Patents

Literature

57 results about "Heat bath" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

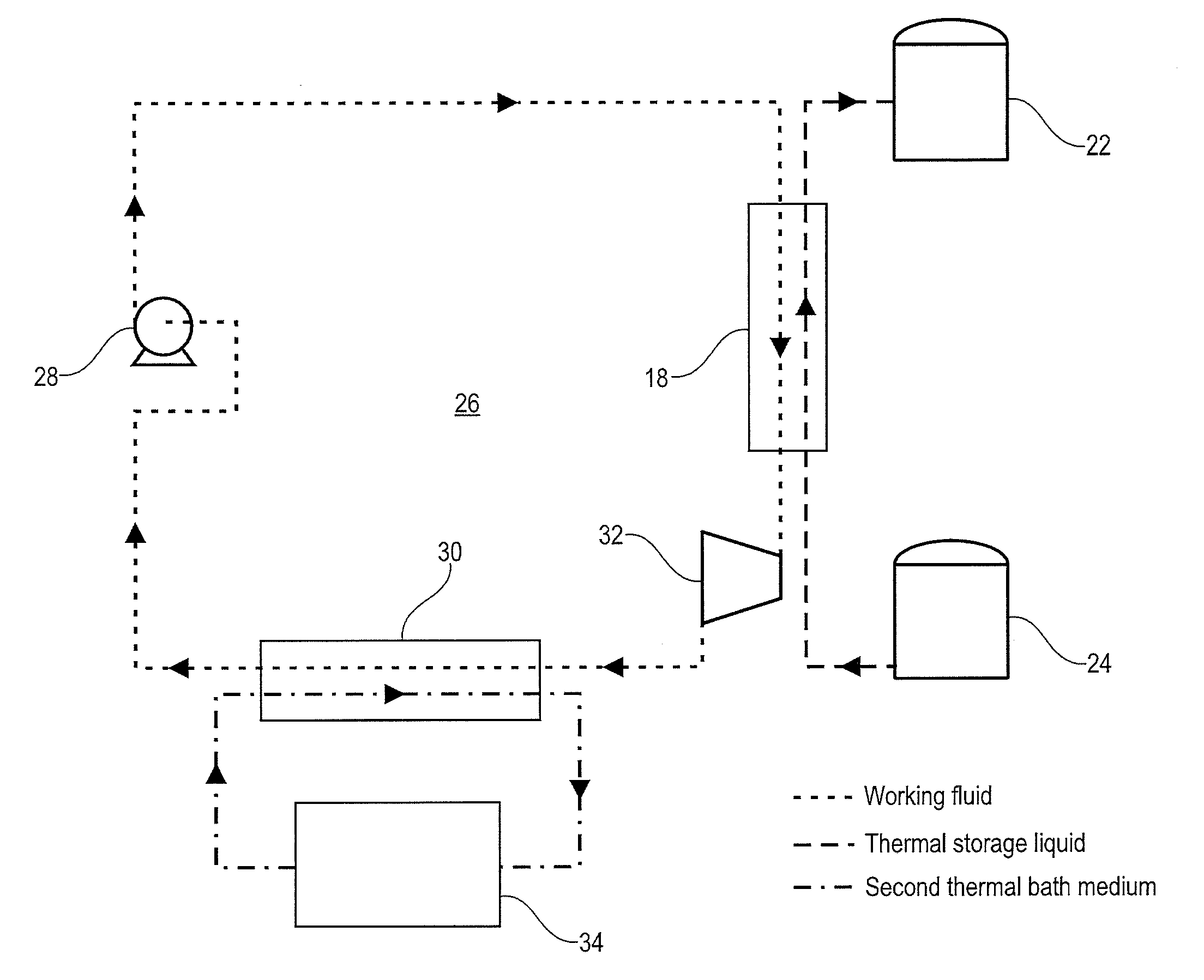

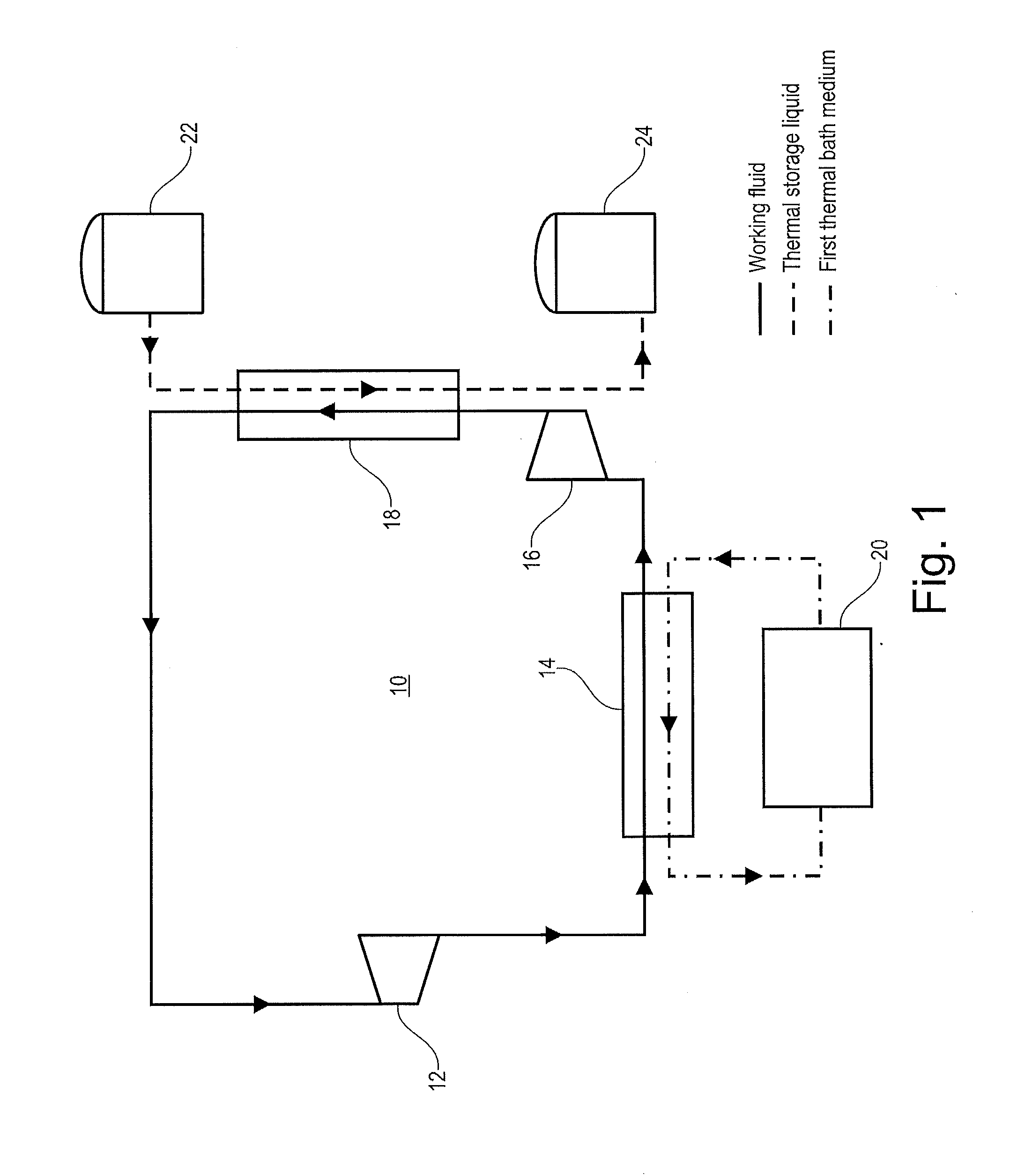

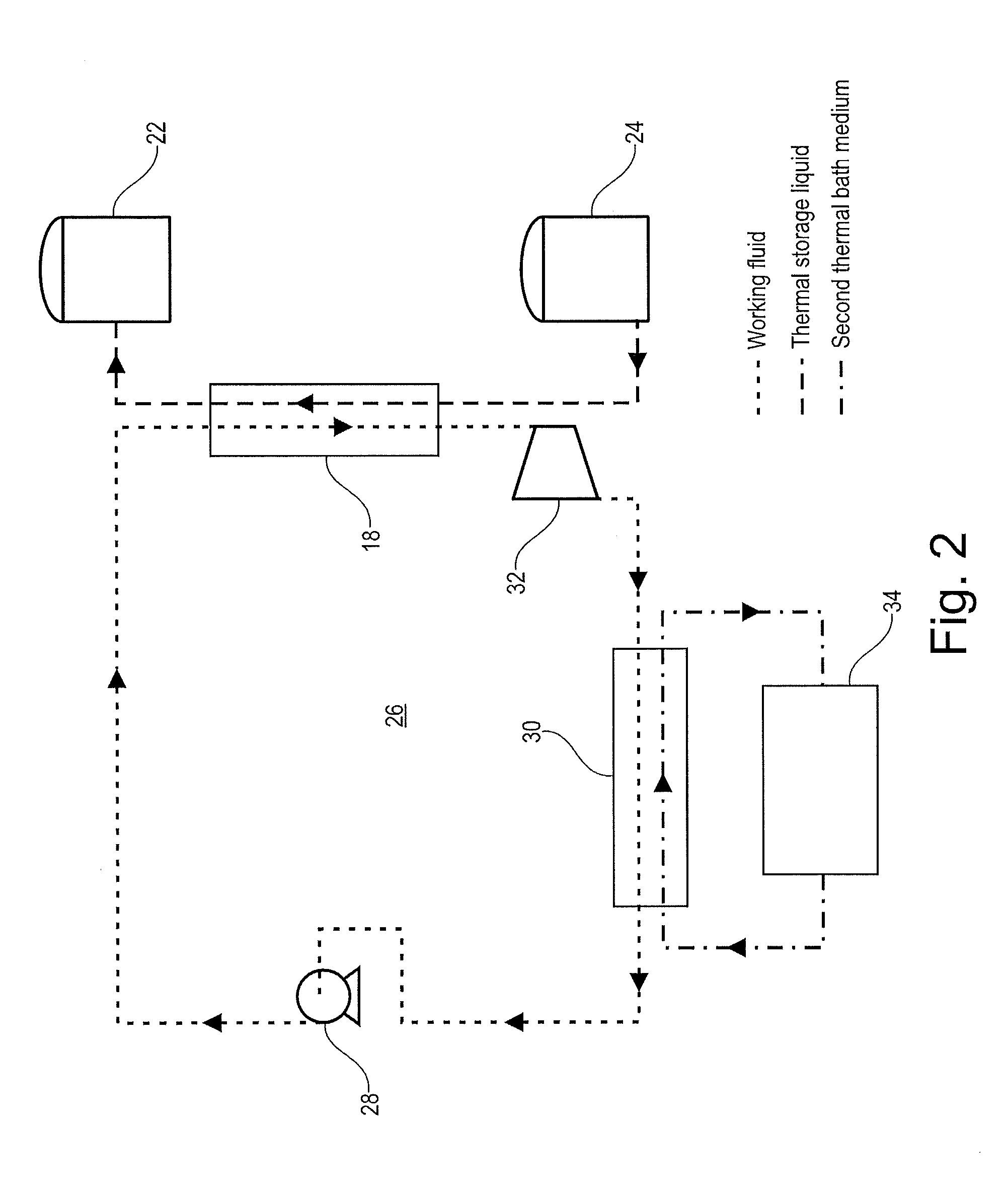

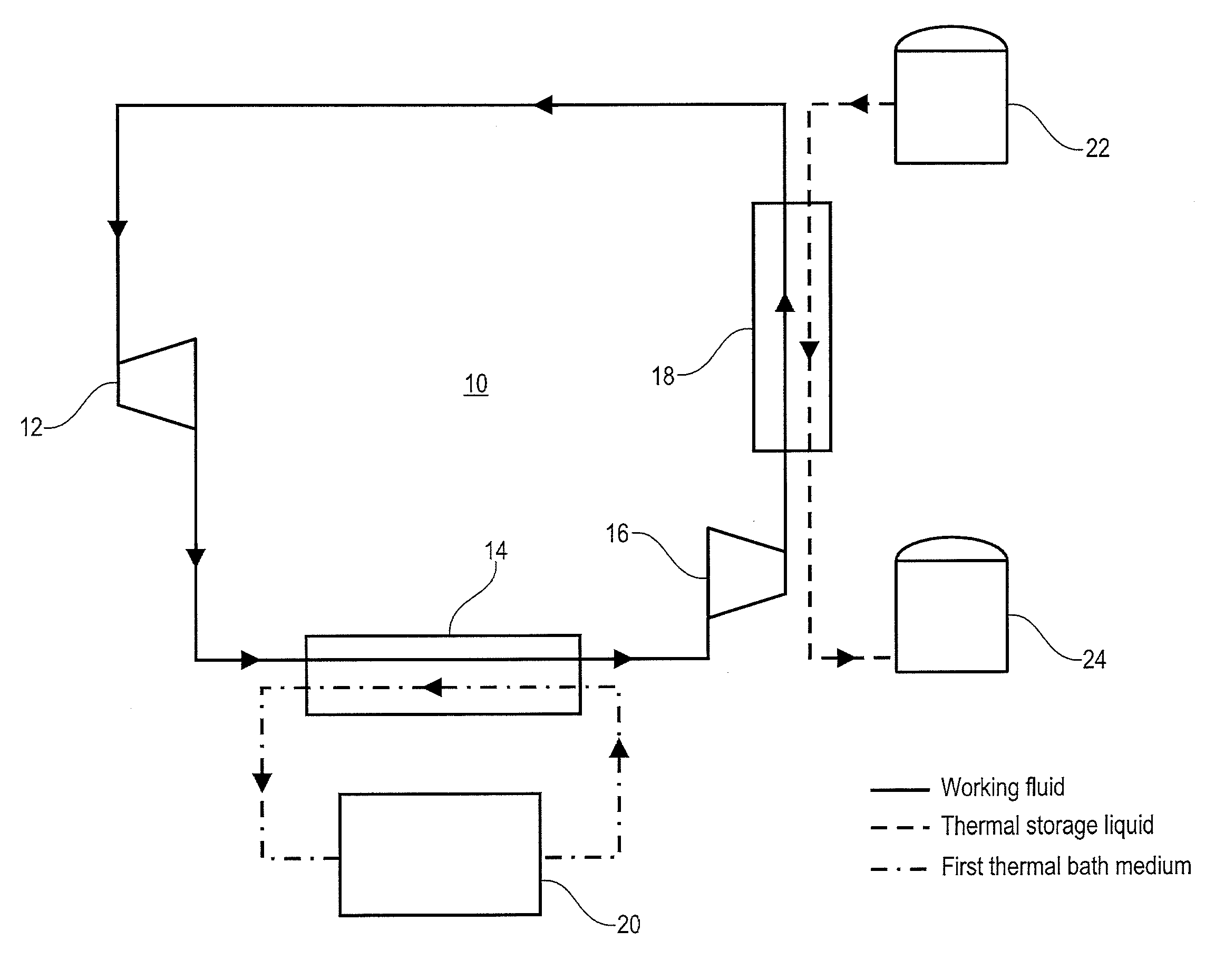

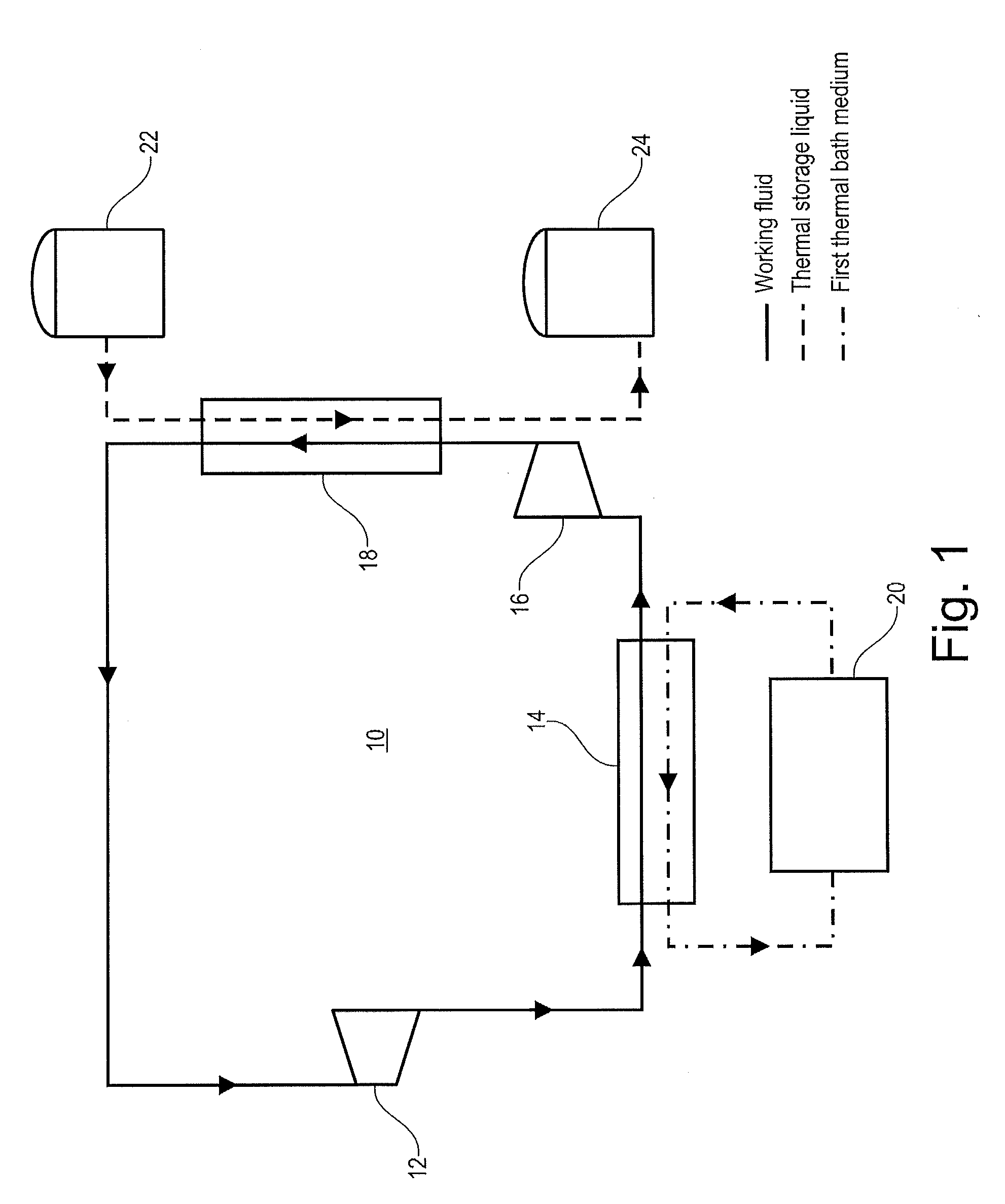

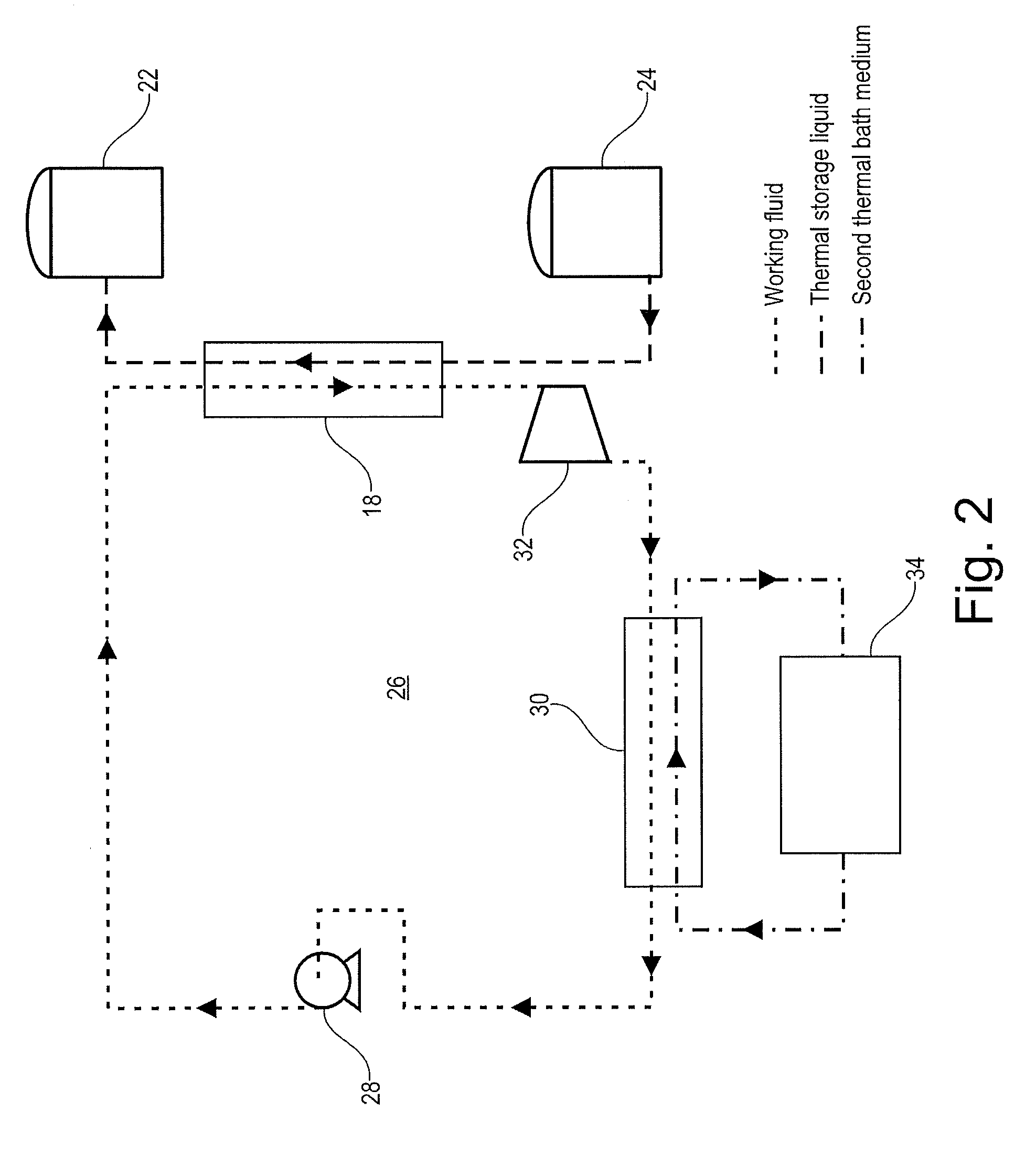

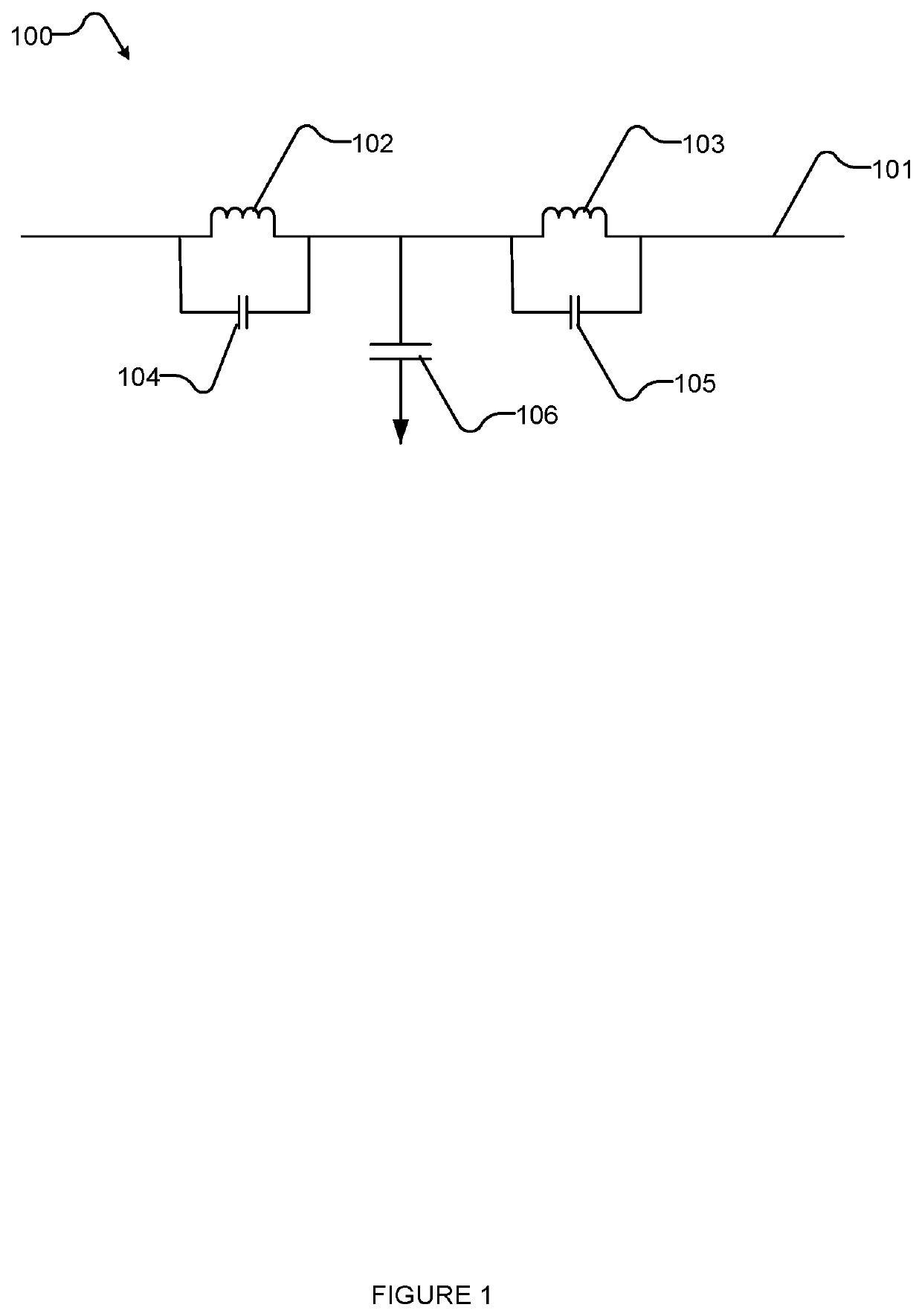

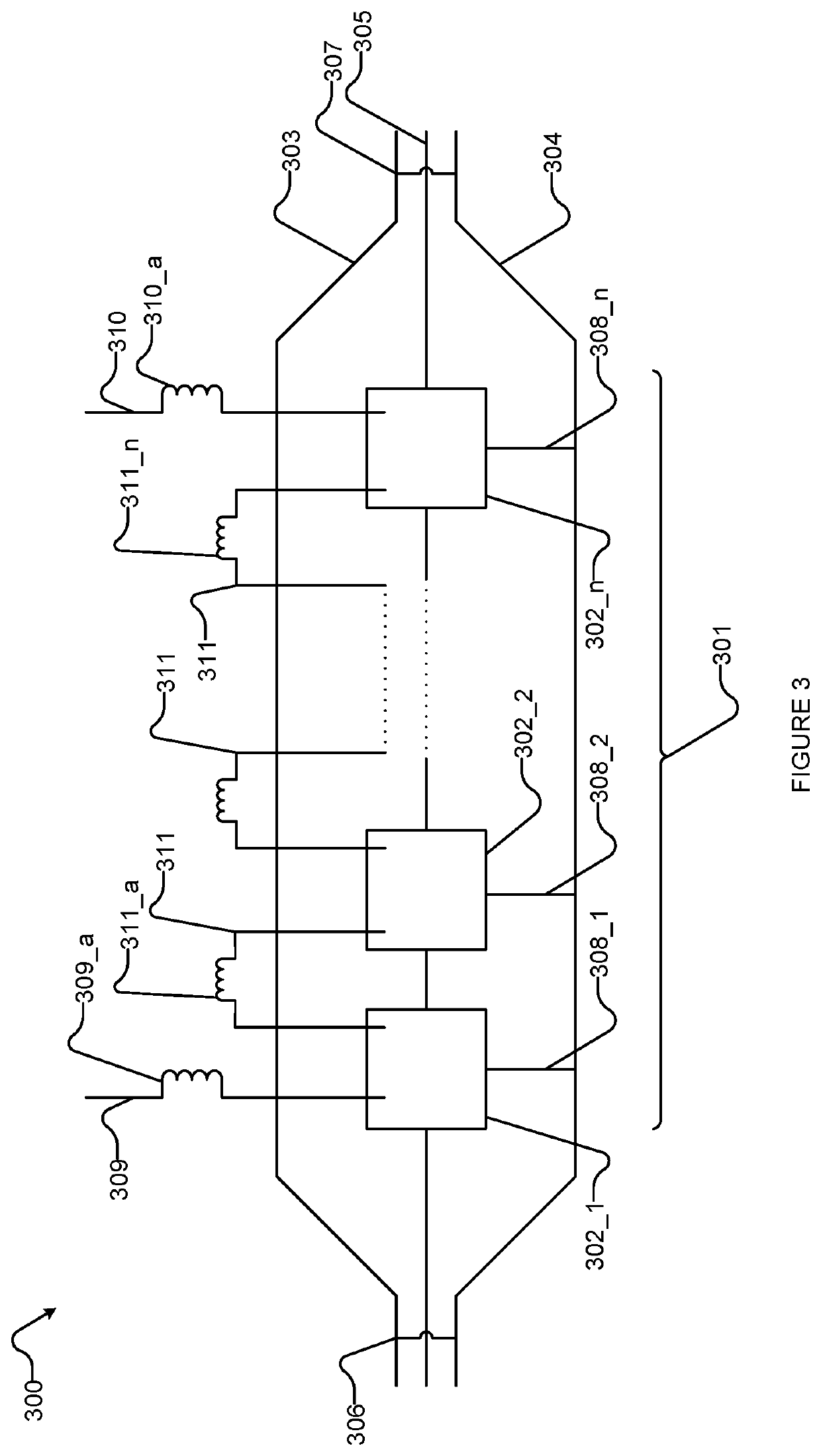

Thermoelectric energy storage system having two thermal baths and method for storing thermoelectric energy

ActiveUS20120060501A1High round-trip efficiencySystem costs involvedThermoelectric device with peltier/seeback effectHeat storage plantsWorking fluidThermal energy storage

An exemplary system and method for storing and retrieving energy in a thermoelectric energy storage system is disclosed. The thermoelectric energy storage system includes a working fluid that is circulated through a first and second heat exchanger, and a thermal storage medium that is circulated through the first heat exchanger. The second heat exchanger is in connection with a first thermal bath during a charging cycle and with a second thermal bath during a discharging cycle. In this way roundtrip efficiency is improved through minimizing the temperature difference between the first thermal bath and the hot storage tank during charging, and maximizing the temperature difference between the second thermal bath and the hot storage tank during discharging.

Owner:ABB (SCHWEIZ) AG

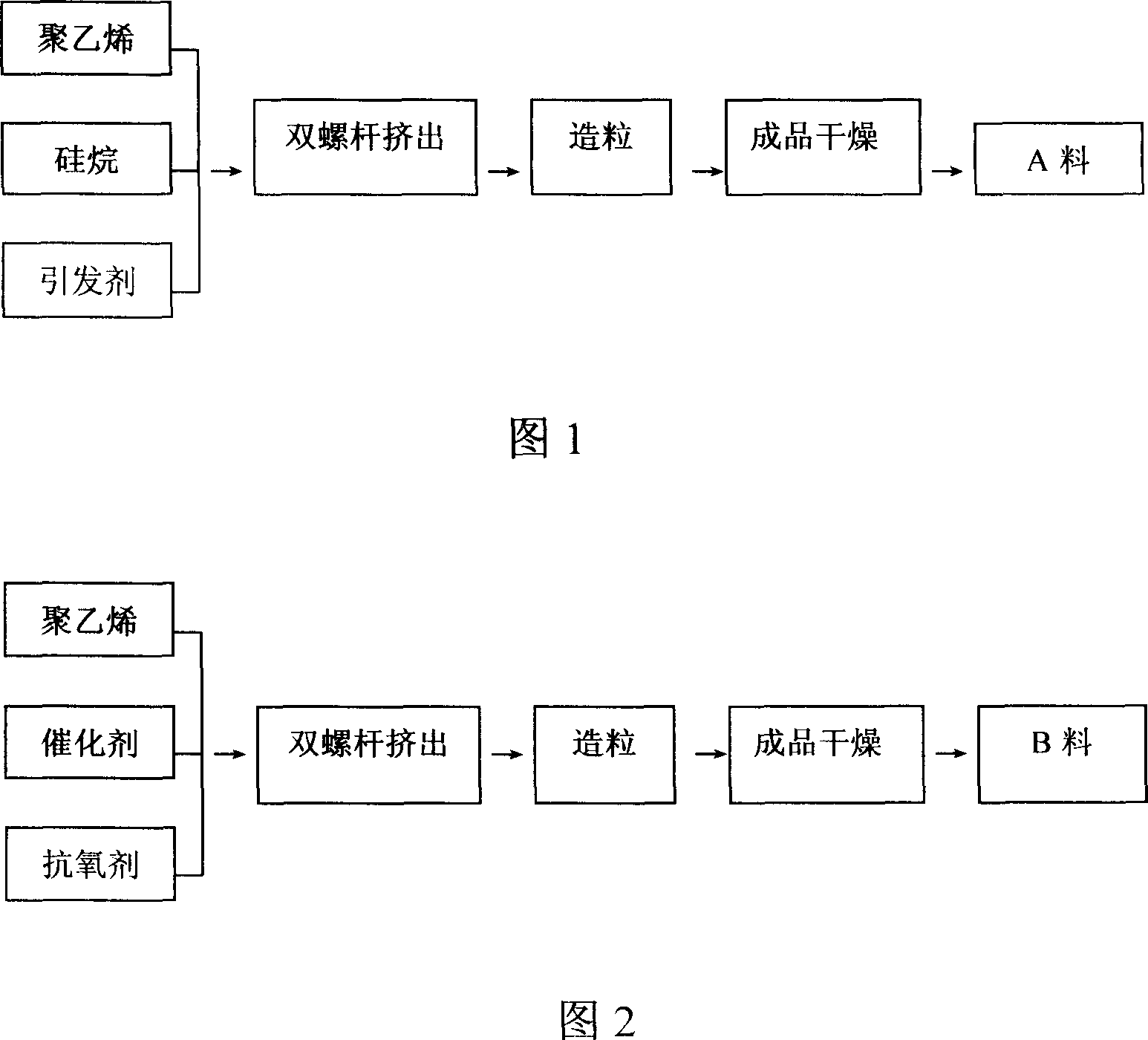

Silane natural-crosslinked polyethylene cable insulating material and its production process

InactiveCN1995120AReduce production processReduce investmentInsulated cablesInsulated conductorsSilanesCross-linked polyethylene

