Anti-aging and wear-resistant belt for bucket wheel belt machine

A wear-resistant belt and belt conveyor technology, used in conveyors, transportation and packaging, etc., can solve the problems of further improvement of wear resistance and aging resistance, affecting performance stability, poor compatibility, etc., to achieve replacement High cost and maintenance cost, improved overall performance, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

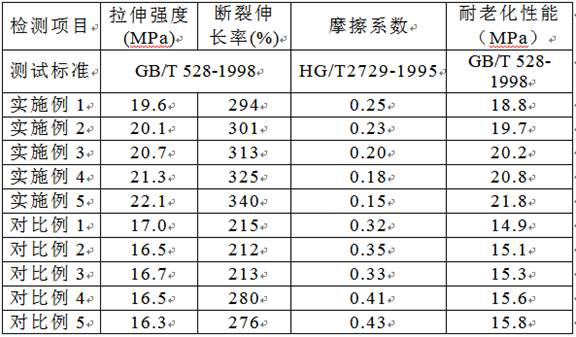

Examples

Embodiment 1

[0024] An anti-aging wear-resistant belt for a bucket wheel belt conveyor, characterized in that it is made of the following components in parts by weight: 30 parts of functional copolymer, 70 parts of isoprene rubber, vinyl hyperbranched polyborosilicate 15 parts of alkane, 5 parts of chlorine-containing hyperbranched siloxane polymer, 3 parts of epoxy-terminated liquid nitrile rubber, 5 parts of silica nanofibers, 2 parts of boron nitride nanofibers, 1 part of borographene, silane 1 part of coupling agent KH550, 0.5 part of azobisisobutyronitrile; the functional copolymer is 2,4-diamino-6-vinyl-S-triazine, N-(4-cyano-3- Trifluoromethylphenyl) methacrylamide, allyl mercapto propionate, and allyl phenyl sulfone are prepared by free radical polymerization.

[0025] The preparation method of the functional copolymer comprises the following steps: combining 2,4-diamino-6-vinyl-S-triazine, N-(4-cyano-3-trifluoromethylphenyl)formazine Acrylamide, allyl mercapto propionate, allyl p...

Embodiment 2

[0028] An anti-aging wear-resistant belt for a bucket wheel belt conveyor, characterized in that it is made of the following components in parts by weight: 33 parts of functional copolymer, 72 parts of isoprene rubber, vinyl hyperbranched polyborosilicate 17 parts of alkanes, 6 parts of chlorine-containing hyperbranched siloxane polymers, 4 parts of epoxy-terminated liquid nitrile rubber, 6 parts of silica nanofibers, 2.5 parts of boron nitride nanofibers, 1.5 parts of borographene, silane 1.5 parts of coupling agent KH560, 0.7 parts of azobisisoheptanonitrile; the functional copolymer is 2,4-diamino-6-vinyl-S-triazine, N-(4-cyano-3- Trifluoromethylphenyl) methacrylamide, allyl mercapto propionate, and allyl phenyl sulfone are prepared by free radical polymerization.

[0029] The preparation method of the functional copolymer comprises the following steps: combining 2,4-diamino-6-vinyl-S-triazine, N-(4-cyano-3-trifluoromethylphenyl)formazine Add acrylamide, allyl mercapto pro...

Embodiment 3

[0032] An anti-aging and wear-resistant belt of a bucket wheel belt conveyor, characterized in that it is made of the following components in parts by weight: 35 parts of functional copolymer, 75 parts of isoprene rubber, vinyl hyperbranched polyborosilicate 20 parts of alkane, 7 parts of chlorine-containing hyperbranched siloxane polymer, 5 parts of epoxy-terminated liquid nitrile rubber, 7.5 parts of silica nanofibers, 3 parts of boron nitride nanofibers, 2 parts of borographene, silane 2 parts of coupling agent KH570, 1 part of azobisisobutyronitrile; the functional copolymer is 2,4-diamino-6-vinyl-S-triazine, N-(4-cyano-3- Trifluoromethylphenyl) methacrylamide, allyl mercapto propionate, and allyl phenyl sulfone are prepared by free radical polymerization.

[0033] The preparation method of the functional copolymer comprises the following steps: combining 2,4-diamino-6-vinyl-S-triazine, N-(4-cyano-3-trifluoromethylphenyl)formazine Add acrylamide, allyl mercapto propionate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com