Patents

Literature

53results about How to "Prevent reflective cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

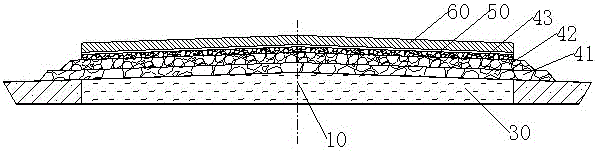

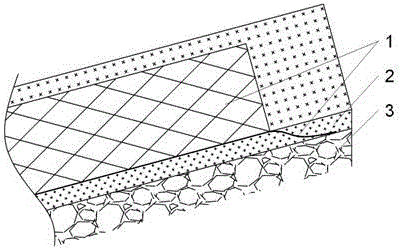

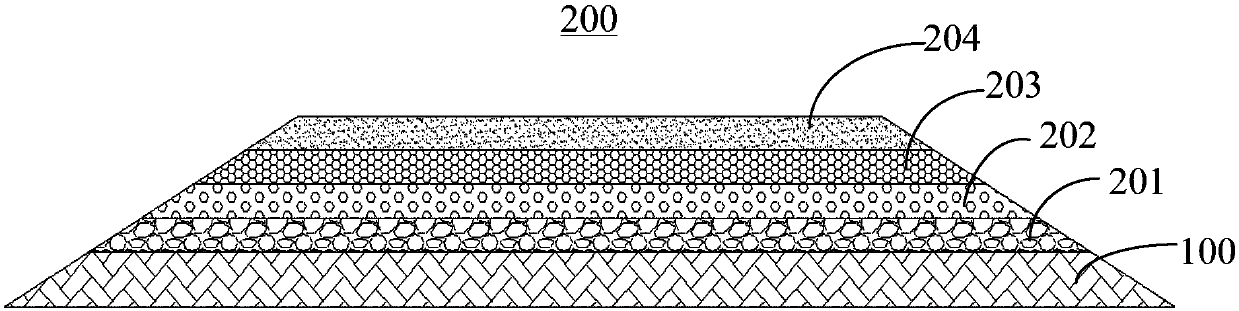

Fiber-reinforced rubber asphalt stress absorbing layer and construction method thereof

The invention provides a fiber-reinforced rubber asphalt stress absorbing layer and a construction method thereof. The fiber-reinforced rubber asphalt stress absorbing layer per square meter comprises the following components: 0.2-1.0 kg of SBS (styrene butadiene styrene) modified emulsified asphalt, 70-150 g of glass fibers, 1.5-3.0 kg of rubber asphalt and 10-20 kg of broken stones. The construction method comprises the following steps of: spraying an SBS modified emulsified asphalt layer and spreading the glass fibers sequentially on the clean and dry surface of a lower supporting layer; after the SBS modified emulsified asphalt breaks emulsion, spraying the rubber asphalt and spreading the broken stones; and finally, rolling a road surface, and controlling the time from the spraying of the rubber asphalt to the completion of the rolling within 10-20 minutes. The rubber asphalt stress absorbing layer prepared by the invention is firmly adhered to the lower supporting layer, can prevent the oil bleeding phenomenon of an asphalt surface layer and the generation of the reflection crack of the asphalt surface layer, improves the anti-cracking performance of the rubber asphalt stress absorbing layer, and prolongs the service life of the road surface.

Owner:广州大象超薄路面技术开发有限公司

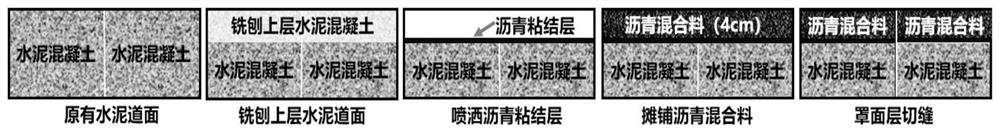

Construction method for reconstruction of old cement pavement into asphalt concrete pavement

InactiveCN104831598AExtended service lifeImprove the immunityIn situ pavingsPaving detailsSocial benefitsSurface layer

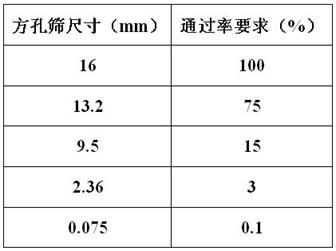

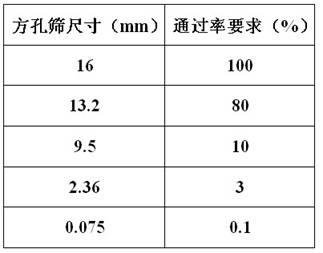

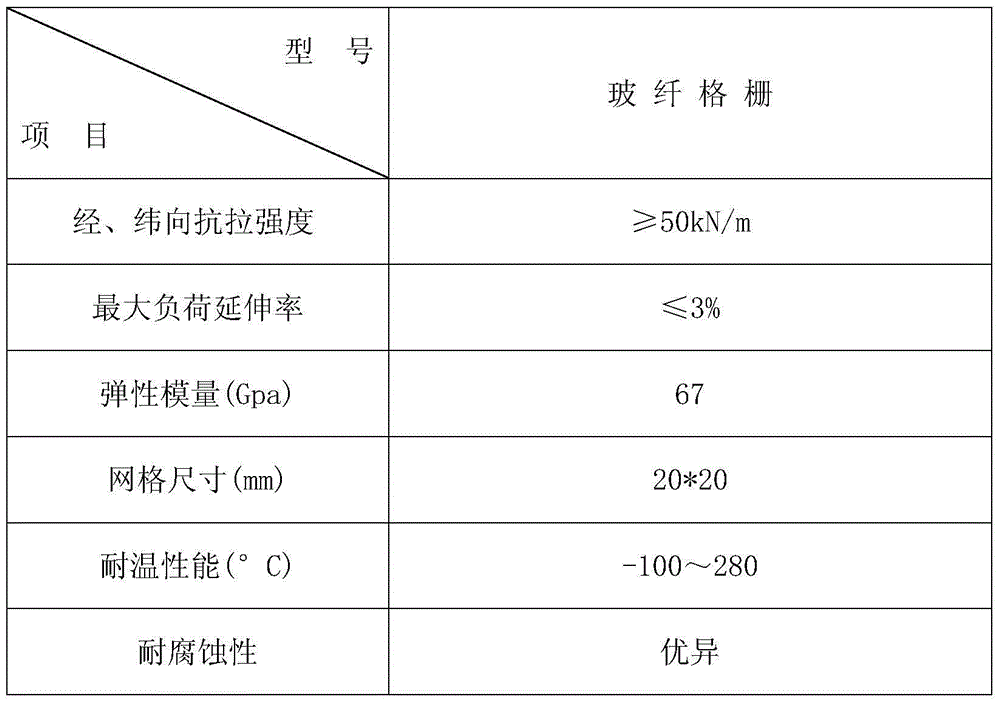

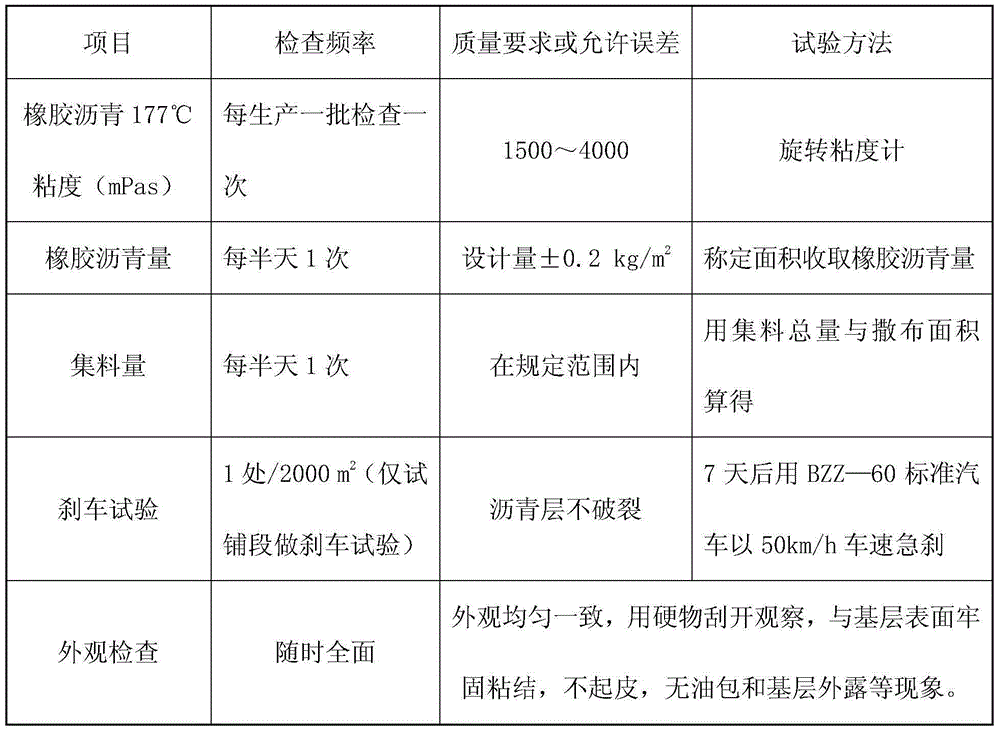

The invention discloses a construction method for reconstruction of an old cement pavement into an asphalt concrete pavement, the steps are as follows: 1, pouring seams of the to-be-reconstructed old cement pavement, 2, judging the damage degree of the to-be-reconstructed old cement pavement, and processing damages; 3, spraying hot rubber asphalt on the damage-processed pavement, spreading an aggregate on the hot rubber asphalt, and rolling to embed the spread aggregate into an asphalt film to form a stress absorption and seepage prevention rubber asphalt stress absorbing layer; 4, paving a grating net sheet on the rubber asphalt stress absorbing layer, and fixing; and, paving an asphalt concrete surface layer on the grating net sheet, wherein the asphalt concrete surface layer is paved in two times. The maintenance cost is greatly reduced, the highway overhaul time is greatly extended, the pavement service life is prolonged more than 1 time, and good economic and social benefits are received. In the rubber asphalt production process, tire waste is used, energy is saved, and the construction method is conducive to environmental protection.

Owner:成军

Pavement splicing method and structure for old cement concrete pavement reconstruction and expansion

ActiveCN106480799AGuaranteed normal operationEasy to handleIn situ pavingsPaving detailsSurface layerCrushed stone

The invention discloses a pavement splicing method and structure for old cement concrete pavement reconstruction and expansion. A cement concrete slab splicing seam is formed in a hard shoulder of an old cement concrete slab, steps are arranged on an old road upper base layer, an old road lower base layer and an old road cushion layer for transition, poor concrete is adopted for a new road upper base layer of an expansion part, and unscreened macadam is adopted for a road bed; a new cement concrete slab and the old cement concrete slab are connected by adopting double-layer reinforcing steel bars; a high-molecular polymer anti-cracking paste is firstly stuck to the cement concrete slab splicing seam, then an asphalt concrete anti-cracking leveling interlayer is paved, and a lower asphalt concrete surface layer and an upper asphalt concrete surface layer are finally paved sequentially, wherein the lower asphalt concrete surface layer is doped with 0.3% by mass of short-cut basalt fiber. According to the method and structure, the problem that the durability of existing old cement concrete pavement reconstruction and expansion engineering is insufficient can be effectively solved, and the important significant is achieved for promoting quicker and better development of transportation industry in China.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

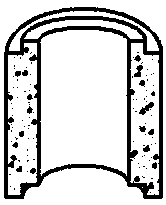

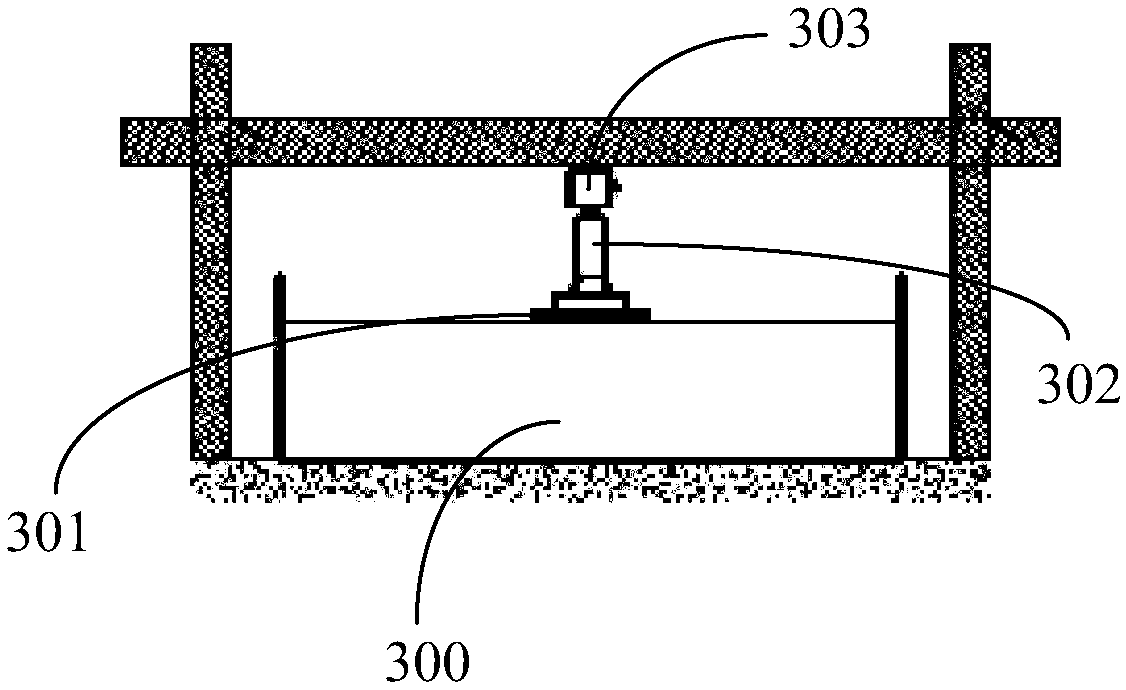

Novel municipal inspection well structure and construction method

PendingCN109972659AEnhance peripheral strengthImprove bearing capacityArtificial islandsTemporary pavingsFiberRoad surface

