Patents

Literature

58results about How to "The polymerization reaction is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Macromolecule bonding agent and preparation method thereof

InactiveCN102977260AStrong forceThe polymerization reaction is easy to controlCarboxylic acid nitrile preparationOrganic compound preparationChemical synthesisPolymer science

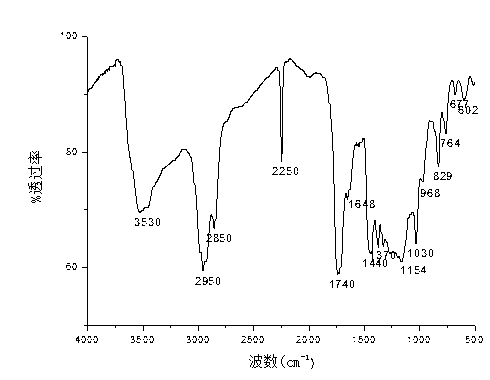

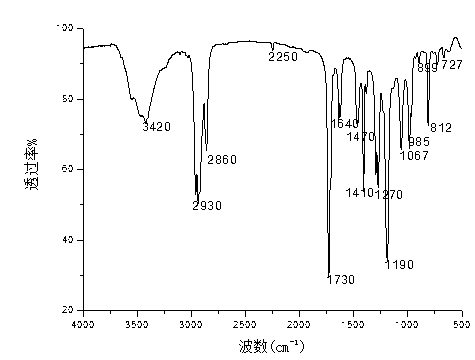

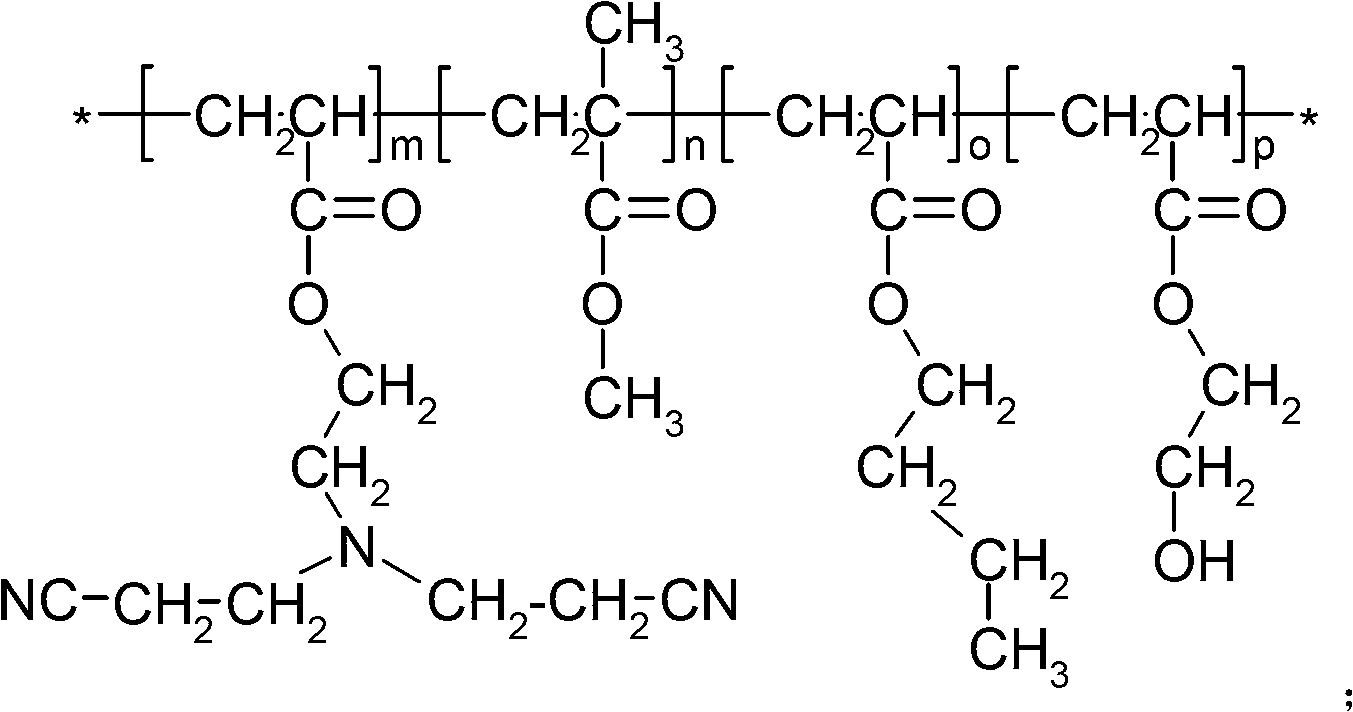

The present invention discloses a macromolecule bonding agent and a preparation method thereof, and belongs to the technical field of chemical synthesis and propellant applications, wherein the obtained product can be adopted as a propellant bonding agent. According to the present invention, N,N-dicyanopropyl aminoethyl acrylate, methyl methacrylate, butyl acrylate and hydroxyethyl acrylate are subjected to copolymerization, wherein a copolymer function chain contains two cyanoalkyl groups, such that an absorption effect is strong; during product preparation, a reactivity ratio of the function monomer is close to reactivity ratios of other copolymerization monomers, such that the reaction is easily controlled; a good bonding effect can be achieved in propellant applications so as to provide a good mechanical property; and advantages of easily-obtained raw materials, easily-achieved preparation process and easy promotion and application are provided.

Owner:SUZHOU UNIV

A kind of method for preparing starch-grafted cationic hyperbranched amide polymer

ActiveCN102286132APolymerization is easyObvious turbidity removal effectWater/sewage treatment by flocculation/precipitationChain transferPolymer chemistry

The invention discloses a method for preparing a starch graft cationic type hyperbranched vinyl or allyl amide polymer. The method comprises the following steps: preparing a mixed phase and a branching reagent phase, preparing a cationic monomer phase, gelatinizing the mixed phase at 25-95 DEG C for 0.1-1 hour, and adjusting the temperature to 40-80 DEG C; then adding a reversible addition-fragmentation chain transfer (RAFT) agent in the gelatinized mixed phase, adding an initiator to initiate a polymerization reaction; and finally adding the cationic monomer phase in a hyperbranched polymer system prepared from the mixed phase, and continuously reacting for 1-24 hours to obtain the starch graft copolymerization cationic type hyperbranched vinyl or allyl amide polymer. The method adopts the RAFT polymerization method and the semi-continuous polymerization technology and uses the diene monomer and the chain transfer agent with a low molar ratio to prepare the starch graft cationic typehyperbranched vinyl or allyl amide polymer in a polar solvent system with high polymerization rate and conversion rate, the polymerization reaction is easy to control and the turbidity removal effectof the product is remarkable.

Owner:ZHEJIANG UNIV

Preparation method of methyl methacrylate-styrene copolymer

The invention relates to a preparation method of a methyl methacrylate-styrene copolymer. Firstly, 40-100 parts of main monomer methyl methacrylate, 5-60 parts of comonomer styrene, 10*10<-4>-150*10<-4> part of initiators and 0.1-0.5 part of chain transfer agents are taken and fully stirred till mixtures are evenly mixed, the mixtures are added into a reactor provided with a backflow condensation device, then oil-bath heating and temperature raising are performed, the reaction temperature is controlled between 90 DEG C and 150 DEG C, a reaction lasts for 7-11 h at the rotation speed of 300-500 r / min, a thick copolymer is formed, and finally the methyl methacrylate-styrene copolymer is formed through sedimentation, filtration and drying. According to the preparation method, polymerization is performed in a one-time feeding mode, operation is easy, a polymerization reaction is easy to control, a whole reaction system is stable and controllable, and the prepared methyl methacrylate-styrene copolymer is high in purity and has good light transmittance.

Owner:SUZHOU DOUBLE ELEPHANT OPTICAL MATERIALS CO LTD

Method for preparing starch grafted hyperbranched amide polymer

ActiveCN102229690AThe polymerization reaction is easy to controlObvious turbidity removal effectWater/sewage treatment by flocculation/precipitationChain transferPolymer chemistry

The invention discloses a method for preparing a starch grafted hyperbranched amide polymer. The method is characterized by: preparing a mixed phase and a branching reagent phase, gelatinizing the mixed phase for 0.1-1 hour at a temperature of 25-95 DEG C, then adjusting the temperature to 40-80 DEG C, adding a RAFT chain transfer agent to the gelatinized mixed phase, then adding a initiator to initiate a polymerization; during the polymerization, adding the branching reagent phase to the mixed phase in a dropwise manner within 1-10 hours, and sequentially carrying out the reaction for 0.5-4 hours after completing the adding, finally, carrying out a high-conversion preparation to prepare the starch grafted hyperbranched amide polymer. With the present invention, diene monomers and the chain transfer agent with low ratio are provided for high-polymerization rate and high- conversion preparation of the starch grafted hyperbranched amide polymer in a polar solvent system by using a semi-continuous polymerization process through a reversible addition and fragmentation chain transfer polymerization; the polymerization is easy to be controlled and turbidity removal effect of the productis significant.

Owner:ZHEJIANG UNIV

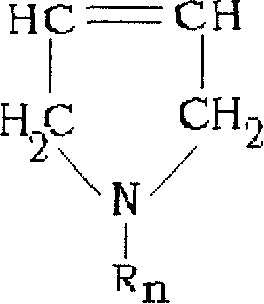

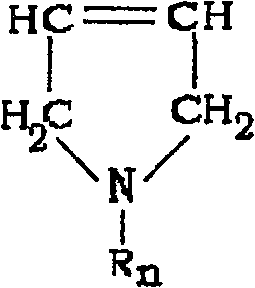

Method for preparing cation type hyperbranched ethylene or acrylamide polymer

The invention discloses a method for preparing a cation type hyperbranched ethylene or acrylamide polymer. The method comprises the following steps of: carrying out reversible addition-fragmentation transfer (RAFT) polymerization; and highly conversing in a polar solvent system by adopting a diene monomer and a chain transferring agent of the RAFT polymerization with low proportion through a semicontinuous operation process to prepare the cation type hyperbranched ethylene or acrylamide polymer. The polymerization process of the method is easily controlled, and molecular weights of a final product and distribution thereof can be controlled.

Owner:ZHEJIANG UNIV

Weather resistant heat resisting flame retardant resin composition and preparation thereof

Owner:PETROCHINA CO LTD

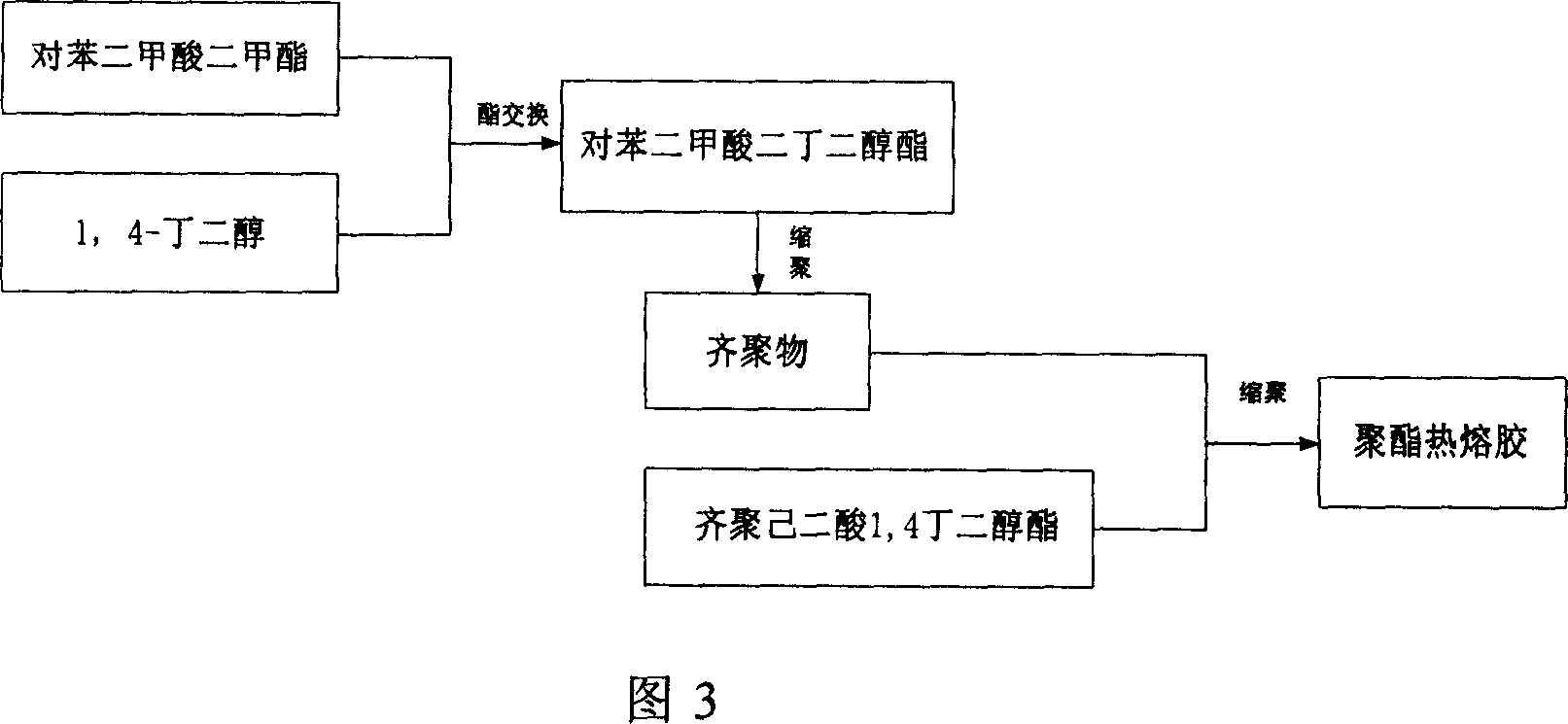

Polyester thermosol and preparation method thereof

The invention provides a polyester hot melt adhesive. It comprises following components: (a) 15- 85 wt% of oligomerization phthalic acid C2- C6 alkylidene ester, with its weight- average molecular weight between 1100- 4400; (b) 15- 85 wt5 of oligomerization C2- C8 alkylidene dicarboxylic acid C2- C6 alkylidene ester with its weight- average molecular weight being 1000- 4000, and the weight- average molecular weight of said polyester hot melt adhesive is 20000- 35000 by taking the total weigth of polyester hot melt adhesive as basis. The method for preparing it comprises following steps: (1) mixing phthalic acid C1- C4 alkyl ester and C2- C6 alkylidene diol according to molar ratio between alcohol and acid being 1.7- 2.0: 1; (2) heating to 250- 260 Deg. C for polycondensation, and getting said phthalic acid C2- C6 alkylidene ester; (3) adding said oligomerization C2- C8 alkylidene dicarboxylic acid C2- C6 alkylidene ester into reaction system, stirring and heating to 240- 260 Deg. C for polycondensation. The polyester hot melt adhesive is characterized by high melting point and good flowability.

