Novel fiber-drawing hot bath medium and application thereof

A heat bath and medium technology, applied in the direction of stretch spinning, etc., can solve the problems of uneven heating of fibers, complex device structure, unfavorable drafting, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

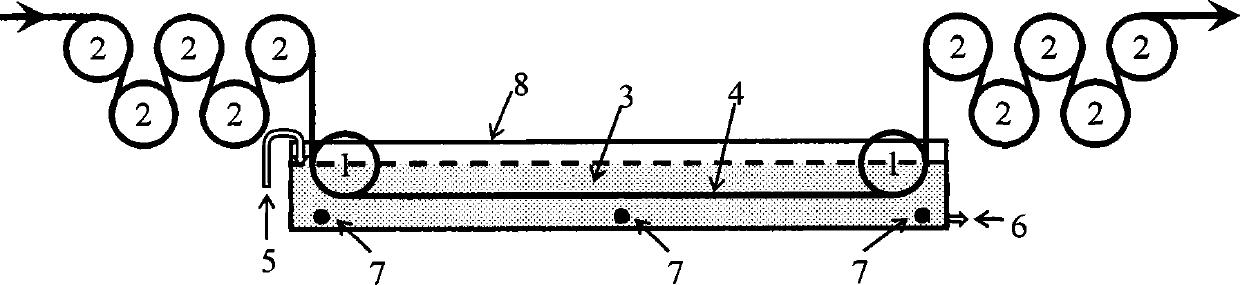

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: the stretching of polyethylene terephthalate (PET) fiber in silicone oil hot bath medium

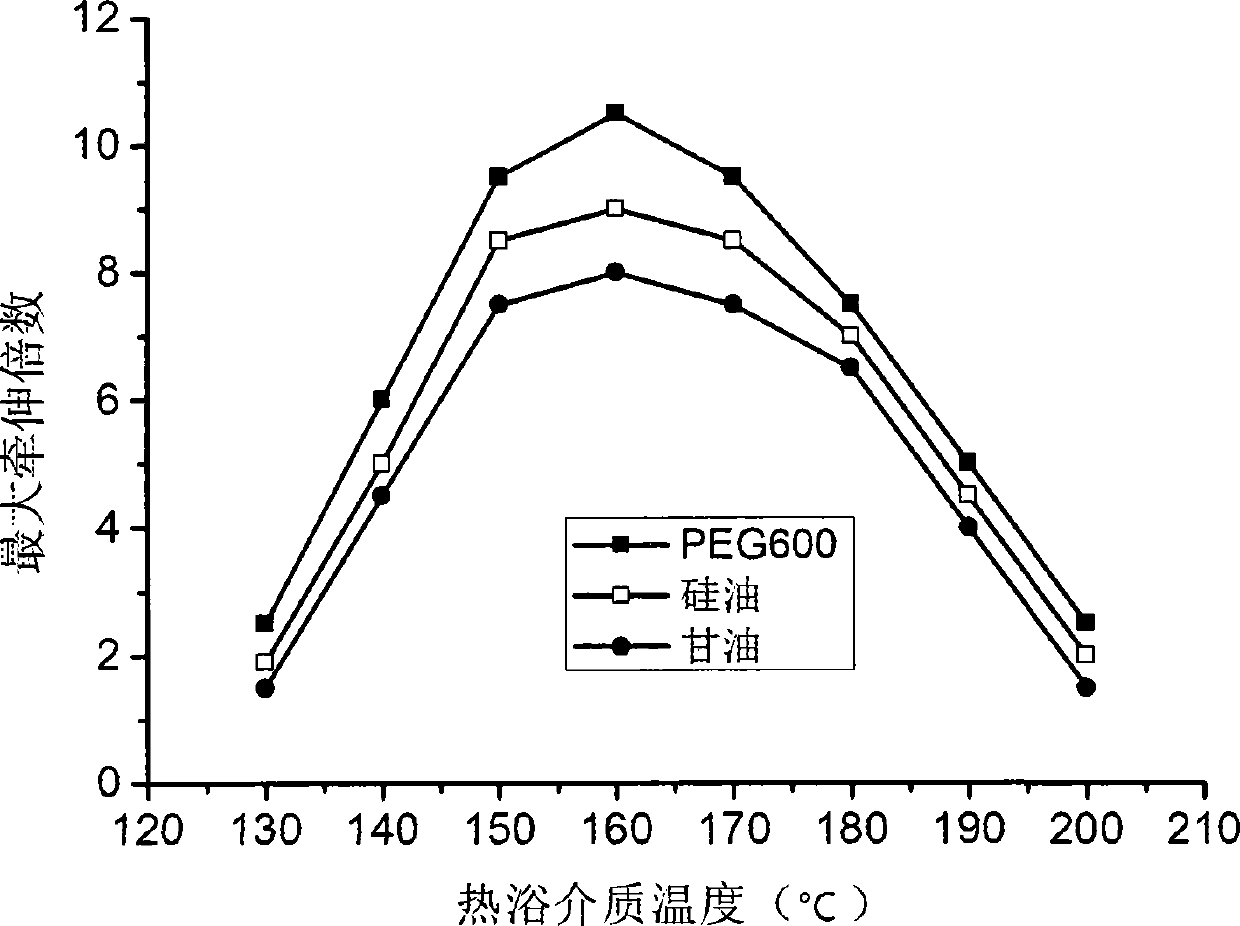

[0032]Silicone oil is used as the hot bath medium, and the hot bath temperature is 180°C. PET pre-oriented yarn (POY) is drawn in the hot bath medium. The residence time of the fiber in the hot bath medium is 3 seconds, and the maximum draw ratio can be up to 9 times. The measured fiber tensile strength is 70-80cN / dtex, and the elongation at break is 6-15%. Under the same residence time conditions in the same hot bath medium, the relationship between the maximum draw ratio and the hot bath temperature is as follows: figure 2 shown.

Embodiment 2

[0033] Embodiment 2: the stretching of polyethylene terephthalate (PET) fiber in the glycerin hot bath medium

[0034] Glycerin is used as the heat bath medium, and the temperature of the heat bath is 170°C. The PET pre-oriented yarn (POY) is drawn in the heat bath medium. The residence time of the fiber in the heat bath medium is 3 seconds, and the maximum draw ratio can be up to 8 times. The measured fiber tensile strength is 60-75cN / dtex, and the elongation at break is 10-20%. Under the same residence time conditions in the same hot bath medium, the relationship between the maximum draw ratio and the hot bath temperature is as follows: figure 2 shown.

Embodiment 3

[0035] Embodiment 3: the drawing-off of polyethylene terephthalate (PET) fiber in glycerin hot bath medium

[0036] Use PEG600 as the heat bath medium, the temperature of the heat bath is 60°C, draw the PET pre-oriented yarn (POY) in the heat bath medium, the residence time of the fiber in the heat bath medium is 3 seconds, and the maximum draw ratio can be up to 10.5 times. The measured fiber tensile strength is 60-90cN / dtex, and the elongation at break is about 5-12%. Under the same residence time conditions in the same hot bath medium, the relationship between the maximum draw ratio and the hot bath temperature is as follows: figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com