The invention belongs to the technical field of municipal engineering, and specifically relates to a novel municipal inspection well structure and a construction method. The novel municipal inspectionwell structure composed of a prefabricated pitshaft, a manhole cover, a base course reinforcement layer, a force holding well ring, color steel fiber concrete and the like, wherein the base course reinforcement layer is located on the periphery of the prefabricated pitshaft and at the bottom of a road base course at the same time; and the force holding well ring is inlaid in the road base course,the manhole cover is fixed to the force holding well ring, and the color steel fiber concrete is arranged on the periphery of the manhole cover with the same color as the road surface. According to the novel municipal inspection well structure and the construction method, intensity on the periphery of an inspection well is improved, the construction efficiency, quality and durability of the inspection well are improved, the accuracy of the mounting height of the well ring is realized, and unification of the color on the periphery of the manhole cover and the color of a road surface structureis realized.

Owner:JINAN URBAN CONSTR GRP

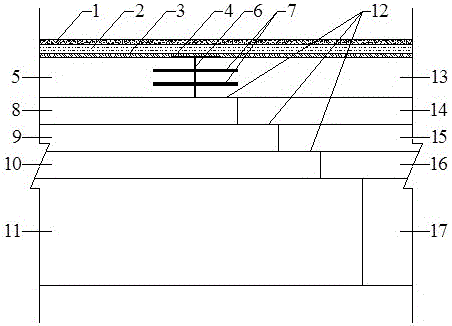

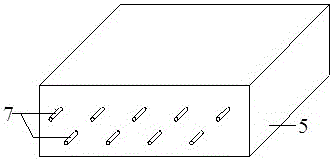

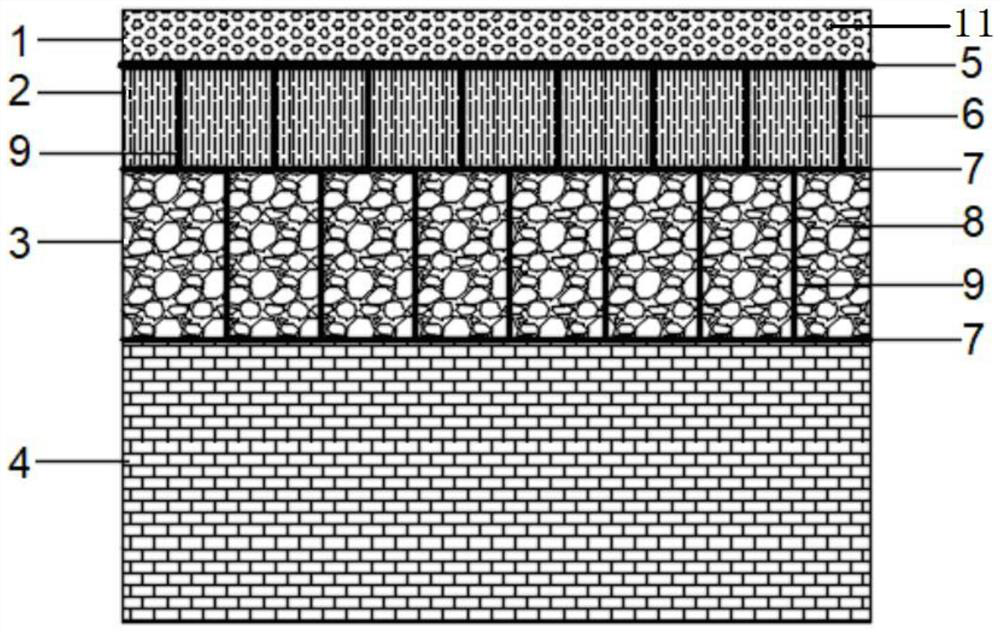

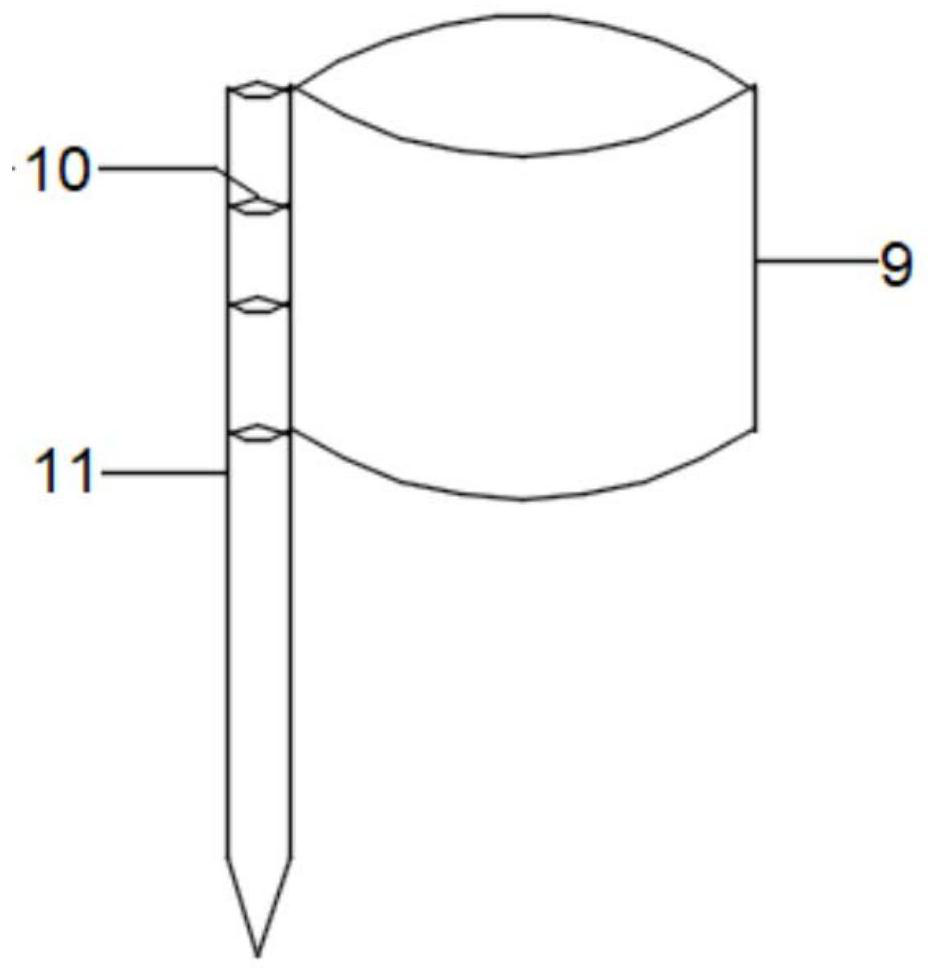

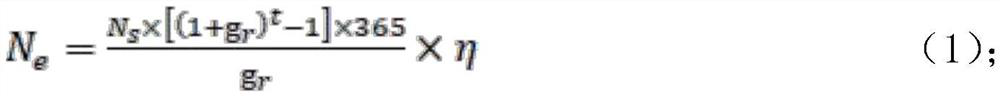

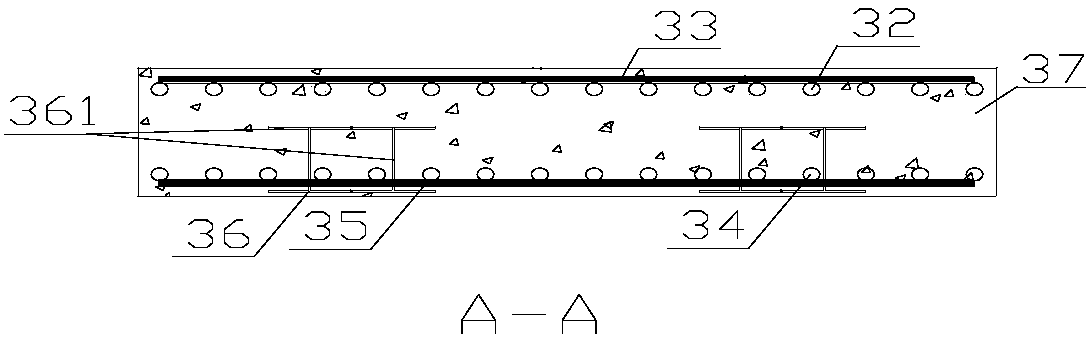

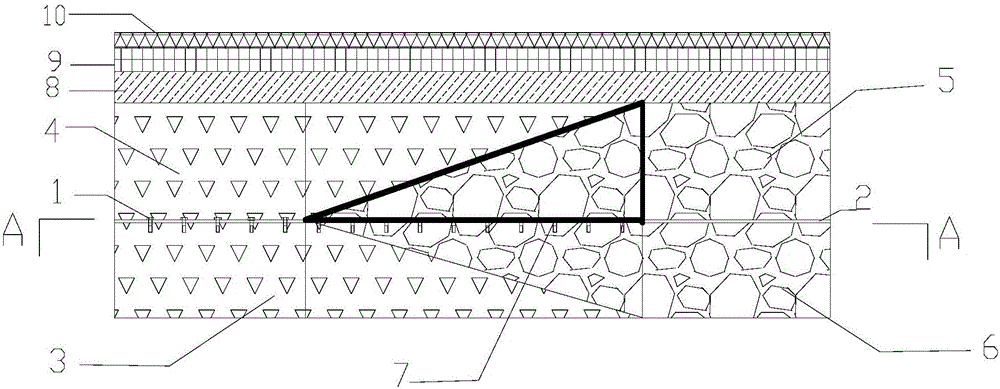

Geocell reinforced cement concrete pavement structure and surface layer plate thickness calculation method

PendingCN111962350AReduce crackingReduce thicknessIn situ pavingsRoads maintainenceCrushed stoneGeocells

The invention discloses a geocell reinforced cement concrete pavement structure and a surface layer plate thickness calculation method. The pavement structure mainly comprises a base layer, a surfacelayer and a wearing layer which are sequentially laid from bottom to top. The base layer is composed of an upper geotextile layer, a lower geotextile layer and a middle geocell reinforced graded broken stone layer; the surface layer is a cement concrete layer reinforced by a geocell; the wearing layer comprises a cement mixture wearing layer and a geogrid; pull rings are reserved on the two sidesof each geocell in a road direction, the geocells are stretched to be in a tensioned state, and wooden wedges penetrate through the pull rings to fix the geocell at the outermost end. The surface layer plate thickness calculation method mainly comprises the steps of traffic analysis, initial simulation of a pavement structure, determination of pavement material parameters, and checking of load stress, temperature stress and a structure limit state. The problems that an existing pavement structure is low in strength, and a cement concrete pavement is subjected to fatigue fracture, mud pumping,slab staggering and the like under heavy-load traffic are solved, so that the pavement structure has high bearing capacity and deformation resistance, and damage to the pavement structure is reduced.

