Patents

Literature

95results about How to "Suitable for continuous industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing alpha-angelica lactone from acetylpropionic acid

ActiveCN101475545AAvoid other side effectsHigh selectivityOrganic chemistryMolecular sieve catalystsPropanoic acidGas phase

The invention provides a method for preparing alpha-angelica lactone by levulinate. The method comprises the following steps: an inorganic liquid acid or a solid acid catalyst which is 1 to 10 weight percent of the levulinate is added into the levulinate; the levulinate and the alpha-angelica lactone in a gaseous phase of a reaction system are separated by rectifying at a temperature of between 100 and 150 DEG C with vacuum degree of between 20 and 150mmHg; the levulinate returns to the reaction system; the alpha-angelica lactone is condensed at a temperature of between 60 and 90 DEG C; and the product is obtained through separating and rectifying. The method has the advantages of high selectivity, high purity, and applicability of serialized industrial production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Microemulsion capsule for tobacco and preparation method of microemulsion capsule

ActiveCN106942787AExpand the range of material selectionRich fragrance and application rangeTobacco smoke filtersEssential-oils/perfumesWater in oilBiomass

The invention relates to a microemulsion capsule for tobacco and a preparation method of the microemulsion capsule. As for the capsule, a water-in-oil reversed-phase microemulsion serves as a core material and biomass glue or synthetic resin is taken as a capsule wall material; the capsule looks as a transparent or semitransparent elastic spherical body which is 2-4mm in grain size; and the wall material is 0.1-0.5mm thick and is 0.5-2.5kg in pop strength. With the application of the tobacco capsule prepared by the method, water-soluble essence, alcohol-soluble essence and oil-soluble essence can be covered well; and the obtained capsule core material is stable in properties, and the wall material is good in water retaining performance and moderate in pressure value. With the application of the tobacco capsule, fragrance can be enriched to a great extent and smoke moisture can be enhanced to a certain degree, so that smoking quality is improved; and the microemulsion capsule is simple and easily feasible in preparation process, safe and environment-friendly in materials and applicable to continuous industrial production.

Owner:YUNNAN XINYUN TECH DEV CO LTD

Capsule for cigarette and preparing method of capsule

InactiveCN105520191AIncrease productivityAdapt to size requirementsTobacco smoke filtersRetention periodLiquid core

The invention relates to the technical field of spice embedding, in particular to a capsule for a cigarette and a preparing method of the capsule. The capsule comprises a solid case and a liquid core material, wherein the solid case is formed by two layer of thin films; the liquid core material is cladded in the solid case; the core material accounts for 80 to 95 percent of the total mass of the capsule; and the solid case accounts for 5 to 20 percent of the total mass of the capsule. The preparing method of the capsule for the cigarette has the advantages that complicated equipment is not needed; the method is suitable for continuous industrial production; the solid case of the prepared capsule is solid but is not tough, and can be easily broken through being pinched; inner core materials cladded in the solid case can be released after the solid case is broken through being squeezed by external force; the solid case which is not broken through being squeezed can provide good protection for the core material; active ingredients are prevented from volatilizing and going bad; and the retention period is prolonged.

Owner:DONGGUAN BOTON FLAVORS & FRAGRANCES

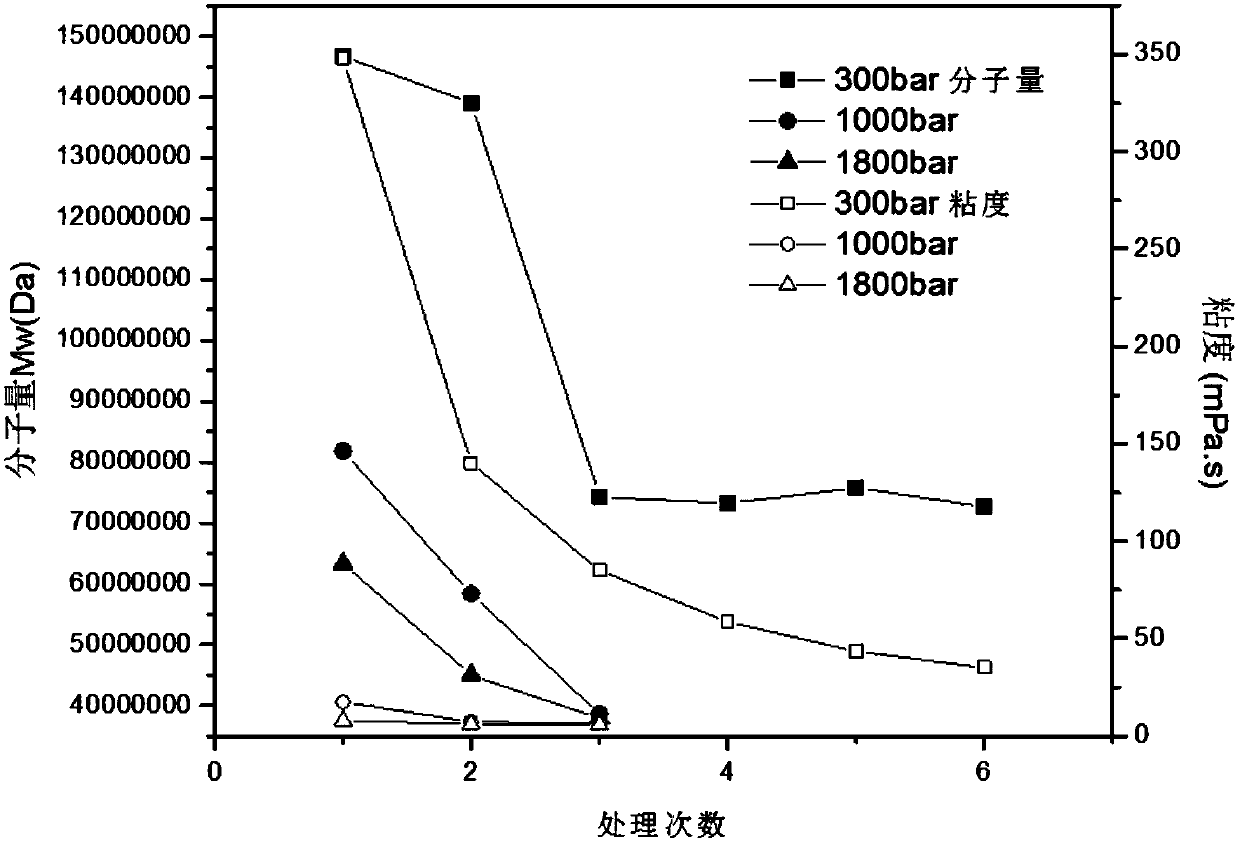

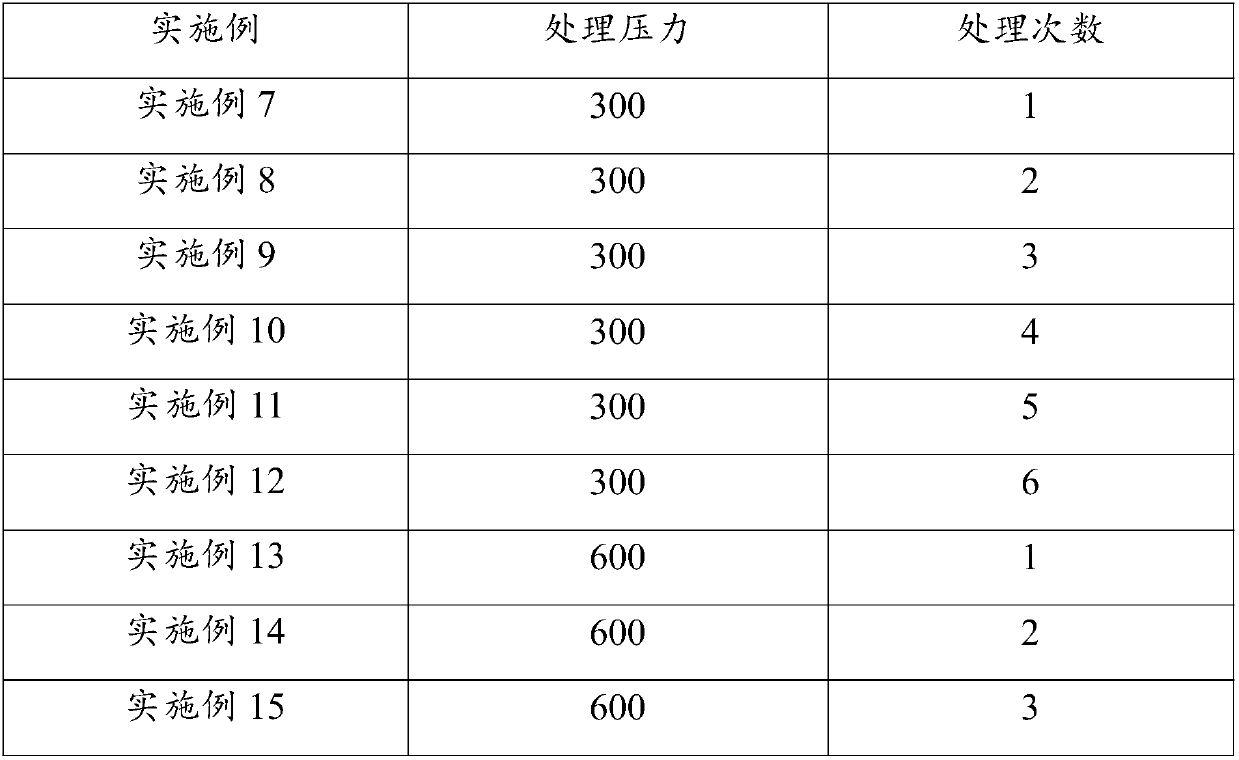

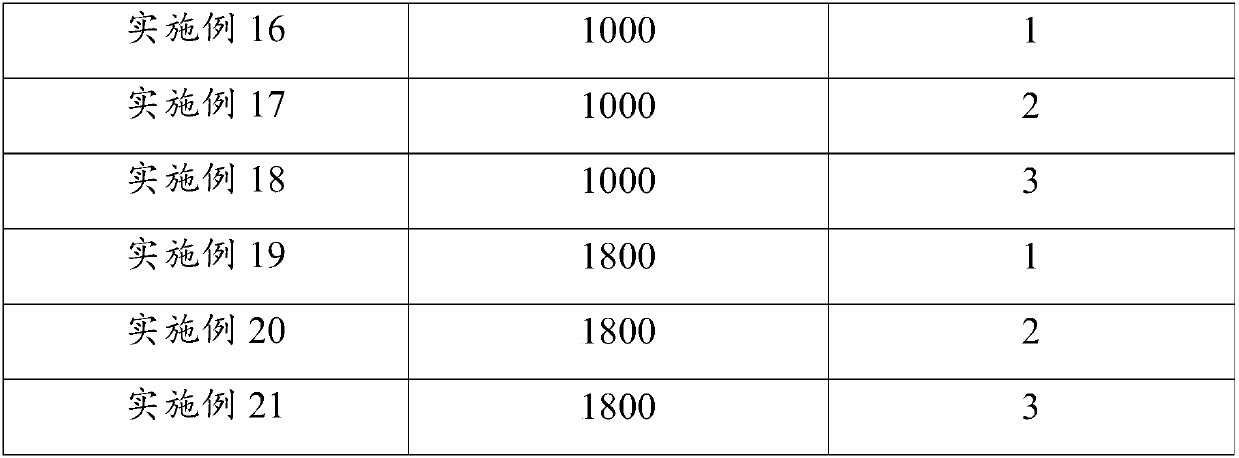

Polysaccharide degradation method and low-molecular-weight polysaccharide

The invention discloses a polysaccharide degradation method and low-molecular-weight polysaccharide, and relates to the field of degradation of a polysaccharides compound. The polysaccharide degradation method comprises the following step: treating a polysaccharide solution by adopting a high-pressure cell crushing device to obtain the low-molecular-weight polysaccharide. The polysaccharide degradation method disclosed by the invention overcomes the shortcomings that a conventional ultrasonic method is long in time and low in efficiency, a chemical method is low in reaction regularity and hasa hardly controlled process, and an enzyme hydrolysis method is low in applicability and high in cost and can hardly realize large-scale production. According to the method, the high-pressure cell crushing device is adopted to degrade polysaccharide, so that the polysaccharide which has a relatively low molecular weight is obtained by shearing and collision at high pressure; the molecular weight of the polysaccharide can be precisely controlled by adjusting the treatment pressure and the number of times; the polysaccharide degradation method has the advantages of small noise, zero pollution and high speed, and the physiological activity of the polysaccharide cannot be destroyed.

