Preparation method of raw fluorinated silicone rubber with high molecular weight

A technology of fluorosilicone rubber and high molecular weight, which is applied in the field of preparation of high molecular weight fluorosilicone rubber raw rubber. It can solve the problems of unstable mass transfer and heat transfer quality, difficult manufacturing, cumbersome process, etc., so as to avoid post-neutralization treatment process, good high temperature stability, and the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

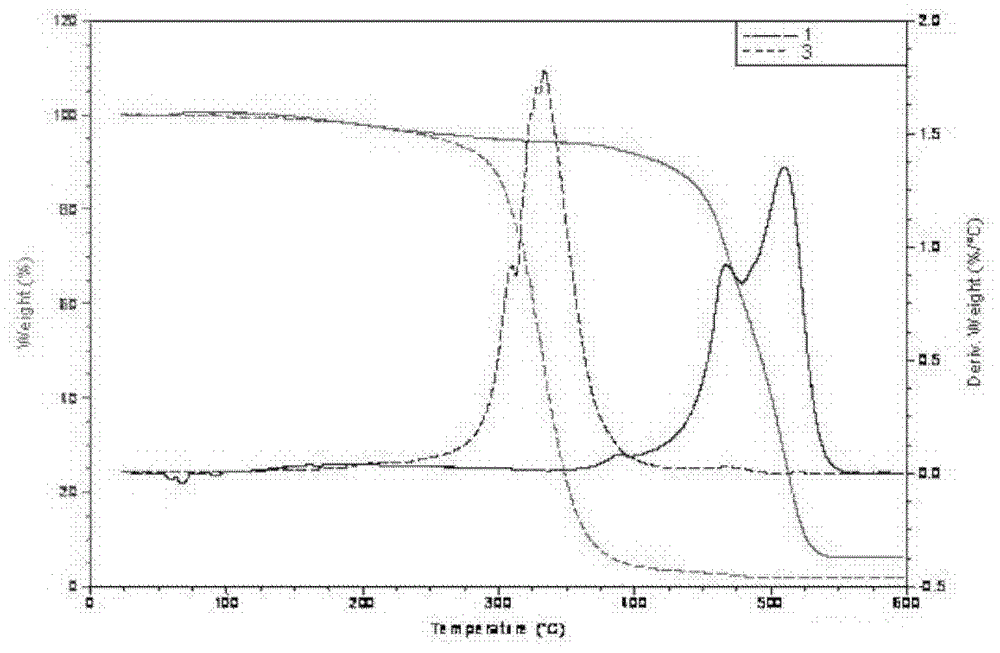

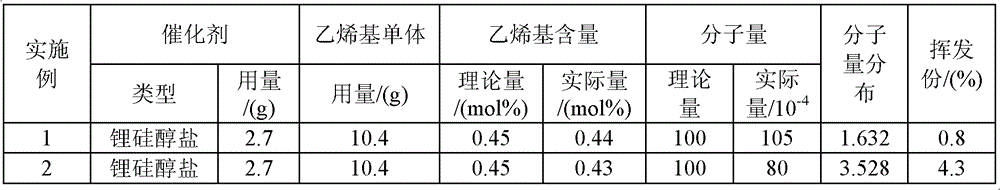

Embodiment 1

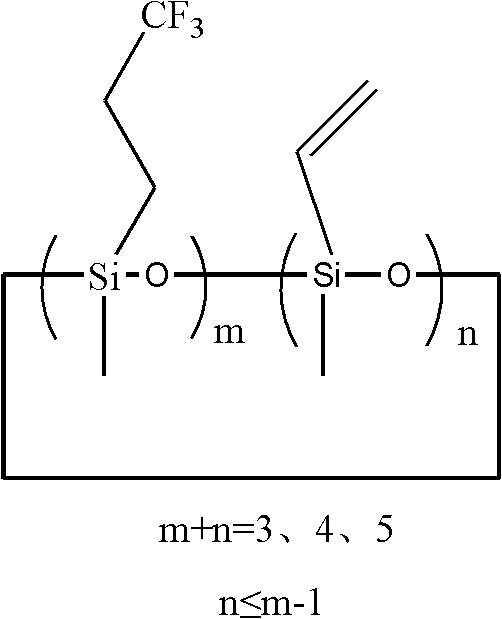

[0033] 50kg D 3 Add F into the reaction kettle, dehydrate for 1 hour at 60°C under a vacuum of -0.01~-0.02MPa, dry nitrogen and ventilate, raise the temperature to 140°C, add 173g of fluorine-containing vinyl rings, mix well and then add lithium silicon alkoxide Catalyst 45g, start polymerization, the viscosity of the system increases, with the increase of viscosity, the rotation speed of the stirring device is correspondingly reduced to 5r / min, and the reaction is 2h. During the polymerization reaction, dry nitrogen gas should be introduced to take away a small amount of moisture produced by the condensation reaction of hydroxyl groups in time. After the polymerization reaction is completed, continue to heat up to 200°C, remove the low boiling point at 133-1330Pa for 2 hours, cool to room temperature, and squeeze out the material from the lower outlet of the polymerization kettle through the hydraulic lifting of the lid.

Embodiment 2

[0035] The procedure described in Example 1 was repeated except that the polymerization process utilized nitrogen sparging instead of mechanical agitation.

Embodiment 3

[0037] Repeat the steps described in Example 1, just D in the polymerization process 3 F does not carry out dehydration treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com