Patents

Literature

58 results about "Aminoethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for depositing silicon dioxide or silicon oxide films using aminovinylsilanes

ActiveUS8460753B2Polycrystalline material growthSemiconductor/solid-state device manufacturingSilazaneSilicon oxide

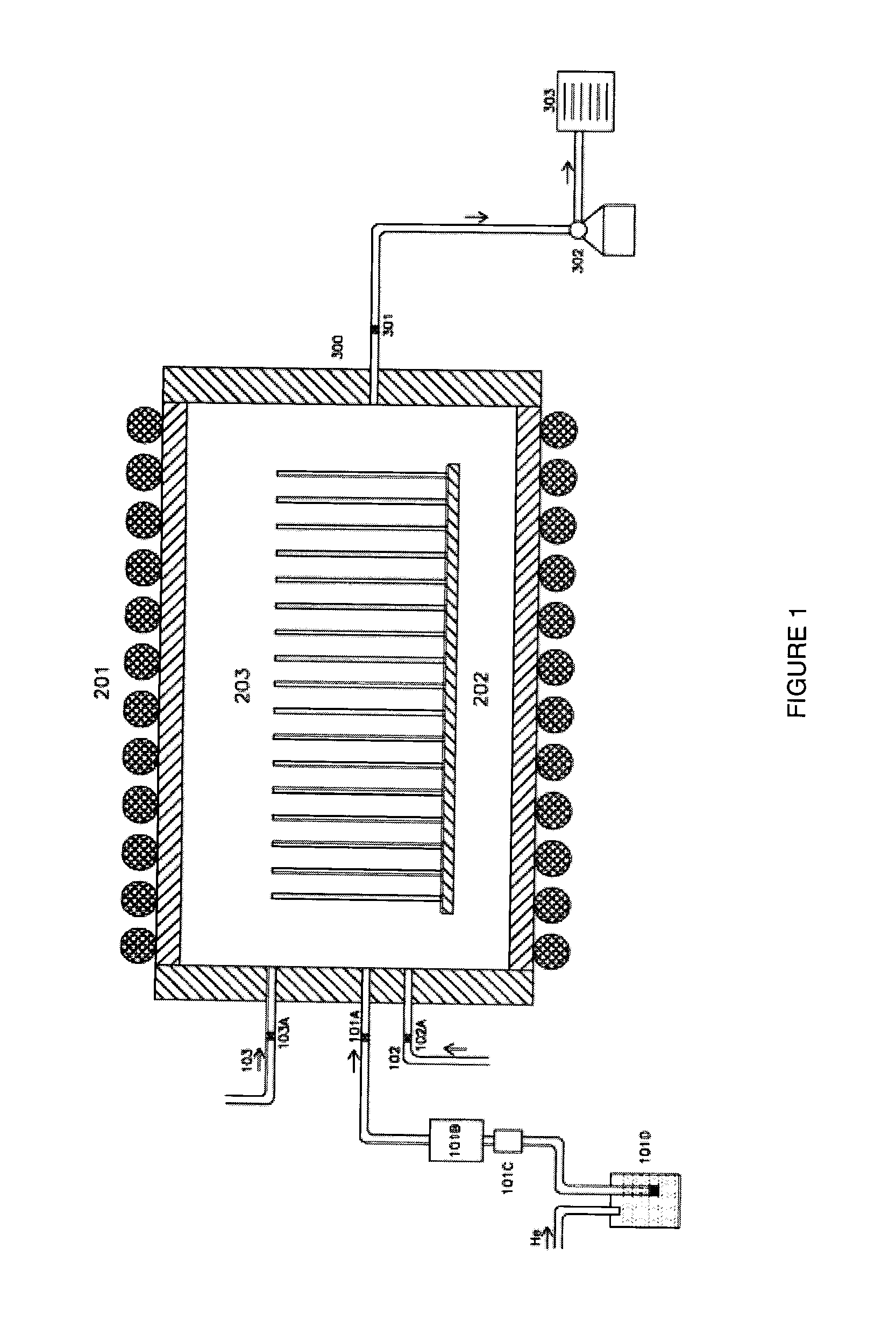

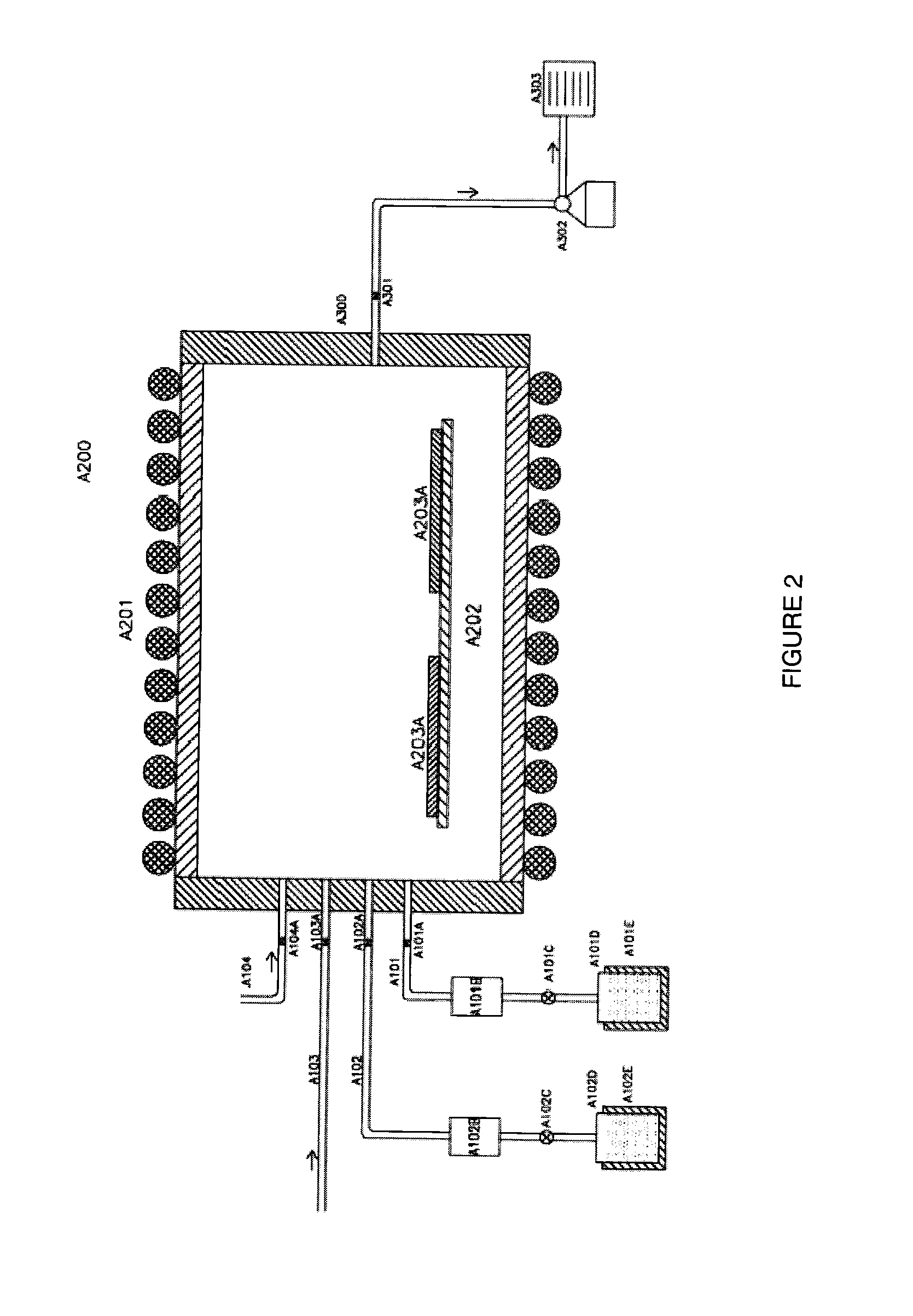

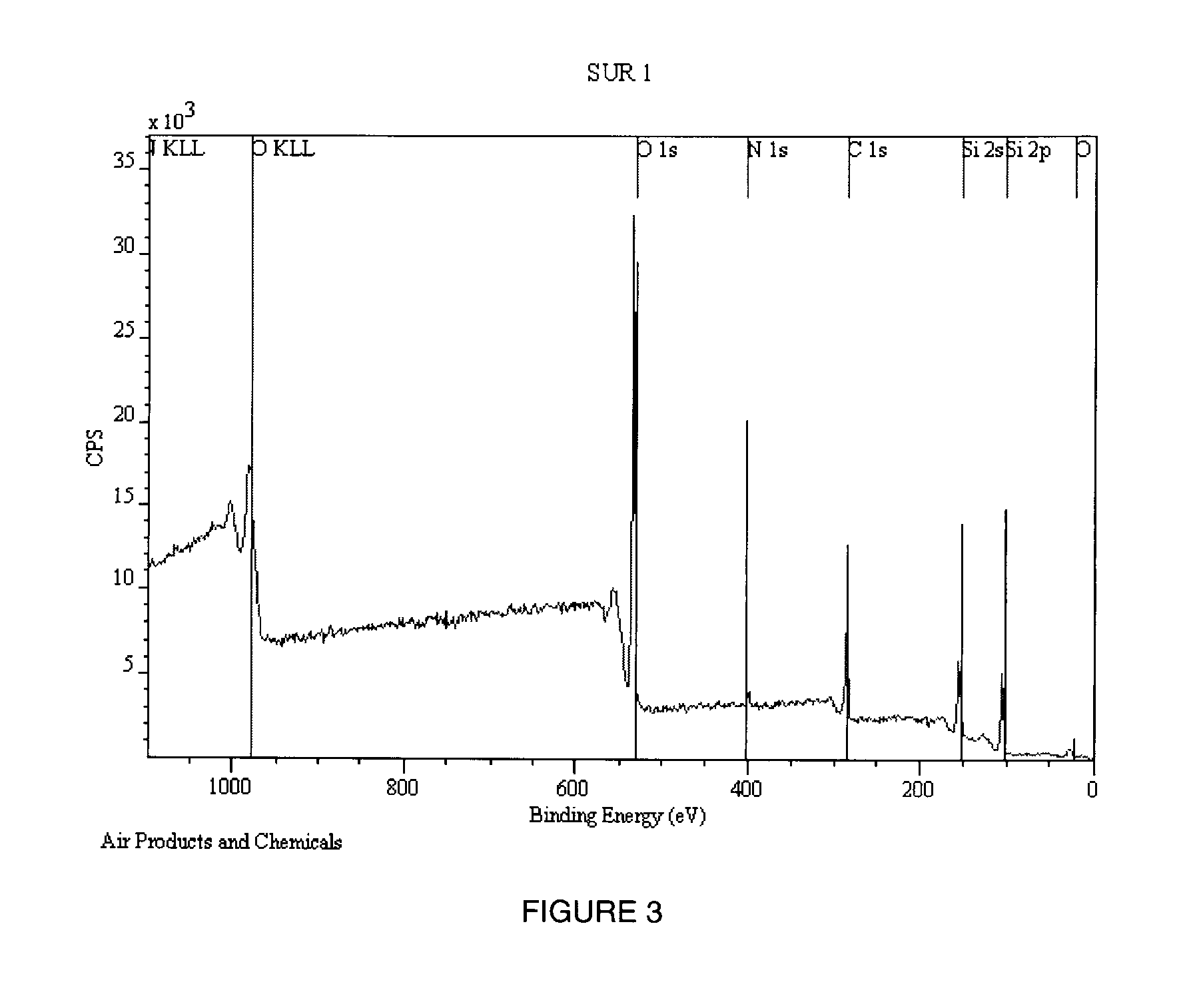

Described herein are methods to form silicon dioxide films that have extremely low wet etch rate in HF solution using a thermal CVD process, ALD process or cyclic CVD process in which the silicon precursor is selected from one of:R1nR2mSi(NR3R4)4-n-m; and,a cyclic silazane of (R1R2SiNR3)p,where R1 is an alkenyl or an aromatic, such as vinyl, allyl, and phenyl; R2, R3, and R4 are selected from H, alkyl with C1-C10, linear, branched, or cyclic, an alkenyl with C2-C10 linear, branched, or cyclic, and aromatic; n=1-3, m=0-2; p=3-4.

Owner:VERSUM MATERIALS US LLC

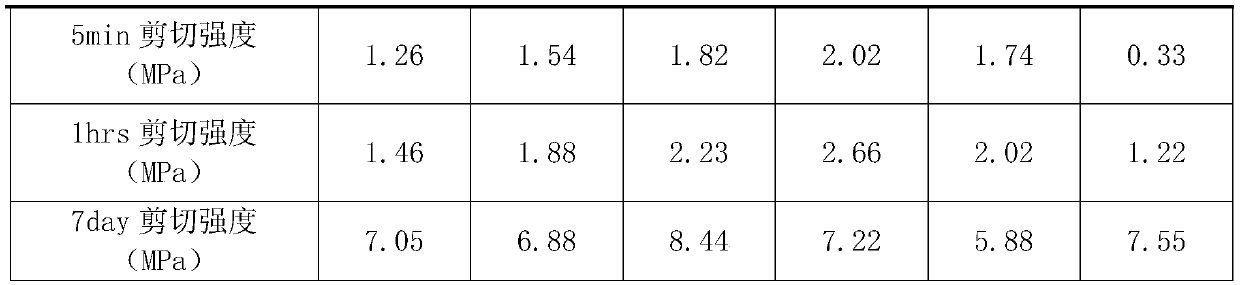

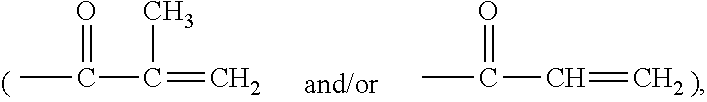

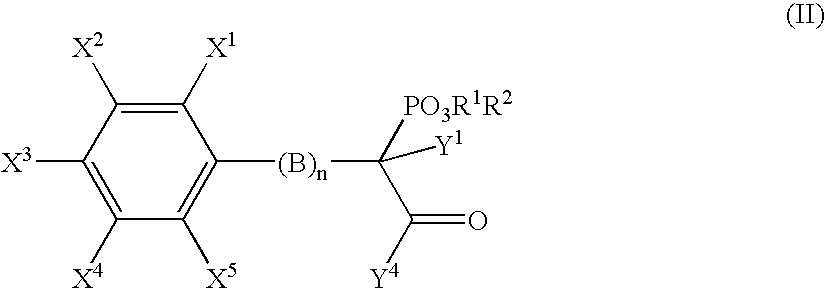

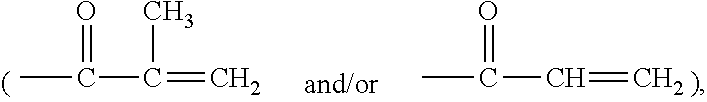

Ultraviolet light and moisture dual-curing polyurethane hot melt adhesive and preparation method thereof