Owner:GUANGDONG MARUBI BIOLOGICAL TECH CO LTD

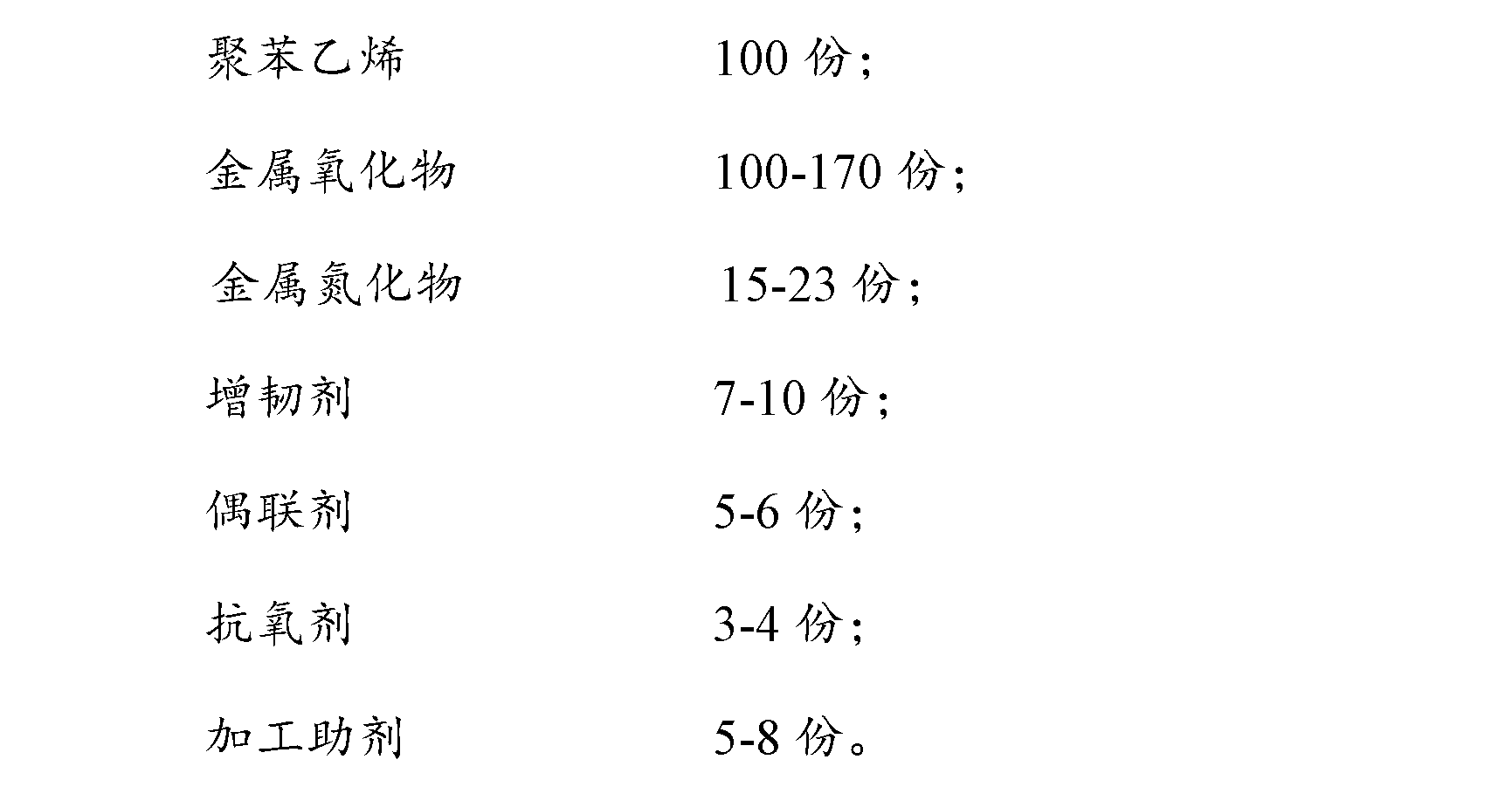

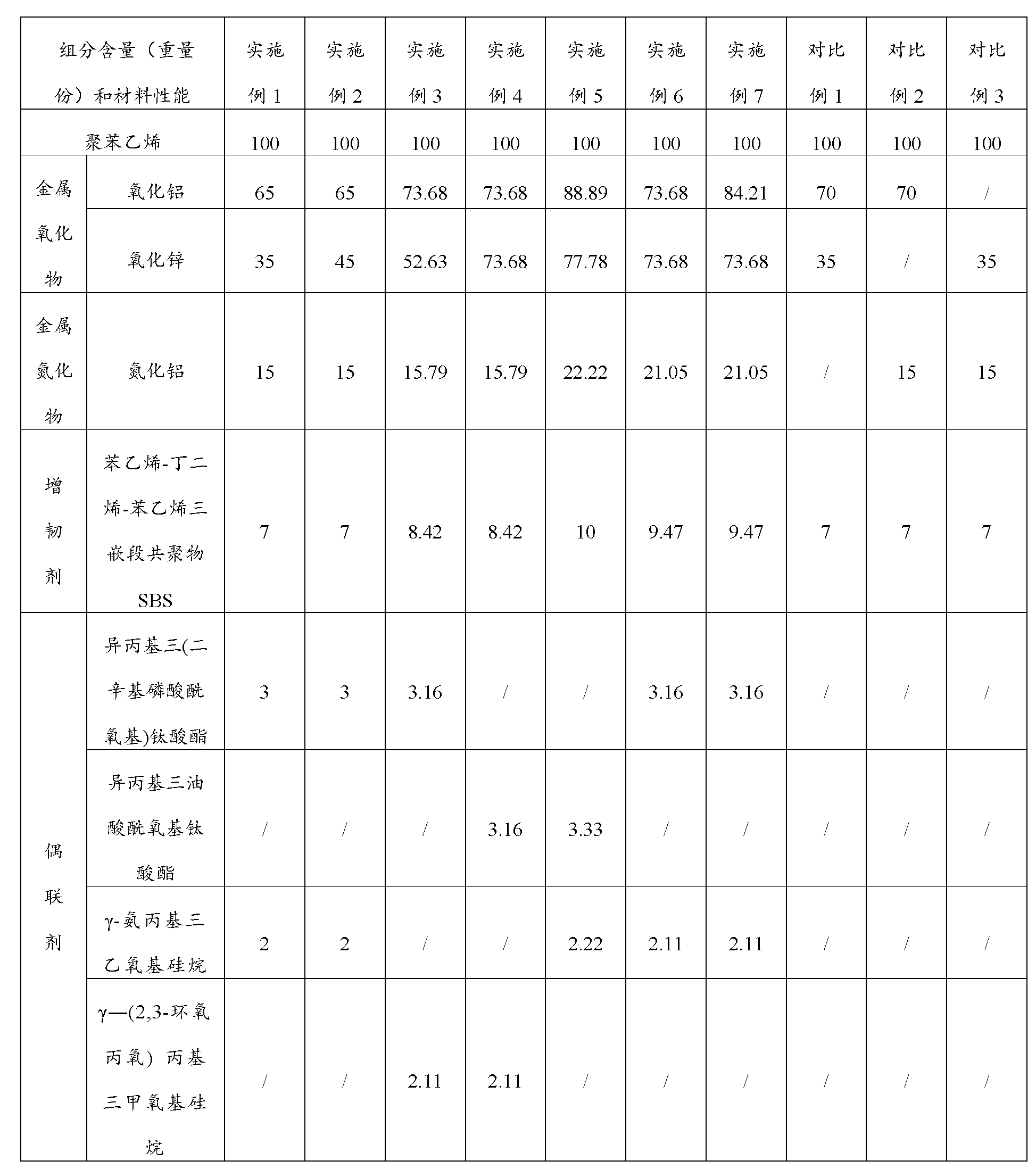

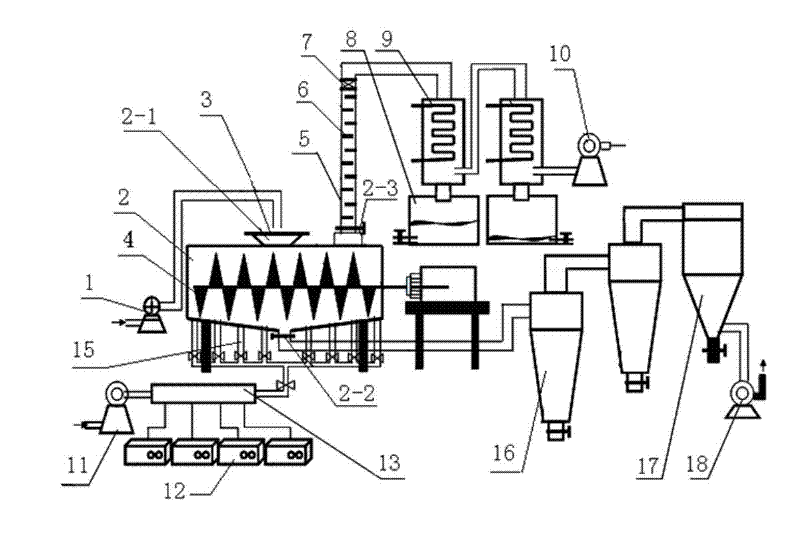

Polystyrene composite material and its preparation method

ActiveCN103232644ASimple preparation processSuitable for continuous industrial productionAntioxidantPolystyrene

The invention discloses a polystyrene composite material and a preparation method thereof. The polystyrene composite material comprises the following components by weight: 100 parts of polystyrene; 100-170 parts of a metal oxide; 15-23 parts of a metal nitride; 7-10 parts of a toughening agent; 5-6 parts of a coupling agent; 3-4 parts of an antioxidant; and 5-8 parts of a processing aid. The preparation process of the polystyrene composite material provided in the invention is simple, and is suitable for continuous industrial production. Compared with the current polystyrene composite materials, the simultaneously prepared polystyrene composite particles have greatly improved thermal conductivity, good thermal conductivity coefficients, and good mechanical properties, thus having good application prospects.

Owner:深圳市比克新材科技有限公司

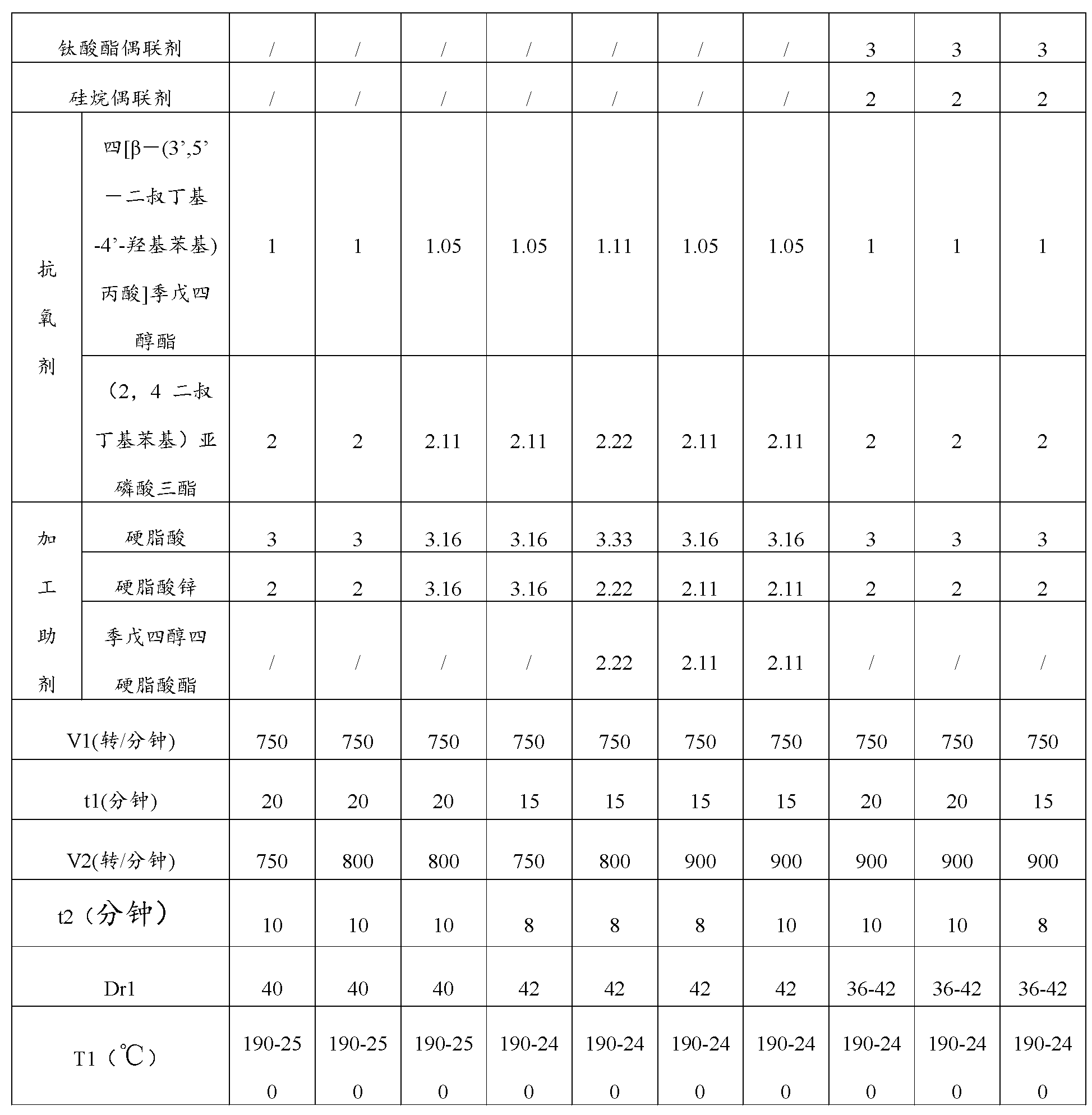

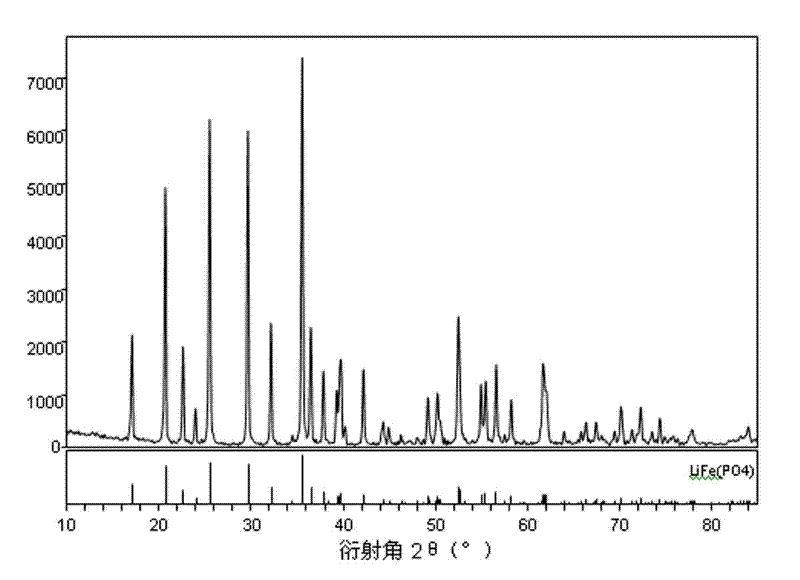

Low-temperature continuous production process for lithium iron phosphate and dedicated device therefor

The invention discloses a low-temperature continuous production process for lithium iron phosphate and a dedicated device therefor. The process comprises the following steps: preparing ferrous oxalate, lithium dihydrogen phosphate, an organic composite carbon source and a composite metal compound which are used as raw materials; mechanically stirring the raw materials in a way of circulation reflux in methanol which is used as a medium; performing fluidized drying on the resulting slurry to obtain a lithium iron phosphate precursor containing the composite carbon source and the composite metal compound; performing micronization and mechanical compaction and then calcining at a low temperature in a protective atmosphere with extremely-low oxygen content; and performing air flow classification and vibratory screening to obtain fine-particle lithium iron phosphate which has uniform grain-size distribution and excellent electrochemical properties and is used as an anode material for lithium ion batteries. The process is simple and easy to operate. The lithium iron phosphate product has excellent electrochemical properties, high tap density and good processing properties. The dedicateddevice has a high production capacity, is suitable for continuous industrial production, does not produce waste, and is environment-friendly and significant in application value.

