Composite diamond coating hard alloy cutter mold and preparation method thereof

A technology of diamond coating and hard alloy knife, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problem of reducing the bonding force of composite coatings, prone to fracture, affecting film bonding force and mechanics Performance and other issues, to avoid stress mutation area, avoid stress mismatch, improve the effect of comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

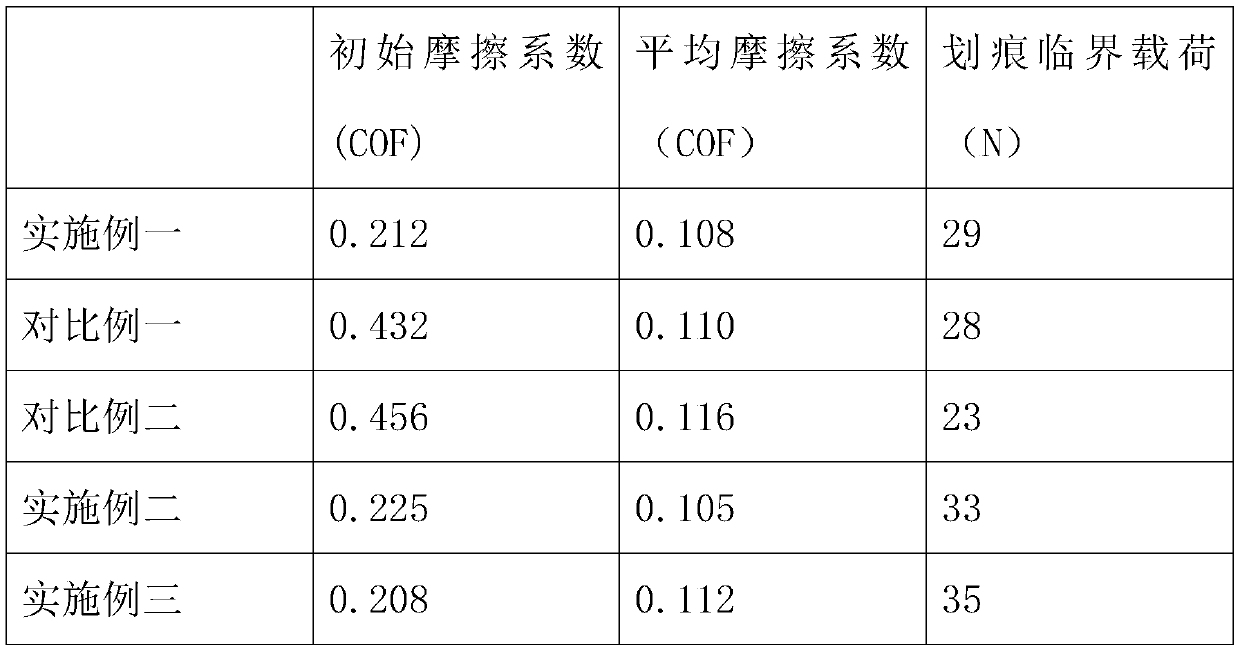

Embodiment 1

[0055] 1. First chemical micro-etching: Put the cemented carbide milling cutter into 50% concentration of sodium hydroxide solution and ultrasonically clean it for 10 minutes with an ultrasonic power of 50W. After cleaning, put it into 20% concentration of hydrogen peroxide for 20 seconds. After etching, it is cleaned and ready for use. (2) Plasma activation treatment: Put the cemented carbide tool into the furnace, vacuumize, heat up to 600°C after vacuuming, then feed in hydrogen gas with a flow rate of 50 sccm, and turn on the power supply of the radio frequency plasma device and the radio frequency bias at the same time. Adjust the power supply of the voltage device, adjust the plasma power to 300W, and the bias voltage to 20V, and process for 90min. (3) Plasma-enhanced gaseous boride treatment: close the bias device; the temperature of the furnace is raised to 800° C., and the flow rate is 20 sccm of diborane. At this time, the furnace is a mixed gas composed of diborane ...

Embodiment 2

[0069]1. First chemical micro-etching: Put the cemented carbide milling cutter into 50% concentration of sodium hydroxide solution and ultrasonically clean it for 10 minutes with an ultrasonic power of 50W. After cleaning, put it into 20% concentration of hydrogen peroxide for 20 seconds. After etching, it is cleaned and ready for use. (2) Plasma activation treatment: Put the cemented carbide tool into the furnace, vacuumize, heat up to 600°C after vacuuming, then feed in hydrogen gas with a flow rate of 50 sccm, and turn on the power supply of the radio frequency plasma device and the radio frequency bias at the same time. Adjust the power supply of the voltage device, adjust the plasma power to 300W, and the bias voltage to 20V, and process for 90min. (3) Plasma-enhanced gaseous boride treatment: close the bias device; the temperature of the furnace is raised to 800° C., and the flow rate is 20 sccm of diborane. At this time, the furnace is a mixed gas composed of diborane a...

Embodiment 3

[0074] 1. First chemical micro-etching: Put the cemented carbide milling cutter into 50% concentration of sodium hydroxide solution and ultrasonically clean it for 10 minutes with an ultrasonic power of 50W. After cleaning, put it into 20% concentration of hydrogen peroxide for 20 seconds. After etching, it is cleaned and ready for use. (2) Plasma activation treatment: Put the cemented carbide tool into the furnace, vacuumize, heat up to 600°C after vacuuming, then feed in hydrogen gas with a flow rate of 50 sccm, and turn on the power supply of the radio frequency plasma device and the radio frequency bias at the same time. Adjust the power supply of the voltage device, adjust the plasma power to 300W, and the bias voltage to 20V, and process for 90min. (3) Plasma-enhanced gaseous boride treatment: close the bias device; the temperature of the furnace is raised to 800° C., and the flow rate is 20 sccm of diborane. At this time, the furnace is a mixed gas composed of diborane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com