Compensating neutron well logging instrument

A technology for compensating neutrons and logging tools, applied in boreholes/well components, earthwork drilling and production, etc., to achieve the effects of high integration, easy use and maintenance, error compensation and accurate data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

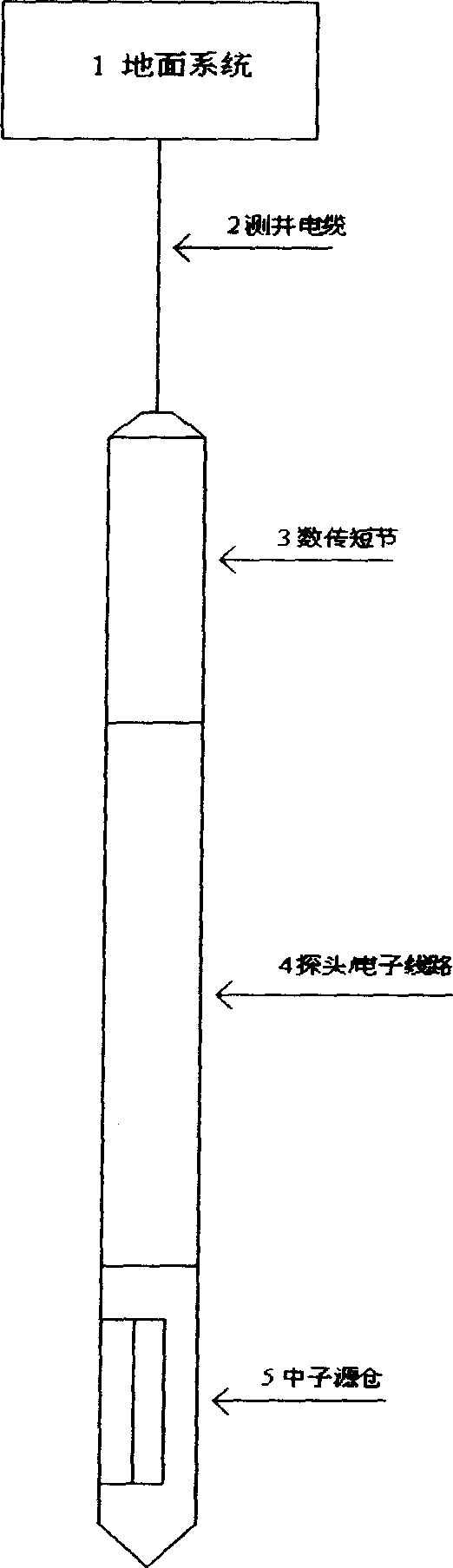

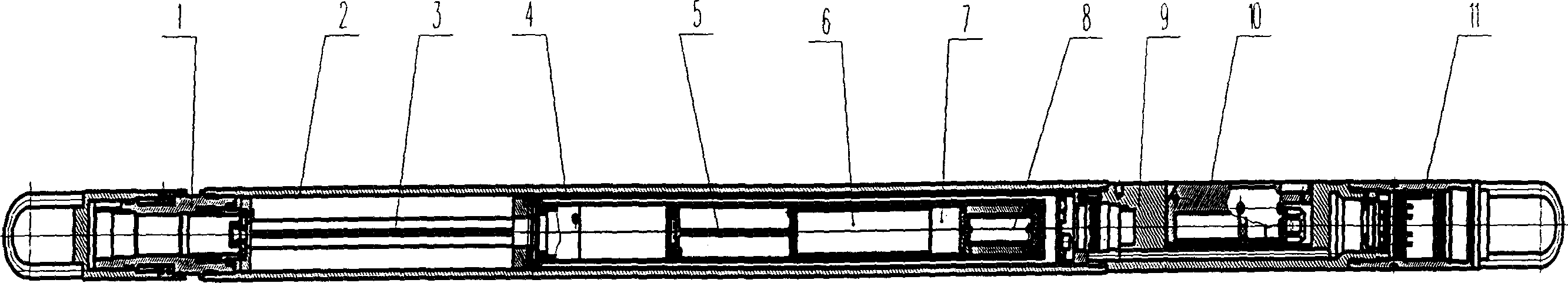

[0014] Refer to attached figure 2 , The compensated neutron logging tool includes: upper joint 1, shell 2, power frame 3, thermos bottle 4, signal processing circuit frame 5, long source distance detector (helium 3 tube) 6, shielding body 7, short source distance detection Mechanical components such as the device, neutron source bin housing 9, neutron source bin 10, lower connector 11, and circuits such as pulse signal processing circuits, communication control and data transmission circuits, and power circuits.