Owner:CENT SOUTH UNIV

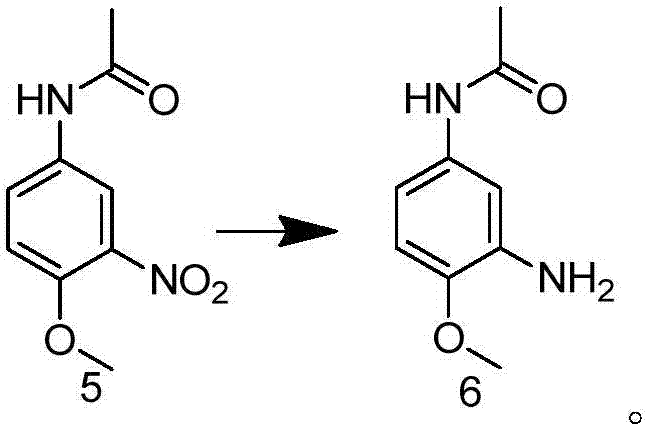

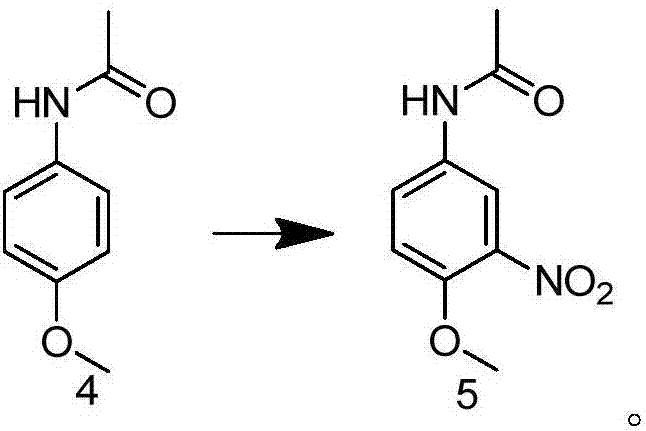

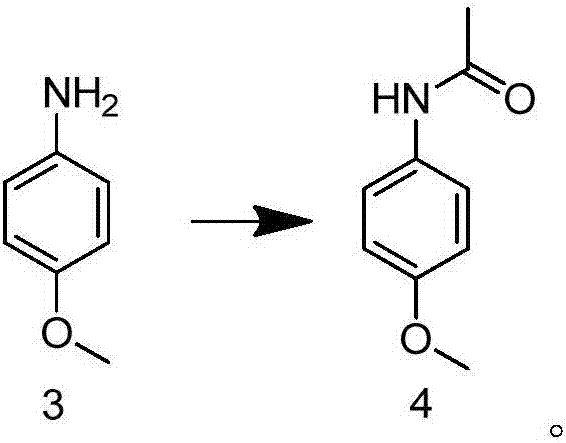

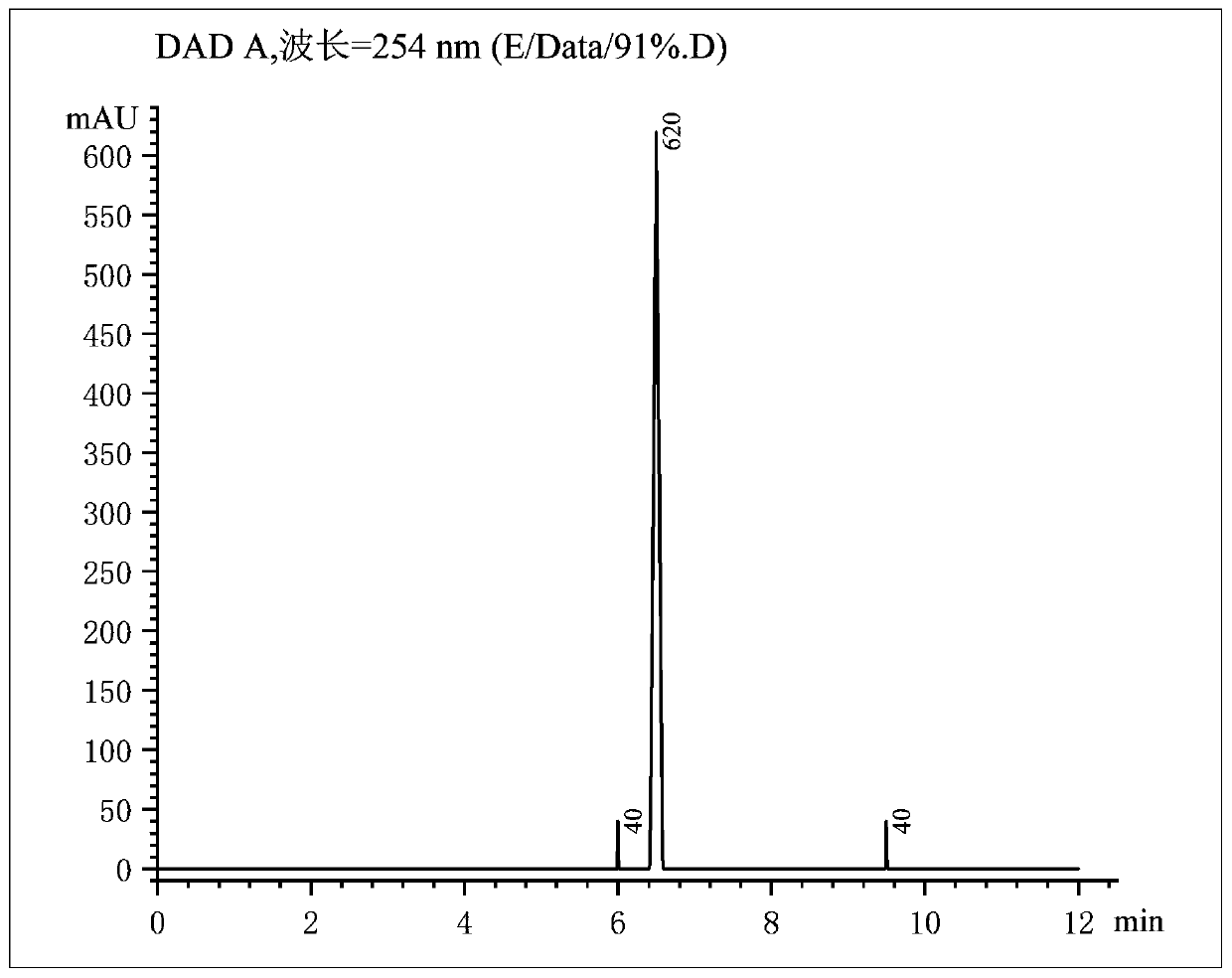

Preparation method of 2-methoxy-5-acetamidoaniline

InactiveCN107286043AEasy to recycleReduce pollutionOrganic compound preparationCarboxylic acid amides preparationHydrogenReaction temperature

The invention discloses a preparation method of 2-methoxy-5-acetamidoaniline. The preparation method comprises the following step: in a solvent, under the action of a catalyst Pd / C, performing a reduction reaction as shown below on a compound as shown in a formula 5 and hydrogen to obtain a compound as shown in a formula 6. The preparation method is low in pollution, high in yield rate, low in cost, convenient in catalyst or solvent recycling, short in reaction time, low in reaction temperature, high in safety and mild in reaction condition.

Owner:SHANGHAI ANOKY GRP +1

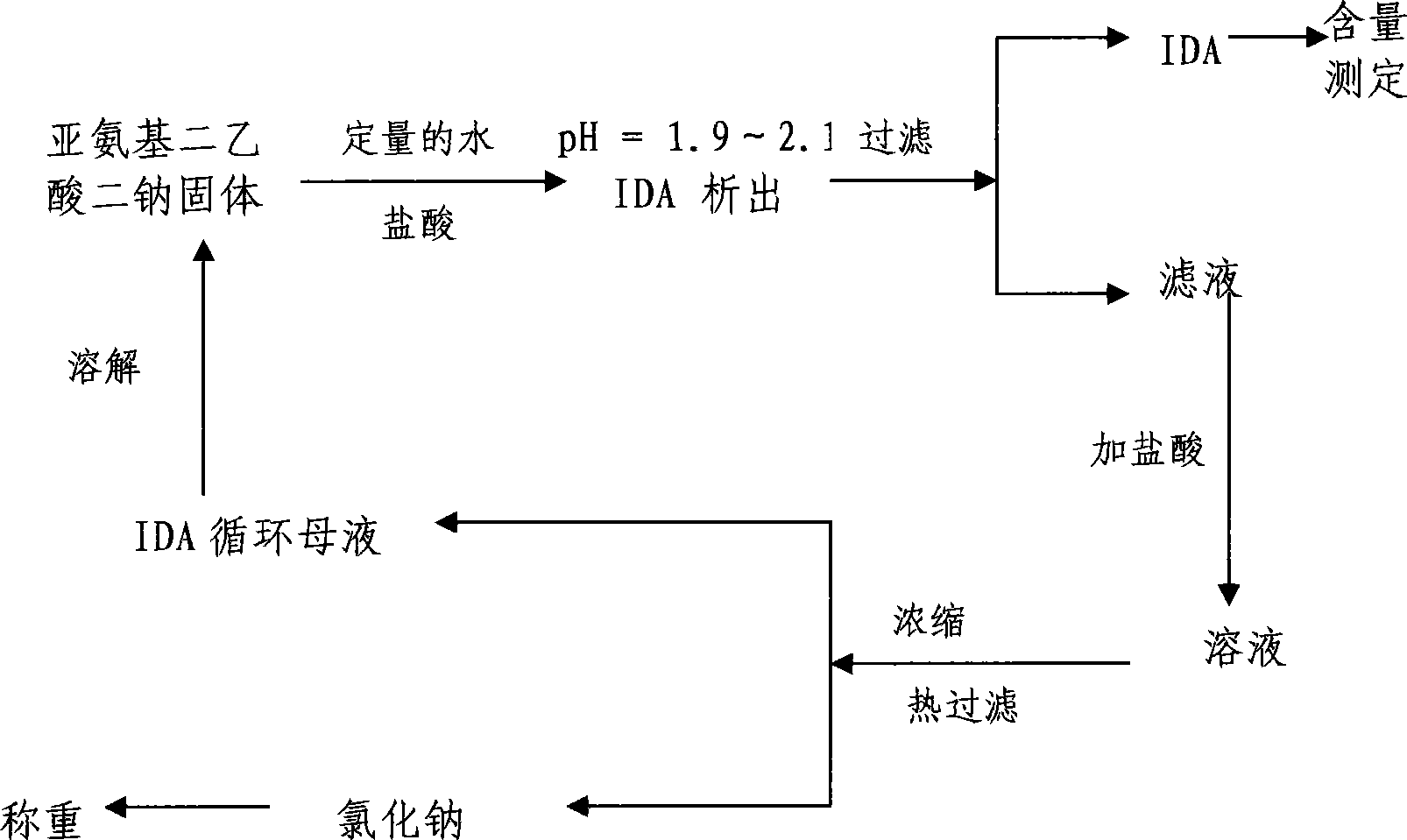

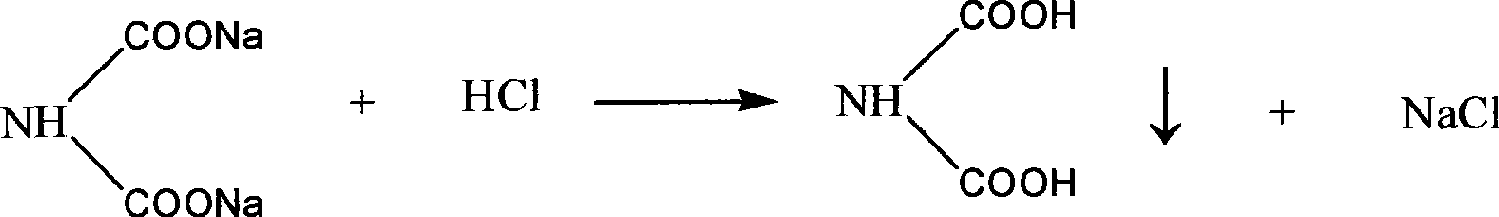

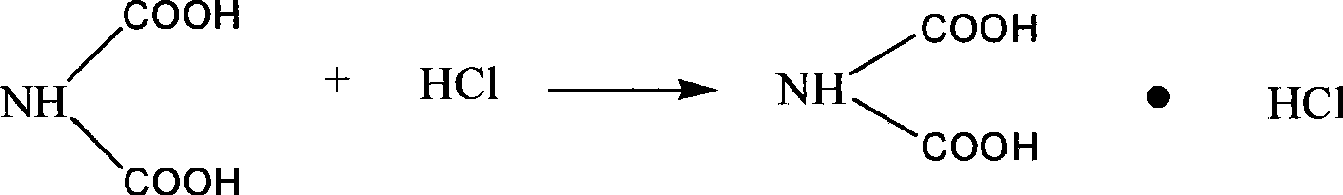

Method for preparing iminodiacetic acid from iminodiacetic acid disodium salt

ActiveCN101445464AReduce investment and energy consumptionMild reaction conditionsOrganic compound preparationAmino-carboxyl compound preparationChemistryIminodiacetic acid

