Multilayer diamond coating, manufacturing method thereof and coating tool

A diamond coating and diamond technology, applied in metal material coating process, coating, superimposed layer plating, etc., can solve the problem of low hardness of multi-layer diamond coating, low wear resistance of tools, and short service life and other problems, to achieve good compactness, which is conducive to precision machining and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

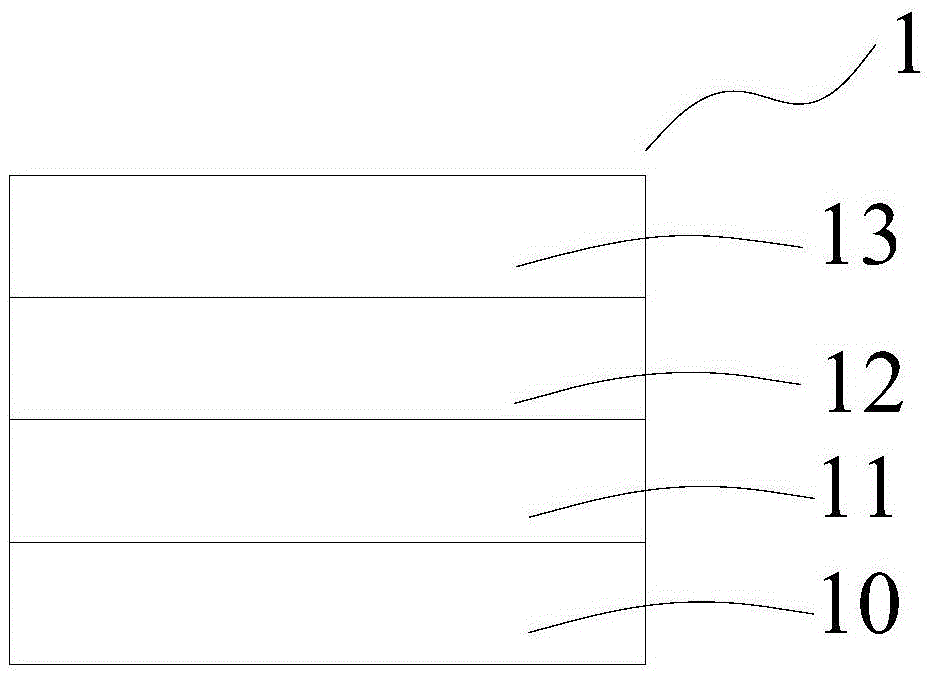

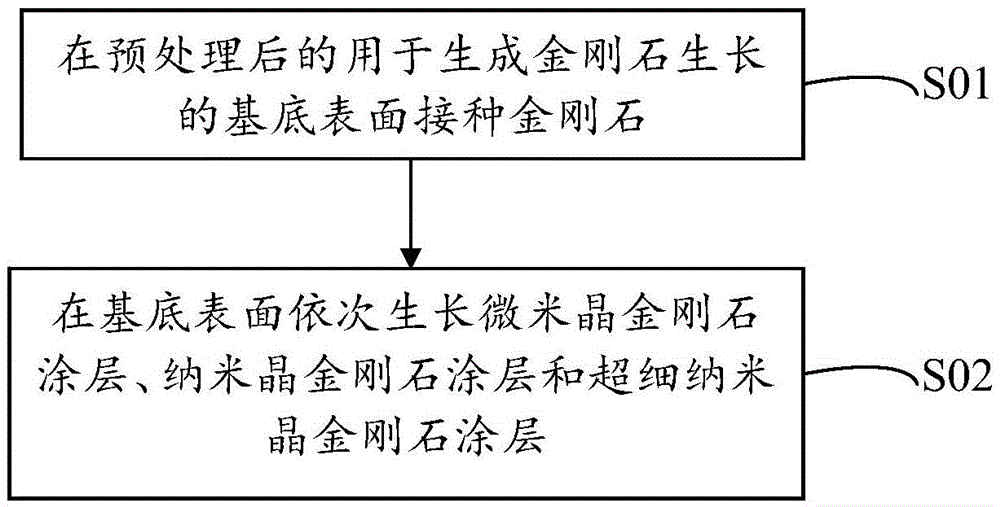

[0023] One embodiment, the multi-layer diamond coating of the embodiment of the present invention only includes a composite diamond coating structural unit, specifically as figure 1 shown. The composite diamond coating structural unit 1 includes a microcrystalline diamond coating 11 , a nanocrystalline diamond coating 12 and an ultrafine nanocrystalline diamond coating 13 which are sequentially grown and combined. That is to say, in this embodiment, the multilayer diamond coating includes a microcrystalline diamond coating 11 , a nanocrystalline diamond coating 12 and an ultrafine nanocrystalline diamond coating 13 which are sequentially grown and bonded.