Owner:HUNAN UNIV OF SCI & TECH

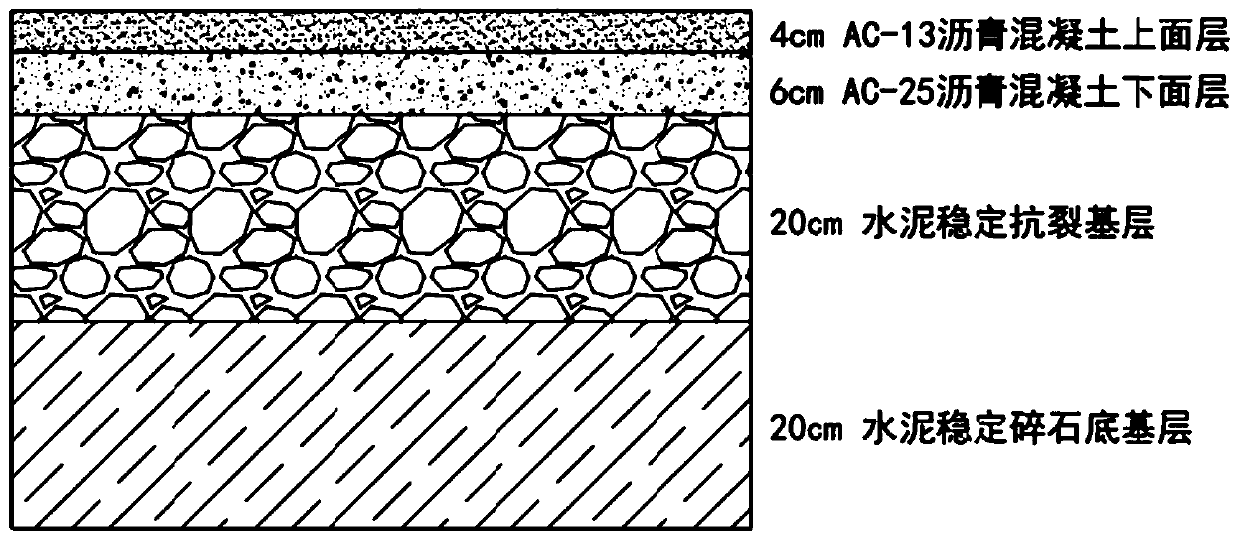

Cement-stabilized anti-crack base newly-built pavement structure and construction method and application thereof

ActiveCN111021178APrevent reflective cracksReduce reflective cracksIn situ pavingsReflective crackGeotechnical engineering

The invention discloses a cement-stabilized anti-crack base layer newly-built pavement structure and a construction method and application thereof. The pavement structure sequentially comprises an asphalt concrete upper surface layer, an asphalt concrete lower surface layer, a cement-stabilized anti-crack base layer and a cement-stabilized subbase layer from top to bottom, wherein the cement-stabilized anti-crack base layer is made of an anti-crack cement-stabilized macadam mixture and mainly comprises cement, large-particle macadam and small-size aggregate, the cement-stabilized anti-crack base layer adopts a road mixing construction mode after on-site layer paving, it is guaranteed that the large-particle macadam makes full contact to form main frameworks, and the small-size aggregate evenly fills gaps between the frameworks. According to the cement-stabilized anti-crack base layer newly-built pavement structure, reflection cracks of a semi-rigid base asphalt pavement structure are reduced, so that various disease problems caused by expansion and penetration of the reflection cracks of a traditional semi-rigid base asphalt pavement structure are solved, various diseases caused byexpansion and penetration of the reflection cracks of the pavement structure are reduced, and the purpose of prolonging the service life of the pavement structure is achieved.

Owner:SOUTHEAST UNIV

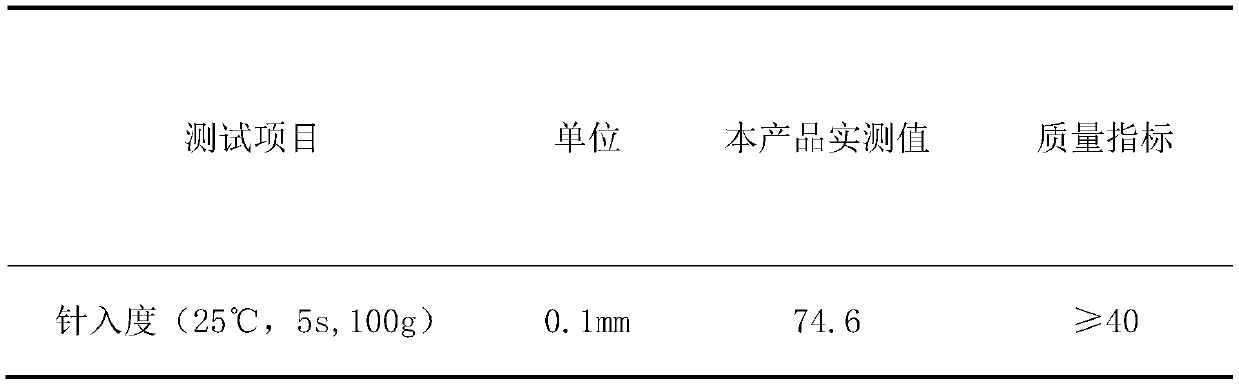

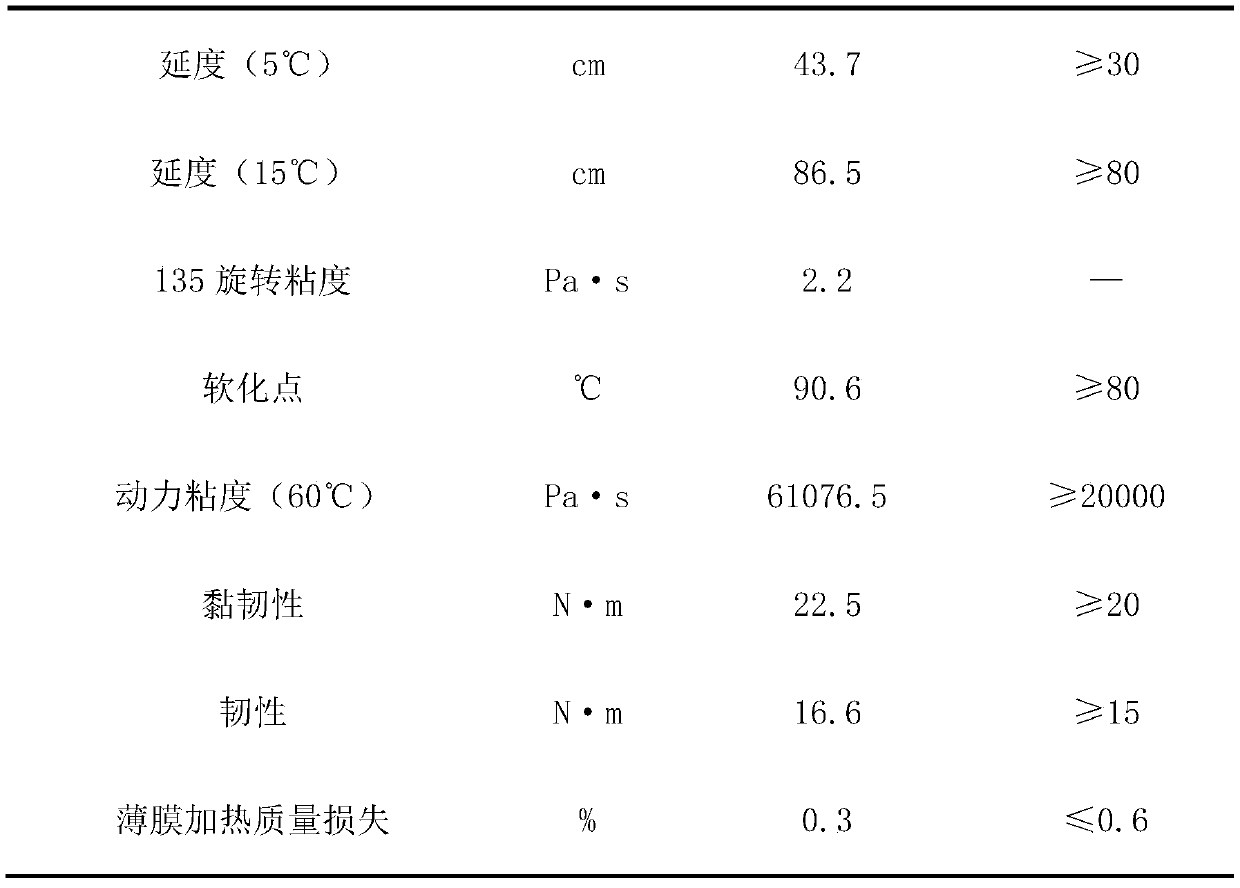

High-adhesion modified asphalt and preparation method thereof

InactiveCN109852085AIncreased durabilityImprove engineering structureBuilding insulationsPolyesterPolymer science

The invention discloses high-adhesion modified asphalt and a preparation method thereof, and belongs to the technical field of road engineering materials. The raw materials of the high-adhesion modified asphalt comprises 500 parts of base asphalt, 300-400 parts of an additive and 10-20 parts of composite reinforcing fibers, and the composite reinforcing fibers are prepared by compounding basalt fibers and polyester fibers and then being coated with base asphalt thin films. When preparing the high-adhesion modified asphalt, the composite reinforcing fibers are added, so that the adhesion, high-temperature stability, fatigue durability of asphalt pavements are greatly improved, and the asphalt has the properties of low-temperature crack prevention and reflection crack prevention. The tensile, shear, compressive and impact strength are effectively improved, and the thermal stability and low temperature resistance of the asphalt are improved.

Owner:河北长大交通科技有限公司

Highway pavement rubblization treatment and reuse laying construction structure and technology

InactiveCN106192698AReduce processing costsReduce investmentRoads maintainenceSurface layerRoad surface

The invention discloses a highway pavement rubblization treatment and reuse laying construction structure and technology and belongs to the field of road construction. The construction structure comprises an original roadbed and a pavement cushion layer. The pavement cushion layer is formed after panel rubblization treatment and roller compaction of an original damaged pavement, and the upper portion of the pavement cushion layer is spread to form a concrete surface layer. The construction technology includes the work steps of early-stage preparation, test site setup, MHB smashing, raw material clearing, compacting and spreading, joining and the like. Investment of raw materials is saved, production cost is reduced, the whole pavement is firm in structure and high in pressure resistance, the whole engineering process is simple, and the construction period is shortened.