The invention discloses a method for preparing iminodiacetic acid from iminodiacetic acid disodium salt. The method comprises the following steps: acidifying aqueous solution of the iminodiacetic acid disodium salt by hydrochloric acid until pH of the aqueous solution is a little less than an isoelectric point of the iminodiacetic acid, wherein, the pH equals 1.9-2.1; standing to separate the iminodiacetic acid out; filtering followed by drying to obtain a dry product; adding a fixed volume of the hydrochloric acid to the filtrate until the pH of the filtrate equals 1.3-1.5; condensing the filtrate to separate sodium chloride out, and filtering to remove the sodium chloride; dissolving the iminodiacetic acid disodium salt solid of the second batch in acid pregnant liquor; and repeating the steps to prepare the iminodiacetic acid product. The method has the characteristics of simple and short process route, convenient operation, little wastes (waste gas, waste water and industrial residue), lower equipment investment and energy consumption, and obvious economic and social benefits.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Method for irradiating modified polysulfone ultrafiltration membrane

InactiveCN104307393ALow costEasy to operateSemi-permeable membranesPhotosensitizerUltraviolet irradiation

The invention provides a method for irradiating a modified polysulfone ultrafiltration membrane. The method comprises the steps of (1) preparing a sample; (2) treating a photosensitizer solution; (3) treating an ethanol solution; and (4) performing ultraviolet irradiation. According to the method for irradiating the modified polysulfone ultrafiltration membrane, optimal conditions of irradiating the modified polysulfone ultrafiltration membrane are obtained according to the changes of the membrane performances such as the flux and the retention rate the polysulfone ultrafiltration membrane caused by different time periods of ultraviolet irradiation, and the hydrophilicity on the surface of the polysulfone ultrafiltration membrane is effectively improved.

Owner:QINGDAO JINGYIXIN ELECTRONICS TECH

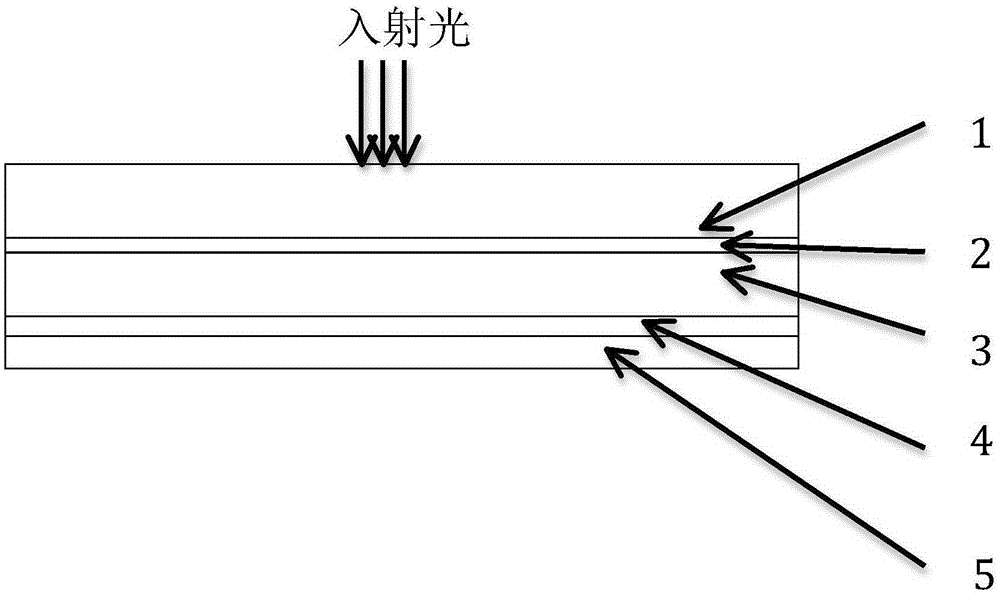

Thin film crystal silicon perovskite heterojunction solar cell manufacturing method

InactiveCN105244442AHighlight substantive featuresLow costFinal product manufactureSolid-state devicesHeterojunctionSolar cell

The invention discloses a thin film crystal silicon perovskite heterojunction solar cell manufacturing method, which relates to a semiconductor device manufacturing method particularly suitable for converting optical energy into electric energy, and is a manufacturing method based on an excimer laser crystallization method. The method of the invention comprises steps: the excimer laser crystallization method is used for manufacturing a P-type thin film crystal silicon layer on a transparent conductive substrate, spin coating of a perovskite light absorption layer is carried out on the P-type thin film crystal silicon layer, an electron transport layer formed by dense titanium dioxide is manufactured on the perovskite light absorption layer, a back electrode is manufactured on the electron transport layer formed by the dense titanium dioxide, and finally, a thin film crystal silicon perovskite heterojunction solar cell composed of the transparent conductive substrate, the P-type thin film crystal silicon layer, the perovskite light absorption layer, the electron transport layer formed by the dense titanium dioxide and the back electrode is manufactured. Defects that the layer transfer technique used in the prior art has multiple steps and is complicated, the obtained thin film crystal silicon has a small size, the finished product rate is low, and the thickness of the thin film crystal silicon can not be over thin can be overcome.

Owner:HEBEI UNIV OF TECH

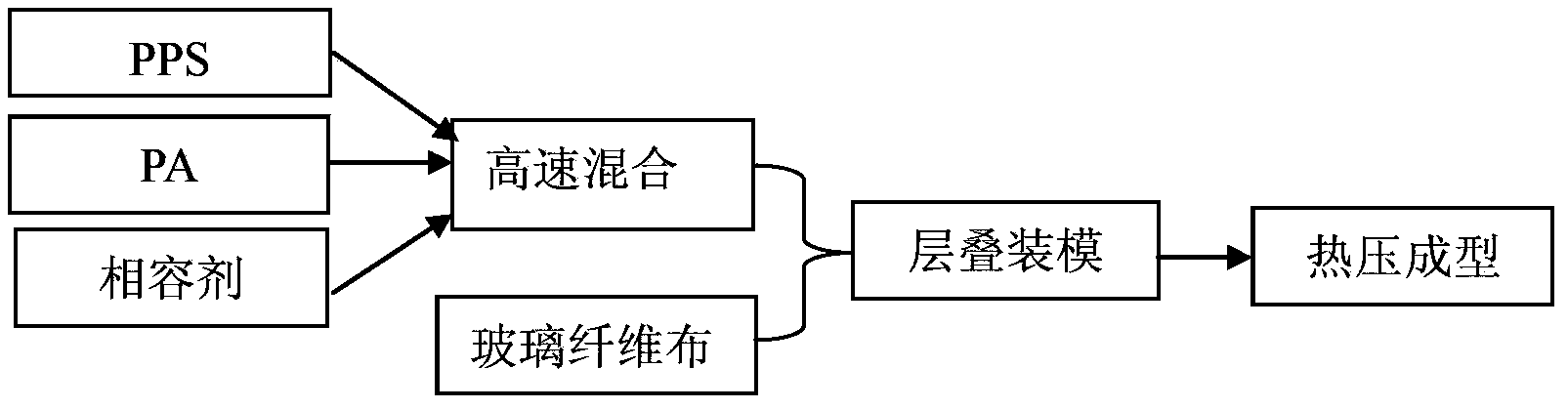

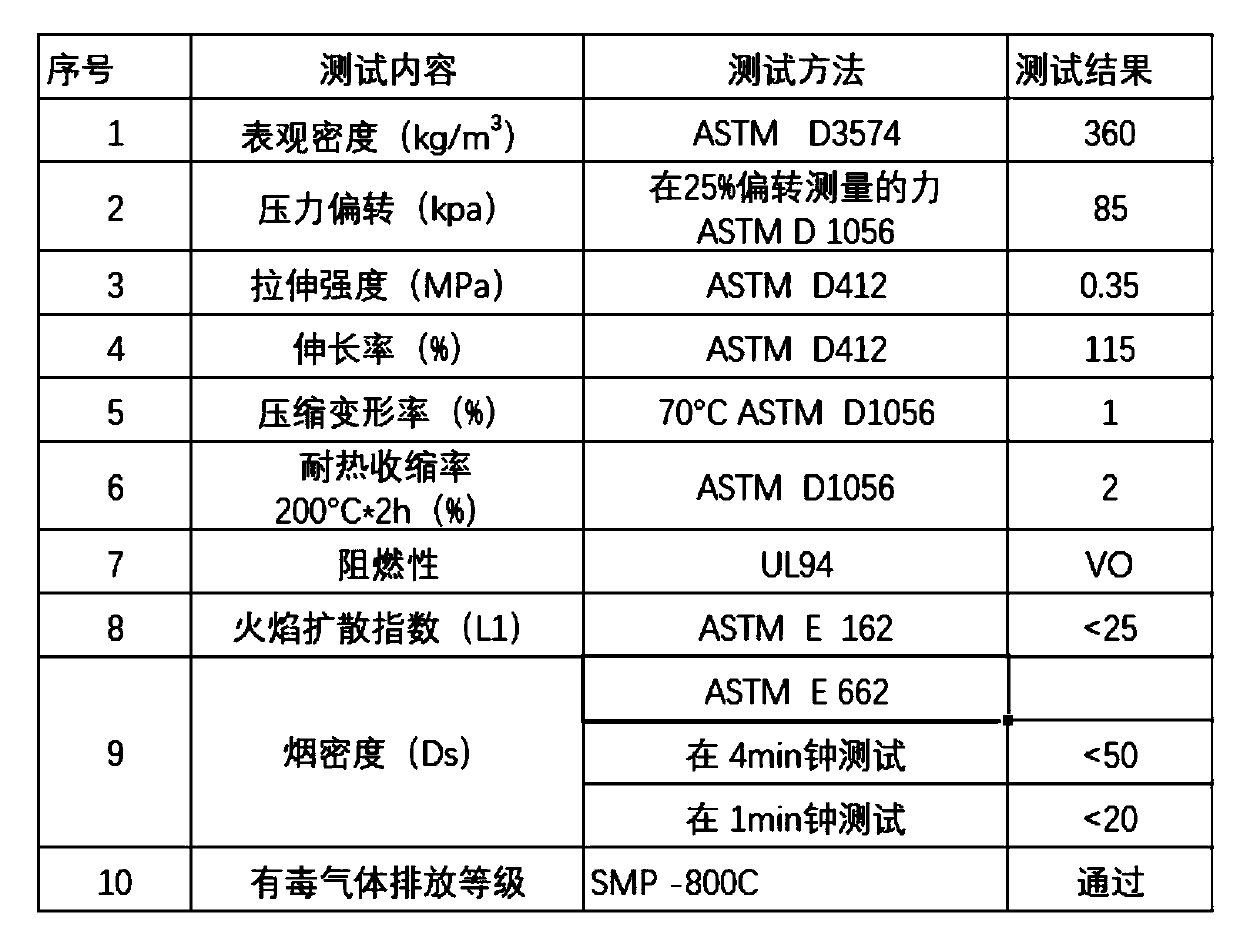

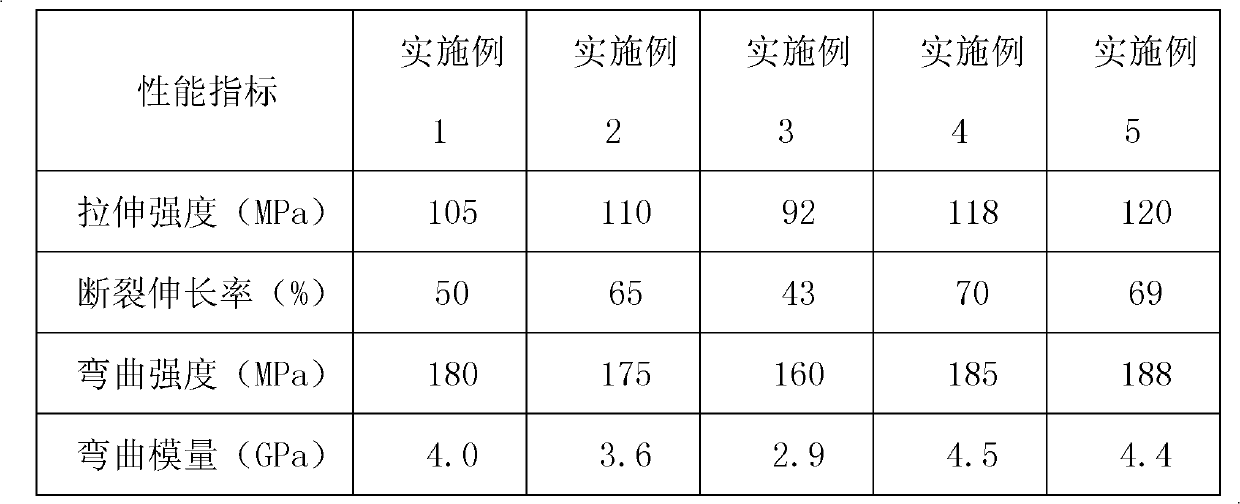

High-performance polyphenylene sulfide laminated composite plate material and preparation method thereof

InactiveCN103450684AOvercome insufficient adhesionBroad application prospectsSynthetic resin layered productsLaminationAerospaceHigh polymer

The invention belongs to the technical field of macromolecular materials, and relates to a polyphenylene sulfide laminated composite plate material and a preparation method thereof. The polyphenylene sulfide laminated composite plate material comprises the following components in parts by weight: 100 parts of polyphenylene sulfide, 10-60 parts of glass fiber cloth, 10-30 parts of high temperature resistant nylon, and 5-15 parts of a compatibilizer. Compared with the prior art, the polyphenylene sulfide laminated composite plate material overcomes the defect of insufficient interlayer interfacial cohesive force, guarantees a good dipping effect between fibers and resins, obtains the polyphenylene sulfide laminated composite material with excellent comprehensive performance, and has broad application prospects in the aviation and aerospace field; moreover, the polyphenylene sulfide composite material has a quite good toughening effect by adding the high temperature resistant nylon; and in addition, the adopted preparation method has simple molding process, and is also suitable for continuous industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Composition for preparing flame-retardant liquid silica gel foam and flame-retardant liquid silica gel foam

The invention relates to a composition for preparing flame-retardant liquid silica gel foam. The flame-retardant liquid silica gel foam is characterized by comprising a material A and a material B ata mass ratio of 1: 1; wherein the material A comprises a first hydroxyl vinyl siloxane, a first reinforcing agent, ethylene-silicon resin and a platinum complex; and the material B comprises a secondhydroxyl vinyl siloxane, a second reinforcing agent, hydrogen-containing silicone oil, a flame retardant, hydroxyl silicone oil and a retarder. The composition for preparing the flame-retardant liquidsilica gel foam is easy to control in the foaming process, good in stability and high in reaction rate, the flame-retardant liquid silica gel foam prepared from the composition is uniform in foam holes and has excellent elasticity, and the permanent deformation rate is within 1%.

