Polyester thermosol and preparation method thereof

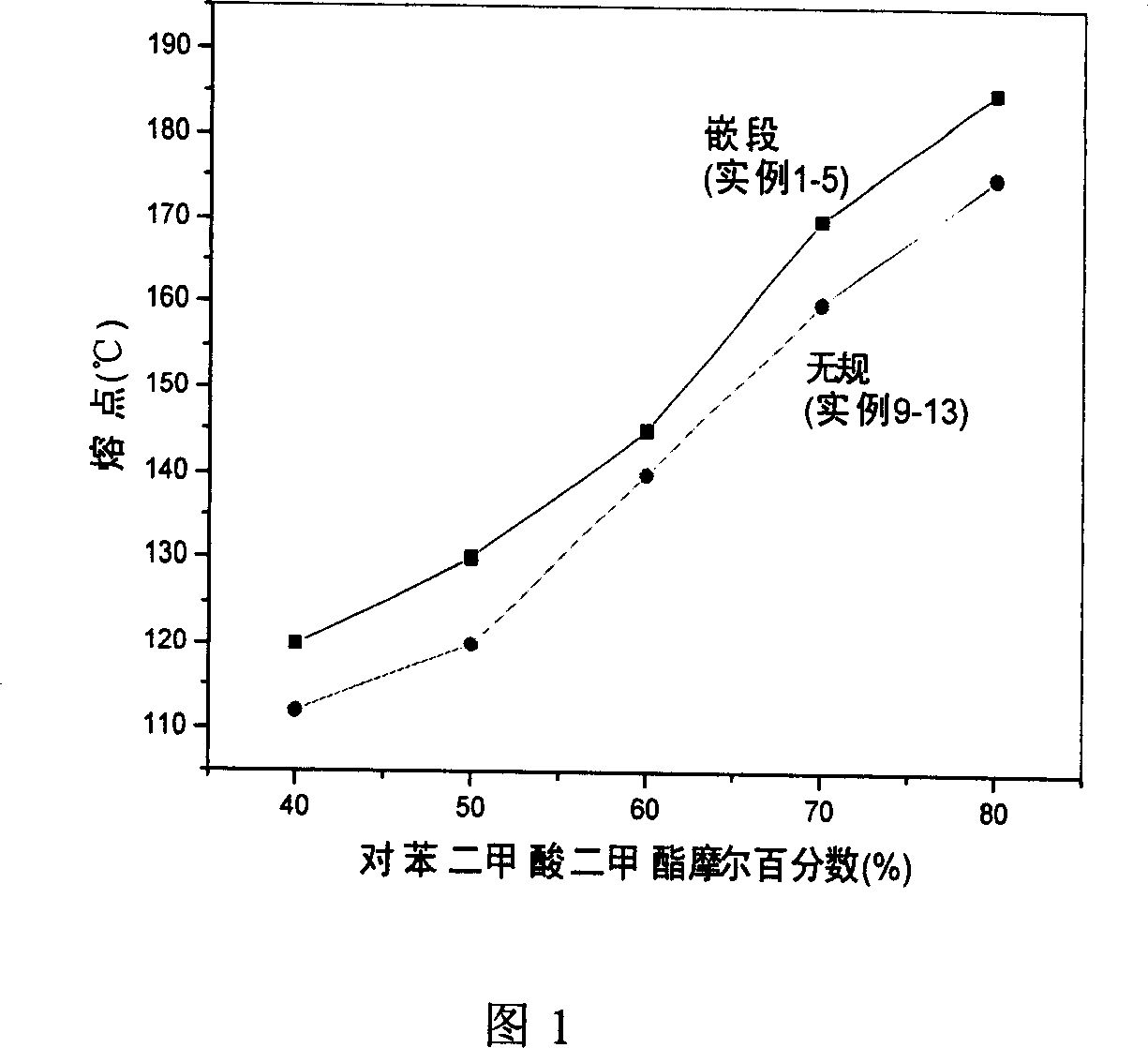

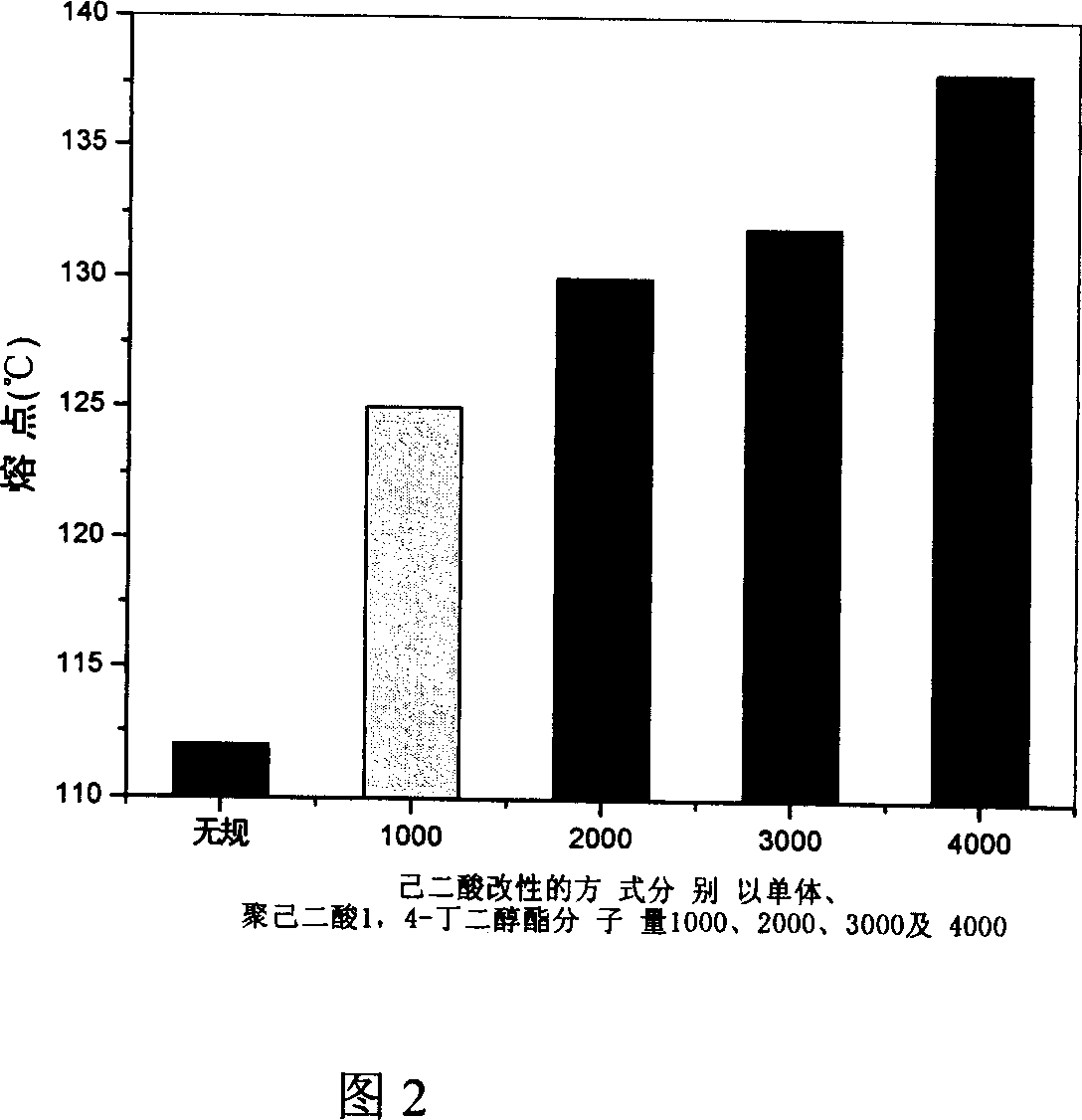

A technology of polyester hot melt adhesive and alkylene ester, which is applied in the direction of adhesives, etc., and can solve the problems of difficult high melting point bonding and low melting point of random polyester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

