Patents

Literature

233results about How to "Improve structural uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

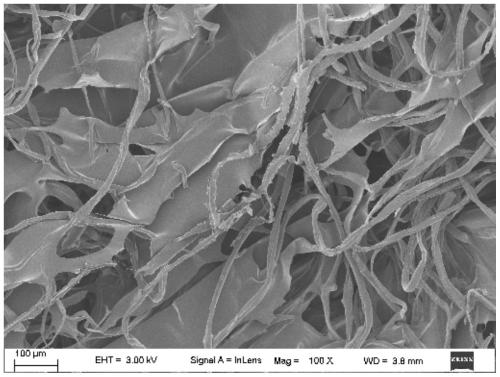

Silicon-dioxide aerogel heat insulation composite material and preparation method thereof

InactiveCN103011745AImprove mechanical propertiesChange the chemical state of the surfaceFiberSupercritical drying

The invention provides a fiber-reinforced silicon-dioxide aerogel heat insulation composite material and a preparation method thereof. According to the preparation method, mineral fibers with high mechanical strength, low heat conductivity and good heat stability serve as a reinforcing phase, silicon alcoholate serves as a precursor, fiber-composite silicon-dioxide wet gel is prepared by adopting an acid-base two-step catalysis method, and the block-shaped fiber-reinforced silicon-dioxide aerogel heat insulation composite material is then obtained through aging, modification, solvent displacement and supercritical drying. The prepared aerogel heat insulation composite material has the advantages of excellent mechanical property, good heat-insulating property and higher heat resistance. The aerogel composite material has a three-dimensional porous network-like structure, the compatibility between fibers and an aerogel matrix is good, the interfacial bonding is firm, and no obvious interfaces exist; and according to the block-shaped aerogel composite material, the density is 0.15-0.25 g / cm<3>, the compressive strength is 10%, the strain energy reaches 0.4-2.0MPa, and the coefficient of heat conductivity is 0.016-0.027 W / mK.

Owner:TIANJIN UNIV

Gelatin sponge and preparation method thereof

InactiveCN101574539AImprove performancePromote absorptionSurgeryAbsorbent padsGelatin spongeIrradiation

The invention provides gelatin sponge, gelatin aqueous solution is irradiated to crosslink to form gelatin hydrogel, and then the gelatin hydrogel is swollen, frozen and dried to obtain the gelatin sponge. The invention also provides a preparation method of the gelatin sponge by an irradiation crosslinking way, the whole process flow is finished in a pure water system, the irradiation and crosslinking processes have sterilizing function and good controllability, the obtained product has better structural uniformity compared with a chemical crosslinking method, and the gelatin sponge has unique advantages as biomedical materials.

Owner:厦门凝赋生物科技有限公司

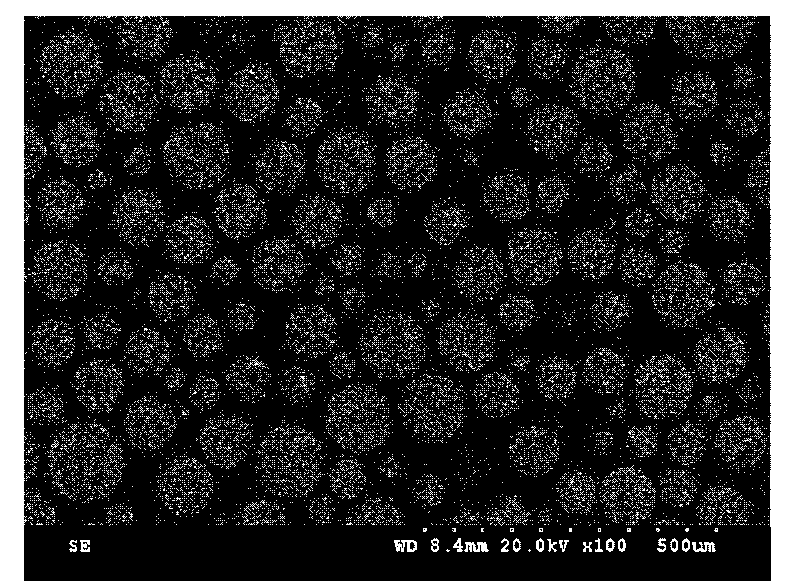

Method for preparing large scale ceramic ball

InactiveCN101125755AHigh strength and structural uniformityAchieve densified sinteringHot isostatic pressingSilicon nitride

The invention relates to a preparation method of a large size ceramic ball, comprising the steps of material mixing, moulding and sintering. The method takes silicon nitride powder and additive as raw materials, of which the weight ratio is 100:15-5; certain amount of raw materials are weighted, evenly mixed by a ball milling method, dry pressed and then treated by cold isostatic pressure to get rough-body; the rough-body is hot isostatic pressure sintered under the protection of nitrogen and argon by adopting glass canning process; after a period of insulation and sintering, the temperature is reduced and the finished products are obtained. Compared with the prior art, the silicon nitride ceramic ball prepared by the invention has no stomata and gape on the surface, has even micro structure, 1500kg / mm2 of microhardness, above 5.4MPa.m1 / 2 of indentation and fracture toughness, and the invention can be widely applied to fields such as bearing ball, etc.

Owner:SHANGHAI RES INST OF MATERIAL

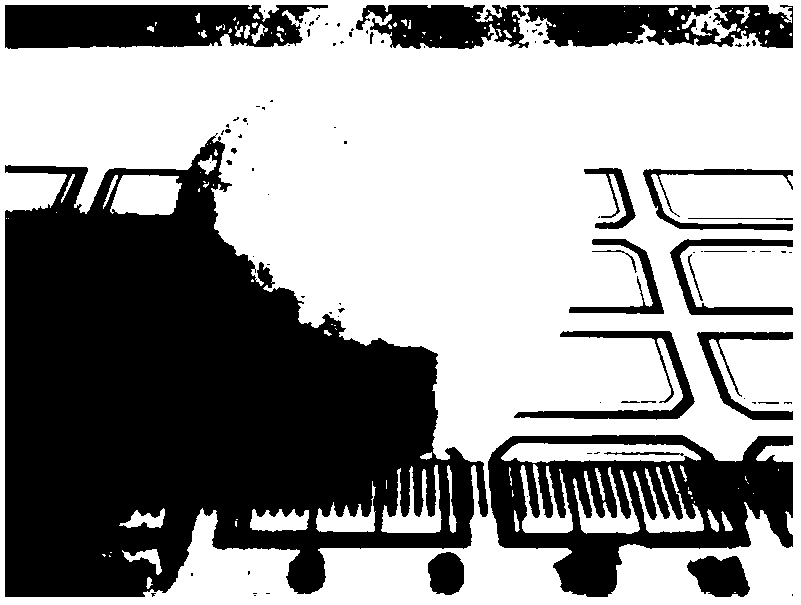

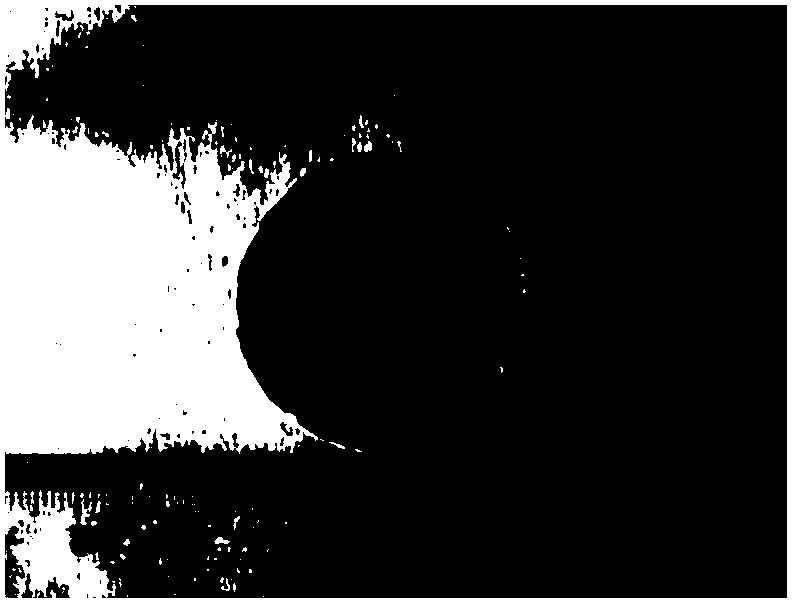

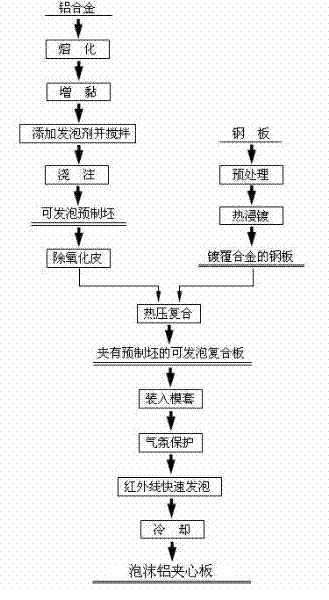

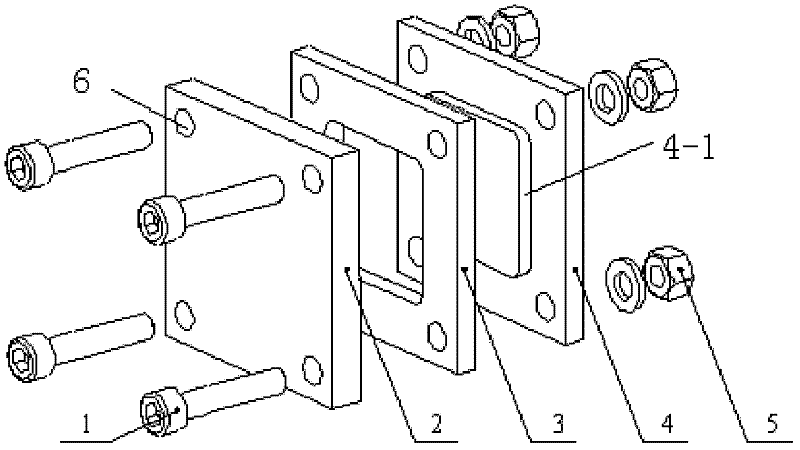

Preparation method of foamed aluminum sandwich plate

ActiveCN102390135AImprove mechanical propertiesAccurate thicknessLaminationLamination apparatusFoaming agentComposite plate

The invention relates to a preparation method of a layered composite material, in particular to a preparation method of a foamed aluminum sandwich plate. The method comprises the following steps of: firstly, uniformly mixing an aluminum alloy, a tackifier and a foaming agent to obtain a platy or blocky foamable precast blank material; then, performing hot-pressing compounding of the precast blankand a steel plate after the surface plating to obtain a foamable composite plate sandwiching the precast blank; placing the foamable composite plate sandwiching the precast blank in a mould sleeve closed around, and delivering into an infrared foaming furnace heating at the upper and lower parts at the same time so as to heat and foam the composite plate sandwiching the precast blank under infrared radiation; and finally, pulling the mould sleeve out of the foaming furnace, and cooling to obtain a foamed aluminum sandwich plate with a fixed thickness. The foamed aluminum sandwich plate prepared by the method provided by the invention has an accurate thickness, a uniform structure and a high yield; and moreover, the preparation processes in the invention can be automatically controlled, thereby being favorable for realizing semi-continuous preparation of the foamed aluminum sandwich plate.

Owner:NORTHEASTERN UNIV

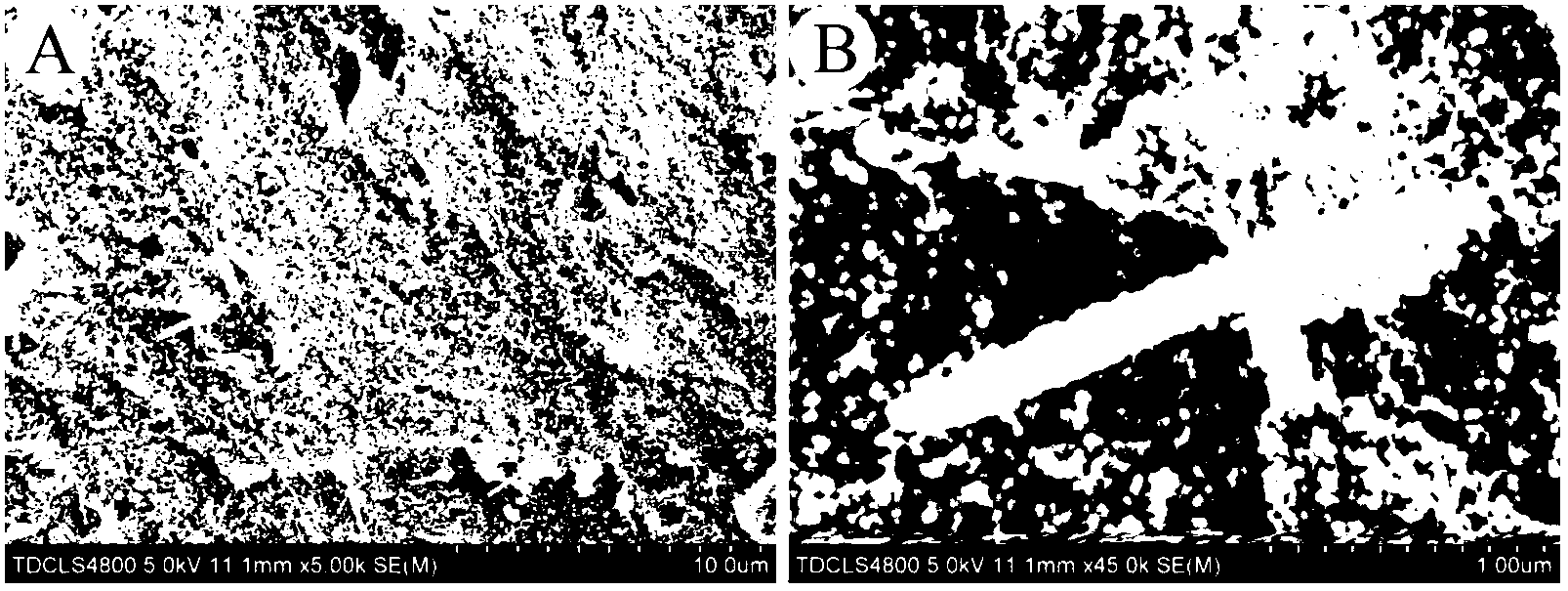

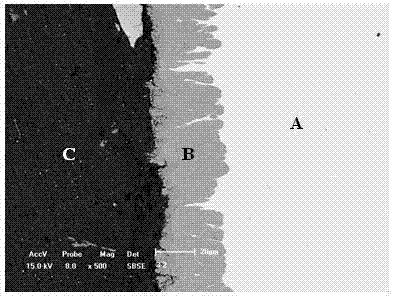

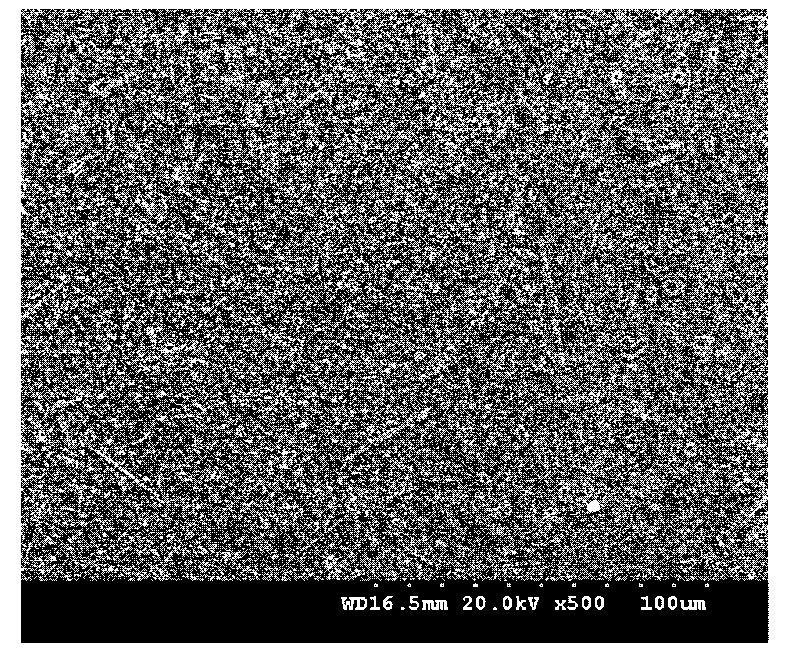

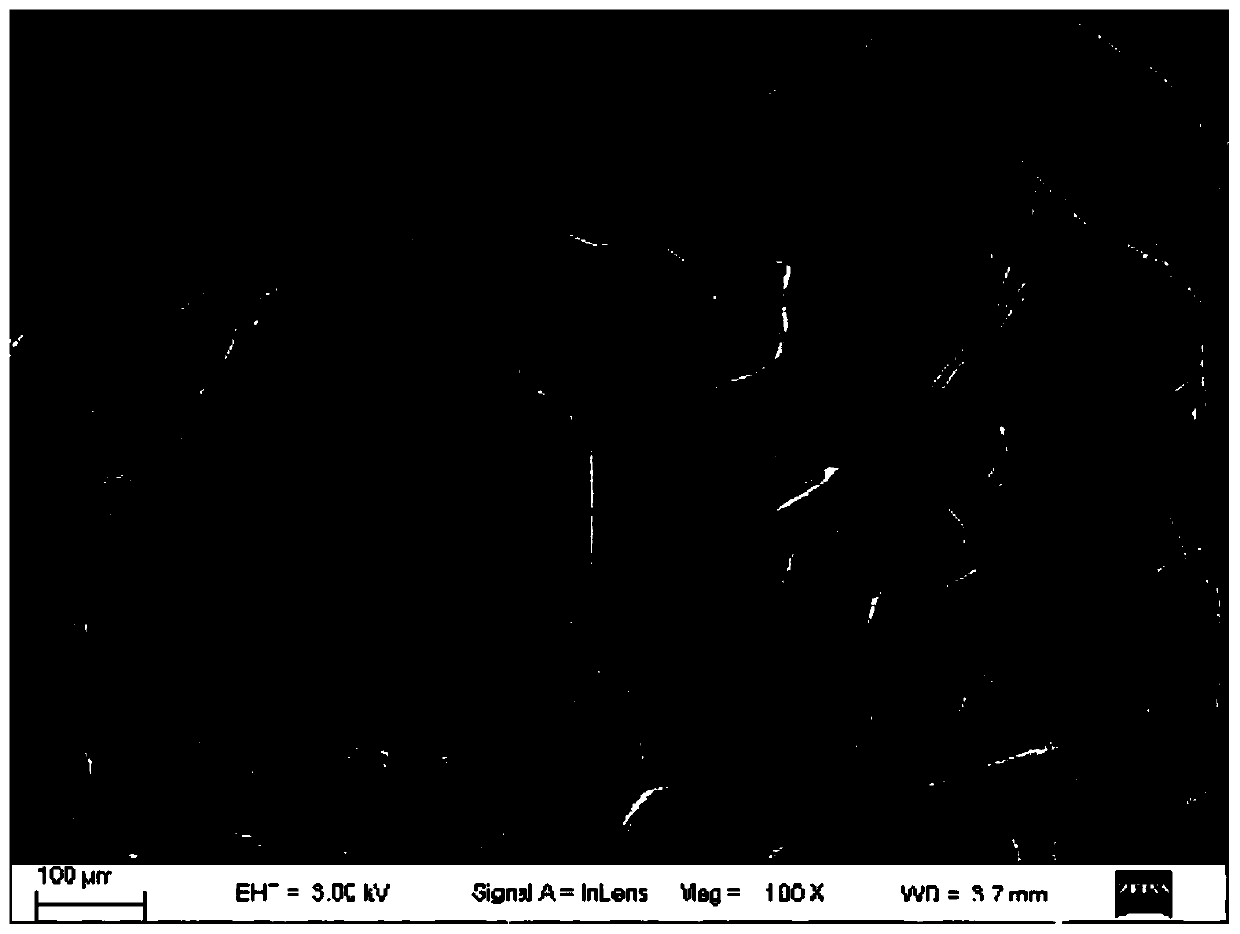

A kind of stainless steel fiber felt used for fuel cell bipolar plate and its manufacturing method

InactiveCN102290582AImprove structural uniformityGood heat and mass transfer performanceCell electrodesMetal fiberFuel cells

The invention discloses a stainless steel fiber felt used for fuel cell bipolar plates and a manufacturing method thereof, belonging to the technical field of fuel cell bipolar plate flow fields. The manufacturing method of stainless steel fiber mat can be divided into four steps: processing stainless steel fiber by cutting method, pretreatment of stainless steel fiber, molding of fiber mat, and high-temperature solid-state sintering. After the metal fibers are sintered, metallurgical bonding is achieved between the fibers, forming a large number of multi-scale pore structures. The manufactured stainless steel fiber felt has the advantages of high porosity, high specific surface area, good heat and mass transfer performance, surface hydrophobicity, simple manufacturing process and low cost. This method is applicable to manufacture various metal porous materials, and its pore size and porosity can be controlled.

