Ultrahigh hard nano twin diamond block material and preparation method thereof

A bulk material and nano-twin technology, applied in the field of superhard materials, can solve the problems of poor thermal stability and low hardness of diamond polycrystalline, and achieve the effect of easy control of parameters and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] (1) Preparation of high-temperature and high-pressure raw materials: Spherical carbon (onion structure) powder (particle size: 5-30nm) is placed in a nitrogen-protected glove box and pressed into a block with a diameter of 1.6mm and a length of 3mm, and it is sealed in a difficult-to-contain Reserve in a metal Re crucible.

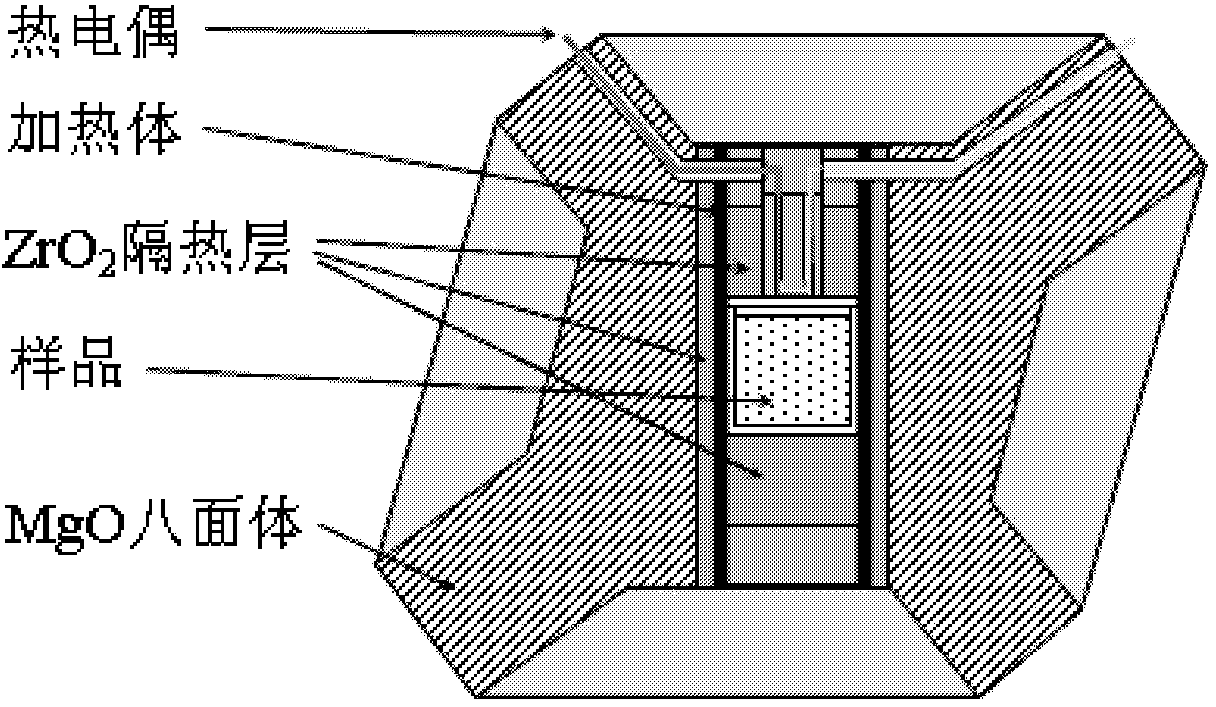

[0079] (2) High temperature and high pressure synthesis: put the above-mentioned pre-pressed block into a hexagonal boron nitride crucible, and then put it into a high temperature and high pressure assembly block (such as figure 2 shown), put the assembly block into a T25 (or cube) ultra-high pressure high temperature synthesis device, and heat it for 30 minutes at a pressure of 15 GPa and a temperature of 1850 ° C. The prepared nano-twinned diamond block is as follows image 3 As shown, the density of the nano-twinned diamond block is 3.5±0.1(g / cm 3 ).

[0080] (3) Properties of the nano-twinned diamond block: the X-ray diffraction spectrum of t...

Embodiment 2

[0082] (1) Preparation of high-temperature and high-pressure raw materials: Spherical carbon (onion structure) powder (particle size: 5-30nm) is placed in a nitrogen-protected glove box and pressed into a block with a diameter of 1.6mm and a length of 3mm, which is sealed in a difficult Put it in a metal hot crucible for later use.

[0083] 2) High temperature and high pressure synthesis: put the above pre-pressed block into a hexagonal boron nitride crucible and a high temperature and high pressure assembly block, and then put it into a T25 or cubic ultra-high pressure high temperature synthesis device, and heat it under 15GPa pressure and 2000°C for 30 minutes to prepare The formed nano-twinned diamond block such as Figure 8 shown.

[0084] (3) Properties of the nano-twinned diamond block: the X-ray diffraction spectrum (XRD) of the prepared nano-twinned diamond block is as follows Figure 9 As shown, its phase composition is pure phase cubic diamond, and the average grai...

Embodiment 3

[0086] (1) Preparation of high-temperature and high-pressure raw materials: Spherical carbon (onion structure) powder (particle size: 5-30nm) is placed in a nitrogen-protected glove box and pressed into a block with a diameter of 1.6mm and a length of 3mm, which is sealed in a difficult Put it in a metal hot crucible for later use.

[0087] (2) High-temperature and high-pressure synthesis: put the above-mentioned pre-pressed block into a hexagonal boron nitride crucible, then put it into a high-temperature and high-pressure assembly block, and then put it into a T25 or cubic ultra-high-pressure high-temperature synthesis device, under the conditions of 12GPa pressure and 1850°C Heating for 30 minutes, the prepared nano-twinned diamond block is as Figure 11 shown.

[0088] (3) Properties of the nano-twinned diamond block: the X-ray diffraction spectrum (XRD) of the prepared nano-twinned diamond block is as follows Figure 12 As shown, its phase composition is pure phase cubi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Knoop hardness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com