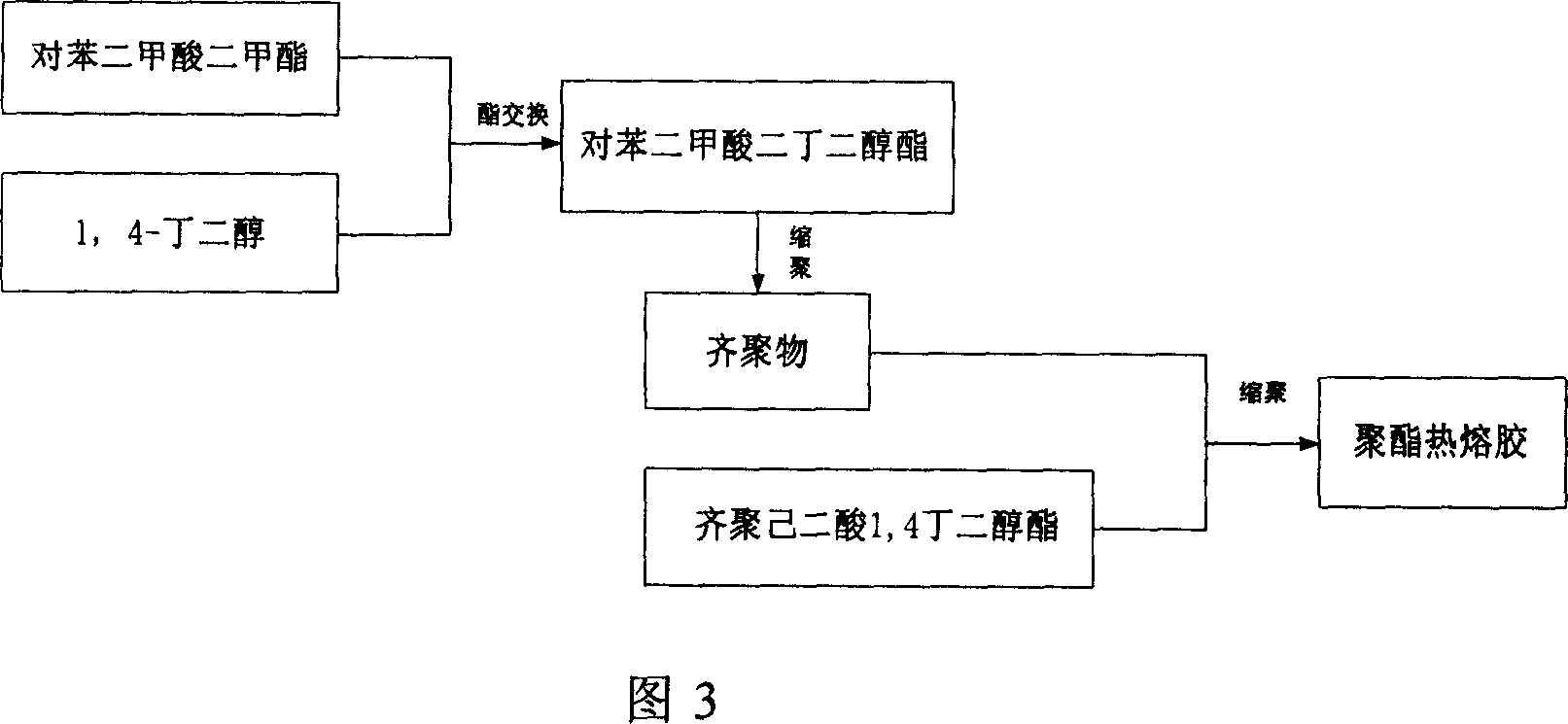

Embodiment 1

[0053] Add 170 grams of dimethyl terephthalate, 158 grams of 1,4-butanediol and 0.20 grams of n-ethyl phthalate in a 1000ml stainless steel reactor with thermometer, mechanical stirrer, fractionation column and condenser. Heat up the temperature, and when the temperature in the kettle reaches 100°C, start stirring immediately. When the temperature rises to about 145°C, methanol droplets begin to distill, and the distillation temperature is 60-70°C. Continue to heat up until the temperature in the kettle reaches about 200°C. When the amount of methanol distilled is greater than 97% of the theoretical amount, the transesterification is completed. Raise the temperature to 250-260°C, depressurize and evacuate with a vacuum pump, and release the vacuum when the stirring power reaches 90-95W. Take a small amount of sample from the reactor, and measure its weight-average molecular weight according to the above-mentioned method, which is 2200-3300, and the hydroxyl value is 40 mgKOH / g...

Embodiment 2-8

[0057] The processing method of following test is identical with embodiment 1, and used formula result is as shown in table 1 below:

[0058] 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com