ActiveCN111117554AHigh functionalityImprove curing speedPolyureas/polyurethane adhesivesPolyesterPolymer science

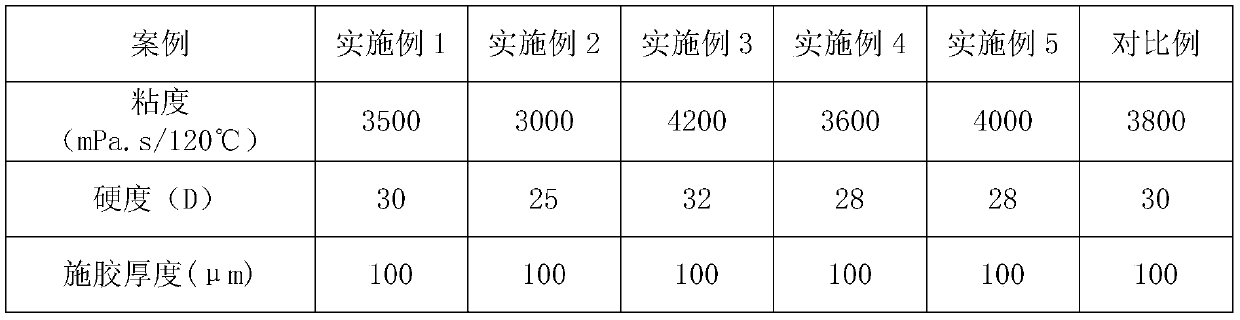

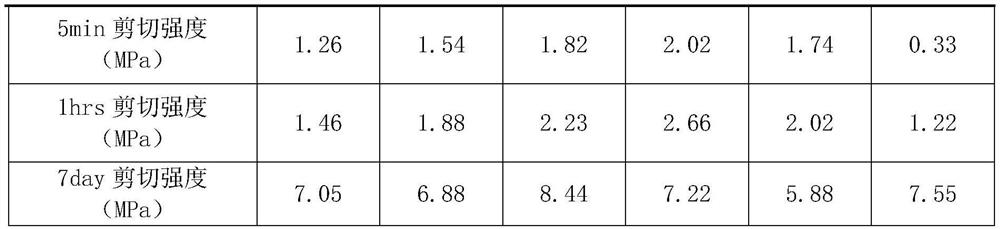

The invention relates to the field of hot melt adhesives, in particular to an ultraviolet light and moisture dual-curing hot melt adhesive and a preparation method thereof. The ultraviolet light and moisture dual-cured polyurethane hot melt adhesive is prepared from the following raw materials in parts by weight: 20 to 50 parts of thermoplastic resin, 20 to 50 parts of polyester polyol, 5 to 35 parts of polyether polyol, 1 to 10 parts of trifunctional small molecular polyol, 1 to 10 parts of hydroxyl-terminated acrylate or amino-terminated vinyl monomer, 2 to 20 parts of polyisocyanate, 0.1 to 1 part of catalyst, 1 to 5 parts of photoinitiator, 0.2 to 2 parts of silane coupling agent and 0.2 to 2 parts of defoaming agent. The polyurethane hot melt adhesive containing double reaction groups of vinyl and isocyanate is prepared by reacting a vinyl functional monomer containing terminal hydroxyl or amino, polyester and polyether polyol with polyisocyanate. After the hot melt adhesive is applied, the molecular weight of the vinyl polymer in the product is further increased through ultraviolet irradiation to form a large-molecular-weight reticular high polymer to generate pressure sensitivity and better initial adhesion strength, so that the functions of quick positioning and no pressure maintaining are achieved.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

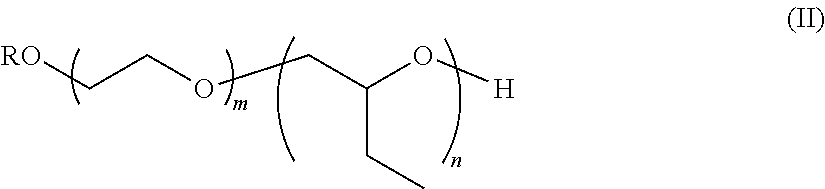

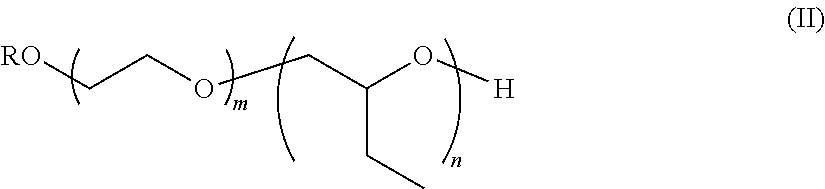

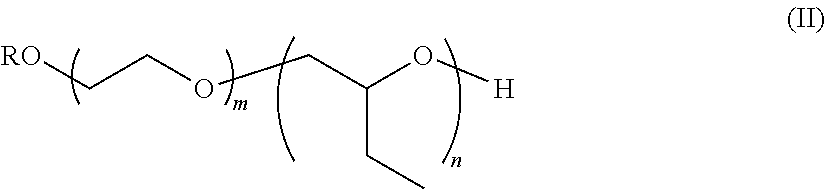

Contact lens packaging solutions

ActiveUS9829723B2Improved and sustainable wettabilitySpectales/gogglesPackage sterilisationHigh pressureMonomer

The present invention relates to improved contact lens products which not only have an improved and sustainable wettability. The contact lens product of the invention comprises a soft hydrogel contact lens immersed and autoclaved in a packaging solution including a polyoxyethylene-polyoxybutylene block copolymer and a high molecular weight copolymer of N-vinylpyrrolidone and at least one amino-containing vinylic monomer. The present invention also provides methods for making contact lens products of the invention.

Owner:ALCON INC

Preparation method of foamed ceramic heat-preserving material

ActiveCN104086214AAccelerated corrosionImprove mildew resistanceCeramicwareViscous liquidKaolin clay

The invention relates to a preparation method of a foamed ceramic heat-preserving material. The preparation method comprises the following steps: 1) dissolving kaolin and an aminovinyl silane coupling agent in water, heating in a water bath, and ultrasonically dispersing to obtain a viscous liquid; 2) adding rinkolite powder and titanium dioxide powder and stirring and dispersing at a high speed to obtain dispersed mixed slurry; 3) adding sodium sulfate powder, ball-milling and pelleting to obtain mixed particles; and 4) ball-milling the mixed particles, a foamed ceramic blank and an inorganic foamer in the ball-mill, and finally carrying out high-temperature sintering. The material provided by the invention has the advantages that 1) kaolin is used as a functional modifier, so that the corrosion resistance and mildew prevention of the ceramic material can be improved, and meanwhile, kaolin also serves as filler to improve the mechanical strength of the foamed ceramic; 2) the used rinkolite powder is an environment-friendly new material; and as a solid-solid phase change energy storage material, the rinkolite powder has high-and-low-temperature resistance and can improve the heat efficiency of the foamed ceramic and reduce the contraction and expansion of the foamed ceramic, thus achieving the effects of light weight and good heat-preserving performance.

Owner:苏州远略知识产权运营有限公司

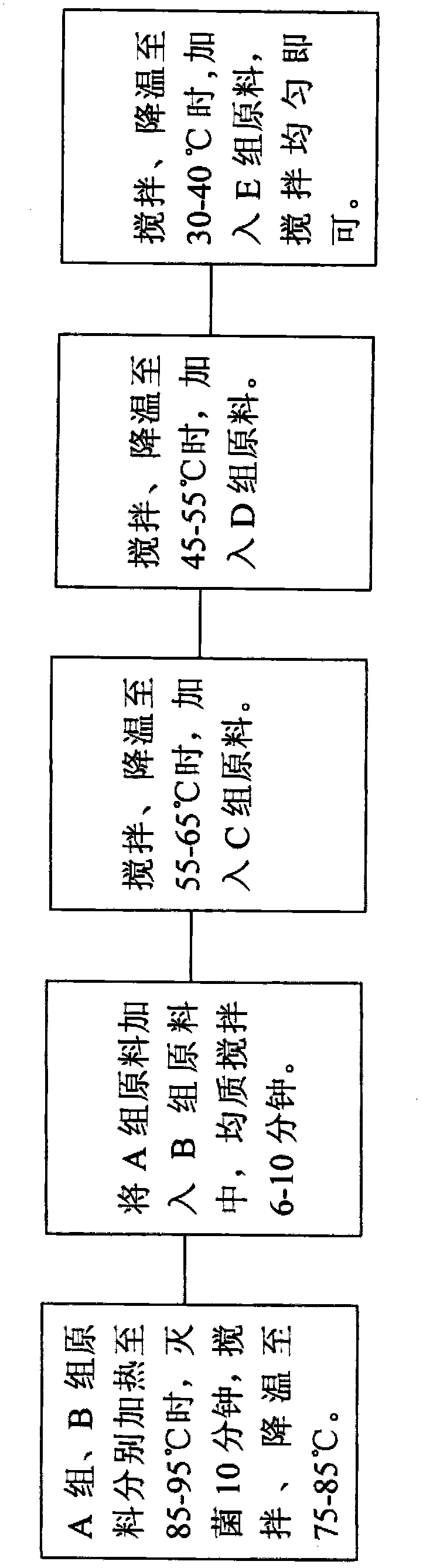

Anti-freckle whitening emulsion

InactiveCN103385838AEasy to buyLow priceCosmetic preparationsToilet preparationsImidazolidinePalmitates

The invention provides an anti-freckle whitening emulsion. The anti-freckle whitening emulsion is produced through the following steps of proportionally mixing a compound emulsifier 9122, squalane, vitamin E, azone, kojic dipalmitate, vitamin C, magnesium phosphate, ditertbutyl-p-cresol, propyl hydroxybenzoate, dimeticone, isopropyl myristate, 1,3-butanediol, an amino acid wetting agent, allantoin, methylparaben, diphenhydramine, ethylene diamine tetraacetic acid disodium salt, purified water, licoflavone, propyleneglycol, 0.5% hyaluronicacid, aloe extract, imidazolidinylurea and an essence together, and then performing an emulsifying process. Compared with the prior art, the anti-freckle whitening emulsion has the following advantages that 1, as no original Chinese herbal medicine raw materials are used in the formula, the product obtained according to the invention is tasteless and colorless; 2, as the strong penetrating agent azone and the antihistamine diphenhydramine are selected in the formula, the product is quick to take effect and non-allergic; 3, as the raw materials are convenient to buy and low in price and the production process is simple, the product is low in production cost.

