Annealing and wool-making method for monocrystalline silicon wafer

A single-crystal silicon wafer, annealing technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve the problems of uneven pyramid size and high reflectivity, and achieve good uniformity and suede reflectivity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

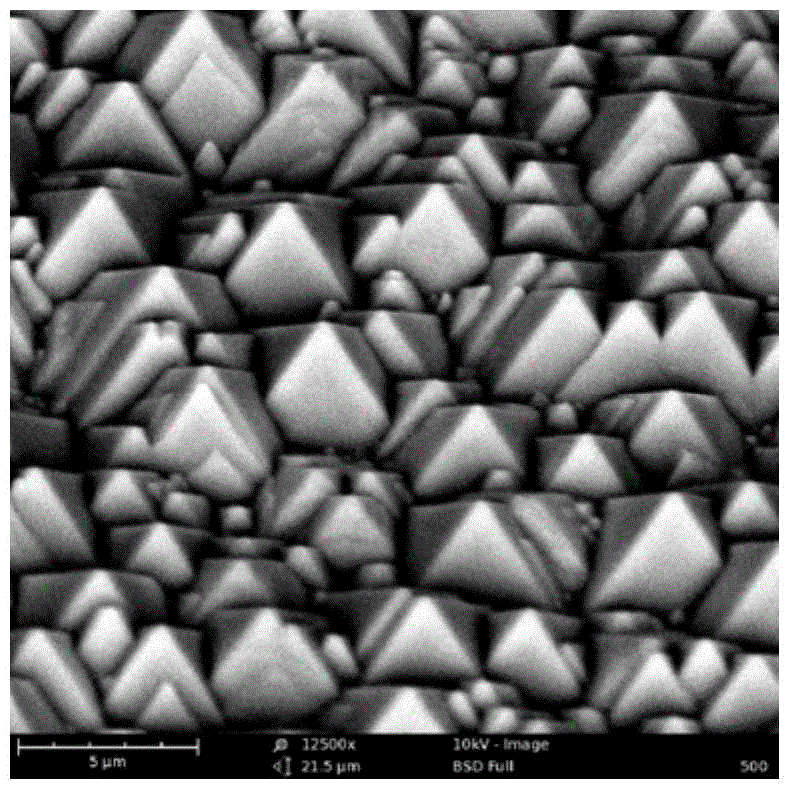

[0018] After the monocrystalline silicon chip is cleaned with a mixture of deionized water, 30% hydrogen peroxide aqueous solution and 30% ammonia aqueous solution in a volume ratio of 5:1 to 2:1, deionized water and The mass fraction is 30% hydrogen peroxide aqueous solution, and the mass fraction is 37% hydrochloric acid aqueous solution, and the volume ratio is 6~8:1~2:1 mixed solution cleaning; The monocrystalline silicon chip after cleaning is hydrofluoric acid, deionized The mixed solution of water and ethanol was rinsed for 1 minute, the volume fraction of hydrofluoric acid in the mixed solution was 8%, and the volume fraction of ethanol was 20%, and then dried with nitrogen; second, take out the silicon chip so that the surface of the silicon chip is stained with texturing liquid, and put it into the tube annealing furnace under N 2 Anneal at 400°C for 20 minutes in the atmosphere, and cool naturally to room temperature after annealing; then place the silicon wafer in ...