The invention discloses a natural crosslinking polyethylene cable insulating material of silane, which consists of material A and material B with weight rate at 85-955- 15, wherein the material A is composed of 100g polyethylene resin, 0.5-3. 5g silane and 0.02-0.2g initiator; the material B is composed of 100g polyethylene resin, 5-20g anti-oxidant and 0.5-5g catalyst. The invention also provides the manufacturing method of natural crosslinking polyethylene cable insulating material of silane, which adopts natural crosslinking polyethylene cable insulating material of silane without immersing in the heat bath after squeezing to crosslink under natural condition.

Owner:SHANGHAI ELECTRIC CABLE RES INST +1

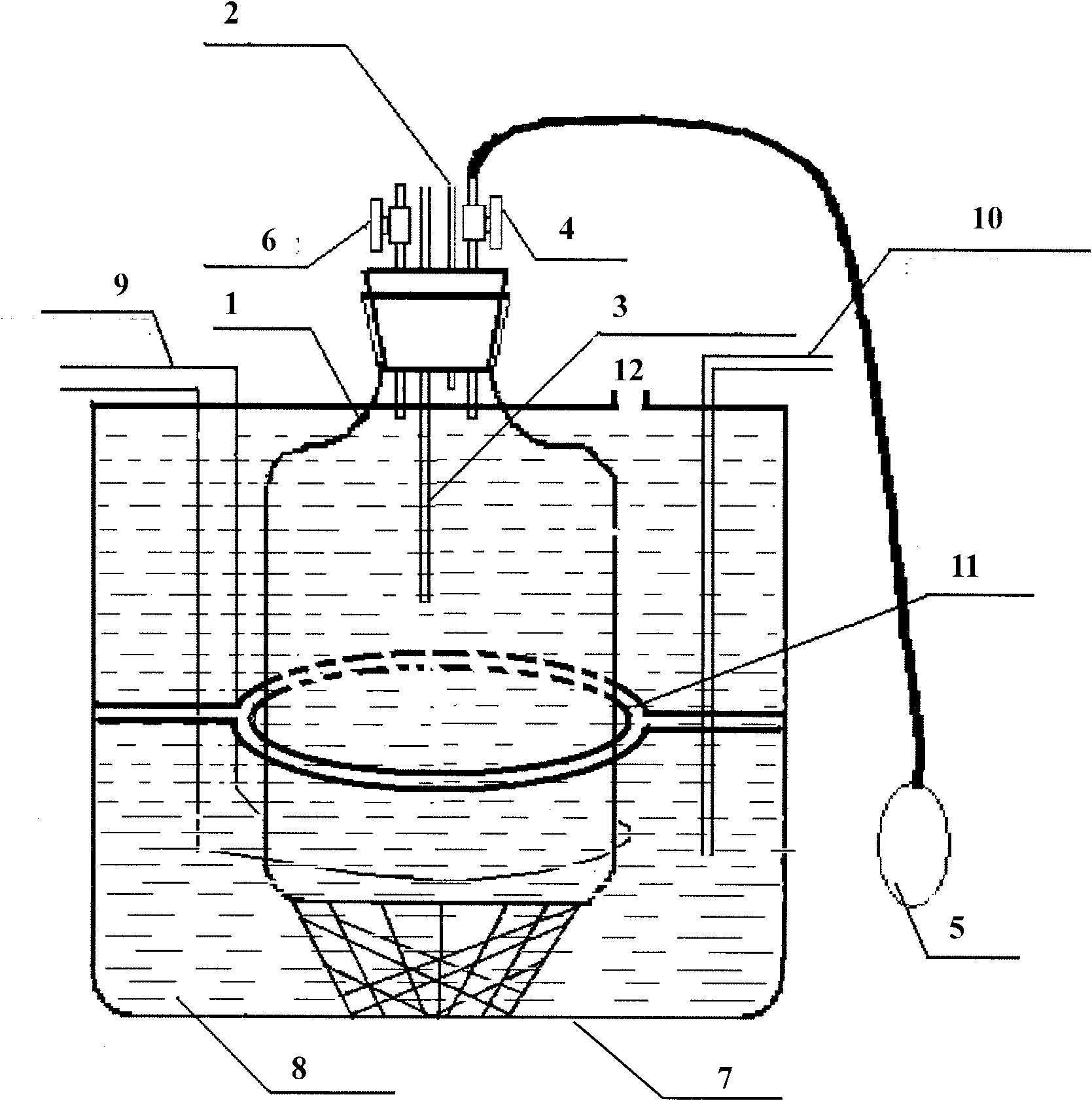

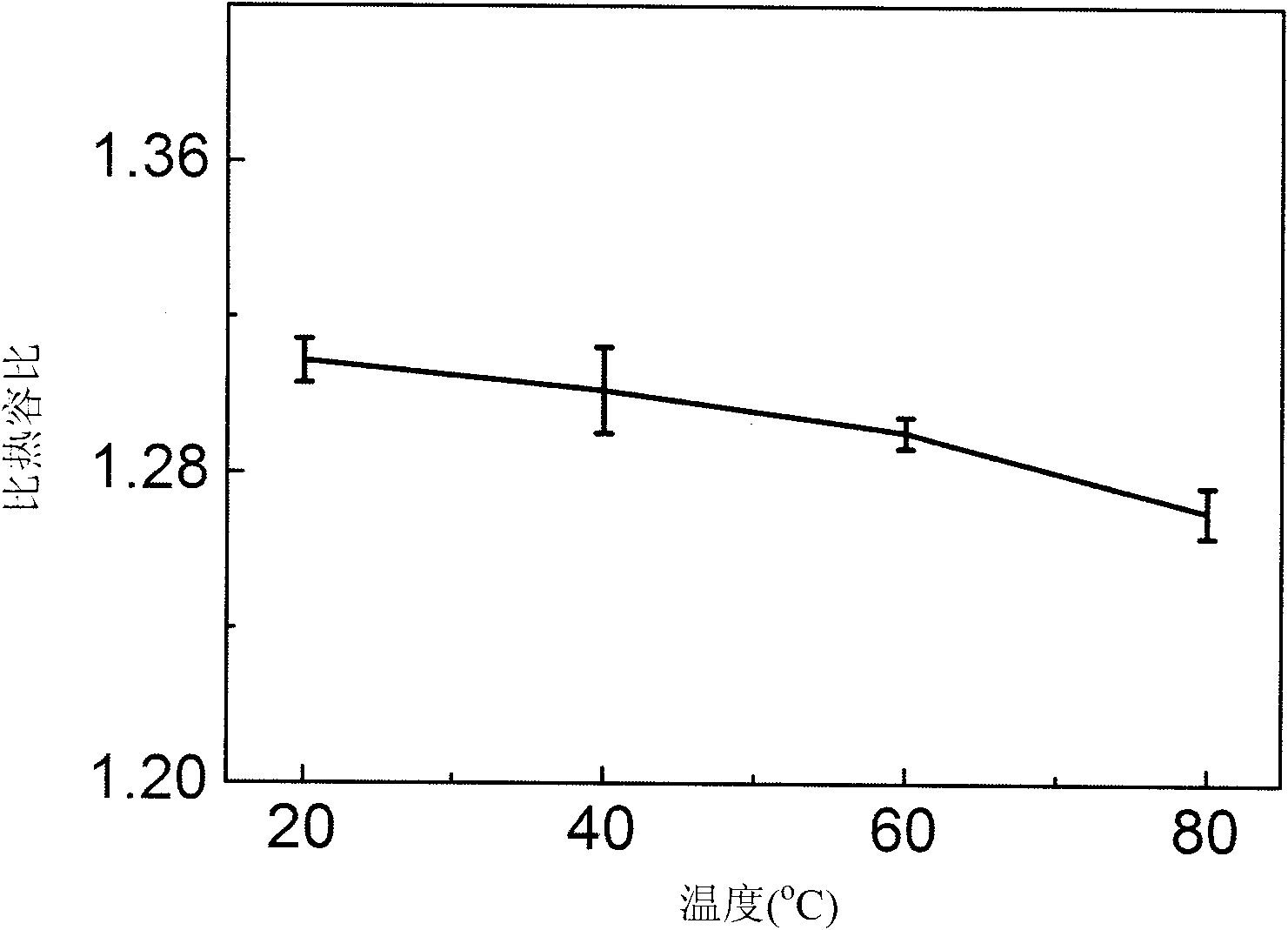

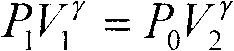

Device and method for measuring specific heat ratio of air under different temperatures

InactiveCN101840650AGuaranteed temperatureAccurate temperatureMaterial heat developmentEducational modelsMicrocontrollerElectricity

The invention provides a device for measuring specific heat ratio of air under different temperatures, which comprises an air storage bottle, a pressure sensor and an air temperature testing sensor which are arranged in the bottle, wherein an air charge part and an air discharge part are fixed on the air storage bottle. The device is characterized in that the device further comprises a temperature display and control device which is arranged around the air storage bottle. The temperature display and control device comprises a heat bath container, an electric heating part, a bath temperature testing sensor and a microcontroller, wherein the electric heating part and the bath temperature testing sensor are fixedly arranged in the heat bath container and are electrically connected with the microcontroller. The invention further provides a method for measuring the specific heat ratio of the air under different temperatures through above device. The device and the method can ensure that the air temperature can be at a precise range, enriches the experimental teaching contents and improves the learning initiatives of the students.