Owner:AESTHETIC TECH BEIJING +2

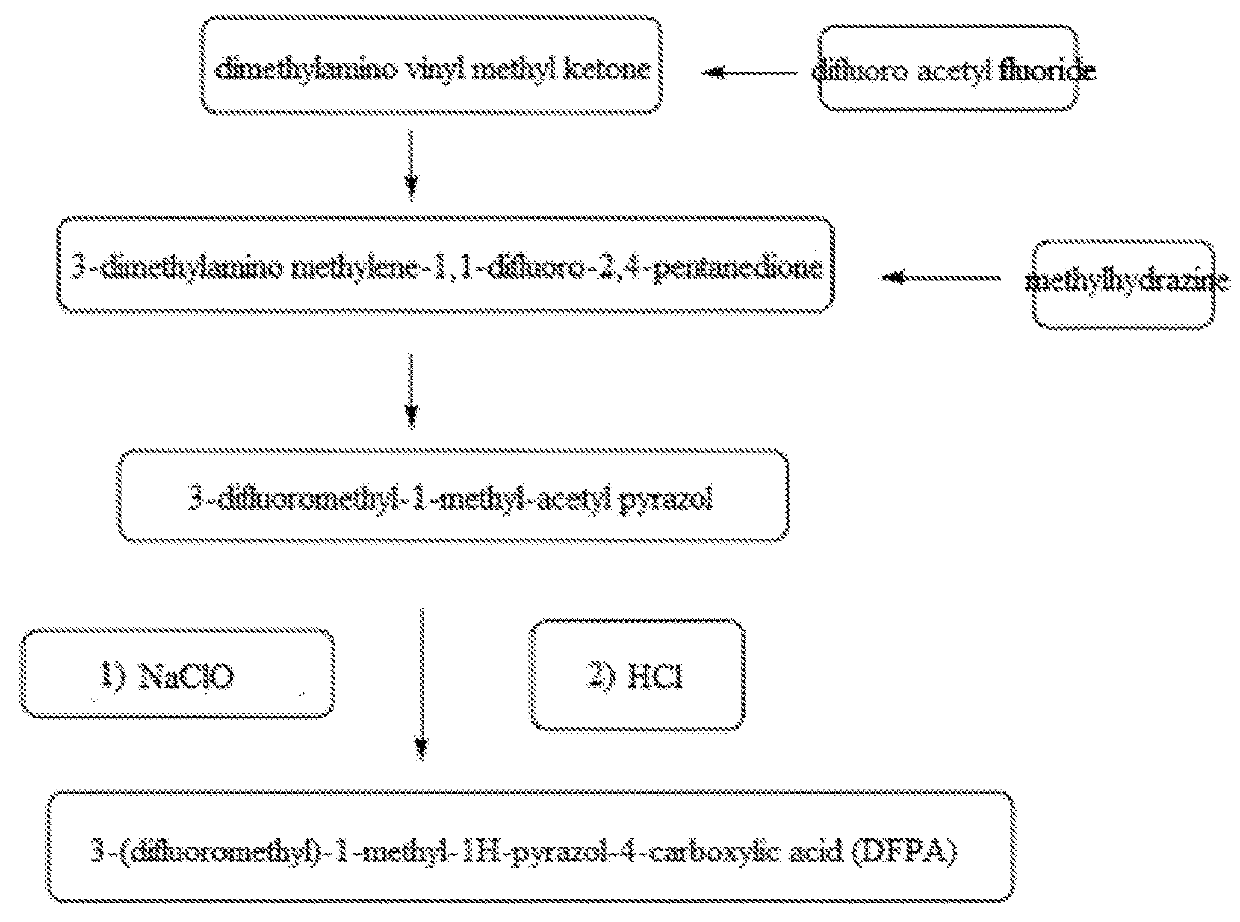

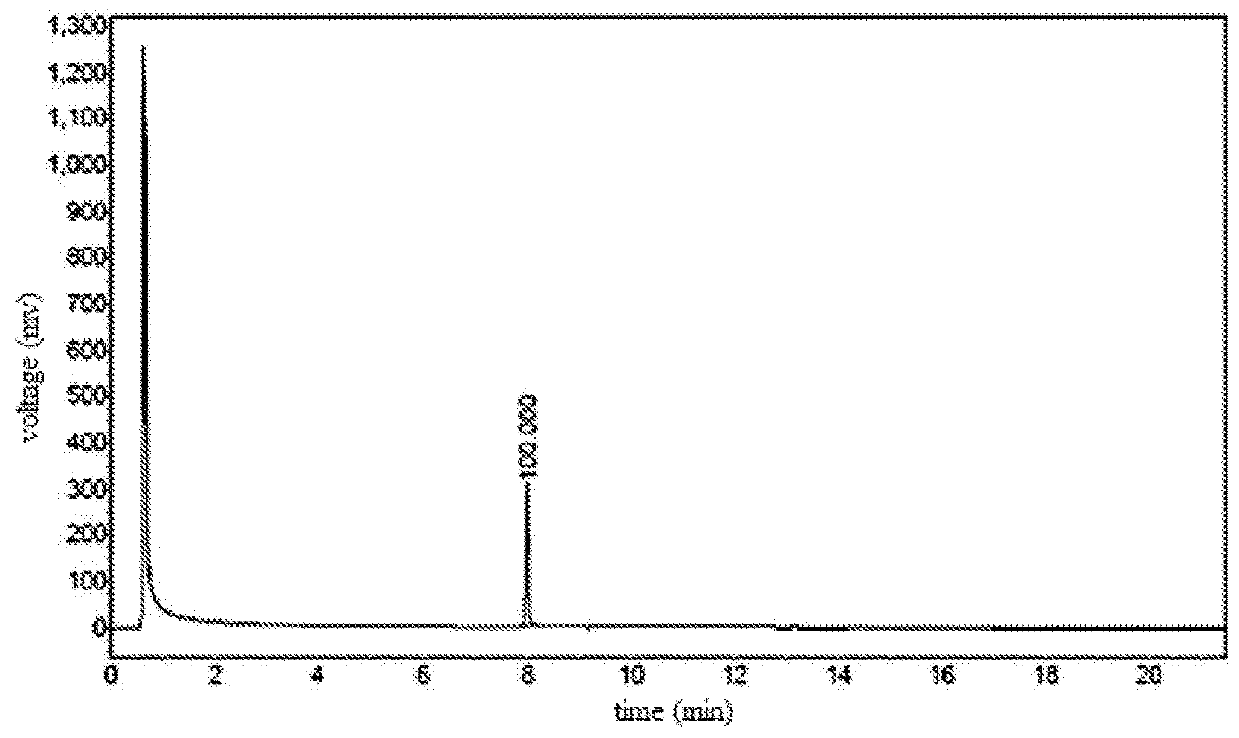

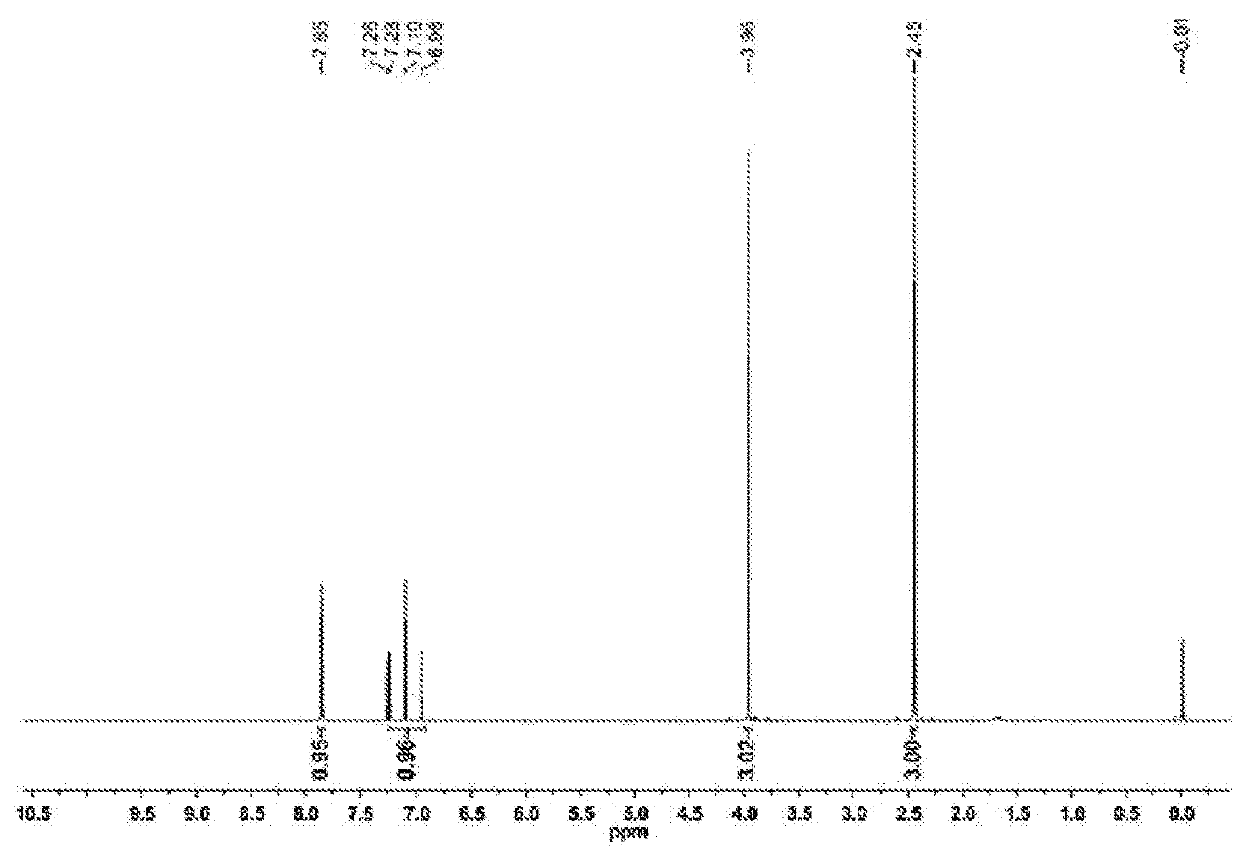

Method for the preparation of 3-fluoroalkyl-1-methylpyrazol-4-carboxylic acid

ActiveUS20180273486A1Reaction route is relatively shortLow raw material costBiocideOrganic chemistryMethylhydrazineCarboxylic acid

The present invention relates to method for the preparation of 3-fluoroalkyl-1-methylpyrazol-4-carboxylic acid, wherein it comprises the following steps: step 1, fluoroacetyl fluoride derivative shown in Formula I undergoes condensation with dimethylamino vinyl methyl ketone, as a result, 3-dimethylamino methylene-fluoro-2,4-pentanedione derivative shown in Formula II is formed; step 2, ring closing reaction takes place between said 3-dimethylamino methylene-fluoro-2,4-pentanedione shown in Formula II and methylhydrazine, in this way, 3-fluoroalkyl-1-methyl-4-acetyl pyrazol derivative shown in Formula III is obtained; step 3, the said 3-fluoroalkyl-1-methyl-4-acetyl pyrazol derivative shown in Formula III is oxidized in the presence of alkali, and then acidified, in this way, 3-fluoroalkyl-1-methylpyrazol-4-carboxylic acid shown in Formula IV is formed. Preparing method of present invention, wherein the required preparing route is simple, the raw material cost is low, the resulting yield of each step is high, and it is suitable for industrialization.

Owner:CHANGZHOU KEYLAB BIOCHEM CO LTD

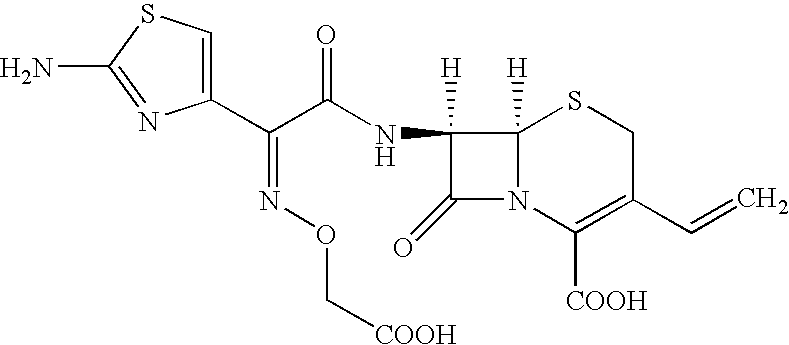

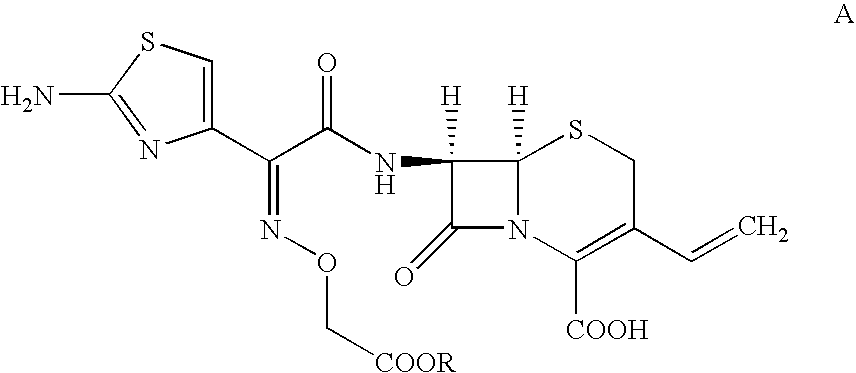

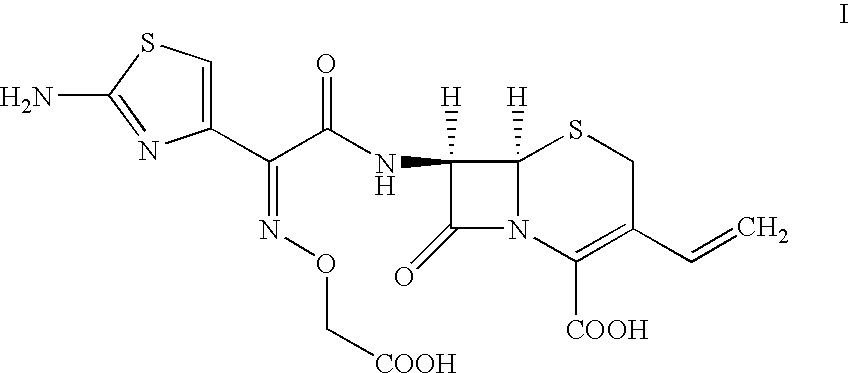

Process For the Preparation of Cefixime

There is provided an improved process for preparing cefixime. Thus, for example, 7-amino-3-vinyl-3-cephem-4-carboxylic acid is reacted with 2-mercapto-1,3-benzothiazolyl-(Z)-2-(2-aminothiazol-4-yl)-2-(methoxycarbonyl)-methoxyimino acetate in tetrahydrofuran and water at 4° C. in the presence of triethylamine. The reaction mass is extracted with ethyl acetate. 7-[2-(2-Amino-4-thiazolyl)-2-(methoxycarbonylmethoxyimino)acetamido]-3-vinyl-3-cephem-4-carboxylic acid triethylamine salt present in the aqueous layer is hydrolyzed with sodium hydroxide in less than 30 minutes and aqueous hydrochloric acid is added immediately to adjust the pH to 4.8 to 5.2. Then, aqueous hydrochloric acid is added at 35° C. to adjust the pH 2.5 and cooled to crystallize cefixime trihydrate in high purity.

Owner:HETERO DRUGS LTD

PVC-based power cable sleeve and preparation method thereof

InactiveCN111499985ASimple and fast operationRaw materials are easy to getPlastic/resin/waxes insulatorsPolymer scienceMeth-

The invention provides a PVC-based power cable sleeve and a preparation method of the power cable sleeve. The PVC-based power cable sleeve is composed of the following raw materials in parts by weight: 30-40 parts of PVC, 20-30 parts of CPVC, 30-40 parts of fluorine-containing triazine-modified PVC, 6-10 parts of vinylferrocene-2,4-diamino-6-vinyl-S-triazine-bis(trimethylsilyl)vinyl phosphate-vinyltrimethoxysilane copolymer, 0.5-1.5 parts of oxidized paraffin, 5-10 parts of nanometer silicon boride and 10-15 parts of a filler. The invention further discloses a preparation method of the PVC-based power cable sleeve. The PVC-based power cable sleeve disclosed by the invention has the advantages of good processing fluidity, low preparation cost, good impact resistance, corrosion resistance, heat resistance, weather resistance and wear resistance, environment friendliness, no toxicity and excellent comprehensive performance.

