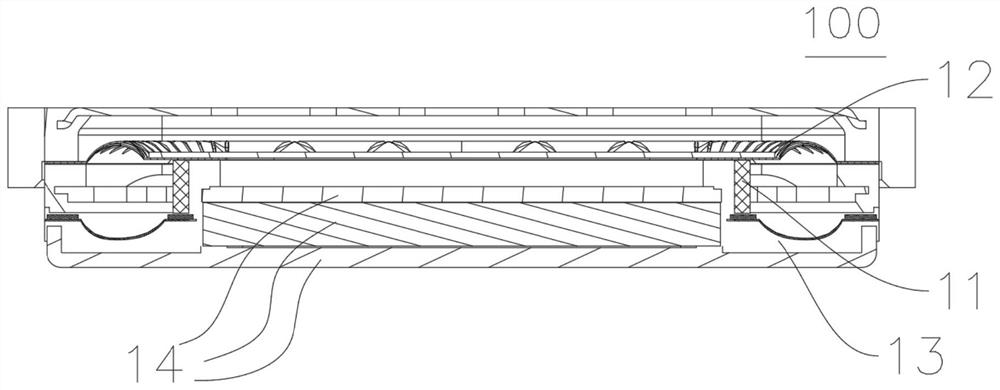

Vibrating diaphragm of sound production device, and sound production device thereof

A sounding device and rubber membrane technology, applied in the field of electroacoustics, can solve the problems of high distortion, poor damping performance, low modulus or hardness, etc., and achieve the effects of reducing distortion, improving damping performance and reducing polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] According to an embodiment of the present invention, there is also provided a method for preparing a diaphragm of a sounding device, including the following steps: S1. Blending and modifying polydimethylsiloxane and polyhedral polysilsesquioxane to form a co- mixed polymers. S2. Cross-linking and molding the blended polymer to form a vibrating membrane.

[0073] Therefore, high damping silicone rubber can be formed by blending polydimethylsiloxane and polyhedral polysilsesquioxane and carrying out crosslinking reaction. At room temperature, high damping silicone rubber is in a high elastic state, and the molecular chain is relatively It is easy to move, has high internal friction resistance between molecules, and has excellent damping performance. Furthermore, the modified silicone rubber film layer of the vibrating membrane can be prepared by using high damping silicone rubber as the raw material, which can not only meet the requirements of high power, waterproof perf...

Embodiment 1

[0085] Blend POSS (polyhedral polysilsesquioxane) and polydimethylsiloxane to form a blend polymer, POSS accounts for 0.5wt% of the blend polymer, form a diaphragm material after cross-linking reaction, and assemble into a product .

[0086] The polydimethylsiloxane formula is as follows:

[0087] In parts by mass, 100 parts of polydimethylsiloxane; 15 to 50 parts of white carbon black; 0.3 to 1 part of siloxane coupling agent; 0.5 to 2 parts of vulcanizing agent; 0.1 to 1.5 parts of catalyst .

Embodiment 2

[0089] POSS (polyhedral polysilsesquioxane) and polydimethylsiloxane are blended to form a blended polymer, POSS accounts for 10 wt% of the blended polymer, and a diaphragm material is formed after a cross-linking reaction to be assembled into a product.

[0090] The polydimethylsiloxane formula is as follows:

[0091] In parts by mass, 100 parts of polydimethylsiloxane; 15 to 50 parts of white carbon black; 0.3 to 1 part of siloxane coupling agent; 0.5 to 2 parts of vulcanizing agent; 0.1 to 1.5 parts of catalyst .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com