Owner:SOUTHWEST JIAOTONG UNIV

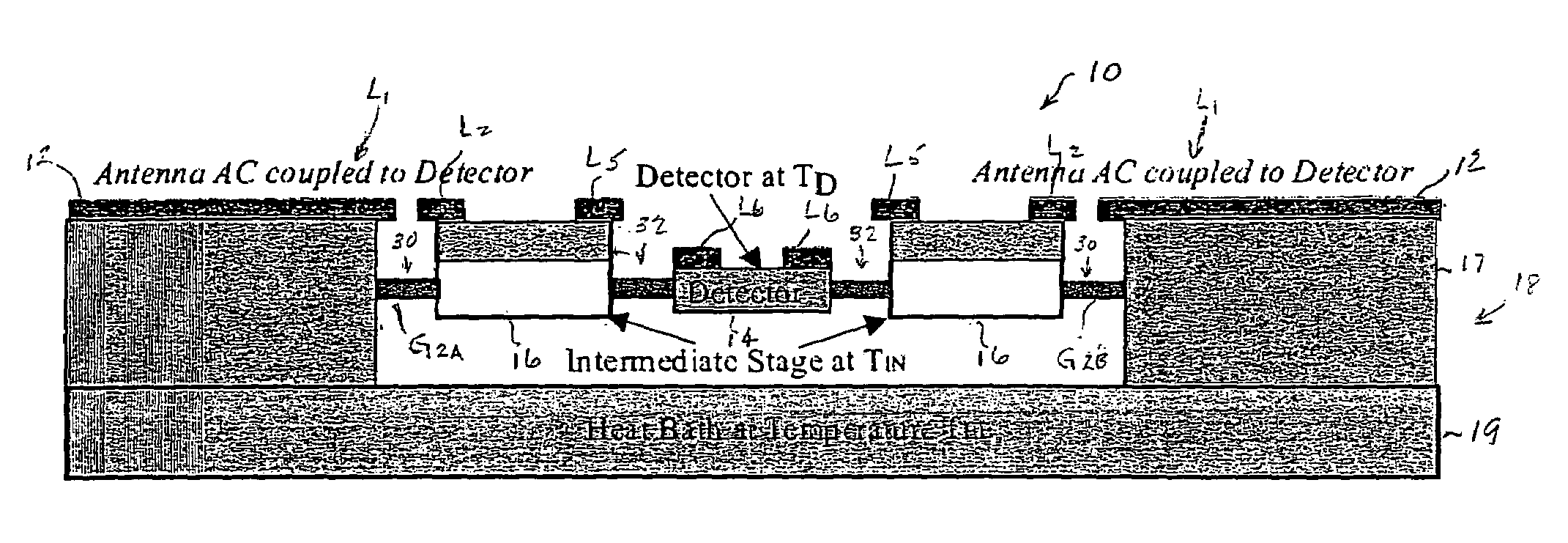

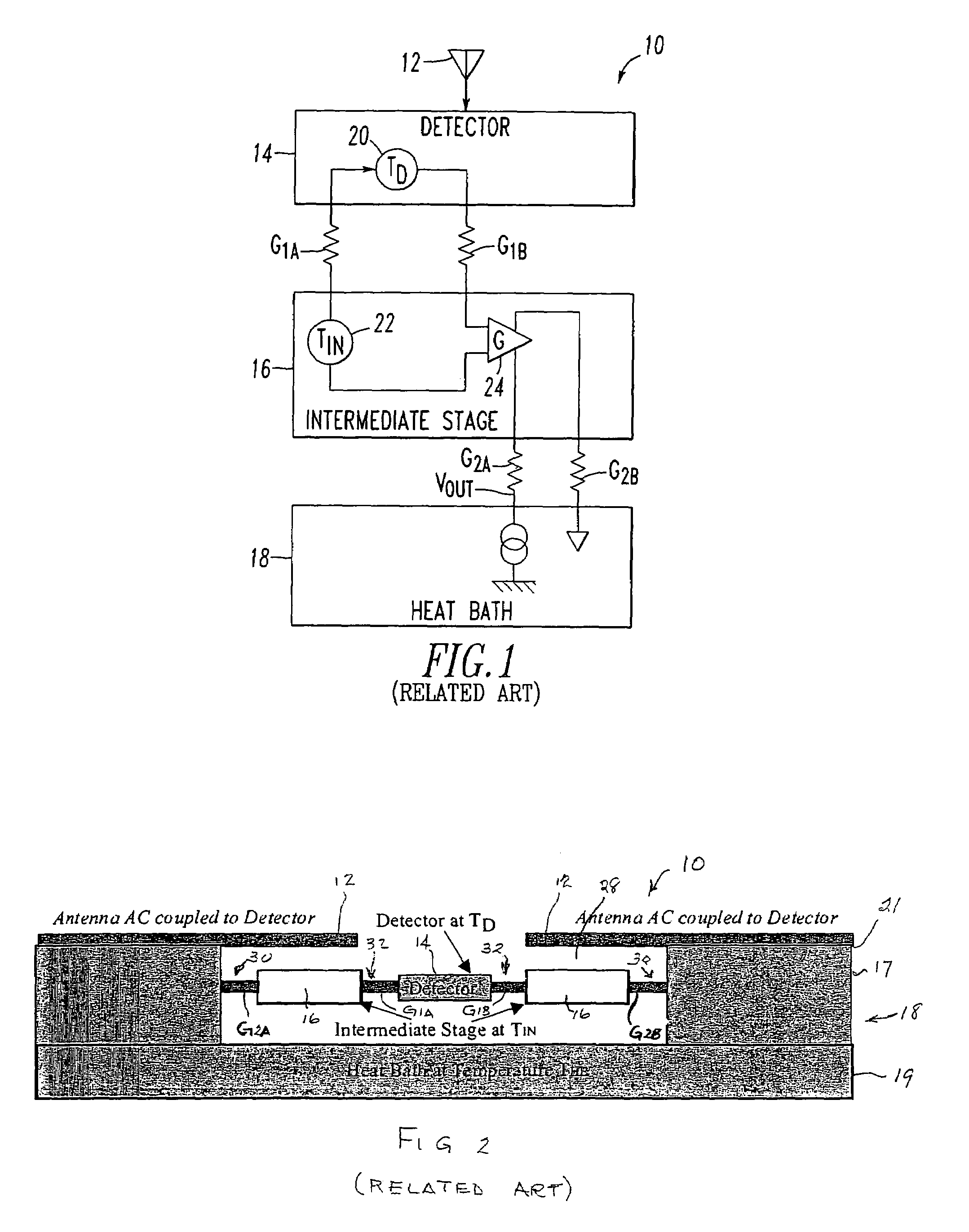

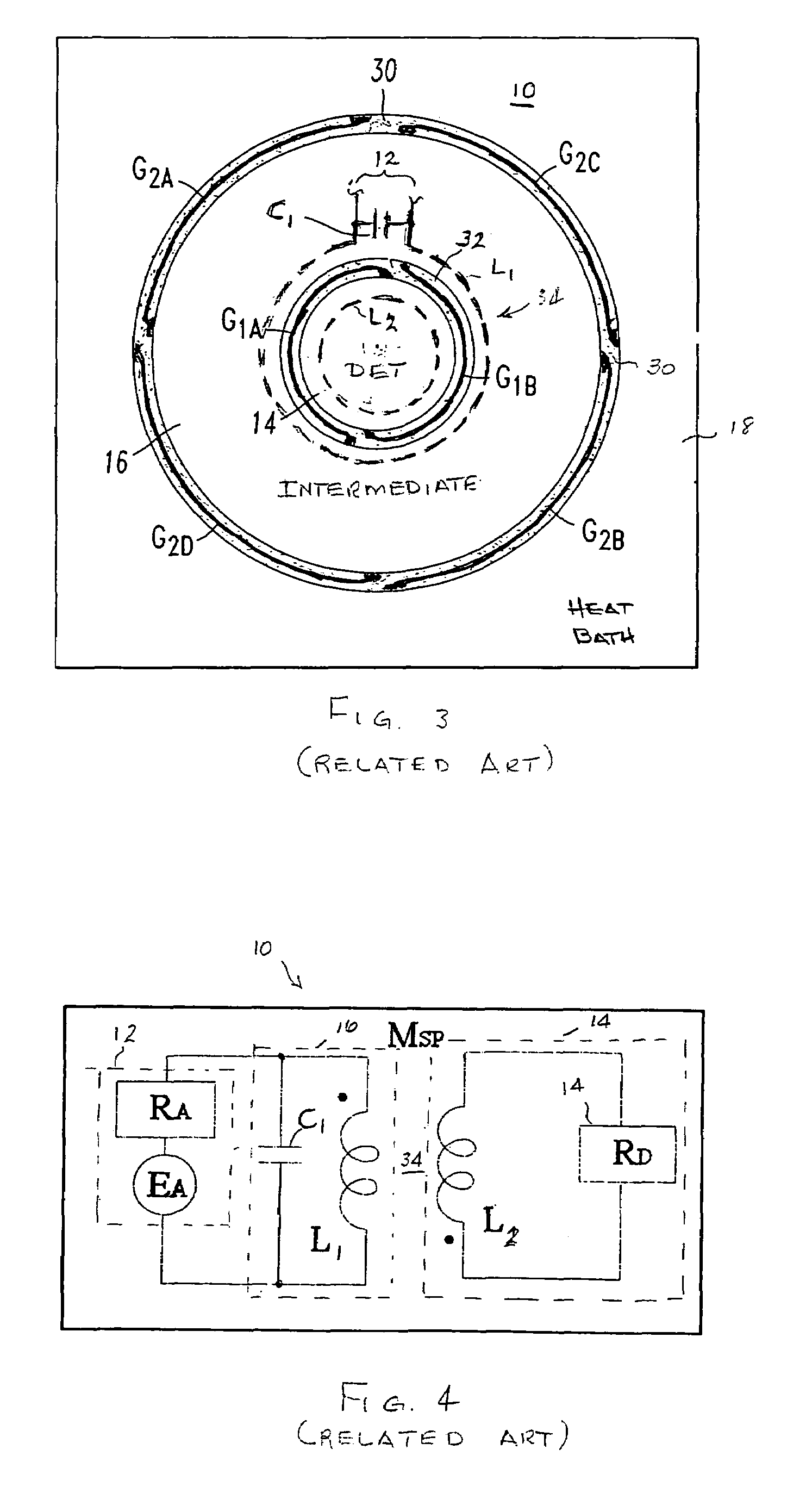

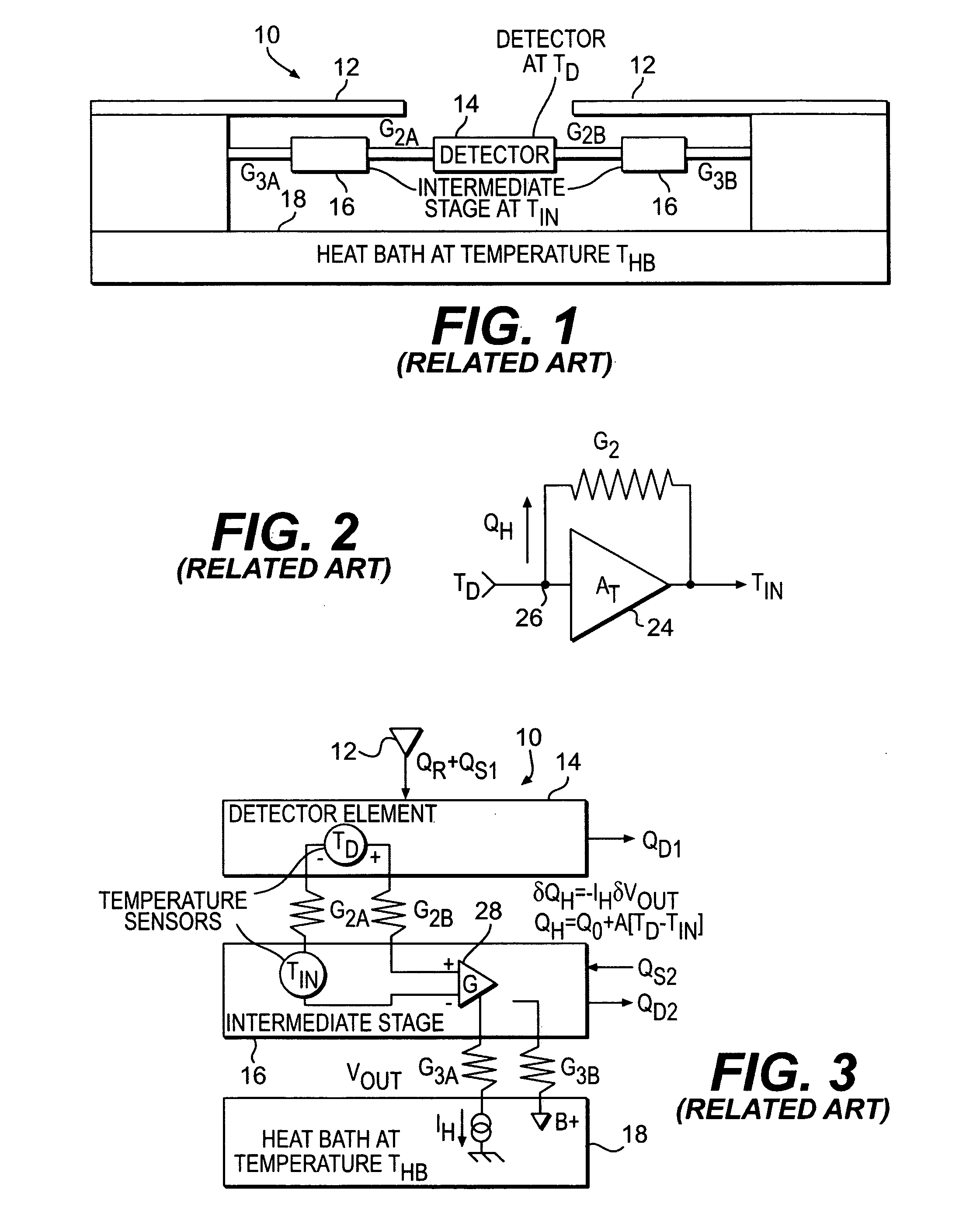

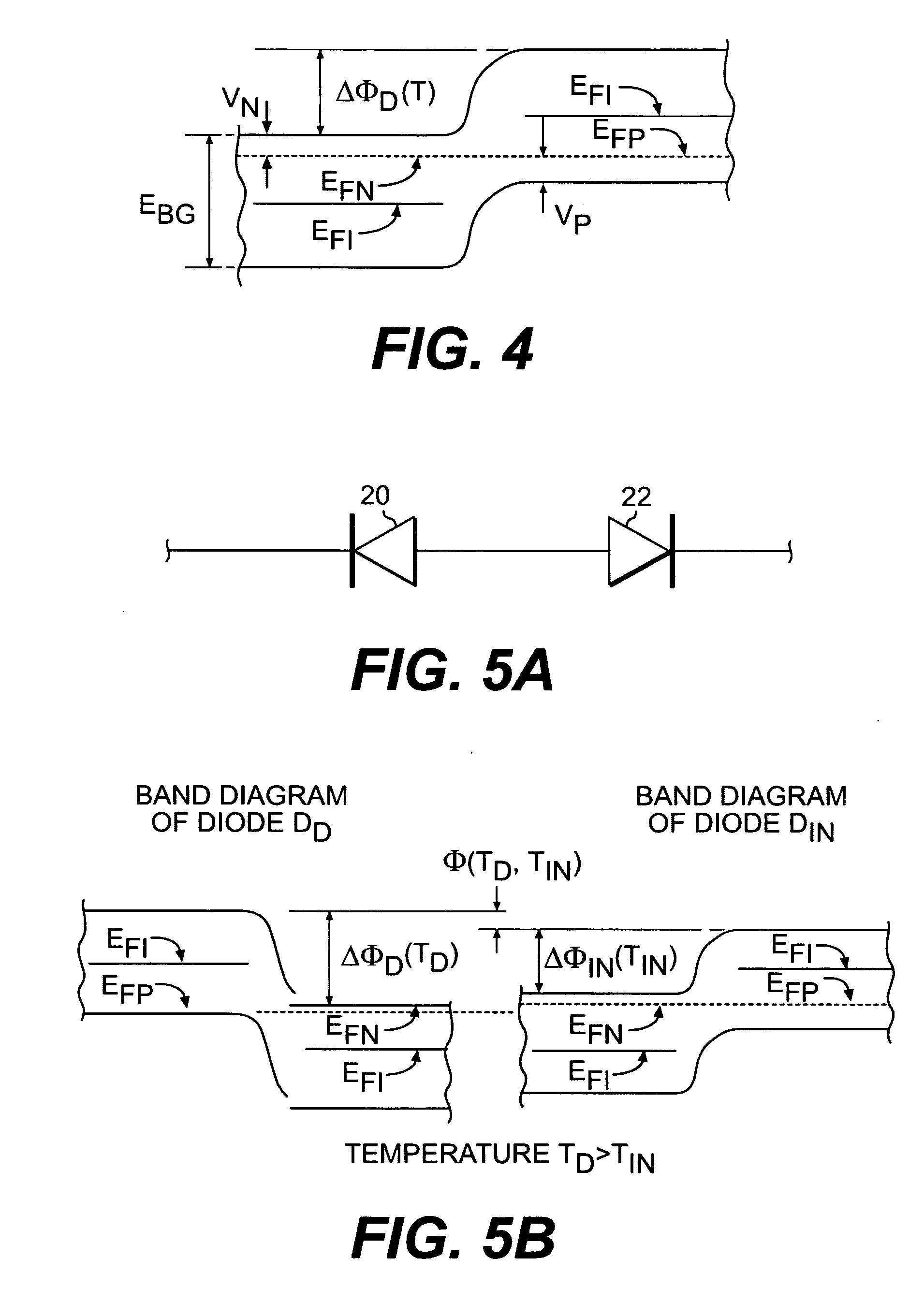

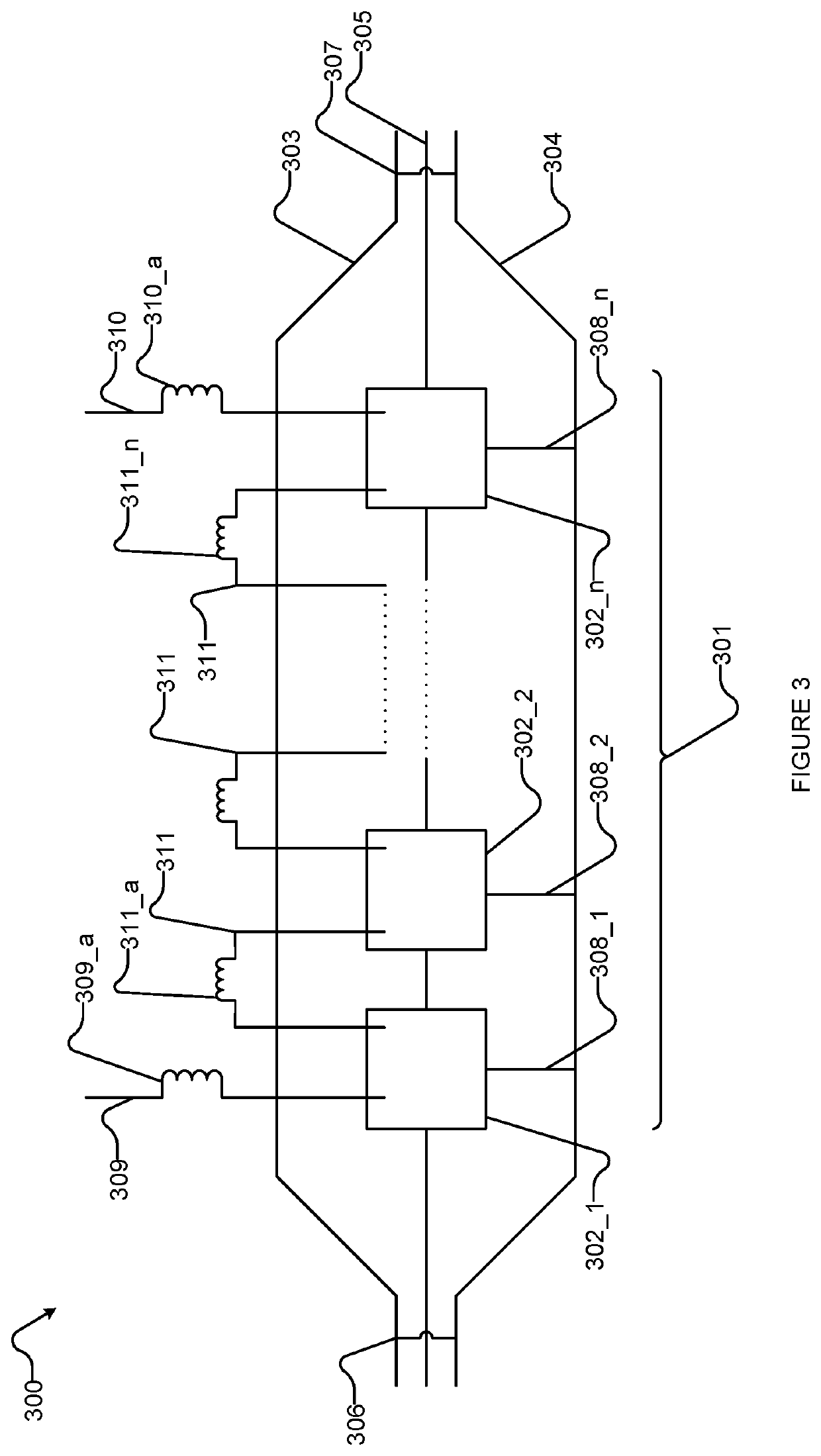

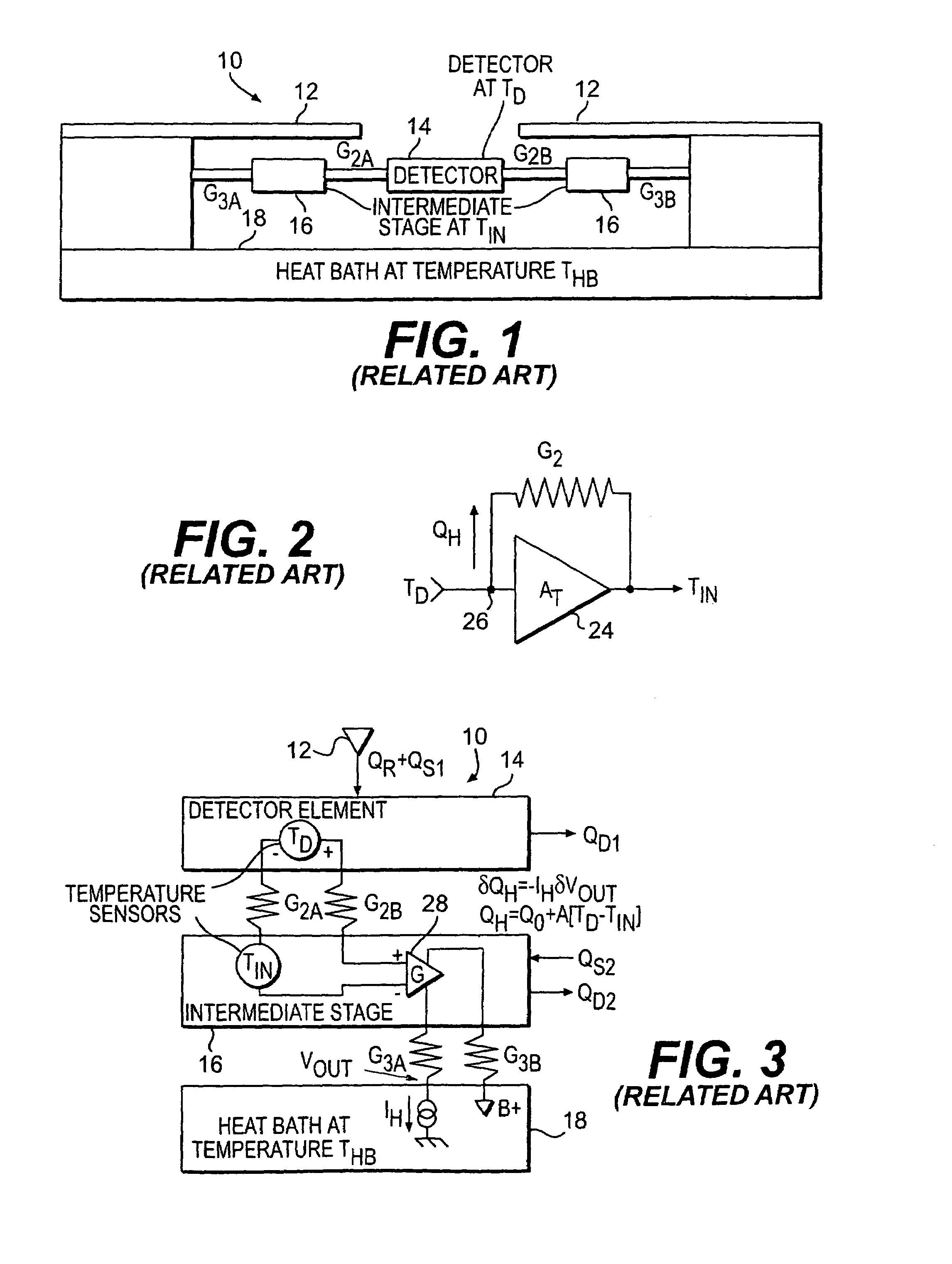

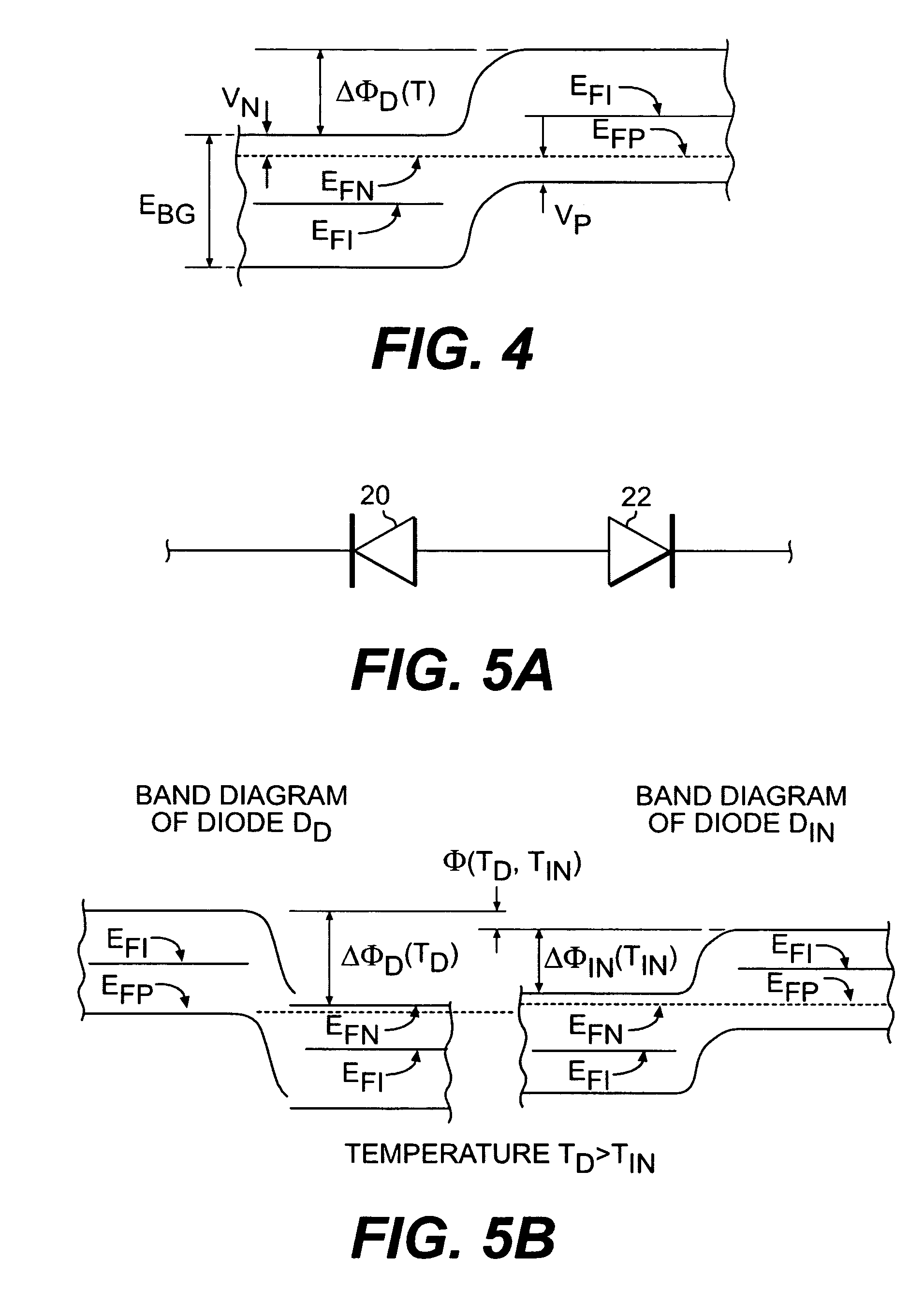

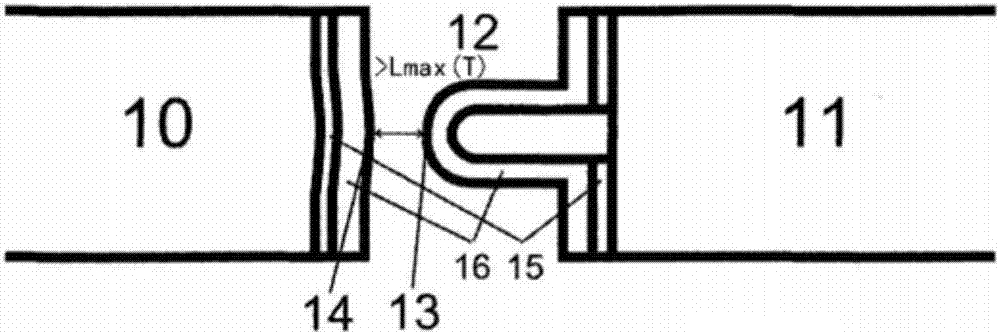

Two stage transformer coupling for ultra-sensitive silicon sensor pixel

ActiveUS7375333B1Minimising overhangRobust mechanical structureSolid-state devicesMaterial analysis by optical meansCouplingIntermediate stage

A bolometer type ultra-sensitive silicon sensor pixel of a multi-pixel sensor wherein each pixel includes a detector stage, an intermediate stage, and a heat bath stage. The detector stage, the intermediate stage and a portion of the heat bath stage are generally co-planar and are interconnected by I-beam bridges so as to permit mutually co-planar rotation in response to stress and strain. Electrical coupling is improved between a micro-antenna and the detector stage by a two stage transformer assembly that couples the micro-antenna to the detector stage.

Owner:NORTHROP GRUMMAN SYST CORP

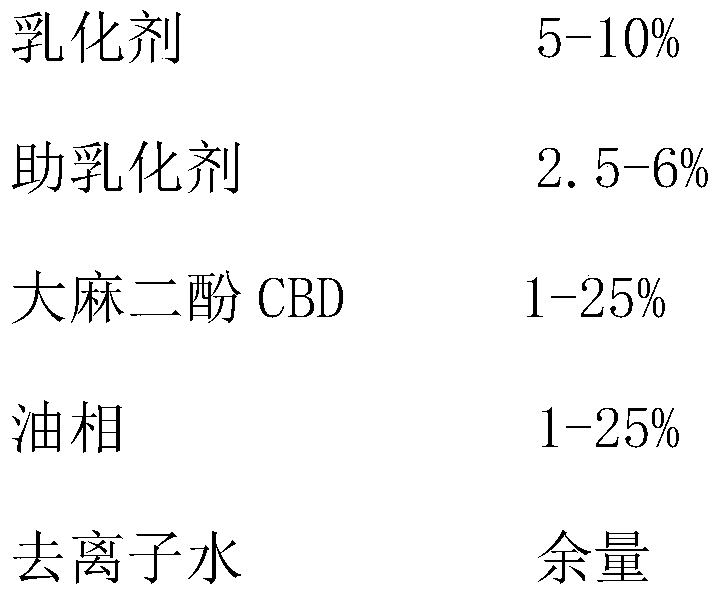

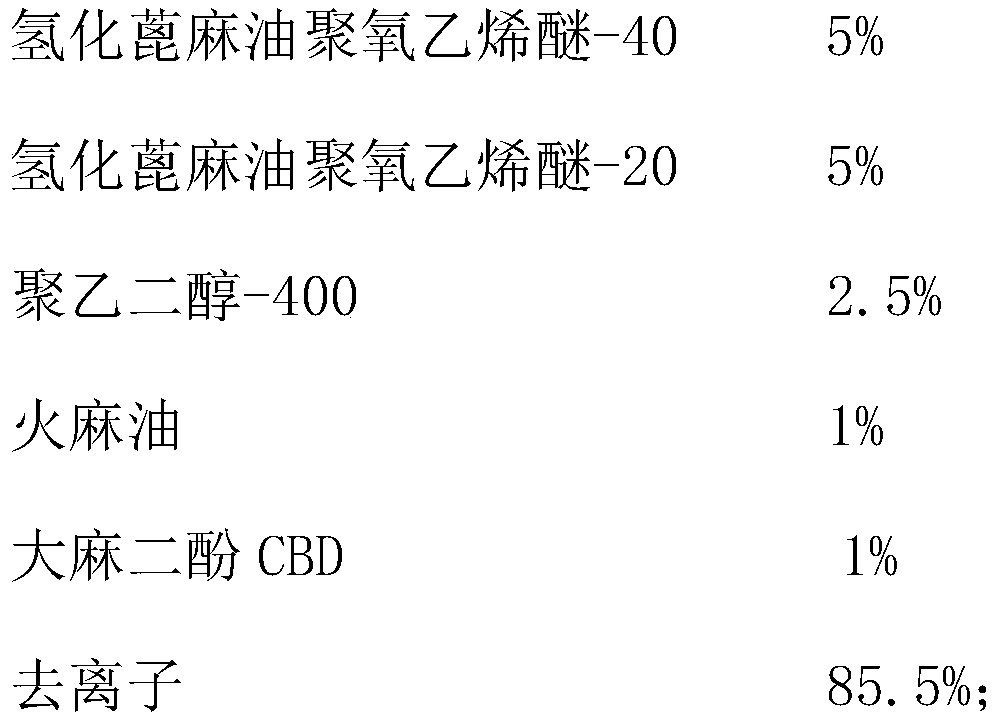

Cannabidiol CBD nano-emulsion and preparation method thereof

InactiveCN110269840ARetain structureImprove bioavailabilityAntibacterial agentsNervous disorderOil phaseWater soluble

The invention provides a cannabidiol CBD nano-emulsion and a preparation method thereof. The cannabidiol CBD nano-emulsion is prepared from the following raw materials in percentage by mass: 5-10 percent of emulsifier, 2.5-6 percent of co-emulsifier, 1-25 percent of cannabidiol CBD, 1-25 percent of an oil phase and the balance of deionized water. According to the