Owner:扬州力泰管业有限公司

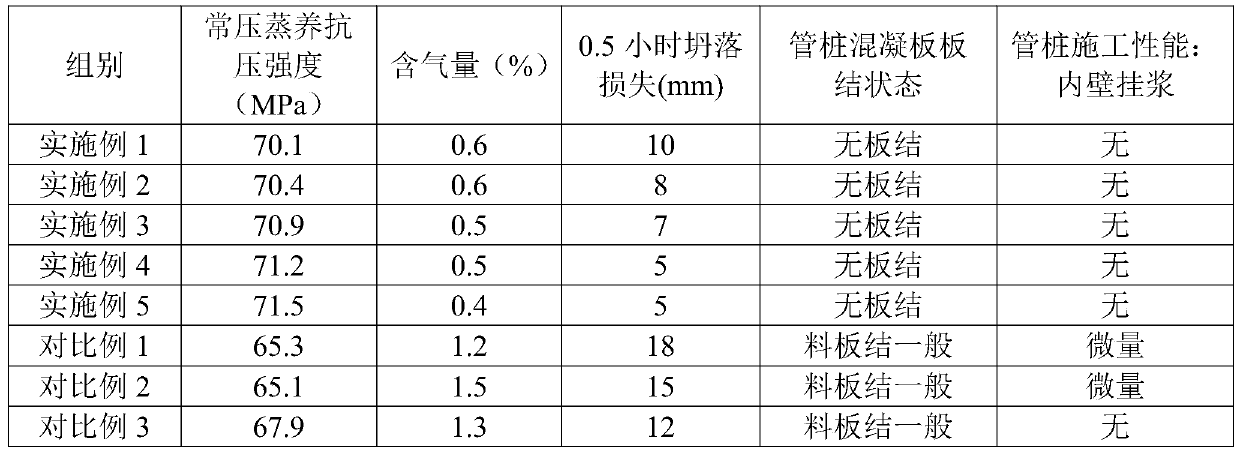

Environment-friendly non-autoclaved tubular pile water reducing agent and preparation method thereof

InactiveCN111423148AImprove production efficiencyImprove manufacturing yieldPolyethylene glycolBoronic acid

The invention discloses an environment-friendly non-autoclaved tubular pile water reducing agent characterized by comprising the following components in parts by weight: 10 to 20 parts of 1,3-bis(oxiranylmethyl)-5-(2-propenyl)-1,3,5-triazine-2,4,6(1H,3H,5H)-trione / 4,6-diamino-1,3,5-triazine-2-acetic acid polycondensate, 5 to 10 parts of 7-amino-3-vinyl-3-cephem-4-carboxylic acid / 4,4'-diaminostilbene-2,2'-disulfonic acid / polyethylene glycol monoallyl ether / 4-vinylphenylboronic acid copolymer, 1 to 3 parts of 9-fluorenecarboxylic acid, 0.3 to 0.6 part of an initiator, 2 to 5 parts of plant polysaccharide and 35 to 45 parts of water. The invention further discloses a preparation method of the environment-friendly non-autoclaved tubular pile water reducing agent. The environment-friendly non-autoclaved tubular pile water reducing agent disclosed by the invention is remarkable in water reducing effect, has the advantages of low dosage, excellent plasticizing performance, no obvious negative influence on the comprehensive performance of concrete, good energy-saving and environment-friendly performance in the preparation and use processes, high reaction activity, low reaction temperatureand capabilities of effectively enhancing the compressive strength, remarkable reduction of the hardening and viscosity of the concrete and improvement of the construction performance of the concrete.

Owner:赵良文

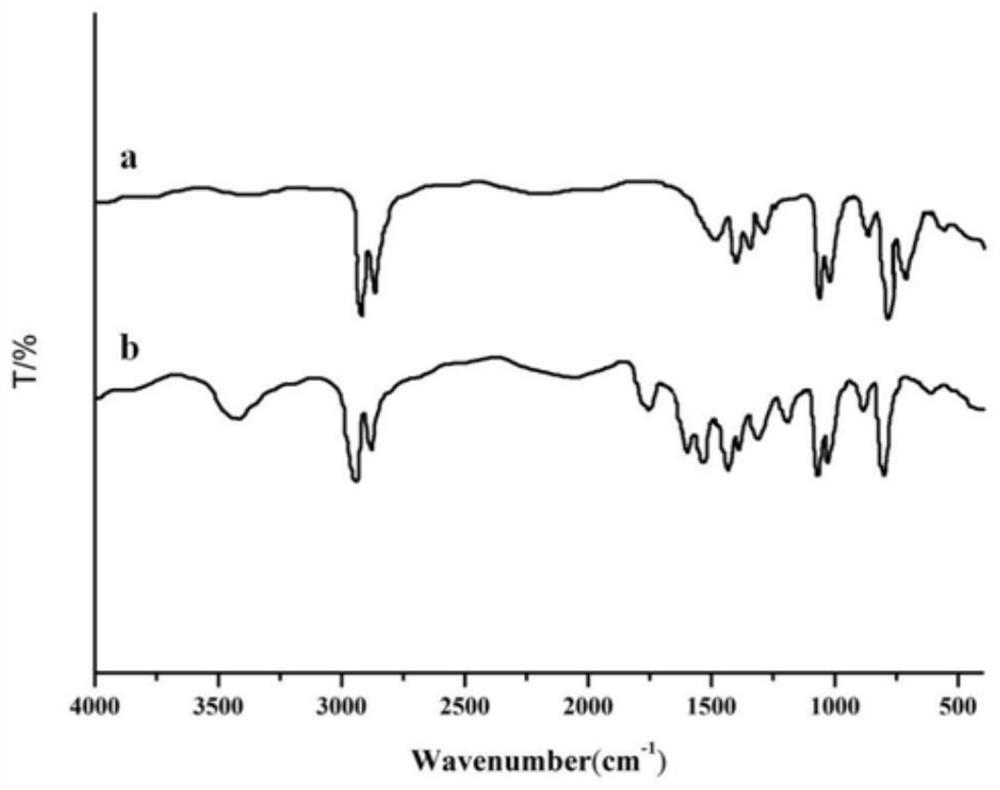

Preparation method and application of polyamino vinyl silicone oil

InactiveCN112961355AGood flexibilityHigh viscosityLight resistant fibresGrip property fibresDisiloxanePolymer science

The invention belongs to the technical field of organic silicon material preparation, and particularly relates to a preparation method and application of polyamino vinyl silicone oil. The preparation method comprises the following steps: 1) under the condition of inert gas, adding a basic catalyst and a siloxane ring body, heating while stirring, reacting for a period of time, then adding a polyamino silane coupling agent and tetramethyl divinyl disiloxane, and continuously reacting for a period of time; and 2) performing heating and continuously performing reacting for a period of time to obtain a semitransparent viscous liquid. The invention solves the problems that in the prior art, an amino silicon oil preparation method is numerous in operation steps and high in manufacturing cost, and softness and yellowing resistance cannot be achieved at the same time.

Owner:山东特龙谱新材料有限公司

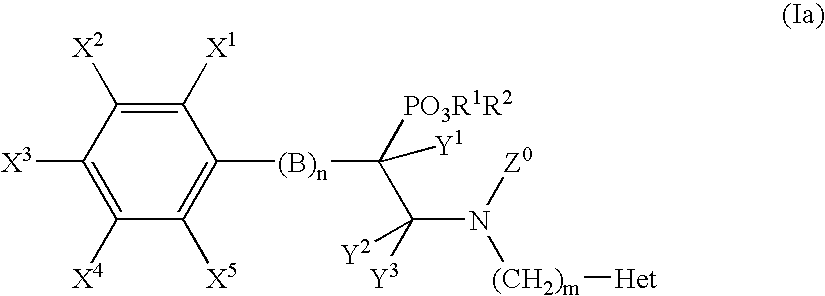

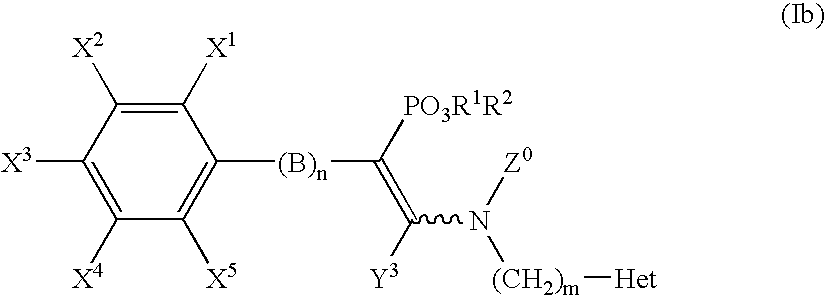

Alpha-substituted beta-aminoethyl phosphonate derivatives

InactiveUS20050187193A1Decrease plasma levelEnhancing thrombolysisBiocidePhosphorous compound active ingredientsVery low-density lipoproteinLow-density lipoprotein

The present invention relates to novel α-substituted-β-aminoethylphosphonate and α-substituted-β-aminovinylphosphonate derivatives and their uses for lowering plasma levels of apo (a), Lp(a), apo B, apo B associated lipoproteins (low density lipoproteins and very low density lipoproteins) and for lowering plasma levels of total cholesterol.

Owner:ILEX PRODUCTS INC

A kind of ultraviolet light and moisture dual curing polyurethane hot-melt adhesive and preparation method thereof

ActiveCN111117554BHigh functionalityImprove curing speedPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to the field of hot melt adhesives, in particular to an ultraviolet light and moisture dual-curing hot melt adhesive and a preparation method thereof. The ultraviolet light and moisture dual-cured polyurethane hot melt adhesive is prepared from the following raw materials in parts by weight: 20 to 50 parts of thermoplastic resin, 20 to 50 parts of polyester polyol, 5 to 35 parts of polyether polyol, 1 to 10 parts of trifunctional small molecular polyol, 1 to 10 parts of hydroxyl-terminated acrylate or amino-terminated vinyl monomer, 2 to 20 parts of polyisocyanate, 0.1 to 1 part of catalyst, 1 to 5 parts of photoinitiator, 0.2 to 2 parts of silane coupling agent and 0.2 to 2 parts of defoaming agent. The polyurethane hot melt adhesive containing double reaction groups of vinyl and isocyanate is prepared by reacting a vinyl functional monomer containing terminal hydroxyl or amino, polyester and polyether polyol with polyisocyanate. After the hot melt adhesive is applied, the molecular weight of the vinyl polymer in the product is further increased through ultraviolet irradiation to form a large-molecular-weight reticular high polymer to generate pressure sensitivity and better initial adhesion strength, so that the functions of quick positioning and no pressure maintaining are achieved.

Owner:COLLTECH DONGGUAN BONDING TECH CO LTD

Environment-friendly automotive interior composite material and preparation method thereof

The invention discloses an environment-friendly automobile interior composite material. Characterized in that it is characterized in that it comprises, the composition comprises the following components in parts by weight: 30 to 40 parts of polypropylene resin; 2, 10-anthracene dicarboxylic acid / 2, 10-anthracene dicarboxylic acid; 10 to 15 parts of 9,10-anthracenedicarboxylic / 2,4-diamino-6-vinyl-S-triazine polycondensate, 20 to 30 parts of N-(4-cyano-3-trifluoromethylphenyl)methacrylamide-allylphenyl carbonate-triisopropanolate methacrylate copolymer, 10 to 15 parts of mullite fiber, 1 to 3 parts of initiator, 0.3 to 0.8 part of antioxidant, 0.5 to 1.5 parts of compatilizer and 2 to 5 parts of nano porous hollow cage-shaped titanium oxide. The invention also provides a preparation method of the environment-friendly automotive interior composite material. The environment-friendly automobile interior composite material disclosed by the invention is excellent in mechanical property, smallin pungent smell, good in flame retardance and impact resistance, excellent in wear resistance, thermal stability, aging resistance, low temperature resistance and scratch resistance, good in comprehensive performance and long in service life.