Owner:SHANGHAI LIGHT IND RES INST +1

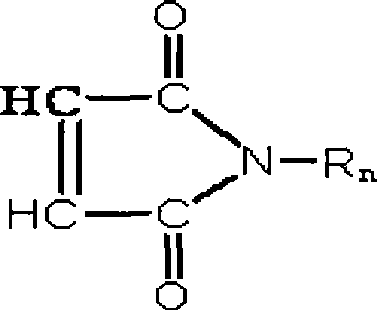

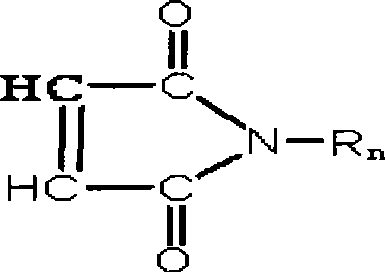

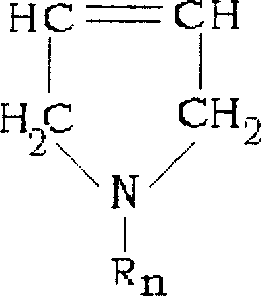

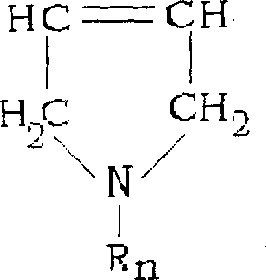

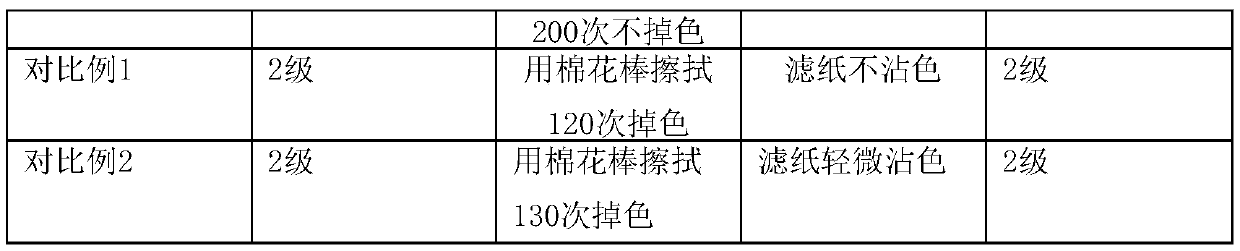

Method for synthesizing latex of heat-resistant resin in maleimide class

This invention discloses a method for synthesizing heat-resistant maleimide resin emulsion. The method comprises four steps: (1) adding emulsifier, part of aryl ethylene monomer, nitrile ethylene monomer and initiator into a reactor equipped with stirrer, and emulsifying to obtain primary emulsion A; (2) adding maleimide monomer, the rest aryl ethylene monomer and nitrile ethylene monomer into a mixing tank, and mixing to obtain homogeneous monomer solution B; (3) adding desalting water, initiator, emulsifier and B into an emulsification tank, and emulsifying to obtain monomer emulsion C; (4) adding C into the reactor, and polymerizing with A.. The obtained heat-resistant maleimide resin emulsion has good appearance, uniform composition and structure, good heat resistance, and high yield. The obtained heat-resistant maleimide resin emulsion can be used for modifying such materials as ABS, PC and PBT, and can also be used lonely for producing heat-resistant components of automobiles and home appliances.

Owner:PETROCHINA CO LTD

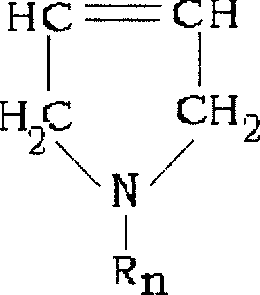

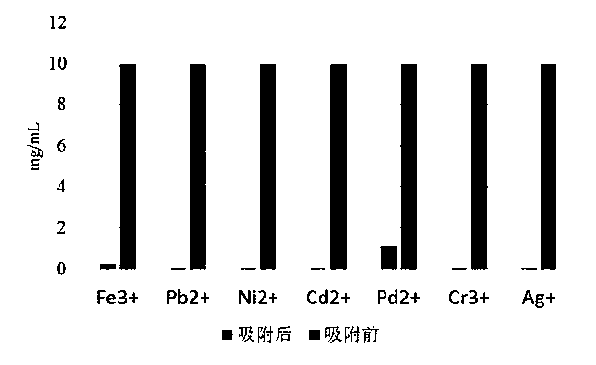

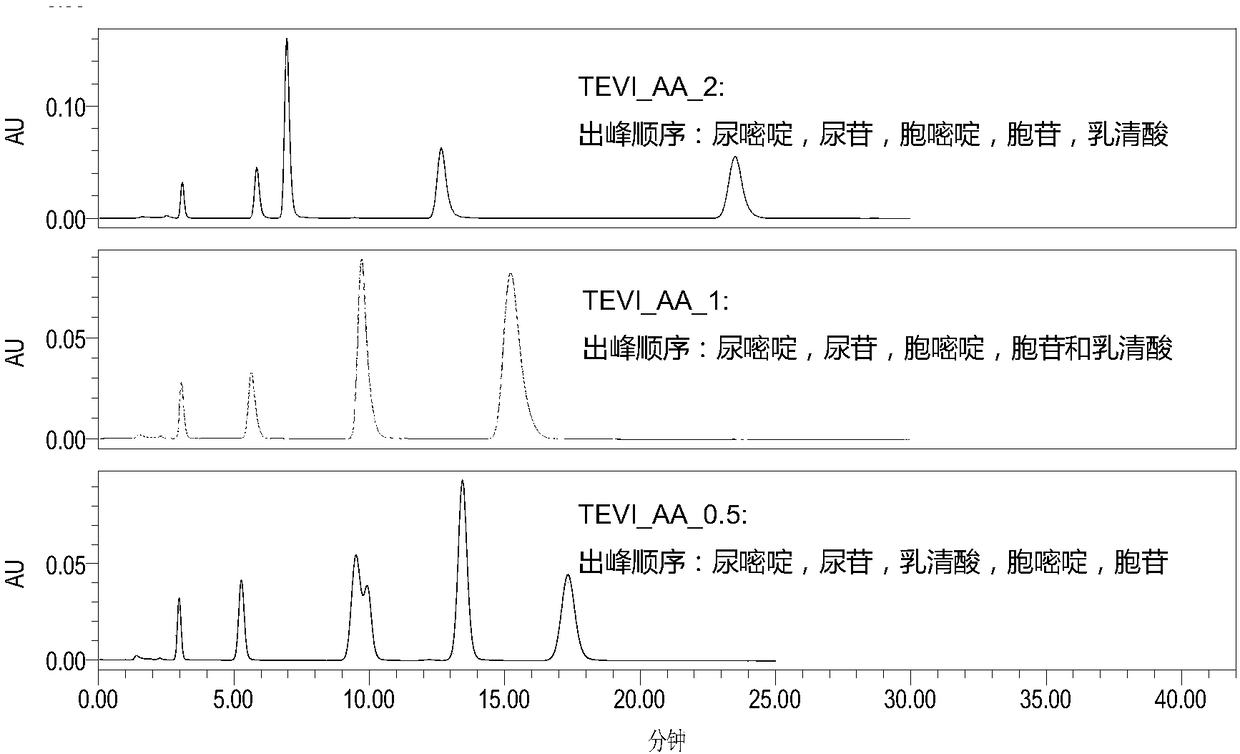

Zwitterionic polymer stationary phase, and preparation and application thereof

InactiveCN108144594AMild reaction conditionsUniform bonding densityIon-exchange process apparatusOther chemical processesIonSide chain

The invention relates to a stationary phase of liquid chromatography. A zwitterionic polymer stationary phase is characterized by being constructed through a manner of anion-cation copolymerization. The zwitterionic polymer stationary phase has a structural formula which is described in the description. In the structural formula, Silica is silica gel; n or m is equal to an integer of 1 to 100; R1is one selected from the group consisting of H or CH3; -R2 is a side chain with a cation radical; and -R3 is a side chain with an anion radical. The zwitterionic polymer stationary phase is prepared by using a controllable anion-cation free radical copolymerization reaction. The method has the following advantages: the rate of the polymerization reaction is controlled through an RAFT reagent in the process of polymerization; reaction conditions are mild; and a polymer stationary phase prepared by using the method provided by the invention has controllable molecular weight, narrow distributionrange and uniform bonding density. The zwitterionic polymer stationary phase provided by the invention can be used as a separation material, and is widely applied to the fields of hydrophilic interaction chromatography, glycopeptide enrichment, heavy metal adsorption, etc.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hyperbranched polymer and preparation method thereof, and application of hyperbranched polymer in preparation of drilling fluid

InactiveCN111171224AImprove temperature resistanceStrong filter loss reduction abilityDrilling compositionBenzoic acidPolymer science

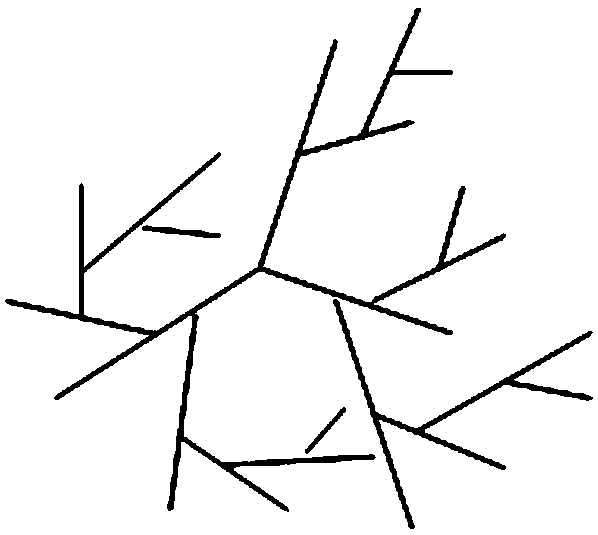

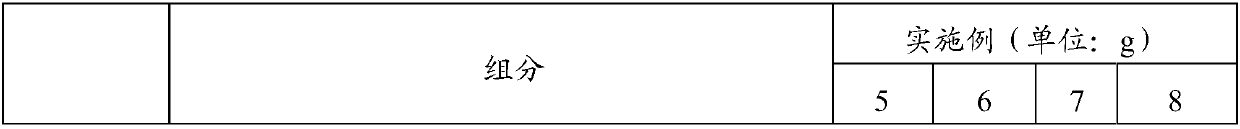

The invention provides a hyperbranched polymer and a preparation method thereof, and applications of the hyperbranched polymer in preparation of a drilling fluid. The preparation method comprises thefollowing steps: mixing an organic acid monomer, acrylamide, N,N-methylene bisacrylamide and a chain transfer agent, and carrying out a copolymerization reaction in water under the action of a pH regulator and an initiator to obtain a hyperbranched polymer with a random hyperbranched structure, wherein the organic acid monomer is 2-acrylamido-2-methylpropanesulfonic acid and / or 2-acryloyloxy-2-methylpropanesulfonic acid, the chain transfer agent is 4-cyanovaleric acid dithiobenzoate and / or (3-phenylmethylmercaptothiocarbonyl sulfide) propionic acid, and the mass ratio of the organic acid monomer to the acrylamide to the N,N-methylene bisacrylamide to the chain transfer agent is (24-66):(34-76):(0.1-5):(0.21-7). The hyperbranched polymer is good in temperature resistance, high in filtrate loss reduction capacity and beneficial to application in drilling fluid.