preparation method, the cannabidiol CBD is directly dissolved in the oil phase, and repeated freezing, unfreezing and heating bath are performed to prepare the cannabidiol CBD nano-emulsion. By utilizing the stable performance of the nano-emulsion, the form of the cannabidiol CBD nano-emulsion can be maintained effectively for a long time, the original structure of the cannabidiol CBD can be maintained, the cannabidiol CBD can be furthest absorbed and utilized, and the bioavailability of the cannabidiol CBD can be greatly improved. Furthermore, the cannabidiol CBD nano-emulsion is water soluble, the application range of the cannabidiol CBD nano-emulsion can be enlarged, and reliable technical support is provided to subsequent application, researches and development.

Owner:云南辰锦威生物科技有限公司

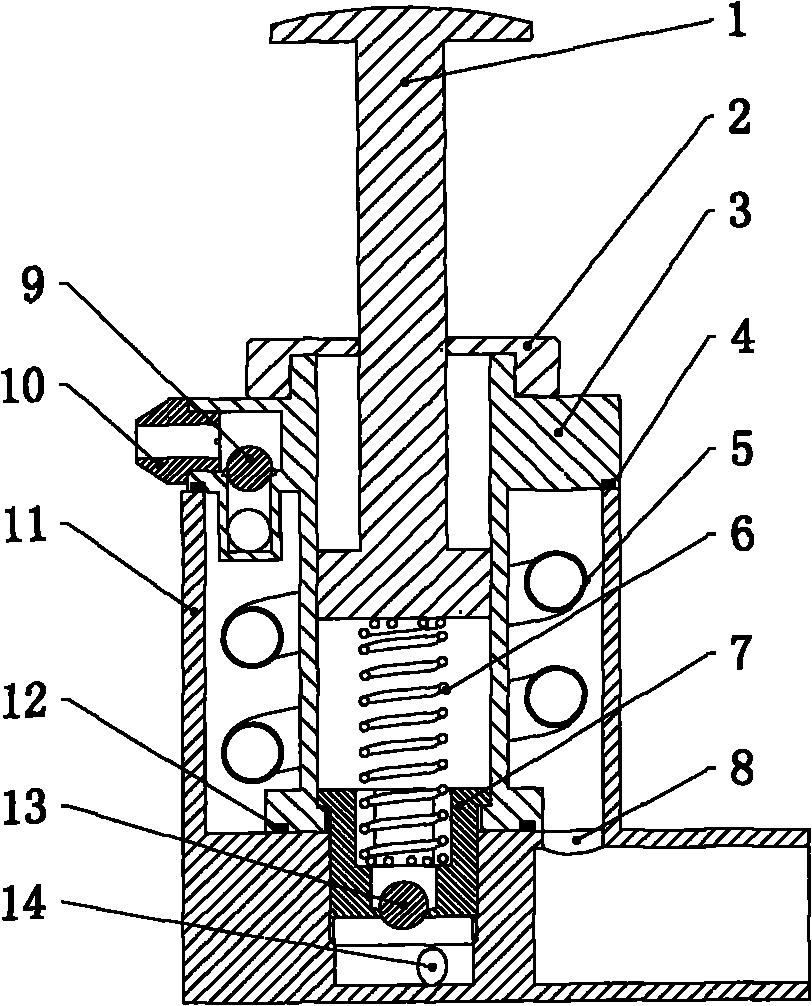

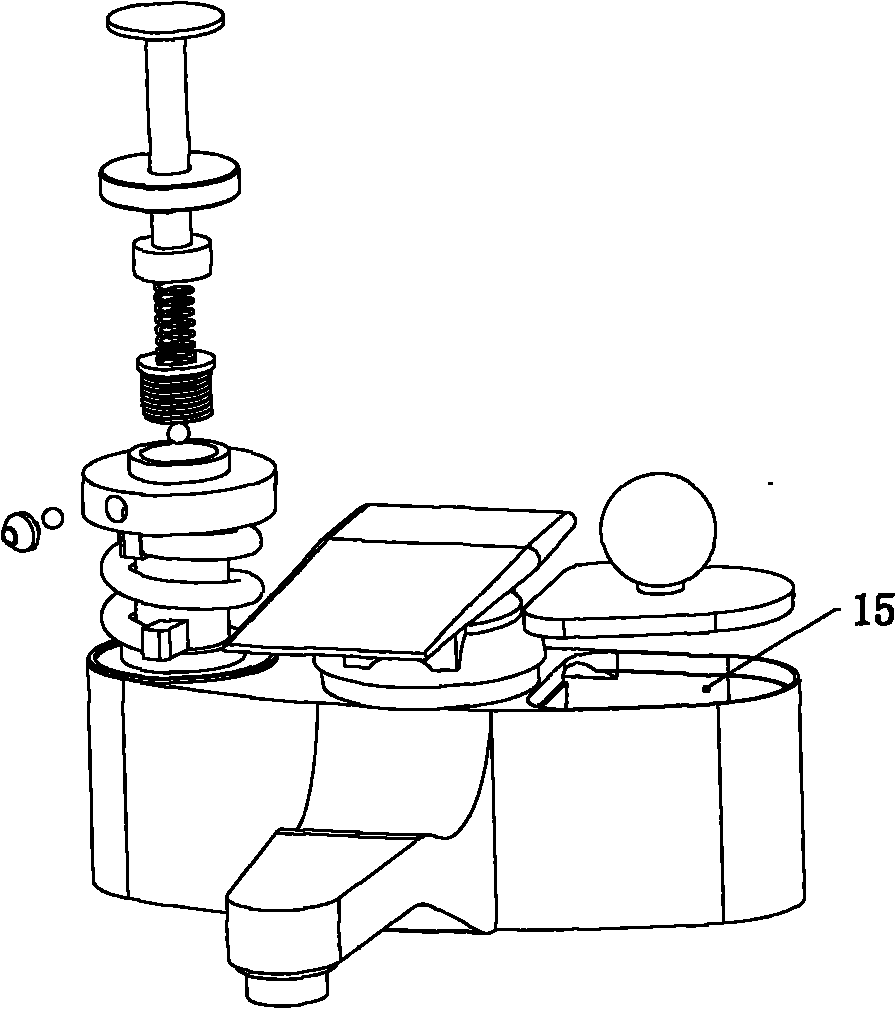

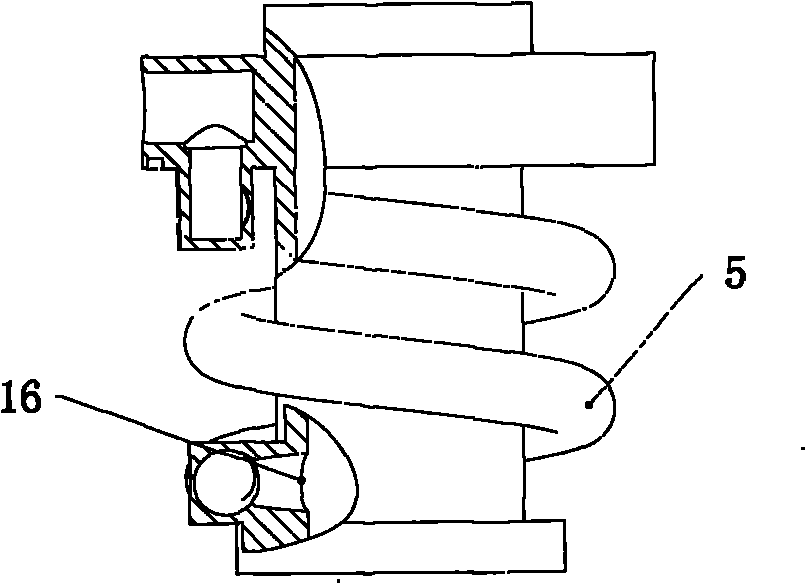

Bath cream liquid heater

The invention discloses a heater utilizing hot-water to heat bath cream and other like liquid. A thin-wall piston cylinder block provided with a thin wall tube is tightly connected on the cavity of a base through a hollow nut, hot water flows from the bottom lateral part of the cavity to fully fill the cavity, part of the energy is transferred to the thin-wall tube and bath cream like liquid in the piston cylinder, and then the hot water flows out from the upper lateral side of the cavity, thus heating the liquid rapidly. When being pressed by hands, a piston rod moves downwards in a piston, and the bath cream like liquid in the piston cylinder is pressed into the thin-wall tube, thereby extruding the heated liquid out of the thin-wall tube. When the piston rod is rebounded by a spring, the bath cream like liquid is sucked from the container thereof into the cavity of the piston cylinder.