Owner:刘超

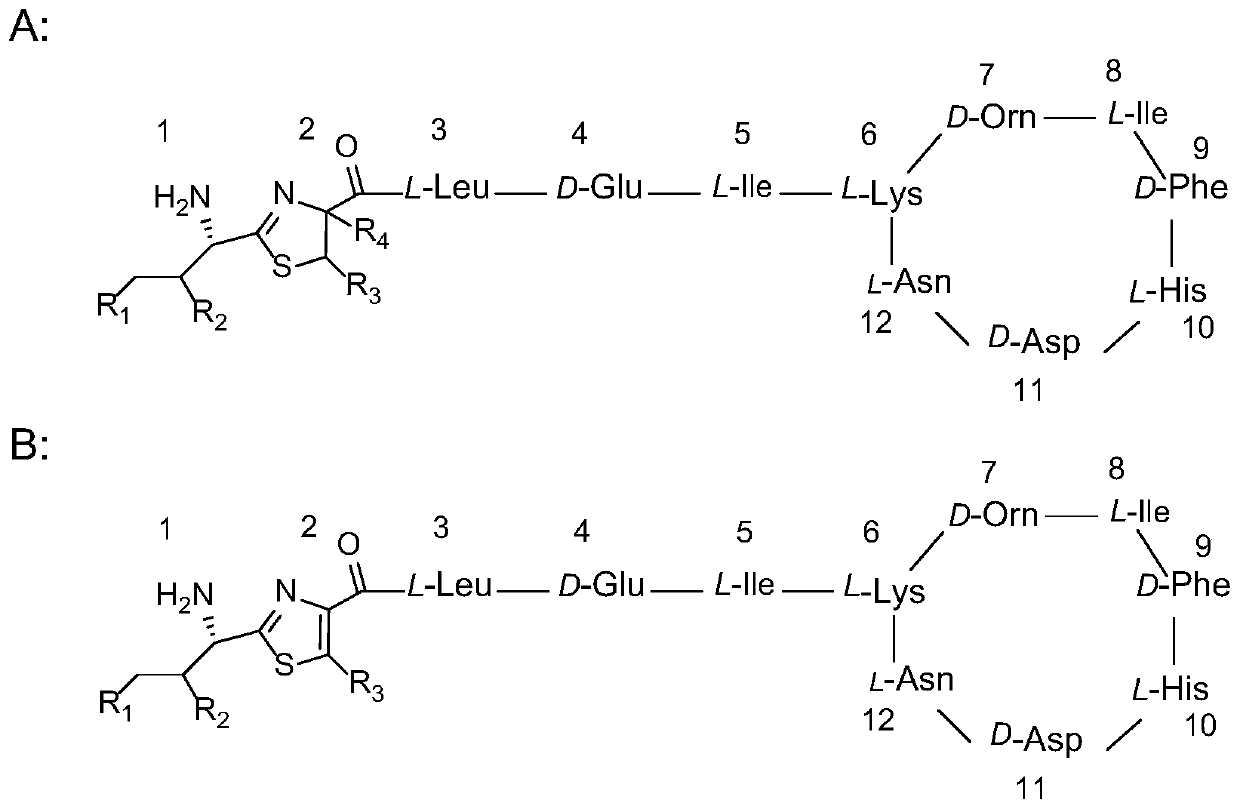

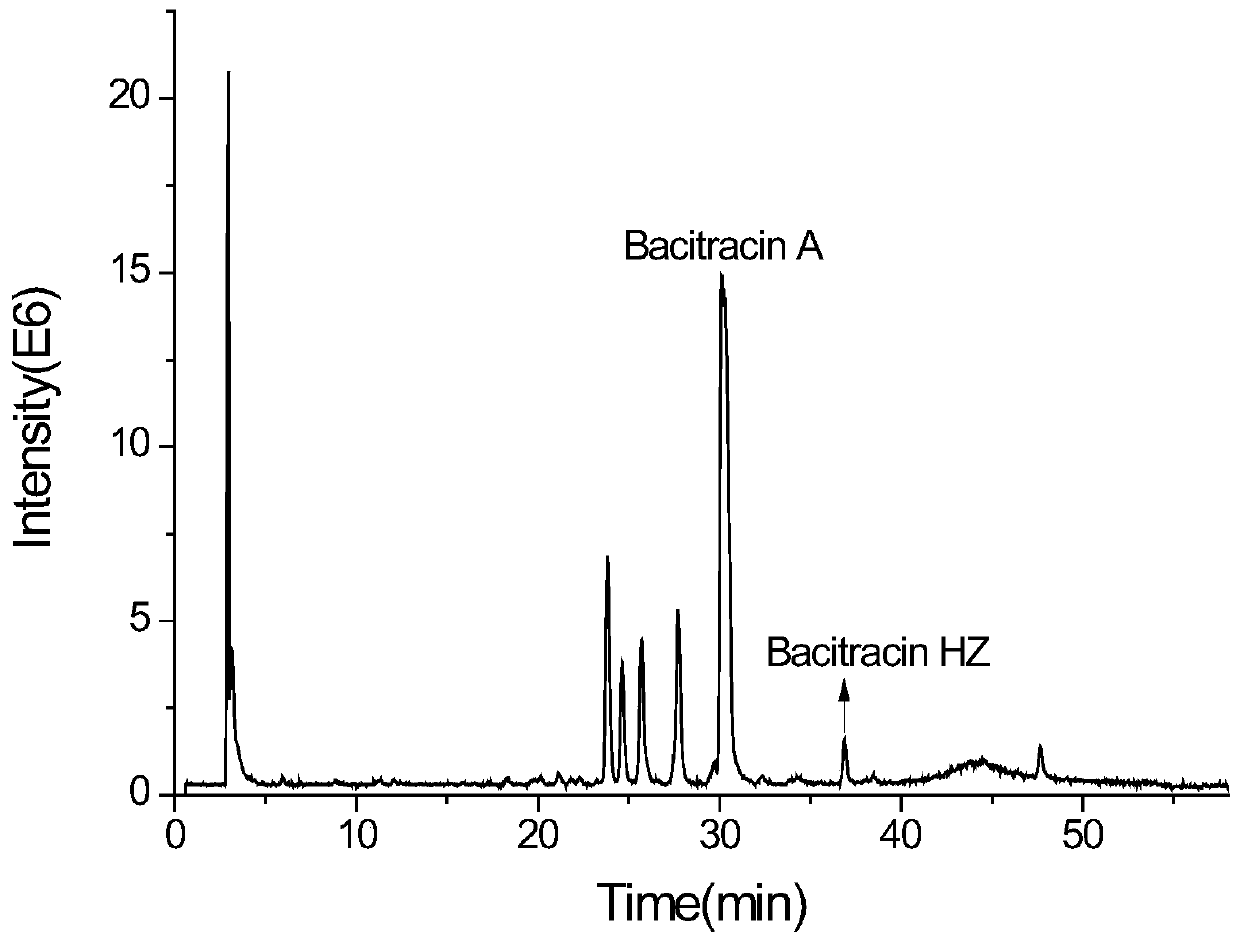

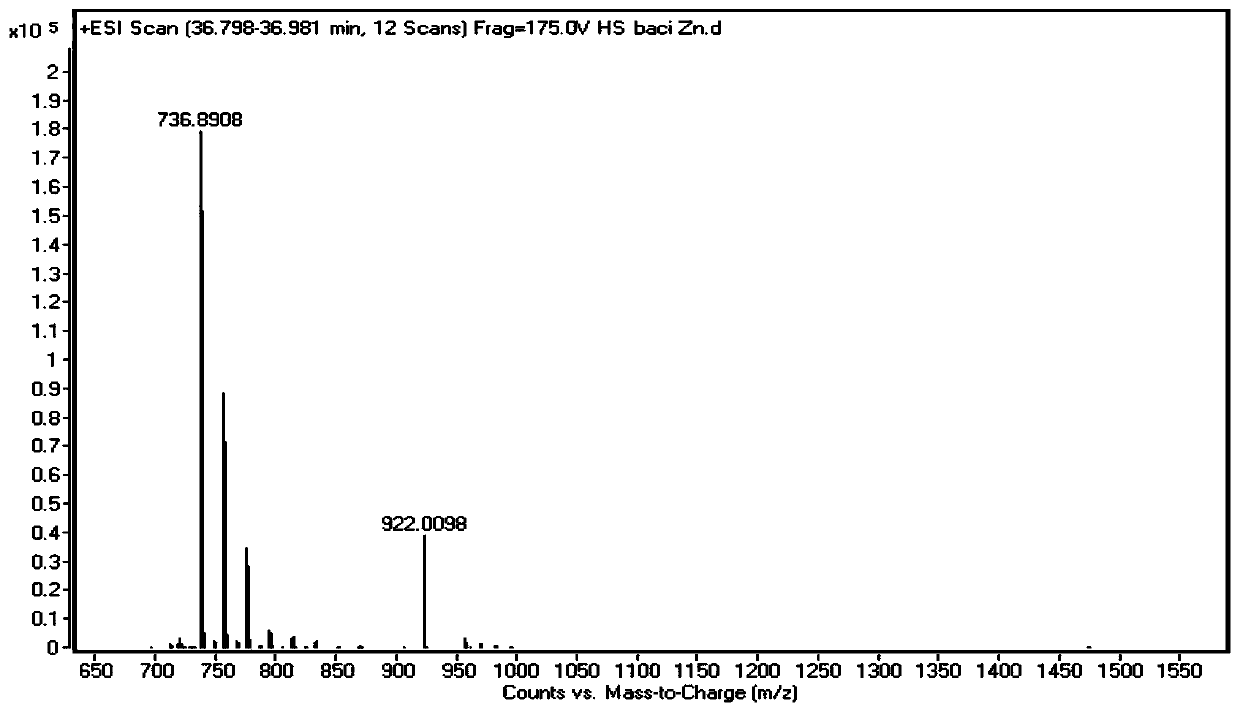

Analysis method of bacitracin and components thereof

The invention discloses a novel bacitracin (Bacitracin) component and a high performance liquid chromatography-mass spectrometry (HPLC-MS) analysis method thereof. The component is verified to be bacitracin A subjected to double methylenation and vinylation or bacitracin Y subjected to double methylenation and ethylation through HPLC-MS (High Performance Liquid Chromatography-Mass Spectrometry) and secondary mass spectrometry, and the novel component is named Bacitracin HZ. The invention discloses the presence of novel non-protein amino acids, such as 2-amino-3-vinyl-5-hexenoic acid, 2-amino-4-vinyl-5-hexenoic acid, 3-vinylcysteine, 2-vinylcysteine and the like. The bacitracin HZ has antibacterial activity or toxicity different from antibacterial activity or toxicity of common bacitracin components and has potential application value; and the structure confirmation of the compounds also provides a research basis for strictly controlling the quality of bacitracin.

Owner:SHANGHAI INST FOR FOOD & DRUG CONTROL

POE graft polymer for enhancing PP printing performance and preparation process thereof

InactiveCN111635483AIncrease surface tensionIncreased surface wetting tensionPolymer scienceCarboxylic acid

The invention relates to a POE graft polymer for enhancing PP printing performance. The POE graft polymer comprises 8-10 parts by weight of 7-amino-3-vinyl-8-oxo-5-thia-1-azabicyclo(4,2,0)oct-2-ene-2-carboxylic acid, 0.30-0.50 part by weight of 2,5-dimethyl-2,5-bis(tert-butyl peroxy)hexane, 0.20-0.30 part by weight of dioctyl tin dilaurate, 0.20-0.25 part by weight of an antioxidant 1010, 0.30-0.35 part by weight of an antioxidant DLTP and 0.8-1.0 part by weight of a wetting agent EBS, wherein the total part by weight of the components is 100. By the adoption of the method, the surface wettingtension is remarkably improved, good printing performance is shown, and the low-temperature impact strength and the antistatic performance are also greatly improved; and the PP polymer has excellentprinting performance and good comprehensive performance.

Owner:JIANGSU ZHONGMEI CABLE

Wear-resistant flame-retardant automotive floor leather and preparation method thereof

InactiveCN111304931AAvoid the defects of weak bondingImprove adhesionRoad vehiclesTextiles and paperMethacrylatePolymer science

The invention discloses wear-resistant flame-retardant automotive floor leather. The wear-resistant flame-retardant automotive floor leather is characterized by consisting of a fiber cloth base layerand a wear-resistant flame-retardant surface adhesive layer, wherein the wear-resistant flame-retardant surface adhesive layer is prepared from the following raw materials in parts by weight: 20-30 parts of 2,4-diamino-6-vinyl-S-triazine / 1-adamantyl methacrylate / 3,4,5-trifluorocinnamic acid copolymer, 8-15 parts of hyperbranched polyurethane acrylate, 50-60 parts of 3,5-di(6-isocyanate hexyl)-2H-1,3,5-oxadiazine-2,4,6(3H,5H)-triketone / 1,3-dihydroxy ethyl adamantane polycondensate, 3-5 parts of epoxy modified hexamethylene tetramine, 1-3 parts of black phosphorus, 10-15 parts of nano boron fibers, 1-3 parts of diamond, 1-3 parts of coupling agent, 3-6 parts of amino modified polysiloxane and 0.2-0.4 parts of azodiisobutyronitrile. The invention also discloses a preparation method of the wear-resistant flame-retardant automotive floor leather. The wear-resistant flame-retardant automotive floor leather disclosed by the invention is good in wear-resisting property, remarkable in flame-retardant effect, excellent in environment protection property and antibacterial property, light in weight, high in mechanical strength, good in aging resistance and weather resistance and long in service life.

Owner:朱冬梅

Alcohol-resistant flame-retardant ink

The invention discloses alcohol-resistant and flame-retardant printing ink, and is characterized in that the ink is prepared from the following components in parts by weight: 30 to 40 parts of carbazole-modified hyperbranched polysulfonamide, 8 to 13 parts of a cyhalothrin / diethyl cyclohexylamino vinyl phosphate / allyl triethoxy silane copolymer, 1 to 2 parts of a dispersing agent, 0.5 to 2 parts of a leveling agent, 0.3 to 0.7 part of an antifoaming agent, 3 to 6 parts of a pigment and 20 to 30 parts of an organic solvent. The invention also discloses a preparation method of the flame-retardant ink. The flame-retardant ink disclosed by the invention is remarkable in flame-retardant effect, high in transparency, good in glossiness, good in flexibility, alcohol resistance and wear resistance, strong in adhesive force and excellent in performance stability.

Owner:HUNAN QIWEI TECH CO LTD

Weather-resistant PVC decorative film

ActiveCN114714713AGood storage stabilityFast film formationSynthetic resin layered productsInksPolymer scienceMeth-

The invention discloses a weather-resistant PVC (polyvinyl chloride) decorative film. Relates to a PVC decorative film. The high-weather-resistant PVC / PMMA composite board comprises a high-weather-resistant PVC bottom layer, a high-weather-resistant printing middle layer and a high-weather-resistant PVDF / PMMA surface layer, printing weather-resistant water-based ink on the upper surface of the high-weather-resistant PVC bottom layer to form a high-weather-resistant printing middle layer; the PVDF / PMMA surface layer is attached to the upper surface of the high-weather-resistance printing middle layer in a pressed mode; wherein the weather-resistant water-based ink comprises modified acrylic resin; the modified acrylic resin is propionic acid resin modified by modified organic silicon; the modified organic silicon is prepared from chloromethyl triisopropoxy silane and 1-amino-2-ethylene cyclopropane carboxylic acid methyl ester; the prepared water-based ink is good in storage stability, high in film forming speed and good in adhesion fastness and has excellent glossiness and acid and alkali resistance, and the prepared PVC decorative film is high in weather resistance and also has excellent pollution resistance.

Owner:江苏万拓新材料科技有限公司

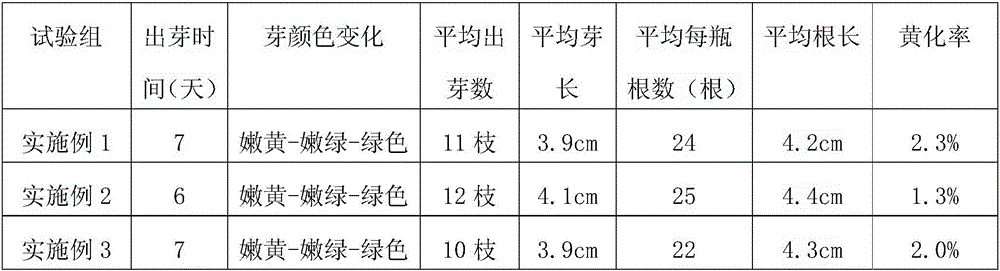

Dracaena sanderiana culture solution

InactiveCN106518427APromote germination and rootingPromote growthCalcareous fertilisersMagnesium fertilisersChemistryTryptophan

The invention belongs to the technical field of dracaena sanderiana planting and particularly provides a dracaena sanderiana culture solution. The culture solution is prepared by mixing a mother solution I, a mother solution II, a mother solution III and a mother solution IV, and the volume ratio of the mother solution I to the mother solution II to the mother solution III to the mother solution IV is (8-11) to (2-5) to (2-5) to (0.04-0.12). The mother solution I comprises the following substances: ammonium nitrate, potassium dihydrogen phosphate, potassium nitrate, calcium chloride and magnesium sulfate; the mother solution II comprises the following substances: ferric sulfate, manganese sulfate, sodium molybdate, cobalt chloride and boric acid; the mother solution III comprises the following substances: tryptophan, threonine and diisopropanolamine; and the mother solution IV comprises the following substances: water-soluble azone, Limbolid, furalane, amobam and methylaminovinylglycine. The nutrient solution provided by the invention has the effects of promoting rooting and sprouting, accelerating growth, strengthening braches and greening leaves and has great significance in popularization.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