Owner:CHINA 19TH METALLURGICAL CORP

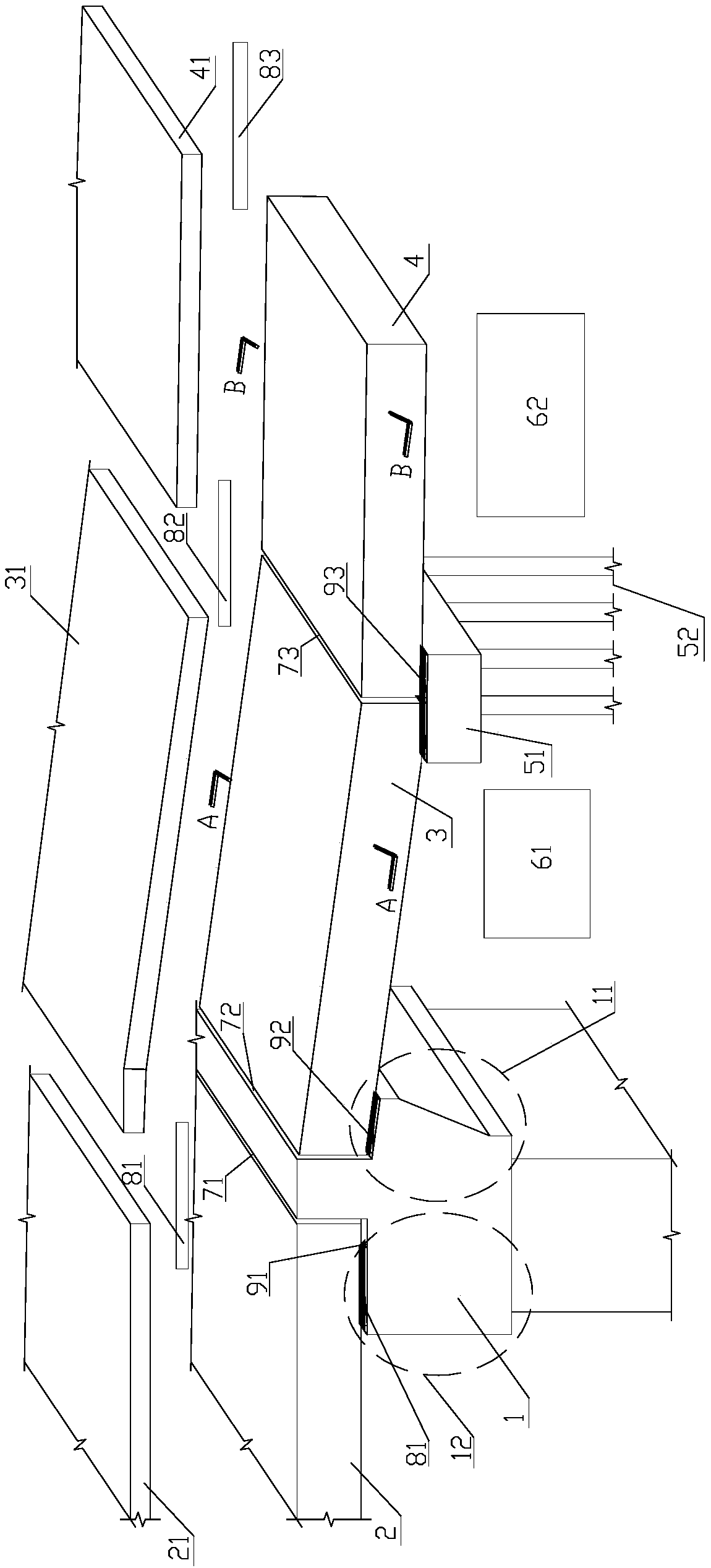

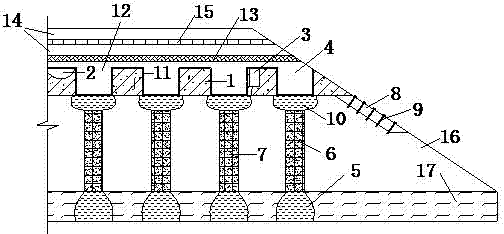

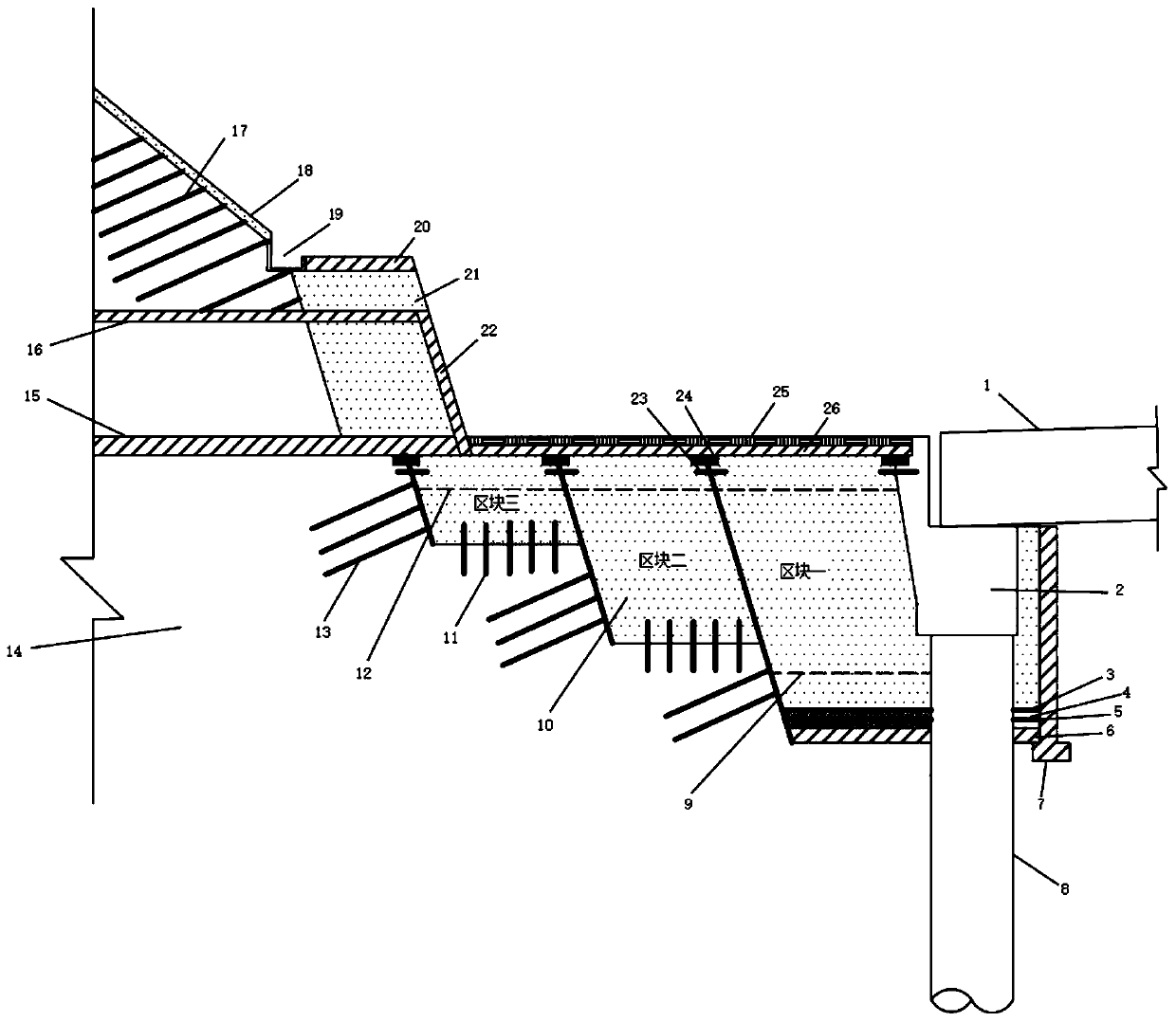

Rigidity-reinforced type bridge head structure for operating highway and governing bump at bridge head and construction method

PendingCN107740339AOvercome the breakOvercoming abutment damageRoadwaysBridge structural detailsEngineeringAbutment

The invention discloses a rigidity-reinforced type bridge head structure for operating a highway and governing a bump at a bridge head. The structure includes a bridge abutment, a bridge edge girder crossing board, a roadbed, a bridge surface paving structure, a first-level butting board, a second-level butting board, a first-level pavement layer, a second-level pavement layer and a supporting platform; the bridge edge girder crossing board is erected on a bridge abutment supporting base, and a bridge surface paving structure is paved on the bridge edge girder crossing board; the first-level butting board is erected between the bridge abutment and the supporting platform, one end of the first-level butting board is erected on a bridge abutment bracket; a far end of the first-level buttingboard is erected on the supporting platform, and the first-level pavement layer is paved on the first-level butting board; one end of the second-level butting board is erected on the supporting platform, the other end of the second-level butting board is erected on the roadbed, and the second-level pavement layer is paved on the second-level butting board; expansion joints exist between the bridgeedge girder crossing board and the bridge abutment, between the first-level butting board and a bridge abutment back, and between the first-level butting board and the second-level butting board. Theinvention also provides a construction method of the rigidity-reinforced type bridge head structure for operating the highway and governing the bump at the bridge head. The structure is great in reliability and low in maintenance cost.

Owner:ZHEJIANG INST OF COMM

Novel environment-friendly asphalt concrete and construction method thereof

The invention discloses a novel environment-friendly asphalt concrete. Each cubic meter of the novel environment-friendly asphalt concrete comprises 2o to 24 kg of waste milling and planing materials of asphalt, 80 to 120 kg of a glass fiber, 0.6 to 0.8 kg of SBS modified emulsified asphalt and 0.2 kg of an asphalt latex recovering agent. A construction method for the asphalt concrete comprises the following steps: successively sprinkling an SBS modified emulsified asphalt layer and spreading the glass fiber on the cleaned and dried surface of an old pavement and sprinkling the screened waste milling and planing materials of asphalt at the same time; and carrying out rolling after completion of the above-mentioned construction, wherein time for synchronous sprinkling construction to completion of rolling is controlled be 10 to 20 min. According to the invention, in preparation of the novel environment-friendly asphalt concrete, large batch of the waste milling and planing materials of asphalt are used, which is energy saving and environment-friendly; the formed new asphalt concrete is firmly bonded with a lower bearing layer, can prevent occurrence of asphalt surface course reflection cracks and pit slots, improves anti-cracking performance of an asphalt stress absorption layer and prolongs the service life of a pavement.

Owner:JIANGSU ZENGGUANG COMPOSITE MATERIAL TECH

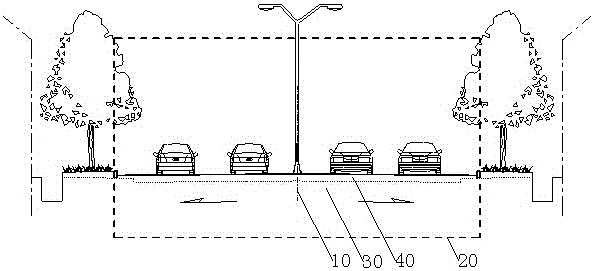

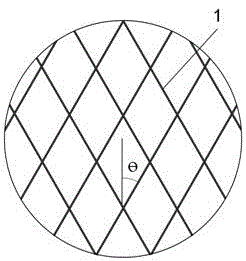

Asphalt pavement additionally laid with rib net

The invention discloses an asphalt pavement additionally laid with a rib net and belongs to the technical field of road construction. The asphalt pavement additionally laid with the rib net structurally comprises a cement concrete base layer and an asphalt concrete pavement layer. The asphalt pavement is further provided with the rib net, wherein the rib net is flatly laid on the upper side of the asphalt concrete pavement layer and embedded into the upper surface layer of the asphalt concrete pavement layer to make the pavement flat wholly, and net ropes of the rib net and the road form angles of 20-40 degrees. The asphalt pavement is additionally laid with the rib net to form a whole structure, the rib net forms a transverse prestressing force, the transverse pushing-extruding effect of tire pressures on the pavement is reduced, and track damages are greatly reduced. In addition, a load is effectively dispersed, the anti-cracking performance and anti-impact performance of the asphalt pavement are improved, accordingly the durability of the pavement is improved, and the service life of the road is prolonged.

Owner:GUANGZHOU RAPID TRANSIT CONSTR

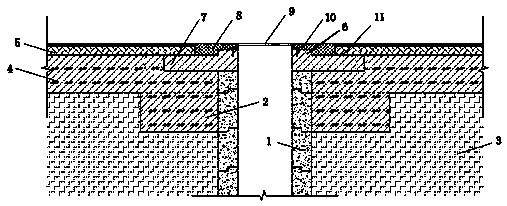

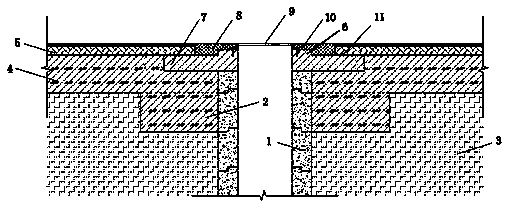

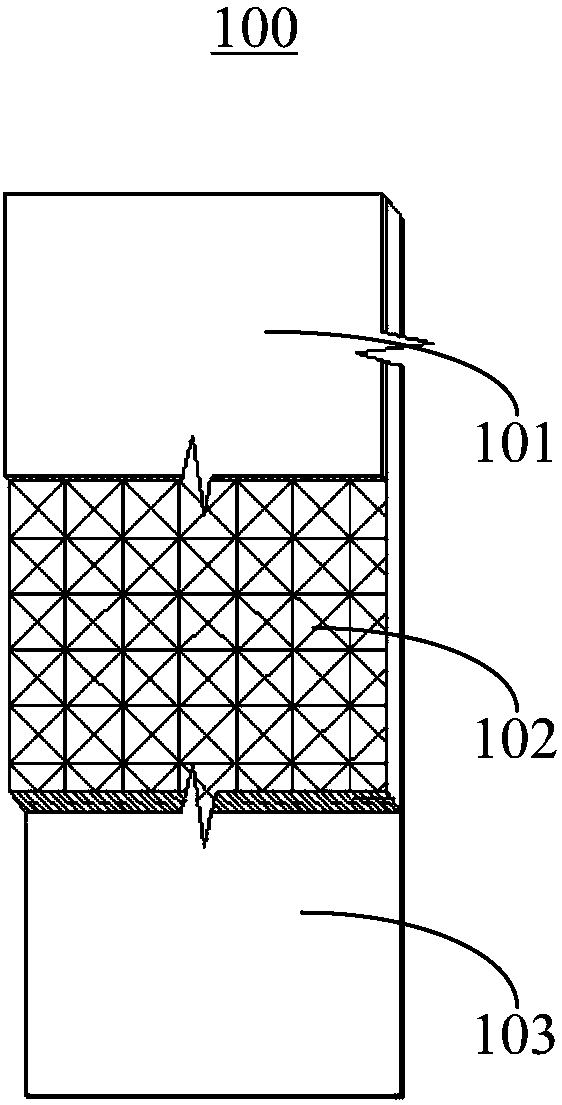

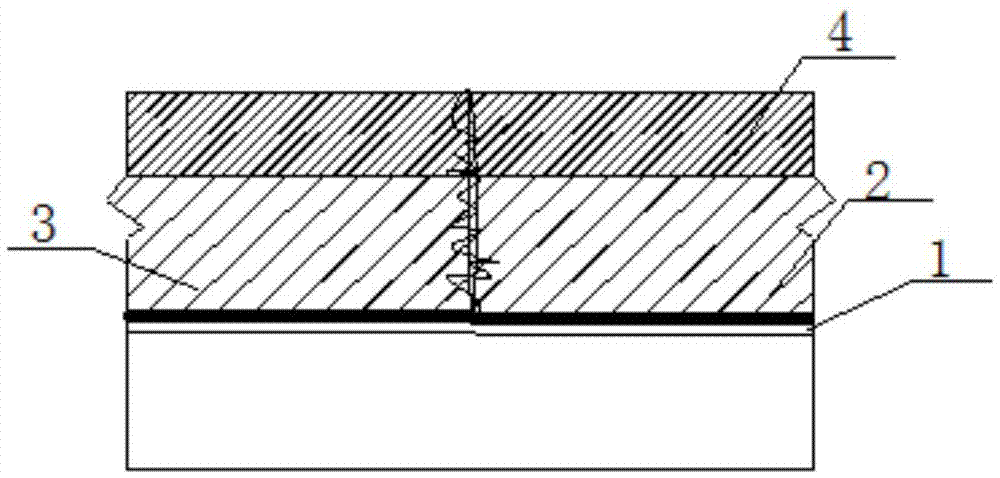

Construction method for transforming cement concrete pavement with embedded reinforced asphalt layer

ActiveCN104328730APrevent reflective cracksImprove tensile propertiesIn situ pavingsRoads maintainenceFoam concreteStructural engineering

The invention relates to a construction method for transforming cement concrete pavement with an embedded reinforced asphalt layer. A basal grouting is arranged in the horizontal direction under an original embankment. More than one geogrid vertical reinforcements are arranged in the vertical direction and are filled with foam concrete light-weight soil. A plate-bottom grouting is arranged above the geogrid vertical reinforcements and under the original cement concrete pavement. Blocking bodies are arranged respectively at the two ends of the plate-bottom grouting and are fixed onto side walls of the original embankment. A well-type connective trough is arranged in the original cement concrete pavement. A lower pavement layer, a stress absorption layer and an upper pavement layer are arranged in the well-type connective trough and on the original cement concrete pavement from bottom to top successively. A later paved asphalt pavement material and the original cement concrete pavement have an excellent connecting performance so that destroy in each structure layer in the pavement can be effectively prevented. The construction method can solve a problem of post-construction settlement and prolongs a service life of a road.