Owner:中石化石油工程技术服务有限公司 +2

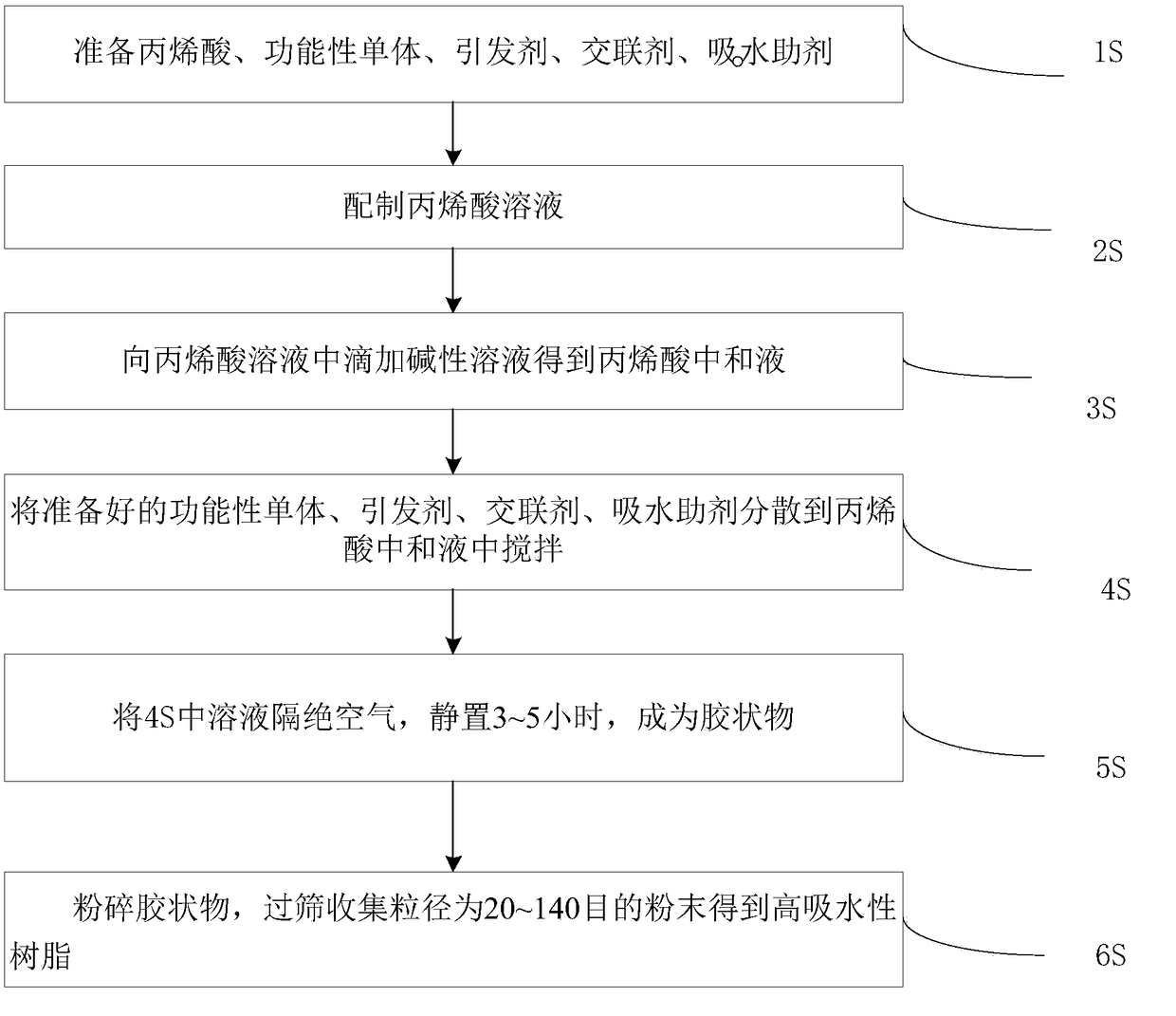

Preparation method of super absorbent resin

The invention discloses a preparation method of a super absorbent resin. The preparation method of the super absorbent resin comprises (1) preparing acrylic acid, functional monomers, initiator, crosslinking agent and water-absorbent auxiliaries; (2) dispersing, by weight part, 35-85 parts of the acrylic acid into 20-40 parts of deionized water to obtain an acrylic acid solution; (3) dropwise adding alkaline solution into the acrylic acid solution to obtain a neutralized acrylic acid solution with a degree of neutralization of 30-85%; (4) sequentially dispersing the functional monomers, the initiator, the crosslinking agent and the water absorbent auxiliaries into the neutralized acrylic acid solution, and stirring the mixture for 5-20 minutes; (5) transferring the solution obtained in thestep (4) in an air-insolated mode to a container for standing for 3-5 hours to obtain a jelly, during which the temperature for standing is 50-90 DEG C; (6) drying and cracking the jelly obtained inthe step (5), screening out 20-140-mesh powder to obtain the super absorbent resin.

