Environment-friendly asphalt structure and construction method thereof

An asphalt and environmentally friendly technology, applied in the field of infrastructure construction, can solve problems such as high energy consumption, environmental pollution, and exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

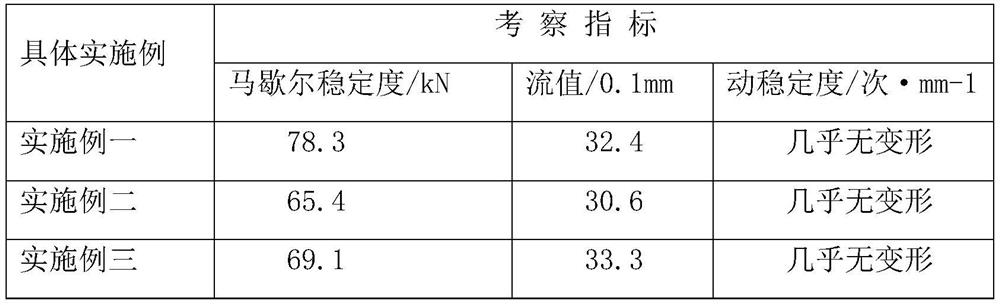

Embodiment 1

[0028] (1) Cement concrete pavement disease treatment

[0029] Firstly, investigate the disease type and damage degree of the cement concrete pavement slab, remove the pavement with a large damaged area and serious degree, cut and break it, and clean up the waste. Secondly, brush the binder on the excavated pavement interface. Thirdly, normal-temperature thermosetting modified asphalt concrete is used for backfill paving, and plate compactors are used for vibratory rolling. Finally, the normal temperature thermosetting modified asphalt mixture was maintained by using the heating wall of the heat regeneration maintenance vehicle, and the maintenance time was 25 minutes.

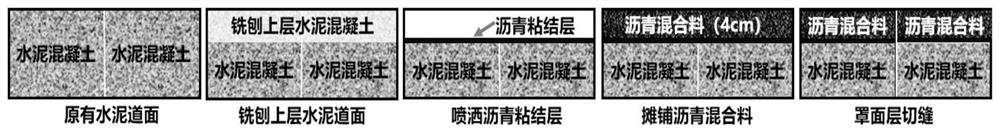

[0030] (2) Milling and cleaning of cement concrete pavement

[0031] First, use a milling machine to mill the cement concrete pavement with a milling depth of 50mm; secondly, use a sweeper and blower to remove milling residue and moisture to ensure that the milled cement pavement is in a clean and dry state....

Embodiment 2

[0040] (1) Cement concrete pavement disease treatment

[0041] Firstly, investigate the disease type and damage degree of the cement concrete pavement slab, remove the pavement with a large damaged area and serious degree, cut and break it, and clean up the waste. Secondly, brush the binder on the excavated pavement interface. Thirdly, normal-temperature thermosetting modified asphalt concrete is used for backfill paving, and plate compactors are used for vibratory rolling. Finally, the normal temperature thermosetting modified asphalt mixture was maintained by using the heating wall of the heat regeneration maintenance vehicle, and the maintenance time was 45 minutes.

[0042] (2) Milling and cleaning of cement concrete pavement

[0043] First, use a milling machine to mill the cement concrete pavement with a milling depth of 40mm; secondly, use a sweeper and blower to remove milling residue and moisture to ensure that the milled cement pavement is in a clean and dry state....

Embodiment 3

[0051] (1) Cement concrete pavement disease treatment

[0052] Firstly, investigate the disease type and damage degree of the cement concrete pavement slab, remove the pavement with a large damaged area and serious degree, cut and break it, and clean up the waste. Secondly, brush the binder on the excavated pavement interface. Thirdly, normal-temperature thermosetting modified asphalt concrete is used for backfill paving, and plate compactors are used for vibratory rolling. Finally, the normal temperature thermosetting modified asphalt mixture was maintained by using the microwave heating wall of the heat regeneration maintenance vehicle, and the maintenance time was 55 minutes.

[0053] (2) Milling and cleaning of cement concrete pavement

[0054] First, use a milling machine to mill the cement concrete pavement with a milling depth of 30mm; secondly, use a sweeper and blower to remove milling residue and moisture to ensure that the milled cement pavement is in a clean and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com