Owner:苏州然创新材料科技有限公司

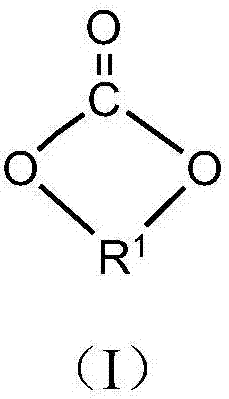

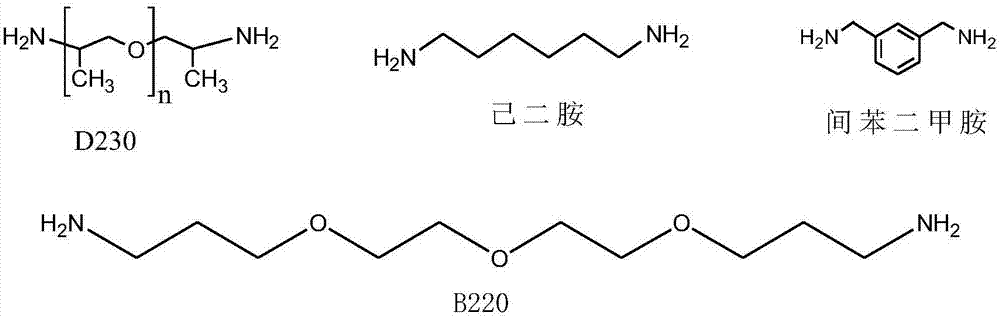

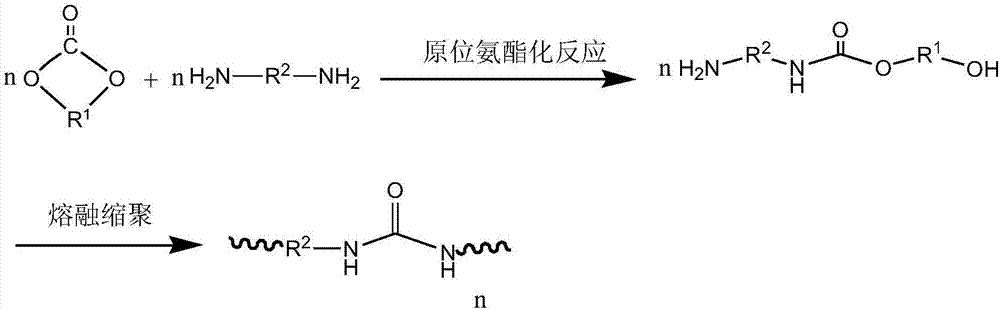

Method for preparing isocyanate thermoplastic polyurea by using one-pot method

ActiveCN107400233AGood mechanical propertiesEasy and efficient to prepareThermoplasticEsterification reaction

The invention discloses a method for preparing isocyanate thermoplastic polyurea by using a one-pot method, and belongs to the technical field of polyurethane. The method comprises the following steps: performing an in-situ esterification reaction on diamine and cyclic carbonate, and further performing melting polycondensation, thereby obtaining irregular or crystallized isocyanate thermoplastic polyurea. The method is simple and convenient to operate, efficient, green and environment-friendly and applicable to continuous industrial production, and the obtained irregular and crystallizable polyurea is good in mechanical property.

Owner:BEIJING UNIV OF CHEM TECH

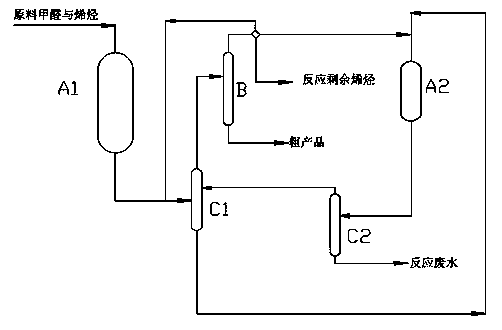

Synthetic method of 1, 3-dioxane type organic compounds

InactiveCN103420973AReduce formaldehyde contentEasy to handleOrganic chemistryPtru catalystSolid acid

The invention relates to a synthetic method of 1, 3-dioxane type organic compounds. The synthetic method comprises: taking industrial formaldehyde and butylene-containing four-carbon hydrocarbons as raw materials, under the effect of a solid acidic resin catalyst, performing a reaction in a secondary fixed catalytic bed and extraction and rectification, reacting formaldehyde with butylenes for a condensation reaction to obtain the 1, 3-dioxane type organic compounds. The effective content of butylenes in the four-carbon hydrocarbons is 15 wt% or more, conjugated diene content is 2000 ppm or less, the butylenes is one or a mixture of 1-butylene, 2-butylene or isobutylene with any proportions, and the formaldehyde is subjected to deionization processing. The method has the advantages of wide raw material source, green and environment-friendly catalyst, high reactant conversion rate, high reaction selectivity, simple operation, easily-separable product and applicability to continuous industrial production.

Owner:武汉椿岭科技有限公司

Preparation method of PTFE/PFA composite membrane high in porosity

The invention discloses a preparation method of a PTFE / PFA composite membrane high in porosity. PTFE resin, PFA resin with the mass fraction of 0-30% and auxiliary oil are uniformly blended, subjectedto blank preparation, extruded, rolled, dried, subjected to longitudinal stretching and transverse stretching, sintered and shaped. The preparation method is simple, low in cost and suitable for massproduction. The average aperture of micropores of the PTFE / PFA composite membrane is 0.2-8 micron, the porosity is 80-92%, and the resistance is 30-120 Pa at the flow speed of 5.3 cm / s; when gas containing particles with the particle size of 0.1-0.3 micron passes through the membrane, the particle capture efficiency is 90-99.9%. The membrane can be applied to various fields such as industrial dust removal, air filtration and liquid phase filtration.

Owner:浙江净膜环保有限责任公司

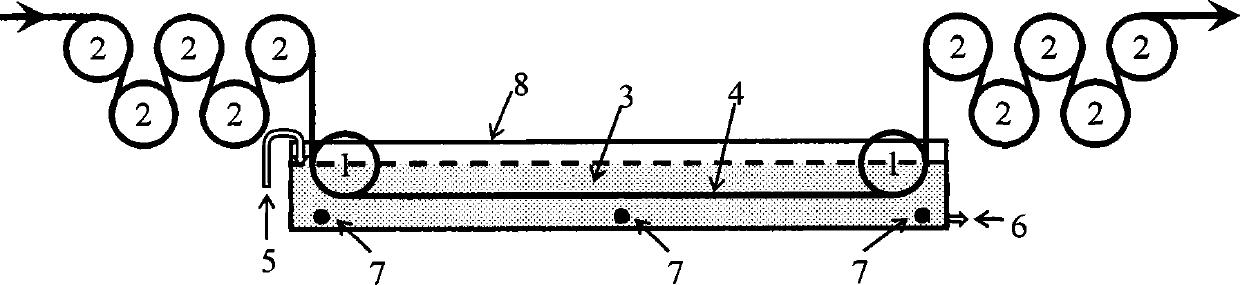

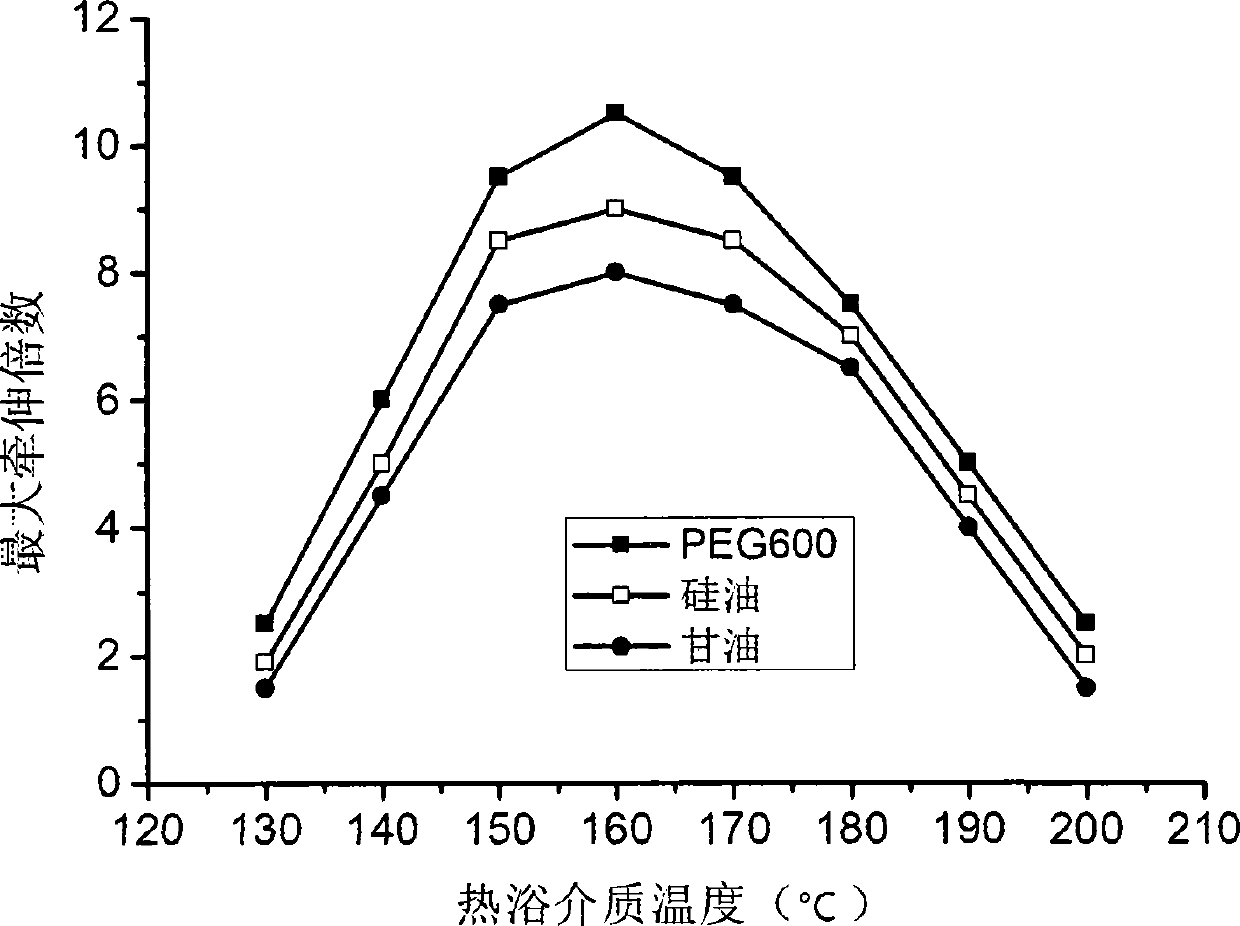

Novel fiber-drawing hot bath medium and application thereof

A novel fiber-drawing hot bath medium is composed of one or multiple of the following components: high-boiling-point polyol, polyoxyethylene oligomer, polyoxypropylene oligomer, mineral oil and silicon oil. By using the medium, fibers can be uniformly and quickly drawn in a high-multiple manner, and producing of fiber products uniform in structure and performance is facilitated.