Owner:李云林 +1

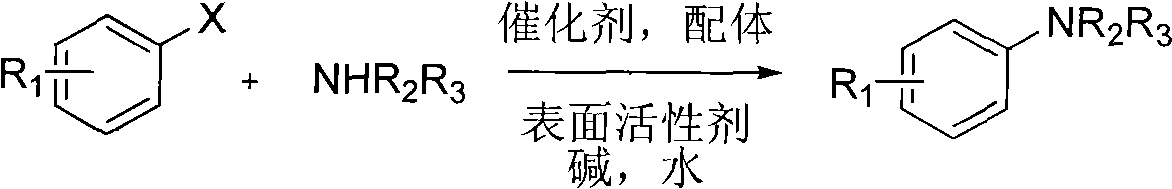

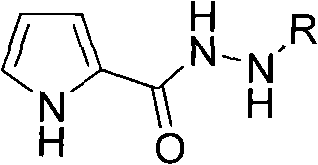

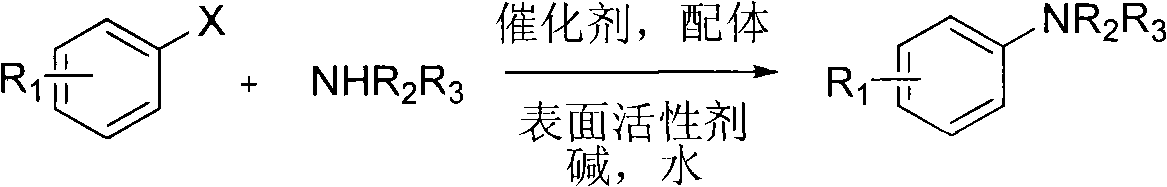

N-arylating method using pyrrole-2-hydrazide compound as ligand in aqueous phase system

ActiveCN101774874AEasy to separateEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIodideCopper oxide

The invention provides an N-arylating method with convenience, mild reaction condition, friendly environment and economical process in an aqueous phase system. An aryl bromide or iodide and amine are used as raw materials, water is used as a solvent, metallic copper or a copper oxide or cuprous salt or cupric salt is used as a catalyst, and a pyrrole-2-hydrazide compound is used as a ligand to produce a C-N coupled reaction; the N-arylating method comprises the following reaction processes: adding the catalyst, the ligand, an aryl halide, the amine, a surfactant and the water into a microwavereactor or a reaction vessel, and carrying out a stirring reaction by adopting a microwave auxiliary heating or ordinary heat bath heating mode; after the reaction is finished, separating a reaction mixed liquid and purifying to obtain an N-arylating product. The method of the invention has the characteristics of simple operation, wide application range of substrates, simple and easy separation of products, high yield, economical process, friendly environment and the like. The water is used as a reaction solvent, the substrates have wide application ranges, and the N-arylating method has broad application prospect in the aspect of preparing natural products, medicaments and pesticides.

Owner:SUN YAT SEN UNIV

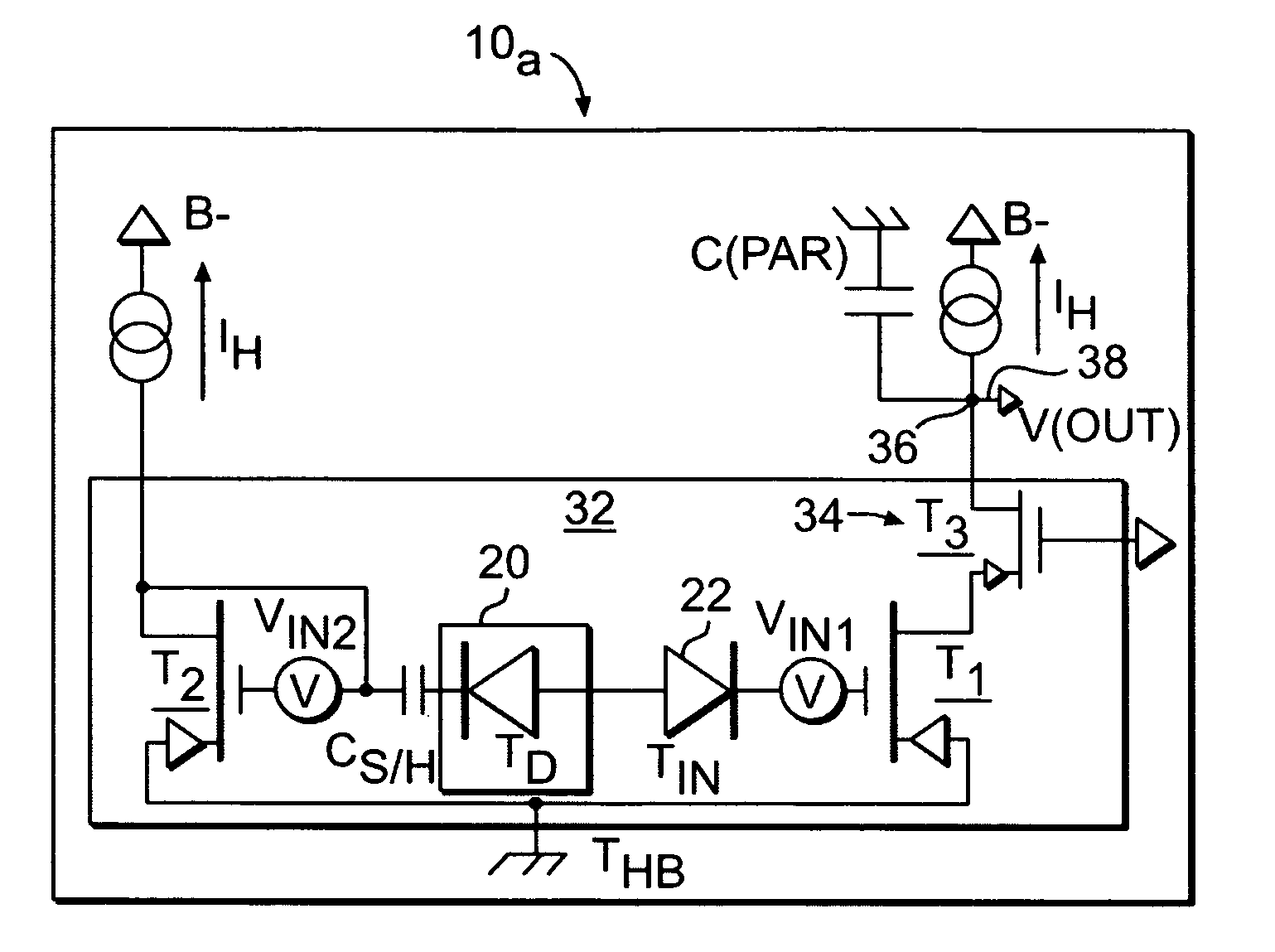

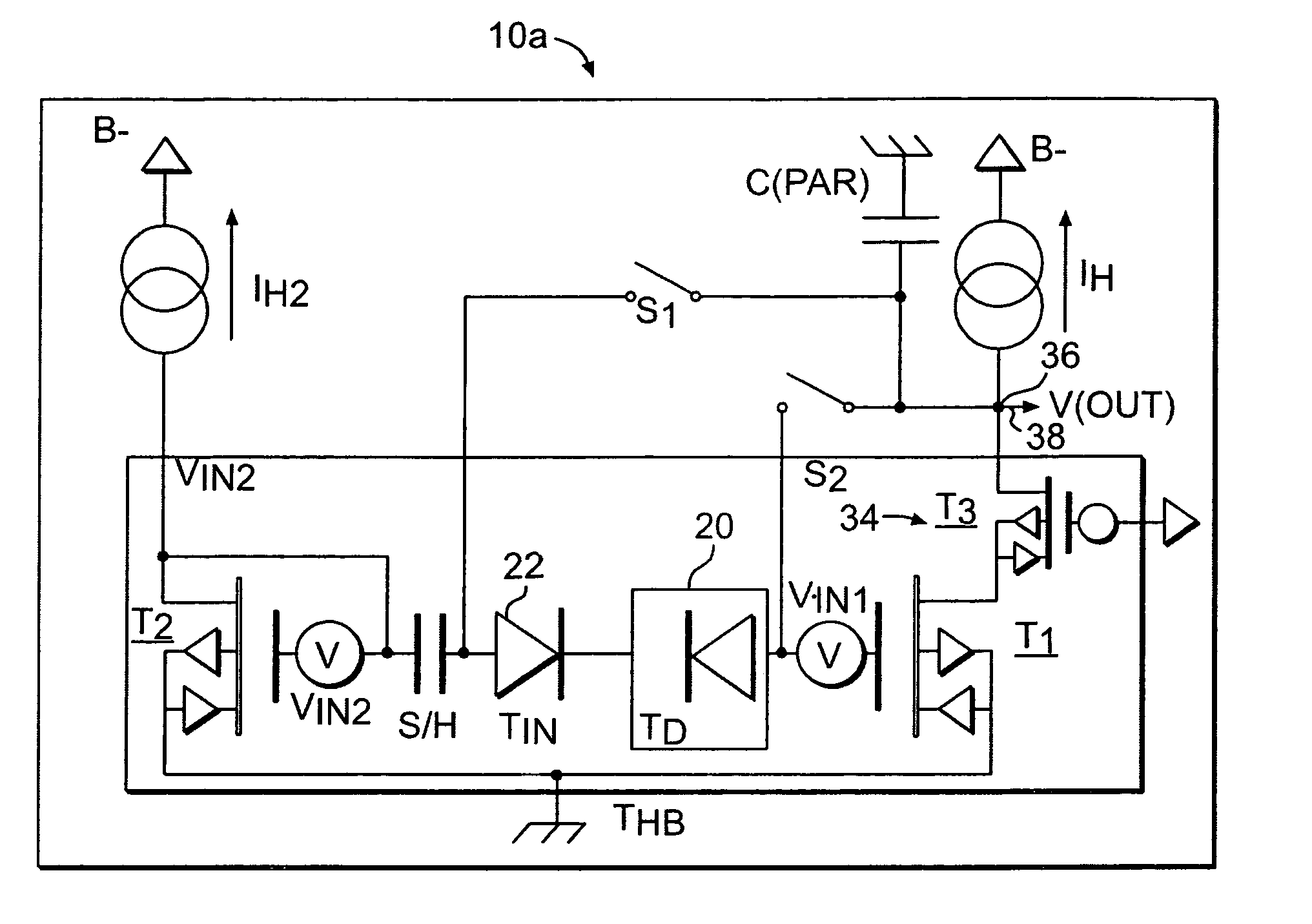

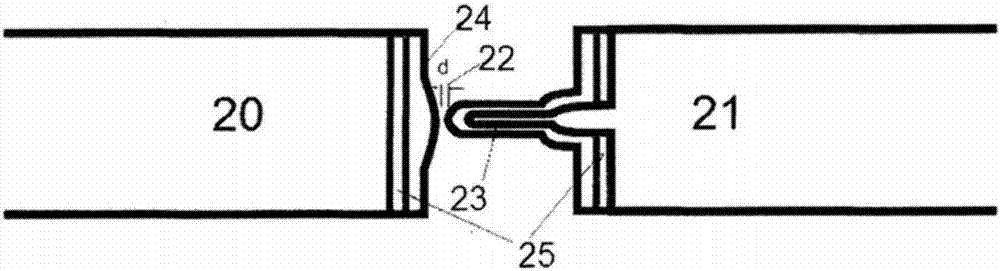

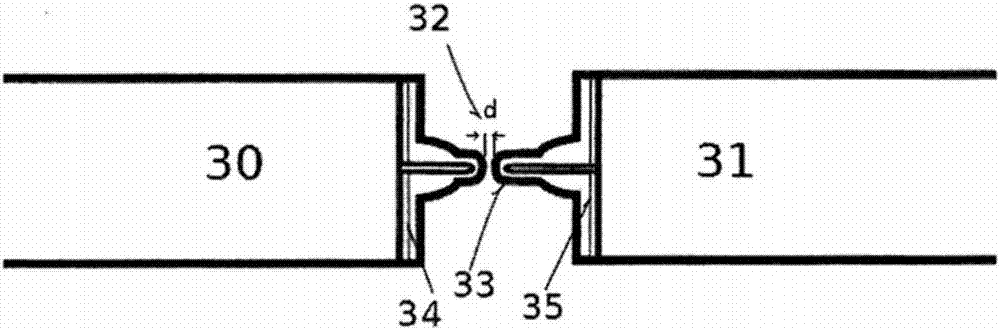

Ultra sensitive silicon sensor readout circuitry

InactiveUS20060081780A1High temperature sensitivityHigh voltage gainMaterial analysis by optical meansPyrometry using electric radation detectorsUltra sensitiveHigh voltage

A readout circuit for a bolometer type sensor including a pair of back-to-back temperature sensing diodes connected in an electro-thermal feedback loop including a semiconductor amplifier circuit located in an intermediate stage between a detector stage and a heat bath stage and wherein the heat generated by the amplifier equalizes the temperature between the intermediate stage and the detector stage. The readout circuitry also includes circuitry for removing local threshold voltage variations and low frequency 1 / f noise components in the readout signal while providing high temperature sensitivity and relatively high voltage gain.

Owner:NORTHROP GRUMAN CORP

Thermoelectric energy storage system having two thermal baths and method for storing thermoelectric energy

ActiveUS8584463B2Minimize the differenceMaximizing temperature differenceThermoelectric device with peltier/seeback effectHeat storage plantsProcess engineeringMechanical engineering

An exemplary system and method for storing and retrieving energy in a thermoelectric energy storage system is disclosed. The thermoelectric energy storage system includes a working fluid that is circulated through a first and second heat exchanger, and a thermal storage medium that is circulated through the first heat exchanger. The second heat exchanger is in connection with a first thermal bath during a charging cycle and with a second thermal bath during a discharging cycle. In this way roundtrip efficiency is improved through minimizing the temperature difference between the first thermal bath and the hot storage tank during charging, and maximizing the temperature difference between the second thermal bath and the hot storage tank during discharging.

Owner:ABB (SCHWEIZ) AG

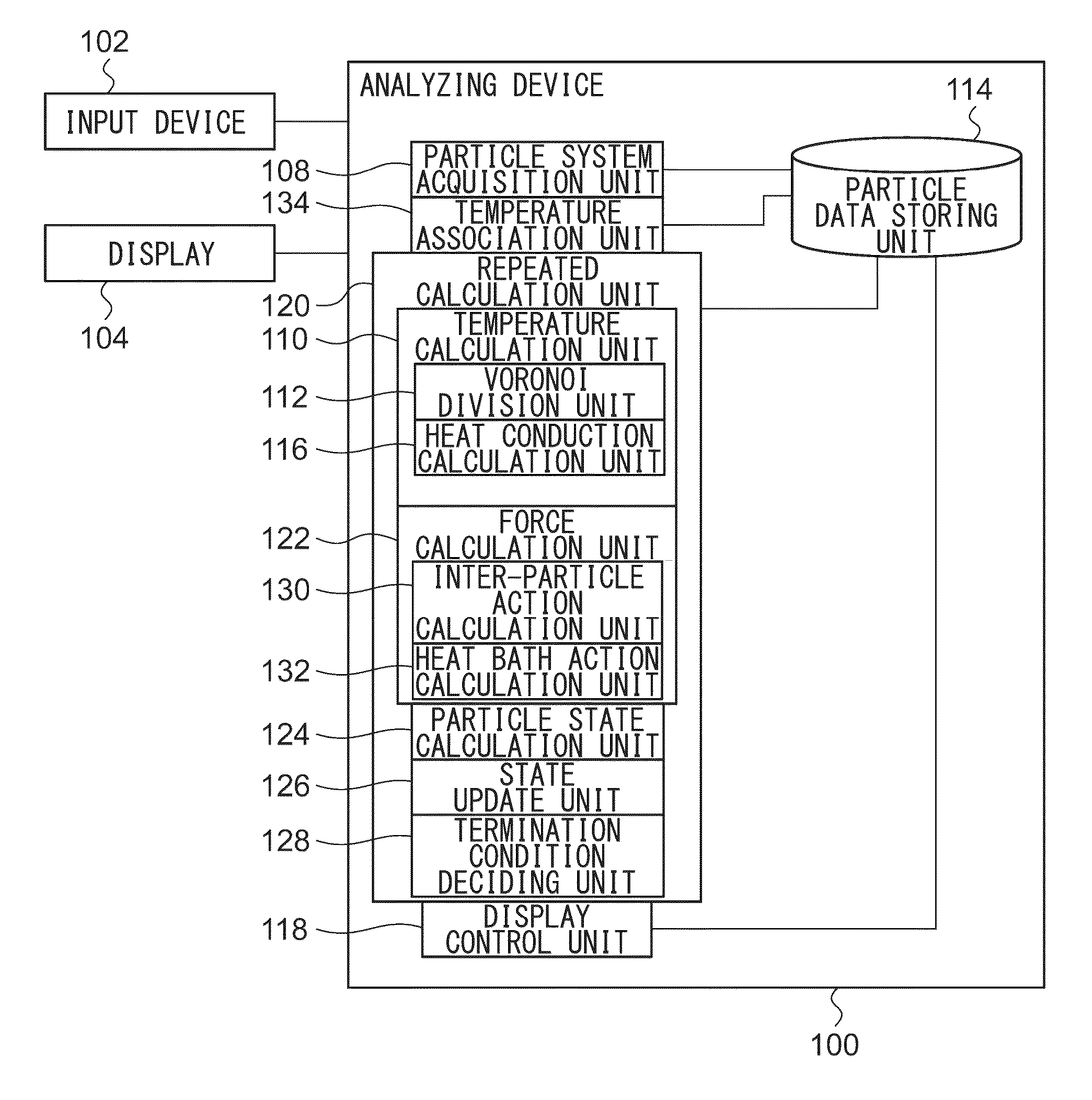

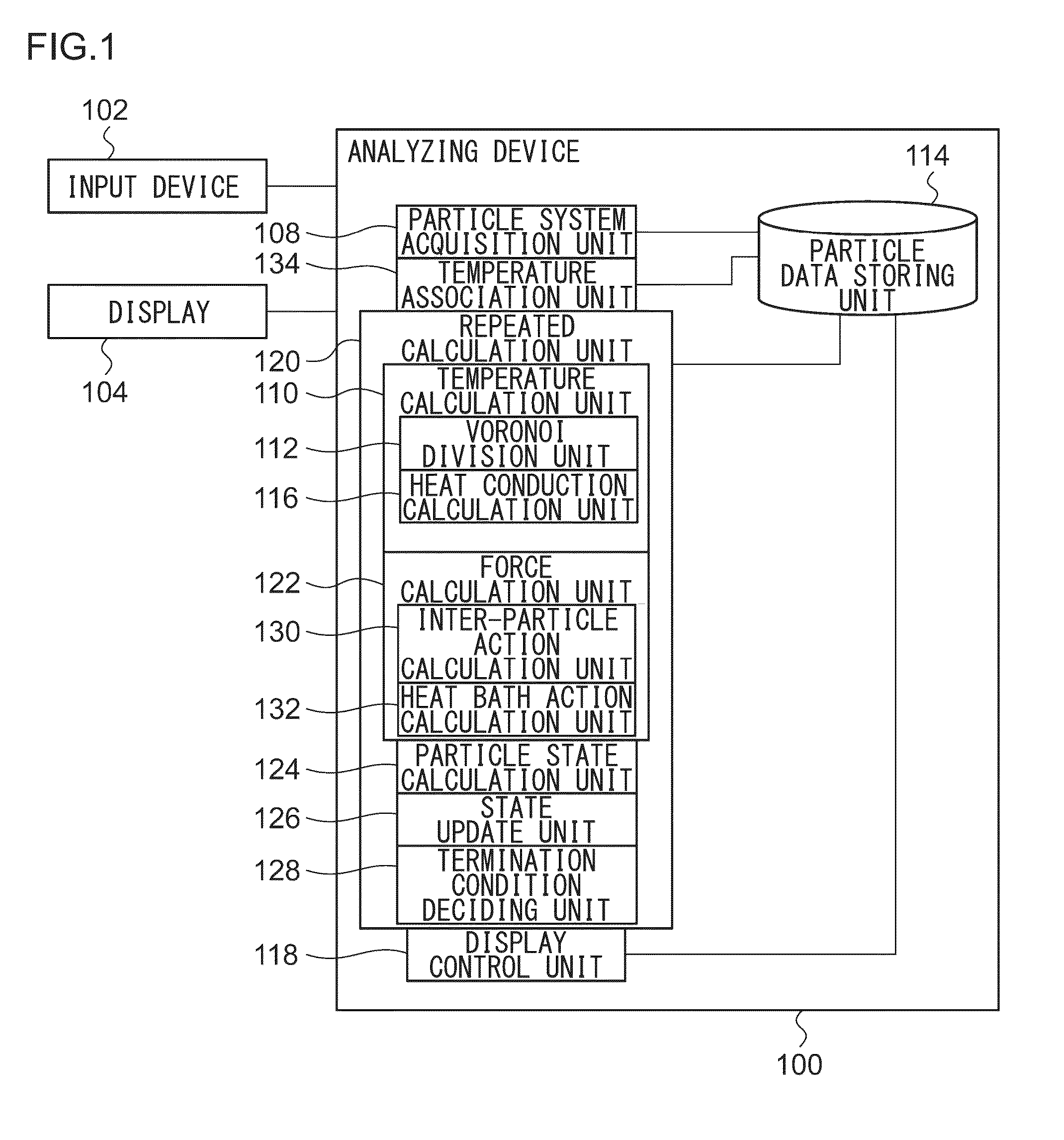

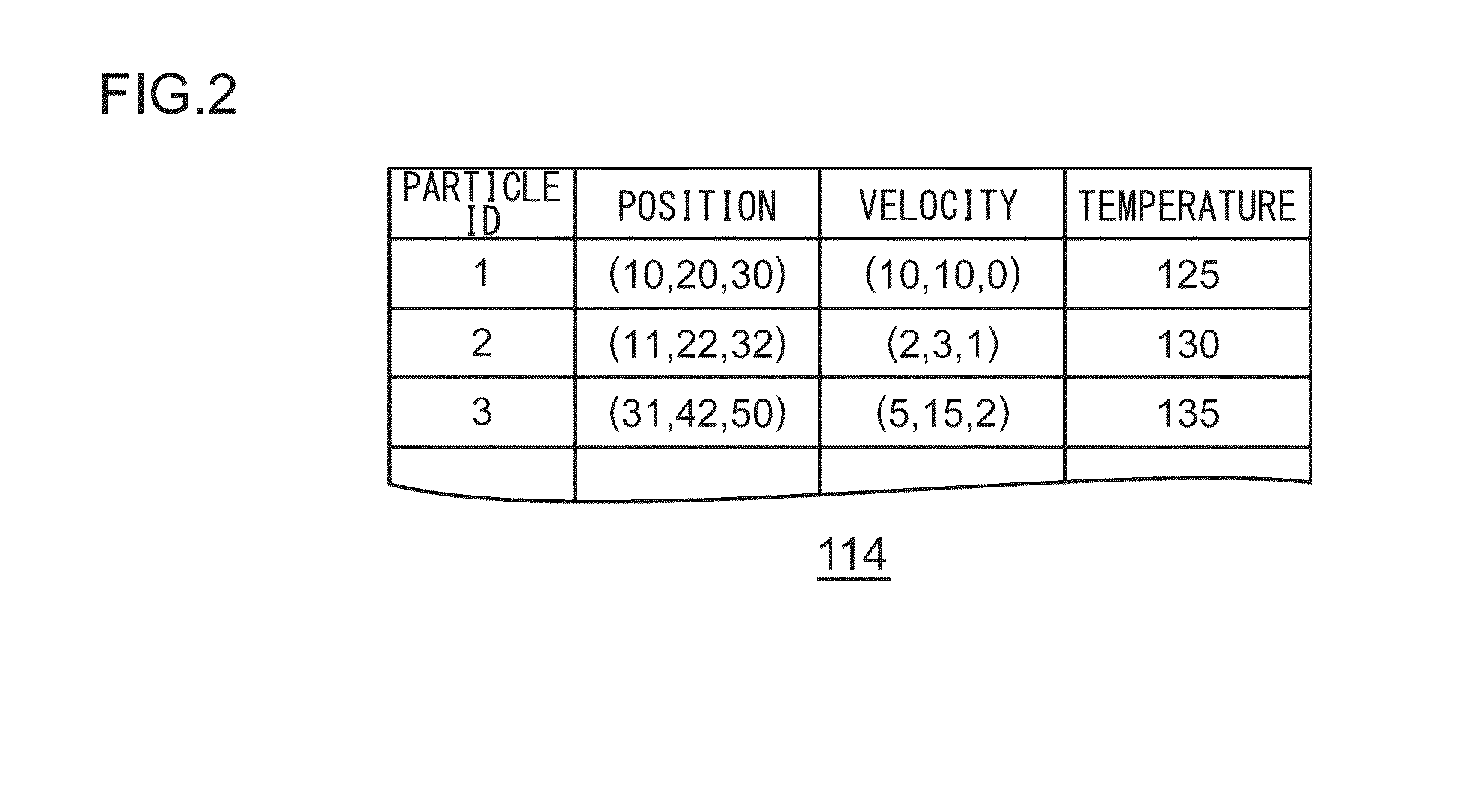

Analyzing device

InactiveUS20150186573A1Example is efficientChemoinformaticsComputation using non-denominational number representationClassical mechanicsHeat bath

An analyzing device analyzes a particle system defined in a virtual system by numerically calculating a governing equation that governs motion of particles in the particle system and includes: a temperature calculation unit that calculates a temperature of a particle, which is one of parameters of particles in the particle system; a force calculation unit that calculates a force exerted on the particle assumed to be immersed in a heat bath of the temperature calculated by the temperature calculation unit; and a state update unit that updates a state of the particle based on the force calculated by the force calculation unit.

