Boron-doped nanocrystalline diamond film and preparation method thereof

A nano-diamond, boron-doped technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problems of poor p-type conductivity and electrochemical performance, and achieve improved conductivity and good conductivity. ability, the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

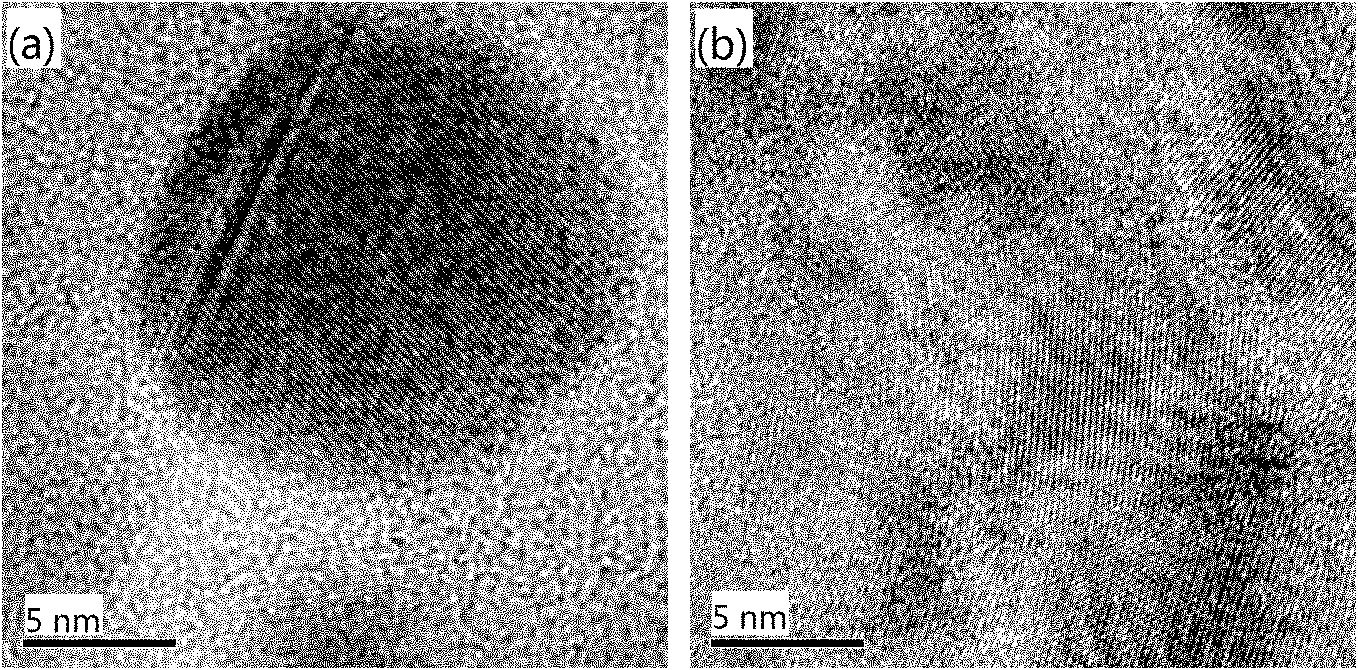

[0030] Polish the monocrystalline silicon wafer with nano-scale diamond powder, and the grinding time is about half an hour. After the polished silicon wafer is cleaned by an ultrasonic machine, it is used as the substrate for the growth of the nano-diamond film. Using hot wire chemical vapor deposition method (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd.), using acetone as carbon source, B 2 h 6 as the boron source, the boron concentration is 500 ppm; acetone is brought into the reaction chamber by hydrogen bubbling, the temperature of the reaction chamber is controlled at 600~700°C, the preparation time is 5 hours, and the boron doped with a thickness of 12.1 μm is prepared nanodiamond film.

[0031] Place the prepared thin film in a quartz tube, use a vacuum pump to pump out the air in the quartz tube, the relative vacuum degree is 5torr (1 torr is 1 millimeter of mercury column (mmHg)), then seal the quartz tube, and annea...

Embodiment 2

[0036] The monocrystalline silicon wafer is polished with nanometer diamond powder, and the polishing time is about half an hour. After the polished silicon wafer is cleaned by an ultrasonic machine, it is used as the substrate for the growth of the nano-diamond film. Using hot wire chemical vapor deposition method (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd.), using acetone as carbon source, B 2 h 6 As a boron source, the boron concentration is 500 ppm; acetone is brought into the reaction chamber by hydrogen bubbling, the temperature of the reaction chamber is controlled at 600-700°C, the preparation time is 6 hours, and a nano-diamond film with a thickness of 12.1 μm is prepared .

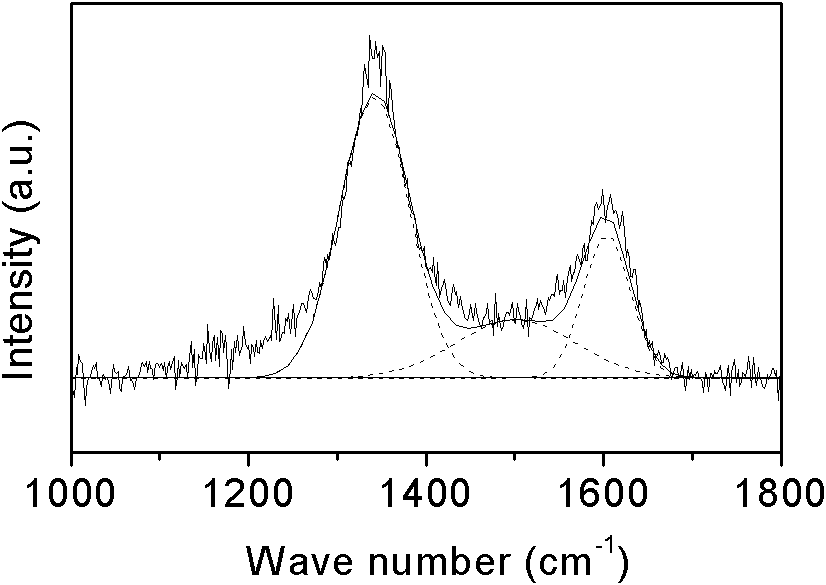

[0037] The prepared film was placed in a quartz tube, and the air in the quartz tube was pumped out with a vacuum pump to a relative vacuum of 5 torr, and then the quartz tube was sealed and annealed in vacuum at 1150° C. for 30 minutes. Raman...

Embodiment 3

[0041] The monocrystalline silicon wafer is polished with nanometer diamond powder, and the polishing time is about half an hour. After the polished silicon wafer is cleaned by an ultrasonic machine, it is used as the substrate for the growth of the nano-diamond film. Using hot wire chemical vapor deposition method (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd.), using acetone as carbon source, B 2 h 6 As a boron source, the boron concentration is 5000 ppm; acetone is brought into the reaction chamber by hydrogen bubbling, the temperature of the reaction chamber is controlled at 600-700°C, the preparation time is 6 hours, and a nano-diamond film with a thickness of 12.3 μm is prepared .

[0042] The prepared film was placed in a quartz tube, and the air in the quartz tube was pumped out with a vacuum pump to a relative vacuum of 5 torr, and then the quartz tube was sealed and annealed in vacuum at 1000° C. for 60 minutes. Adop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Oxygen evolution potential | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com