Owner:ANHUI FURUIXUE CHEM SCI & TECH INC

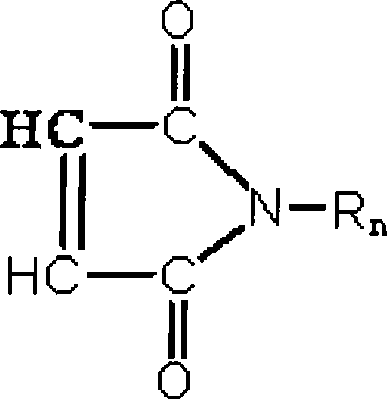

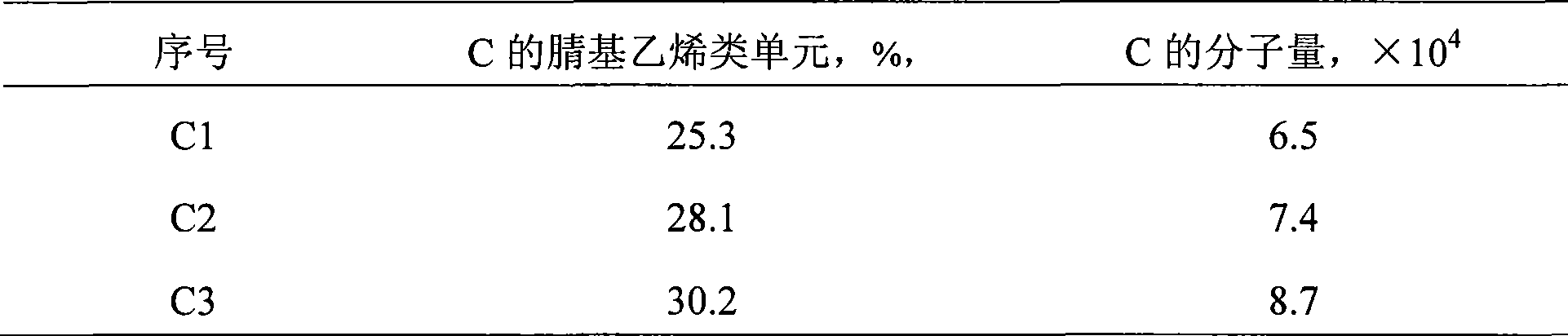

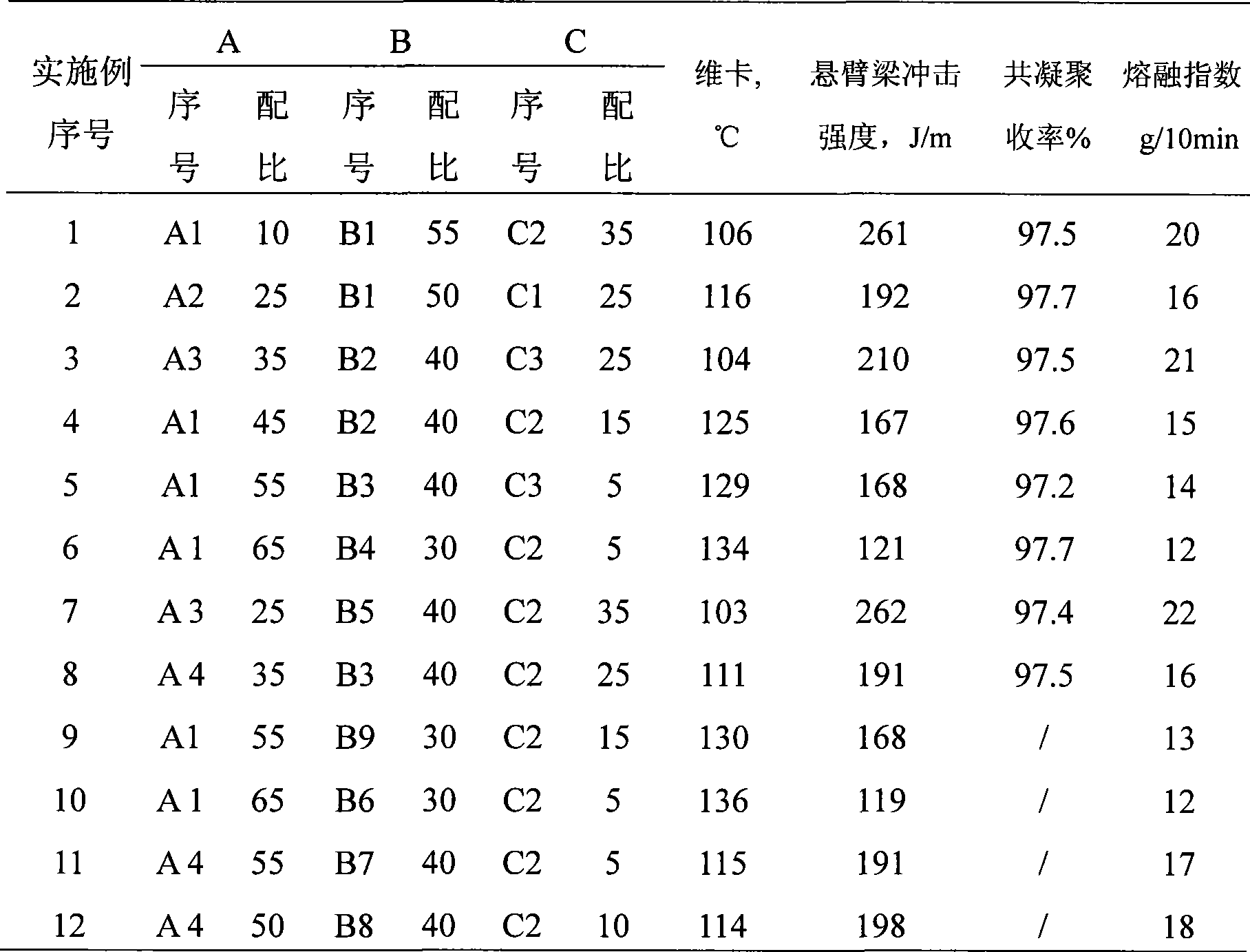

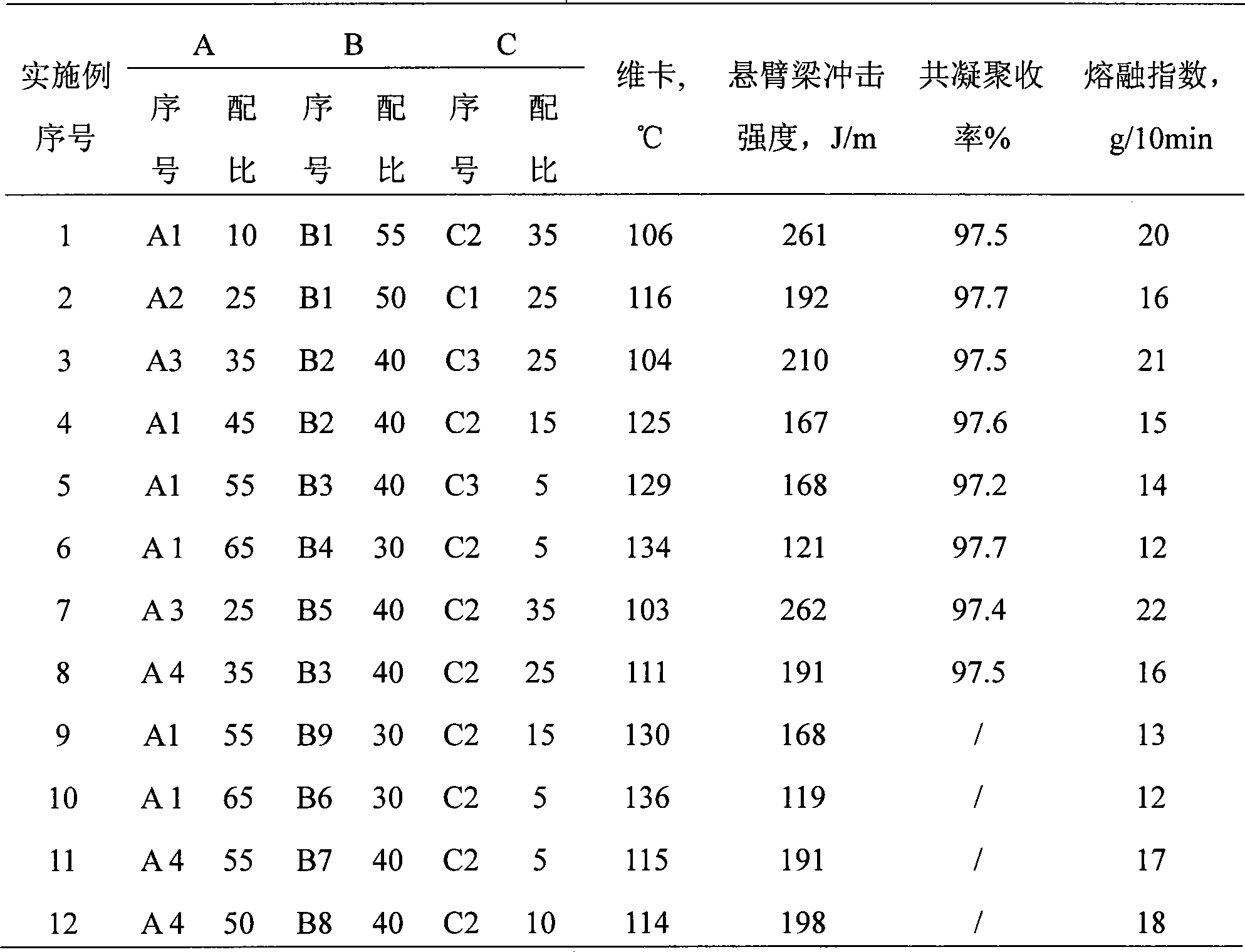

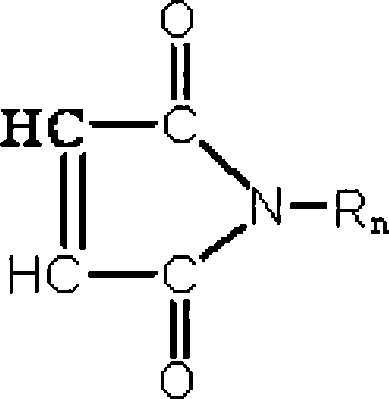

Maleimide heat resisting composition and preparation

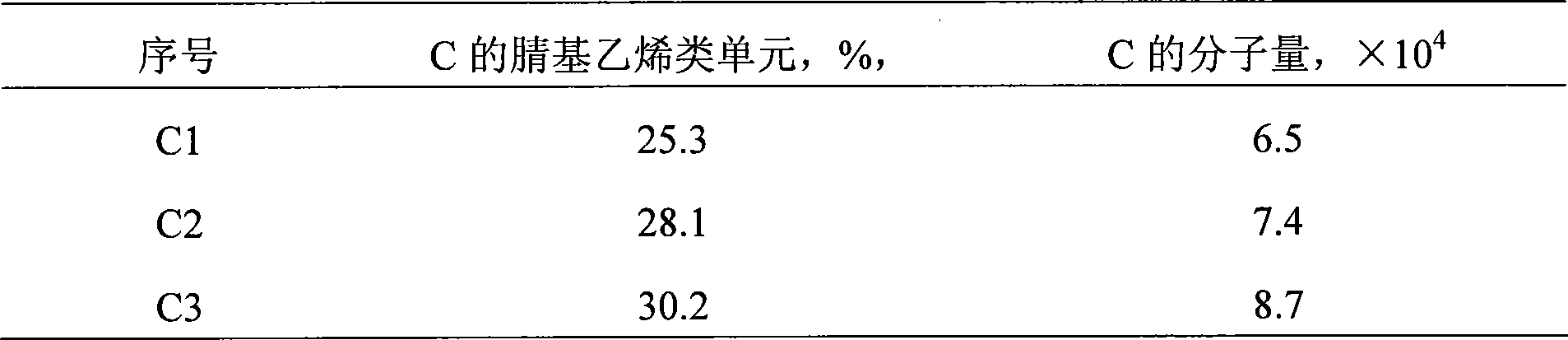

The invention relates to a maleimide heat-resistant resin composition and a preparation method thereof. The resin composition comprises 10-65 parts of maleimide heat-resistant resin, 30-55 parts of a graft polymer of a conjugated diene rubber graft aryl ethylene unit and a nitrile vinyl unit and 5-35 parts of a binary copolymer of aryl ethylene monomers and nitrile vinyl monomers. The maleimide heat-resistant resin composition prepared by the method has the advantages of nice appearance and high heat resistance, and the resin composition is a heat-resistant material with excellent properties. The prepared heat-resistant resin can be widely used in heat resistance and modification of such materials as ABS, PC, PBT and the like. As a material with excellent heat-resistant property, the resin composition can be used alone for preparing high heat-resistant parts of automobiles and household electrical appliances.

Owner:PETROCHINA CO LTD

Method for preparing high molecular weight modified polymethyl methacrylate

The invention relates to a method for preparing high molecular weight modified polymethyl methacrylate. The method includes the steps that firstly, the raw materials of 80-100 parts of monomer methyl methacrylate, 5-30 parts of copolymerization modified monomer, 10*10-4-150*10-4 parts of initiator and 0.1-0.5 part of chain transfer agent are taken and fully stirred so that the raw materials can be mixed evenly; the mixture is put into a reactor provided with a backflow condensing device, oil bath heating and temperature rising are conducted, the reaction temperature is controlled to range from 80 DEG C to 150 DEG C, a stirring reaction is conducted for 6-10 h under the rotating speed of 300-500 r / min, a viscous copolymerization product is formed, and finally the modified polymethyl methacrylate is prepared after aftertreatment. According to the method, polymerization is conducted in a one-time feeding mode, operation is simple, the polymerization reaction is easy to control, the polymerization rate is high, and the prepared polymer has high molecular weight.

Owner:SUZHOU DOUBLE ELEPHANT OPTICAL MATERIALS CO LTD

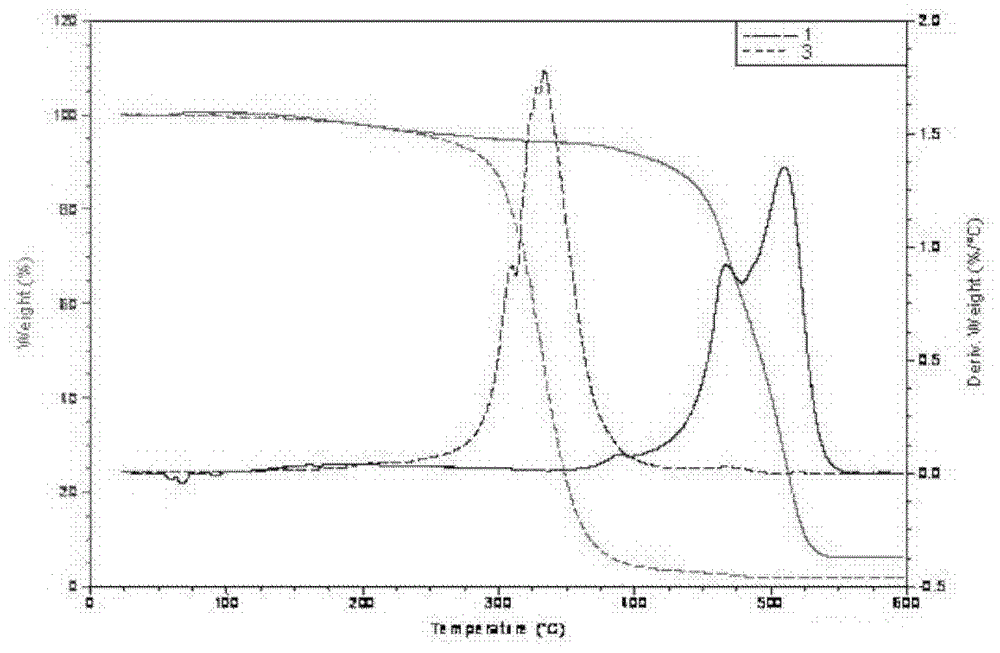

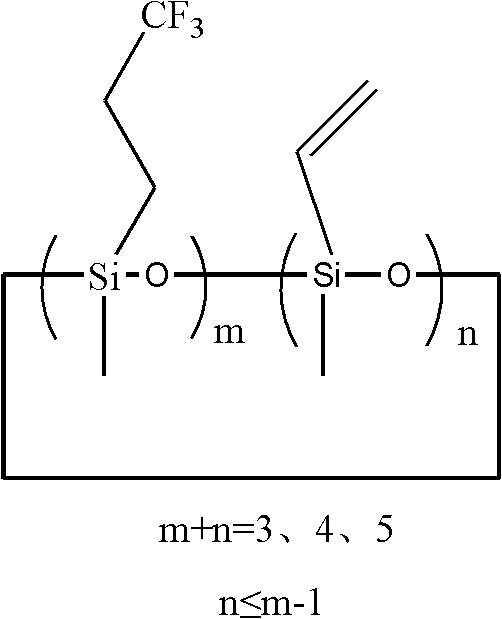

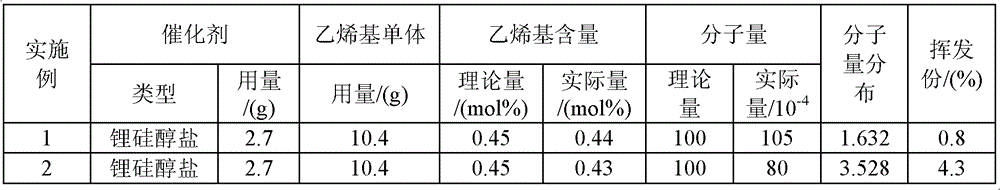

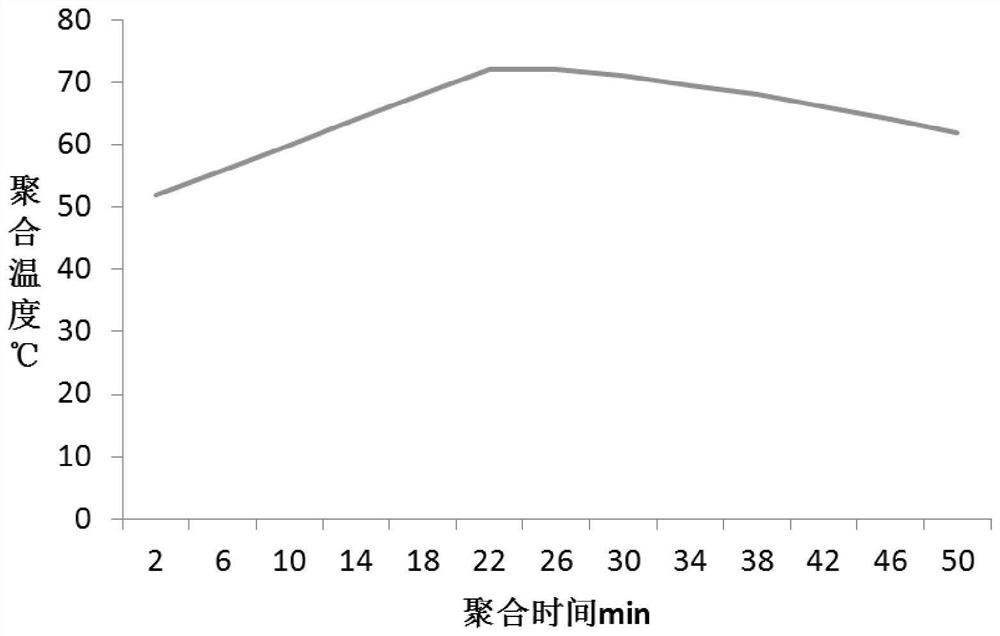

Preparation method of raw fluorinated silicone rubber with high molecular weight

The invention relates to a preparation method of raw fluorinated silicone rubber with a high molecular weight. The preparation method comprises the following steps: adding D3F in a polymerization reaction kettle for dehydration; after dehydration, and then adding fluorine-containing methyl-vinyl-cyclosiloxan and a silicone alcohol lithium salt catalyst; and continuously introducing nitrogen at normal pressure and stirring for polymerization reaction so as to prepare the raw rubber, wherein the polymerization temperature is 110-150 DEG C, the polymerization time is 0.5-3 hours, and the stirring speed is controlled at 1-50r / min. In the method, the fluorine-containing methyl-vinyl-cyclosiloxan with a high ring opening rate is used, thereby solving the problem that vinyl is not distributed on the main chain of the polymer; and the non-balanced silicone alcohol lithium salt is used as a catalytic system and a simple polymerization process and equipment are adopted, thereby solving the heat transfer and mass transfer problems in the polymerization process. Thus, the raw fluorinated silicone rubber with the high molecular weight and high temperature stability is prepared, is more suitable for industrial amplification production, can be widely applied to the environments in the fields of aviation and aerospace, nuclear industry, electronic communication, chemical engineering, medicine, ship and the like, and has good economic benefits and popularization value.

Owner:SHANDONG UNIV

Heat resisting resin composition and preparation thereof

The invention relates to a heat-resistant resin composition and a preparation method thereof. The resin composition comprises the following: 10 to 65 portions of maleimide heat-resistant resin, 30 to 55 portions of graft polymer of conjugated diene rubber grafted aryl ethylene unit body and nitrile vinyl unit, and 5 to 35 portions of biopolymer of aryl ethylene monomer and nitrile vinyl monomer. The heat-resistant resin composition prepared by the method for preparing the maleimide heat-resistant resin composition has the advantages of good appearance and high heat resistance, and is a heat-resistant material with good performance. The prepared heat-resistant resin can be widely used for heat-resistant modification of materials, such as ABS, PC, PBT and the like. As a material with excellent heat-resistant performancs, the resin composition can be independently used, and can also be used for preparing high heat-resistant parts of automobiles and home appliances.