Owner:SOUTH CHINA UNIV OF TECH

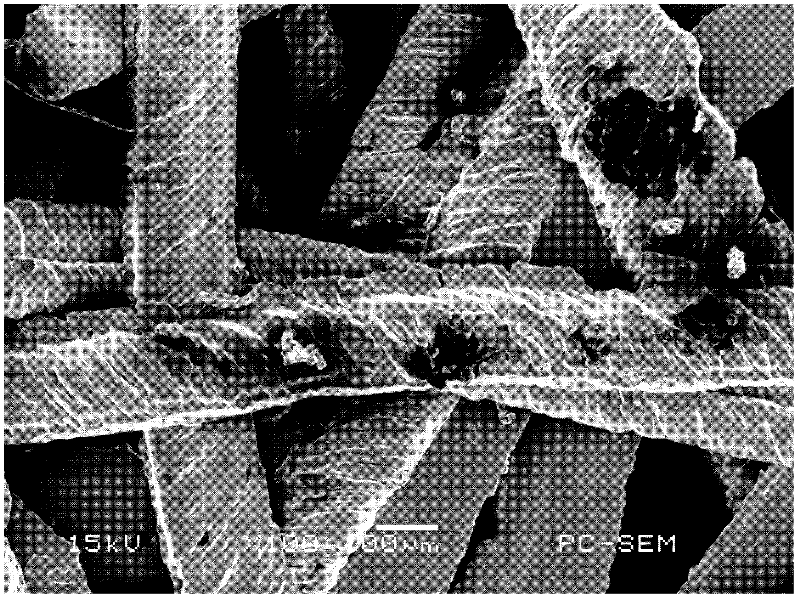

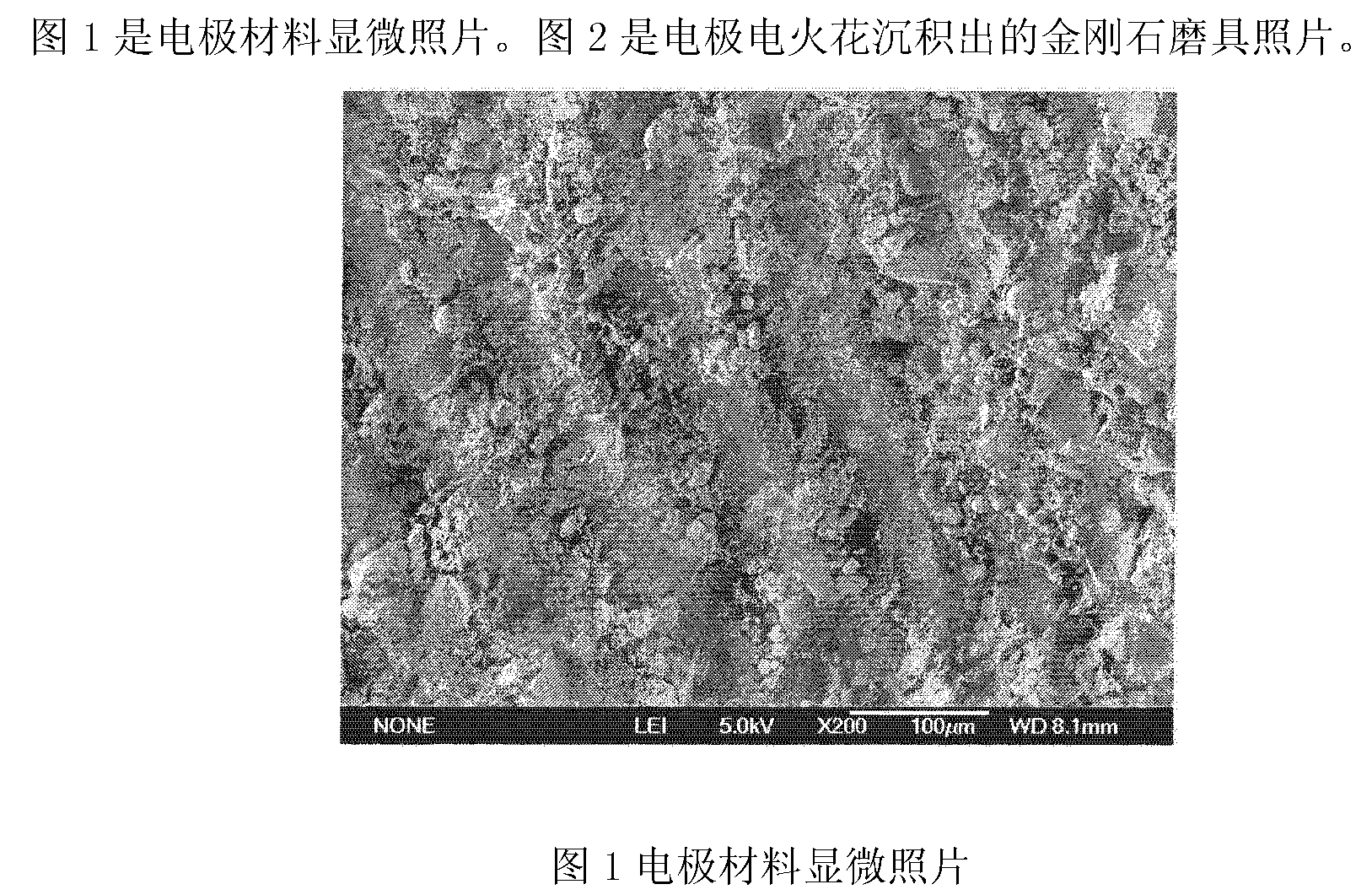

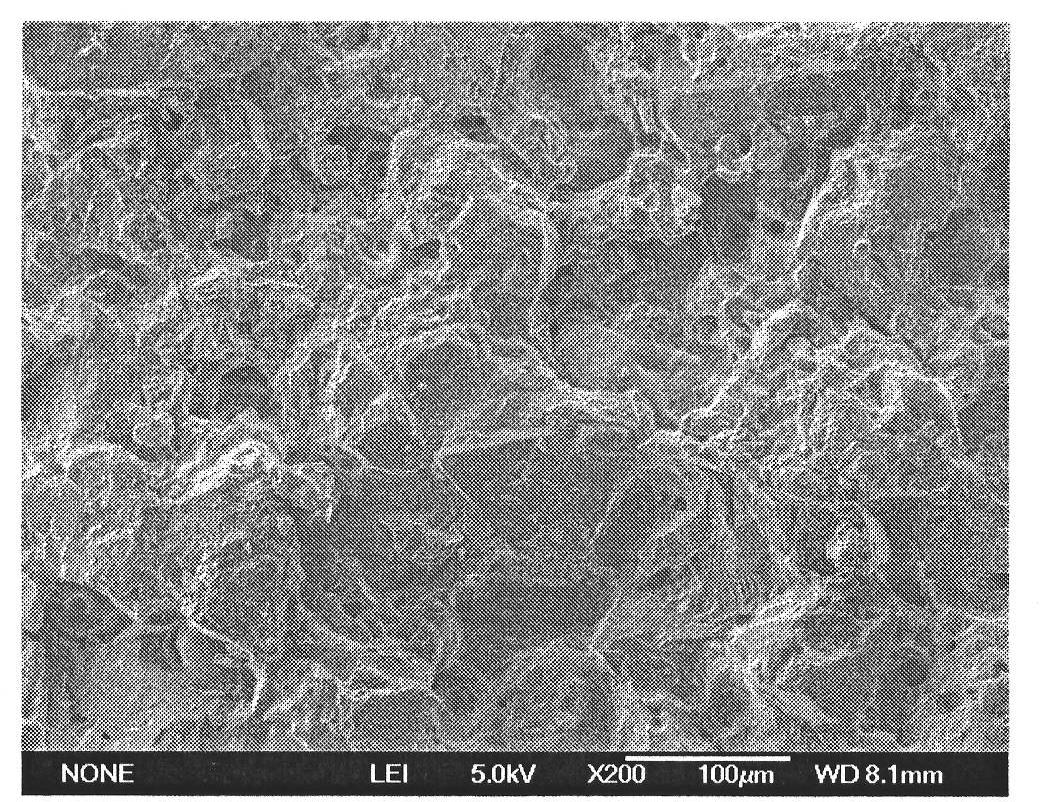

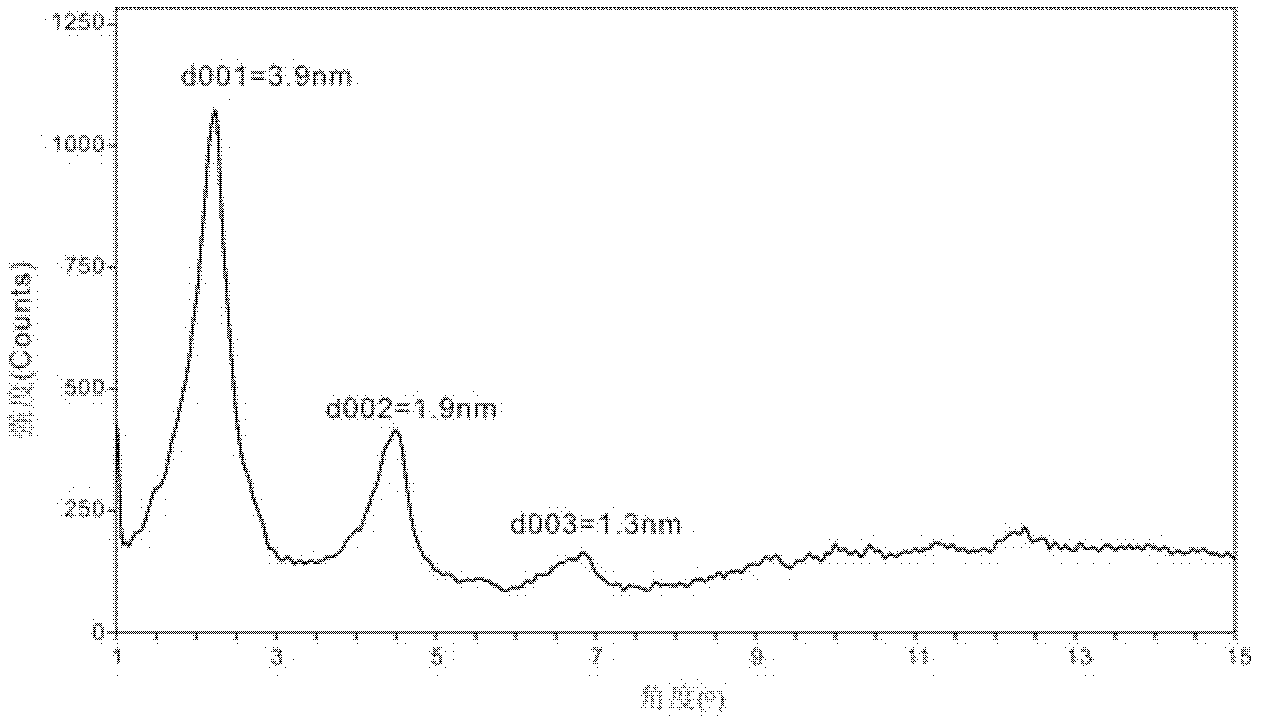

Electrode preparation process for depositing diamond abrasive tool with electric sparks

The invention relates to an electrode preparation process for depositing a diamond abrasive tool with electric sparks, comprising the steps of: dipping a diamond abrasive material into anhydrous ethanol for ultrasonic cleaning; then dipping a diamond in industrial aluminum sol for 5 min; fishing out the abrasive material with a copper wire mesh; repeating the steps twice after the abrasive material is dried; placing surface-modified diamond into a box-type furnace; raising temperature to 700 DEG C at a temperature rise rate of 5 DEG C per min; keeping warm for 1 h, cooling together with the furnace to obtain the diamond abrasive material with an Al2O3 coating coated on the surface; uniformly mixing the diamond abrasive material, cobalt powder, copper powder, tungsten carbide powder and silver powder in the mass ratio of 25: 20: 40: 10: 5 under ball milling conditions; adding a mixed electrode raw material to a cylindrical graphite die, wherein the inner bore diameter of the die is 20mm; sintering the cylindrical graphite die on an SM80 sintering machine, wherein the pressure at two ends of the die is 15KN, the voltage is 10V; keeping warm for 5 min when the temperature reaches 800 DEG C, stopping heating the die; and cooling naturally to obtain an electrode material. The electrode material structure prepared by utilizing the process has favorable consistency and high diamond abrasive material content; and the diamond abrasive tool with uniform structure and high abrasive material concentration can be deposited by utilizing the electrode.

Owner:刘小磐

Full-dull polyamide 6 fibre and method for producing the same

ActiveCN101463506AAvoid yellowingImprove structural uniformityFilament/thread formingHeating/cooling textile fabricsYarnPolymer science

The invention relates to a chemical fiber and a manufacturing method thereof, in particular to a full-dull daiamid 6 fiber added with titanium dioxide and a manufacturing method thereof. The full-dull daiamid 6 fiber and the manufacturing method thereof which have less polymer degradation, even yarn levelness, less filoplume and uniform dyeing aim at solving the disadvantages of easy degradation of high polymer fusant, poor evenness of the yarn levelness, high fluctuation of oiling rate, easy occurrence of more filoplume, bad uniformity of dyeing, etc. The invention mainly has the technical proposal that daiamid 6 particle with more than or equal to 1.6% of TiO2 is taken as raw material, treated by melt spinning and cross air blasting through twice of rectification and oiling, and is wound; finally, the full-dull daiamid 6 fiber is obtained.

Owner:YIWU HUADING NYLON

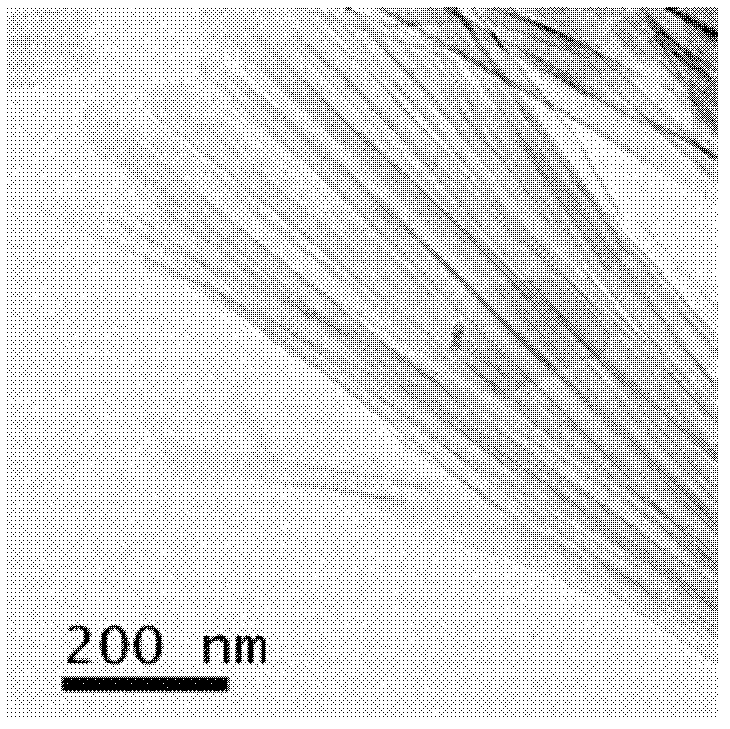

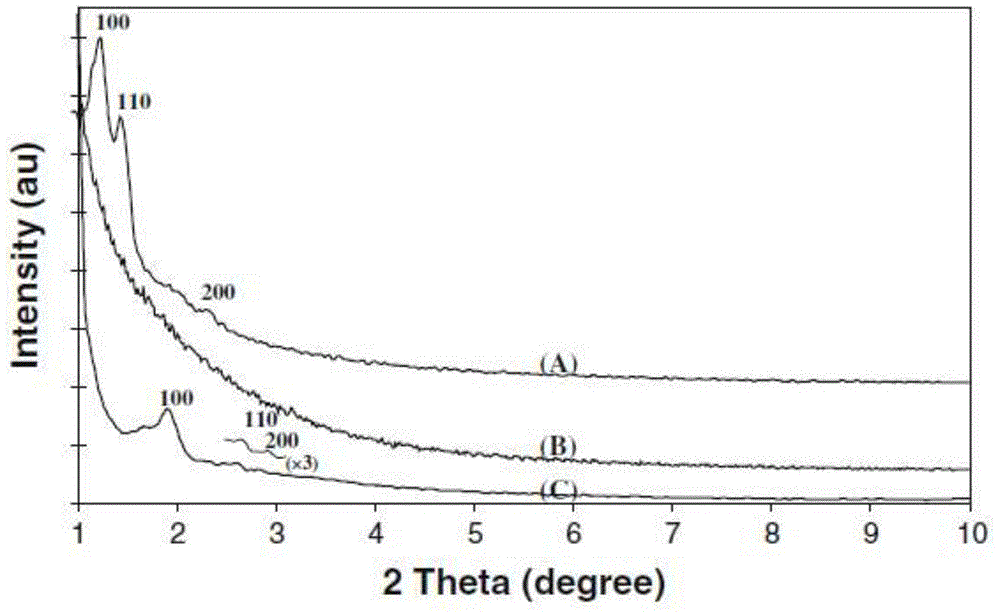

Method for preparing aluminosilicate nanotube by using kaolinite raw material

ActiveCN102583413ASimple stepsSimple processAluminium silicatesNanotechnologyKaoliniteSURFACTANT BLEND

The invention discloses a method for preparing an aluminosilicate nanotube by using a kaolinite raw material. The method comprises the following steps of: preparing a kaolinite-dimethyl sulfoxide compound; preparing a kaolinite-methanol compound; dissolving a cationic surfactant into methanol; adding into the kaolinite-methanol compound obtained in the step 2 for preparing the aluminosilicate nanotube, and the like. The method has the advantages and positive effects that: an aluminosilicate nanotube material with high purity and a uniform structure and shape is prepared, the material has low cost, simple flow, low pollution and low energy consumption, and is easy for popularizing and applying.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

