Hyperbranched polymer and preparation method thereof, and application of hyperbranched polymer in preparation of drilling fluid

A technology of hyperbranched polymers and monomers, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of affecting the stability of the drilling fluid system, difficult to provide fluid loss control, insufficient high temperature stability, etc., to achieve The polymerization reaction is easy to control, the fluid loss reduction ability is strong, and the effect of good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

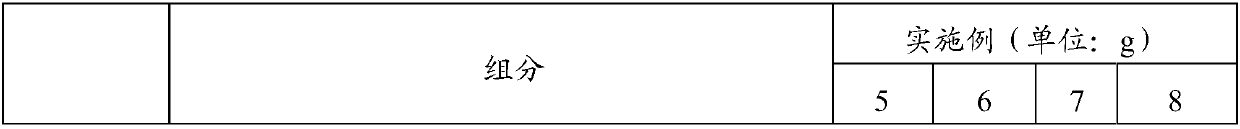

[0030] The raw materials for the preparation of the polymer provided by the present invention include organic acid monomers and acrylamide (AM) monomers, wherein the organic acid monomers are 2-acrylamido-2-methylpropanesulfonic acid (AMPS) and one or more of 2-acryloyloxy-2-methylpropanesulfonic acid.

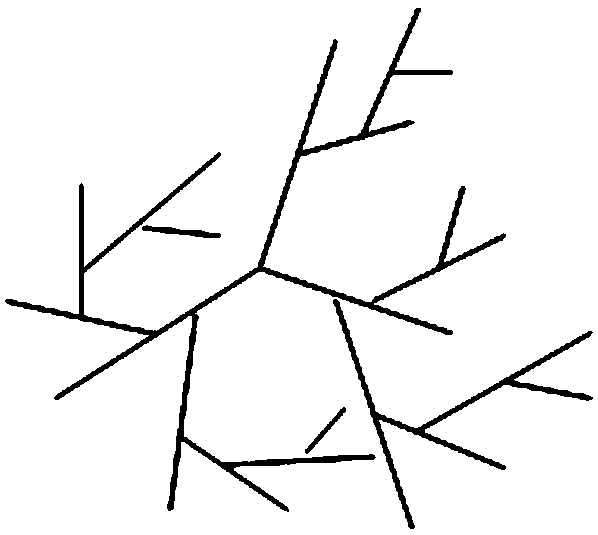

[0031] The invention adopts N,N-methylenebisacrylamide as a branching agent to form a hyperbranched polymer. Moreover, the present invention uses one or more of 4-cyanopentanoic acid dithiobenzoate and (3-benzylmercaptothiocarbonylthio)propionic acid as the chain transfer agent. The present invention adopts the reversible addition-fragmentation chain transfer radical polymerization method (RAFT polymerization method), and adds a chain transfer reagent with a high chain transfer constant to the traditional radical polymerization system to achieve the purpose of "active" polymerization and realize a random hyperbranched structure . The polymer of the invention has low viscosit...

Embodiment 1

[0051] Add 66g of 2-acrylamido-2-methylpropanesulfonic acid to 300g of water, adjust the pH value to 6 with 40% sodium hydroxide solution after fully dissolving, add 34g of acrylamide, 0.10g of N,N-methylene Bisacrylamide, 0.263g 4-cyanopentanoic acid dithiobenzoate, nitrogen for 20min, slowly add 0.15g ammonium persulfate and 0.15g sodium bisulfite initiator under constant stirring, at 35°C After heat preservation for 12 hours, 92.0 g of viscous water-soluble branched polymer fluid loss control agent was obtained.

Embodiment 2

[0053] Add 24g of 2-acryloyloxy-2-methylpropanesulfonic acid to 300g of water, adjust the pH value to 7 with 40% sodium hydroxide solution after fully dissolving, add 76g of acrylamide, 0.3g of N,N-methylene Base bisacrylamide, 0.42g (3-phenylmethylmercaptothiocarbonylthio)propionic acid, nitrogen gas 20min, slowly add 0.2g ammonium persulfate and 0.2g sodium bisulfite initiator under constant stirring, at 40 ℃ After heat preservation for 8 hours, 90 g of viscous water-soluble branched polymer fluid loss control agent was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com