Owner:PETROCHINA CO LTD

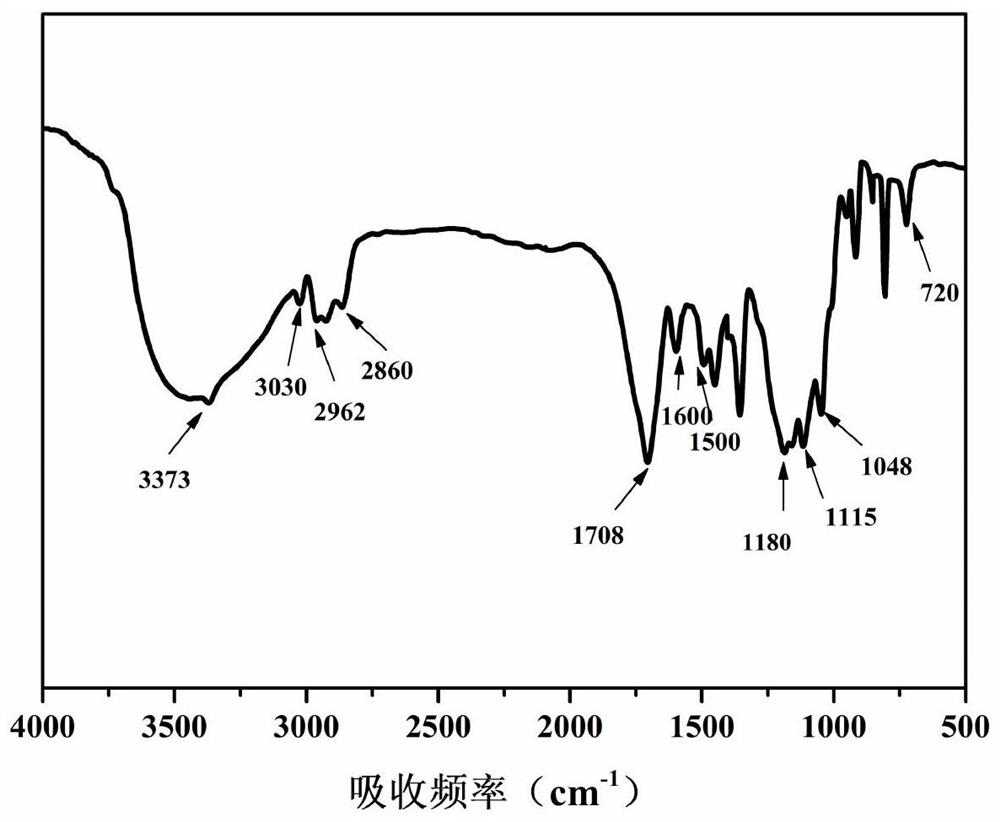

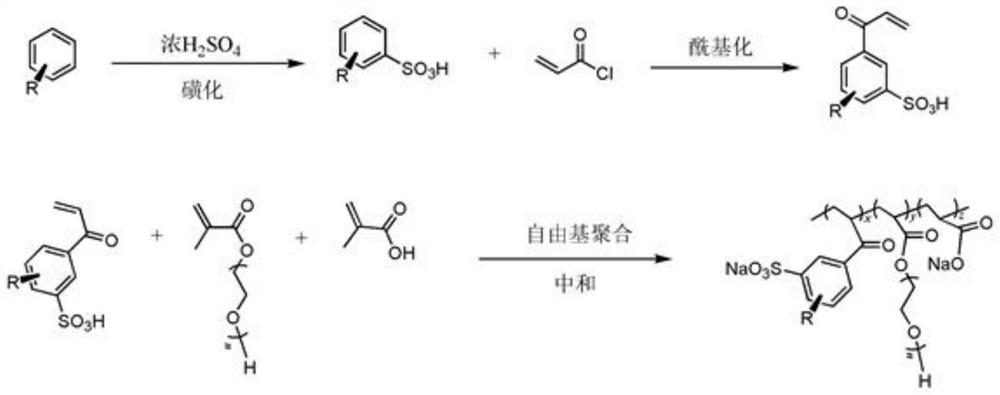

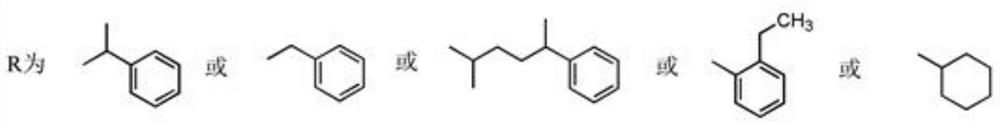

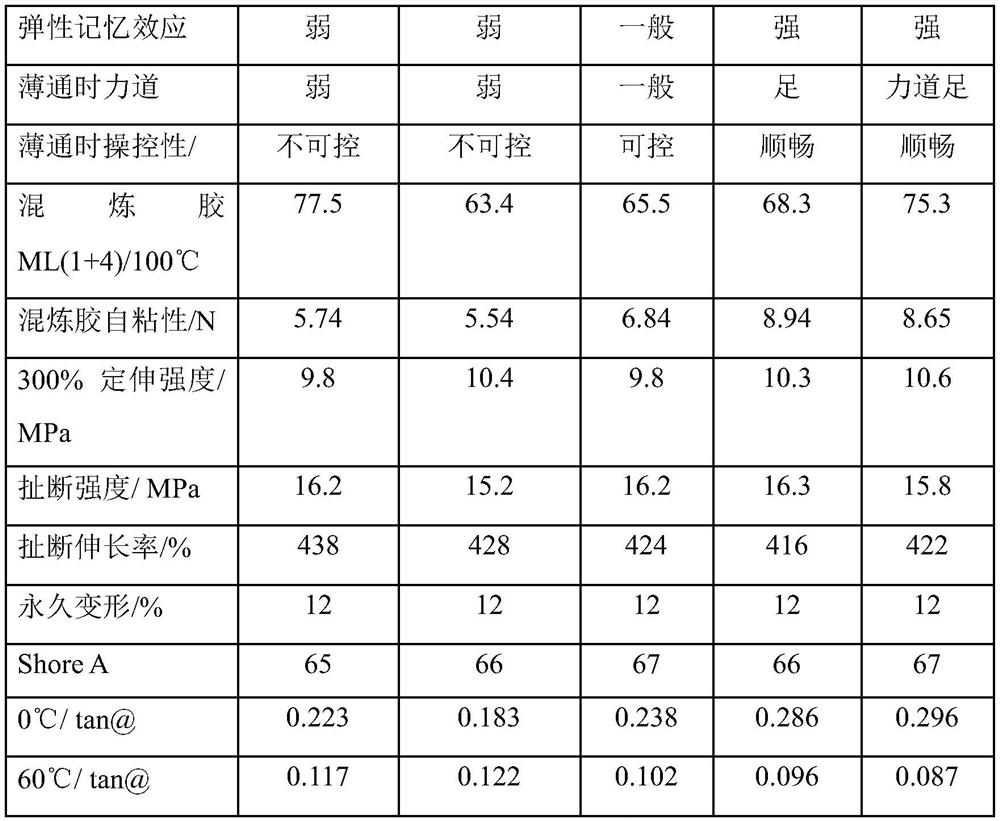

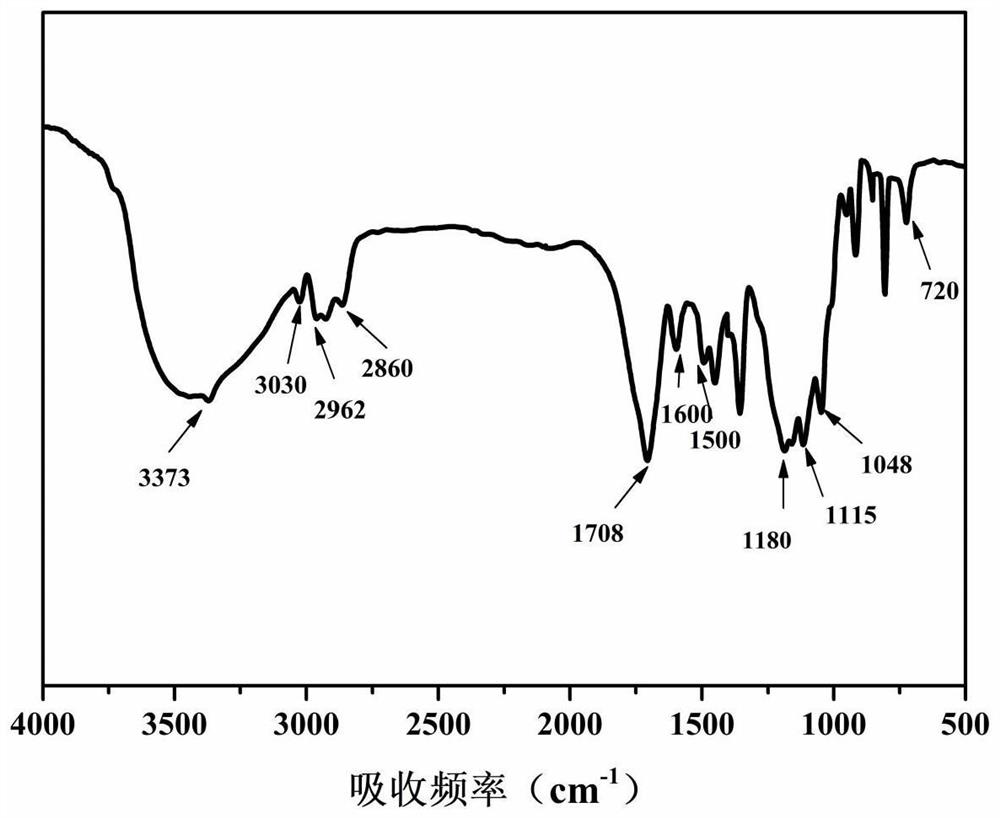

Method for preparing polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues

ActiveCN113698546AImprove workabilityHigh water reduction rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsMolecular sieveCarbon nanotube

The invention relates to a method for preparing a polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues. The polyether polycarboxylic acid type high-efficiency water reducing agent is prepared by free radical polymerization of arone olefin, a double-bond-containing macromonomer and a micromolecular monomer, and the arone olefin is prepared by catalytic acylation of poly-ethylbenzene sulfonic acid and unsaturated acylate by using a bifunctional molecular sieve encapsulated catalyst. The bifunctional molecular sieve encapsulated catalyst is prepared by one-step hydrothermal reaction of sodium metaaluminate, sodium hydroxide, modified silicon dioxide, N,N,N-trimethyl-1-amantadine, carbon nanotubes and (2,2'-bipyridine) nickel diiodide. The polyethylbenzene sulfonic acid is prepared by sulfonating the high-boiling residues at the bottom of a polyethylbenzene tower. According to the method, the polyethylbenzene tower bottom high-boiling residues serve as raw materials, polyether polycarboxylic acid type high-efficiency water reducing agent molecules are prepared through the steps of sulfonation, acylation, free radical polymerization and the like, and the polyether polycarboxylic acid type high-efficiency water reducing agent is practically applied to the building field and has important significance in resourceful treatment of the ethylbenzene tower bottom high-boiling residues.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing halogen substituent maleimide heat-proof flame-proof resin emulsion

The present invention is a preparation method for a halogen substitute maleimide Imide-like anti-heat resin emulsion: a reactor is added with emulsifier, some aryl vinyl monomer, cyano-ethylene monomer, and oil-soluble thermal decomposition initiator and other agents for emulsification so as to generate primary emulsion (a); the remained maleimide monomer, aryl vinyl monomer, cyano-ethylene monomer, and oil-soluble thermal decomposition initiator and other agents are added into a mixing trough so as to generate homogeneous monomer mixed liquid(b); the emulsifier and (b) are added into the emulsifier and are stirred for emulsion so as to generate monomer emulsion (c); the monomer emulsion (c) is added into the reactor to mix with (a) for polymerization reaction which generates heat-resistant polymer resin emulsion (d). The anti-heat resin emulsion obtained by the present invention has the advantages of good appearance, even composition and structure, high heat-resistant effectiveness, high fire-retardant and polymerization efficiency and so on. The anti-heat flame-retardant resin emulsion can be widely used in the improvement of anti-heat and flame-retardant effectiveness of ABS, PC, PBT and other materials. When used alone, the anti-heat flame-retardant resin emulsion can also be used in the anti-heat and flame-retardant components of automobiles and domestic appliances.

Owner:PETROCHINA CO LTD

Method for synthesizing latex of heatresistant resin in maleimide class

ActiveCN1872887AShorten the production cycleMake up for the shortcomings of low utilizationEmulsionHeat resistance

This invention discloses a method for synthesizing heat-resistant maleimide resin emulsion. The method comprises: (1) adding the emulsifier, part of arylethylene monomer, part of nitrilethylene monomer and the initiator into a reactor equipped with a stirrer, and emulsifying to obtain a primary emulsion; (2) adding maleimide monomer, the rest nitrilethylene monomer and the rest arylethylene monomer into a mixing tank to form a homogeneous mixed solution of the monomers; (3) adding desalted water, the initiator, the emulsifier and the mixed solution into an emulsator, and emulsifying to obtain a monomer emulsion; (4) adding the emulsion to the reactor, and polymerizing with the primary emulsion to obtain the heat-resistant resin emulsion. The heat-resistant resin emulsion has such advantages as good appearance, uniform composition and structure, good heat resistance and high yield. The heat-resistant resin emulsion can be used for heat-resistant modification of ABS, PC and PBT, and for manufacturing high heat-resistant elements of vehicles and electric appliances.