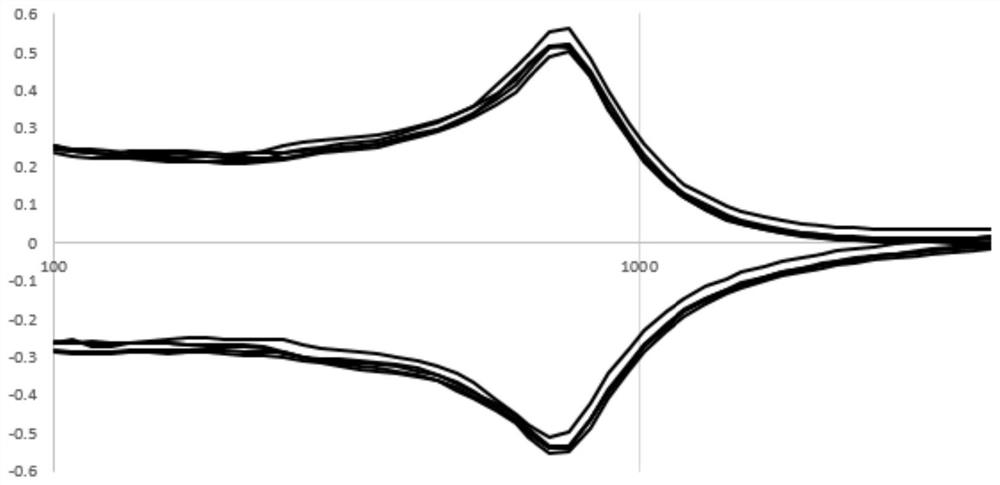

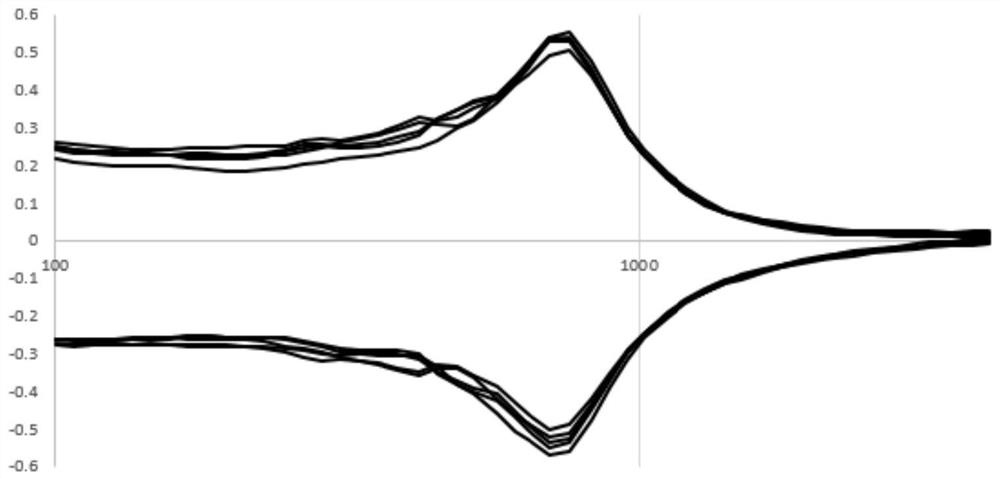

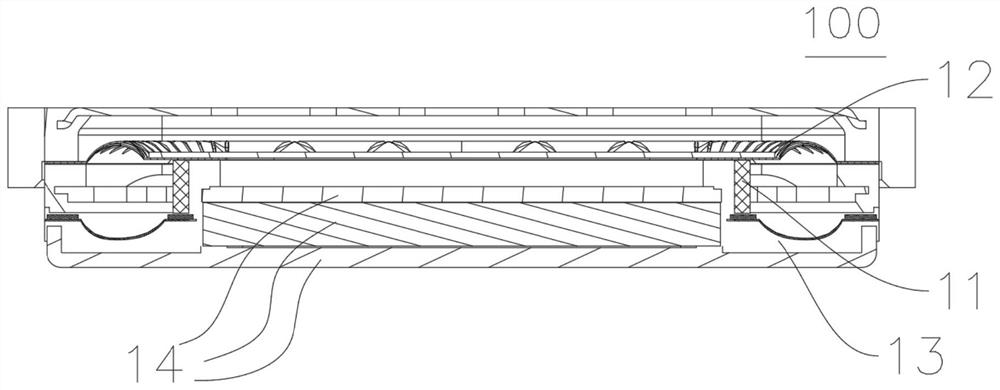

Vibrating diaphragm of sound production device, and sound production device thereof

The invention discloses a vibrating diaphragm of a sound production device, and the sound production device. The vibrating diaphragm of the sound production device comprises at least one modified silicone rubber membrane layer, the modified silicone rubber membrane layer is made of modified silicone rubber, the modified silicone rubber is prepared by cross-linking reaction of a polymer blend of polydimethylsiloxane and polyhedral polysilsesquioxane, the molecular formula of polyhedral polysilsesquioxane is (RSiO3 / 2)n, the ratio of silicon atoms to oxygen atoms in the molecular formula is 2: 3, n is a natural number, R in the molecular formula is a first group or a substituent group of the first group, and the first group is H, alkyl, alkylene, epoxy group, amino, vinyl, aryl or arylene. The vibrating diaphragm is prepared from the modified silicone rubber which is formed by adding polyhedral polysilsesquioxane with high steric hindrance into the silicone rubber for blending and grafting, so that the vibrating diaphragm has good rebound resilience, the damping performance of the vibrating diaphragm is improved, and polarization reduction and distortion reduction are facilitated.

Owner:GOERTEK INC

Contact lens packaging solutions

ActiveUS20170160565A1Improved and sustainable wettabilitySpectales/gogglesPackage sterilisationChemistryHigh pressure

The present invention relates to improved contact lens products which not only have an improved and sustainable wettability. The contact lens product of the invention comprises a soft hydrogel contact lens immersed and autoclaved in a packaging solution including a polyoxyethylene-polyoxybutylene block copolymer and a high molecular weight copolymer of N-vinylpyrrolidone and at least one amino-containing vinylic monomer. The present invention also provides methods for making contact lens products of the invention.

Owner:ALCON INC

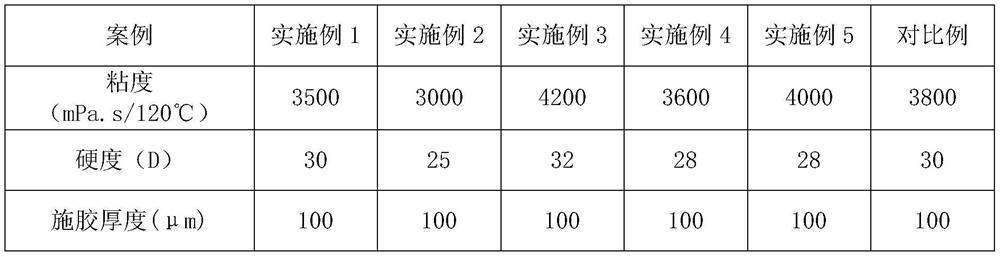

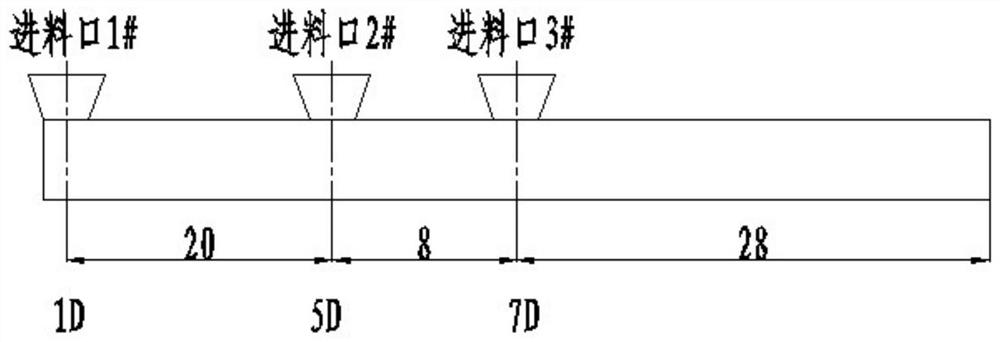

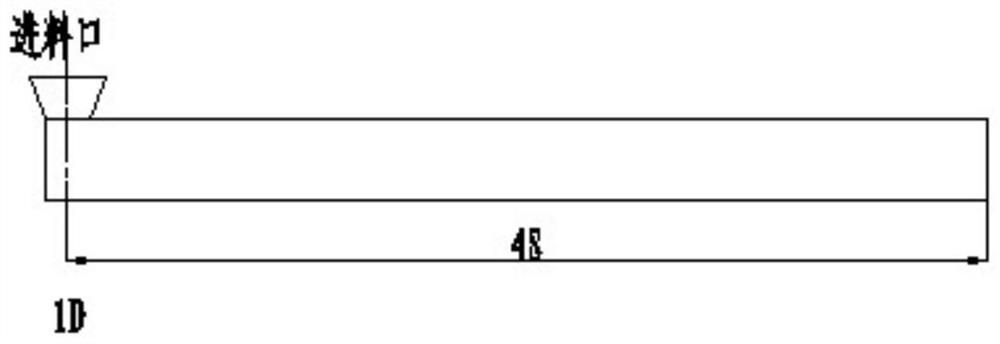

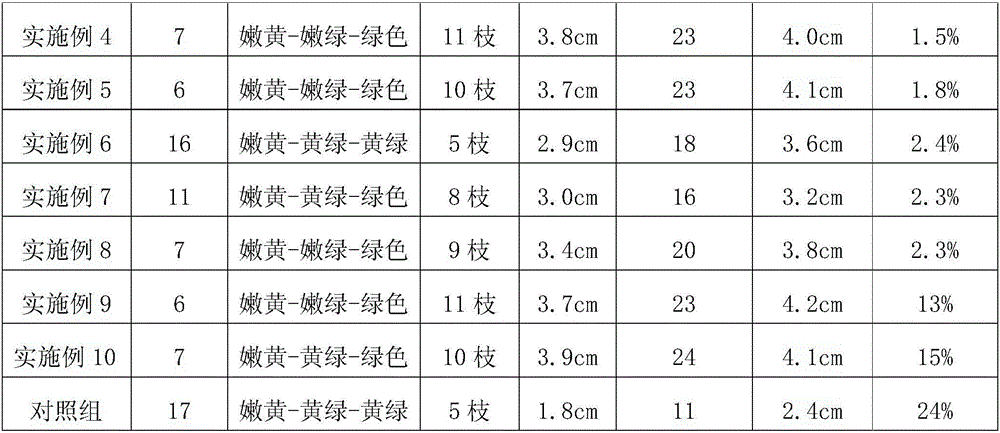

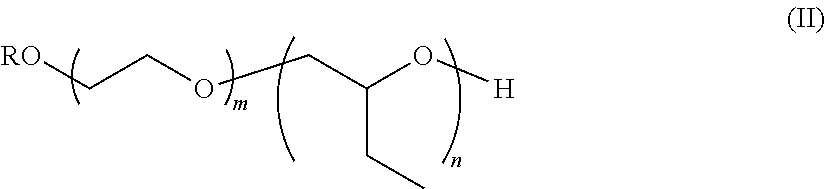

Preparation method of 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2-carboxylic acid

The invention relates to a preparation method of 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2-carboxylic acid. The method comprises the following steps: step 1, removing a 4th site carboxyl protector of GVNE under effect of phenol, and removing a 7th site amino protective group in the presence of penicillin acylase to obtain a water solution containing 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo [4.2.0]oct-2-ene-2-carboxylic acid basic salt; and step 2, adding acid into the water solution obtained in the step 1 to precipitate 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo [4.2.0]oct-2-ene-2-carboxylic acid solid and then dissolve the solid, so as to obtain a solution containing 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo [4.2.0]oct-2-ene-2-carboxylic acid acid salt; and extracting the solution by an organic solvent, and adding alkali into the water phase to precipitate the 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo [4.2.0]oct-2-ene-2-carboxylic acid, so as to obtain 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo [4.2.0]oct-2-ene-2-carboxylic acid with light color and low impurity content.

Owner:GUANGZHOU BAIYUNSHAN PHARM CO LTD

Anti-aging and wear-resistant belt for bucket wheel belt machine

The invention discloses an anti-aging and wear-resistant belt for a bucket wheel belt machine. The anti-aging and wear-resistant belt is characterized by comprising the following components in part byweight of 30-40 parts of a functional copolymer, 70-80 parts of isoprene rubber, 15-25 parts of vinyl hyperbranched polyborosiloxane, 5-10 parts of a chlorine-containing hyperbranched siloxane polymer, 3-7 parts of epoxy-terminated liquid nitrile rubber, 5-10 parts of silica nanofibers, 2-4 parts of boron nitride nanofibers, 1-3 parts of borophene, 1-3 parts of a coupling agent and 0.5-1.5 partsof an initiating agent, wherein the functional copolymer is prepared by free radical polymerization of 2,4-diamino-6-vinyl-S-triazine, N-(4-cyano-3-trifluoromethyl phenyl) methylacrylamide, allyl thiopropionate and allyl phenyl sulfone. The belt for the bucket wheel belt machine has the advantages of excellent wear resistance, aging resistance and high temperature resistance, good comprehensive performance, long service life and good mechanical properties.

