Polyetheretherketone/polyimide/polyphenyl thioether ternary alloy and preparation method thereof

A technology of polyimide and polyether ether ketone, which is applied in the field of polyetheretherketone/polyimide/polyphenylene sulfide ternary alloy and its preparation, can solve the problem of high price of a single product in the market and achieve improvement Performance, overcome the effect of expensive, simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

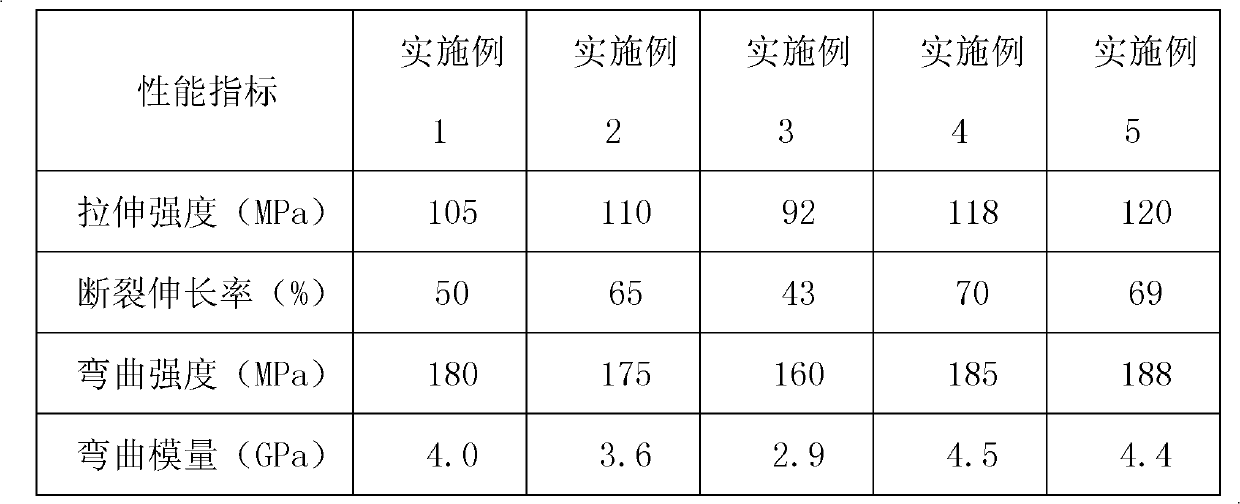

Examples

Embodiment 1

[0028] Weigh the ingredients according to the following weights:

[0029] 90 parts of polyether ether ketone,

[0030] 5 parts polyimide,

[0031] 5 parts polyphenylene sulfide,

[0032] Weigh the raw materials of each component according to the above weight, dry the weighed polyether ether ketone, polyimide, and polyphenylene sulfide at 100-140°C for 2-6 hours; then stir in a high-speed mixer for 5-15 minutes Mix uniformly; put the uniformly mixed material into a twin-screw extruder, extrude and pelletize at a temperature of 300-370°C, and the screw speed is at 10-30r / min, cool, pelletize, and dry to obtain polyether ether ketone / poly Imide / polyphenylene sulfide ternary alloy pellets.

Embodiment 2

[0034] Weigh the ingredients according to the following weights:

[0035] 5 parts polyether ether ketone,

[0036] 90 parts of polyimide,

[0037] 5 parts polyphenylene sulfide,

[0038] Weigh the raw materials of each component according to the above weight, dry the weighed polyether ether ketone, polyimide, and polyphenylene sulfide at 100-140°C for 2-6 hours; then stir in a high-speed mixer for 5-15 minutes Mix uniformly; put the uniformly mixed material into a twin-screw extruder, extrude and pelletize at a temperature of 300-370°C, and the screw speed is at 10-30r / min, cool, pelletize, and dry to obtain polyether ether ketone / poly Imide / polyphenylene sulfide ternary alloy pellets.

Embodiment 3

[0040] Weigh the ingredients according to the following weights:

[0041] 5 parts polyether ether ketone,

[0042] 5 parts polyimide,

[0043] 90 parts of polyphenylene sulfide,

[0044] Weigh the raw materials of each component according to the above weight, dry the weighed polyether ether ketone, polyimide, and polyphenylene sulfide at 100-140°C for 2-6 hours; then stir in a high-speed mixer for 5-15 minutes Mix uniformly; put the uniformly mixed material into a twin-screw extruder, extrude and pelletize at a temperature of 300-370°C, and the screw speed is at 10-30r / min, cool, pelletize, and dry to obtain polyether ether ketone / poly Imide / polyphenylene sulfide ternary alloy pellets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com