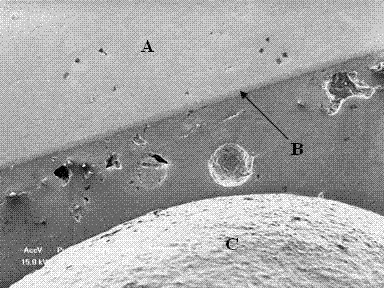

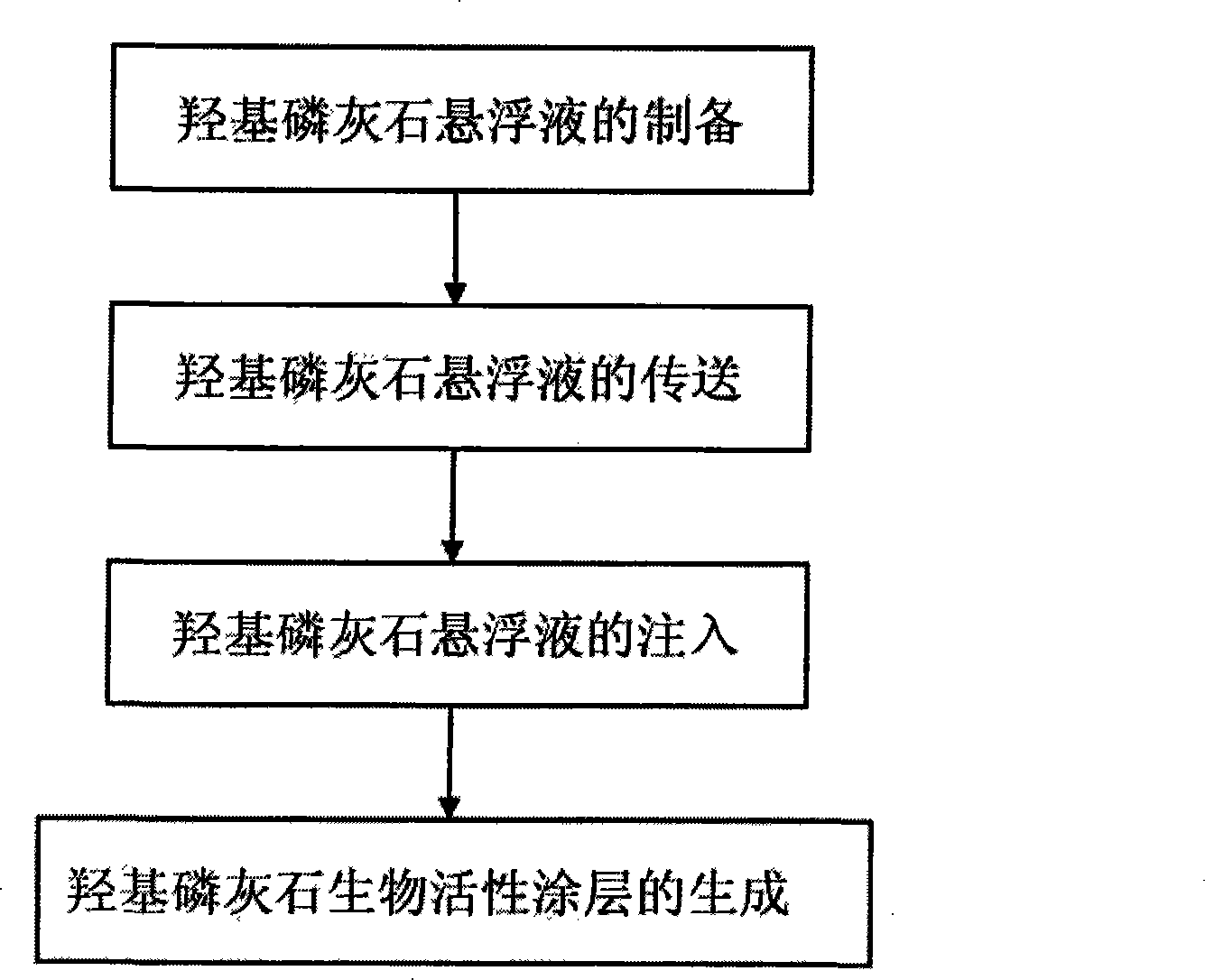

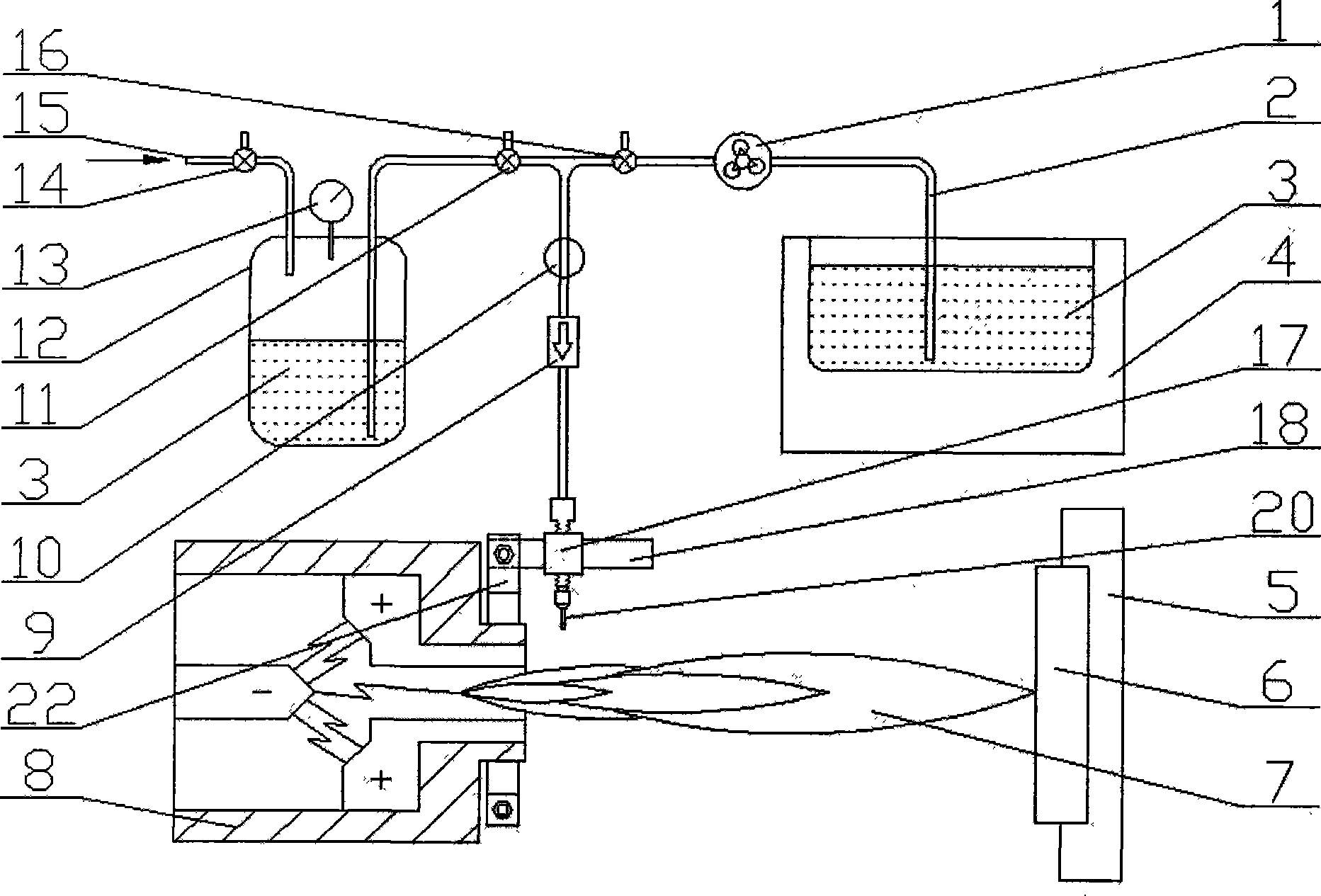

Method for suspending liquid plasma spraying preparation of hydroxyapatite bioactivity coatings

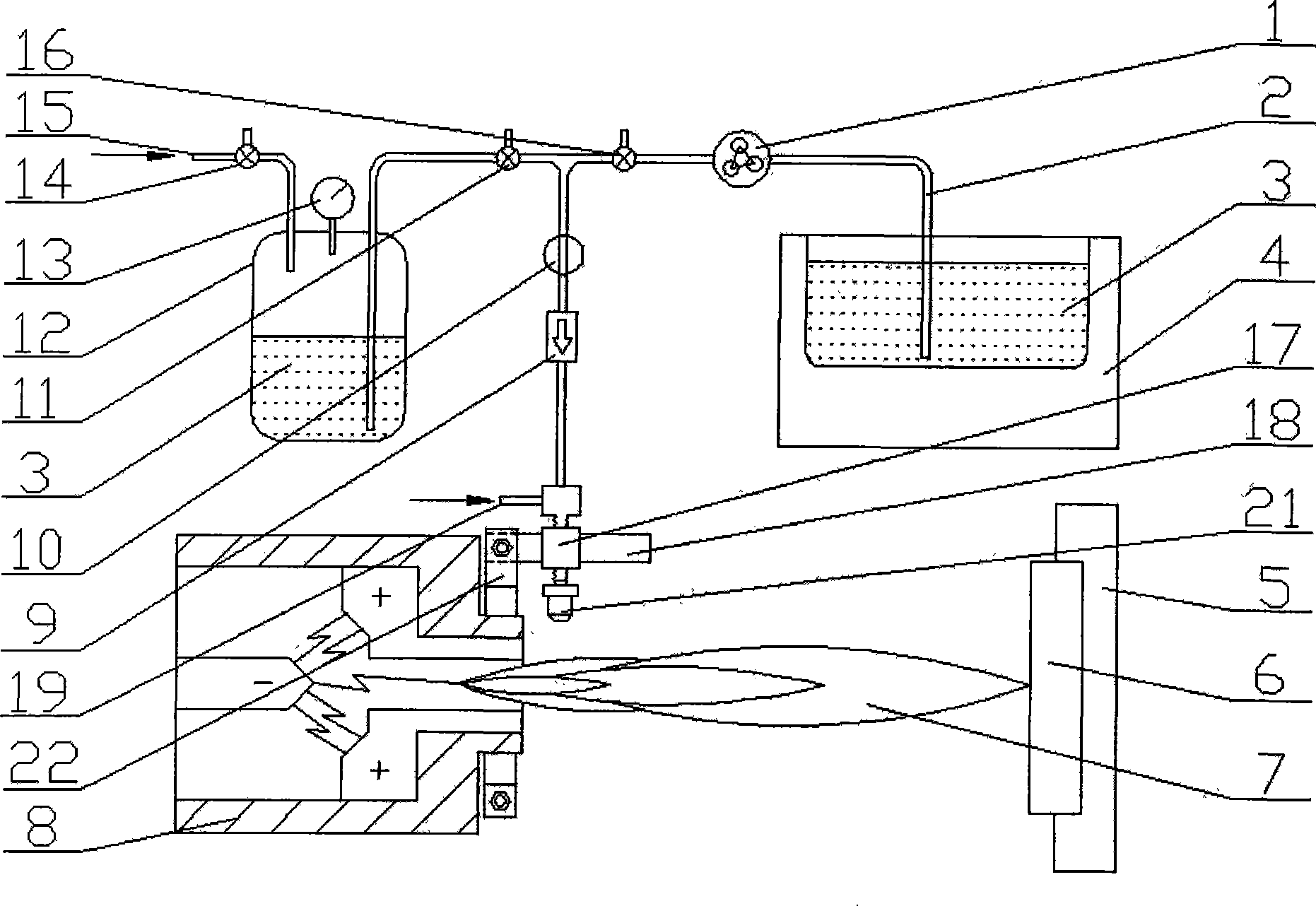

InactiveCN101250681AIncrease productivityReduce manufacturing costMolten spray coatingProsthesisPeristaltic pumpApatite

The invention relates to a method for spraying suspending liquid plasma to prepare hydroxyapatite bioactive coating, which comprises following steps: adopting hydroxyapatite suspending liquid as plasma spraying raw materials, adopting a pressure tank or an electronic peristaltic pump as a power transmitting device to transmit the hydroxyapatite suspending liquid, adopting an atomizing nozzle with a small angle to inject the hydroxyapatite suspending liquid into a central region of plasma flame directly and radially or adopting a duct with small diameter to inject the hydroxyapatite suspending liquid into the central region of the plasma flame directly and radially in a linear type jet-flow mode, exchanging heat between the suspending liquid and high temperature plasma flame through transmitting and injecting the suspending liquid, and directly generating the hydroxyapatite bioactive coating on the surface of a biological medical metal base through vaporizing liquid in the suspending liquid, crushing particles, smelting and depositing. The method simplifies a tedious technological link for preparing the spraying raw materials in a method for spraying powder plasma, the spraying raw materials and energy are saved, and the structural homogeneity of the hydroxyapatite bioactive coating which is prepared is good.

Owner:SICHUAN UNIV

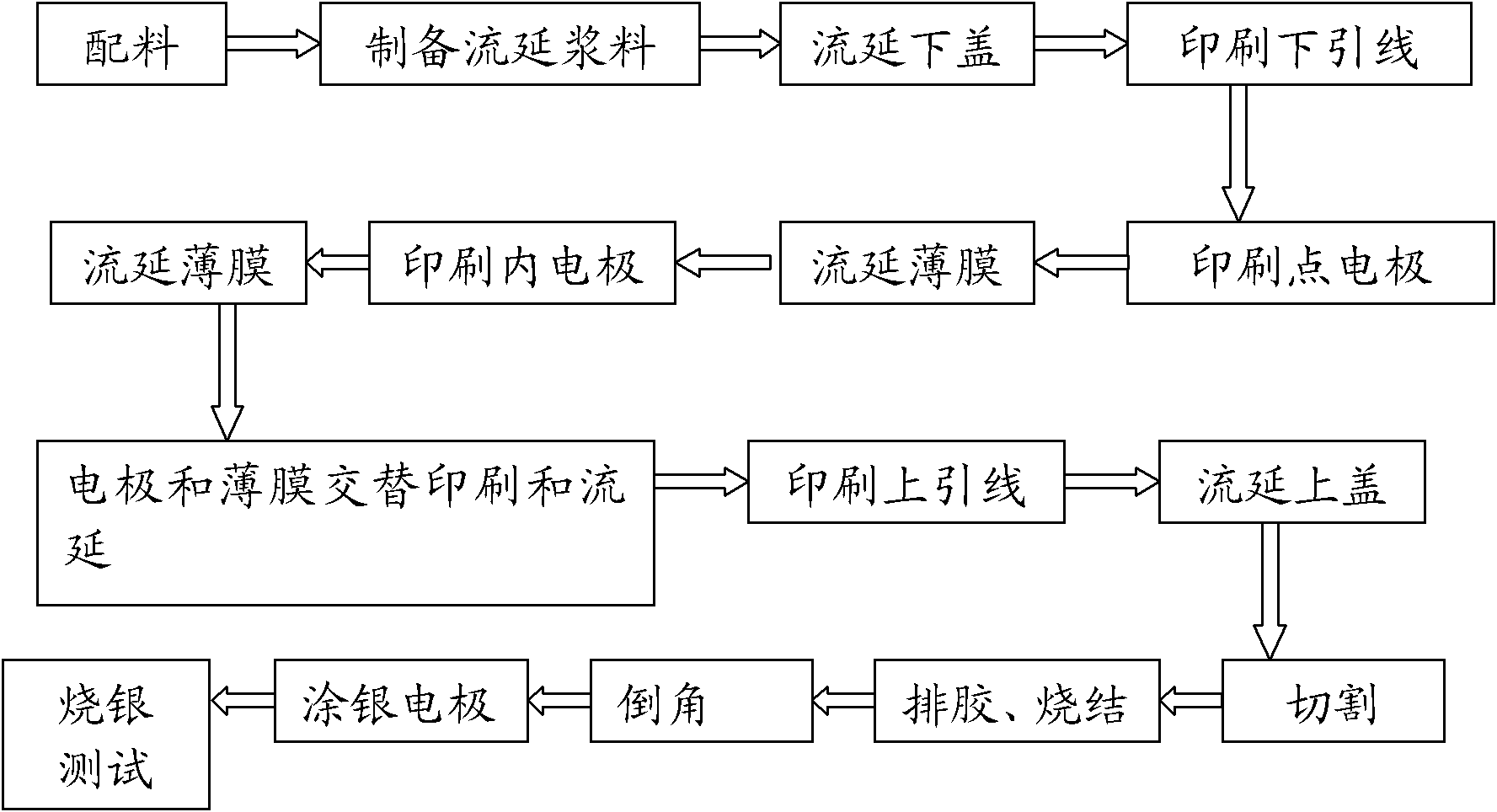

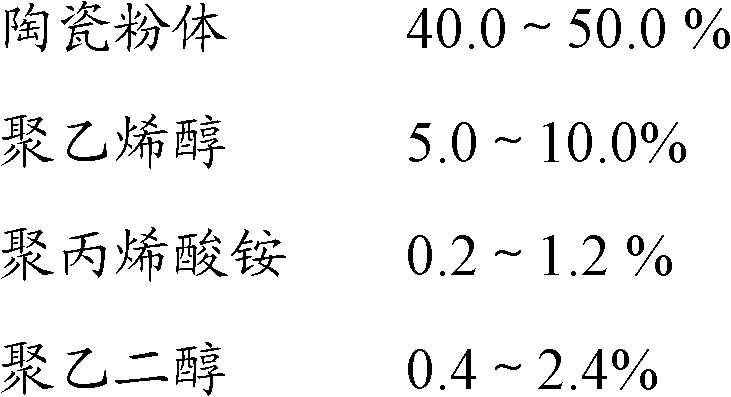

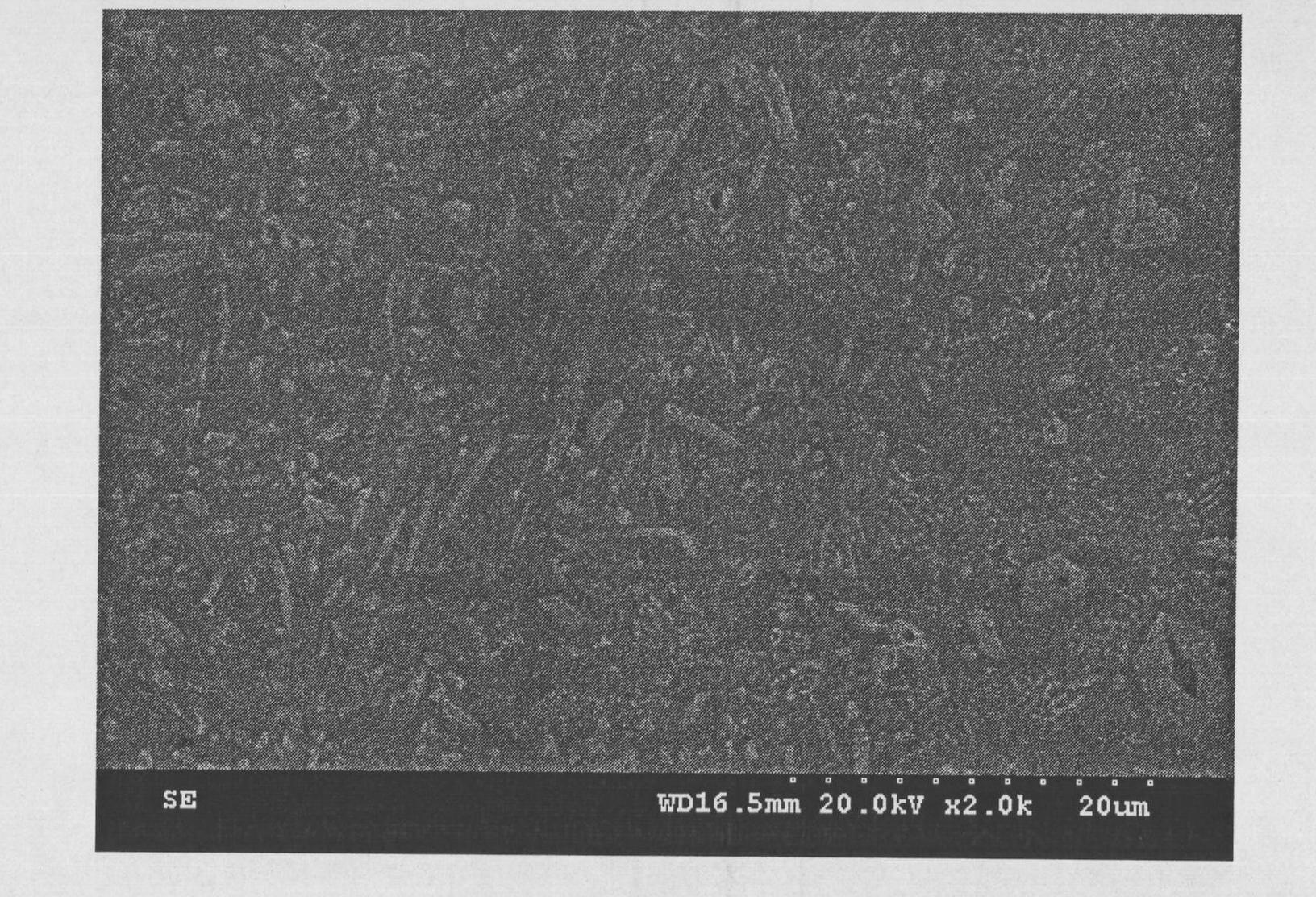

Water-base tape casting slurry and water-base tape casting wet method for preparing multilayer chip component

