Construction process for closed connection of aluminum alloy/steel-glass fiber reinforced plastic composite ship

A construction process and glass fiber reinforced plastic technology, which is applied in ship parts, ship construction, ships, etc., can solve the problems of large differences in elastic deformation of materials, complex processes, and different toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

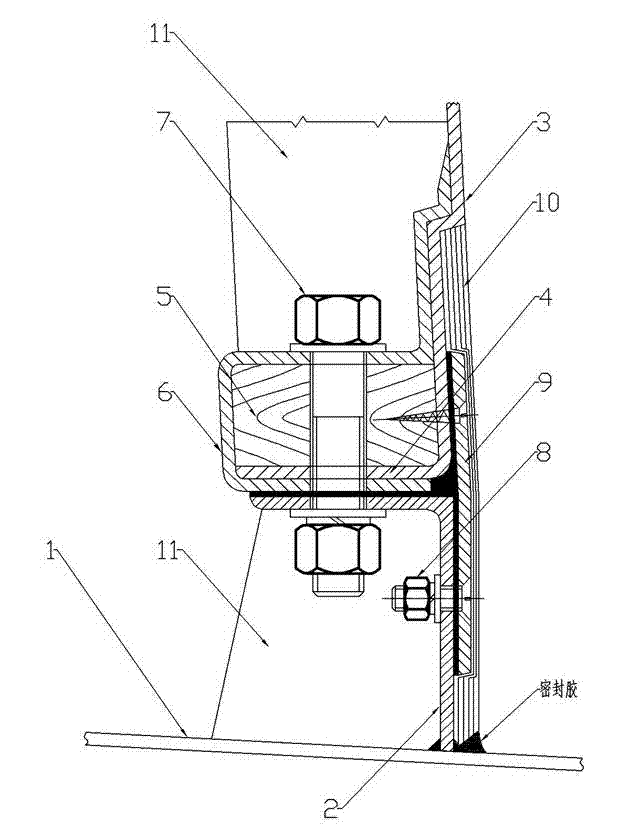

[0021] In this embodiment, the present invention is a construction technique for closing and connecting an aluminum alloy / steel-glass reinforced plastic composite ship, wherein the aluminum alloy / steel-glass reinforced plastic composite ship includes a glass fiber reinforced plastic superstructure, and an aluminum alloy / glass fiber reinforced plastic composite ship under the superstructure. a steel hull and connecting structures for fixing said superstructure to said hull, such as figure 1 As shown, the connection structure includes an angle aluminum / angle steel 2 connected to the aluminum alloy / steel deck 1, a hardwood 5 whose bottom surface is attached to the reverse side 4 of the glass fiber reinforced plastic side wall 3, and a wrapper that wraps the hardwood 5. Hardwood glass fiber reinforced plastic 6, vertical bolt 7 and horizontal bolt or screw 8, it is characterized in that: the construction technology of described aluminum alloy / steel-glass fiber reinforced plastic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com