Owner:INST OF CHEM CHINESE ACAD OF SCI

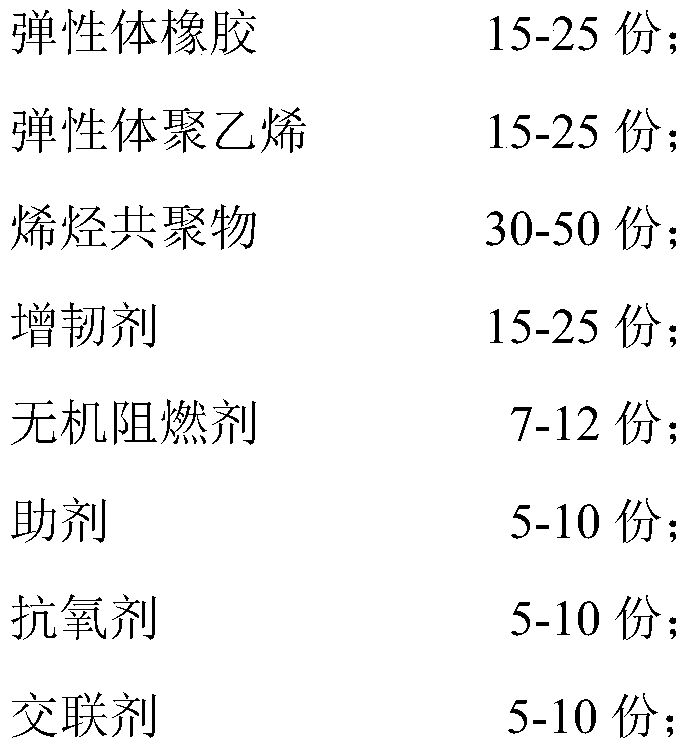

High-voltage soft polyolefin wire material for new energy automobile and preparation method thereof

ActiveCN110903589AIncreased durabilityImprove anti-aging propertiesPlastic/resin/waxes insulatorsElastomerPolymer science

The invention discloses a soft polyolefin wire material for a high-voltage wire of a new energy automobile. The soft polyolefin wire material is characterized by comprising the following components inparts by weight: 15-25 parts of elastomer rubber; 15-25 parts of elastomer polyethylene; 30-50 parts of an olefin copolymer; 15-25 parts of a toughening agent; 7-12 parts of an inorganic flame retardant; 5-10 parts of an auxiliary agent; 5-10 parts of an antioxidant and 5-10 parts of a cross-linking agent; the polyolefin electric wire material is prepared in an irradiation crosslinking mode, wherein the olefin copolymer is prepared from 1, 1, 1-trifluoro-2-(trifluoromethyl)-4-pent-2-ol, 1, 3-adamantanediol monoacrylate and acrylonitrile through a free radical copolymerization reaction. According to the high-voltage soft polyolefin wire material for the new energy automobile, disclosed by the invention, the flexibility of the two materials is retained; according to the present invention, the olefin cable material can meet the use characteristics of the high-voltage line by adding the special fillers, and the irradiation cross-linking manner is used in the preparation method, such thatthe thermal stability, the aging resistance and the service life of the olefin cable material are improved.

Owner:苏州铂玛新材料有限公司

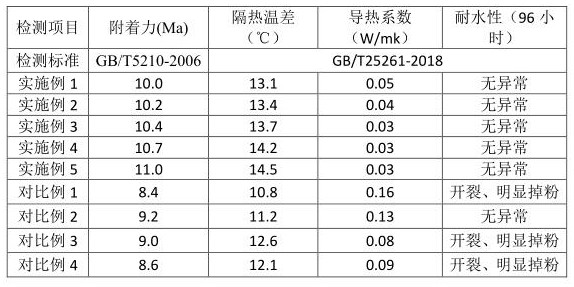

Thermal insulation coating and preparation method thereof

InactiveCN112521852AEasy to prepareEasy constructionFireproof paintsAntifouling/underwater paintsMolecular sievePolymer science

The invention discloses a thermal insulation coating. The thermal insulation coating is prepared from the following raw materials in parts by weight: 8-10 parts of foamy carbon with modified sealed holes embedded with hollow nanoparticles, 3-5 parts of a hydrophilic molecular sieve, 30-40 parts of amino-terminated hyperbranched polybenzimidazole, 10-20 parts of sulfonated polybenzimidazole, 30-40parts of an inorganic filler, 2-4 parts of a defoaming agent, 1-3 parts of a dispersing agent and 10-15 parts of a solvent. The invention also provides a preparation method of the thermal insulation coating. The thermal insulation coating provided by the invention is excellent in comprehensive performance, better in thermal insulation effect, better in performance stability and water resistance, stronger in adhesive force with a base material and longer in service life.

Owner:泗县钧科新材料科技有限公司

Light fast pink chromogen pigment red for a solvent-based ink material, and preparation method thereof

The invention relates to light fast pink chromogen pigment red for a solvent-based ink material, wherein the light fast pink chromogen pigment red comprises the following components in parts by weight: 15-22 parts of alkaline red, 1-5 parts of glacial acetic acid, 1-6 parts of disodium hydrogen phosphate, 11-17 parts of sodium tungstate, 18-24 parts of sodium molybdate, 2-5 parts of a pigment aid,25-35 parts of hydrochloric acid, 2-6 parts of rosin and 2-5 parts of liquid caustic soda, wherein the pigment aid comprises the following components in parts by weight: 2-6 parts of 3-(1-methylethyl)-1H-1,2,4-triazole-5-amine, 1-3 parts of hyperbranched polyethyleneimine, 2-6 parts of hyperbranched polyglycidyl ether, 3-6 parts of oxibetaine, 2-7 parts of ethylenediamine tetraacetic acid disodium salt, 3-5 parts of diazolidinyl urea, 55-65 parts of water, 1-2 parts of a dispersant, 1-3 parts of an emulsifier, and 12-18 parts of a cosolvent. The invention further discloses a preparation method of the light fast pink chromogen pigment red. The light fast pink chromogen pigment red of the invention is low in red viscosity, good in storage and transportation stability, good in dispersity, high in tinting strength, high in light fastness, weather fastness and solvent resistance, and bright in color and luster.

Owner:吴江山湖颜料有限公司

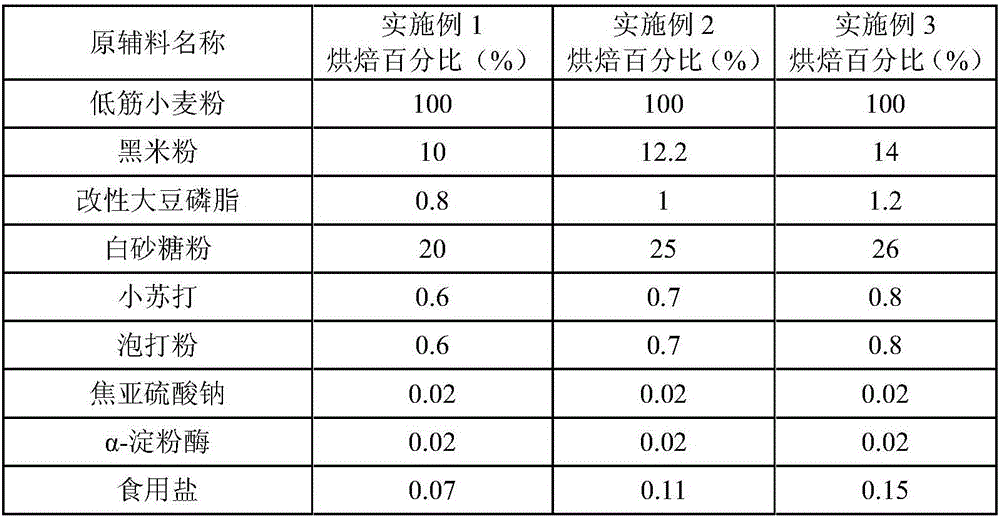

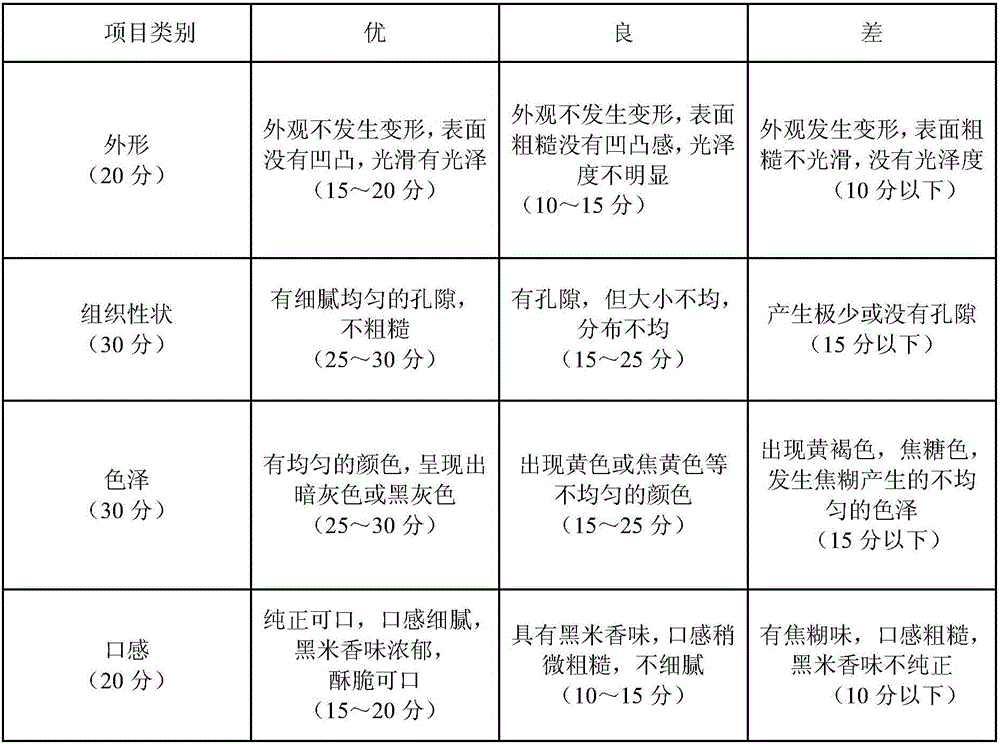

Black rice hard biscuit premixed flour and preparation method thereof and application

InactiveCN106070422AEasy to manufactureReduce the burden onDough treatmentDough/pre-mixesSodium bicarbonateSodium metabisulfite

The invention discloses black rice hard biscuit premixed flour. By baking percentage, the black rice hard biscuit premixed flour comprises 100% of low gluten wheat flour, 20-26% of white granulated sugar powder, 10-14% of black rice powder, 0.8-1.2% of modified soybean phospholipil, 0.6-0.8% of sodium bicarbonate, 0.6-0.8% of baking powder, 0.07-0.15% of salt, 0.02% of alpha-amylase with enzyme activity of 2000 u / g and 0.02% of sodium metabisulfite. The invention further provides a method for preparing the black rice hard biscuit premixed flour. The black rice hard biscuit premixed flour can be applied to manufacture of a black rice hard biscuit. The invention also provides a method for preparing the black rice hard biscuit. The black rice hard biscuit premixed flour fills the market blank, the black rice raw material having rich nutrition and various functions is added, and the product is delicious and healthy. The product is low in cost and has good popularization values.

Owner:李红涛

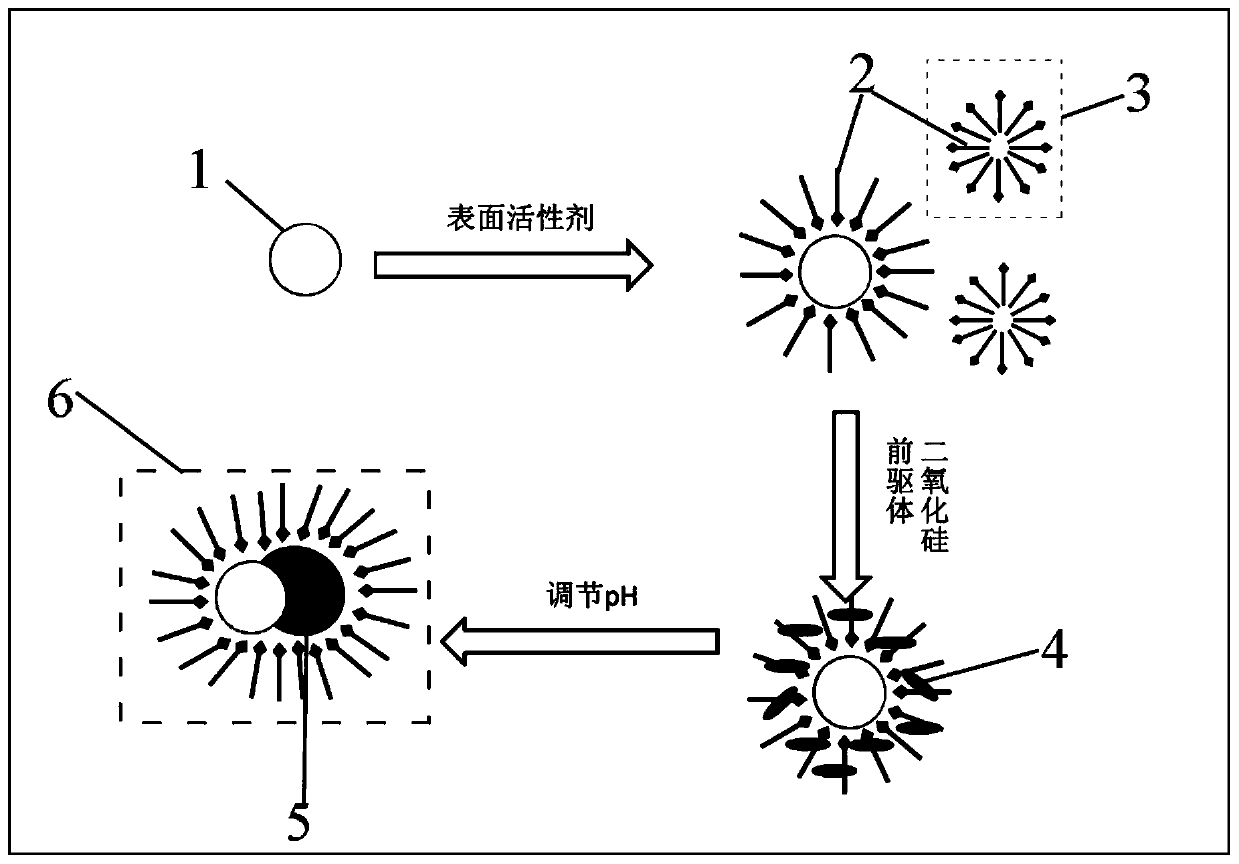

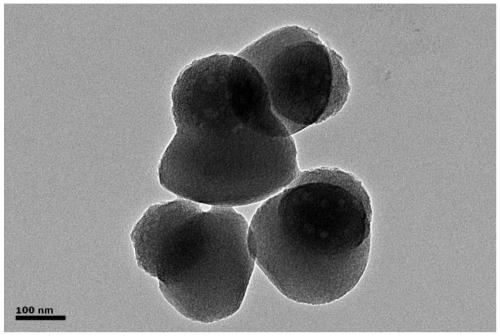

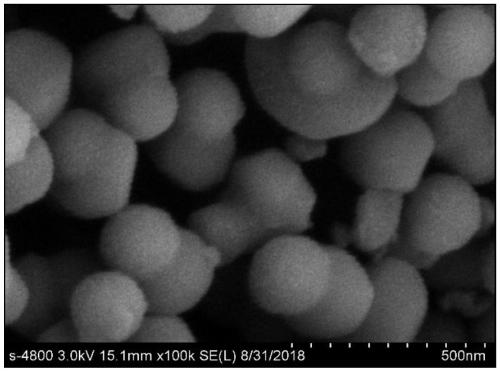

Janus type porous silicon dioxide compound nanoparticle and preparing method thereof

