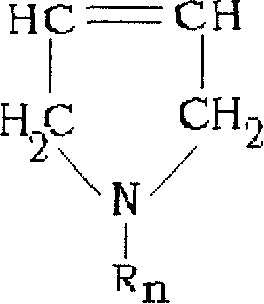

Method for preparing halogen substituent maleimide heat-proof flame-proof resin emulsion

A technology of flame retardant resin and imide, which is applied in the field of preparation of heat-resistant flame retardant resin emulsion, can solve the problems of no polymerization method and slow reaction speed, and achieve uniform composition and structure, stable reaction process and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A. Preparation of monomer mixture

[0051] Add 30 parts of N-tribromophenylmaleimide, 45 parts of styrene, 25 parts of acrylonitrile, 0.35 parts of azobisisobutyronitrile, and 0.1 part of mercaptan into the mixing tank at 30°C, start stirring and mix to form Homogeneous monomer mixture (a).

[0052] B. Preparation of Monomer Emulsion

[0053] Add 130 parts of desalted water and 3.0 parts of sodium lauryl sulfate into the emulsifier at 30°C, start stirring and add (a) into the emulsifier for emulsification. After emulsification for 33 minutes, monomer emulsion (b) was obtained. Its pH was determined to be 9-10.

[0054] C. Preparation of heat-resistant and flame-retardant resin emulsion

[0055] Add 30 parts of water into the reactor, and after the temperature rises to 79°C, immediately add (b) into the reactor continuously and uniformly and keep the temperature of the system at 80°C to carry out the polymerization reaction. Control the feed rate of (b) so that it i...

Embodiment 2

[0061] A. Preparation of monomer mixture

[0062] Add 30 parts of N-tribromophenylmaleimide, 45 parts of styrene, 25 parts of acrylonitrile, 0.35 parts of azobisisobutyronitrile, and 0.15 parts of mercaptan into the mixing tank at 35°C, start stirring and mix to form Homogeneous monomer mixture (a).

[0063] B. Preparation of Monomer Emulsion

[0064] Add 130 parts of desalted water, 2.2 parts of sodium lauryl sulfate and 1.0 part of synthetic fatty acid potassium into the emulsifier at 35°C, start stirring and add (a) into the emulsifier for emulsification. After emulsification for 34 minutes, monomer emulsion (b) was formed. Its pH was determined to be 9-10.

[0065] C. Preparation of heat-resistant and flame-retardant resin emulsion

[0066] Add 30 parts of water into the reactor, and after its temperature rises to 77°C, immediately add (b) into the reactor continuously and evenly to mix with (a) and maintain the temperature of the system at 80°C for polymerization. Co...

Embodiment 3

[0070] A. Preparation of monomer mixture

[0071] Add 30 parts of N-tribromocyclohexylmaleimide, 45 parts of styrene, 25 parts of acrylonitrile, 0.35 parts of azobisisobutyronitrile, and 0.1 part of mercaptan into the mixing tank at 30°C, start stirring and mix to form Homogeneous monomer mixture (a).

[0072] B. Preparation of Monomer Emulsion

[0073] Add 130 parts of desalted water, 1.7 parts of sodium lauryl sulfate and 1.0 part of synthetic fatty acid potassium into the emulsifier at 30°C, start stirring and add (a) into the emulsifier for emulsification. After emulsification for 31 minutes, monomer emulsion (b) was obtained. Its pH was determined to be 9-10.

[0074] C. Preparation of heat-resistant and flame-retardant resin emulsion

[0075] Add 30 parts of water into the reactor, and after its temperature rises to 79°C, immediately add (b) into the reactor continuously and evenly to mix with (a) and maintain the temperature of the system at 85°C for polymerization....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Vicat softening temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com