Heavy-load long-service-life highway structure and construction method

A life-saving, road-based technology, applied to roads, roads, on-site coagulation pavements, etc., can solve problems such as insufficient rigidity of the roadbed, achieve high construction accuracy, avoid alternating shear stress changes, and prevent reflective cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

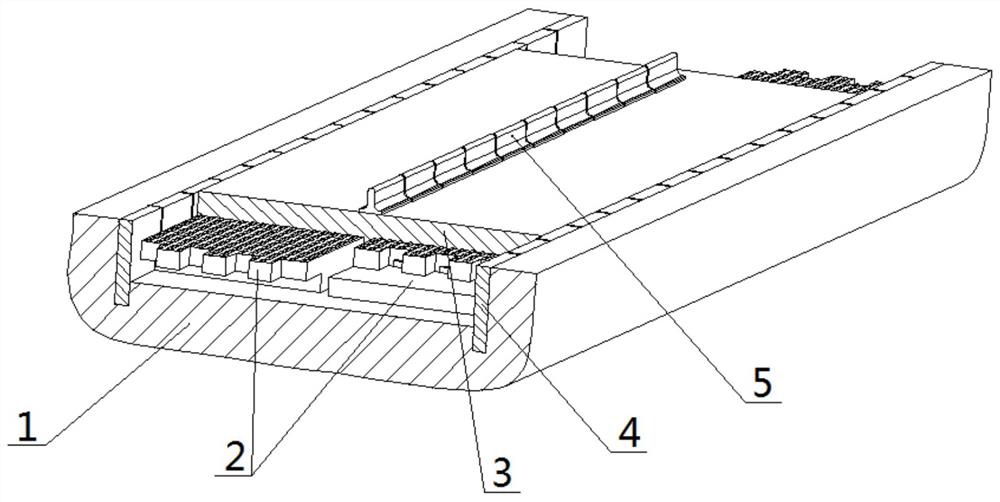

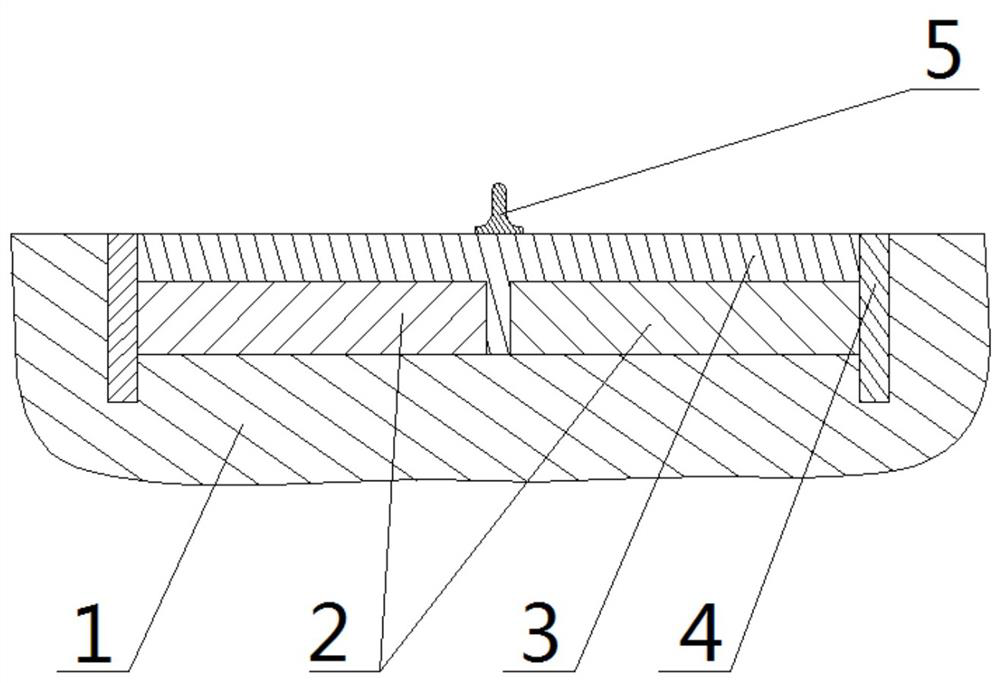

[0041] A heavy-duty and long-life road structure, including a roadbed 1, a base plate 2, and an asphalt pavement layer 3; the base plate 2 is a prefabricated part, which is produced in a cement product prefabrication factory; It is made by pouring and curing cement mortar; the base plate 2 is fixedly arranged on the upper part of the roadbed 1; the asphalt pavement layer 3 is laid on the upper part of the base plate 2; shoulders 4 are arranged on both sides of the base plate 2 and the asphalt pavement layer 3; the asphalt pavement There is an isolation pier 5 in the middle of layer 3;