Embodiment 2

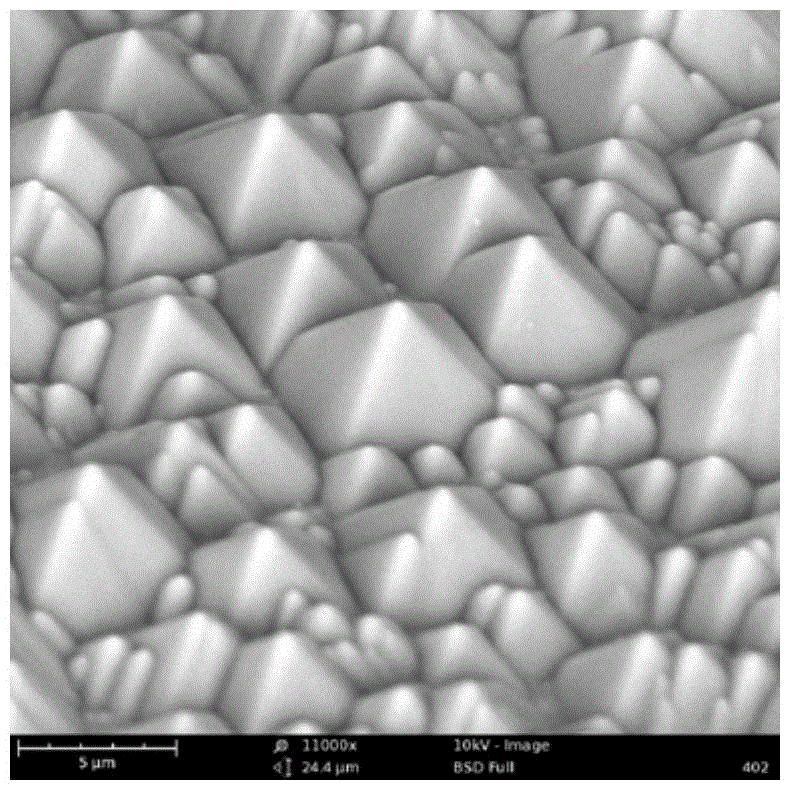

[0021] The annealing condition of the present embodiment is: at N 2 Annealing at 200° C. for 20 minutes under atmosphere, other steps are the same as in Example 1.

Embodiment 3

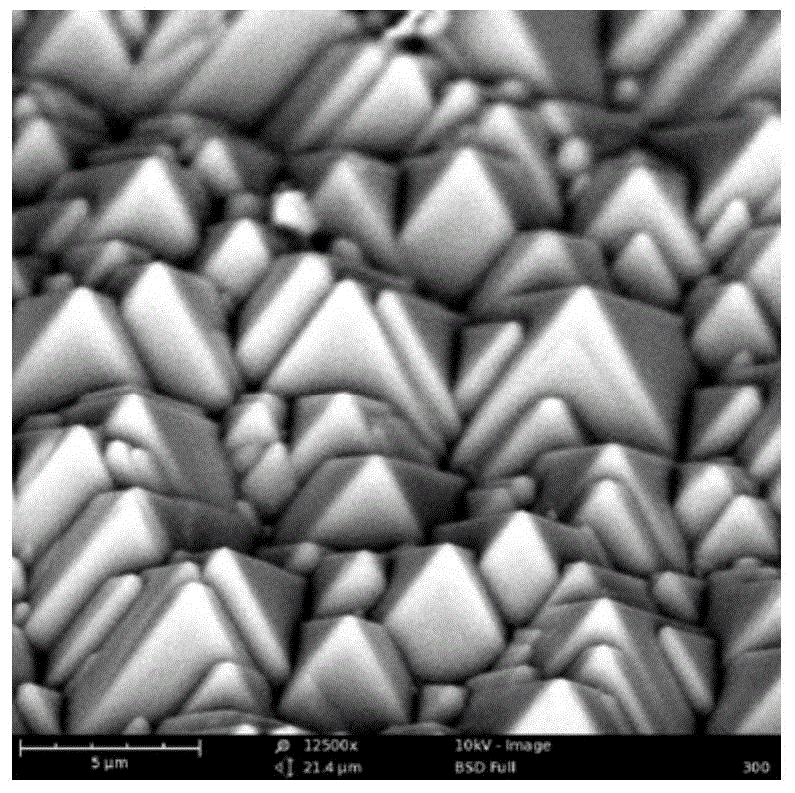

[0023] The annealing condition of the present embodiment is: at N 2 Annealing at 300° C. for 20 minutes under atmosphere, other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com