PendingCN110104654ASimple preparation processSynthetic conditions are mildSilicaZinc oxides/hydroxidesNanoparticleRoom temperature

The invention discloses a Janus type porous silicon dioxide compound nanoparticle and a preparing method thereof. The method includes the steps of mixing a cationic surfactant, nanospheres and a solvent to form a dispersoid A, adjusting the dispersoid A to be alkaline to obtain a dispersoid B, and conducting the temperature raising reaction after adding a silicon dioxide precursor to the dispersoid B to prepare the Janus type porous silicon dioxide compound nanoparticle. A one-way growth guiding agent is adopted, the Janus type porous silicon dioxide compound nanoparticle is directly induced to be generated in the water dispersoid, the reaction is conducted at a room temperature, the reaction conditions are mind, the size of the nanoparticle is easy to adjust and control, universality is high, and the nanoparticle can be directly applied to other fields.

Owner:ANHUI UNIVERSITY

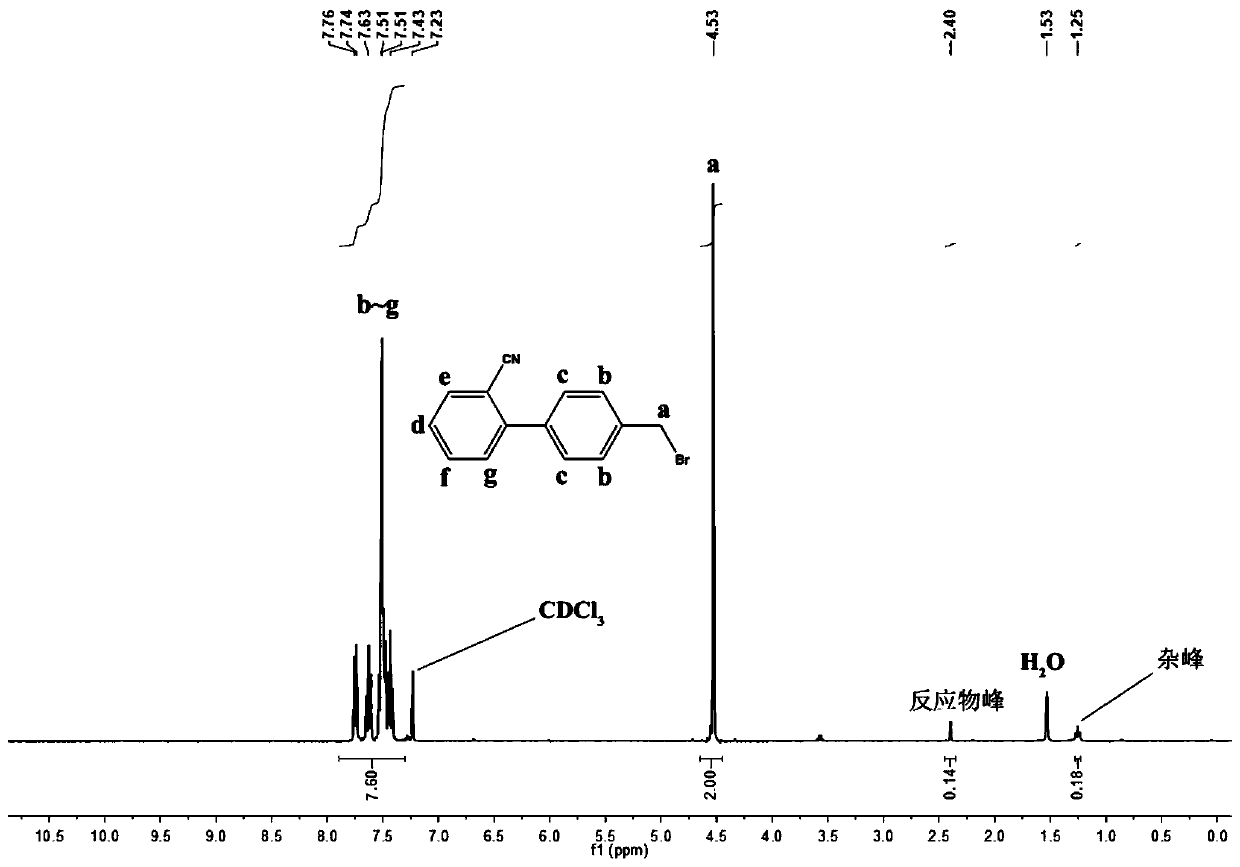

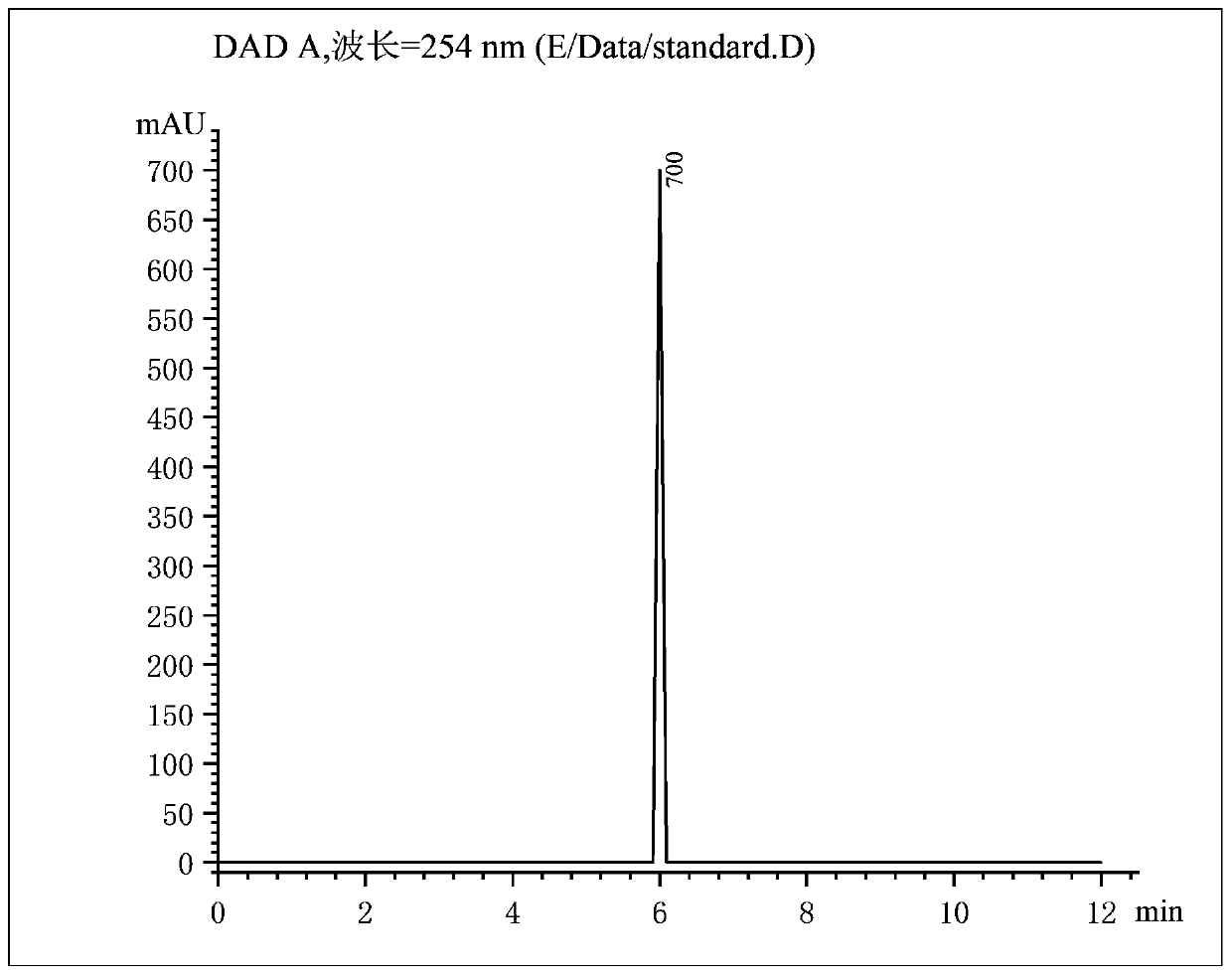

Preparation method of normal-temperature bromoethyl cyanobiphenyl based on dibromohydantoin

InactiveCN111320555AHigh purityHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationCombinatorial chemistryMethyl palmoxirate

The invention discloses a preparation method of normal-temperature bromoethyl cyanobiphenyl based on dibromohydantoin, and belongs to the technical field of pharmaceutical chemicals, and particularlydiscloses a method for preparing substituent-containing bromoethyl cyanobiphenyl by using a flowing photochemical method. According to the method, an oxidant and a radical initiator are not needed; methyl biphenyl is used as a raw material, dibromohydantoin is used as a bromination reagent, acetone, dichloromethane, petroleum ether or acetonitrile is used as a solvent, and after the raw material and the bromination reagent are respectively mixed with the solvent, the mixture flows into a pipeline through an injection pipe, is mixed by a mixer, then enters a constant-temperature water bath reactor and is subjected to a reaction through illumination. The 2-cyano-4 '-bromomethylbiphenyl synthesized by the method is good in purity, high in yield, simple in reaction system and low in toxicity,is suitable for industrial application in the field of biological medicines, can be suitable for an automatic continuous production process, and conforms to the development concepts of green chemicalindustry, high efficiency and economy.

Owner:JIAXING UNIV

Concentrated natural latex flocculation method

The invention belongs to the technical field of production of natural rubber, and relates to a concentrated natural latex flocculation method. The concentrated natural latex flocculation method comprises the following steps: firstly, slowly adding concentrated natural latex in a seawater-like flocculating agent under the condition of stirring, after addition of the concentrated natural latex is completed, keeping stirring for 20-40 min, reacting the concentrated natural latex and the seawater-like flocculating agent under set conditions, and then naturally cooling to the temperature of 15-35 DEG C to obtain gel blocks; secondly, cleaning the gel blocks by using 300 ml of deionized water; and finally, successively placing the gel blocks in an open mill and a drying machine for dewatering and drying separately to obtain natural rubber. The concentrated natural latex flocculation method has the advantages that firstly, the seawater-like flocculating agent is low in price, and is environmentally friendly, secondly, the requirements for equipment are low, the equipment are conventional equipment, reaction conditions are mild, the equipment are not corroded, thirdly, in the technologicalprocess, irritating odor is avoided, influences to operators are small, and the method is environmentally friendly, and fourthly, influences of factors such as weather, the quality of the concentrated natural latex and latex stopping period to continuous production of the natural rubber are overcome.

Owner:QINGDAO UNIV OF SCI & TECH

Polyetheretherketone/polyimide/polyphenyl thioether ternary alloy and preparation method thereof

ActiveCN103374199AImprove performanceOvercoming expensive flawsPoly ether ether ketoneMolecular materials

The invention belongs to the technical field of high-molecular materials, and particularly relates to a polyetheretherketone / polyimide / polyphenyl thioether ternary alloy and a preparation method thereof. The polyetheretherketone / polyimide / polyphenyl thioether ternary alloy is prepared from the following components in parts by weight: 5-90 parts of polyetheretherketone, 5-90 parts of polyimide and 5-90 parts of polyphenyl thioether. The preparation method comprises the following steps of: weighing all the components, and carrying out heat drying; stirring the obtained components in a high-speed stirrer, and uniformly mixing; and adding the obtained uniformly mixed materials to a double-screw extruder, extruding, granulating, cooling, dicing, and drying. The polyetheretherketone / polyimide / polyphenyl thioether ternary alloy disclosed by the invention has the advantages that the defect of property limit in an existing single material is overcome, the cost is reduced, the integrated advantage of the materials are better exerted, the defect of high price of the single material is overcome through blending and compounding and the cost is reduced. The preparation method disclosed by the invention is simple in forming process and suitable for continuous industrial production.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

Method for modifying polysulfone ultrafiltration membrane by ultraviolet irradiation

A technical scheme adopted by the invention is a method for modifying a polysulfone ultrafiltration membrane by ultraviolet irradiation. The method includes the following steps of: (1) sample preparation; (2) photosensitizer solution treatment; (3) ethanol solution treatment; and (4) ultraviolet irradiation. Based on changes in membrane properties like flux and retention rate caused by different UV light irradiation time on the polysulfone ultrafiltration membrane, optimum conditions for ultraviolet irradiation modification on the polysulfone ultrafiltration membrane are obtained, so as to effectively improve the surface hydrophilicity of the polysulfone ultrafiltration membrane.