Owner:SUMITOMO HEAVY IND LTD

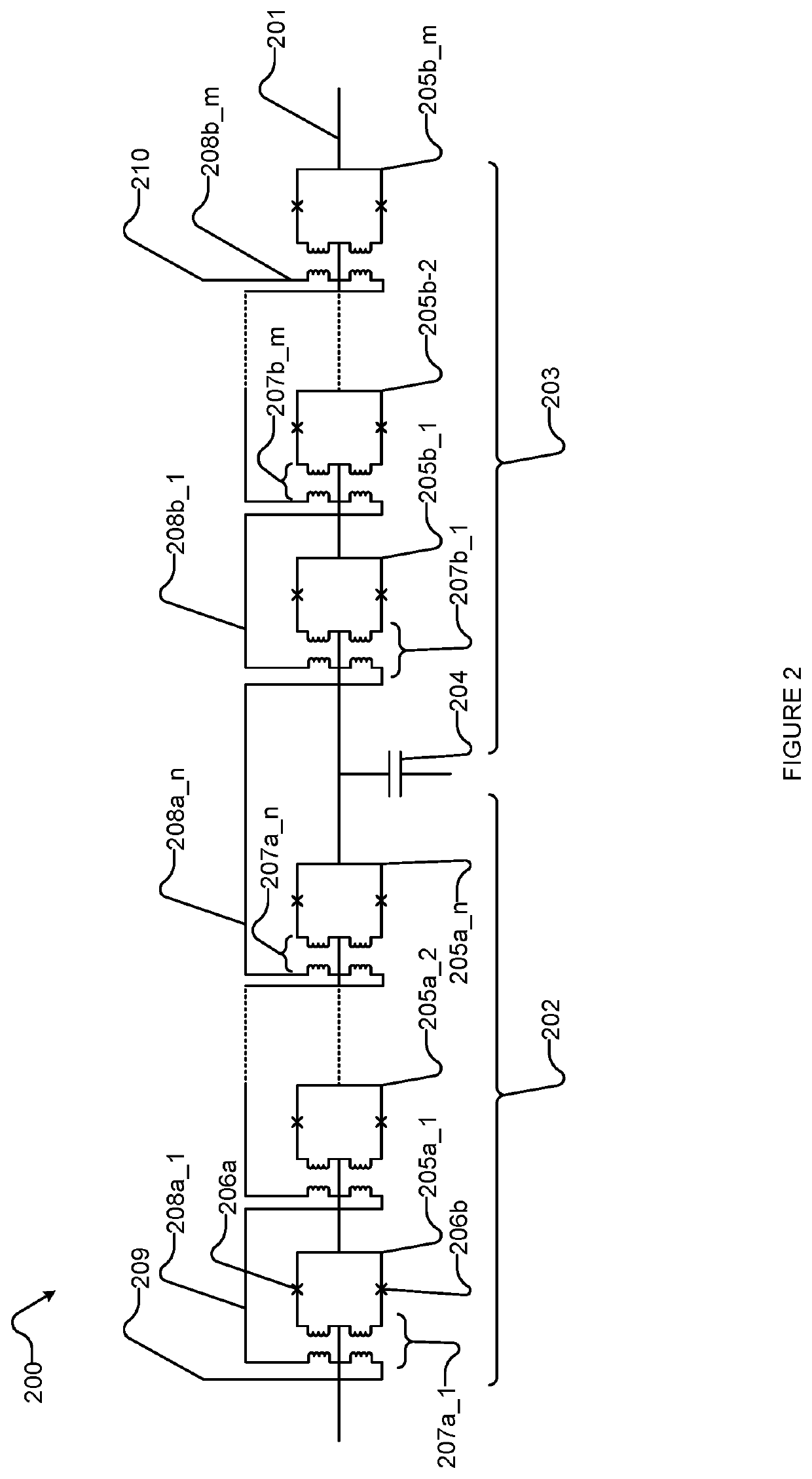

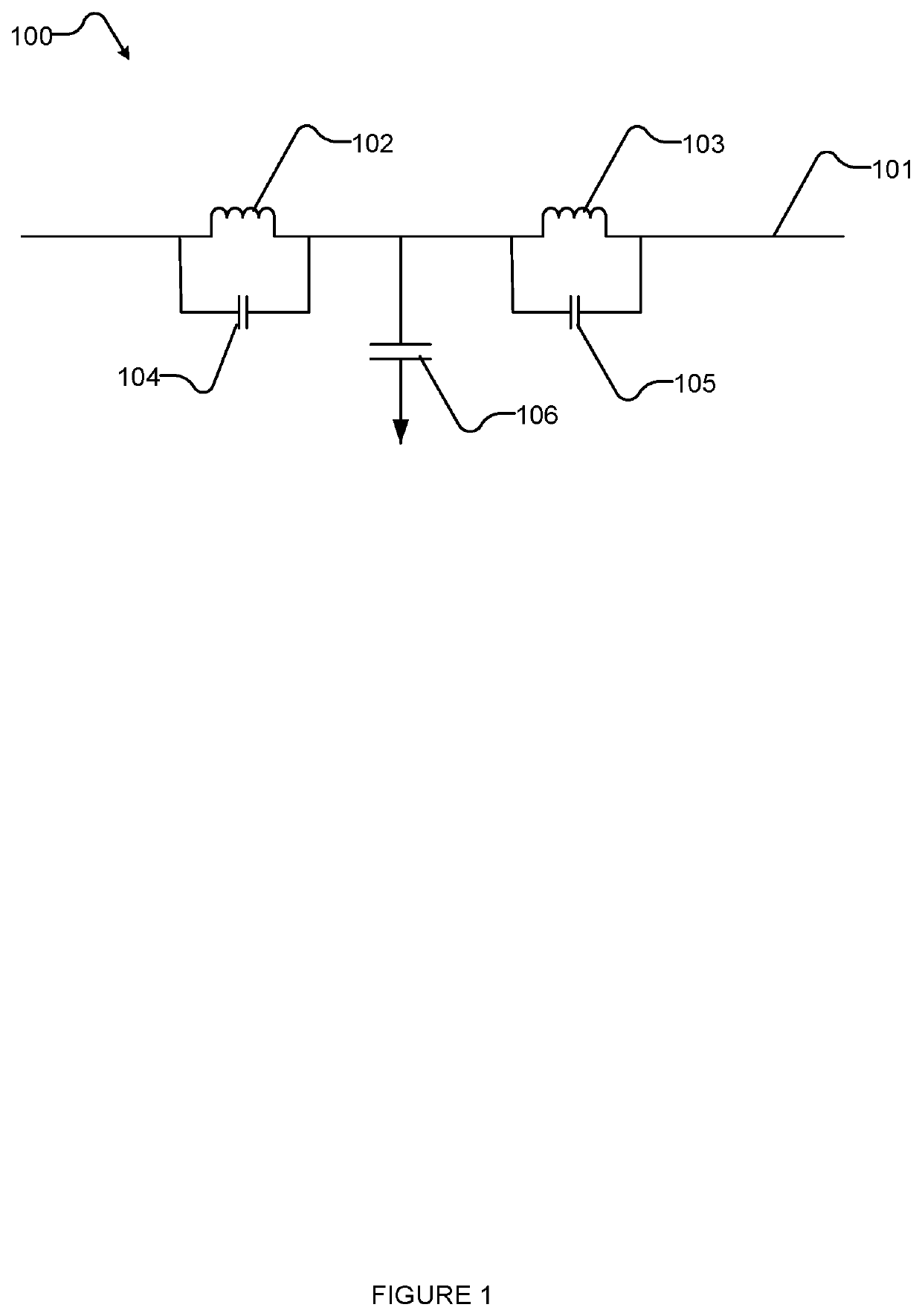

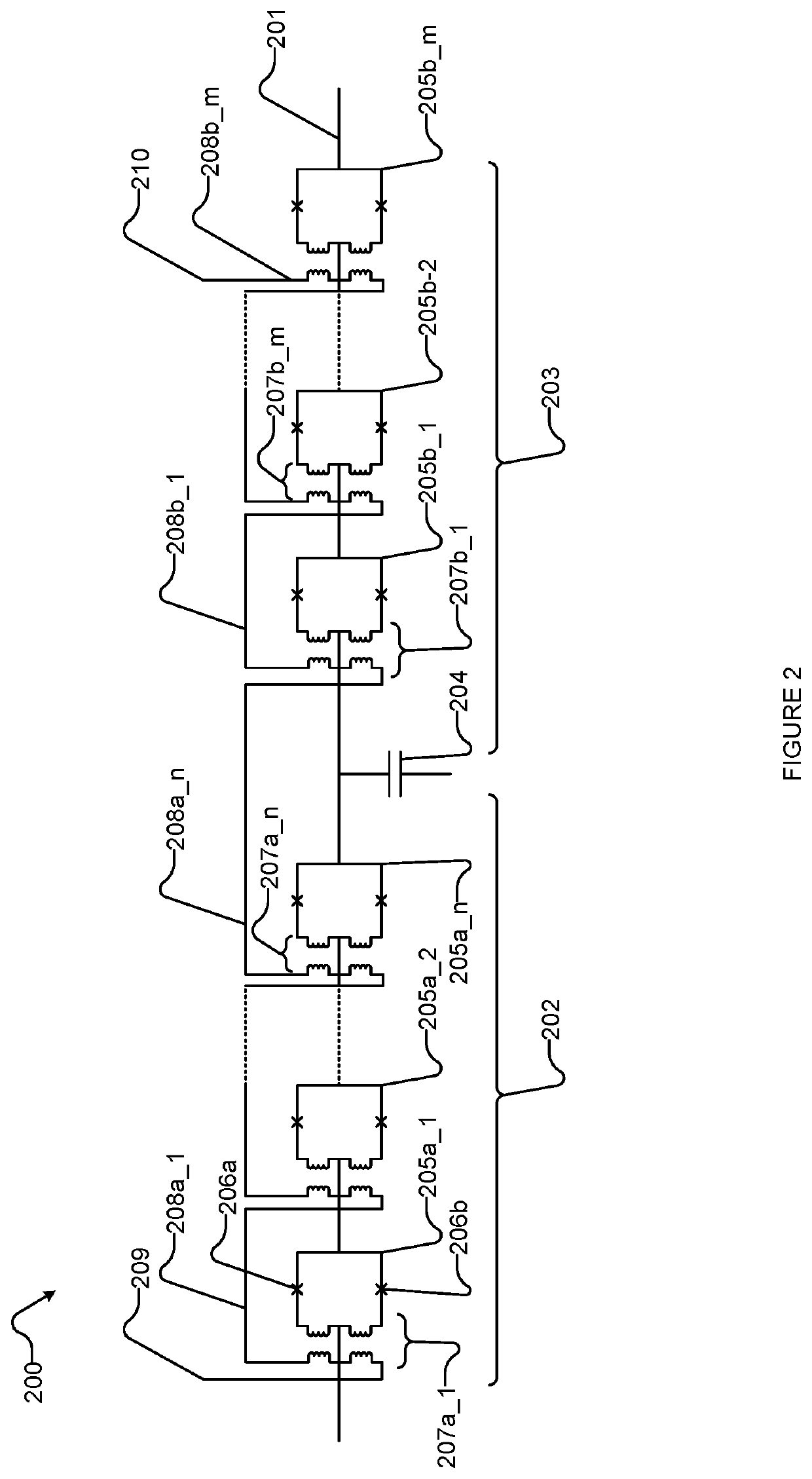

Dynamical isolation of a cryogenic processor

ActiveUS20190369171A1Quantum computersMagnetic field measurement using superconductive devicesComputational physicsBroadband

A device is dynamically isolated via a broadband switch that includes a plurality of cascade elements in series, wherein each cascade element comprises a first set of SQUIDs in series, a matching capacitor, and a second set of SQUIDs in series. The broadband switch is set to a passing state via flux bias lines during programming and readout of the device and set to a suppression state during device's calculation to reduce operation errors at the device. A device is electrically isolated from high-frequencies via an unbiased broadband switch. A device is coupled to a tunable thermal bath that includes a broadband switch.

Owner:D WAVE SYSTEMS INC

Annular PTC heater

PendingCN107726611AAchieve heatAccelerate the change from cold to warmElectric heating systemAir heatersThermodynamicsEngineering

Owner:AUPU HOME STYLE CORP LTD

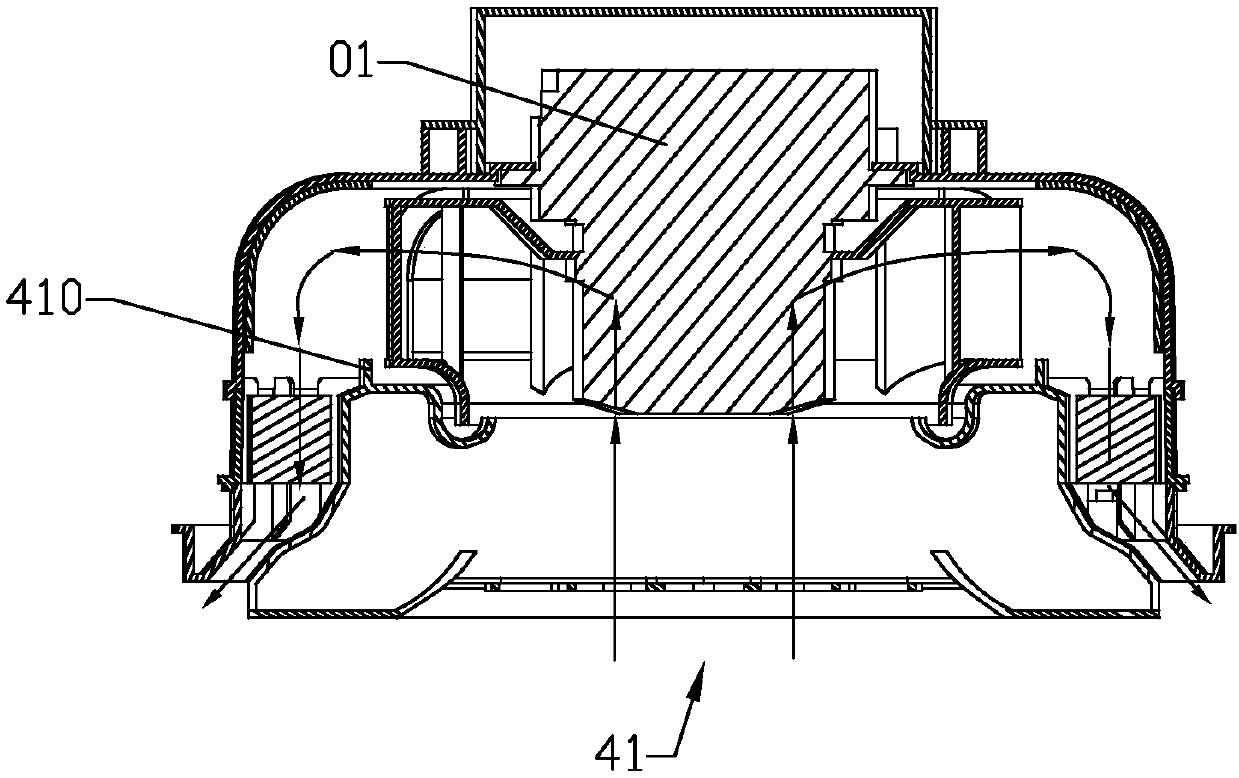

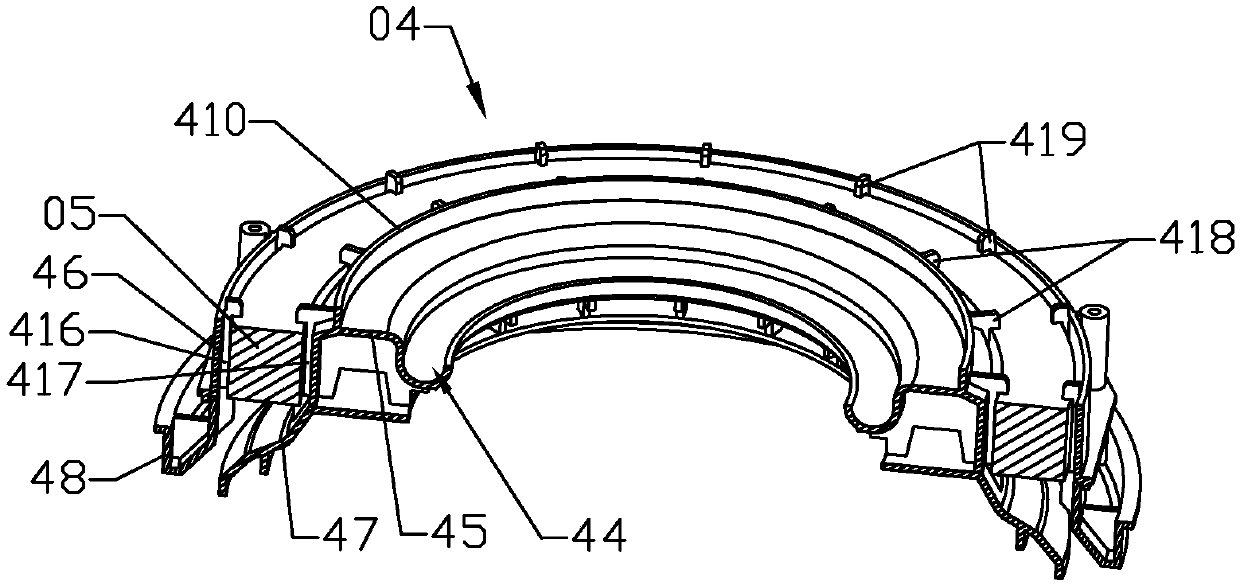

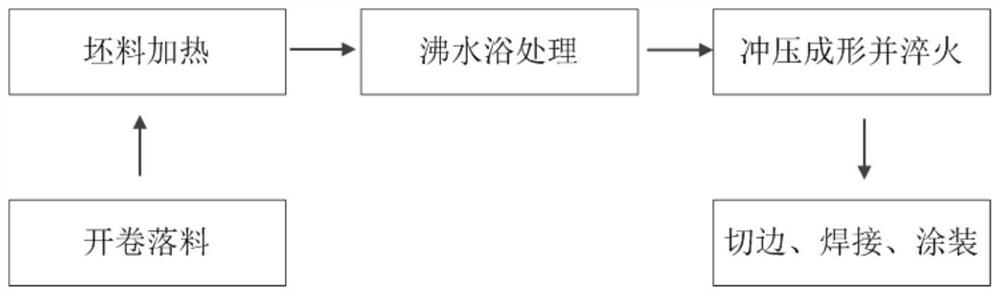

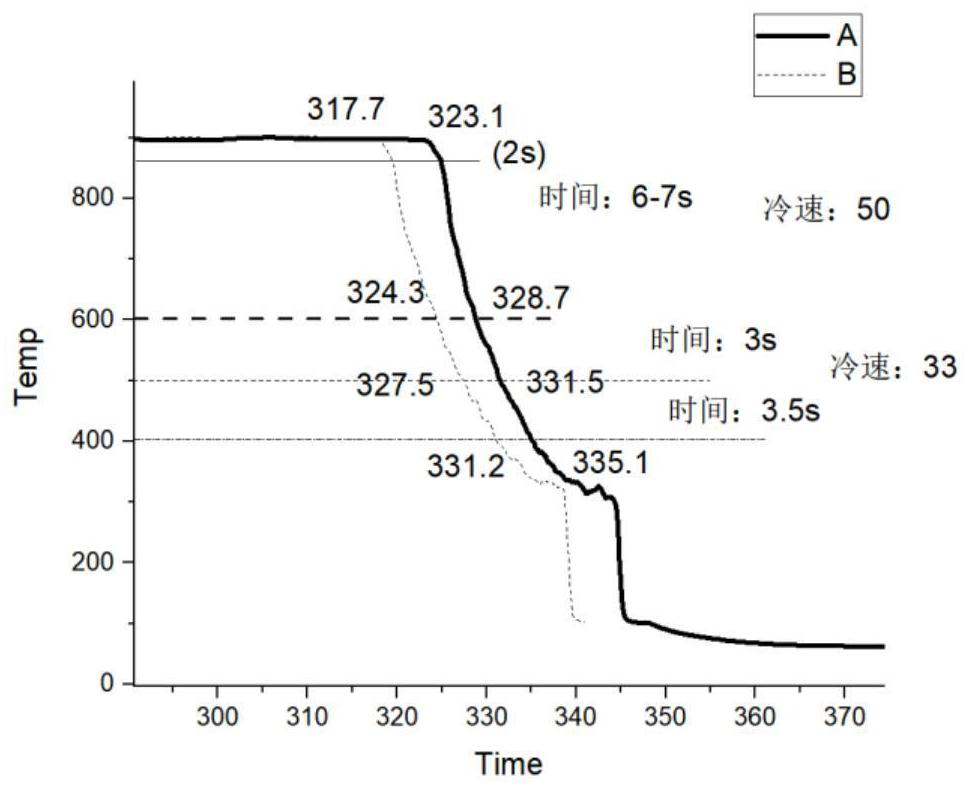

Hot bath forming process of high-corrosion-resistance and easy-to-weld hot-pressing part

ActiveCN113751410AEasy to implementClear unevenSolid state diffusion coatingCleaning using liquidsHot stampingThin slab

The invention provides a hot bath forming process of a high-corrosion-resistance and easy-to-weld hot-pressing part, and relates to the field of thin plate hot stamping and sheet metal part manufacturing. The process comprises the following steps of S1, heating a plated hot-formed steel plate in a heating furnace until the plated hot-formed steel plate is in a complete austenitizing state; S2, transferring the heated plated hot-formed steel plate into a boiling water tank, immersing the plated hot-formed steel plate in boiling water, and cleaning an oxide layer; S3, forming the coating hot forming steel plate under the combined action of boiling water, an upper mold and a lower mold, carrying out pressure maintaining and quenching, obtaining a part; and S4, taking out the part to perform air blowing or drying treatment in a drying furnace, and moisture in a plating layer of the part is removed. According to the process, the plate is immersed in the boiling water, a surface oxide layer is uniformly and controllably removed by virtue of bubbles generated between the boiling water and a hot plate, the forming temperature of the plate is uniformly and accurately controlled, and meanwhile, forming and quenching are performed in the boiling water, so that the production quality of parts can be improved, the service life of a mold is prolonged, and the production cost is saved.