Owner:德达交通建设发展集团有限公司

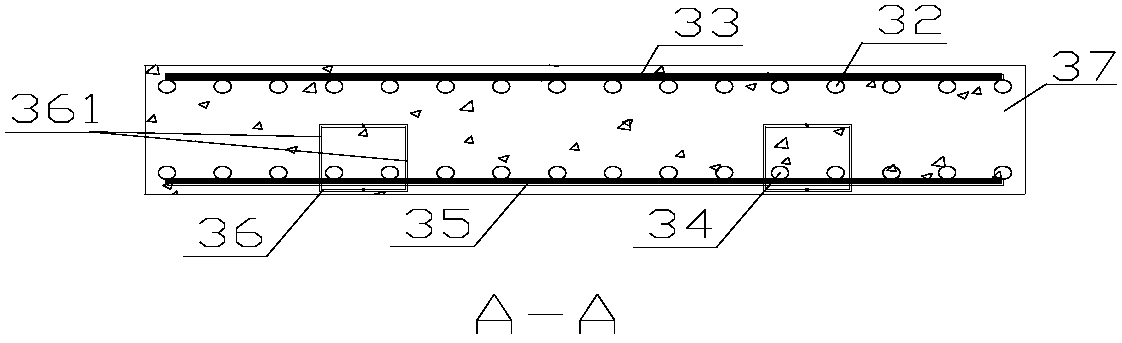

Ribbed waterproof and water-draining coiled material and construction method thereof

InactiveCN108035333AImprove carrying capacityPrevent reflective cracksRoadwaysProtective foundationSubgradeMaterials science

The invention discloses a ribbed waterproof and water-draining coiled material and a construction method thereof. The ribbed waterproof and water-draining coiled material comprises a waterproof layer,a supporting layer and a water-draining layer, wherein the supporting layer is positioned between the waterproof layer and the water-draining layer; and the waterproof layer, the supporting layer andthe water-draining layer are connected integrally. The waterproof layer, the supporting layer and the water-draining layer are simultaneously arranged on the ribbed waterproof and water-draining coiled material, so that the ribbed waterproof and water-draining coiled material simultaneously has functions of improving foundation or roadbed carrying ability, obstructing underground water and solving the problem of water drainage of a foundation or a roadbed, then uneven sedimentation of the pavement of the foundation and roadbed is reduced, reflection cracks between structure layers of the pavement of the foundation and roadbed are prevented, the stability of the integral structure of the foundation and roadbed is improved, and the service lives of a building structure and a road are prolonged.

Owner:WUHAN POLYTECHNIC UNIVERSITY

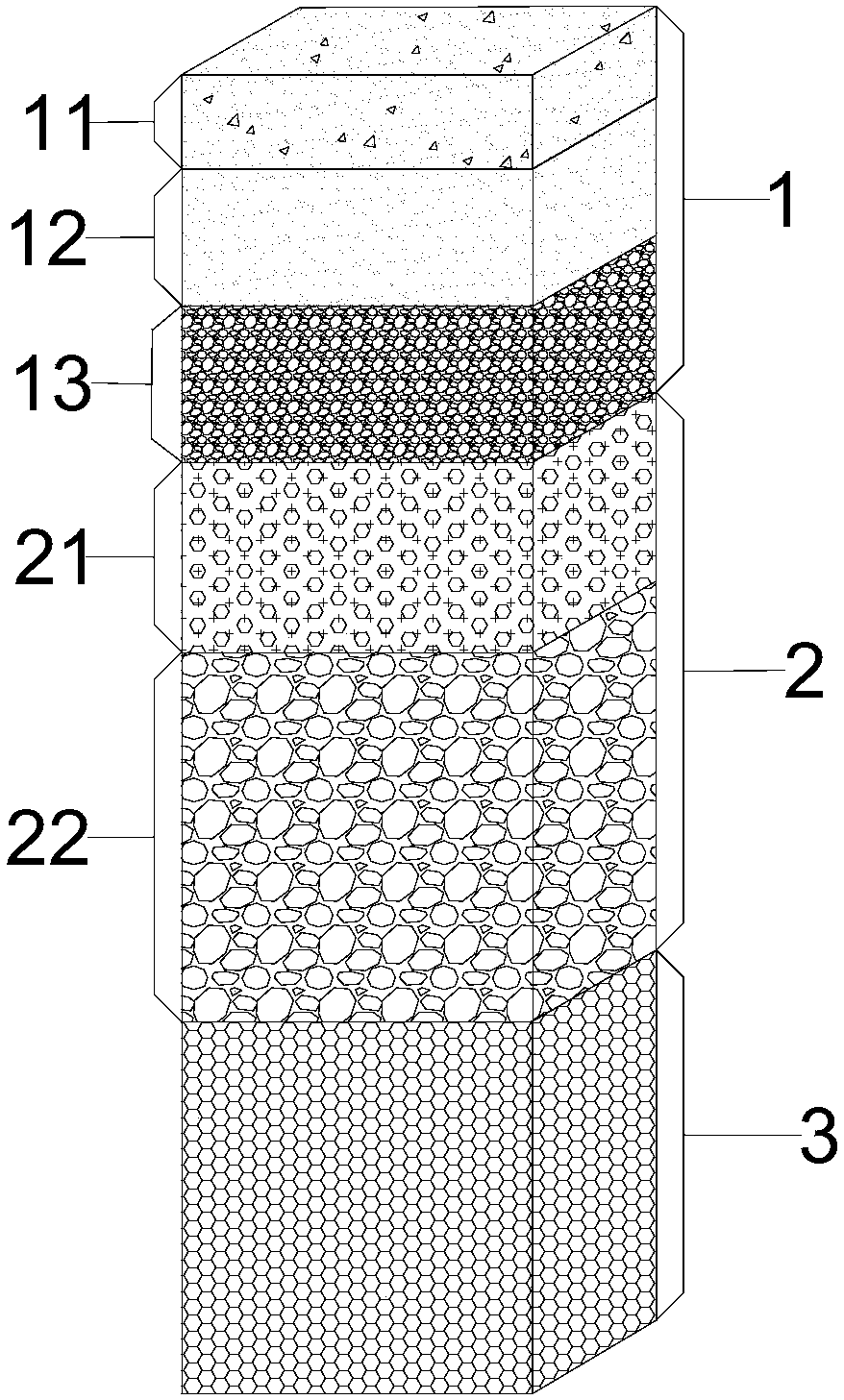

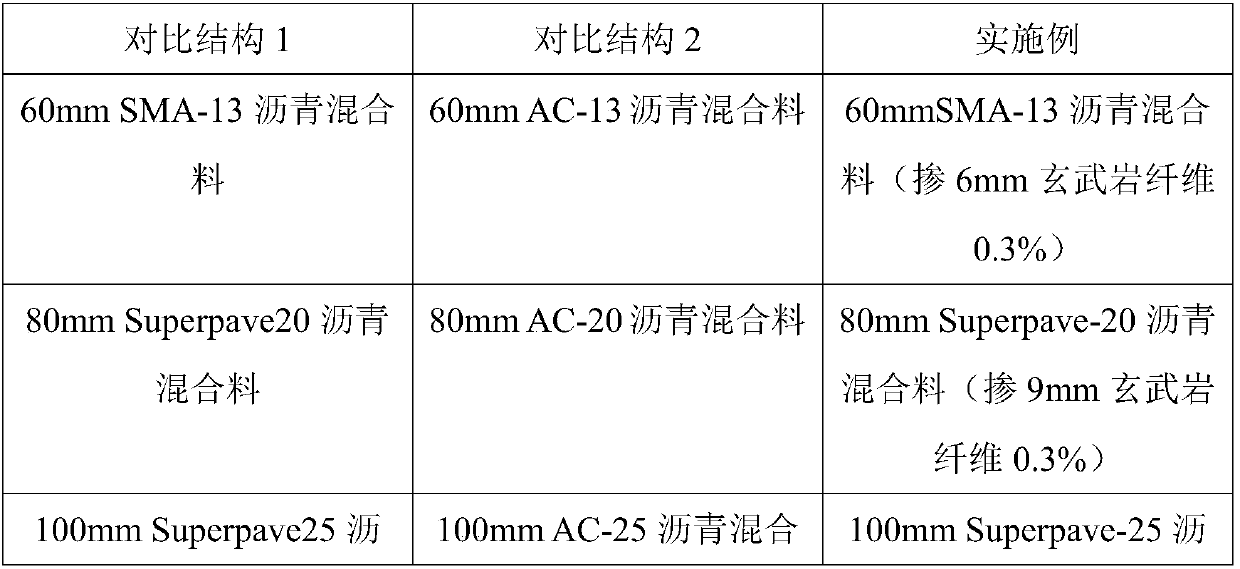

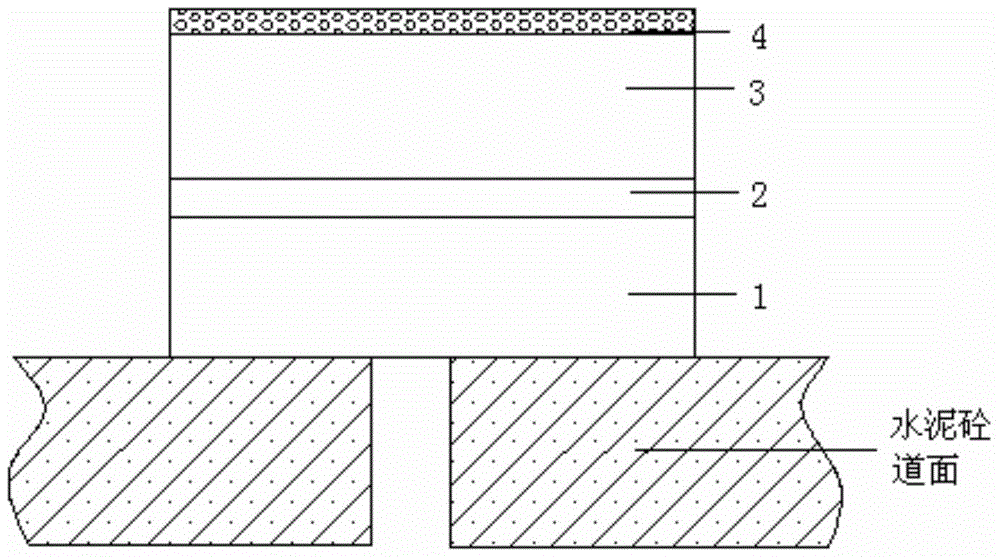

Long-life asphalt pavement structure

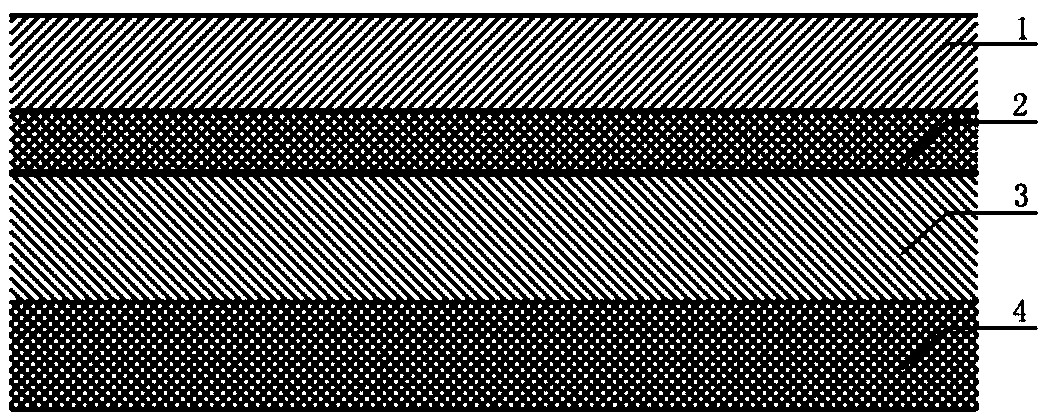

InactiveCN107761502AImprove fatigue lifeImprove high temperature stabilityIn situ pavingsBasementSurface layer

The invention discloses a long-life asphalt pavement structure paved above a soil matrix. The long-life asphalt pavement structure comprises an asphalt surface layer (1), a basement layer (2) and a subbase layer (3), wherein the asphalt surface layer (1) comprises a surface wearing layer (11), a middle surface layer (12) and a lower surface layer (13), the surface wearing layer (11) adopts SMA-13grading asphalt mixture, the middle surface layer (12) adopts Superpave-20 grading asphalt mixture, and the lower surface layer (13) adopts Superpave-25 grading asphalt mixture; the basement layer (2)is a crack-resistant rigid-flexible combined basement layer and comprises a flexible upper basement layer (21) and a semi-rigid lower basement layer (22), the flexible upper basement layer (21) adopts ATB-25 asphalt stabilized macadam, and the semi-rigid lower basement layer (22) is cement stabilized aggregates; and the subbase layer (3) is stabilized type soil. The long-life asphalt pavement structure disclosed by the invention has the advantages that the pavement quality can be greatly improved, and the road service life is prolonged.