The invention provides water-base tape casting slurry and a water-base tape casting wet method for preparing a multilayer chip component. The water-base tape casting slurry comprises, by weight, from 40.0 to 50.0% of ceramic powder, from 5.0 to 10.0% of polyvinyl alcohol, from 0.2 to 1.2% of ammonium polyacrylate, from 0.4 to 2.4% of polyethylene glycol, from 0.1 to 0.5% of defoaming agent and from 30 to 48% of water. The water-base tape casting wet method includes preparing the water-base tape casting slurry; preparing a ceramic matrix; preparing a green chip of the multilayer chip component; and preparing the multilayer chip component. The water-base tape casting slurry is moderate in viscosity and short in drying time and is safe and nontoxic; the ceramic matrix prepared from the slurry is uniform in structure and smooth in surface; and the water-base tape casting wet method for preparing the multilayer chip component is simple in process and is safe, nontoxic, economical and environment-friendly, the prepared multilayer chip component is firm in structure, the thickness of the multilayer chip component can reach 20 micrometers, the inductance value of the multilayer chip component is high, yield of multilayer chip components reaches 90% at least, and production cost is lowered by 75% at least.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

Method for preparing Ti5Si3/TiAl composite material

The invention discloses a method for preparing a Ti5Si3 / TiAl composite material, relates to a method for preparing a composite material and aims to solve the problems of poor uniformity, relatively lower compactness and high cost of a TiAl composite material prepared by using the prior art. The method comprises the following steps of: stacking pure titanium particles into a steel mold to obtain a porous titanium prefabricated body; and linearly cutting an Al-Si alloy ingot into blocks, placing the blocks on the porous titanium prefabricated body for hot pressing and sintering under a vacuum condition, cooling the porous titanium prefabricated body to room temperature and demolding the porous titanium prefabricated body to obtain the Ti5Si3 / TiAl composite material. The method has the advantages of effectively improving material compactness (95 to 98 percent) and structural uniformity, improving high-temperature strength, creep property and oxidation resistance, meeting requirements on practicability, saving the process of ball milling and powder mixing in a powder metallurgical process, reducing the probability of the oxidation of Ti and Al and the blending of new impurities, and reducing the negative influence of the oxidation and the impurities on Ti Al-base alloy plates, and also has the advantages of simple process, easy operation, less equipment and low cost.

Owner:HARBIN INST OF TECH

Preparing method of Ti Al-based alloy plate

InactiveCN101758236AOvercome the defect of poor deformability during cold and hot processingLow melting pointTension/compression control deviceMetal rolling arrangementsRoom temperatureTitanium

The present invention discloses a preparing method of a Ti Al-based alloy plate, which relates to a preparing method of an alloy plate. The present invention solves the problems that the existing Ti Al-based alloy is not easy to process into to form at room temperature; Ti Al-based alloy plates prepared by powder metallurgy technique are easy to pollute by interstitial elements with many impurities containing oxygen; and Ti Al-based alloy plates prepared by casting metallurgy technique and precision casting art have the disadvantages of crude grain structure, low strength and loose structure. In the method, pure titanium grains are piled in a steel module to obtain a multi-hole titanium prefabricated body; an Al-Si alloy casting wire is cut into block bodies; the block bodies are arranged on the multi-hole titanium prefabricated body to be sintered to obtain a Ti - Al double alloy complex body; the Ti - Al double alloy complex body is coldrolled to obtain a Ti - Al double alloy complex plate; the Ti - Al double alloy complex plate is sintered again, and is cooled to room temperature; the Ti - Al double alloy complex plate is retreated from the steel module to obtain the Ti Al-based alloy plate. The Ti Al-based alloy is processed to be formed at the room temperature, so the Ti Al-based alloy plate has the advantages of compaction, even structure, thin grain structure and high strength, and the negative effect of oxidation and impurities is reduced.

Owner:HARBIN INST OF TECH

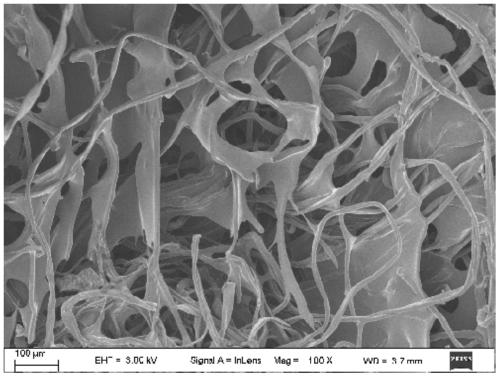

Three-dimensional fiber-based composite aerogel type adsorbent preparation method

InactiveCN110038529AImprove mechanical propertiesMaintain structureOther chemical processesWater contaminantsFreeze-dryingSorbent

The invention discloses a three-dimensional fiber-based composite aerogel type adsorbent preparation method. According to the method, cellulosic fiber, chitosan and sodium alginate which generally exist in natural world are utilized as raw materials. The method comprises the steps: firstly, utilizing periodate and metaphosphoric acid to sequentially chemically modify the cellulosic fiber; then crosslinking the modified cellulosic fiber with the chitosan; then compounding with the sodium alginate; freeze drying to obtain a three-dimensional fiber-based composite aerogel type adsorbent. The prepared adsorbent disclosed by the invention has high safe stability, has a good adsorption effect on negative ion pollutants and positive ion pollutants and can be applied to purifying heavy metal ion wastewater and dyestuff wastewater; in addition, the cellulosic fiber added into the adsorbent disclosed by the invention not only can serve as a framework and a reinforcing material, but also can be crosslinked with the chitosan to improve compression strength, morphology and structural stability of the whole aerogel adsorbent; thus, the adsorbent can be repeatedly used for many times, and the characteristics of rice inner holes and large specific surface area of the aerogel are fully played.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Gold nanorod vertical array and preparing method thereof

ActiveCN103506629ARegular array structureEasy to operatePolycrystalline material growthFrom normal temperature solutionsCarbon numberGold nanorod

The invention discloses a preparing method of a gold nanorod vertical array and the gold nanorod vertical array obtained through the preparing method. The preparing method comprises the steps that first, a water solution of a gold nanorod decorated by trimethyl cetyl ammonium bromide is prepared, centrifugal redissolving treatment is conducted, the concentration of the trimethyl cetyl ammonium bromide in the water solution is made to be 5-20 umol / L, and the concentration of the gold nanorod is 0.5-2nmol / L; second, the mixed liquid of monohydric alcohol with the carbon number being 1-3 and alkyl hydrosulfide with the carbon number being 9-12 is in contact with the water solution obtained in the first step; third, chloroform and / or dichloroethane are / is mixed with the mixed liquid obtained in the second step, the mixed liquid is stood, and the gold nanorod vertical array is obtained. According to the preparing method of the gold nanorod vertical array, the millimeter-graded super-large scale gold nanorod vertical array with the ordered array structure can be obtained, and the advantages that operating is easy, conditions are moderate, the structural uniform is high and the like are achieved.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

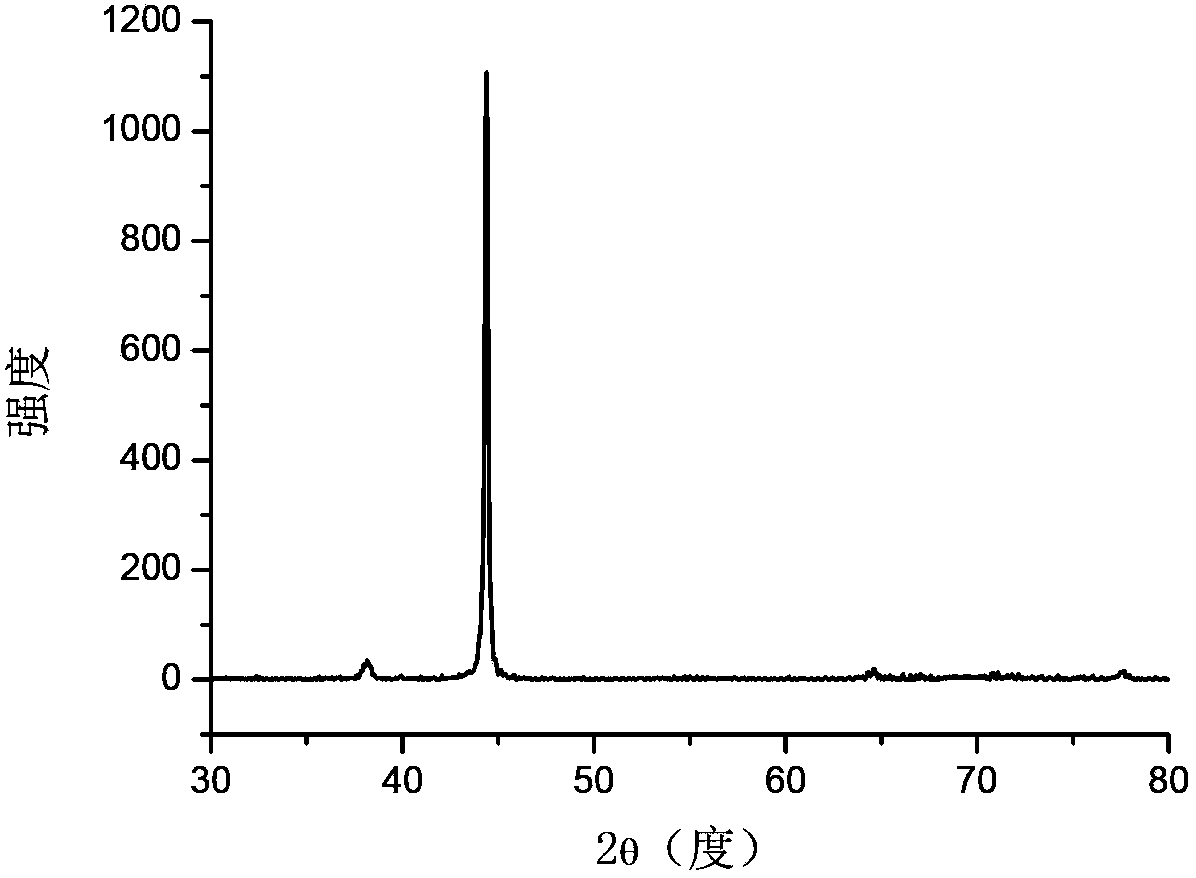

Sub-micro grain hard alloy anvil and preparation method thereof

ActiveCN103572136AEffective control of flexural strengthAdjust the flexural strengthTemperingVitamin C

The invention discloses a sub-micro grain hard alloy anvil and a preparation method thereof. The sub-micro grain hard alloy anvil comprises the following alloy components: WC (Wolfram Carbide), 10% of Co, 0.4-0.6% of Cr3C2 and 0.2-0.3% of VC (Vitamin C); the particle size of an alloy crystal is 0.8-0.9mum; the porosity of an alloy is A00B00C00; the hardness of the alloy is 90.5-91.5HRA; the coercive force of the alloy is 205-245Oe. The preparation method comprises the steps: with WC powder with the Fisher particle size of 1.0-1.2mum and Co powder with the Fisher particle size of 0.8-1.0mum as raw materials, adding Cr and V additives in the alloy in the preparation process of the WC powder; preparing an alloy mixture by using a rolling wet grinding process, wherein the wet grinding time is 55-60h, and the mass ratio of a ball material is 4:1; drying and granulating the wet ground mixture by using a spray drying granulation method; and sintering a pressed anvil blank at the temperature of 1400-1410 DEG C by using a pressure sintering process, wherein the pressed anvil blank is obtained through cold isostatic compaction; and carrying out copious cooling treatment on the sintered pressed anvil blank by using liquid nitrogen with the temperature of 180 DEG C below zero to 190 DEG C below zero, and then, carrying out subsequent reinforcement treatment on a refined anvil by using a 350-400 DEG C medium-temperature tempering treatment process.

Owner:DALIAN FAR EASTERN CARBIDE

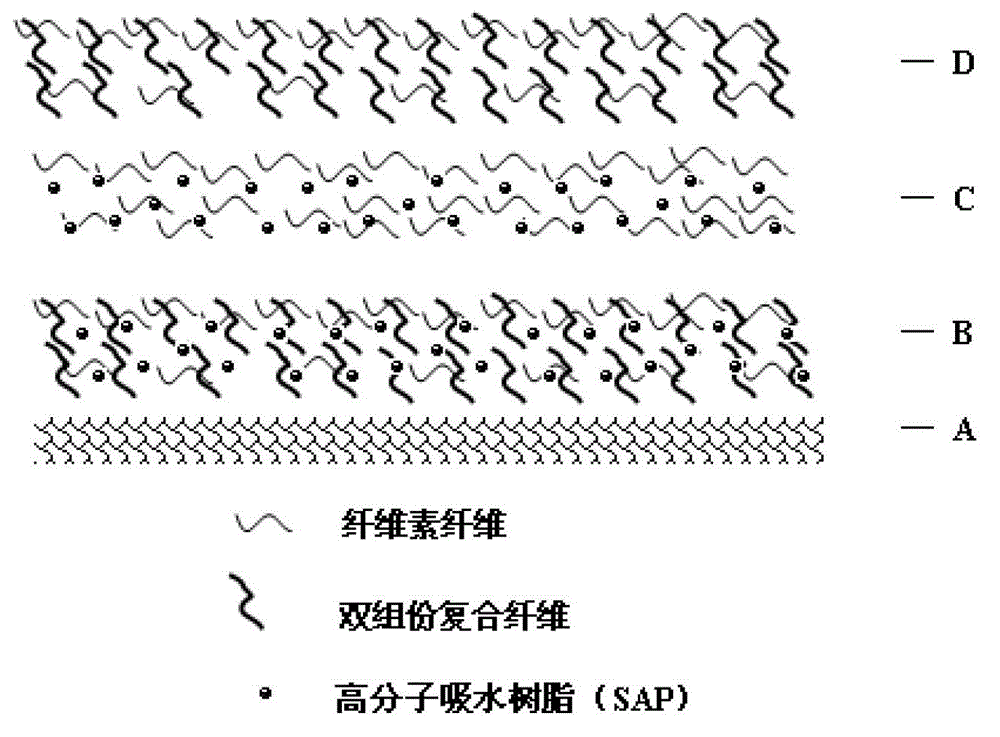

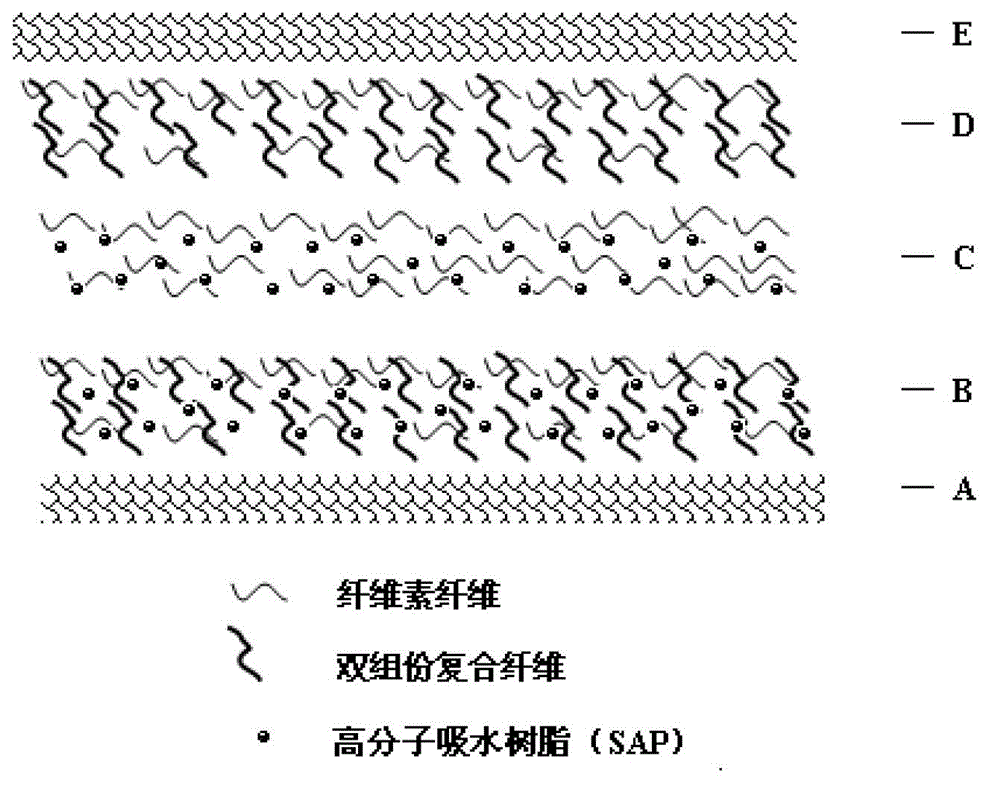

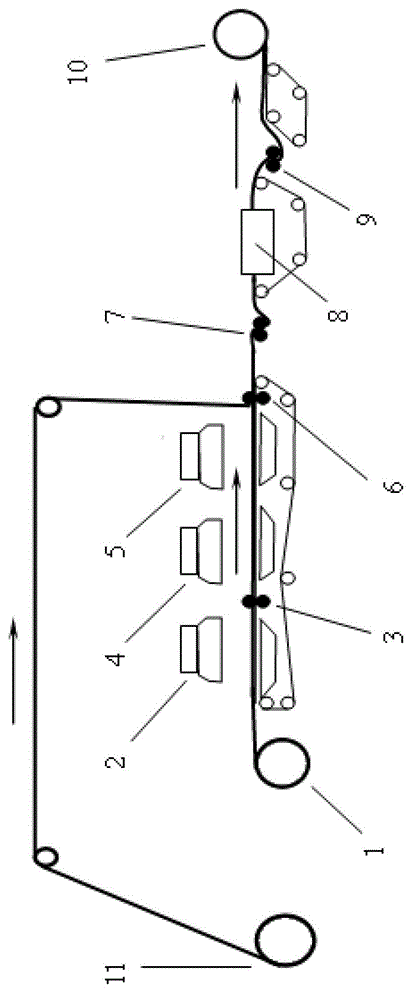

Multi-group press polish treating thin dust-free paper used for absorbing liquid, and manufacturing method and purposes thereof