Owner:CSR QINGDAO HUAXUAN WATER

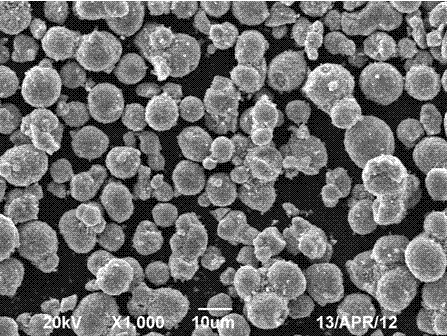

A kind of preparation method of spherical nickel-manganese binary material

Owner:ANHUI ALAND NEW ENERGY MATERIALS

PTFE composite glue blocking film for LCP high-temperature lamination and production process thereof

ActiveCN111040649ASimple production processEasy to implementFilm/foil adhesive release linersPolymer chemistryPtfe composite

The invention discloses a PTFE composite glue blocking film for LCP high-temperature lamination, which is characterized in that the PTFE composite glue blocking film sequentially comprises a first release film layer, a first adhesive layer, a high-temperature glue blocking layer, a second adhesive layer and a second release film layer from top to bottom, the first adhesive layer and the second adhesive layer are independently formed by a high-temperature adhesive; and the high-temperature glue blocking layer is a PTFE / PE / hydroxyl-terminated methyl vinyl fluorosilicone oil blended film layer. The invention also provides a production process of the PTFE composite glue blocking film for LCP high-temperature lamination. The PTFE composite glue blocking film for LCP high-temperature laminationdisclosed by the invention is remarkable in release and glue blocking effects, excellent in mechanical property, long in service lifetime and good in high-temperature resistance.

Owner:苏州市新广益电子股份有限公司

Skin care film and preparation method thereof

InactiveCN111195216AEasy to prepareEasy to operateCosmetic preparationsToilet preparationsPolyesterBiocompatibility

The invention discloses a skin care film. The film is prepared from the following raw materials in parts by weight: 10 to 20 parts of vinyl modified hyperbranched polylysine, 0.1 to 0.3 part of strontium acetylacetonate hydrate, 2 to 4 parts of isopulegol, 3 to 5 parts of glycidyl ether-terminated allyl alcohol random polyether, 5 to 10 parts of ionized imidazolium salt-based polycarbonate-based polyester polycondensate, 1 to 3 parts of hyaluronic acid and 0.02 to 0.05 part of an initiator. The invention further discloses a preparation method of the skin care film. The skin care film disclosedby the invention is good in biocompatibility, sufficient in strength, good in air permeability and remarkable in skin care effect, can effectively prevent wound infection, accelerate wound healing, promote skin growth and reduce scars, and further has multiple functions of whitening, resisting skin aging and the like.

Owner:李虹

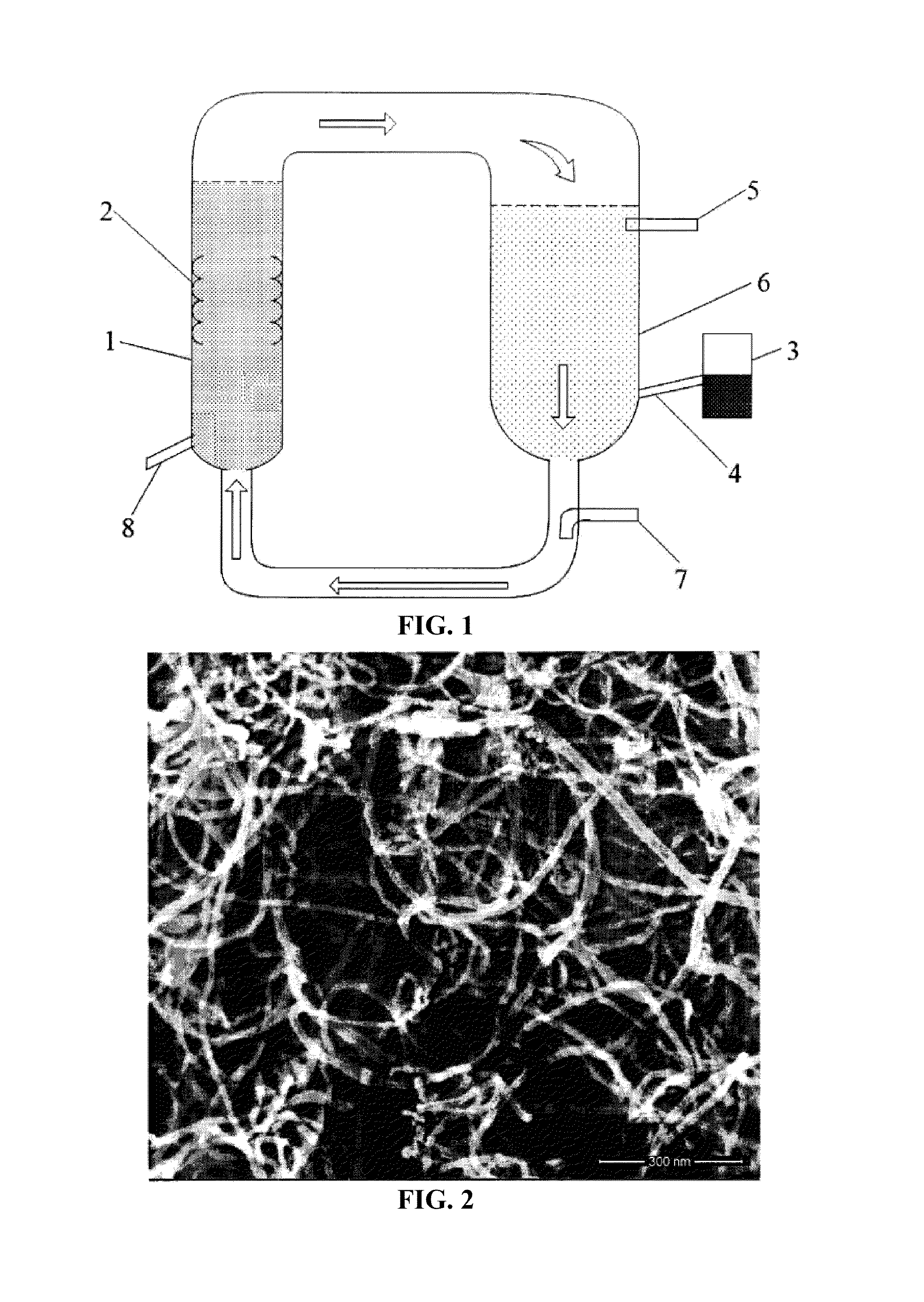

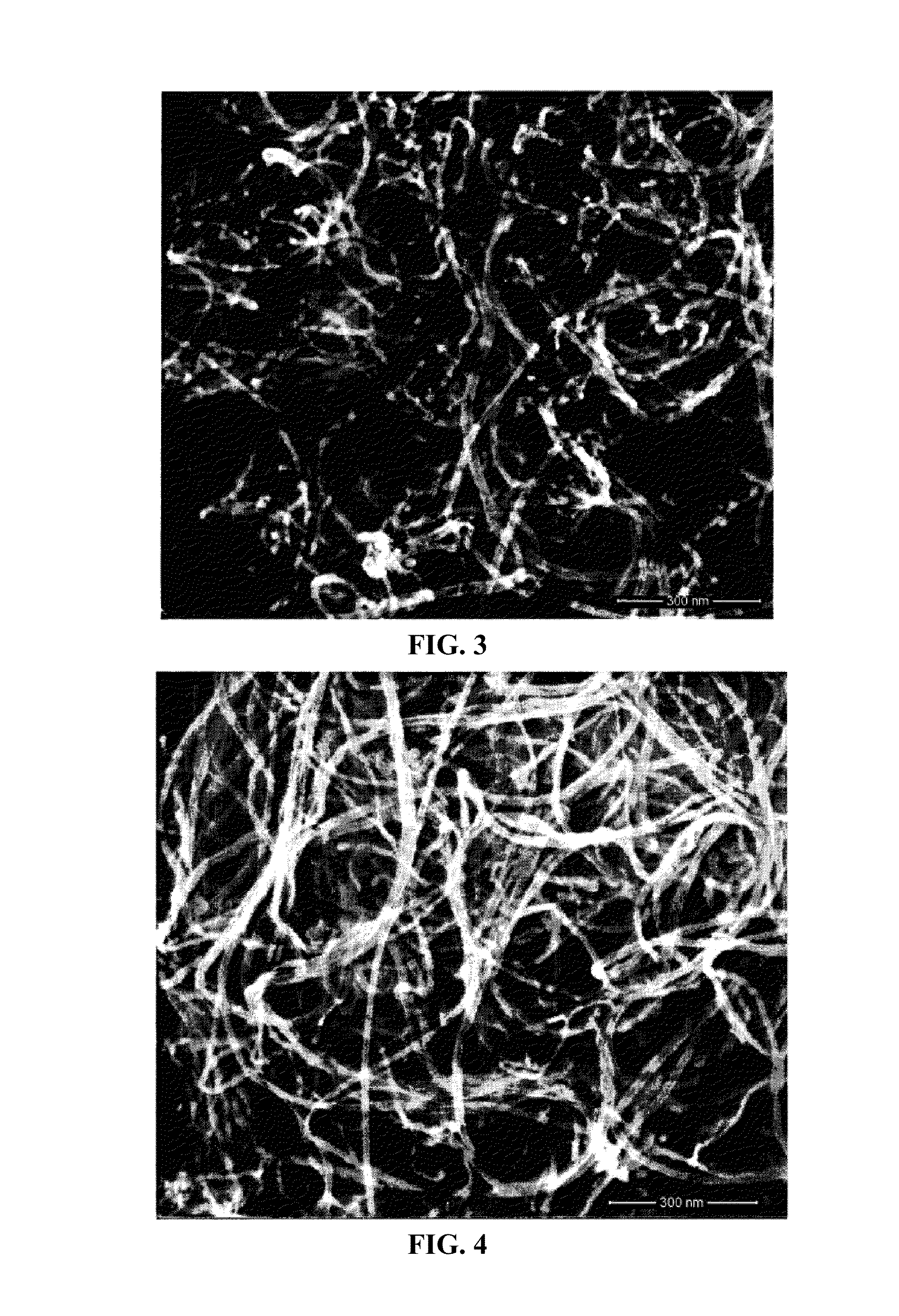

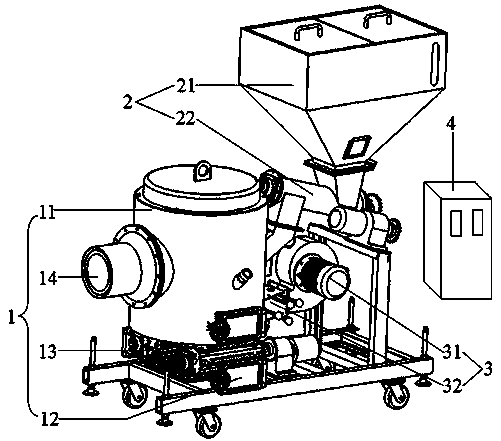

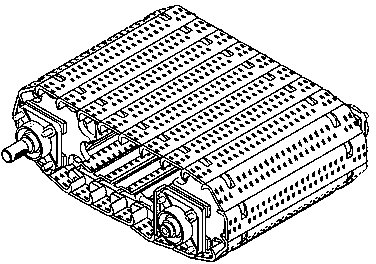

Method and synthesis reactor for producing carbon nanotubes

ActiveUS20160152476A1Low production costIncrease profitGaseous chemical processesLiquid-gas reaction of thin-film typeRed mudCarbon nanotube

A synthesis reactor for producing carbon nanotubes. The reactor includes a main reactor, a feeder, a settler, an air inlet device, and a product outlet. The main reactor communicates with the settler in the form of a communicating vessel. The feeder communicates with the settler via a catalyst inlet. The air inlet device is disposed under the settler. The wall of the main reactor is provided with a heat exchanger. The product outlet is disposed at the lower part of the main reactor. A method for producing a carbon nanotube, includes: 1) drying red mud for 1 to 4 hour(s) at the temperature of between 101° C. and 109° C.; 2) smashing and sieving the red mud through a 200-mesh sieve to yield a catalyst; and 3) adding the catalyst to a synthesis reactor.

Owner:SHANDONG DAZHAN NANO MATERIALS

Coking-resistant biomass combustor

InactiveCN103939887AEliminate hidden dangers of cokingEliminate manual coke cleaning processFuel supply regulationTravelling grateCombustorCombustion chamber

The invention provides a coking-resistant biomass combustor. The coking-resistant biomass combustor comprises a combustion furnace, a feeding system, an air supply system and an intelligent control system. A combustion chamber, a setting chamber and a chain grate stoker are arranged in the combustion furnace. The chain grate stoker is arranged between the combustion chamber and the setting chamber and is driven by the motor to conduct uniform motion. A nozzle is arranged on one side of the combustion chamber and the other side of the combustion chamber is connected with the feeding system. The feeding system comprises a hopper and a spiral feeding machine. The air supply system comprises a fan and air ducts used for air supply. The air ducts comprise the first air duct, the second air duct and the third air duct. The biomass combustor is provided with the chain grate stoker. Biomass fuel is combusted on the chain grate stoker so that under the condition that generated coke is not cooled, the coke can also fall into the setting chamber along with the uniform motion of the chain grate stoker and the potential safety hazard that coking on the chain grate stoker is generated can be eliminated. Meanwhile, three-time air supply is adopted, so that the fuel is combusted more thoroughly and the combustion efficiency is improved.

Owner:天津市双鑫锅炉辅机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com