Owner:YANGZHOU UNIV

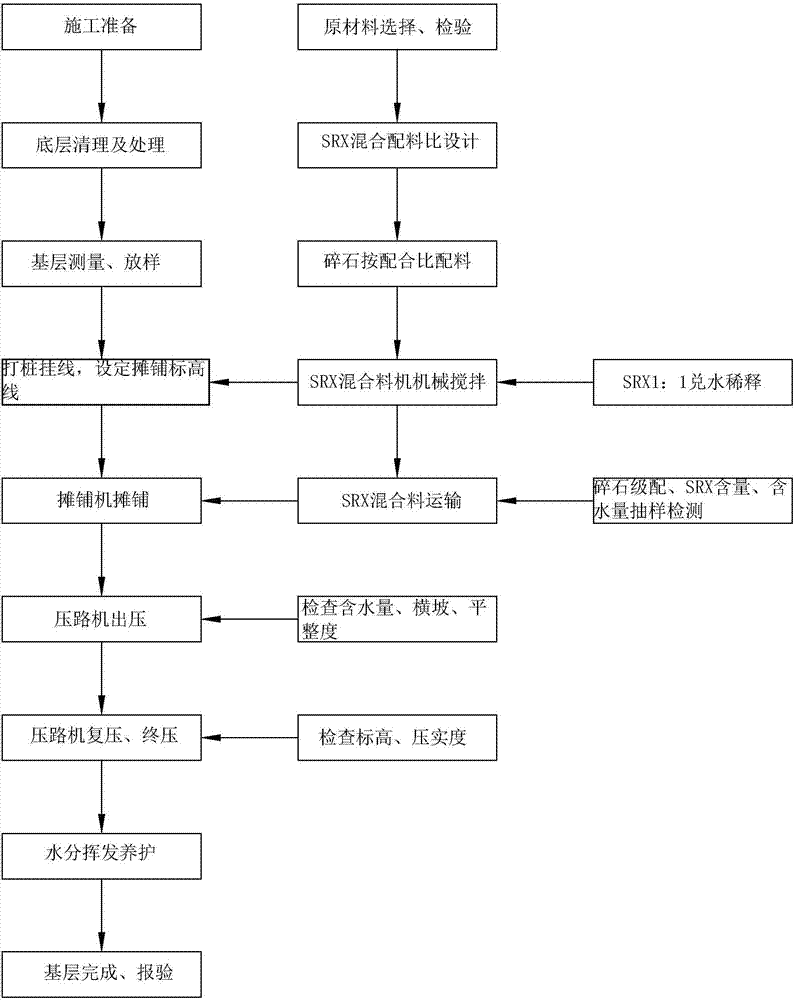

Polymer SRX asphalt road construction process

InactiveCN107460801AHigh strengthGood toughnessIn situ pavingsClimate change adaptationHigh intensityPolymer

The invention discloses a polymer SRX asphalt road construction process, which is characterized by comprising the steps of A, performing preparation required before construction; B, performing bottom layer clearing and treatment; C, performing base layer measurement and sample lofting; D, performing piling and wire hanging; E, stirring mixed materials; F, transporting polymer SRX stable macadam mixtures; G, spreading the polymer SRX stable macadam mixtures; H, performing roller compaction on the polymer SRX stable macadam mixtures; I, caring the polymer stable macadam base layer. By using the technical scheme, the road composite structure made of the polymer SRX stable macadam mixtures has the characteristics of high intensity and high toughness; the road cracking condition is avoided; the service life of the road is prolonged; the effect of the full-thick type asphalt pavement can be achieved only by using half of the manufacturing cost of the conventional asphalt concrete of the polymer SRX stable macadam mixtures; the economic benefits are improved.

Owner:江苏先达建设集团有限公司

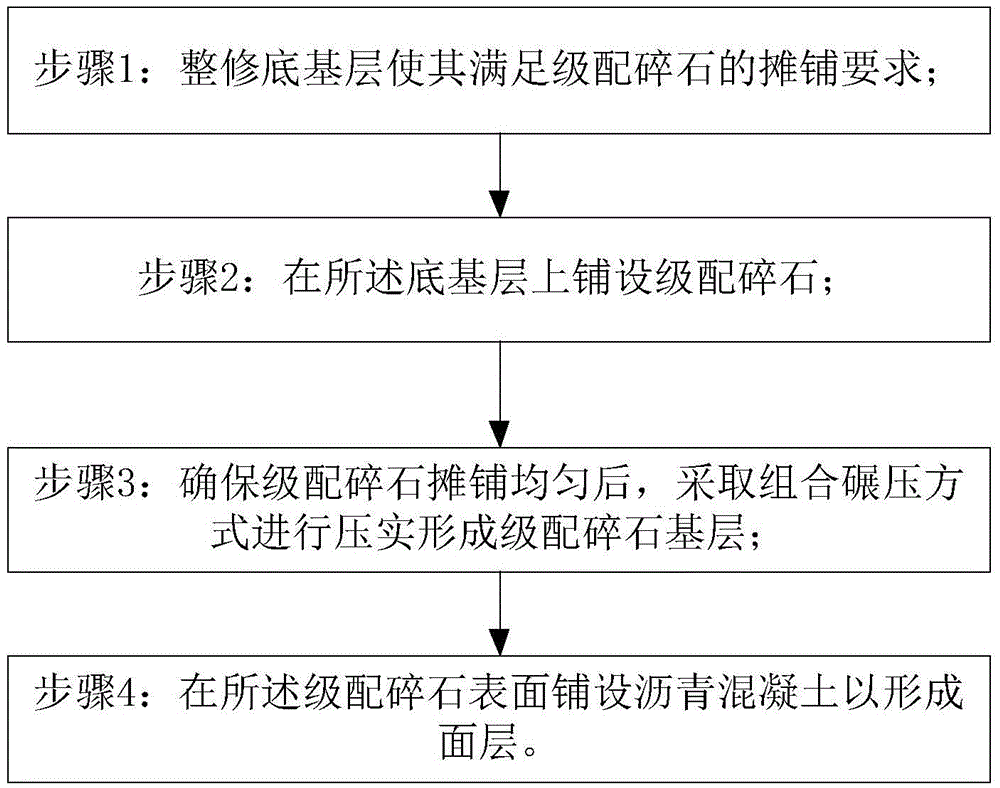

Paving method for tropical zone road surface

The invention discloses a paving method for a tropical zone road surface. The paving method comprises the steps that 1, a subbase layer is renovated so as to meet the paving requirements for graded broken stone; 2, the subbase layer is paved with the graded broken stone; 3, after the effect that the graded broken stone is paved uniformly is ensured, the graded broken stone is compacted in a combination rolled mode to form a graded broken stone base layer; the compaction steps comprise that on the first day, the graded broken stone is subjected to initial rolling and re-rolling, in the first time re-rolling process, the graded broken stone is moisturized and then subjected to final rolling, and surface finishing and slurry purifying are conducted; and on the second day, the graded broken stone is re-rolled again; and 4, the surface of the graded broken stone is paved with bituminous concrete to form a surface layer. According to the paving method for the tropical zone road surface, the road surface structural design of combining the subbase layer and the graded broken stone base layer with the surface layer is adopted and has great advantages on the aspects that the reflection cracks of a tropical zone road which is located in a zone with long rainy season time and is prone to being damaged by water are prevented, the base layer can drain the water away quickly to prevent water damage, and the damage of the base layer is self-healed.

Owner:SHANGHAI CONSTRUCTION GROUP

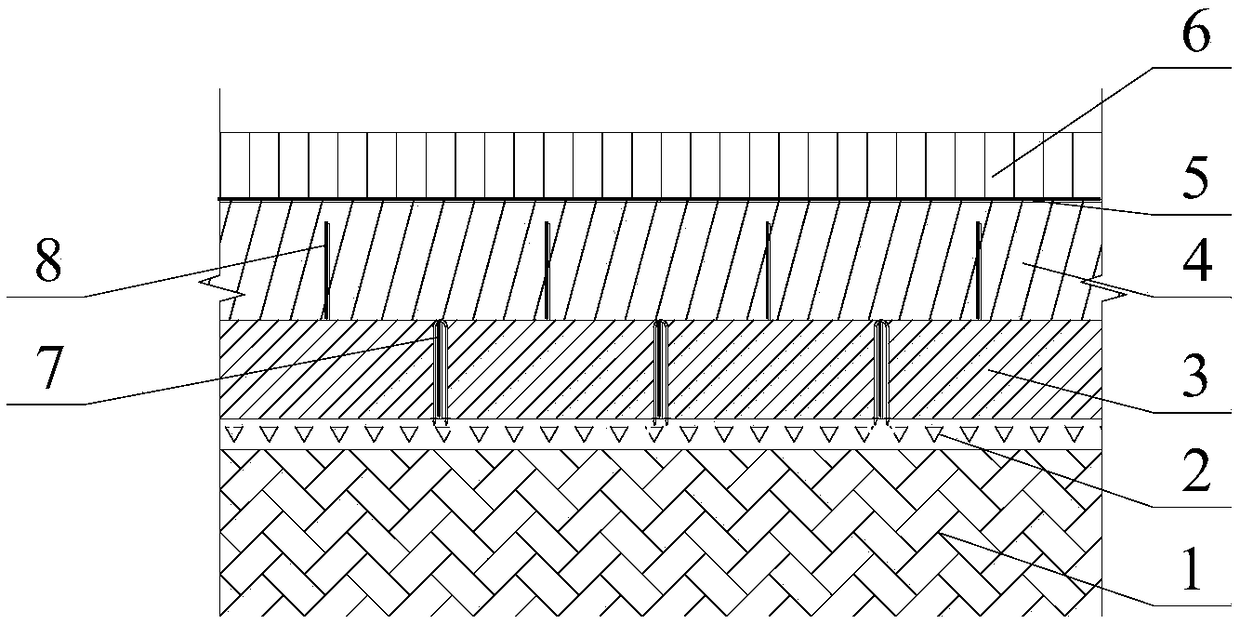

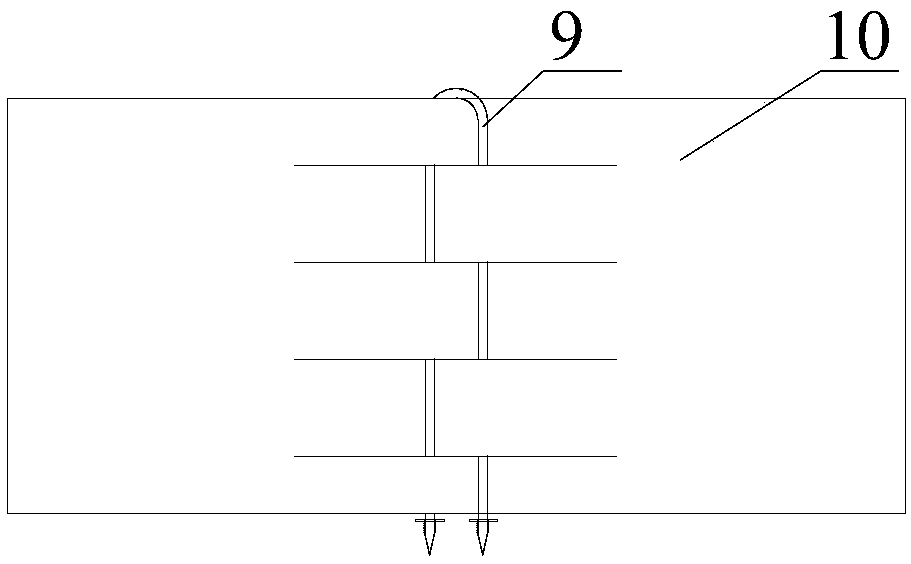

High-strength anti-crack asphalt pavement structure and construction method thereof

PendingCN109235176AEnhanced lateral restraintImprove carrying capacityPaving reinforcementsIn situ pavingsSurface layerGeocells

The invention discloses a high-strength anti-crack asphalt pavement structure and a construction method thereof, which comprises a cushion layer sequentially paved on the roadbed from bottom to top, Asubbase lay, a base layer and a surface lay, wherein that cushion layer is a gravel or gravel layer, the subbase layer is a plug-in geocell reinforce asphalt concrete layer, the base layer is a welding geocell reinforced asphalt concrete layer, the surface layer is an asphalt concrete layer, and the welding geocell and the plug-in geocell are staggered-jointed and laid. The plug-in type geocell comprises a reinforcement band and a special-shaped insert, wherein the reinforcement band is fixed through the special-shaped insert, and the thickness of the subbase layer is equal to the thickness of the plug-in type geocell. The invention can effectively improve the bearing capacity and the deformation resistance of the asphalt concrete pavement, limit the development of the structural damage crack and the deformation of the asphalt pavement, prolong the service life of the asphalt pavement, reduce the cost and facilitate the construction.