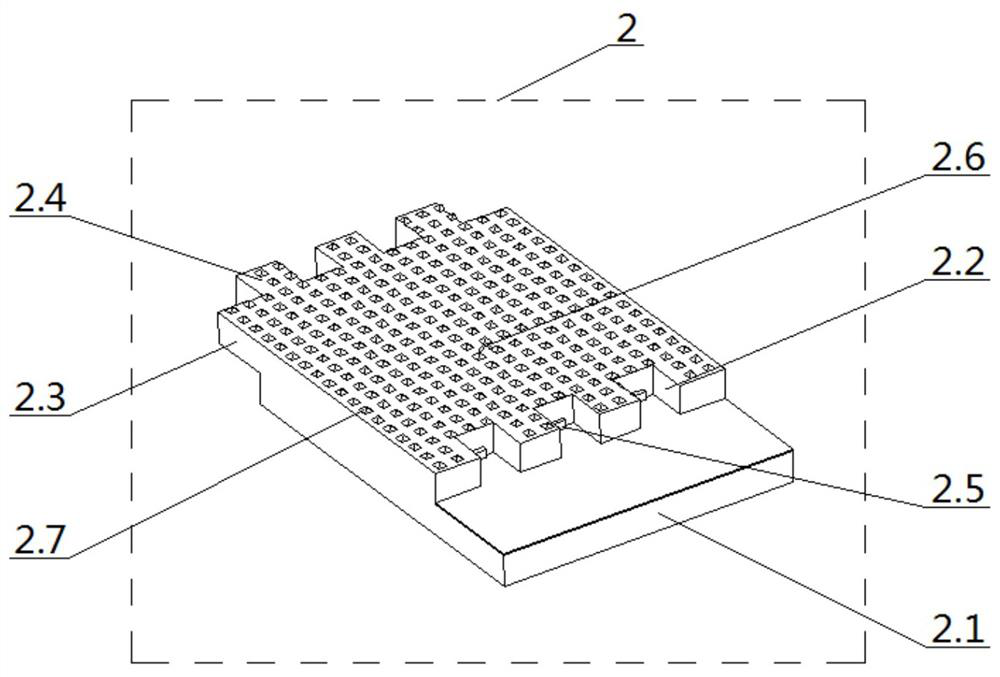

[0042] The substrate 2 is plate-shaped, with a lower substrate crimping plate 2.1 on the lower side of one end, and an upper substrate crimping plate 2.3 on the upper side of the other end; the substrate with the lower substrate crimping plate 2.1 The end of 2 is provided with a substrate docking groove 2.2, and the end of the crimping plate 2.3 on the substrate is provided with a substrate doc...

Embodiment 2

[0056] A heavy-duty and long-life road structure, including a roadbed 1, a base plate 2, and an asphalt pavement layer 3; the base plate 2 is a prefabricated part, which is produced in a cement product prefabrication factory; It is made by pouring and curing cement mortar; the base plate 2 is fixedly arranged on the upper part of the roadbed 1; the asphalt pavement layer 3 is laid on the upper part of the base plate 2; shoulders 4 are arranged on both sides of the base plate 2 and the asphalt pavement layer 3; the asphalt pavement There is an isolation pier 5 in the middle of layer 3;

[0057] The substrate 2 is plate-shaped, with a lower substrate crimping plate 2.1 on the lower side of one end, and an upper substrate crimping plate 2.3 on the upper side of the other end; the substrate with the lower substrate crimping plate 2.1 The end of 2 is provided with a substrate docking groove 2.2, and the end of the crimping plate 2.3 on the substrate is provided with a substrate doc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com