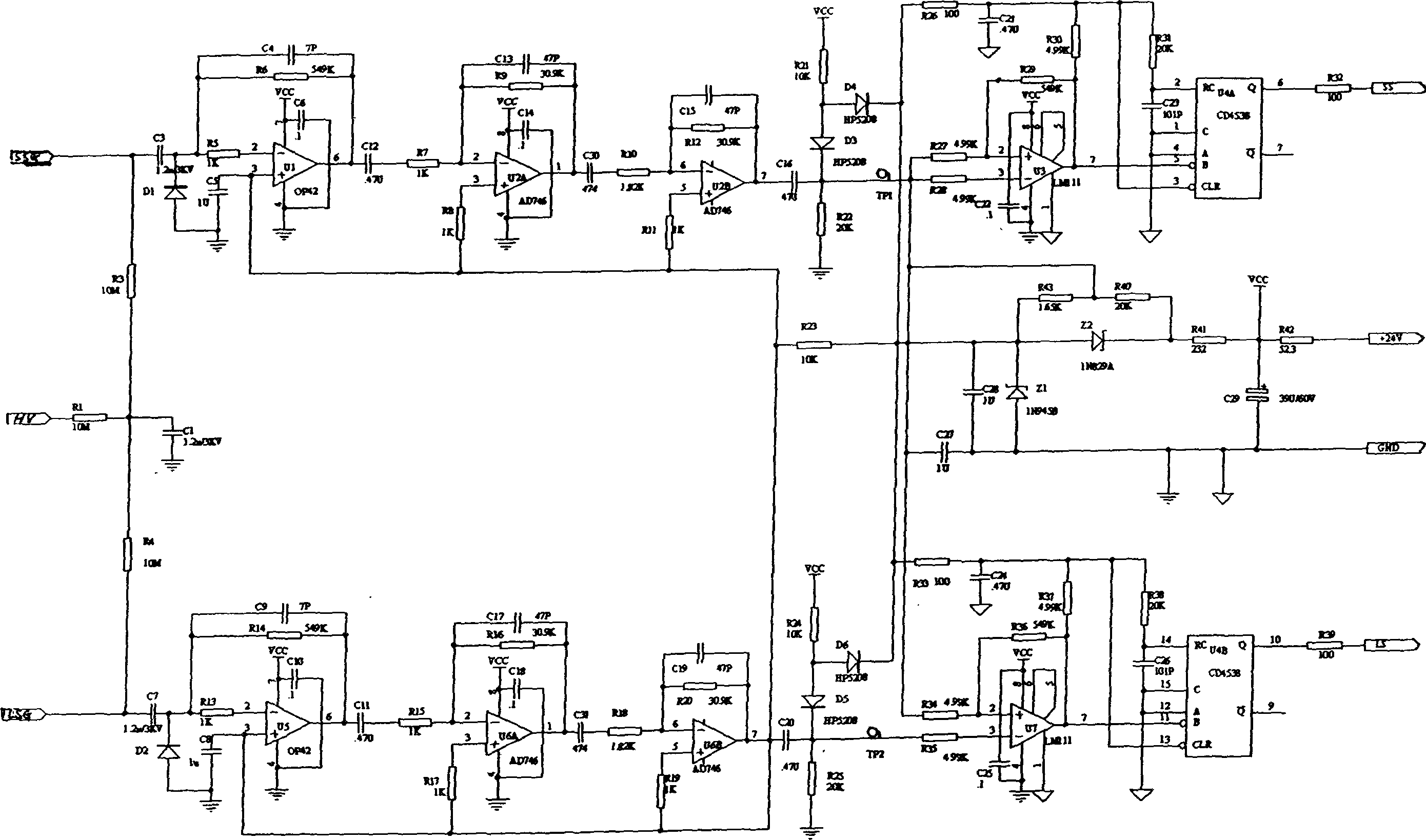

[0015] When the instrument works, it needs to supply 180V AC from the ground. The power supply circuit of the downhole instrument converts 180V AC power into two stable +24V and one +5V DC power supplies. One of the channels +24V is input to the high-voltage black bar. The high-voltage black rod generates +1150V±50V working high voltage to supply long and short source distance neutron detectors. Another +24V input to the pulse signal processing circuit. The +5V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com