ActiveCN103144368AHigh densityAbsorbentNon-fibrous pulp additionPersonal careFiberProcess engineering

Owner:FITESA CHINA AIRLAID

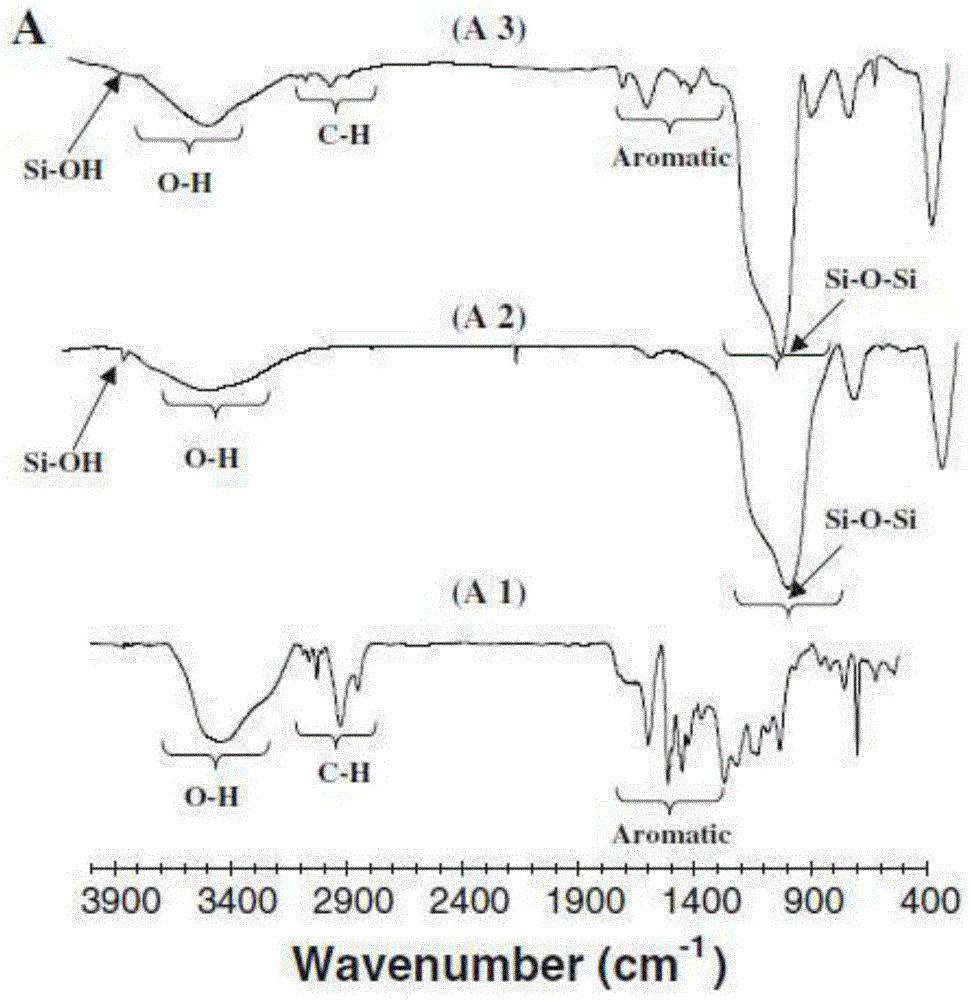

Preparation method of high-oil-absorption and biodegradable lignin-based microporous molecular sieve

ActiveCN104448340AImprove oil absorption efficiencyIncreased competitive adsorption rateOther chemical processesMolecular sieveAcetic anhydride

The invention discloses a preparation method of a high-oil-absorption and biodegradable lignin-based microporous molecular sieve. The method can be used for synthesizing a high-oil-absorption and biodegradable lignin-based microporous molecular sieve, and is simple in preparation process. The method comprises the following steps: 1) synthesis of acetyl lignin: dissolving lignin in a mixing liquid of pyridine and an organic solvent, dropwise adding an acetic anhydride reagent so that an acetylation reaction is achieved between the alcoholic hydroxyl group in the lignin and acetic anhydride, so as to obtain the acetyl lignin; 2) synthesis of silyl acetyl lignin: dissolving the acetyl lignin in a mixing liquid of pyridine and triethoxy chlorosilane so that a synthesis reaction is achieved between the phenolic hydroxyl group in the acetyl lignin and triethoxy chlorosilane, so as to obtain the silyl acetyl lignin; and 3) preparing the microporous molecular sieve by virtue of copolymerization: adding the silyl acetyl lignin to a microporous molecular sieve suspension dissolved in the organic solvent for copolymerization, thus obtaining a solid matter which is the high-oil-absorption and biodegradable lignin-based microporous molecular sieve.

Owner:蒋吉平

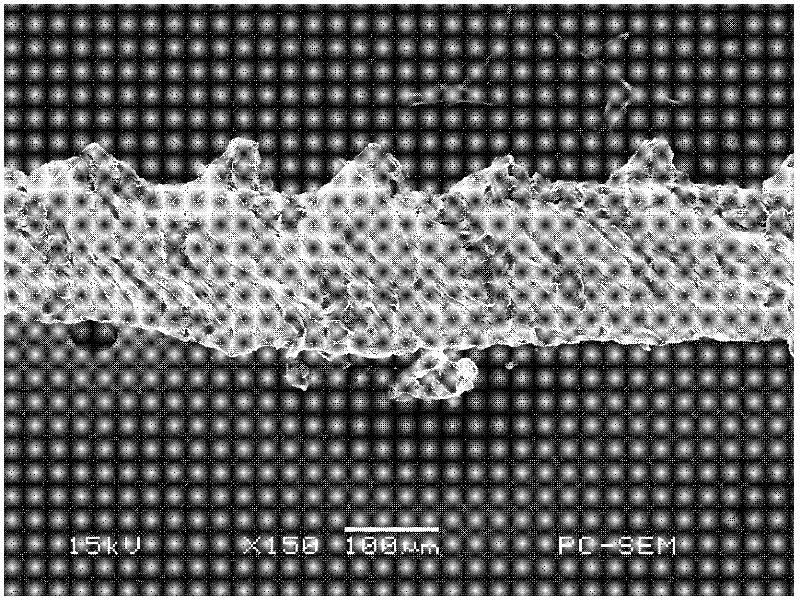

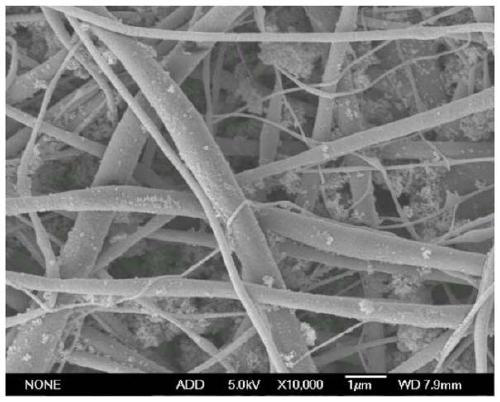

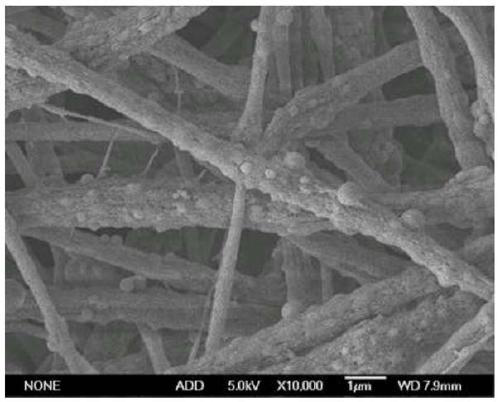

Preparation method and application of grafted dendritic polymer electrostatic spinning nanofiber membrane oil-water separation material

PendingCN111266024AControllable diameterHigh porositySemi-permeable membranesMembranesSilane couplingElectrospun nanofiber

The invention relates to a preparation method of a grafted dendritic polymer electrostatic spinning nanofiber membrane oil-water separation material. The preparation method comprises the following steps: 1, by using a dendritic polymer as a raw material, modifying the dendritic polymer by a silane coupling agent to obtain a modified dendritic polymer; 2, carrying out a reaction on the modified dendritic polymer with the electrostatic spinning nanofiber membrane coated with polydopamine on the surface to obtain a modified electrostatic spinning nanofiber membrane; 3, modifying the inorganic nano-particles by adopting a modifying substance to obtain modified inorganic nano-particles; 4, placing the modified electrostatic spinning nanofiber membrane in a modified inorganic nanoparticle solution for a period of time to complete a grafting reaction so as to obtain the dendritic polymer electrostatic spinning nanofiber membrane oil-water separation material. Due to special functional groupson the surface of the dendritic polymer, the dendritic polymer has a large adjusting space for wettability of a nanofiber membrane and has a good application prospect.

Owner:雅邦绿色过程与新材料研究院南京有限公司

Gelatin sponge and preparation method thereof

The invention provides gelatin sponge, gelatin aqueous solution is irradiated to crosslink to form gelatin hydrogel, and then the gelatin hydrogel is swollen, frozen and dried to obtain the gelatin sponge. The invention also provides a preparation method of the gelatin sponge by an irradiation crosslinking way, the whole process flow is finished in a pure water system, the irradiation and crosslinking processes have sterilizing function and good controllability, the obtained product has better structural uniformity compared with a chemical crosslinking method, and the gelatin sponge has uniqueadvantages as biomedical materials.

Owner:厦门凝赋生物科技有限公司

Tobacco flake sorting method based on flake-shaped structure grouping processing

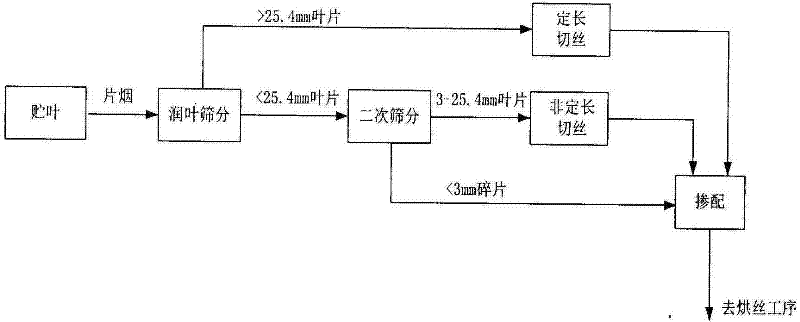

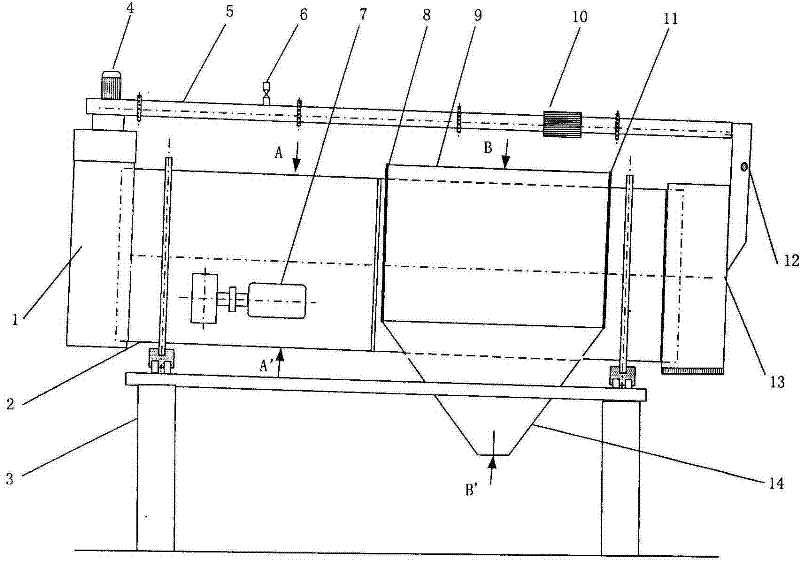

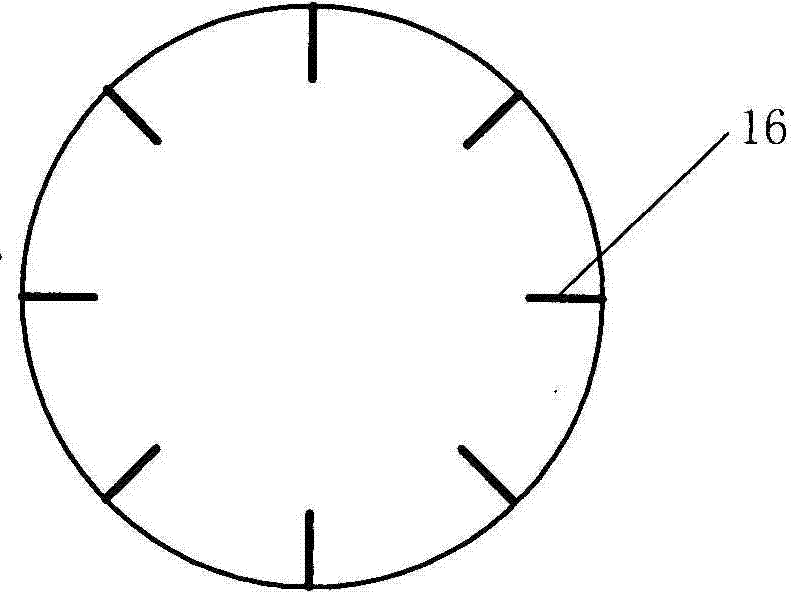

InactiveCN102342580AImprove structural uniformityImprove physical qualityTobacco preparationMechanical engineeringMaterials science

The invention discloses a tobacco flake sorting method based on flake-shaped structure grouping processing, comprising the following concrete process flows of: outputting flaked tobacco by a leaf storage cabinet, then, enabling the flaked tobacco to enter into a conditioning and sieving unit, conditioning and loosing the flaked tobacco, and meanwhile, sieving to obtain tobacco flakes larger than and smaller than 25.4mm; feeding large tobacco flakes into a shredding unit with a length-limit shredding mode; further secondarily sieving small tobacco flakes to obtain tobacco flakes smaller than 3mm and tobacco flakes with the length of 3-25.4mm; feeding the secondarily sieved tobacco flakes with the length of 3-25.4mm into the other shredding unit with a non-length-limit shredding mode; and directly mixing the sieved tobacco flakes with the length of 3mm with cut tobacco obtained after the large tobacco flakes and the tobacco flakes with the length of 3-25.4mm are cut without shredding, and then entering a subsequent cut tobacco drying process. The tobacco flakes are subjected to multistage sorting by combining roller type conditioning and loosing sieving and orifice plate type vibrating sieving, thus, the grouping processing of a shredding process of different flaked raw materials can be realized, the stability of physical quality of cigarette products is improved, and the tobacco flake sorting method is easy to realize on the basis of the traditional cut tobacco preparing and processing equipment.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

