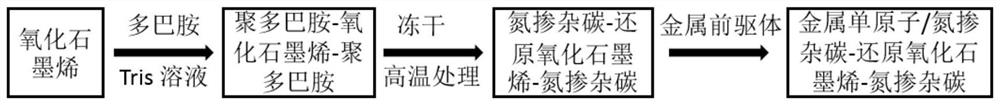

Carbon-based double-confinement interface loaded monatomic catalyst and preparation method thereof

A catalyst and confinement technology, applied in the field of single-atom catalysts and their preparation, can solve the problems of low content and limited application scope, and achieve the effects of strengthening physical confinement, convenient operation and increasing metal loading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

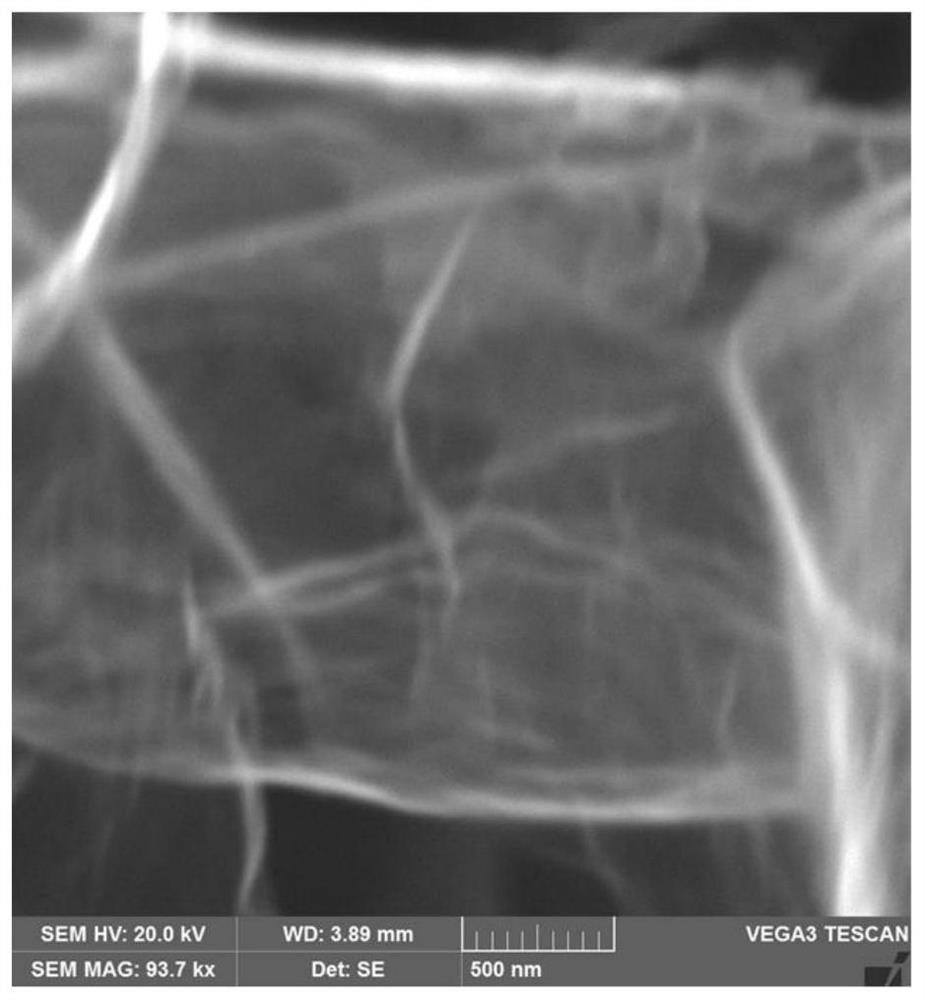

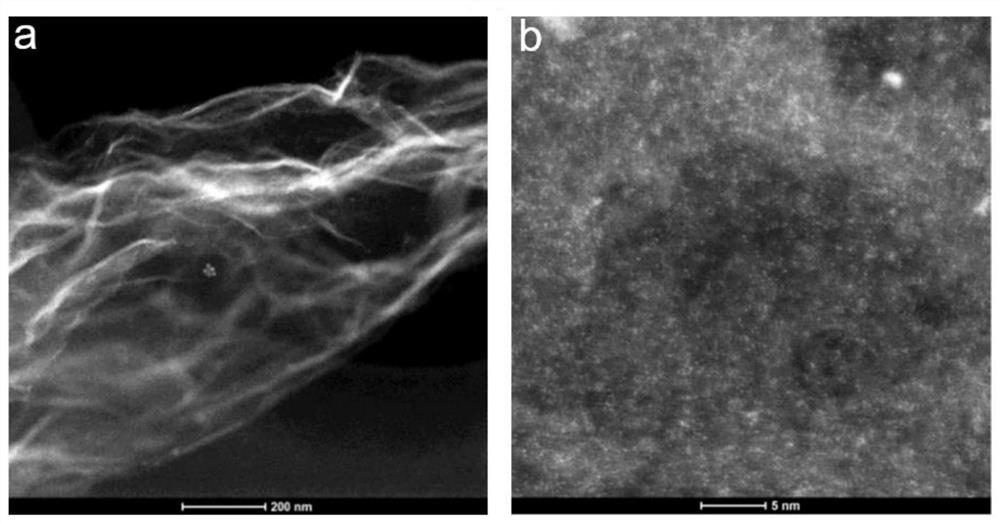

[0035] Synthesis of Pd1 / NC-RGO-CN single-atom catalyst:

[0036] (1) Synthesis of PDA-RGO-PDA composite material: 5 mL (10 mg / mL) of GO dispersion was added to 100 mL of tris (15 mM) solution to obtain a dispersion, and then hydrochloric acid was added Dopamine 300 mg, stirred and reacted for 6 hours, the dopamine hydrochloride was polymerized to form polydopamine and wrapped on the GO sheet to obtain the PDA-RGO-PDA composite material;

[0037] (2) Synthesis of NC-RGO-CN composite material: the PDA-RGO-PDA composite material obtained in the step (2) was annealed at 700°C for 3 hours under the protection of an inert gas atmosphere, Obtain NC-RGO-CN composite material;

[0038] (3) Synthesis of Pd1 / NC-RGO-CN single-atom catalyst: Disperse 50 mg NC-RGO-CN composite material in 100 mL deionized water to obtain NC-RGO-CN aqueous dispersion, and then, in an ice bath (0 ℃) environment with 2.0 mg metal salt precursor K 2 PdCl 4 Added into the solution, stirred and reacted for 2 ...

Embodiment 2

[0041] Synthesis of Pd1 / NC-RGO-CN single-atom catalyst:

[0042] (1) Synthesis of PDA-RGO-PDA composite material: 10 mL (5 mg / mL) of GO dispersion was added to 100 mL of tris (20 mM) solution to obtain a dispersion, and then hydrochloric acid was added Dopamine 250 mg, stirred and reacted for 10 hours, the dopamine hydrochloride was polymerized to form polydopamine and wrapped on the GO sheet to obtain the PDA-RGO-PDA composite material;

[0043] (2) Synthesis of NC-RGO-CN composite material: the PDA-RGO-PDA composite material obtained in the step (2) was annealed at 900°C for 0.5 hours under the protection of an inert gas atmosphere, Obtain NC-RGO-CN composite material;

[0044] (3) Synthesis of Pd1 / NC-RGO-CN single-atom catalyst: Disperse 50 mg NC-RGO-CN composite material in 100 mL deionized water to obtain NC-RGO-CN aqueous dispersion, and then, in an ice bath (0 ℃) with 1.5 mg metal salt precursor K 2 PdCl 4 Added to the solution, stirred and reacted for 3 hours, suct...

Embodiment 3

[0046] (1) Synthesis of PDA-RGO-PDA composite material: Add 7 mL (7.2 mg / mL) of GO dispersion to 100 mL of tris (12 mM) solution to obtain a dispersion, and then add hydrochloric acid Dopamine 250 mg, stirred and reacted for 12 hours, the dopamine hydrochloride was polymerized to form polydopamine and wrapped on the GO sheet to obtain the PDA-RGO-PDA composite material;

[0047] (2) Synthesis of NC-RGO-CN composite material: the PDA-RGO-PDA composite material obtained in the step (2) was annealed at 500°C for 3 hours under the protection of an atmosphere of an inert gas, Obtain NC-RGO-CN composite material;

[0048] (3) Synthesis of Pd1 / NC-RGO-CN single-atom catalyst: Disperse 50 mg NC-RGO-CN composite material in 100 mL deionized water to obtain NC-RGO-CN aqueous dispersion, then, in an ice bath (2 ℃) environment with 0.8 mg metal salt precursor K 2 PdCl 4 Added to the solution, stirred and reacted for 2.5 hours, suction filtered, and freeze-dried to obtain the Pd1 / NC-RGO-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com