Owner:PETROCHINA CO LTD

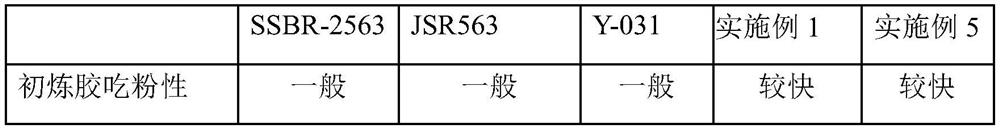

Wide-distribution, high-elasticity and functionalized solution polymerized styrene-butadiene rubber, preparation method and application thereof in tire tread rubber

PendingCN111777729AReduce rolling resistanceImprove wet skid resistanceSpecial tyresRolling resistance optimizationEndcappingPolymer science

The invention discloses a wide-distribution, high-elasticity and functionalized solution polymerized styrene-butadiene rubber, a preparation method and application thereof in tire tread rubber. The preparation method includes: firstly adding divinyl benzene, conjugated diene and an alkyl lithium initiator into an anionic polymerization solution system for polymerization reaction; sequentially adding a diazo reagent and a styrene / butadiene mixed monomer, and carrying out random copolymerization reaction; finally, adding a polar end-capping reagent for end-capping reaction, and conducting hydrolysis and coagulation, thus obtaining the solution polymerized styrene-butadiene rubber (SSBR) with wide molecular weight mass distribution (D is greater than or equal to 1.8), long and short branchedchains, wide molecular fraction and high melt elasticity, wherein functional groups at the tail ends of molecular chains are closed in a head-tail mode, and the end capping rate is larger than 75%. The rubber replaces existing conventional SSBR to be used for tire tread rubber, the processability can be obviously improved, and the rolling resistance of a tire is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues

ActiveCN114752020AImprove workabilityHigh water reduction rateOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsPolymer sciencePtru catalyst

The invention relates to a method for preparing a polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues. The polyether polycarboxylic acid type high-efficiency water reducing agent is prepared by free radical polymerization of arone olefin, a double-bond-containing macromonomer and a micromolecular monomer, and the arone olefin is prepared by catalytic acylation of poly-ethylbenzene sulfonic acid and unsaturated acylate by using a bifunctional molecular sieve encapsulated catalyst. The bifunctional molecular sieve encapsulated catalyst is prepared by one-step hydrothermal reaction of sodium metaaluminate, sodium hydroxide, modified silicon dioxide, N, N, N-trimethyl-1-amantadine, carbon nanotubes and (2, 2 '-bipyridine) nickel diiodide, and the polyethylbenzene sulfonic acid is prepared by sulfonating high-boiling residues at the bottom of a polyethylbenzene tower. According to the method, the polyethylbenzene tower bottom high-boiling residues serve as raw materials, polyether polycarboxylic acid type high-efficiency water reducing agent molecules are prepared through the steps of sulfonation, acylation, free radical polymerization and the like, and the polyether polycarboxylic acid type high-efficiency water reducing agent molecules are practically applied to the building field and have important significance in resourceful treatment of the ethylbenzene tower bottom high-boiling residues.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ti-Ni match as composite catalyst and its application in preparing branch polyethylene from ethylene

InactiveCN1216082CFlow dispersiveUniform particle distributionLow-density polyethylenePolymer science

Owner:SUN YAT SEN UNIV

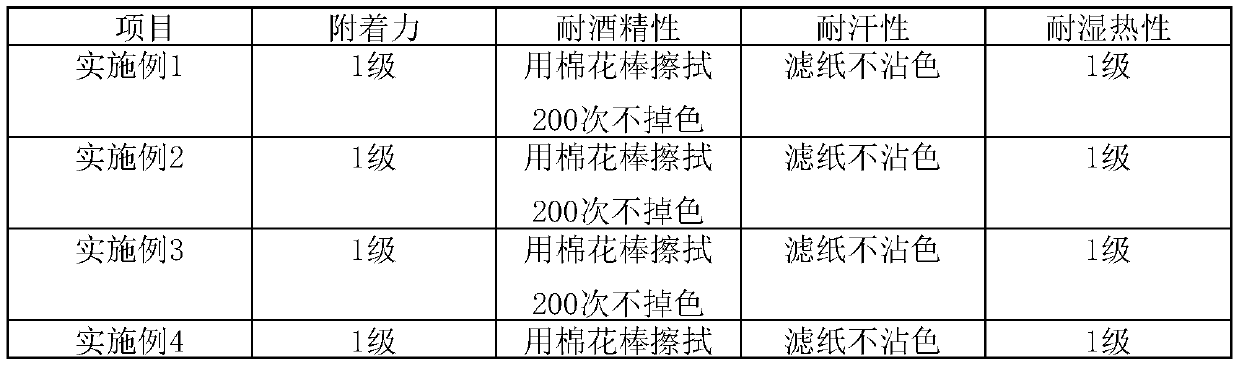

Technology for printing color-variable logo through 3D magnetic printing ink and 3D magnetic printing ink

ActiveCN111016480AEmbodied RecognitionWith anti-counterfeiting functionPattern printingInksScreen printingProcess engineering

The invention relates to the technical field of logo manufacturing of tempered glass, in particular to a technology for printing a color-variable logo through 3D magnetic printing ink. The technologyincludes the following steps that firstly, the tempered glass is taken out, and cleaning and inspecting are conducted on the tempered glass; secondly, the 3D magnetic printing ink is adopted for screen printing of the logo on the tempered glass; and thirdly, the tempered glass on which the 3D magnetic printing ink is printed in a screen printing manner is baked and inspected. By means of the technology for printing the color-variable logo through 3D magnetic printing ink, the 3D magnetic printing ink is used for printing the color-variable logo to the product, the variable-color logo can havea strong 3D visual effect, different color changes can be seen from different angles, the logo can be printed on a tempered glass production film and has good adhesive force, corrosion resistance andwear resistance, the hardness is high, disengagement is not likely to happen, and the service life is long. By means of the technology, operation control is convenient, the production efficiency is high, the production cost is low, the product quality is stable, and industrial mass production is facilitated.

Owner:东莞市嘉逸光电有限公司

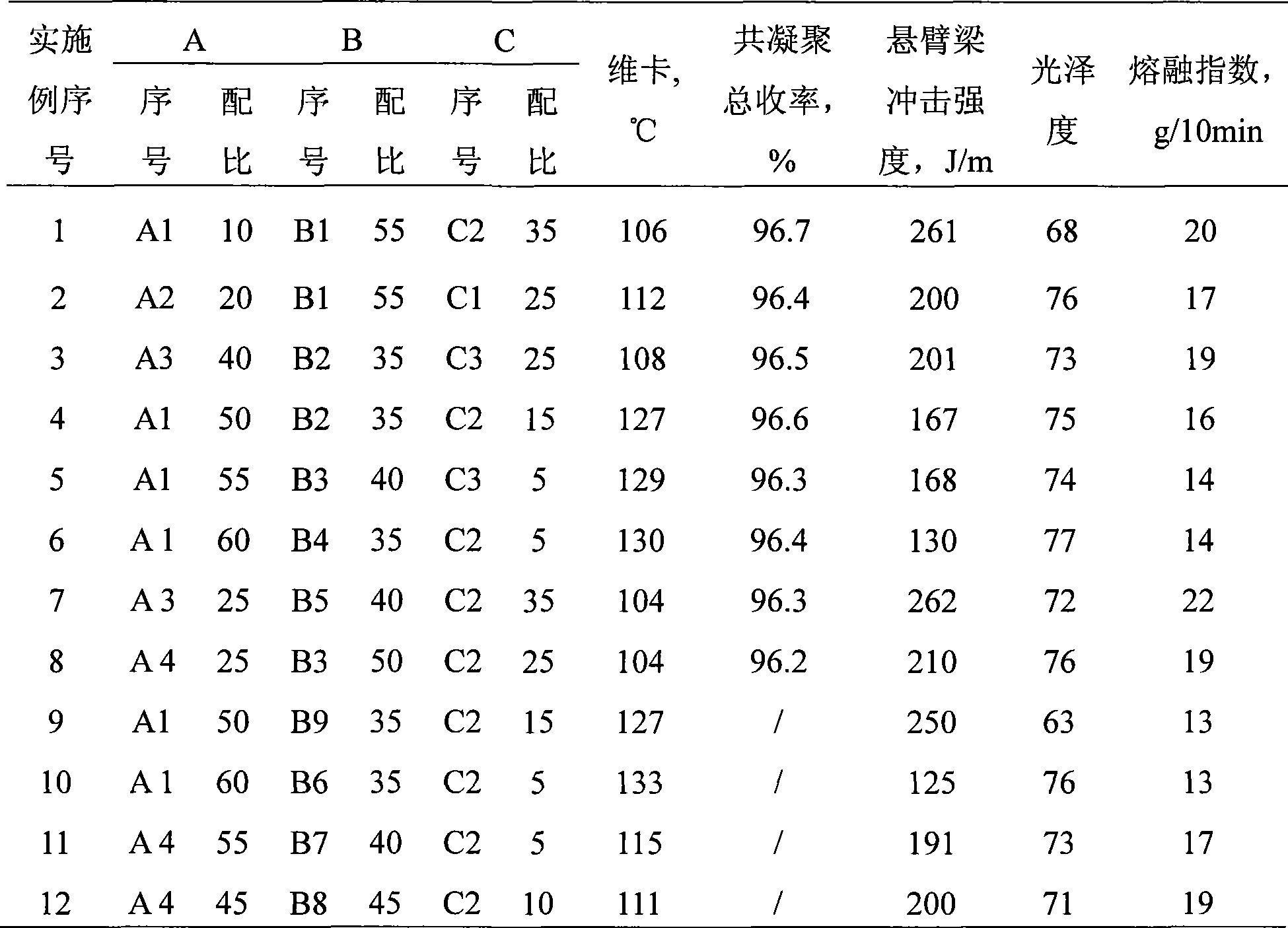

Maleimide heat resisting resin composition with improved glossiness and preparation thereof

The invention provides a maleimide heat-resistant resin composition with improved lustrousness. The heat-resistant resin composition comprises the following raw materials based on 100 mass portions: 10 to 65 portions of maleimide heat-resistant resin, 30 to 55 portions of graft polymer of conjugated diolefine rubber graft aryl vinyl monomer, nitrile grouping vinyl monomer or / and copolymerizable acrylic ester monomer of which copolymerizable acrylic ester monomer accounts for 0 to 10 mass percent, and 5 to 35 portions of biopolymer of aryl ethylene monomer and nitrile vinyl monomer. The heat-resistant composition prepared by a preparation method of the maleimide heat-resistant composition has the advantages of excellent comprehensive performance, attractive appearance, high heat resistance and good lustrousness. The prepared heat-resistant resin can be widely applied in the aspect of heat resistance and modification of ABS, PC, PBT and other materials, can be used as a material with excellent heat-resistant performance, can be independently used, and can be used for preparing high heat-resistant parts of automobiles and household electrical appliances.

