Preparation method for multilayer micro-porous membrane of lithium ion battery

A technology of lithium-ion batteries and microporous membranes, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of large performance differences, low transverse strength, and low permeability of microporous membranes, and achieve a multiplier Discharge performance and electrolyte retention rate are good, the degree of lateral orientation is increased, and the effect of improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

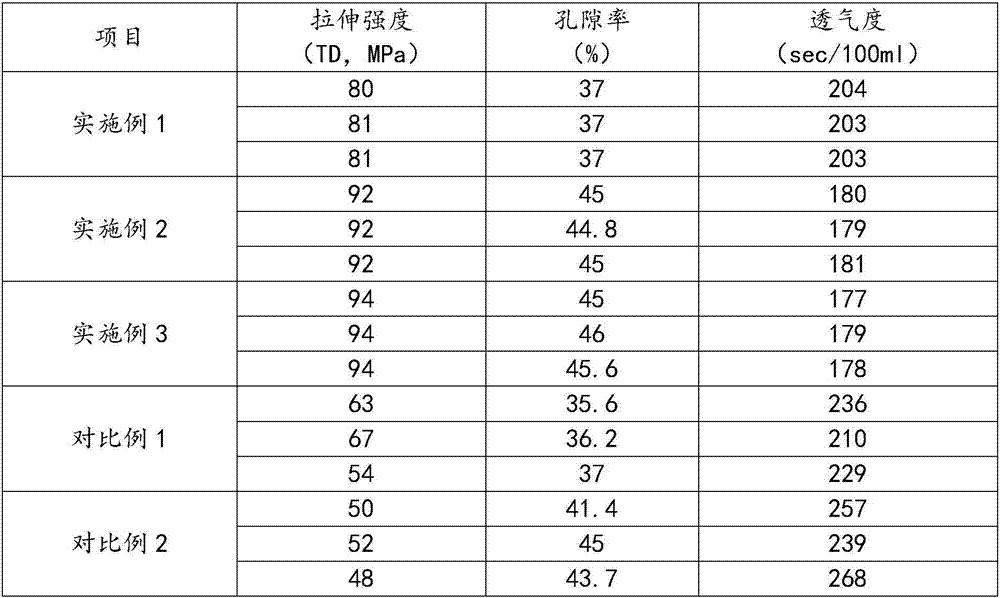

[0021] The embodiment of the present invention discloses a preparation method of a multilayer microporous membrane for lithium ion batteries, comprising the following steps: mixing polyolefin resin and auxiliary additives, and stirring to obtain a mixture; adding the mixture to an extruder, melting Plasticizing to obtain a melt; extruding the melt from a die head and tape-casting to obtain an intermediate film; taking multiple rolls of the intermediate film and compounding it through a compound device with a transverse stretching function to obtain a compound film For intermediates, the transverse stretching tension is 0.2-4.5N, the transverse stretching ratio is 1.0-2.5, and the temperature of the composite roll is 40-70°C; stretched to obtain a multilayer microporous membrane for lithium ion batteries.

[0022] As a preferred solution, the polyolefin resin is one or more of polypropylene, polyethylene and polyvinylidene fluoride. The auxiliary additives are one or more of p...