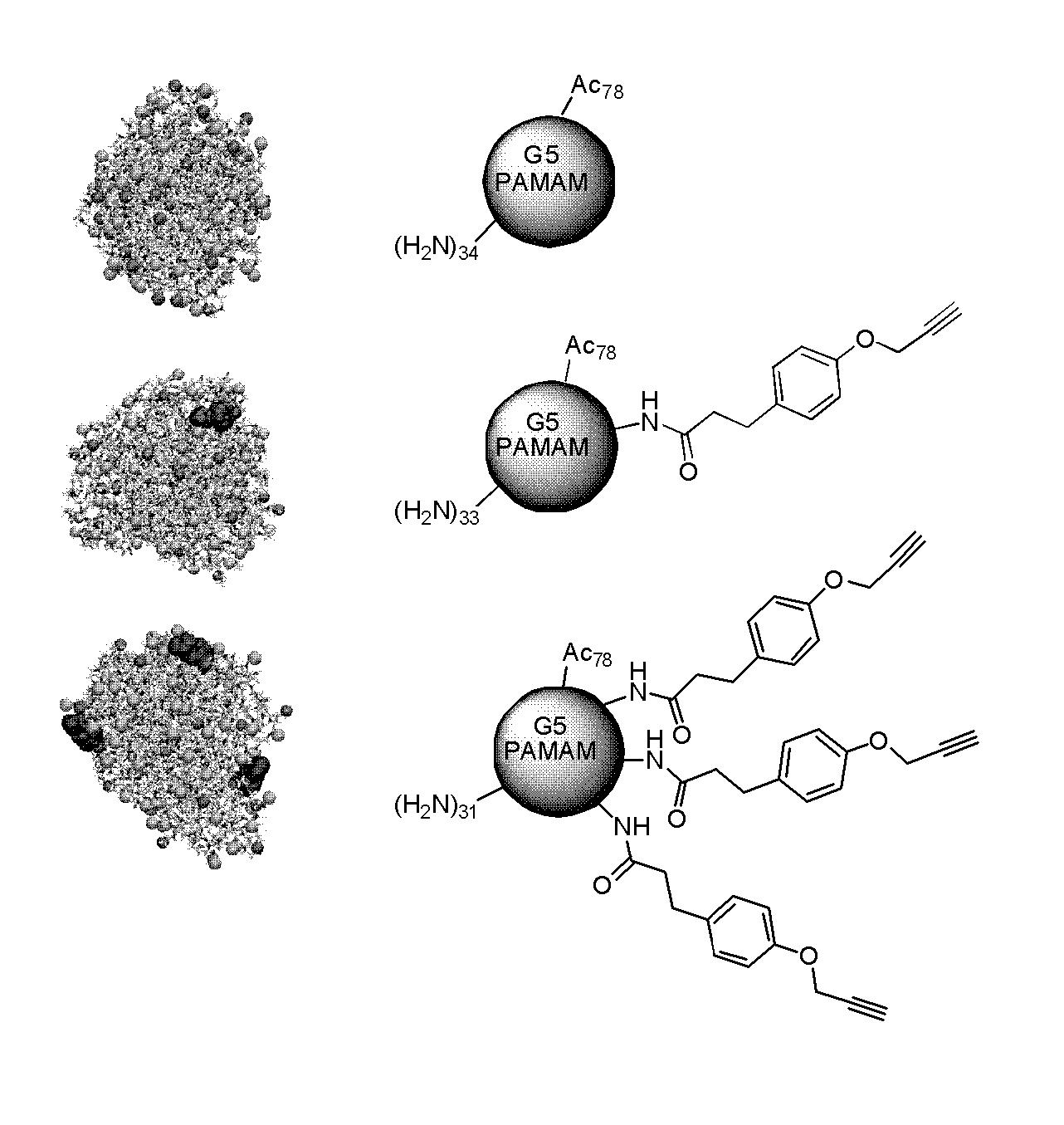

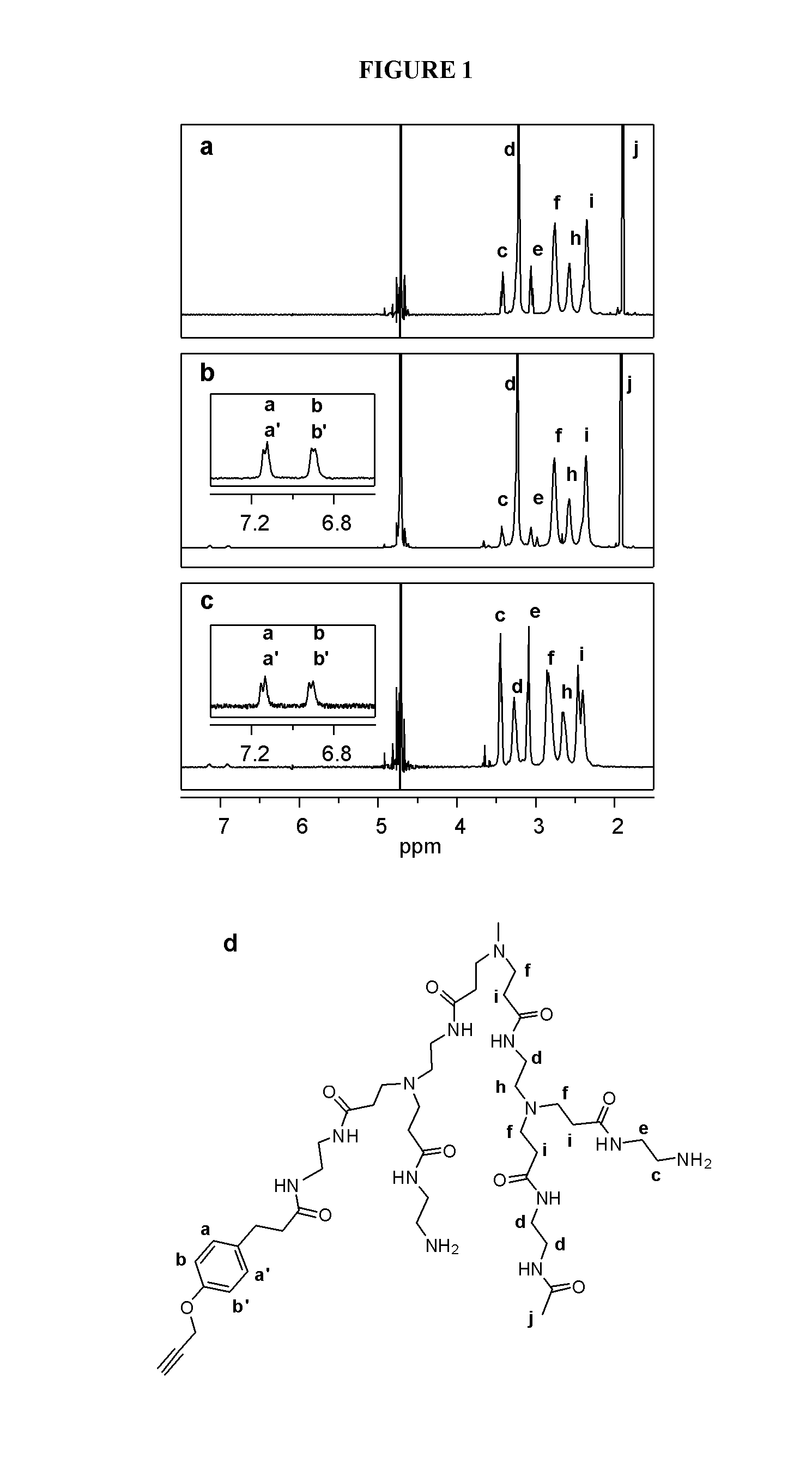

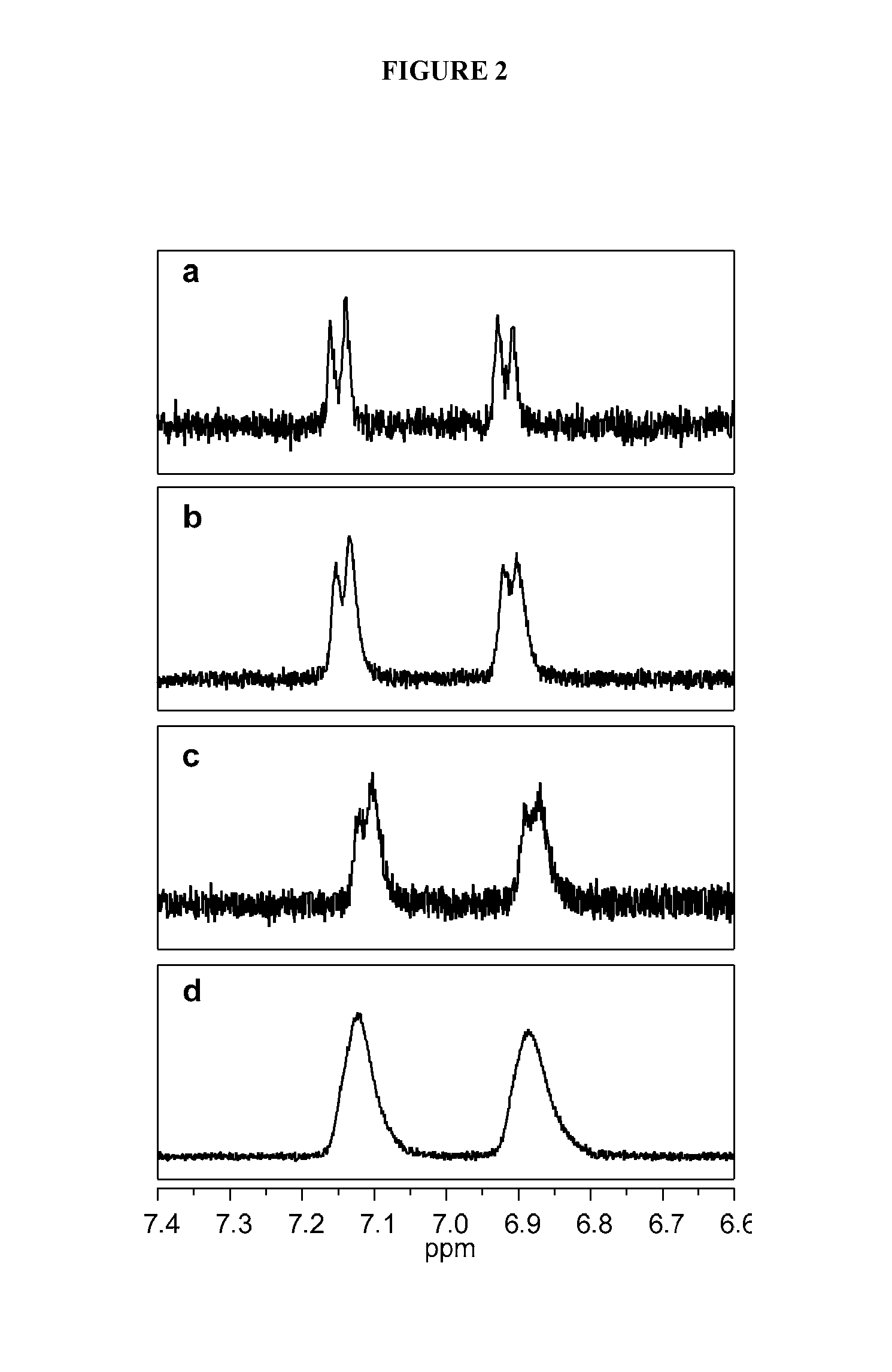

Synthesis and isolation of dendrimer systems

InactiveUS20120232225A1Improve structural uniformityWidely distributedAntineoplastic agentsChemistryPain therapy

The present invention relates to novel methods of synthesis and isolation of dendrimer systems. In particular, the present invention is directed to novel dendrimer conjugates with defined and limited numbers of ligand conjugates and high levels of structural uniformity, methods of synthesizing the same, compositions comprising the conjugates, as well systems and methods utilizing the conjugates (e.g., in diagnostic and / or therapeutic settings (e.g., for the delivery of therapeutics, imaging, and / or targeting agents (e.g., in disease (e.g., cancer) diagnosis and / or therapy, pain therapy, etc.)).

Owner:RGT UNIV OF MICHIGAN

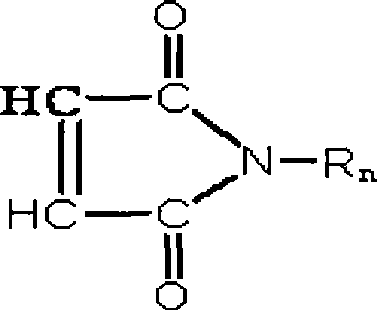

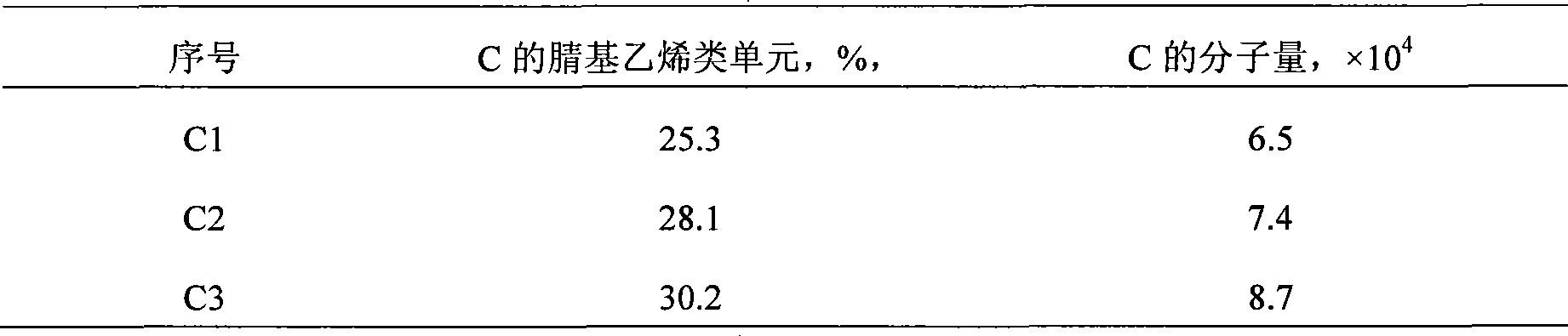

Production of maleimide resin emulsion

Production of maleimide resin emulsion is carried out by adding maleimide monomer, aryl vinyl monomer, nitrile aryl monomer and evocating agent into mixing tank, agitating while mixing to obtain homogeneous monomer mixed liquid(a), adding emulsifier into reactor, agitating while raising temperature, adding (a) into reactor continuously, and polymerizing to form resin emulsion(b). It has excellent appearance and uniform structure, better heat-resistance and polymerization efficiency. It can be used to modify ABS, PC and PBT materials and parts of vehicles and household electrical appliances.

Owner:PETROCHINA CO LTD

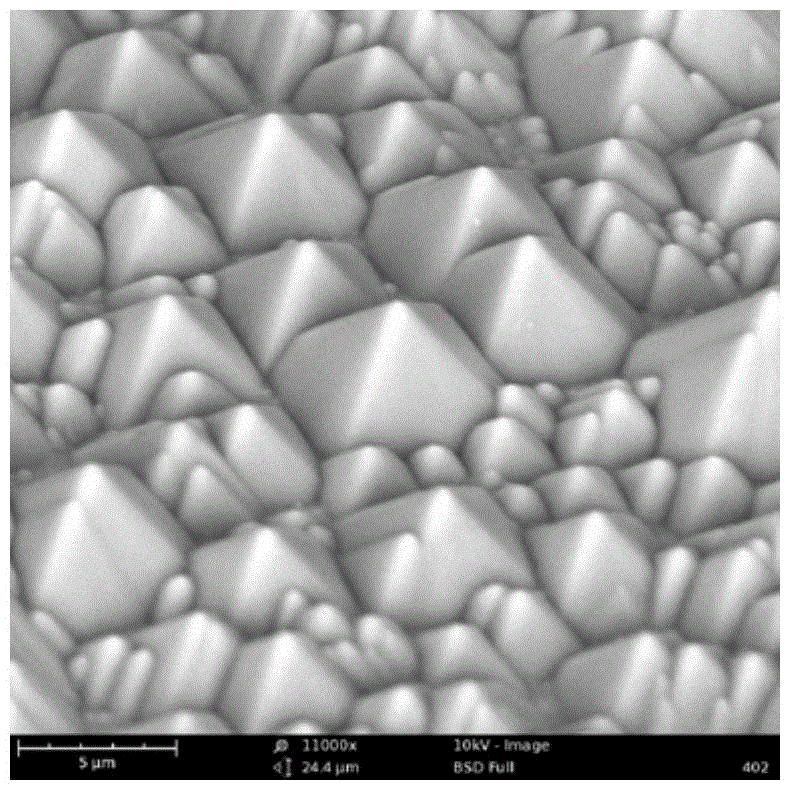

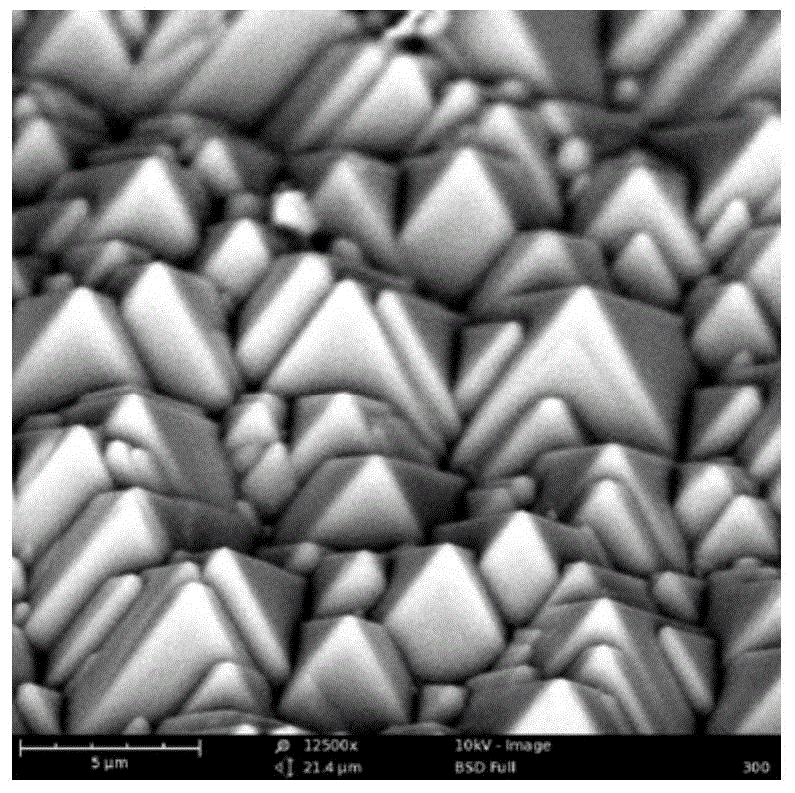

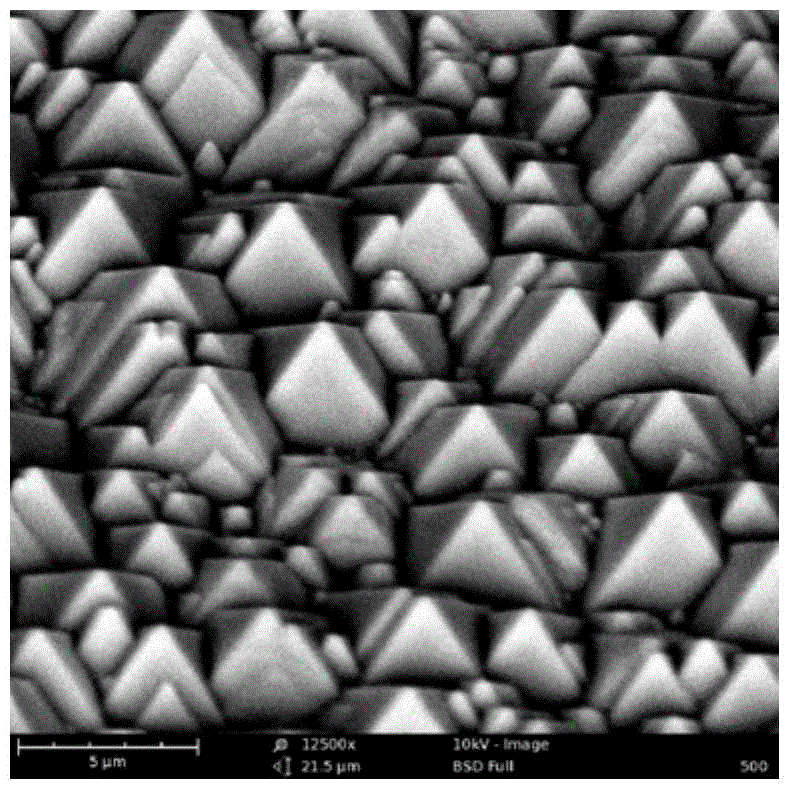

Annealing and wool-making method for monocrystalline silicon wafer

InactiveCN103981575AImprove structural uniformityAfter-treatment detailsHydrofluoric acidAqueous solution

The invention discloses an annealing and wool-making method for a monocrystalline silicon wafer. The method includes: rinsing a cleaned monocrystalline silicon wafer in a mixed solution of an aqueous hydrofluoric acid solution and an aqueous ethanol solution, adding the monocrystalline silicon wafer moistened with a wool-making liquid into an annealing furnace and annealing, adding the silicon wafer into the wool-making liquid after annealing is finished, and performing wool making. The method is convenient in operation, stable in process and easy to control. The surface pyramids of the silicon wafer after wool making are good in uniformity. The reflectivity of the wool surface is low.

Owner:SHAANXI NORMAL UNIV

Composite metal ceramic powder, furnace roller coated with same and preparation method thereof

ActiveCN101838767AImprove compactnessImprove structural uniformityMolten spray coatingChromium carbideSurface layer

The invention discloses a composite metal ceramic powder, a furnace roller coated with the same and a preparation method thereof. The composite metal ceramic powder contains the following components in percentage by weight: 35-70 percent of MCrAlY or MCrAlTaY, 25-45 percent of Cr3C2 and 5-20 percent of Na2Ti6O13 or K2Ti6O13, wherein M is Ni, Co or Ni-Co alloy. The furnace roller comprises a workpiece substrate and a coating sprayed on the workpiece substrate, wherein the coating comprises a surface layer and a bottom layer or a single surface layer, and the surface layer is made of the composite metal ceramic powder. The furnace roller is prepared by adopting a high-speed oxygen flame spraying method and has excellent heat resistance, wear resistance and nodule resistance performances and average service period reaching over 2 years.