Owner:PETROCHINA CO LTD

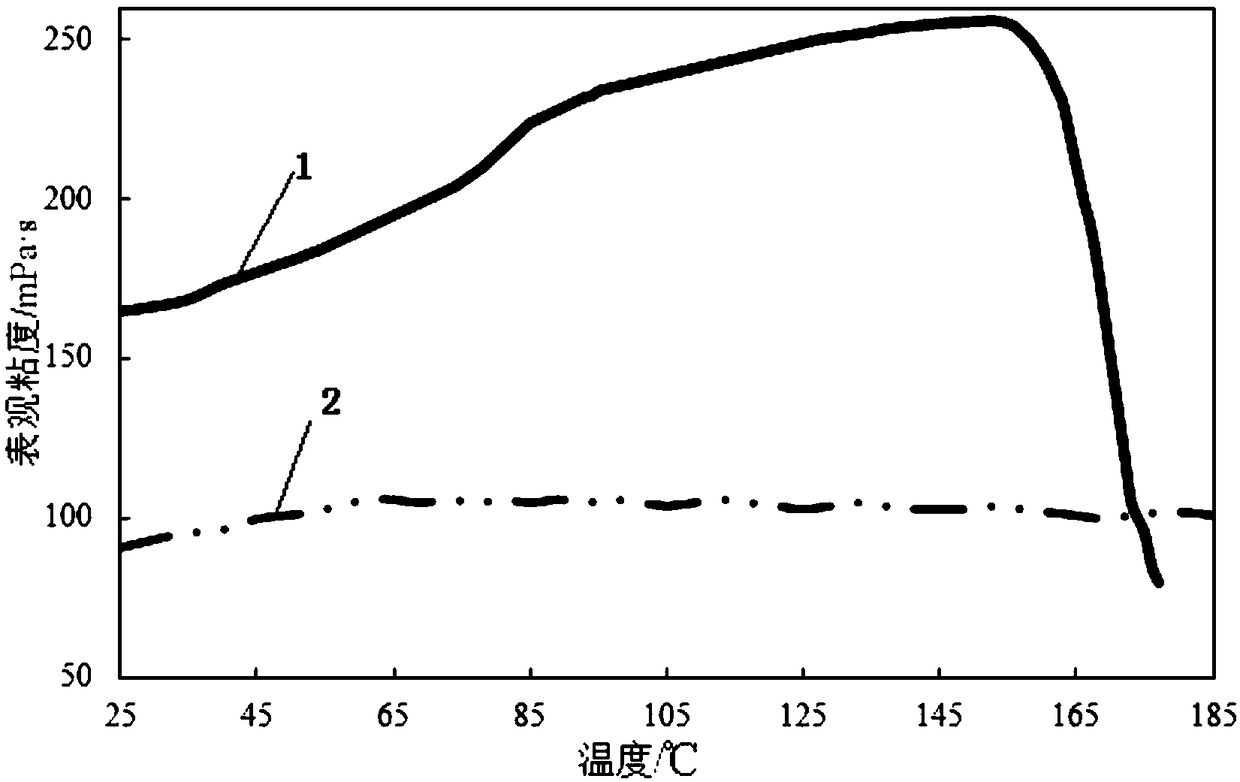

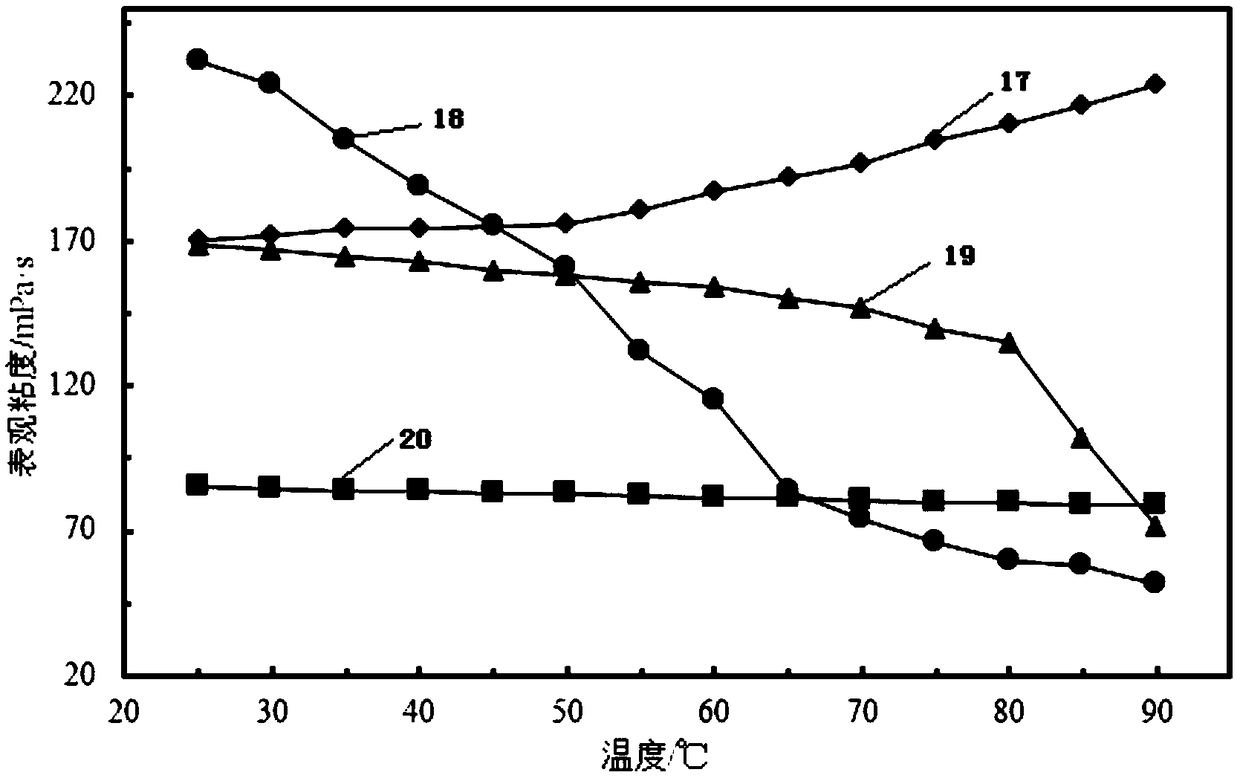

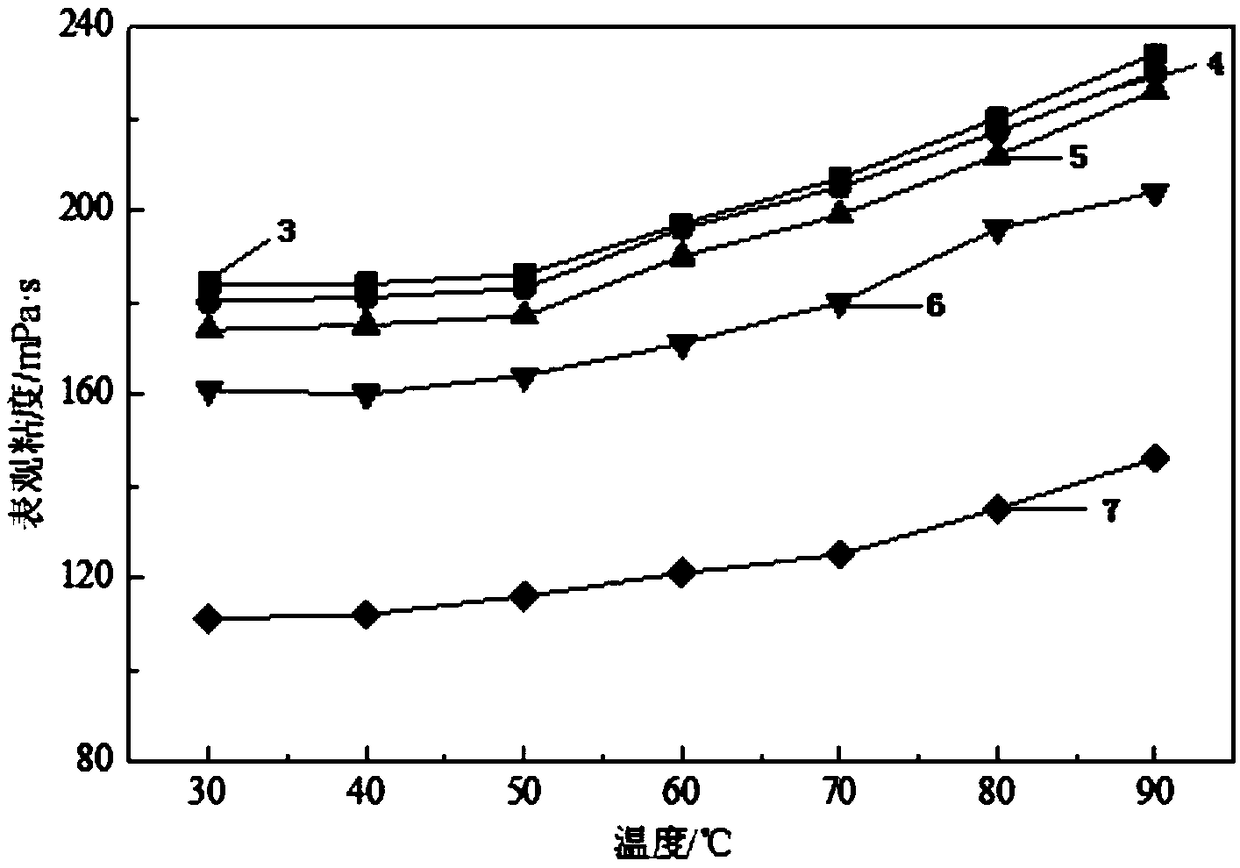

Oil well cement sedimentation stabilizer suitable for oil and gas well cementation, preparation method thereof and cementing slurry

ActiveCN109485788ARheological influenceInitial consistency effectSolid waste managementDrilling compositionWell cementingCement slurry

The invention belongs to the field of petroleum and natural gas well cementation projects and particularly relates to an oil well cement sedimentation stabilizer suitable for oil and gas well cementation, a preparation method thereof and a cementing slurry. The oil well cement sedimentation stabilizer contains structural unit A shown as formula (I), structural unit B shown as formula (II) and structural unit C shown as formula (III). The molar ratio of the structural units A, B and C is x:y:z=1:(0.07-0.22):(0.03-0.11); in the formulas, R1, R2 and R3 are H, or C1-C4 is substituted or non-substituted alkyl group, and m is 15, 17, 19 or 21. The oil well cement sedimentation stabilizer allows zero thickening at low temperature and thickening at high temperature; the problem that the cementingslurry settles and loses stability is effectively solved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Ti-Ni match as composite catalyst and its application in preparing branch polyethylene from ethylene

InactiveCN1363616AFlow dispersiveUniform particle distributionLow-density polyethylenePolymer science

A catalyst for preparing branched polyethylene from ethylene is composed of main catalyst prepared by carrying Ti compoud-Ni compound on the MgCl2 ZnCl2, or SiO2 and the co-catalyst which is composite alkylaluminium (AlEt2Cl-AlR3). It is prepared by dipping reaction.

