Method for preparing polyether polycarboxylic acid type high-efficiency water reducing agent from polyethylbenzene tower bottom high-boiling residues

A technology of polyether polycarboxylic acid and high-efficiency water reducing agent, which is applied in the preparation of sulfonic acid, chemical instruments and methods, catalysts for physical/chemical processes, etc., can solve the problems of high industrialization cost, large amount of benzene, and high impurity content in products. Achieve good industrial application prospects, improve water reduction performance, and improve the effect of water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

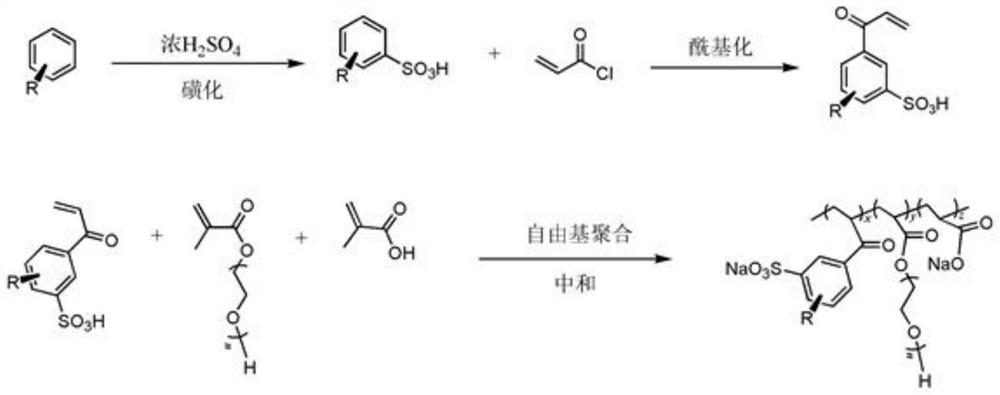

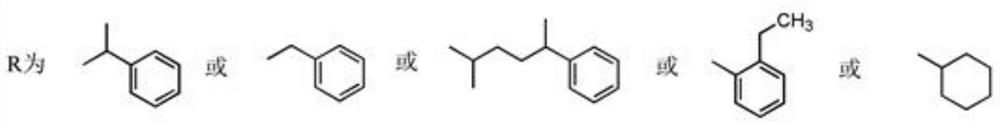

Method used

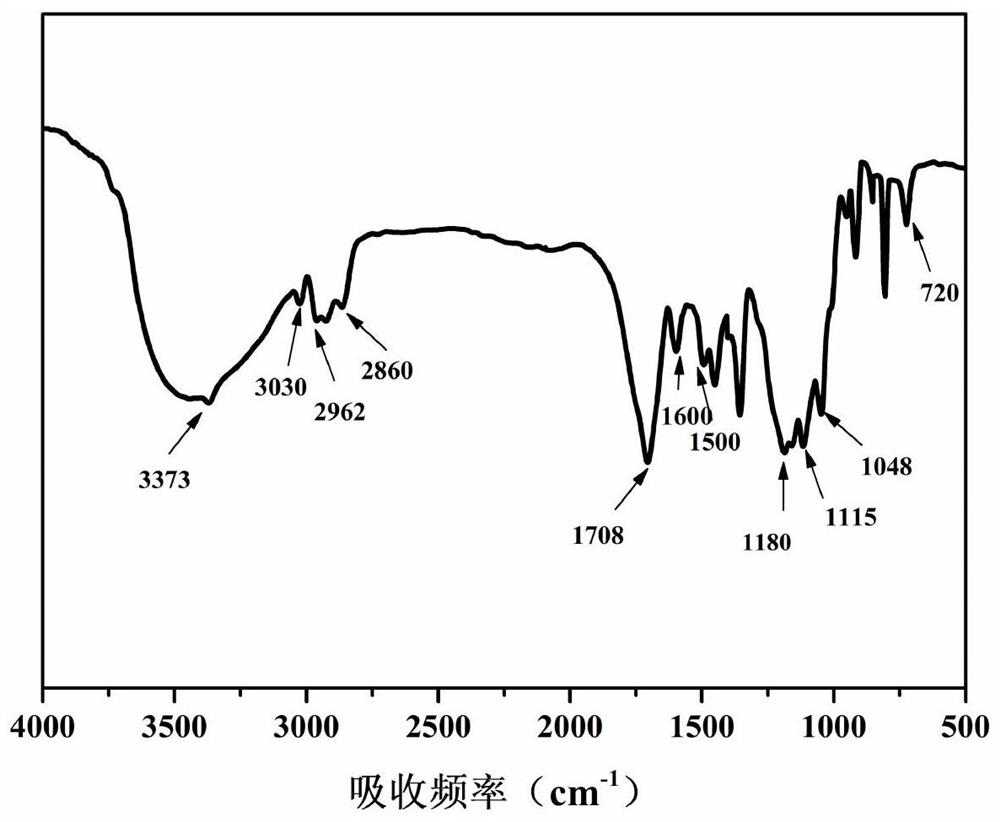

Image

Examples

Embodiment 1

[0036] Step 1) At 25°C, add 50g polyethylbenzene tower bottom high boilers and 50g 98wt% concentrated sulfuric acid into the reaction kettle, react at 135°C for 4h, let stand to separate layers, collect the lower liquid, polyethylbenzenesulfonic acid ;

[0037] Step 2) At 25°C, add 2.0g of fumed silica and 100g of deionized water into the reactor, react at 80°C for 2h, add 12g of 1wt.% N-[3-(trimethoxysilyl)propane Base] methanol solution of aniline, continue to react for 6 hours, filter, wash the filter cake with 180g ethanol and dry at 80°C for 24 hours to obtain modified silica;

[0038] Step 3) At 25°C, 0.3g of sodium metaaluminate, 3.0g of anhydrous sodium hydroxide, 1.6g of the modified silica prepared in step 2), 3.6g of N,N,N-trimethyl- Add 1-adamantanamine, 1.5g carbon nanotubes, and 0.6g (2,2'-bipyridine) nickel diiodide into the reaction kettle, react with 400W microwave at 120°C for 5d, filter, and wash the filter cake with deionized water until The pH of the fil...

Embodiment 2