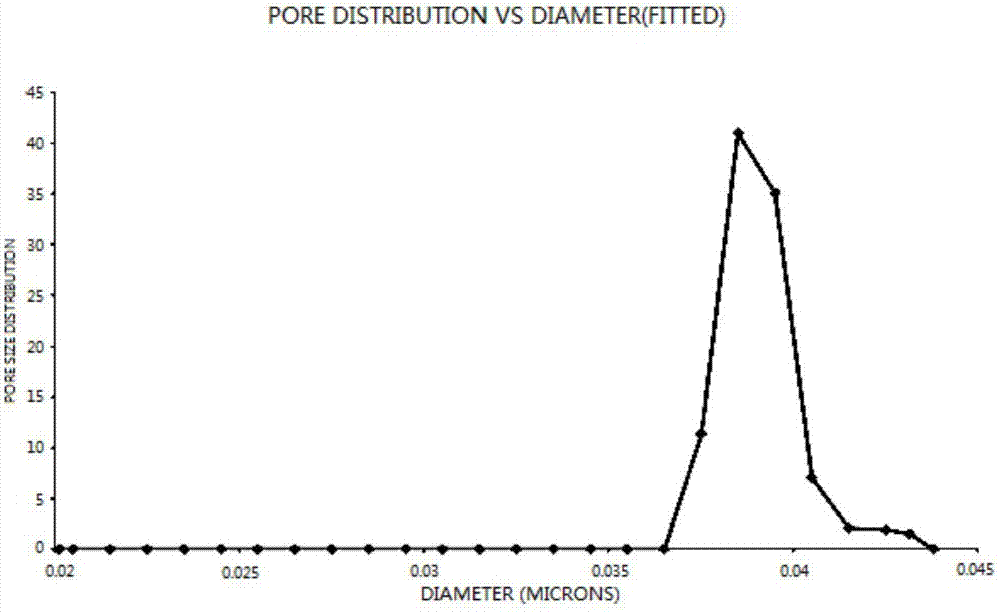

Embodiment 1

[0033] This embodiment provides a microporous membrane, the main raw material of which is polypropylene resin, the auxiliary materials are antistatic agent and antioxidant, the thickness of the microporous membrane is 16 μm, and the porosity is 37%. The content of the main resin polypropylene is 95% by mass percent, and the contents of the antistatic agent and antioxidant are respectively 2% and 3% by mass percent.

[0034] The method for preparing described microporous membrane, comprises the steps:

[0035] 1. Stir the main polyolefin resin and auxiliary additives evenly under certain conditions with a high-speed mixing mixer, the stirring speed is 2500rpm, and the stirring time is 20min to obtain the mixture I;

[0036] 2. Add the above mixture I into the extruder, melt and plasticize evenly under certain conditions, and the temperature of the extruder is 210°C;

[0037] 3. Extrude the cast sheet from the above melt through the die, and then enter the casting process, the ...

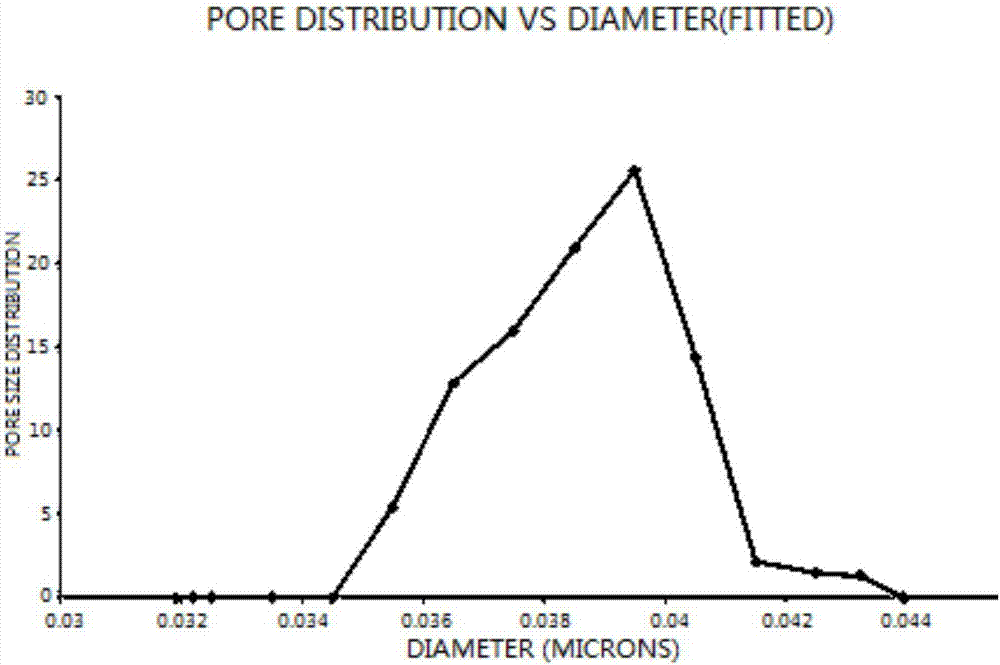

Embodiment 2

[0042] This embodiment provides a microporous membrane, the main raw material of which is polypropylene resin, the auxiliary materials are antistatic agent and antioxidant, the thickness of the microporous membrane is 16 μm, and the porosity is 45%. The content of the main resin polypropylene is 95% by mass percent, and the contents of the antistatic agent and antioxidant are respectively 2% and 3% by mass percent.

[0043] The method for preparing the microporous membrane is basically the same as in Example 1, except that in the fourth step of the compounding process, the temperature of the compounding roll is 65° C., and the transverse stretching ratio is 1.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com