Owner:HUNAN CHANGZHONG MACHINERY

A kind of button with cotton and linen effect and preparation method thereof

ActiveCN110343402BWith cotton effectMeet the needs of physical and chemical propertiesClothes buttonsDyeing processPolymer scienceCellulose acetate

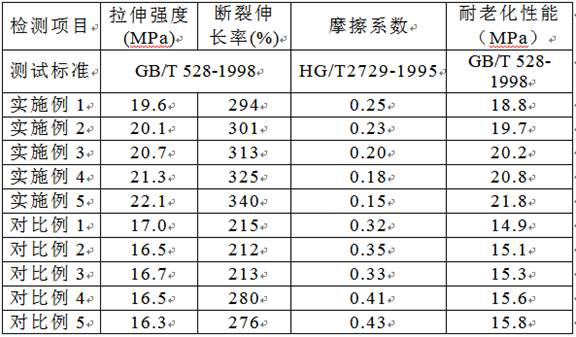

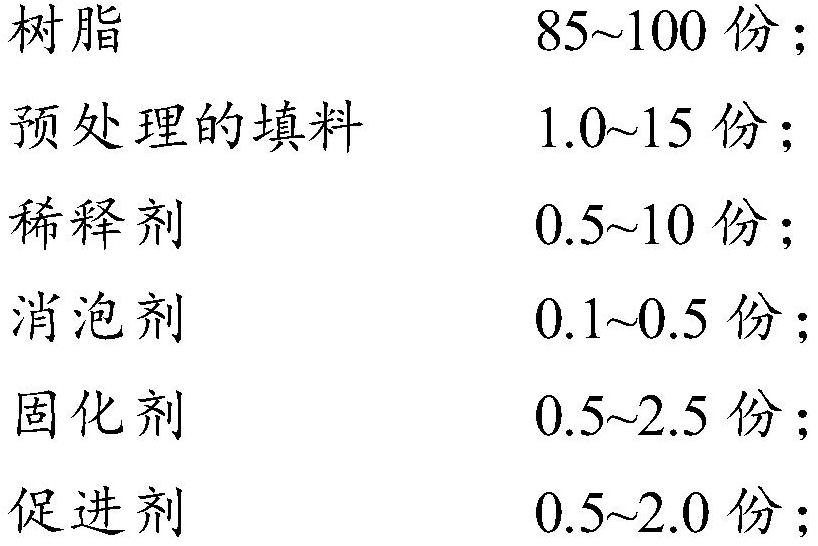

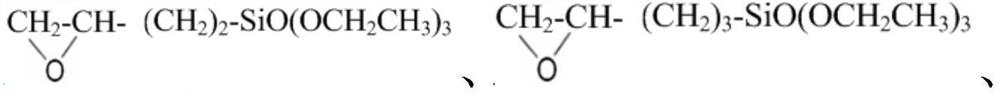

The invention provides a button with cotton and linen effect and a preparation method thereof. The button with cotton and linen effect provided by the present invention comprises: 85-100 parts of resin; 1.0-15 parts of pretreated filler; 0.5-10 parts of diluent; 0.1-0.5 part of defoamer; 0.5 to 2.5 parts; accelerator 0.5 to 2.0 parts; the pretreated fillers include fillers and pretreatment agents covering the fillers; the fillers are selected from one of milk enzymes, lignin, cellulose acetate, diatomite and kaolin. one or more; pretreatment agent is selected from Y‑R‑SiOX 3 One or more of; wherein, Y is selected from amino, vinyl, epoxy, cyano or methacryloyloxy; R is alkylene; X is selected from chlorine atom, methoxy, ethoxy group, methoxyethoxy or acetoxy. The surface of the button has the effect of cotton and linen, and can meet the necessary functional requirements when the button is used on clothing.

Owner:ZHEJIANG WEIXING IND DEV

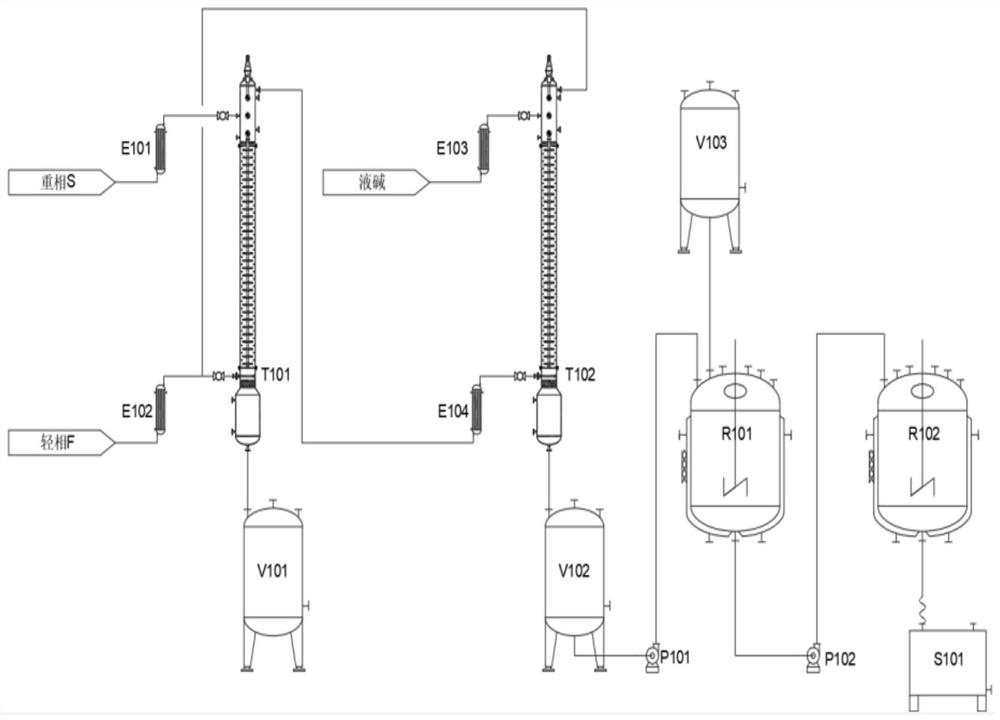

Continuous production method for recovering phenylacetic acid from 7-amino-3-vinyl cephalosporanic acid production wastewater

PendingCN113861019AHigh recovery rateResidue reductionOrganic compound preparationWater contaminantsPhenylacetic acidCephalosporanic Acids

The invention discloses a continuous production method for recovering phenylacetic acid from 7-amino-3-vinyl cephalosporanic acid production wastewater. The method comprises the following steps: acidifying wastewater, extracting phenylacetic acid in the wastewater into an organic phase by using an organic solvent, stripping the organic solvent from the extracted wastewater, directly discharging the wastewater into a sewage station, washing the organic phase containing phenylacetic acid by using liquid caustic soda, and washing phenylacetic acid in the organic phase into water; and after the washing,recycling and reusing organic phase in the raw wastewater for phenylacetic acid extraction, after washing, acidifying water phase, and then performing cooling crystallization to recover phenylacetic acid. According to the process, the problem that phenylacetic acid is difficult to recover from the phenylacetic acid-containing wastewater can be solved, the recovered phenylacetic acid can be sold as a byproduct, and after the phenylacetic acid is recovered, the wastewater can be directly discharged to a sewage station after the organic solvent is stripped, so that the environment is protected, and certain economic benefits are generated.

Owner:山东普洛得邦医药有限公司 +1

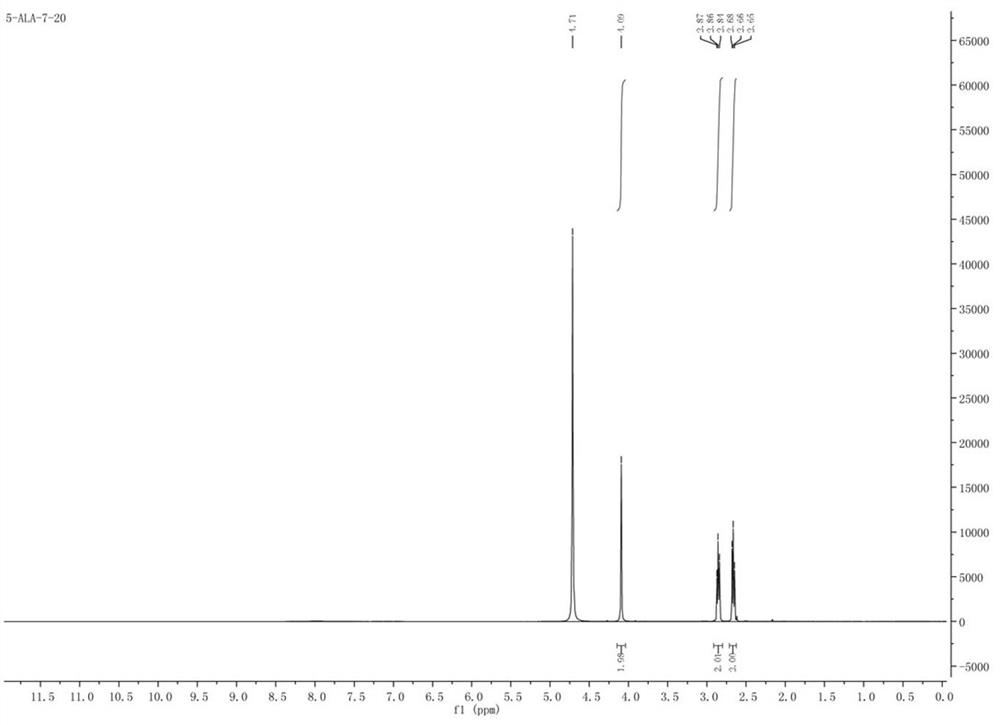

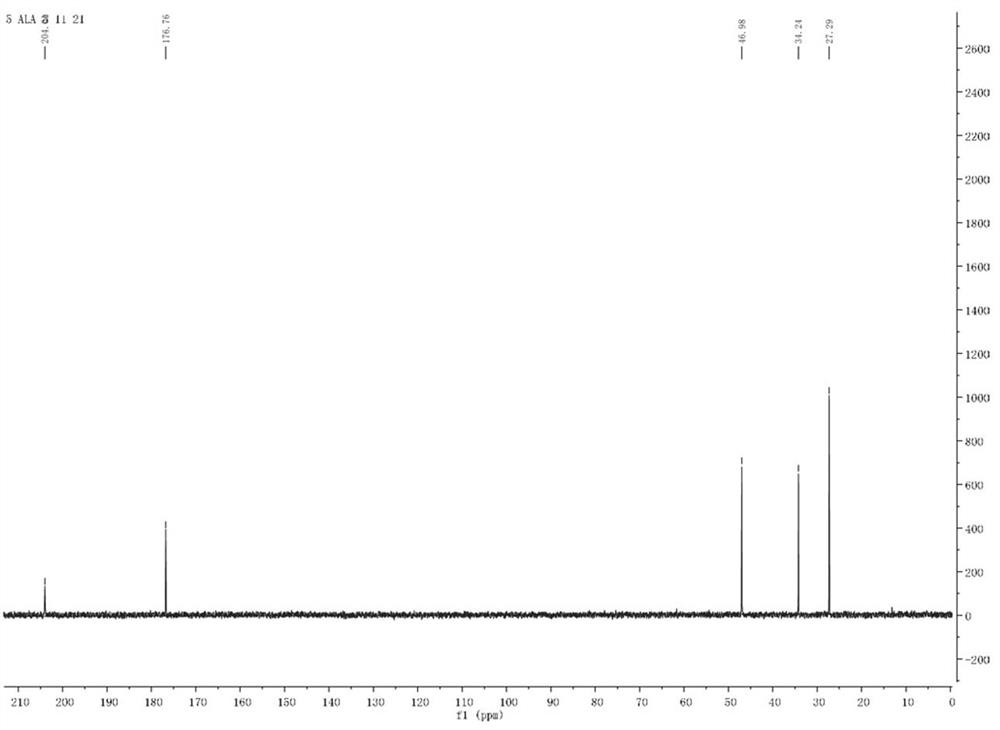

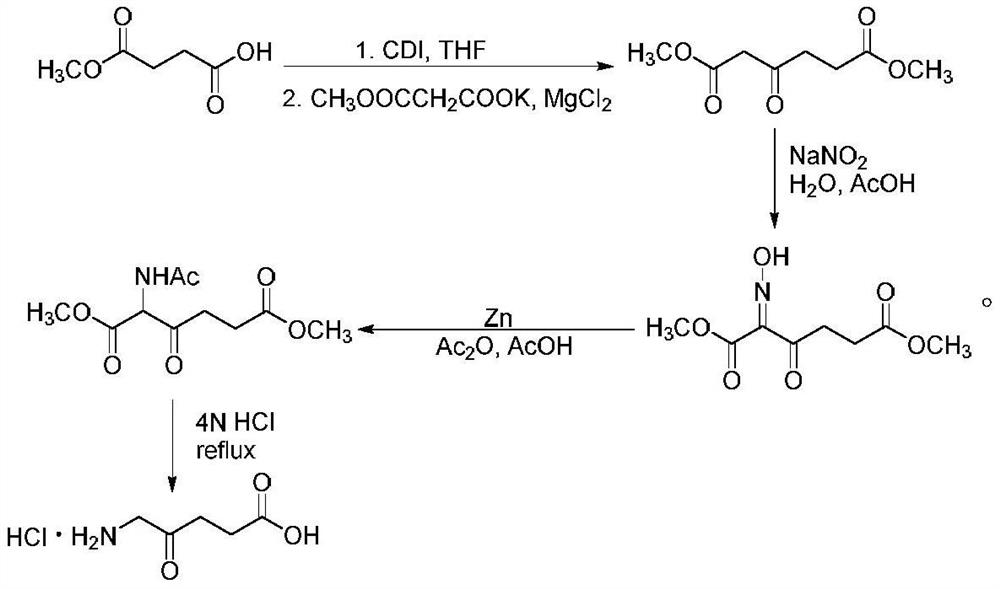

A kind of synthetic method of 5-aminolevulinic acid hydrochloride

ActiveCN109265341BSimple processRaw materials are easy to obtainOrganic compound preparationCarboxylic acid esters preparationPropanoic acidButanedioic acid

The invention relates to a synthesis method of 5-aminolevulinic acid hydrochloride, comprising: using succinic anhydride as a raw material, performing monoesterification with methanol to obtain monomethyl succinate; monomethyl succinate and N, N'-carbonyldiimidazole undergoes a nucleophilic substitution reaction to obtain 4-(1-imidazole)-4-oxobutanoic acid methyl ester; 4-(1-imidazole)-4-oxobutanoic acid methyl ester and nitromethane A nucleophilic substitution reaction occurs under the catalysis of a basic compound to obtain methyl 5-nitro-4-oxopentanoate; methyl 5-nitro-4-oxopentanoate undergoes a reduction reaction with a metal reducing agent and undergoes hydrolysis 5-aminolevulinic acid hydrochloride is obtained. The process of the present invention is simple, the raw materials are easy to obtain, no special rectification and recrystallization devices are needed to process the intermediate products, no toxic and expensive raw materials are used, and the use of heavy metal reducing agents is avoided, so as not to pollute the environment, and the synthesis cost It is cheap, and the purity of the synthesized product can reach 97% after recrystallization detection, and the total yield is high, which can reach more than 70%.

