Weather resistant heat resisting flame retardant resin composition and preparation thereof

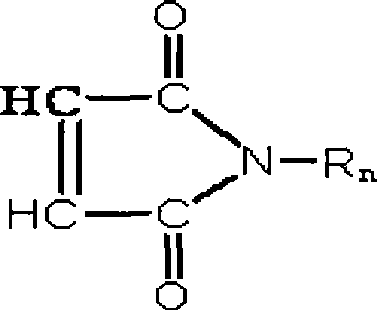

A flame-retardant resin and weather-resistant technology, which is applied in the field of preparation of weather-resistant halogen-substituted maleimide-based heat-resistant flame-retardant resin compositions, can solve the problem of poor thermal stability, poor weather-resistant, heat-resistant, flame-retardant performance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

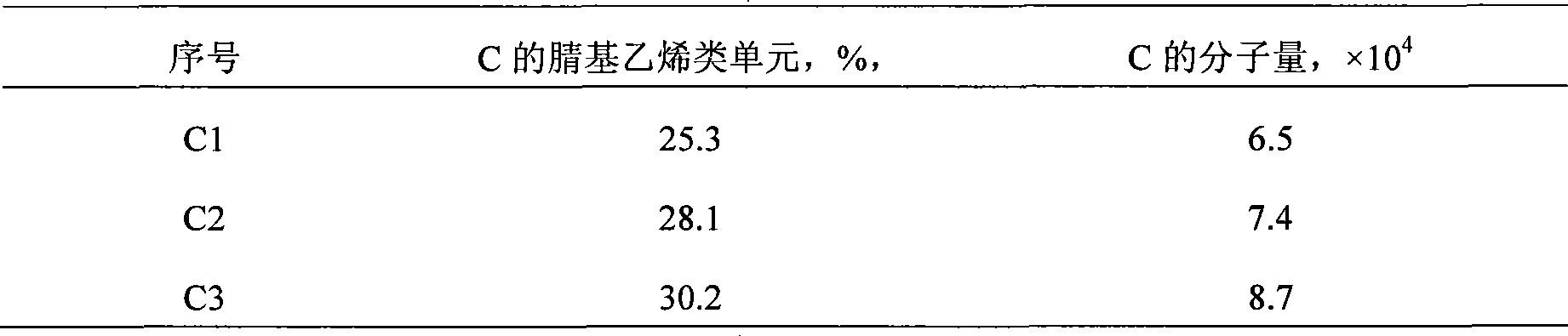

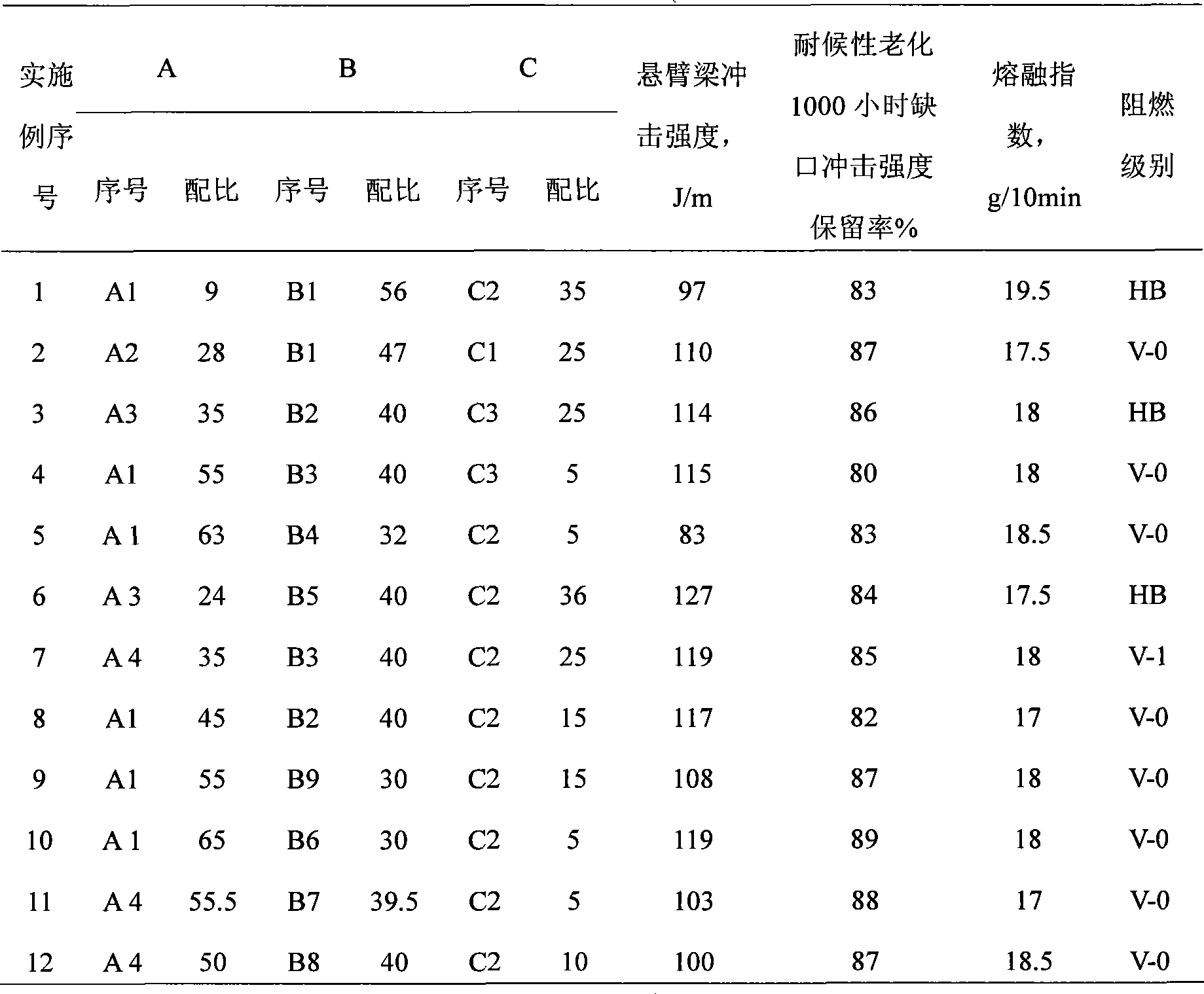

[0141] Mix the heat-resistant and flame-retardant resin emulsion A1 with the emulsion of ABS emulsion B1 and additives at a ratio of 9:56:0.82, and add 100 parts of the mixed emulsion continuously at 25°C until the temperature is 65°C while stirring. In the aqueous solution of 300 parts of 5 ‰ of magnesium sulfate at ℃, maintain a uniform feeding speed and finish adding within 30 to 35 minutes. After adding the emulsion, raise the temperature of the mixture to 95°C and maintain it for 1 hour before cooling down to complete the coagulation process. The condensed slurry is filtered, washed with desalted water, and then dried to form a mixture of A1 and B1. Mix 65.82 parts of the dried A1 and B1 mixture with 35 parts of C2 and 5.8 parts of blending aids in a high-speed blender. The blend can be passed through a twin-screw extruder to obtain a heat-resistant and flame-retardant resin composition product. The performance of the product is shown in Table 2.

Embodiment 2