Owner:湖北省交通规划设计院股份有限公司

Reflection crack repairing structure and reflection crack repairing process

InactiveCN105442407AImprove high temperature stabilityImprove stabilityIn situ pavingsPaving detailsPolyesterFiltration

The invention discloses a reflection crack repairing structure and a reflection crack repairing process. The reflection crack repairing structure comprises a waterproof adhesive layer, a fiberglass-polyester paving mat anti-crack layer, a first backfill layer and a second backfill layer, wherein the waterproof adhesive layer is arranged on a grooved bottom surface of a reflection crack; the fiberglass-polyester paving mat anti-crack layer is arranged on the upper surface of the waterproof adhesive layer; the first backfill layer is arranged on the upper surface of the fiberglass-polyester paving mat anti-crack layer; and the second backfill layer is arranged on the upper surface of the first backfill layer. By milling materials around the crack and backfilling the fiberglass-polyester paving mat anti-crack layer and backfill, the reflection crack repairing structure disclosed by the invention has favorable integrity, continuity and durability. When the reflection crack repairing structure is applied to a pavement structure, the reflection crack repairing structure has the functions of isolation, seepage prevention, filtration, drainage and the like, can improve the resistance to fatigue cracking of an asphalt surface course, can prevent the reflection crack and deformation resistance, and can improve the use quality of a semi-rigid base asphalt pavement with obviously insufficient old road intensity, large traffic flow, frequent heavy overload vehicles and severe cracking, thereby prolonging the service life of the pavement structure.

Owner:JIANGSU SINOROAD ENG TECH RES INST CO LTD

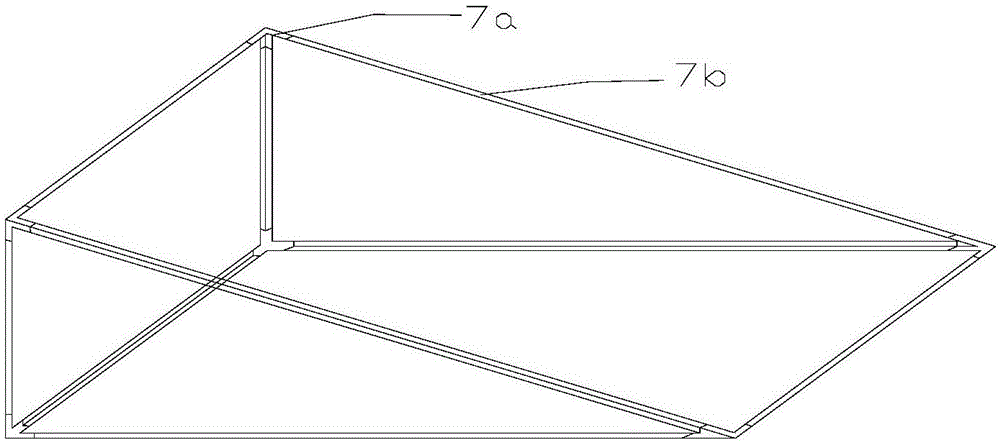

Rigid-flexible base double-slope transition structure and construction method thereof

ActiveCN106801369AMake a smooth transitionPrevent reflective cracksRoadwaysSurface layerStructure of the Earth

The invention discloses a rigid-flexible base double-slope transition structure and a construction method thereof. The rigid-flexible base double-slope transition structure is characterized by being sequentially provided with a cement stabilized crushed stone lower base, a graded crushed stone lower base, a graded crushed stone upper base and a cement stabilized crushed stone upper base from bottom to top; a geotechnical grille is arranged between the graded crushed stone lower base and the graded crushed stone upper base; an upper surface of the cement stabilized crushed stone upper base is sequentially provided with a lower surface layer, a middle surface layer and an upper surface layer from bottom to top; and a first slope transition section and a second slope transition section are arranged in a longitudinal section of the transition structure separately, a structural steel frame is arranged according to an outer contour shape of the graded crushed stone upper base, and the graded crushed stone upper base is laid in a frame of the structural steel frame. According to the rigid-flexible base double-slope transition structure and the construction method, good transition from a semi-rigid base to a flexible base, including from a rigid base to the flexible base, can be realized, the structure is stable, and the engineering quality can be effectively improved.

Owner:HEFEI UNIV OF TECH

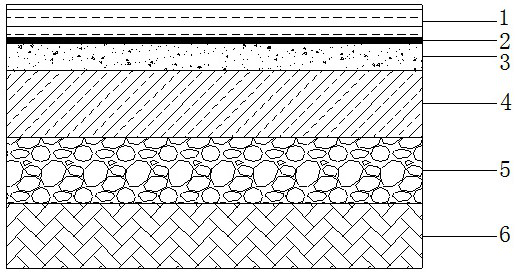

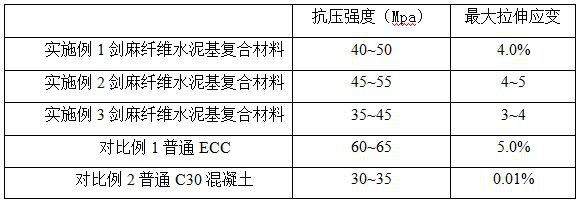

Composite pavement road with asphalt layer coated on sisal hemp fiber cement-based composite material

PendingCN112553994AIncreased durabilityLow costIn situ pavingsPaving detailsSocial benefitsSuperplasticizer

The invention provides a composite pavement road with an asphalt layer coated on a sisal hemp fiber cement-based composite material. A pavement structure of the composite pavement road sequentially comprises an epoxy asphalt concrete surface layer, an interface performance enhancing layer, a sisal hemp fiber cement-based composite material bearing layer, a base layer and a sub-base layer from topto bottom. And the base layer is made of graded stabilized macadam with a flexible characteristic. Main components of the sisal hemp fiber cement-based composite material are cement, fly ash, fine sand, a superplasticizer, an adhesive and sisal hemp fibers, and the sisal hemp fiber cement-based composite material is used as a bearing layer, so that early-stage diseases such as pavement cracks, water damage and ruts can be effectively prevented, the pavement durability is greatly improved, and the service life is prolonged. The coated asphalt layer can improve driving comfort. Meanwhile, due tothe fact that the thickness of the asphalt layer is reduced, the manufacturing cost of the road surface can be remarkably reduced, environmental protection is facilitated, and good social benefits and huge economic benefits are reflected.

Owner:FUZHOU UNIV +1

Pavement multi-hammer rubblization construction method

InactiveCN108797298AFast constructionImprove structural uniformityRoads maintainenceEconomic benefitsArchitectural engineering

The invention discloses a pavement multi-hammer rubblization construction method. The pavement multi-hammer rubblization construction method comprises the following steps of (1) preparation before construction is performed; (2) trial pavement section setting is performed; (3) MHB crushing is performed; (4) compaction is performed; (5) bituminous seal is performed, specifically, emulsified bituminous seal is immediately constructed to pavement after the compaction, the solid content of emulsified asphalt is controlled to be 50%-55%, the using amount of the emulsified asphalt is 2.0-3.5kg / m<2>,then aggregate materials are evenly perfused on the surface of the emulsified bituminous seal, wherein the particle diameter of the aggregate materials is 4.75-9.5mm, Los Angeles abrasion loss is lessthan or equal to 28%, water absorption is less than or equal to 2.0% and silt content is less than 3%, and finally a pneumatic-tired roller is used for rolling compaction of the pavement for 2-4 times. The pavement multi-hammer rubblization construction method can realize full collection of parameters of the pavement, performs adjustment and monitoring in time, performs timely adjustment for different pavement conditions, performs various types of pavement rubblization construction, and has a stable crushing effect, good economic benefits and broad market promotion value.

Owner:广西驰胜农业科技有限公司

Construction technology of expressway capable of bearing operation of heavy trucks

InactiveCN104947563AImprove carrying capacityImprove high temperature stabilityIn situ pavingsFiberPolyester

The invention discloses a construction technology of an expressway capable of bearing operation of heavy trucks. The construction technology comprises the following steps: uniformly stirring granite blocks and rubber granules, paving a stable base course, pouring slurry into the granite blocks and the rubber granules, and after the stable base course is solidified, pouring a concrete composite soil cushion course; and mixing high-elastic rubber granules and polyester fibers into an asphalt mixture for paving the surface course, stirring the asphalt, the rubber granules, the polyester fibers, gravel and granite blocks into a mixture by using a binder at temperature of 70-140 DEG C, and sequentially paving a road carpet and a skid-resisting surface course so that the bonding strength with concrete and all the courses can be reinforced, the elasticity can be improved, and damage caused by temperature difference change can be prevented. With the construction technology, the high-temperature stability and the fatigue durability of the pavement can be greatly improved, so that the pavement has low-temperature cracking resistance and has no reflection crack, the tension, the water resistance and the skid resistance can be enhanced, and the running noise can be lowered.

Owner:YELLOW RIVER CONSERVANCY TECHN INST

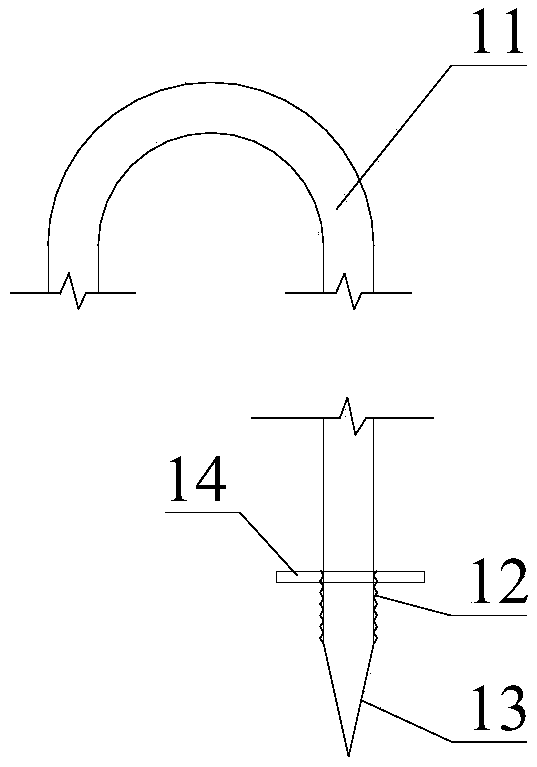

Stress segmentation-type pavement structural layer

InactiveCN110055848AHigh strengthImprove toughnessPaving reinforcementsIn situ pavingsSurface layerClimate change

The invention discloses a stress segmentation-type pavement structural layer. Joint-type stress bars are laid longitudinally in a structural layer of asphalt concrete pavement, the joint-type stress bars laid on an upper layer can prevent cracks generated by traffic loads and climate change, laid on a lower layer can prevent reflection cracks of a base layer, and laid on the base layer can preventcracks appearing on the base layer in the hardening process. According to the stress segmentation-type pavement structural layer, the problem of the horizontal cracks of a road is solved, the servicelife of the road is prolonged, later supporting of the road is delayed, the thickness of a pavement surface layer is reduced, and a pavement structure of a strong-base thin surface can be realized.

Owner:CHANGAN UNIV

Anti-reflection-crack waterproof coiled material used in airport runway and construction method thereof

In an embodiment, the invention discloses an anti-reflection-crack waterproof coiled material used in airport runways. The anti-reflection-crack waterproof coiled material includes, in a successive arrangement from bottom to top: a first stress dissipation layer, being formed from special modified asphalt; a second stress dissipation layer, being formed from a special polyester nonwoven cloth; a third stress dissipation layer, being formed from special modified asphalt; and a rock sheet layer, being formed by rock sheets in 8-10 meshes. A construction method of the anti-reflection-crack waterproof coiled material used in the airport runways is also provided, wherein the construction method comprises: (1) coating a treatment agent on two sides of slab joints of a cement concrete pavement and all cracks to ensure binding fastness between the coiled material and the cement concrete pavement during construct of a thermal melting method; (2) releasing the coiled material and adjusting the position of the coiled material, and then rolling-up the coiled material and performing full-sticking through the thermal melting method; and (3) paving and sticking the coiled material on upper surfaces of the slab joints or the cracks, wherein the slab joints or the cracks are required to be at the center of the coiled material after the coiled material paved, the overlap width of the coiled material is required to be not less than 150mm with the rock sheets at the overlapped portion required to be removed. The anti-reflection-crack waterproof coiled material allows the stress generated during shrinkage of the cement concrete pavement to be uniformly dispersed.