Owner:SD STEEL RIZHAO CO LTD

Self-heating bath foam and preparation method thereof

PendingCN112245338AImprove liquidityTo promote metabolismCosmetic preparationsToilet preparationsIRRITATION SKINActive agent

The invention provides a self-heating bath foam and a preparation method thereof. The self-heating bath foam comprises a thermal sensitizer, soothing essential oil, a skin conditioner, a humectant, anampholytic surfactant and an anionic surfactant. The preparation method comprises the following steps of mixing the ampholytic surfactant, the anionic surfactant and deionized water according to theformula ratio, adding the humectant and the skin conditioner, regulating the pH value, adding the thermal sensitizer and the soothing essential oil, and dispersing to obtain the self-heating bath foam. According to the preparation method, by adding the thermal sensitizer into raw materials, the prepared bath foam has a self-heating effect, can promote blood circulation and accelerate metabolism, and can generate a better relieving and relaxing effect in combination with the relieving effect of the essential oil; and through reasonable proportioning of the raw materials, the prepared self-heating bath foam is reasonable in heat production, does not irritate the skin, is mild, is simple and efficient in preparation process, is energy-saving and environment-friendly, and has a wide application value.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

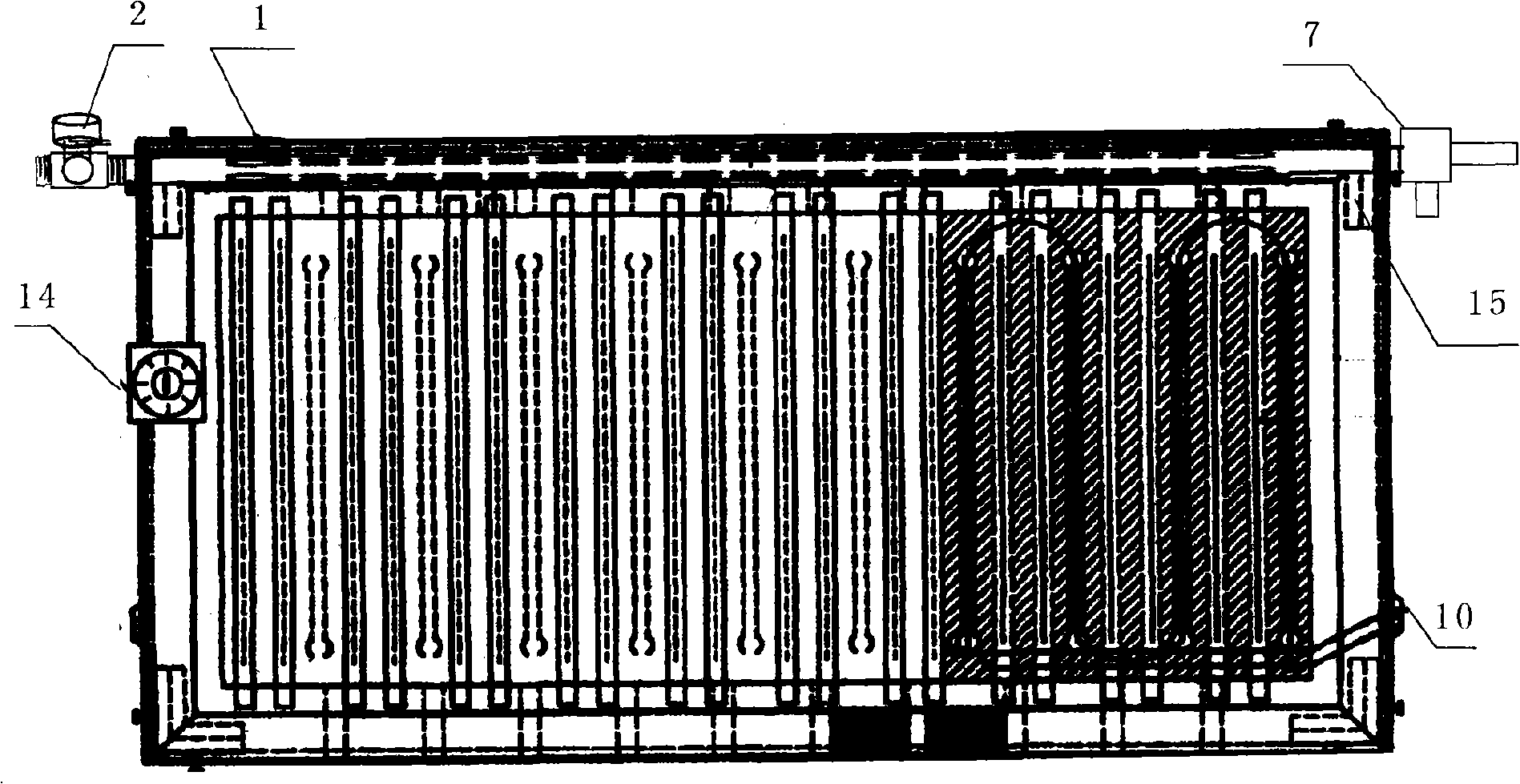

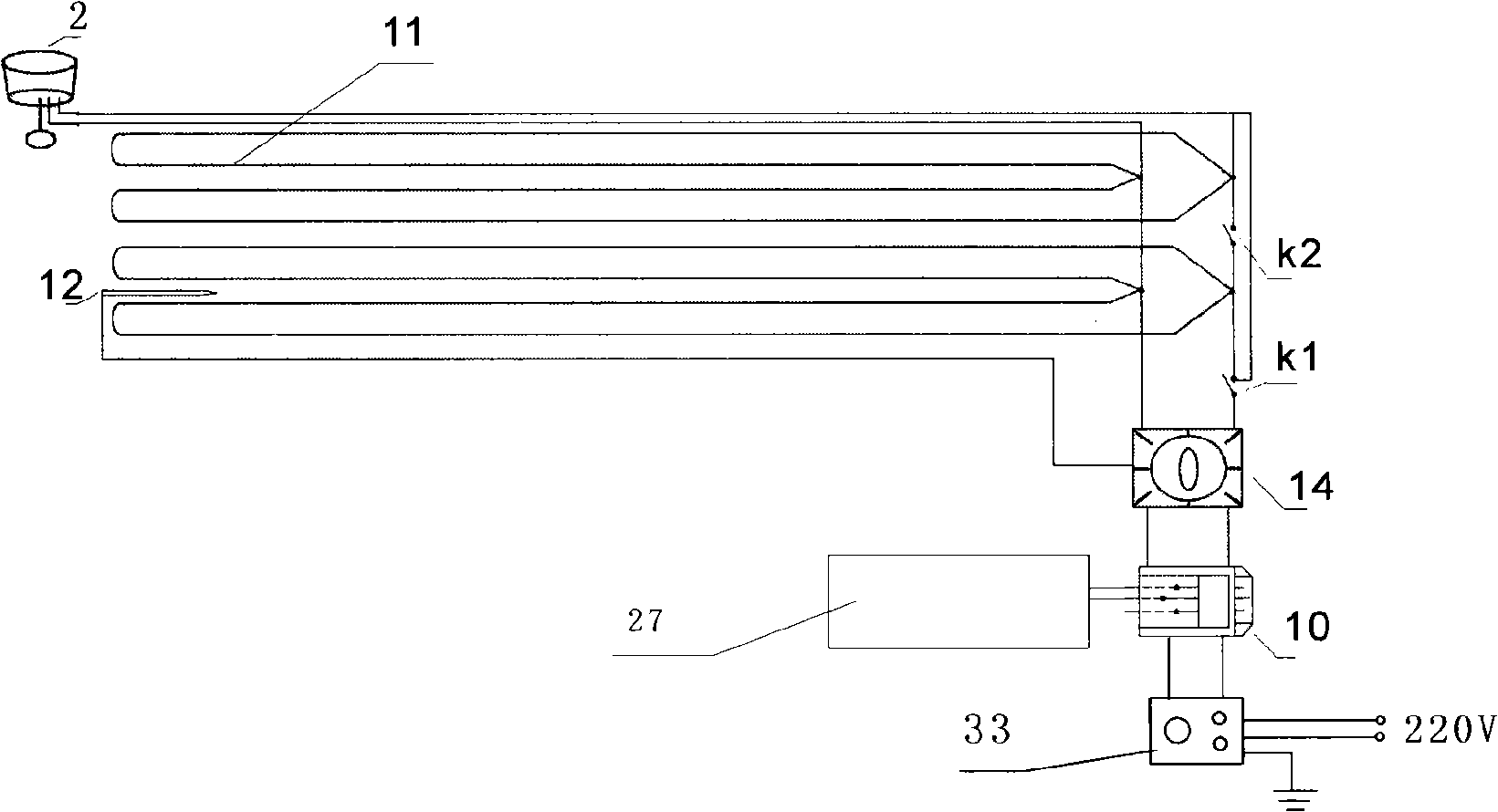

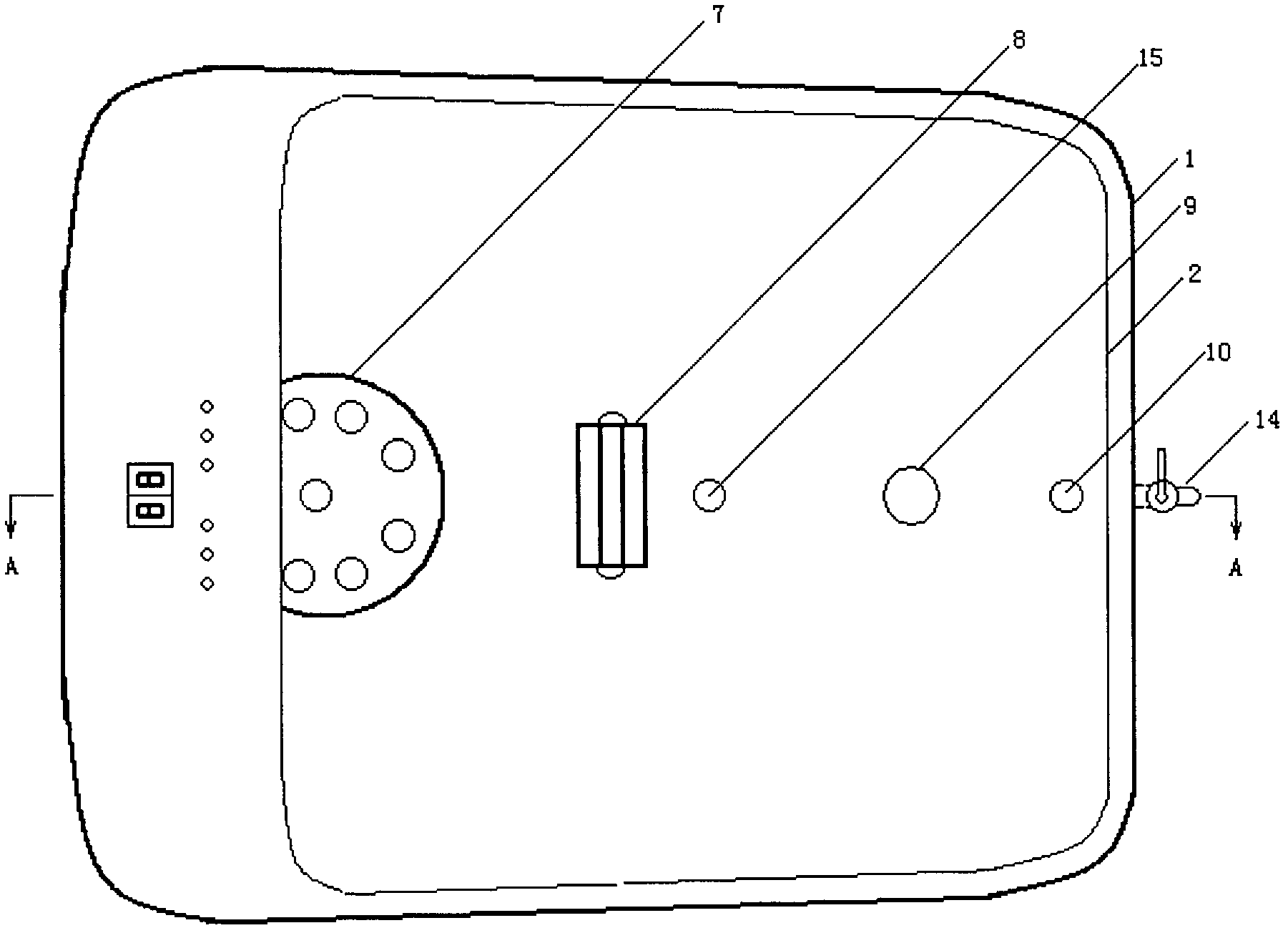

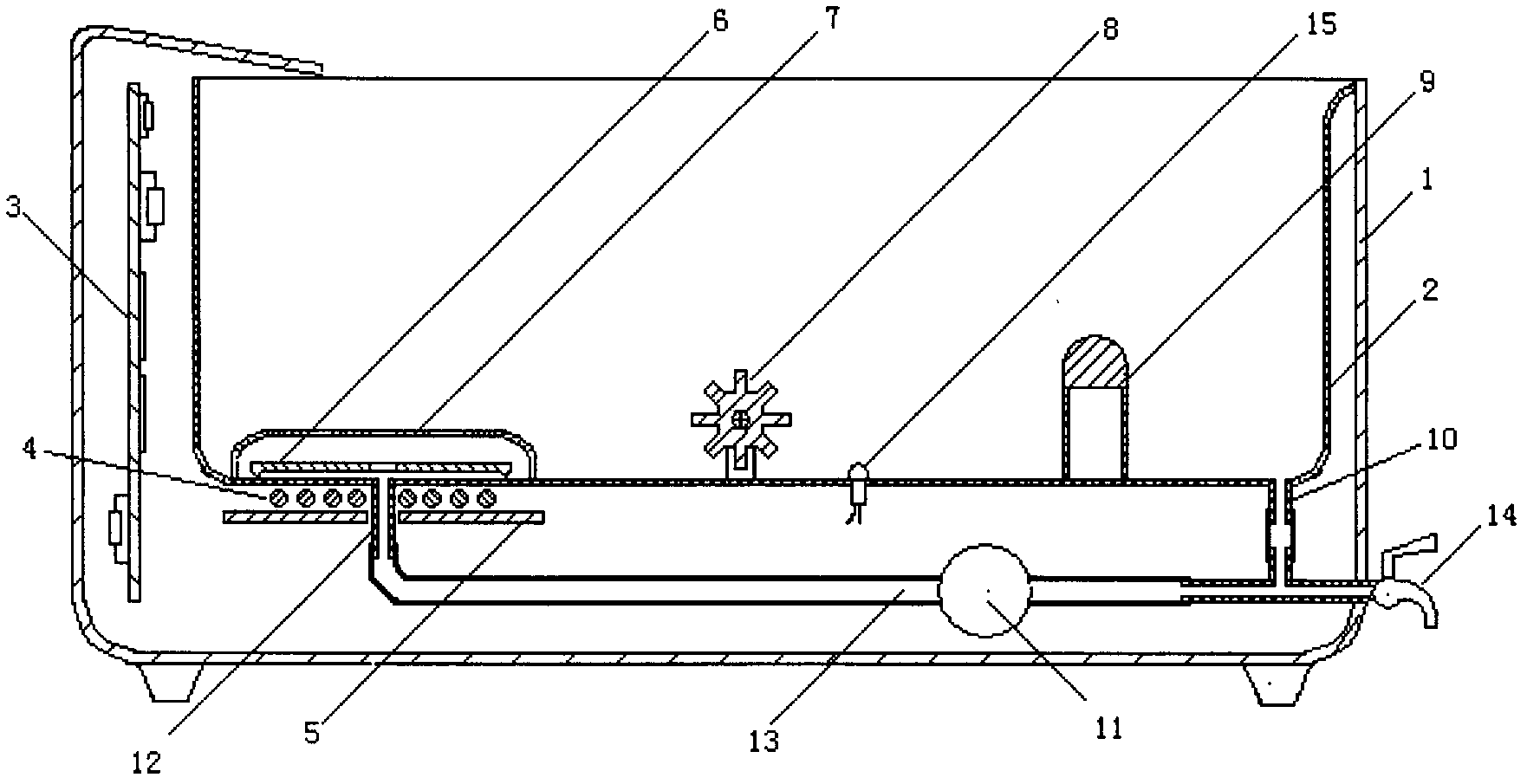

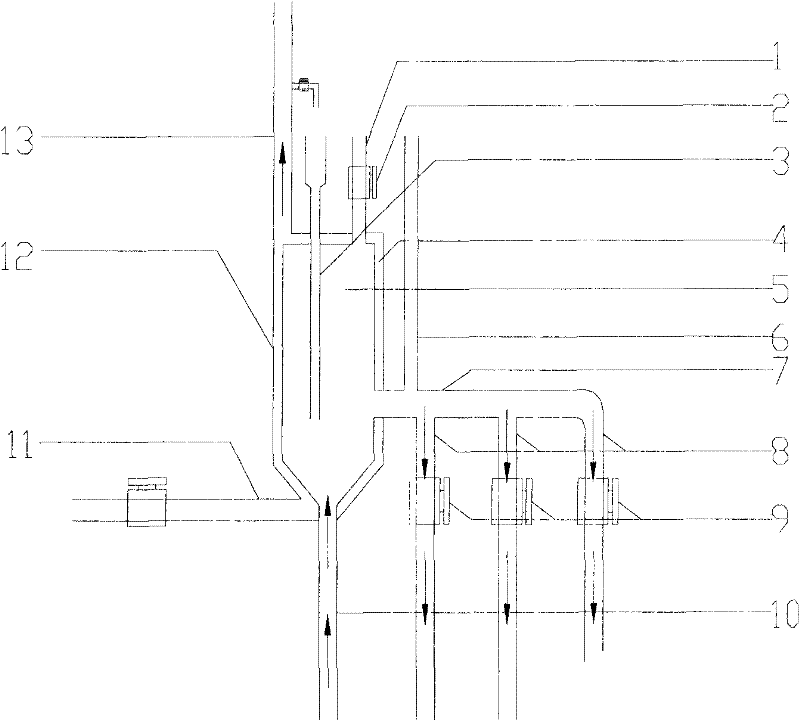

Heating method and device of multifunctional carbon fiber electrically heated bath water heater

InactiveCN101315208AEasy to useReduce manufacturing costLoose filtering material filtersDomestic hot-water supply systemFiberCarbon fibers

The invention discloses heating method and device for a multifunctional carbon fiber electric water heater. The heat in the cavity of the electric water heater is used for heating a cavity wing-type water heater which is arranged inside the upper transverse frame of a frame. The device comprises a double-frame electric heater and a cavity wing-type water heater. The cavity wing-type water heater is arranged inside the cavity of a frame sectional material (1) at the top end of the double-frame electric heater. The inlet end of the cavity wing-type water heater is connected in series with an electronic valve, a carbon ball filter (3) and a three-way piece (4) via a pipeline. One end of the three-way piece is connected with a solar hot water pipe, and the other end of the three-way piece is connected with a tap water pipe. One end of a three-way piece (7) which is arranged at the output end of the cavity wing-type water heater is connected with a shower via a pipeline, and the other end thereof is connected with a hot drinking water pipe (9) via a pipeline. The heating device is particularly suitable for heat supply and hot water supply. Since the heating device has water filtration and electrical leakage-protection functions and ensure the hygiene of drinking water and bath safety. The device has the advantages of low production costs, environmental friendliness, low energy consumption, protection against electrical leakage, comfortable use and low cost.

Owner:胡振永

Ultra sensitive silicon sensor readout circuitry

InactiveUS7157708B2High temperature sensitivityHigh voltage gainMaterial analysis by optical meansPyrometry using electric radation detectorsEngineeringUltra sensitive

A readout circuit for a bolometer type sensor including a pair of back-to-back temperature sensing diodes connected in an electro-thermal feedback loop including a semiconductor amplifier circuit located in an intermediate stage between a detector stage and a heat bath stage and wherein the heat generated by the amplifier equalizes the temperature between the intermediate stage and the detector stage. The readout circuitry also includes circuitry for removing local threshold voltage variations and low frequency 1 / f noise components in the readout signal while providing high temperature sensitivity and relatively high voltage gain.