Owner:HENAN UNIVERSITY

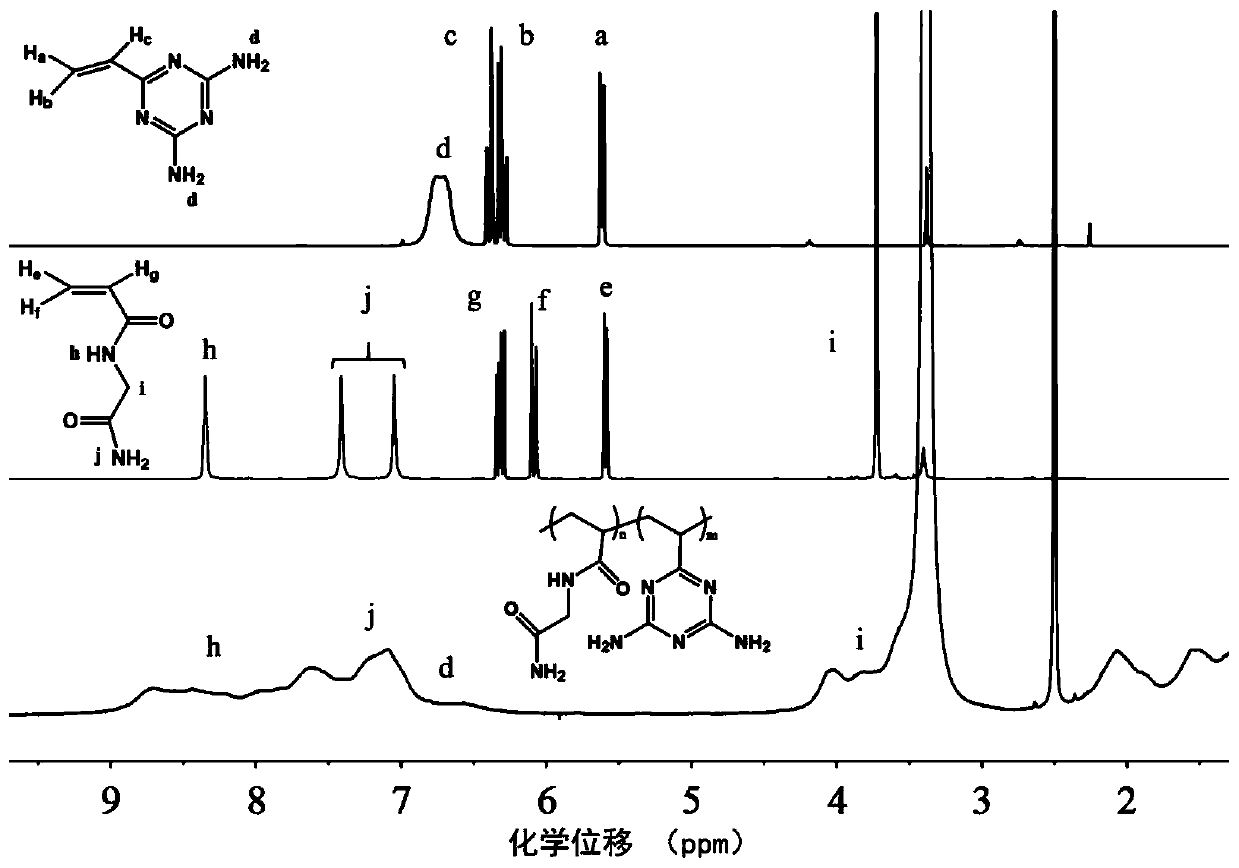

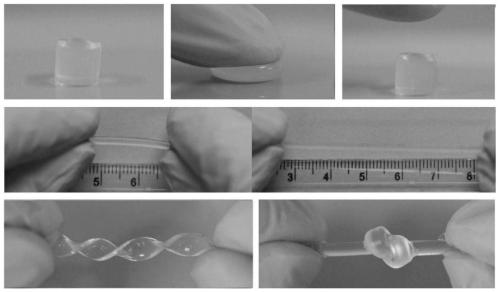

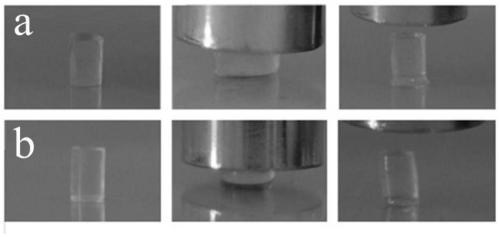

High-strength copolymerized hydrogel based on acrylamide glycinamide and preparation method thereof

The invention discloses a high-strength copolymer hydrogel based on acryloylaminoglycinamide, and a preparation method thereof. The high-strength copolymer hydrogel based on acryloylaminoglycinamide is prepared through free radical polymerization of acryloylaminoglycinamide and 2,4-diamino-6-vinyltriazine monomers, and dihydrogen bonds are formed between acrylamido-glycinamido groups, between 2,4-diamino-6-vinyltriazinyl groups and between the acrylamido-glycinamido group and the 2,4-diamino-6-vinyltriazinyl group on the side chains of the molecules of the copolyme hydrogel. The method has theadvantages of simplicity in operation, and easiness in preparation, and allows the hydrogel to have the advantages of pH response, high strength, high stability and the like.

Owner:TIANJIN UNIV

Synthesis of hexavalent chromium imprinted material on graphene oxide-mesoporous silicon surface and its application in water treatment

ActiveCN108246265BStrong specificityGood removal effectOther chemical processesWater contaminantsFunctional monomerCross linker

Owner:GUANGDONG UNIV OF TECH

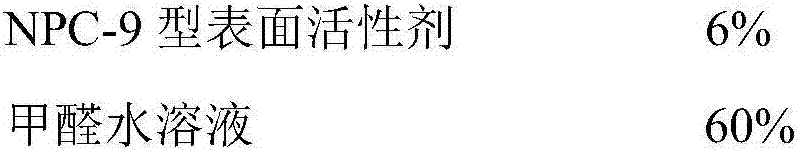

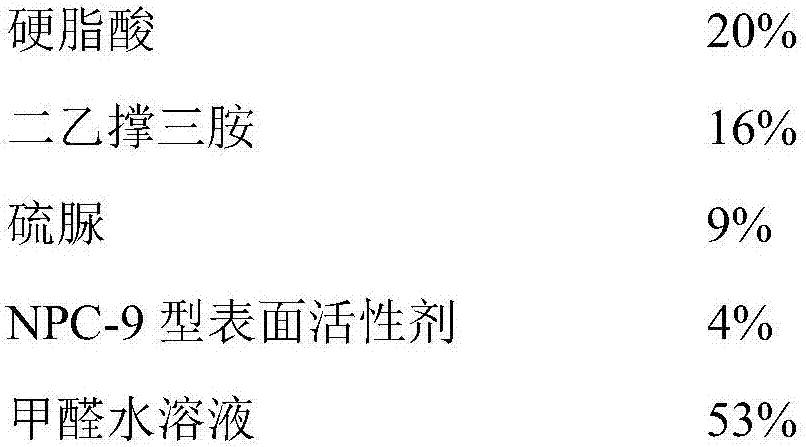

Hydrogen sulfide corrosion inhibitor applied to thermal recovery of thickened oil and preparation method thereof

ActiveCN107459984AHigh temperature resistanceHigh corrosion inhibition efficiencyDrilling compositionBorehole/well accessoriesThioureaDiethylenetriamine

The invention relates to a hydrogen sulfide corrosion inhibitor applied to thermal recovery of thickened oil and a preparation method thereof, belonging to the fields of formulas and technologies of chemical agents used for oil fields. The corrosion inhibitor comprises the following components in percentages by mass: 15% to 30% of stearic acid, 14% to 24% of diethylenetriamine, 5% to 15% of thiourea, 1% to 6% of an NPC-9 type surfactant and 30% to 60% of a formaldehyde aqueous solution. The preparation method comprises the following steps: (1) adding stearic acid and diethylenetriamine into a xylene solvent, carrying out heating to 150 to 160 DEG C, carrying out stabilizing for 2 to 3 h, then carrying out heating to 190 to 200 DEG C, carrying out a reaction for 3 h, and carrying out cooling so as to obtain an imidazoline stearate intermediate; (2) adding the imidazoline stearate intermediate, diethylenetriamine and thiourea into the xylene solvent, carrying out heating to 100 to 130 DEG C, carrying out a reaction for 4 to 5 h, and carrying out cooling so as to obtain aminoethylene-thioureidoimidazoline; and (3) uniformly mixing the formaldehyde aqueous solution with the NPC-9 type surfactant under stirring, adding aminoethylene-thioureidoimidazoline, and carrying out uniform mixing so as to obtain a required corrosion inhibitor. According to the invention, the preparation method is simple; and the corrosion inhibitor has the advantages of good temperature resistance, good compatibility with an additive, good adsorption effect and good corrosion inhibition effect.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

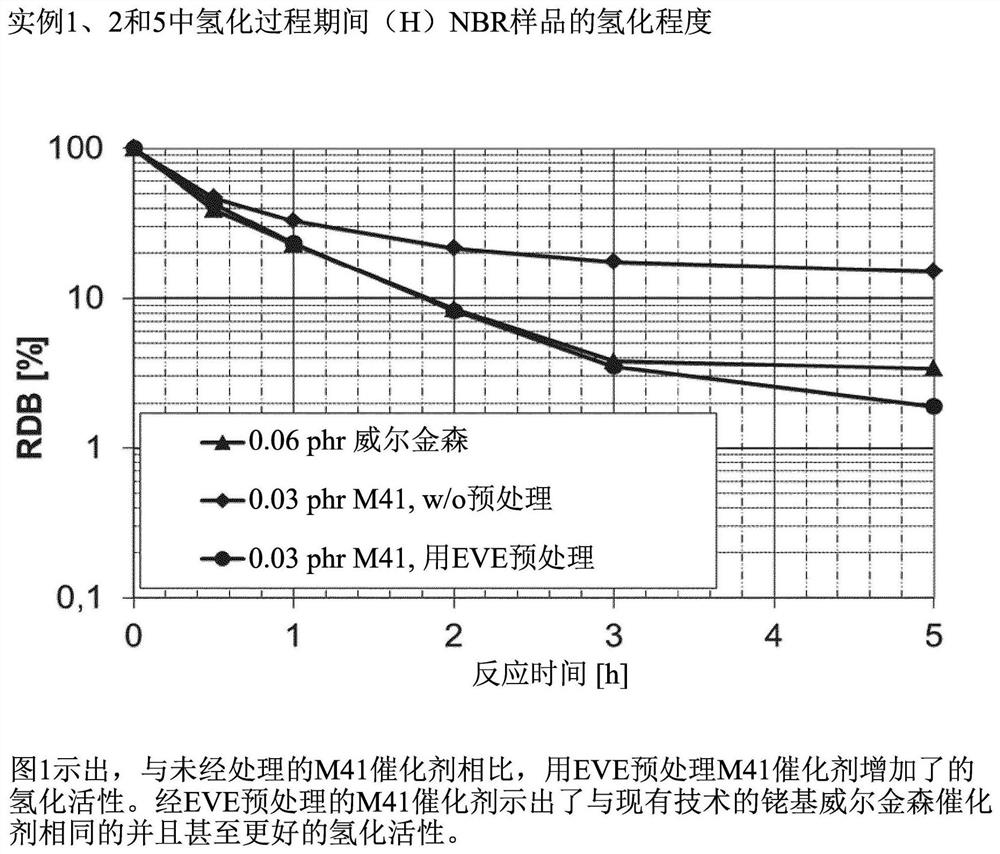

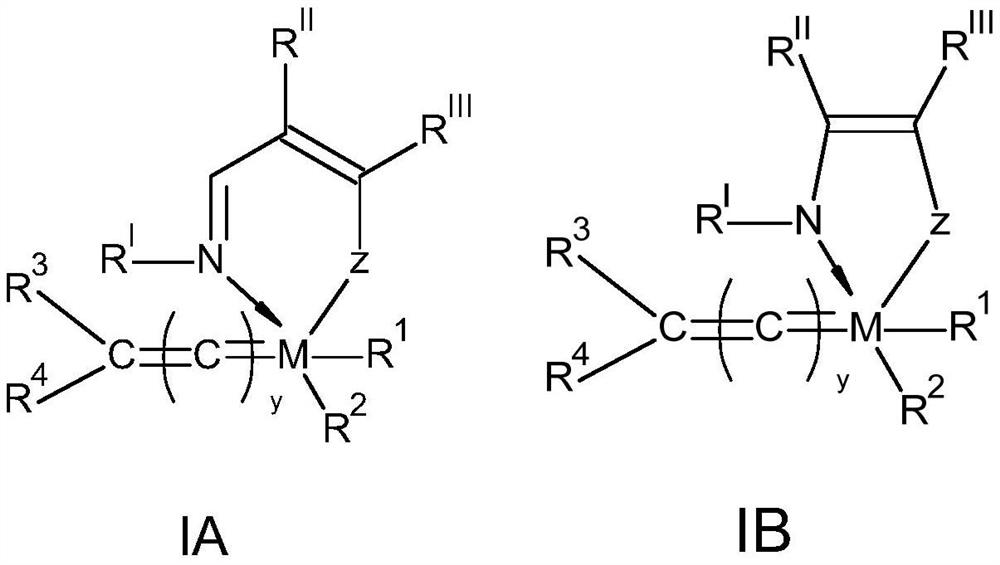

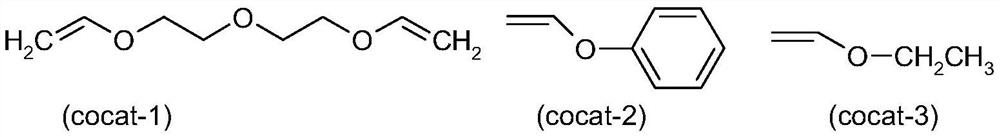

Hydrogenation catalyst compositions and their use for hydrogenation of nitrile rubber

PendingCN112004598AImprove hydrogenation activityIncrease the degree of hydrogenationOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsVinyl etherPolymer science

This invention relates to novel hydrogenation catalyst compositions obtainable from reacting metal-based complex hydrogenation catalysts, preferably (annellated) iminovinyloxy Ru species such as knownby the trade names Umicore M41 or Umicore M42, with specific co-catalysts such as ethyl vinyl ether (EVE) and to a process for selectively hydrogenating nitrile rubbers in the presence of such novelhydrogenation catalyst compositions, optionally with prior metathetic decrease of molecular weight.

Owner:ARLANXEO DEUT GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2-carboxylic acid Preparation method of 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2-carboxylic acid](https://images-eureka.patsnap.com/patent_img/d232af73-0c25-4f34-92ec-1f693d1270b1/BDA0000100188700000011.PNG)

![Preparation method of 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2-carboxylic acid Preparation method of 7-amino-3-ethenyl-8-oxo-5-thia-1-azabicyclo[4.2.0]oct-2-ene-2-carboxylic acid](https://images-eureka.patsnap.com/patent_img/d232af73-0c25-4f34-92ec-1f693d1270b1/BDA0000100188700000021.PNG)