Owner:SHENYANG LAN GUANG XING CHEN WATERPROOF MATERIAL TECH

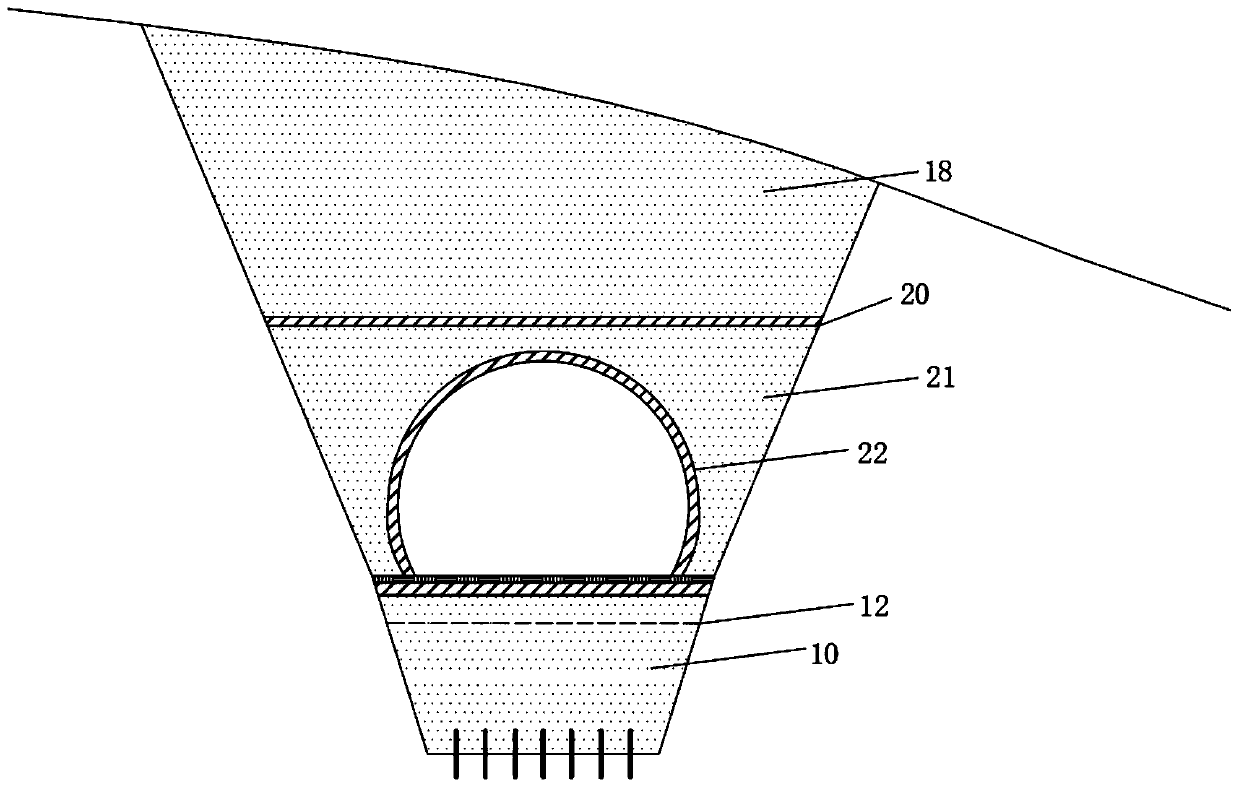

High-steep terrain bridge-tunnel connecting digging-after-filling foam concrete transition structure and construction method

PendingCN111441789ALittle self-relianceGood self-relianceRoadwaysUnderground chambersFoam concreteGlass fiber

The invention relates to a high-steep terrain bridge-tunnel connecting digging-after-filling foam concrete transition structure. The high-steep terrain bridge-tunnel connecting digging-after-filling foam concrete transition structure comprises a bridge abutment, a bridge pile, a foam concrete embankment, recycling anchor rods, a tunnel bottom plate, a tunnel lining, glass fiber reinforced plasticanchor rods, reinforced concrete chipping table, a foam concrete filling body, a reinforced concrete portal, a bituminous pavement and a reinforced concrete plate. The foam concrete embankment is mounted on a transition segment between the bridge abutment and a tunnel portal, steps are mounted on a foundation on the bottom of the foam concrete embankment, slopes are mounted on two sides of the steps and the foam concrete embankment, the recycling anchor rods are mounted in slope surface foundations of the step slopes, anti-sliding anchor nails are mounted on the bottoms of the steps, and the structure has the beneficial effects that the foam concrete embankment is mounted on the transition segment between the bridge abutment and the tunnel portal, the foam concrete embankment is small in mass, small in foundation settlement and meanwhile, good in strength and whole rigidity, the elasticity modulus of foam concrete is close to a tunnel and a bridge, and transition from the tunnel to thebridge is uniform through the foam concrete embankment

Owner:ZHEJIANG UNIV CITY COLLEGE

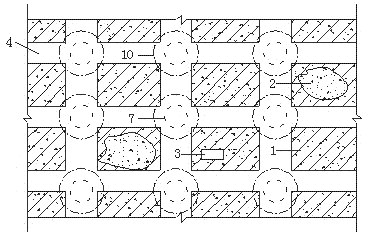

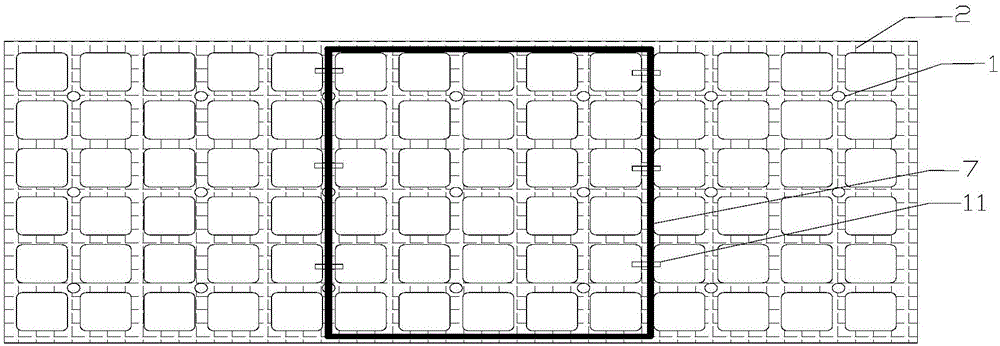

Method for splicing durable road structure by brickworks formed by organic mixture truss

ActiveCN103255695ARealize self-lockingRelieve stress concentrationIn situ pavingsTime segmentRoad construction

The invention relates to a method for splicing a durable road structure by brickworks formed by organic mixture trusses. The method is characterized by comprising the specific steps of: firstly, manufacturing truss structures; combining manufactured truss space bodies in a bidirectional break joint manner; putting the combined manufactured truss space bodies on a seat plate; respectively pouring an inorganic mixture into the manufactured truss space bodies to form an integral road base layer structure; and paving a conventional abrasion layer on the road base layer structure. The method disclosed by the invention adopts the truss formed by an organic mixture and the inorganic mixture is filled into the truss to form the brickworks; the brickworks are spliced into a durable road structure so that the aims of shortening a construction period and prolonging the usable time period of construction can be realized and the road construction working period can be effectively shortened; and the structure of a truss bridge sheet sufficiently utilizes the characteristic of the stability of a triangle so that the service life of a road can be prolonged in the use process.

Owner:CHANGCHUN MUNICIPAL ENG & RES INST CO LTD

Dual emulsion for asphalt rejuvenation

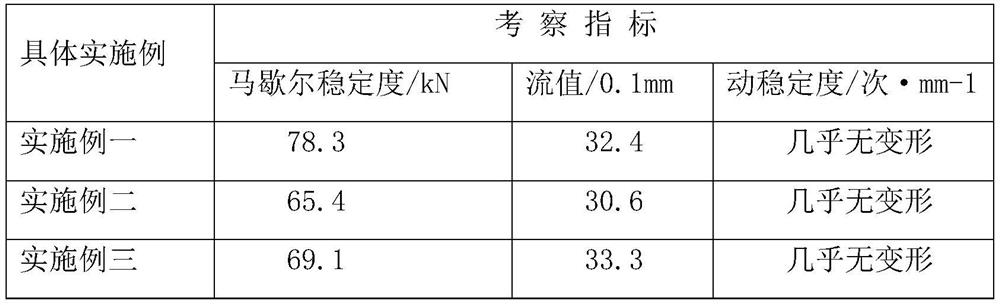

PendingUS20190300714A1Reduce quality problemsHigh Marshall StabilityIn situ pavingsBuilding insulationsBiomedical engineeringSetting time

Formulations and methods of making and using two emulsions, one emulsion having a rejuvenating agent and another emulsion having an asphalt phase. The two emulsions may be serially applied or blended together to form a dual emulsion for various deteriorated pavement surface treatments. The two emulsions may be used with a recycled asphalt product, either being mixed with the recycled asphalt product or serially applied to the recycled asphalt product. The two emulsions when blended together may form a dispersion having different phases with different setting times. The surfactant in the rejuvenating emulsion may be faster setting for a preferred initial break and better interaction with the pavement product, while the surfactant in the asphalt emulsion may break more slowly and provide more time to combine with the rejuvenated binder and fully coat the deteriorated asphalt product, and any virgin aggregate added to the mix.

Owner:ERGON INC

Environment-friendly asphalt structure and construction method thereof

ActiveCN111851193AGood flexibilityAvoid thermal expansion and contractionIn situ pavingsBituminous material adhesivesJoint compoundExhaust gas emissions

The invention discloses a thin-layer asphalt overlay construction and joint treatment method for an airport parking apron cement pavement. The asphalt overlay structure comprises a cement concrete pavement, a thermosetting modified asphalt macadam sealing layer and an asphalt concrete overlay layer from bottom to top. The method comprises the following steps: (1), treating cement concrete pavementdiseases; (2), milling and planing the cement concrete pavement; (3), performing construction of a thermosetting modified asphalt macadam sealing layer; (4), constructing a cover surface layer; and (5), performing cover surface layer joint cutting and joint pouring construction. Binding materials adopted in the step (1), the step (3) and the step (4) are normal-temperature thermosetting modifiedasphalt of different formulas, and joint sealing materials adopted for joint sealing are silicone sealants. The binding materials are used at normal temperature, so that the energy consumption and waste gas emission during production, paving and compaction of the hot-mixed asphalt mixture are greatly reduced, and the environmental pollution is reduced.

Owner:南京励米青新材料科技有限公司

Flexible asphalt concrete pavement construction method

InactiveCN104088211AReduce usageImprove crack resistanceIn situ pavingsSurface layerCrack resistance

The invention relates to a flexible asphalt concrete pavement construction method. The method comprises the following steps: treating a lower supporting layer, arranging an elevation measuring wire, blending an asphalt mixed material and paving the asphalt mixed material, wherein the paving step comprises paving of a bottom layer, paving of a middle layer, paving of an upper layer and compaction of the asphalt mixed material; light, intermediate and heavy-type road rollers are used for construction according to a sequence of being light, intermediate and heavy; and the compactness is controlled to be larger than 95%. The method disclosed by the invention has the advantages of greatly reducing the use of a stone material in steps, also greatly saving the use of an asphalt raw material, remarkably improving the crack resistance of asphalt concrete, effectively preventing generation of reflection cracks on an asphalt surface layer and prolonging the service life of a pavement.

Owner:POWERCHINA MUNICIPAL CONSTR GRP CO LTD

A recycled asphalt pavement

InactiveCN106320127BSolving Recycling ProblemsImprove road performanceIn situ pavingsBuilding insulationsSurface layerRoad surface

The invention relates to a recycling asphalt pavement which comprises a cushion layer, a base layer, a sealing layer and a surface layer. The base layer is arranged on the cushion layer. The sealing layer is arranged on the base layer. The surface layer is arranged on the sealing layer. The surface layer is prepared from, by mass, 70-90% of recycling asphalt pavement material, 1-3% of modified asphalt material, 1-3% of first additive and the balance modified aggregated rock, wherein the sum of the mass percentages of all the components is 100%. By means of the recycling asphalt pavement structure and the surface layer material composition technology, the technical problems of recycling and pavement performance of the recycling pavement material are effectively solved, the blending ratio of the recycling pavement material is 60% or above, and the cyclic utilization rate within a certain area reaches 100%.

Owner:陕西长大博源公路养护科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com