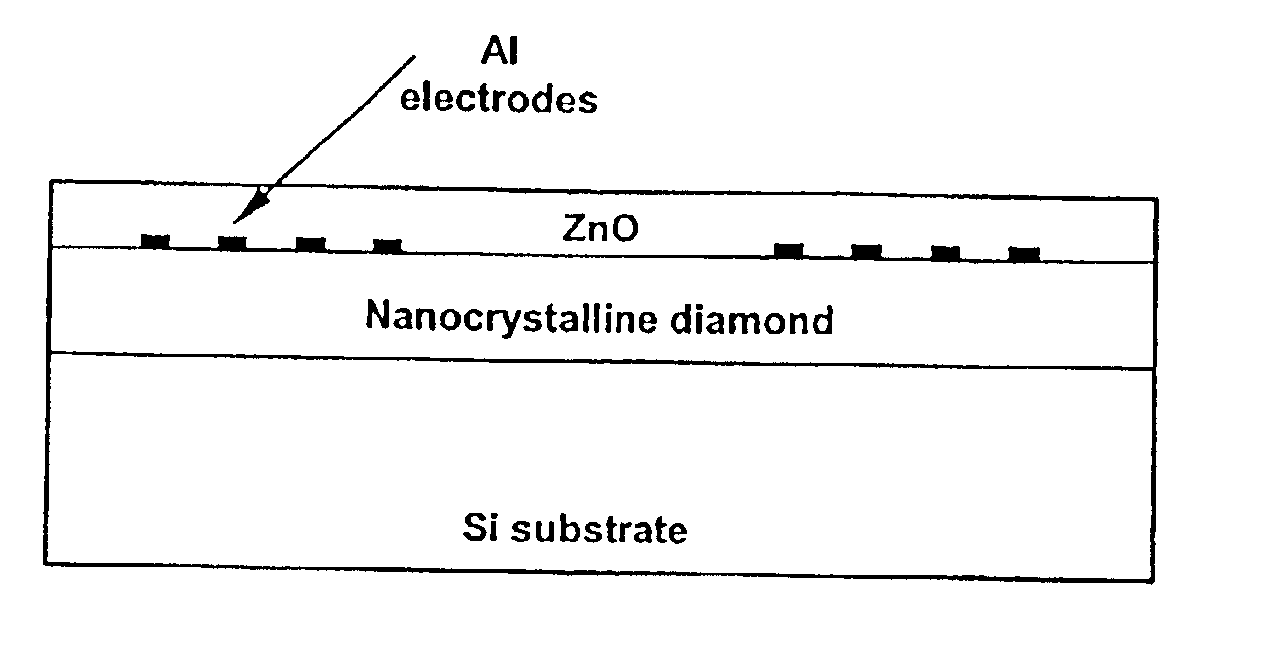

A high frequency surface acoustic wave device is disclosed. The disclosed high frequency surface acoustic wave device can modulate its central frequency easily, by changing the thickness of its nanocrystalline diamond layer. The disclosed high frequency surface acoustic wave device comprises: a silicon substrate; a nanocrystalline diamond layer located above the silicon substrate; a piezoelectric layer formed on the surface of the nanocrystalline diamond layer; an input transformation unit; and an output transformation unit, wherein the input transformation unit and the output transformation unit are formed in pairs on the surface or beneath of the piezoelectric layer. Besides, the thickness of the nanocrystalline diamond layer is preferably between 0.5 μm and 20 μm. The piezoelectric layer is preferably made of ZnO, AlN, or LiNbO3, wherein the thickness of the piezoelectric layer is preferably between 0.5 μm and 5 μm.

Owner:TATUNG COMPANY +1

Surface acoustic wave (SAW) devices based on cubic boron nitride/diamond composite structures

ActiveUS7579759B2Reduce surface roughnessAvoid distractionPiezoelectric/electrostriction/magnetostriction machinesImpedence networksPolycrystalline diamondSurface acoustic wave

A surface acoustic wave (SAW) device which is made of cBN / diamond composite structures and the fabrication method are disclosed. In the SAW device based on cubic boron nitride and diamond composite structures, the diamond hard layer includes randomly-oriented polycrystalline diamond (poly-D), oriented (heteroepitaxial) diamond, single-crystal diamond wafers and nanocrystalline diamond (nano-D) films. The cBN film with a sound velocity close to that of diamond serves as the piezoelectric layer, which was directly deposited on diamond hard layer without any soft sp2-BN incubation layer by ion assisted physical vapor deposition (PVD) and plasma-enhanced (or ion assisted) chemical vapor deposition (PECVD). Due to the high sound velocity and the low velocity dispersion between the cBN and diamond layered materials, the present SAW device based on cubic boron nitride and diamond composite structures can improve the device performance and operate at ultra-high frequency range.

Owner:CITY UNIVERSITY OF HONG KONG

Electron multiplier detector formed from a highly doped nanodiamond layer

ActiveUS20130146778A1Low mobilityRisk of defectPhotometryMaterial analysis by optical meansSecondary electronsOutput device

A system for detecting electromagnetic radiation or an ion flow, including an input device for receiving the electronic radiation or the ion flow and emitting primary electrons in response, a multiplier of electrons in transmission, for receiving the primary electrons and emitting secondary electrons in response, and an output device for receiving the secondary electrons and emitting an output signal in response. The electron multiplier includes at least one nanocrystalline diamond layer doped with boron in a concentration of higher than 5·1019 cm−3.

Owner:PHOTONIS FRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com