Owner:BAOSHAN IRON & STEEL CO LTD

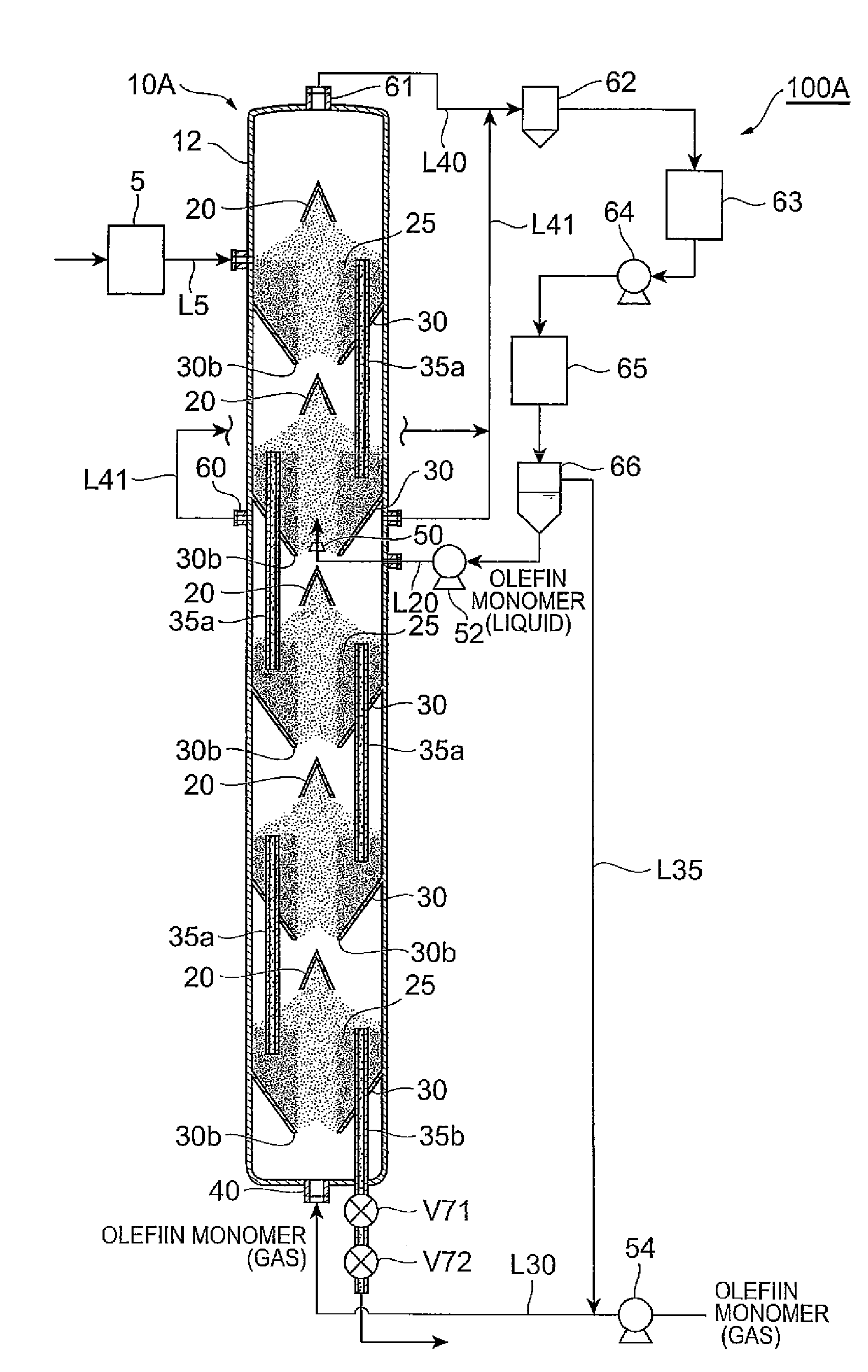

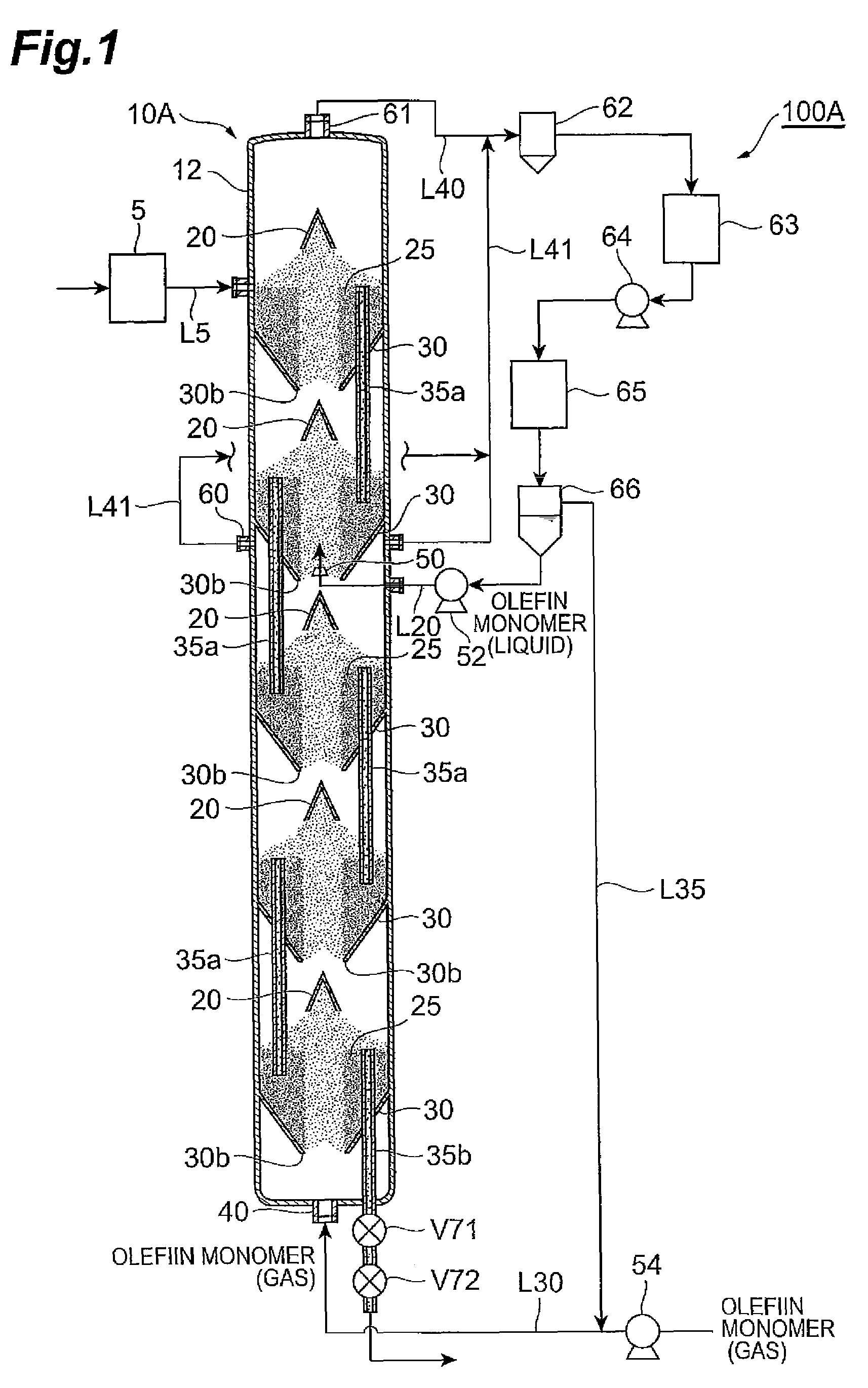

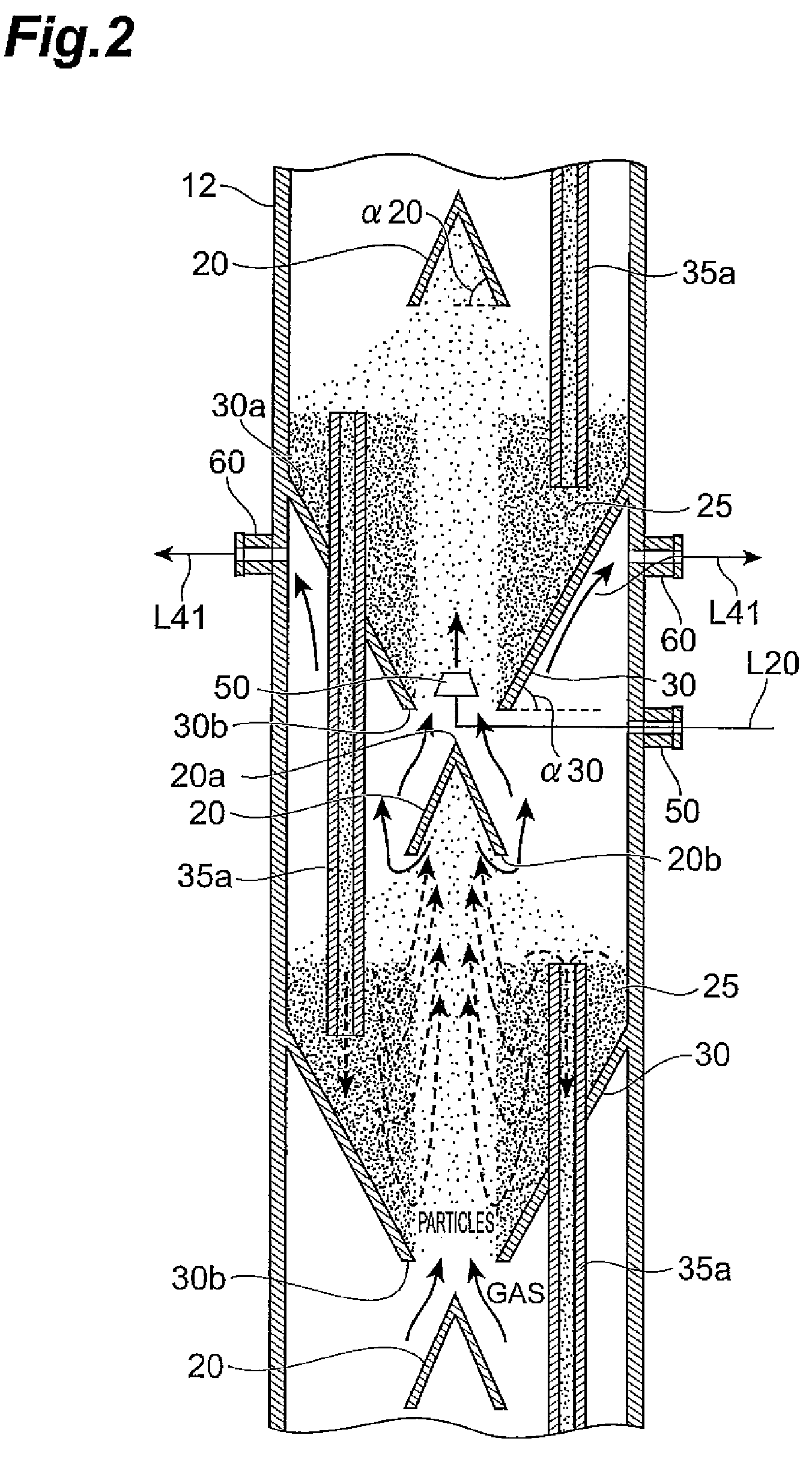

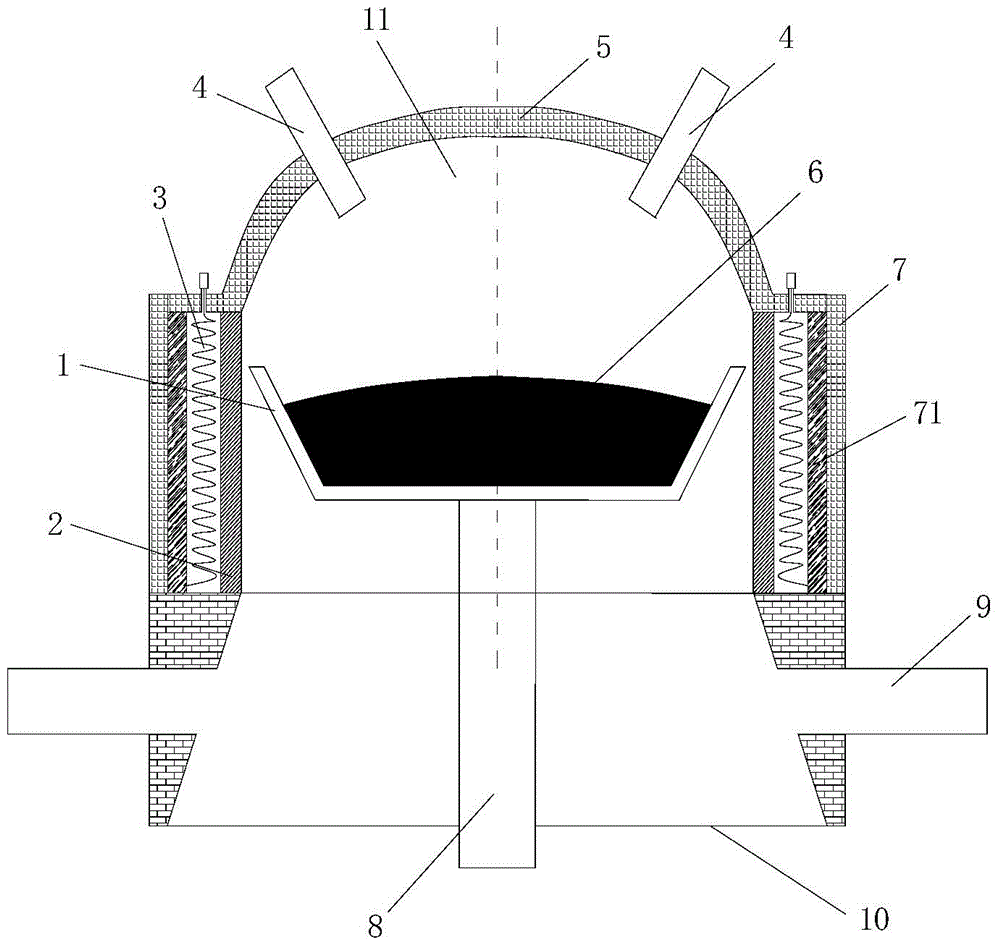

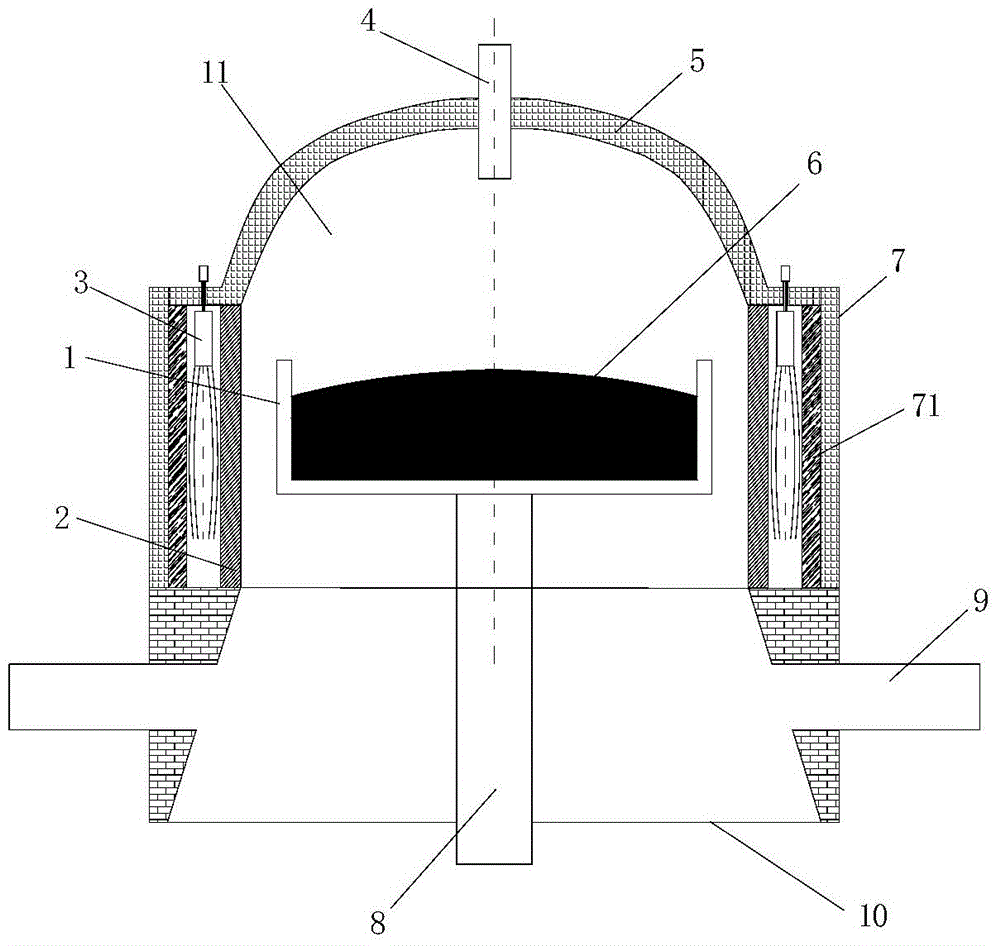

Olefin polymerization reactor, polyolefin production system, and polyolefin production process

ActiveUS7993593B2Easy constructionReduce distributionChemical/physical/physico-chemical stationary reactorsPolyolefinReaction zone

An olefin polymerization reactor of the present invention includes a cylinder which extends vertically, and a decreasing diameter member which is formed on the cylinder, has an inside diameter that decreases progressively downward and has a gas inlet orifice at a bottom end thereof. A spouted bed is formed inside a reaction zone enclosed by an inside surface of the decreasing diameter member and an inside surface of the cylinder above the decreasing diameter member.

