Wide-distribution, high-elasticity and functionalized solution polymerized styrene-butadiene rubber, preparation method and application thereof in tire tread rubber

A solution-polymerized styrene-butadiene rubber, high-elasticity technology, used in special tires, tire parts, transportation and packaging, etc. Issues such as literature submission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

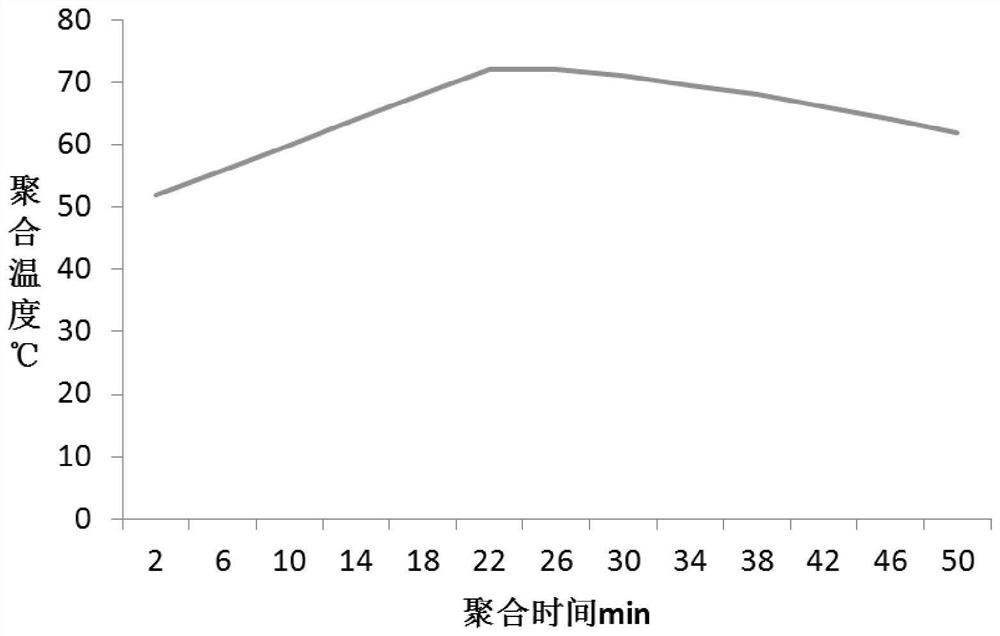

[0058]In a 10-liter polymerization kettle under the protection of nitrogen, add 7000 mL of cyclohexane solution with a mass fraction of 10% n-hexane, start stirring, then add 3 mL of 99.0% tetrahydrofurfuryl alcohol ethyl ether ETE, 0.8 mol / L of DVB 8ml of cyclohexane solution, 4.0mL of isoprene and 16mL of 0.72mol / L NBL, heated to 52°C and reacted for 15-20min; then added 1.0mL of DBU, followed by 200mL of styrene and 800mL of butanediol The mixed monomers of olefins are subjected to two-stage copolymerization reaction, and the temperature rise-time curve of random copolymerization reaction is shown in figure 1 , when the polymerization temperature rises to the highest temperature of 72°C, react for 28 minutes, then add 0.70mol / L N,N'-dimethylimidazolinone 12mL to the active glue in the polymerization kettle, Capping reaction 25 ~ 30min, that is. Finally, the glue is discharged, hydrolyzed, coagulated, and dried to become F-SSBR raw rubber.

[0059] The vinyl mass content o...

Embodiment 2

[0061] The relevant process conditions in Example 1 were kept unchanged, except that the DBU added was 0.8 mL. The second-stage polymerization state is as follows: the initial polymerization temperature of the second stage is 53.5°C, the heating time of the mixed monomer polymerization is 16min, the highest polymerization temperature is 69.5°C, and the total polymerization time of the second stage is 60min; then the active glue in the polymerization kettle Add 15mL of 0.70mol / L N,N'-dimethylimidazolidinone to the mixture, react at 55~60℃ for 20min, then add 0.70mol / L trimethylsilyl chloride to the polymerization glue 8mL can be condensed with lithium on dimethylimidazolinone for 15min.

[0062] After the glue is discharged, hydrolyzed, coagulated, and dried, it becomes F-SSBR raw rubber. The vinyl mass content of the butadiene segment in the F-SSBR molecule was measured to be 60.4%, the number average molecular weight of the polymer Mn=102700, the molecular weight distributio...

Embodiment 3

[0064] The relevant process conditions in Example 1 were kept unchanged, except that the added DBU was 1.2mL, DVB was 10mL, and NBL was 19mL. The second-stage polymerization state is as follows: the initial polymerization temperature of the second stage is 47.6°C, the heating time of the mixed monomer polymerization is 20min, the highest polymerization temperature is 66°C, and the total polymerization time of the second stage is 70min; then the active glue in the polymerization kettle Add 15 mL of 0.70 mol / L N,N'-dimethylimidazolidinone to the polymer solution, and react at 66°C for 20 min, then add 0.70 mol / L trimethyl-chlorosilane 8 mL and Lithium on the dimethylimidazolinone can be condensed for 15 minutes.

[0065] After the glue is discharged, hydrolyzed, coagulated, and dried, it becomes F-SSBR raw rubber. The vinyl mass content of the butadiene segment in the F-SSBR molecule was measured to be 66.4%, the number average molecular weight of the polymer Mn=86300, the mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com