[0045] Step 1) At 25°C, add 60g of polyethylbenzene tower bottom high boilers and 55g of 98wt% concentrated sulfuric acid into the reaction kettle, react at 120°C for 2.5h, let stand to separate layers, collect the lower liquid, polyethylbenzenesulfonate acid;

[0046] Step 2) At 25°C, add 2.5g of fumed silica and 125g of deionized water into the reactor, react at 85°C for 1.5h, add 12.5g of 3wt.% N-[3-(trimethoxysilyl ) methanol solution of propyl]aniline, continue to react for 6.5h, filter, wash the filter cake with 250g of ethanol and dry at 85°C for 24h to obtain modified silica;

[0047] Step 3) At 25°C, 0.5g of sodium metaaluminate, 5g of anhydrous sodium hydroxide, 2.6g of modified silica prepared in step 2), 4g of N,N,N-trimethyl-1- Add amantadine, 1.8g carbon nanotubes, and 0.7g (2,2'-bipyridine) nickel diiodide into the reaction kettle, react with 500W microwave at 130°C for 5d, filter, and wash the filter cake with deionized water to the pH of the filtrate 7, drie...

Embodiment 3

[0051] Step 1) At 25°C, add 30g of polyethylbenzene tower bottom high boiler and 30g of fuming sulfuric acid into the reaction kettle, react at 90°C for 8h, let stand to separate layers, collect the lower liquid, polyethylbenzenesulfonic acid;

[0052] Step 2) At 25°C, add 4g of fumed silica and 200g of deionized water into the reactor, react at 75°C for 2h, add 20g of 1wt.% methanol solution of vinyltriethoxysilane, and continue the reaction for 6h , filtered, washed the filter cake with 500g ethanol and dried at 90°C for 24h to obtain modified silica;

[0053] Step 3) At 25°C, 0.1g of sodium metaaluminate, 1g of anhydrous sodium hydroxide, 0.5g of the modified silica prepared in step 2), 1.2g of N,N,N-trimethyl-1 - Add amantadine, 0.5g carbon nanotubes, 0.2g (2,2'-bipyridine) nickel diiodide into the reaction kettle, react with 500W microwave at 100°C for 3d, filter, wash the filter cake with deionized water to the filtrate pH is 7, dried at 80°C for 12 hours to obtain SSZ-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com