Owner:SUN YAT SEN UNIV

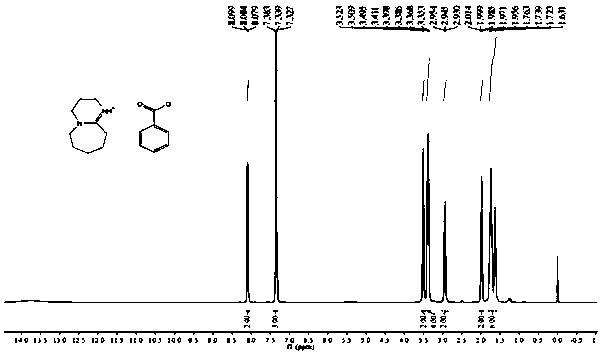

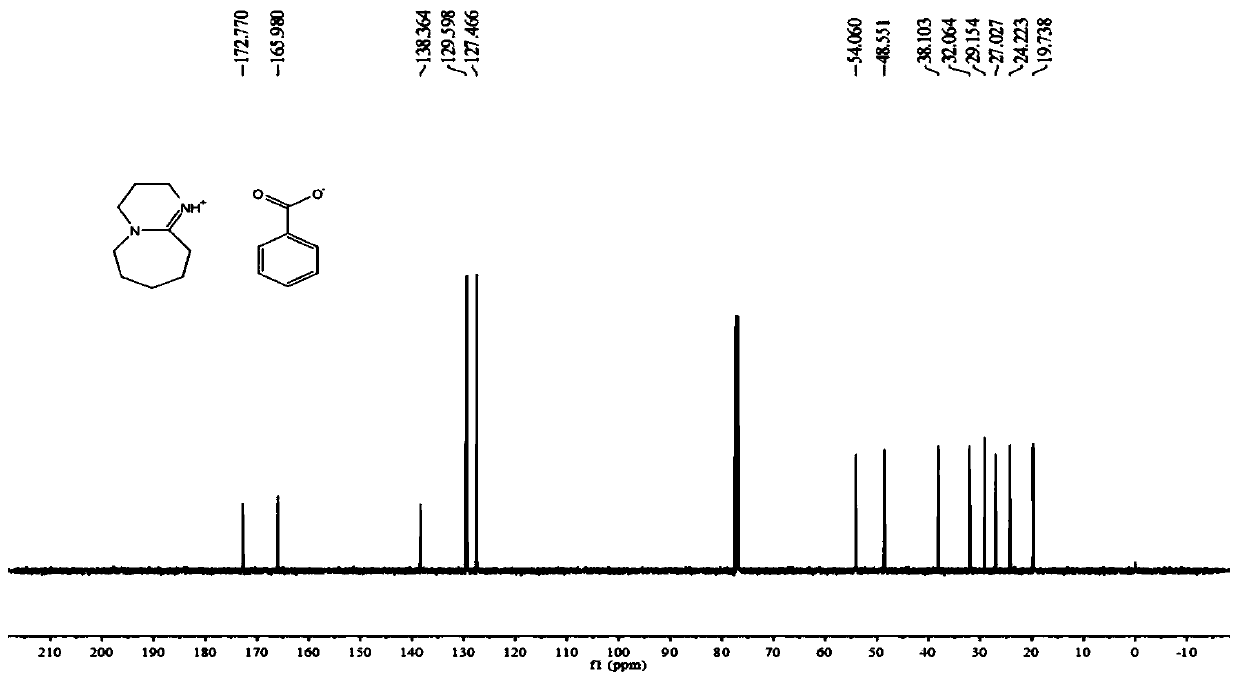

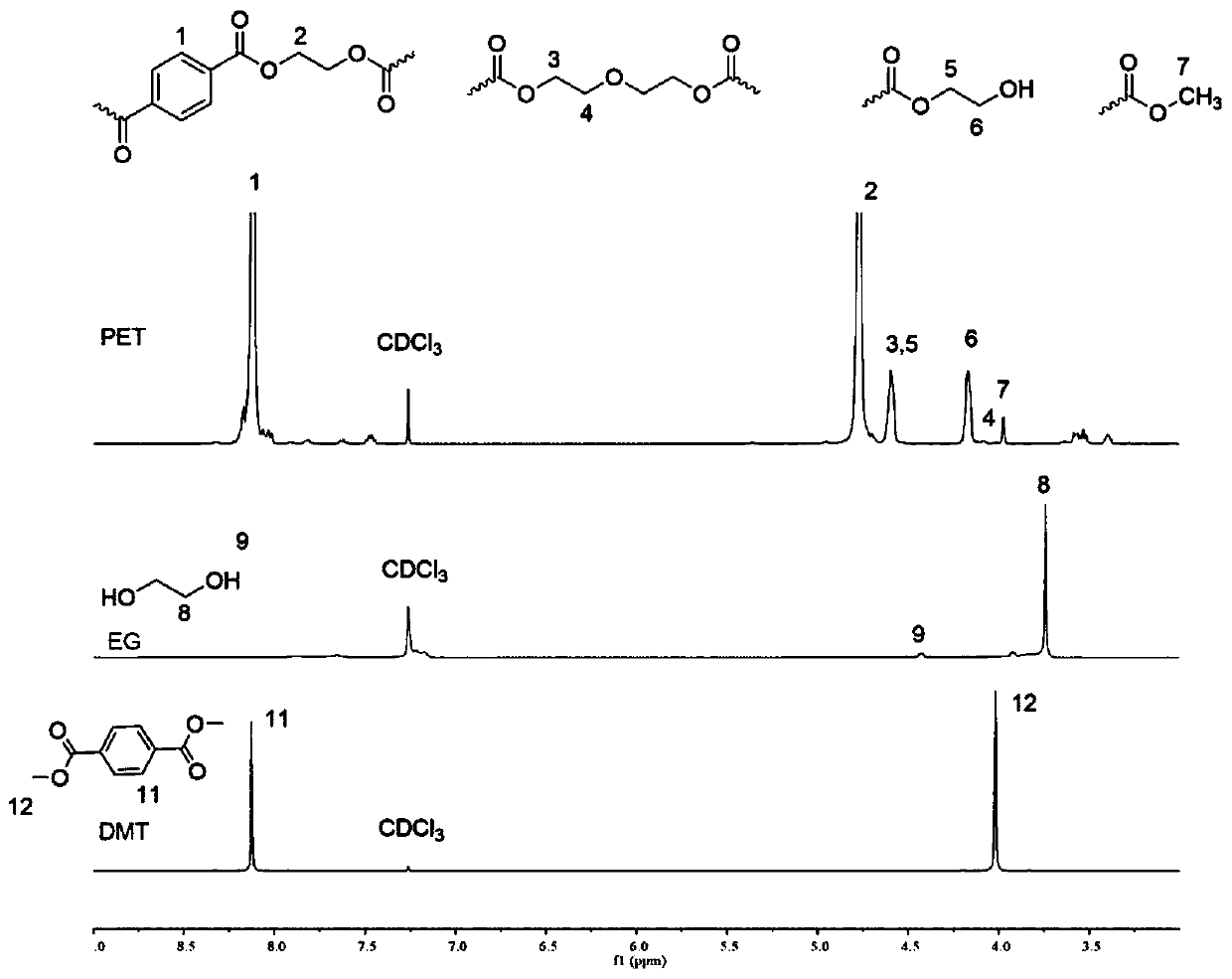

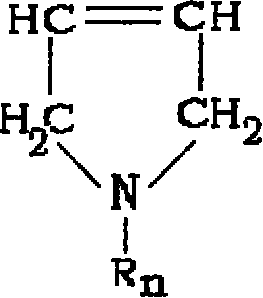

Preparation method of bio-based polyester

The invention belongs to the technical field of organic synthesis, and particularly relates to a preparation method of bio-based polyester. Terephthalic acid and derivatives thereof are synthesized into high-molecular-weight polyester compounds by adopting a two-step method. By adopting the method disclosed by the invention, efficient, mild and controllable polymerization reaction is realized, introduction of any metal in a catalytic polymerization reaction process is completely avoided, a depolymerization reaction of the catalyst in a secondary (or subsequent) process is avoided, polymer molecules with a predetermined structure are constructed, and design and control of the performance of a polymer material are realized.

Owner:NANJING UNIV OF TECH

Method for synthesizing halogen substituent maleimide heat-proof flame-proof resin emulsion

ActiveCN101139422AShorten the production cycleMake up for the shortcomings of low utilizationOrganic chemistryPolymer scienceSynthesis methods

The present invention relates to the synthesis method of a halogen substitute maleimide Imide-like anti-heat flame-retardant resin emulsion. The synthesis process can be divided into four steps. The components and the operating condition of the present invention are: emulsifier, some aryl ethylene monomer, cyano-ethylene monomer, initiator and other agents are added into a reactor for emulsification so as to generate the primary emulsion (a); the halogen substitute maleimide monomer, the remained aryl ethylene monomer and cyano-ethylene monomer are added into a mixing trough to form homogeneous monomer mixture (b); desalination of water, initiator, emulsifier, and (b) are added into a emulsifier for emulsification so as to generate monomer emulsion (c); when (a) is formed,(c) is added into the reactor to mix with (a) for polymerization reaction. The anti-heat flame-retardant resin emulsion obtained by the present invention has the advantages of good appearance, even composition and structure, high heat-resistant effectiveness, high fire-retardant and polymerization efficiency and so on. The anti-heat flame-retardant resin emulsion can be widely used in the improvement of anti-heat and flame-retardant effectiveness of ABS, PC, PBT and other materials. When used alone, the anti-heat flame-retardant resin emulsion can also be used in the anti-heat and flame-retardant components of automobiles and domestic appliances.

Owner:PETROCHINA CO LTD

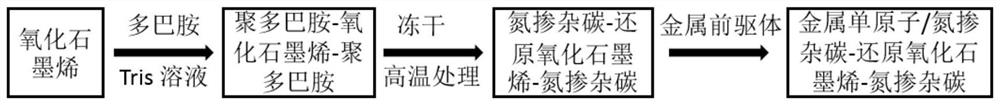

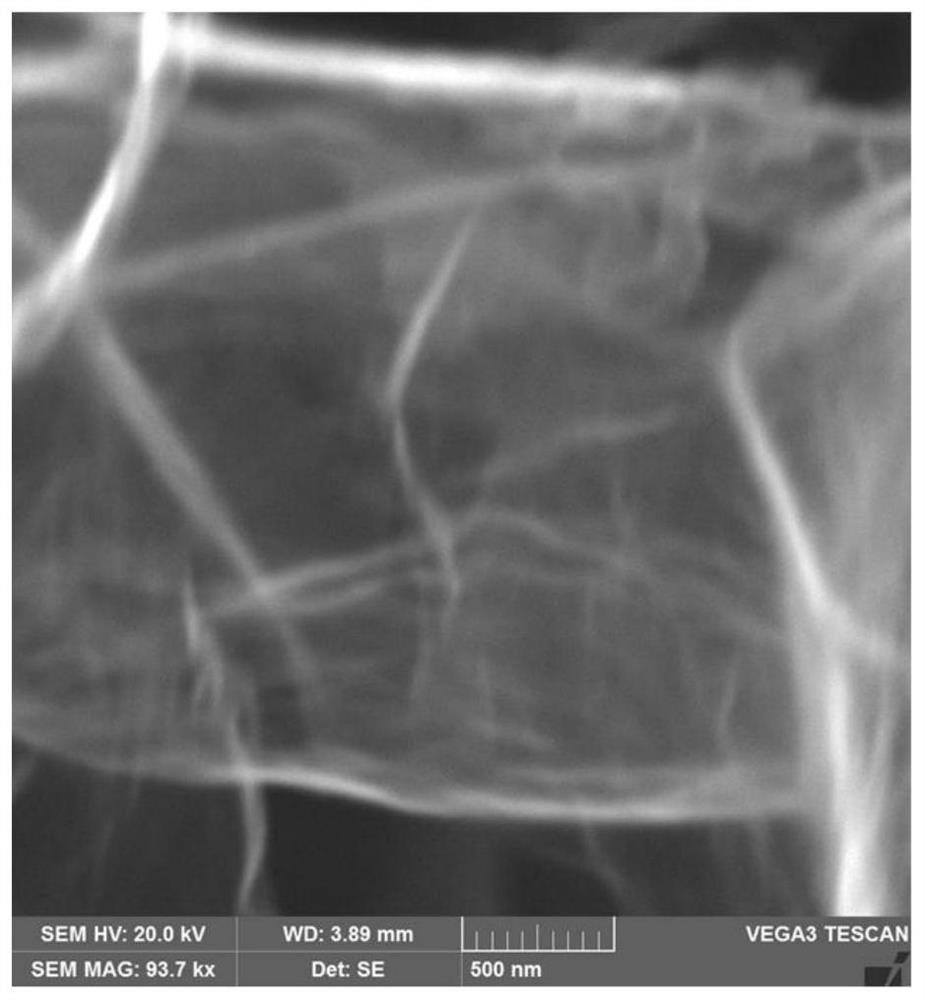

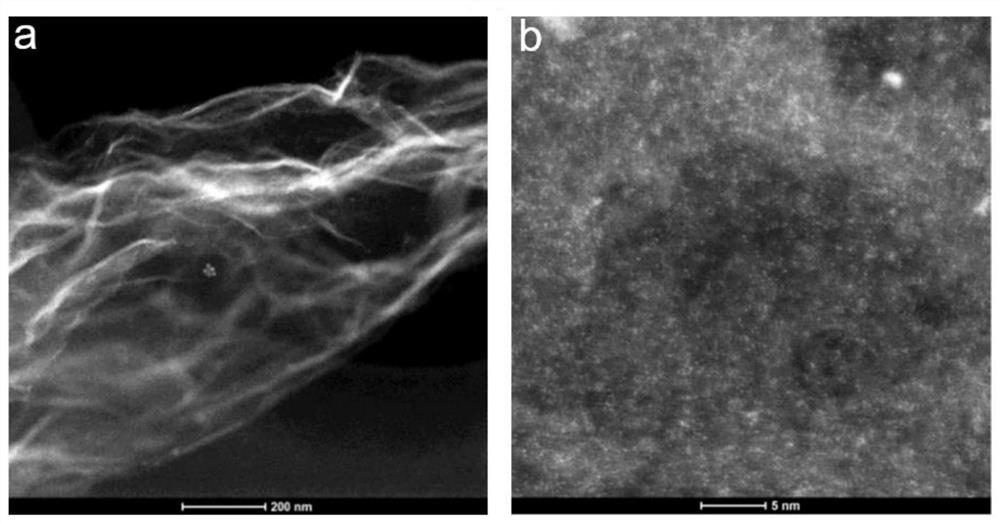

Carbon-based double-confinement interface loaded monatomic catalyst and preparation method thereof

PendingCN111659442AImprove stabilityGood dispersionCatalyst activation/preparationPtru catalystOrganic chemistry

The invention belongs to the technical field of catalysts, and particularly relates to a carbon-based double-confinement interface loaded monatomic catalyst and a preparation method thereof. The preparation method comprises the following steps: synthesizing a PDA-GO-PDA composite material in which graphene oxide (GO) is coated with polydopamine (PDA); synthesizing an NC-RGO-CN double-confinement interface composite material in which reduced graphene oxide (RGO) is coated with nitrogen-doped carbon (NC); and synthesizing the M1 / NC-RGO-CN double-confinement interface monatomic catalyst of the NC-RGO-CN double-confinement interface composite material loaded with the metal monatomic (M1). By improving the whole process flow and the reaction conditions and parameters of each key process step, the dispersity, the catalyst activity and the cycling stability of metal single atoms can be effectively improved.

Owner:ZHUHAI FUDAN INNOVATION INST

Method for preparing halogen substituent maleimide heat-proof flame-proof resin emulsion

The present invention is a preparation method for a halogen substitute maleimide Imide-like anti-heat flame-retardant resin emulsion. The halogen substitute maleimide Imide monomer, aryl vinyl monomer, cyano-ethylene monomer and other initiators are added into a mixing trough, and are mixed and stirred to generate homogeneous monomer mixture (a); emulsifier and other agent are added into a emulsifier, wherein (a) is also added for emulsification so as to generate monomer emulsion (b); desalination water and (b) are added to a reactor for added to the reactor polymerization reaction at the temperature of 60 DEG C to 90 DEG C; then anti-heat flame-retardant resin emulsion (c) is obtained. The anti-heat flame-retardant resin emulsion obtained by the present invention has the advantages of good appearance, even composition and structure, high heat-resistant effectiveness, high fire-retardant and polymerization efficiency and so on. The anti-heat flame-retardant resin emulsion can be widely used in the improvement of anti-heat and flame-retardant effectiveness of ABS, PC, PBT and other materials. When used alone, the anti-heat flame-retardant resin emulsion can also be used in the anti-heat and flame-retardant components of automobiles and domestic appliances.

Owner:PETROCHINA CO LTD

Method for synthesizing halogen substituent maleimide heat-proof flame-proof resin emulsion

ActiveCN100560623CSmooth responseThe polymerization reaction is easy to controlOrganic chemistryPolymer scienceFire retardant

A method for synthesizing a halogen substituent maleimide heat-resistant flame-retardant resin emulsion, which is divided into four parts, and its composition and operating conditions are: adding emulsifier, part of aryl vinyl monomers, nitrile vinyl monomers, initiators, etc., emulsified to form a primary emulsion (a); the halogen substituent maleimide monomers, the rest of the Add the monomer into the mixing tank to form a homogeneous monomer mixture (b); add desalted water, initiator, emulsifier, (b) into the emulsifier for emulsification to form a monomer emulsion (c); (a) form After that, (c) is added to the reactor and mixed with (a) for polymerization. The obtained heat-resistant and flame-retardant resin emulsion has the advantages of good appearance, uniform composition and structure, high heat resistance, flame retardancy, and high yield in the polymerization process, and can be widely used in heat-resistant and flame-retardant materials such as ABS, PC, and PBT. modification. Used alone, it can also be used to prepare highly flame-retardant and heat-resistant parts for automobiles and household appliances.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com