Owner:SUMITOMO CHEM CO LTD

High-heat-conducting carbon/carbon composite material and preparation method thereof

The invention relates to a high-heat-conducting carbon / carbon composite material and a preparation method thereof, and belongs to the technical field of carbon material manufacturing. The preparationmethod comprises the following steps: alternately laying a carbon fiber cloth and intermediate phase asphalt felt to obtain a laminated structure, wherein the thermal conductivity of the carbon fibercloth is greater than 500W / mK at room temperature; carrying out hot-pressing forming on the laminated structure, and carrying out high-temperature treatment and high-pressure graphitizing treatment toobtain the high-heat-conducting carbon / carbon composite material. The method has the advantages of simple process, little time consumption, low energy consumption and the like, and the preparation rate and efficiency of the high-heat-conducting carbon / carbon composite material can be greatly improved. The prepared high-heat-conducting carbon / carbon composite material has a uniform internal structure and excellent heat conduction and mechanical properties, and has wide application prospects in the aspects of heat control and heat management in the fields of aerospace, nuclear reactor, electronic industry and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

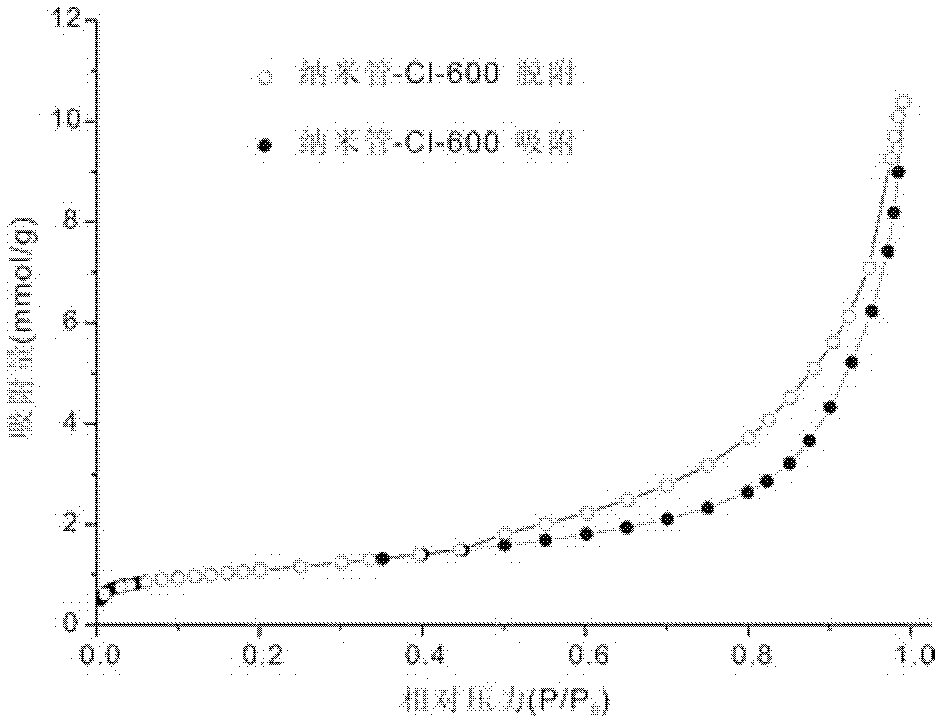

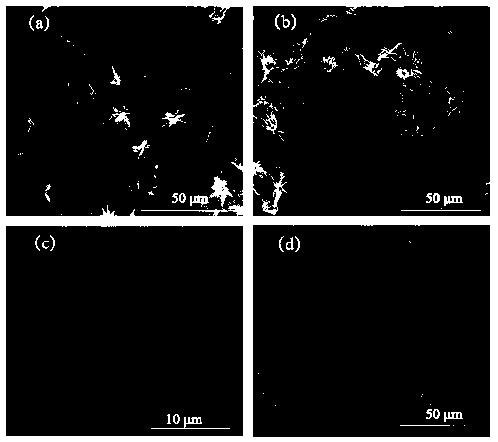

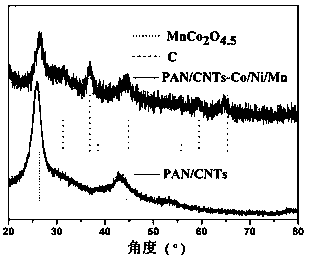

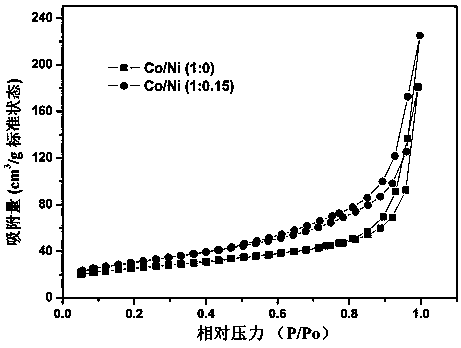

Preparation method of porous carbon-supported transition metal oxide composite material

InactiveCN109786766AImprove structural uniformityLarge specific surface areaFuel and primary cellsCell electrodesPorous carbonCarbon nanotube

The invention relates to a preparation method of a porous carbon-supported transition metal oxide composite material. A porous carbon material is firstly prepared by the following steps of completelydissolving polyacrylonitrile in dimethylamide, and uniformly dispersing carbon nanotubes in absolute ethyl alcohol; mixing the two liquids, adding PMMA in proportion and uniformly dispersing the PMMAby ultrasonic; slowly evaporating the organic solvent under natural conditions; and annealing under N2 atmosphere to obtain the porous carbon material. The preparation method of a porous carbon-supported transition metal oxide composite material comprises the following steps of dissolving cobalt nitrate hexahydrate, nickel nitrate hexahydrate, manganese chloride, ammonium fluoride, urea and cetyltrimethylammonium bromide in proportion to the deionized water, placing the obtained solution and the porous carbon material in a reaction vessel, and preparing the porous carbon-supported transition metal oxide composite material by hydrothermal reaction. The invention has the advantages of simple process, low cost, good material structure uniformity, large specific surface area and excellent electrochemical performance, and is used for preparing an oxygen reduction catalyst for a zinc-air battery cathode.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

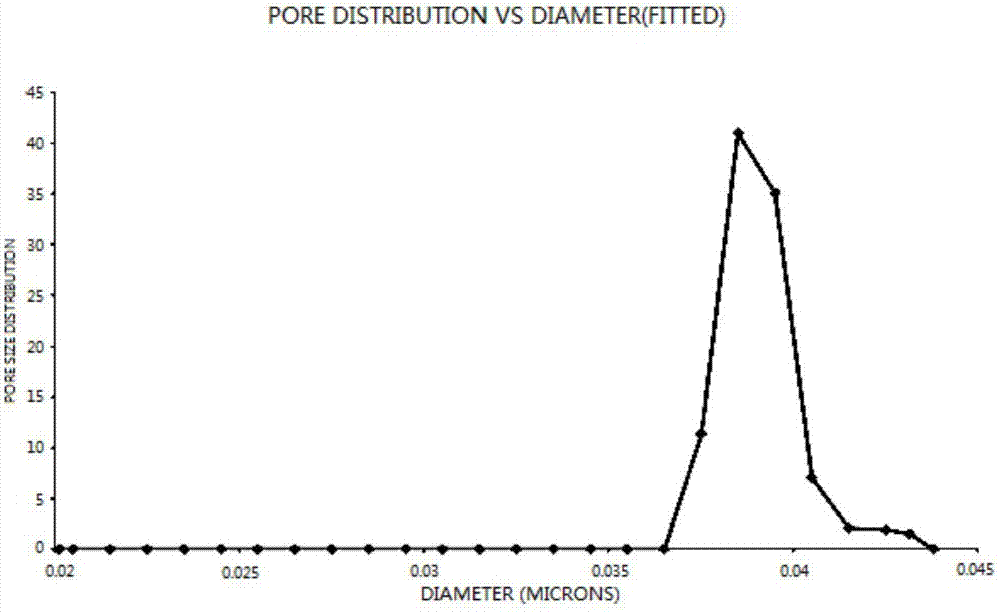

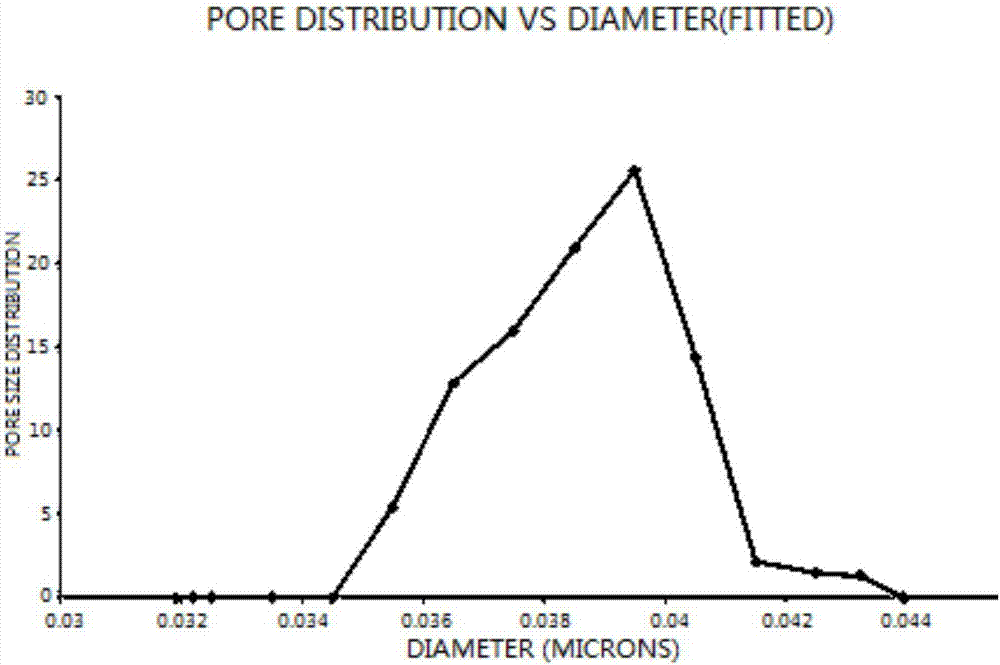

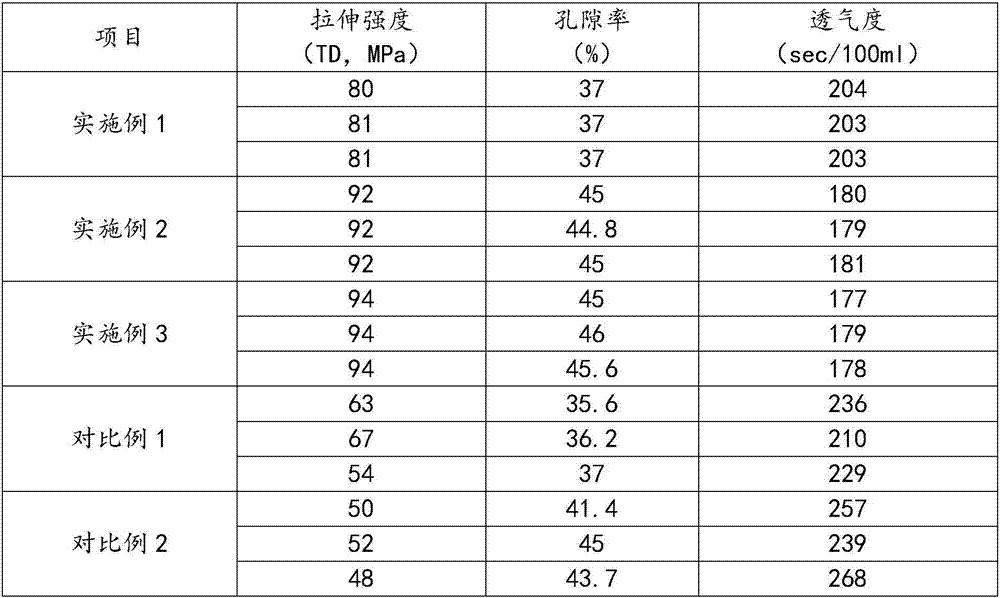

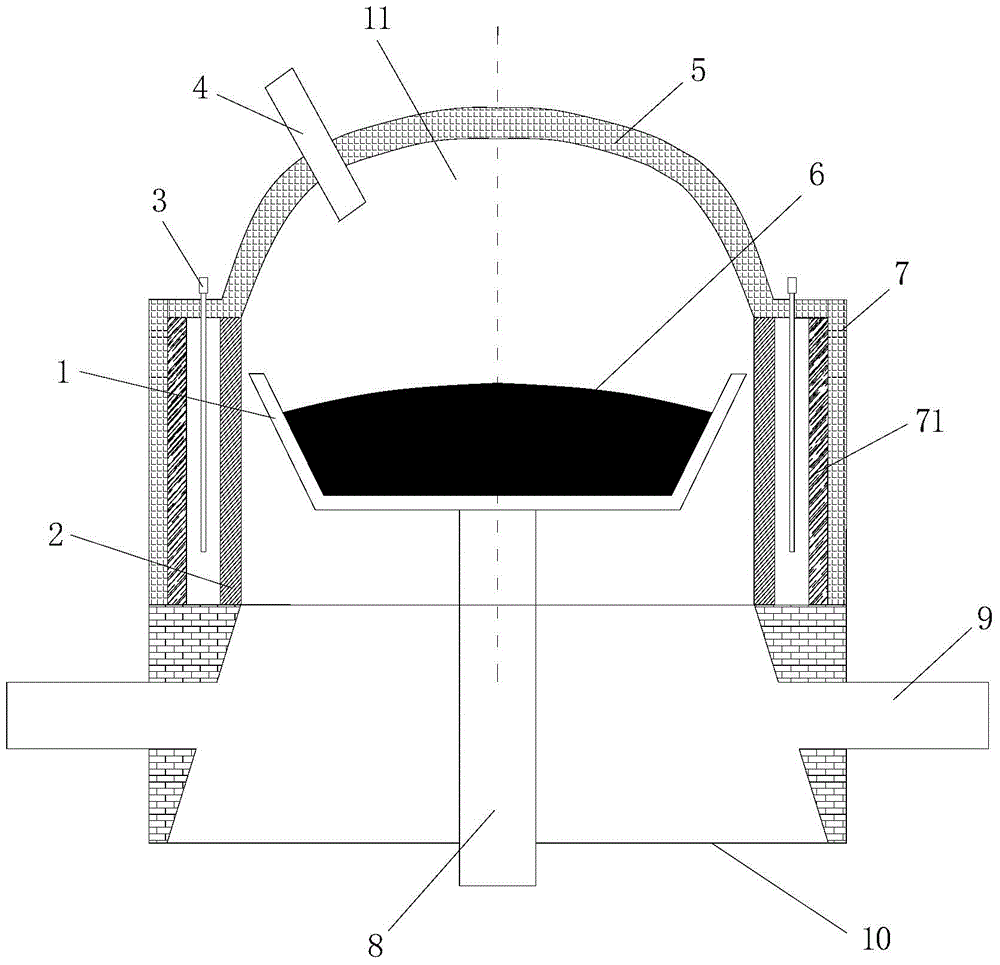

Preparation method for multilayer micro-porous membrane of lithium ion battery

ActiveCN106981608AImprove securityImprove rate discharge performanceSecondary cellsCell component detailsPolyolefinPorous membrane

The invention provides a preparation method for a multilayer micro-porous membrane of a lithium ion battery. The method comprises the following steps: taking polyolefin resin and auxiliary additive as raw materials, fusing and plastifying, thereby acquiring a flux; extruding by a die head and performing tape casting, thereby acquiring intermediate membranes; taking multiple coils of intermediate membranes and compounding by adopting a compounding device with a horizontal stretching function, thereby acquiring a compound intermediate; and performing annealing treatment under an effect of bidirectional micro-tension and longitudinally stretching, thereby acquiring the multilayer micro-porous membrane of the lithium ion battery. According to the invention, a compounding roll is heated in a compounding process of the intermediate membranes, the inner macromolecular structure crystallization of the intermediate membranes is further perfected, and meanwhile, the intermediate membranes horizontally extend under the effect of bidirectional micro-tension and the horizontal orientation degree is increased, so that the micro-pores of the prepared micro-porous membrane are uniform, the horizontal strength is promoted, the capacity of resisting against lithium dendrite puncture is effectively promoted, the micro-short circuit phenomenon is avoided and the micro-porous membrane is suitable for large-scale production. The multilayer micro-porous membrane prepared according to the invention is high in structure uniformity and is effective in promoting the safety of the battery.

Owner:SHENZHEN SENIOR TECH MATERIAL

Method for preparing highly-uniform synthetic quartz glass weight

ActiveCN104926088AUniform radialUniform axial distributionGlass shaping apparatusSilica particleCombustor

The invention discloses a method for preparing a highly-uniform synthetic quartz glass weight. Preparing is conducted through a vertical depositing furnace based on chemical vapor deposition, raw materials are led into a combustor and chemically reacted in the depositing furnace, silicon dioxide particles are formed, the depositing foundation of the quartz glass weight is a concave depositing pool formed by a bottom face and a side wall, the silicon dioxide particles formed based on chemical vapor synthesis are melted and freely scattered and deposited in the depositing pool, and the temperature gradient of the depositing face is lower than 20 DEG C. According to the method for preparing the highly-uniform synthetic quartz glass weight, the distributing consistency of quartz glass weight components is improved, and the quartz glass weight uniform in radial and axial structure is produced.

Owner:CHINA BUILDING MATERIALS ACAD

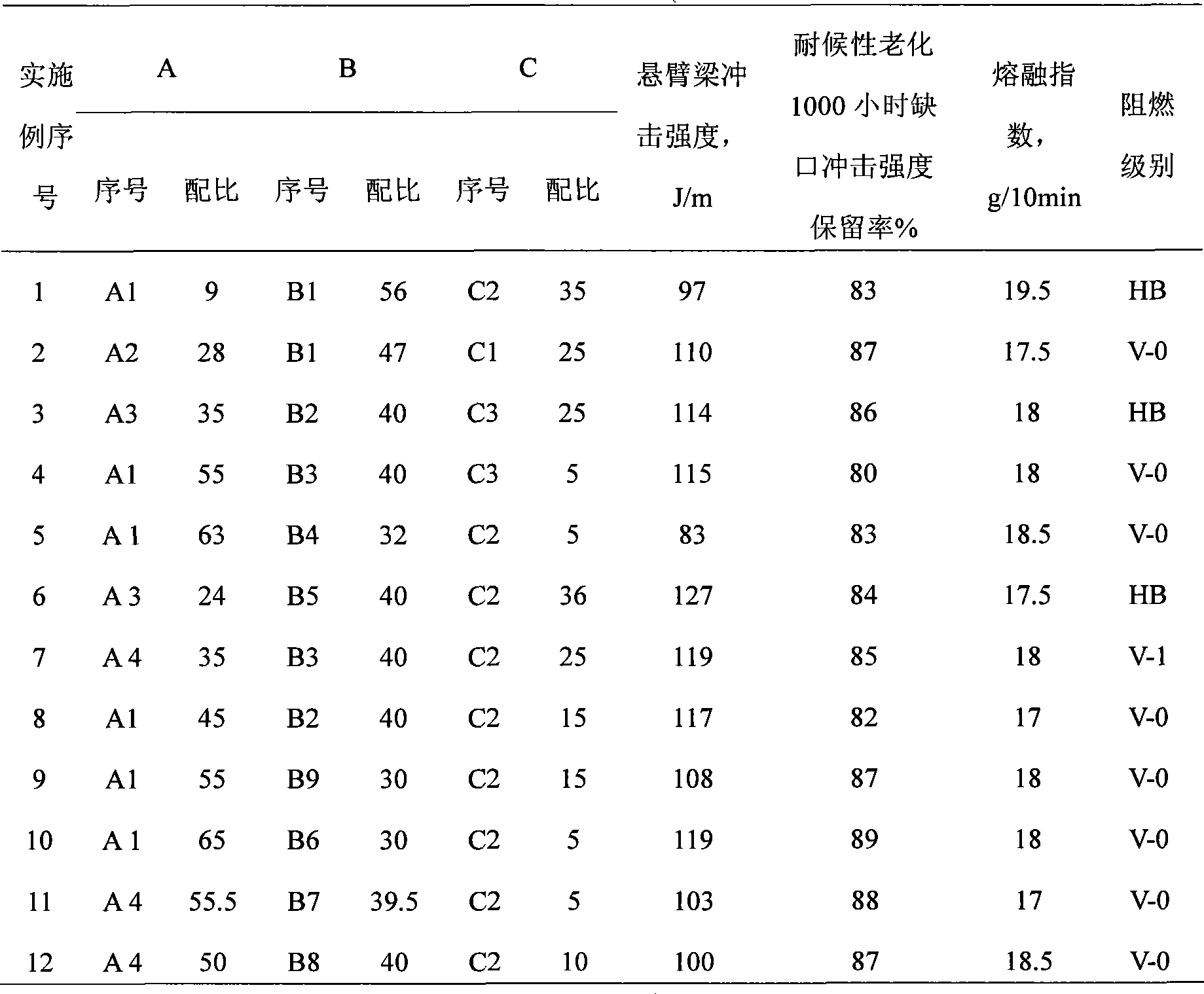

Weather resistant heat resisting flame retardant resin composition and preparation thereof

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com