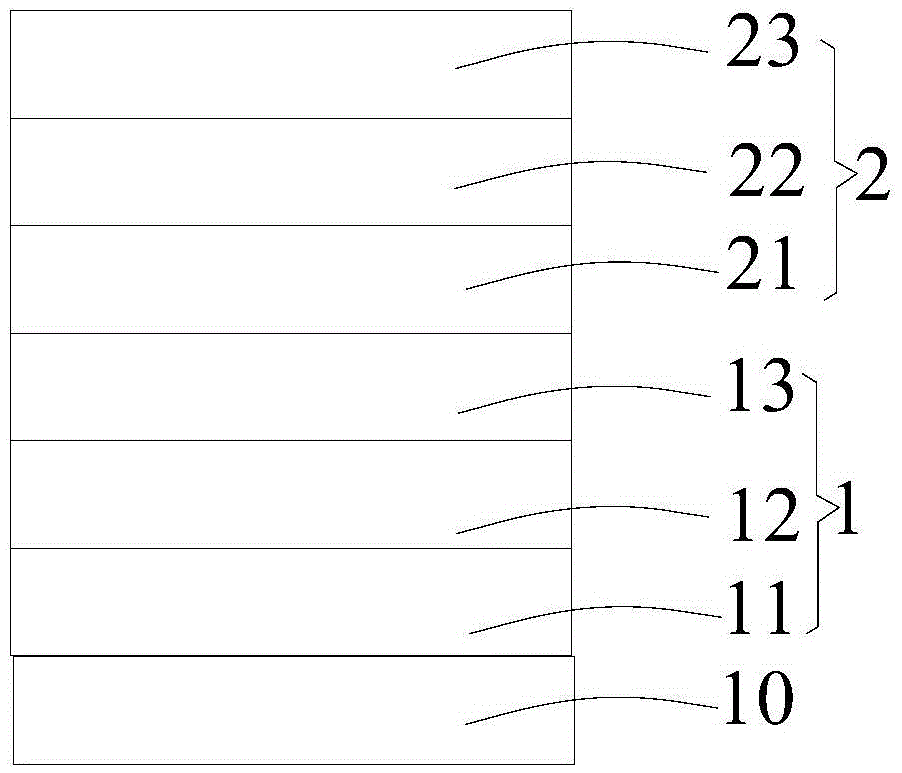

[0024] In another embodiment, the multilayer diamond coating in the embodiment of the present invention includes two composite diamond coating structural units, namely composite diamond coating structural unit 1 and composite diamond coating structural unit 2, specifically as figure 2 shown. The composite diamond coating...

Embodiment 1

[0062] The embodiment of the present invention provides a WC-6% Co cutting tool with a multi-layer diamond coating on the surface. Its preparation method is as follows:

[0063] S11.WC-6% Co tool surface pretreatment:

[0064] (a) Put the WC-Co tool in an acetone solution for ultrasonic cleaning for 10 minutes, and dry it in a constant temperature drying oven at 60°C for 10 minutes;

[0065] (b) Put the cleaned carbide tool into K 3 (Fe(CN) 6 +KOH+H 2 O (wt%=1:1:10) alkali mixed solution was ultrasonicated for 15min, and distilled water was taken out for cleaning, and then washed with H 2 SO 4 +H 2 o 2 (vol%=1:10) Soak for 15s, take out distilled water to wash, dry at constant temperature at 60°C, and dry for 10min;

[0066] (c) Put the pretreated cutter into a diamond suspension solution with a particle size of 1-5 μm and a diamond suspension particle proportion of 10% of the total mass of the solution for ultrasonication for 20 minutes, take out the alcohol, clean it...

Embodiment 2

[0074] An embodiment of the present invention provides a TiC-Co tool with a multi-layer diamond coating on its surface. Its preparation method is as follows:

[0075] S21. TiC-Co tool surface pretreatment:

[0076] (a) Put the TiC-Co tool in an acetone solution for ultrasonic cleaning for 10 minutes, and dry it in a constant temperature drying oven at 80°C for 5 minutes;

[0077] (b) Put the cleaned carbide tool into K 3 (Fe(CN) 6 +KOH+H 2 O (wt%=1:1:10) alkali mixed solution was ultrasonicated for 10min, and distilled water was taken out for cleaning, and then washed with H 2 SO 4 +H 2 o 2 (vol%=1:10) Soak for 10s, take out distilled water to wash, dry at constant temperature at 80°C, and dry for 5min;

[0078] (c) Put the pretreated cutter into a diamond suspension solution with a particle size of 1-5 μm and a diamond suspension particle proportion of 15% of the total mass of the solution for ultrasonication for 20 minutes, take out the alcohol, clean it, and dry it....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com