[0143] Mix the heat-resistant and flame-retardant resin emulsion A2 with the emulsion of ABS emulsion B1 and additives at a ratio of 28:47:0.80, and add 100 parts of the mixed emulsion continuously at 30°C until the temperature is 60°C In the aqueous solution of 100 parts of 2 ‰ of magnesium sulfate, maintain a uniform feed rate and finish adding within 30 to 35 minutes. After adding the emulsion, raise the temperature of the mixture to 97°C and maintain it for 1 hour before cooling down to complete the coagulation process. The condensed slurry is filtered and washed with desalted water, then dried and set aside. Mix 75.8 parts of dried A1 and B1 mixture with 25 parts of C1 and 5.8 parts of blending aid in a high-speed blender. The blend can be passed through a twin-screw extruder to obtain a heat-resistant and flame-retardant resin composition product. The performance of the product is shown in Table 2.

Embodiment 3

[0145] Mix the heat-resistant and flame-retardant resin emulsion A3 with the emulsion of ABS emulsion B1 and additives at a ratio of 35:40:1.20, and add 100 parts of the mixed emulsion continuously at 30°C until the temperature is 70°C In the aqueous solution of 500 parts of 8 ‰ of magnesium sulfate, maintain a uniform feed rate and finish adding within 30 to 35 minutes. After adding the emulsion, raise the temperature of the mixture to 100°C and maintain it for 1 hour before cooling down to complete the coagulation process. The condensed slurry is filtered and washed with desalted water, then dried and set aside. Mix 76.2 parts of dried A1 and B1 mixture with 25 parts of C3 and 5.8 parts of blending aid in a high-speed blender. The blend can be passed through a twin-screw extruder to obtain a heat-resistant and flame-retardant resin composition product. The performance of the product is shown in Table 2.

[0146] Embodiment 4~7, only the kind and consumption of A, B, C are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com