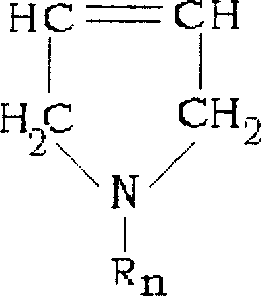

Method for synthesizing halogen substituent maleimide heat-proof flame-proof resin emulsion

A synthesis method and heat-resistant resin technology, which is applied in the field of halogen-substituent maleimide heat-resistant flame-retardant resin emulsion synthesis, can solve the problems of no polymerization method and slow reaction speed, and achieve uniform composition and structure, and easy Controlling and resolving unstable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Preparation of emulsion of additives:

[0051] 5.0% potassium oleate soap, 10% antioxidant 1076, 5% plasticizer dibutyl phthalate and 80% desalted water are prepared in an emulsification tank at 75°C to prepare an emulsion of additives.

Embodiment 1

[0053] A. Preparation of Primary Emulsion

[0054] Add 30 parts of desalted water, 0.3 parts of sodium lauryl sulfate, 0.7 parts of styrene, 0.3 parts of acrylonitrile, and 0.1 parts of azobisisobutyronitrile into a stirred reactor at 30°C, and start stirring for emulsification. After 30 minutes of emulsification, the temperature of the water phase in the reactor was raised to 78° C. within 30 minutes, and kept at a constant temperature for 10 minutes to form the primary emulsion (a).

[0055] B. Preparation of monomer mixture

[0056] Add 30 parts of N-tribromophenylmaleimide, 44 parts of styrene, 25 parts of acrylonitrile, 0.35 parts of azobisisobutyronitrile, and 0.1 part of mercaptan into the mixing tank at 30°C, start stirring and mix to form Homogeneous monomer mixture (b).

[0057] C. Preparation of Monomer Emulsion

[0058] Add 130 parts of desalted water and 2.7 parts of sodium lauryl sulfate into the emulsifier at 30°C, start stirring, and add (b) into the emulsif...

Embodiment 2

[0066] A. Preparation of Primary Emulsion

[0067] Add 30 parts of desalted water, 0.3 parts of sodium dodecylbenzenesulfonate, 0.7 parts of styrene, 0.3 parts of acrylonitrile, and 0.1 parts of azobisisobutyronitrile into a stirred reactor at 30°C, and start stirring for emulsification . After 30 minutes of emulsification, the temperature of the water phase in the reactor was raised to 78° C. within 30 minutes, and kept at a constant temperature for 10 minutes to form the primary emulsion (a).

[0068] B. Preparation of monomer mixture

[0069] Add 30 parts of N-tribromophenylmaleimide, 44 parts of styrene, 25 parts of acrylonitrile, 0.35 parts of azobisisobutyronitrile, and 0.1 part of mercaptan into the mixing tank at 30°C, start stirring and mix to form Homogeneous monomer mixture (b).

[0070] C. Preparation of Monomer Emulsion

[0071] Add 130 parts of desalted water, 1.7 parts of sodium lauryl sulfate and 1.0 part of synthetic fatty acid potassium into the emulsifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com