Owner:NORTHROP GRUMAN CORP

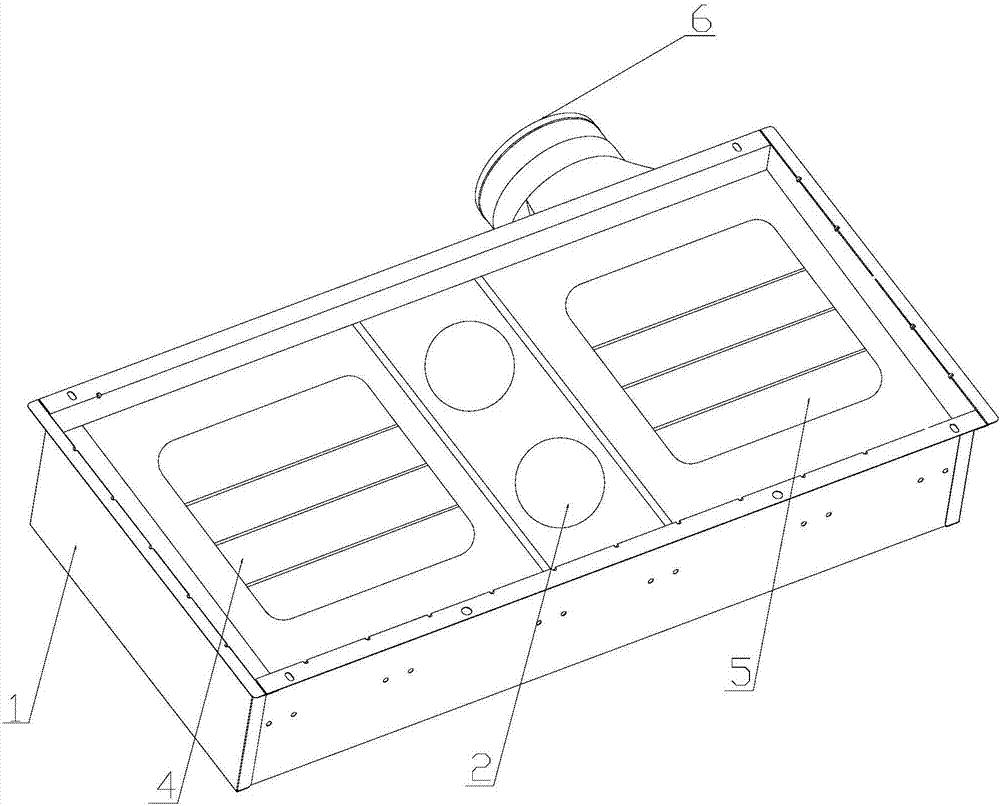

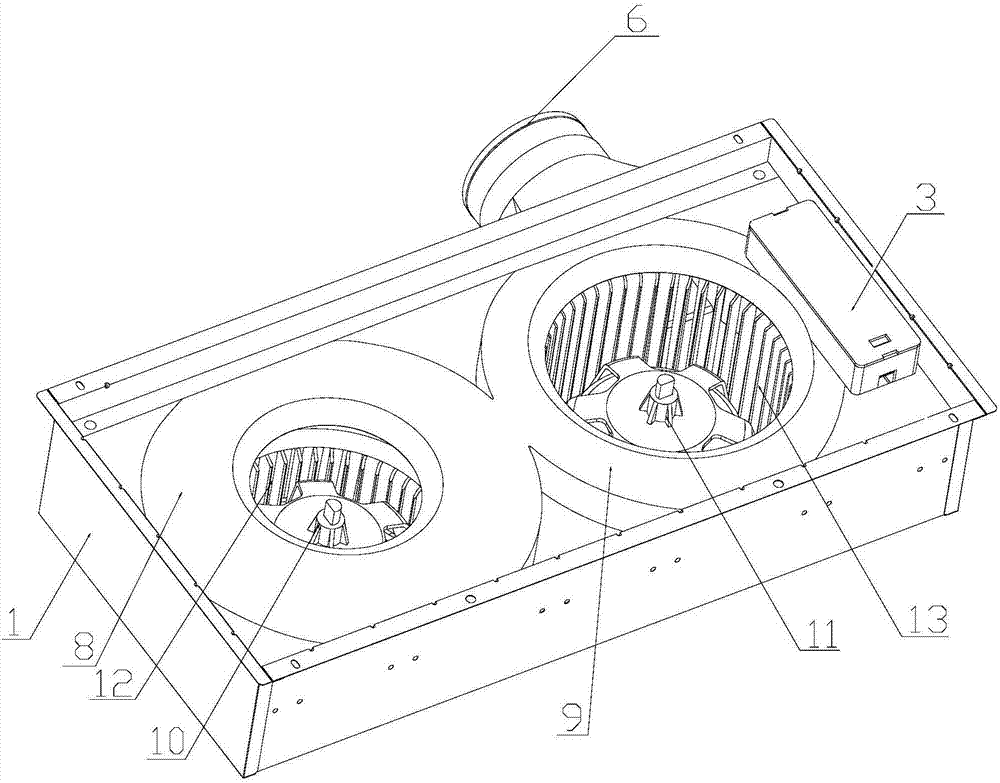

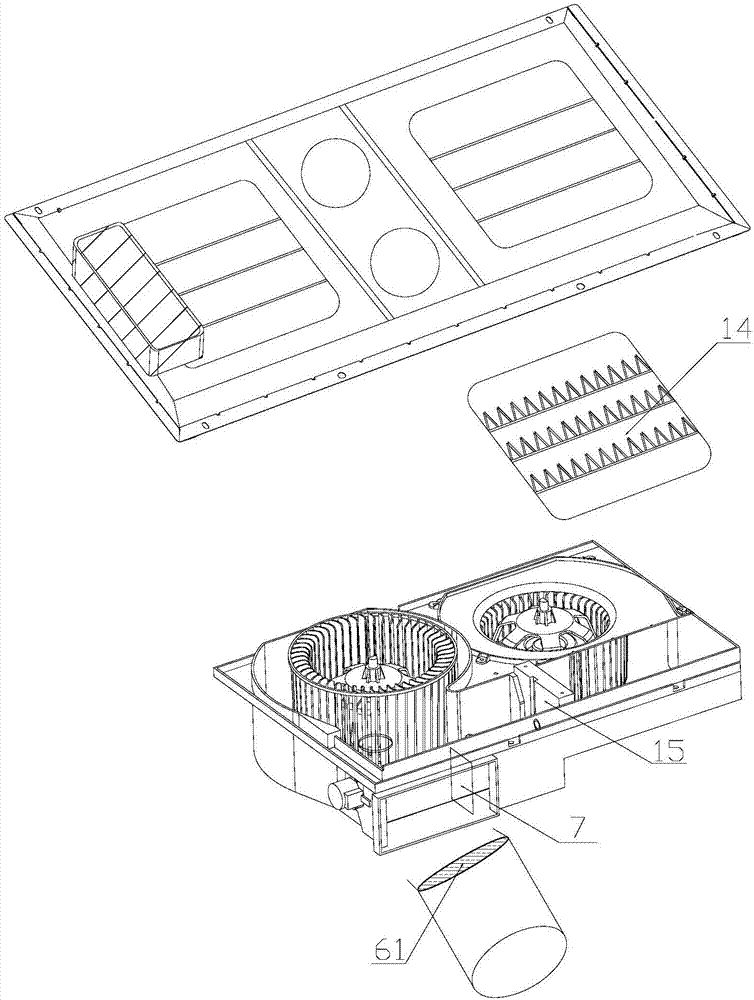

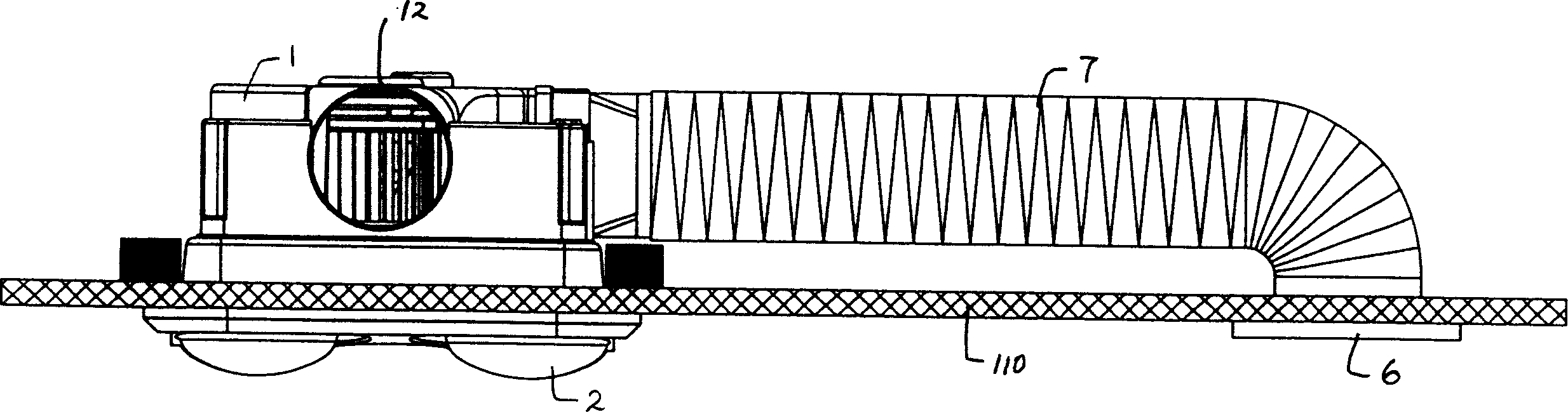

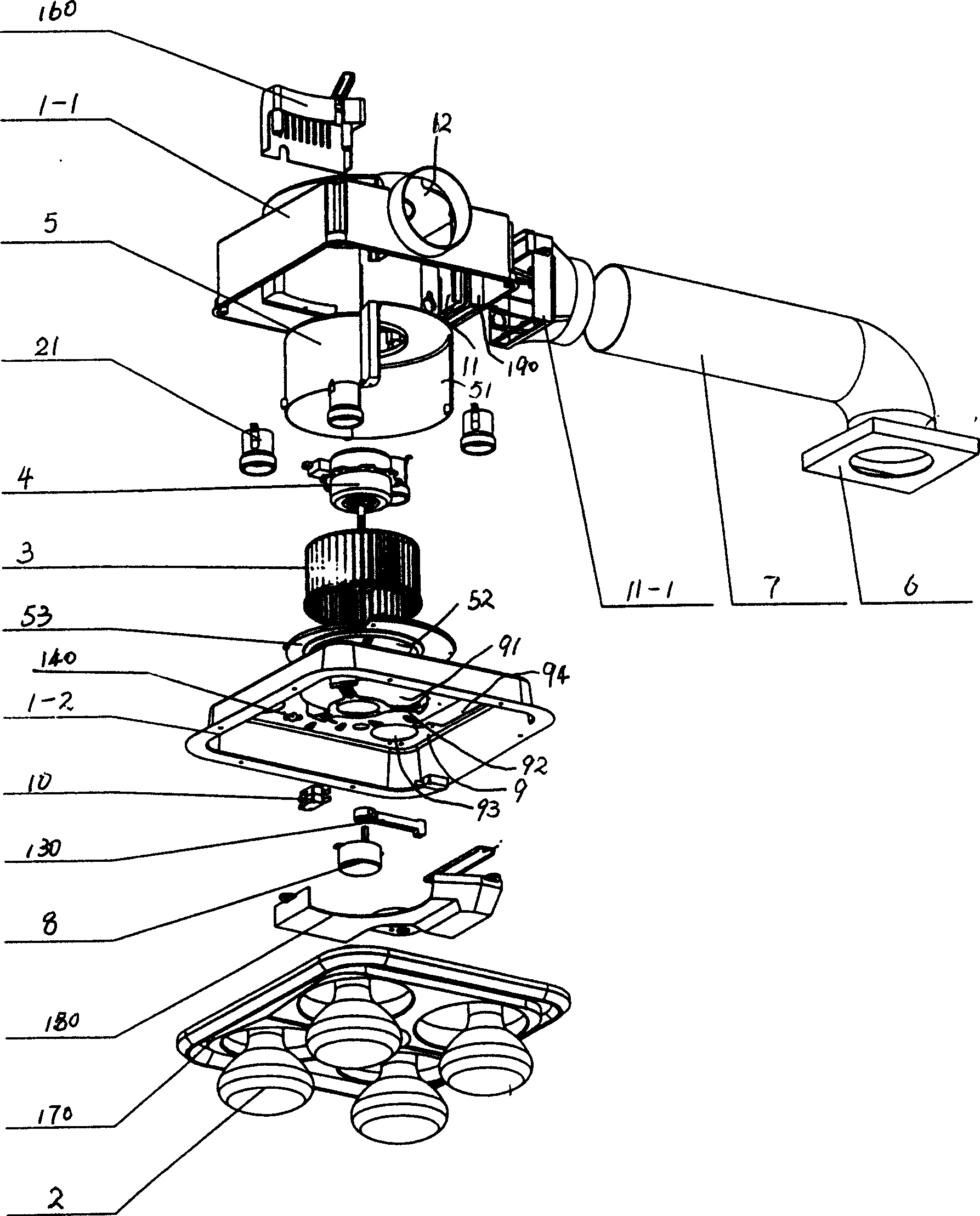

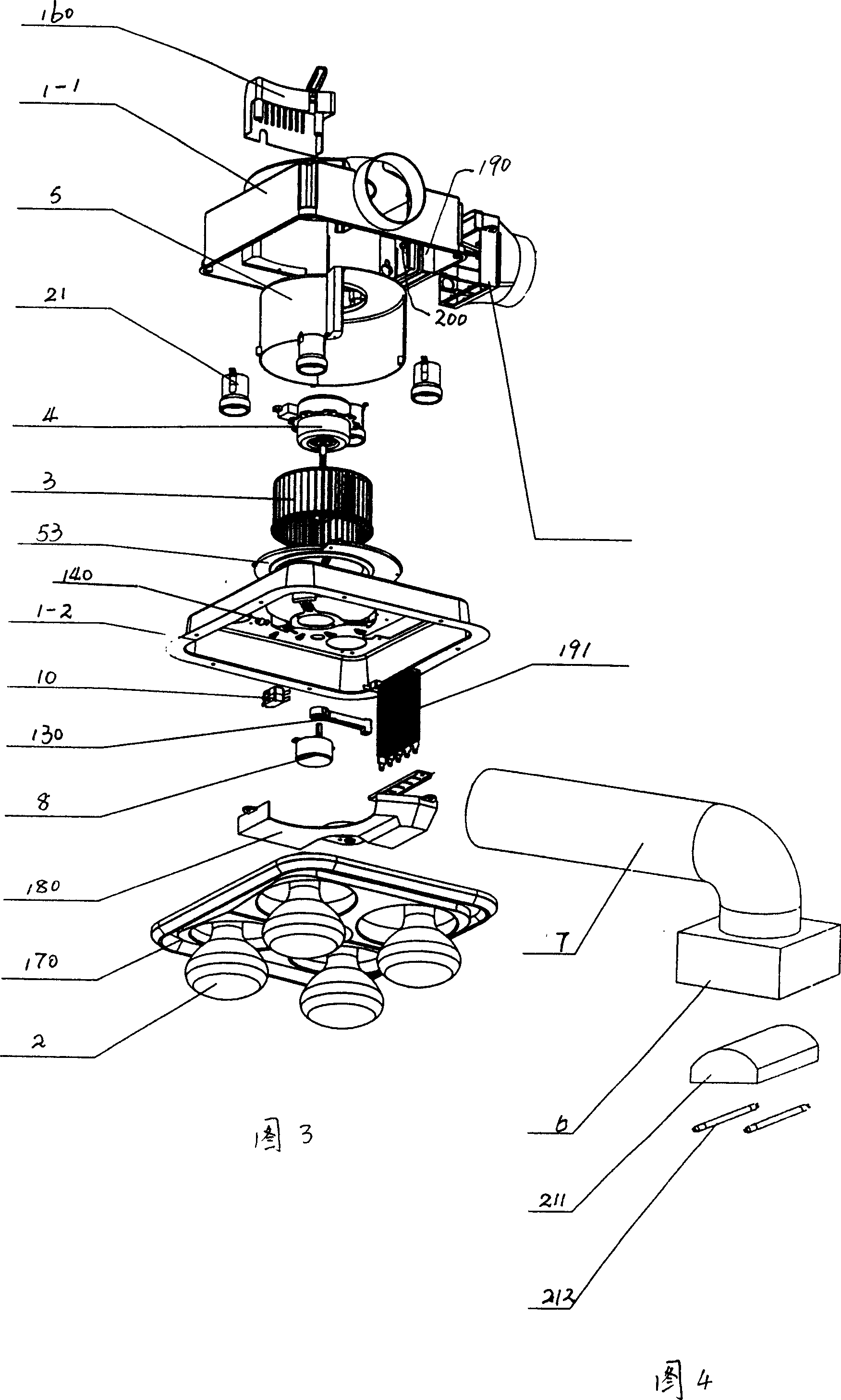

Cooling-heating bath heater

InactiveCN107166493AComfortable bathing environmentProtect healthLighting and heating apparatusElectric heating systemCold airEngineering

The invention discloses a cooling-heating bath heater. The cooling-heating bath heater comprises a tank body, an LED lamp, a control device, a heating air outlet, an indoor air hole, an outdoor air hole, an outdoor air door, a first centrifugal volute casing, a second centrifugal volute casing, a first motor, a second motor, a first wind wheel, a second wind wheel, a heating device and a baffle plate, wherein the first centrifugal volute casing and the second centrifugal volute casing are mounted inside the tank body side by side; the first centrifugal volute casing communicates with the second centrifugal volute casing; a baffle plate capable of being opened and closed is arranged on a communication part of the first centrifugal volute casing and the second centrifugal volute casing; the second motor is a switching motor; the second wind wheel is a two-way centrifugal wind wheel; and an outdoor air door capable of being opened and closed is arranged on a communication part of the outdoor air hole and the tank body. The cooling-heating bath heater can switch an air inlet mode and an air outlet mode of the bath heater, increases a cold air blowing function, can provide a comfortable batching environment for the human body in winter and summer, and also keeps cleanliness of air of a bathroom.

Owner:董玉明

Energy-saving safety shower device

An energy saving safety bath device, which contains casing, infrared heating bulb, centrifugal blowing wheel and driving motor, volute casing, air outlet, air inlet head. Said invention secondary utilizes the heat generated by infrared bulb to heat bath room and educe the temperature in casing and to prolong the service life of said bath device with energy saving and safety.

Owner:顾建军

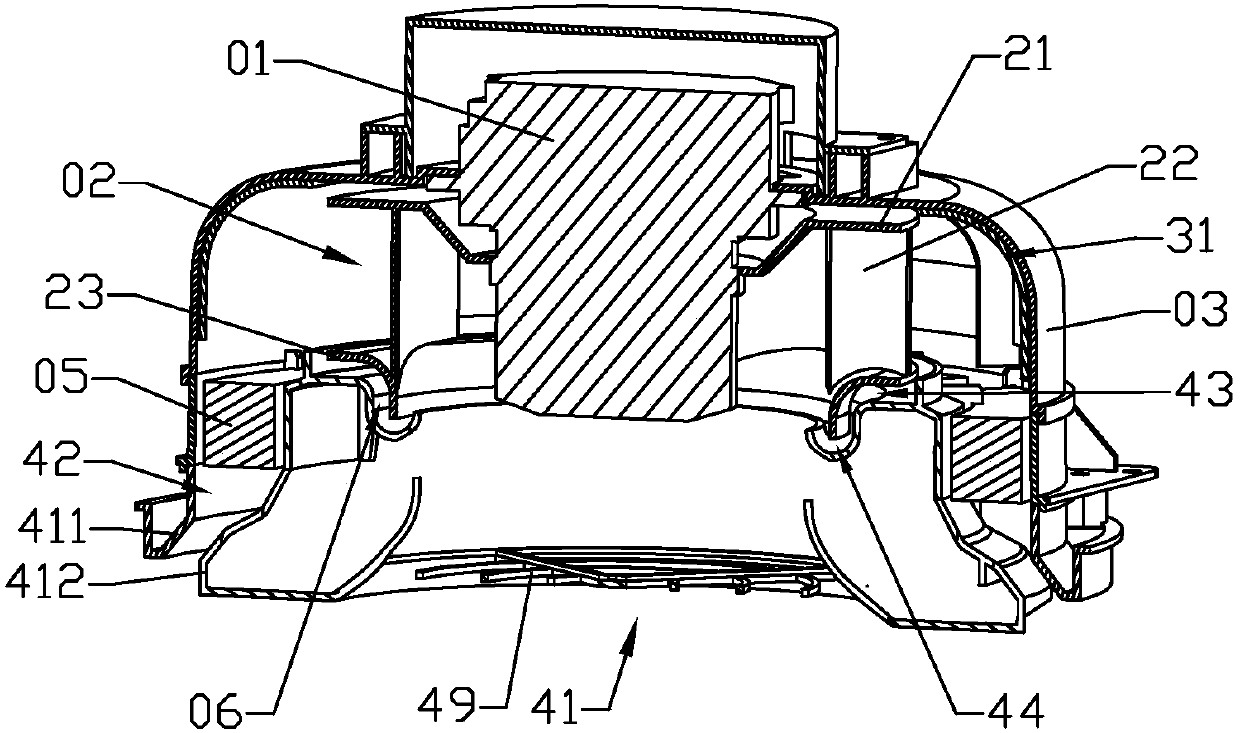

Safe electromagnetically-heated footbath

The invention discloses a safe electromagnetically-heated footbath, which comprises a base, a footbath body, a master control circuit board, a coil, a water circulating system, a heating plate, an anti-scalding screen, a massage wheel and a foot rubbing stone. The coil is spirally coiled on a plane to be fixedly mounted below the bottom of the footbath body and electrically connected with a control circuit, the heating plate is fixedly mounted on the inner bottom of the footbath body and corresponds to the coil, and the heating plate and the coil are concentric. The safe electromagnetically-heated footbath is characterized in that the coil generates an alternating magnetic field to enable the heating plate at the inner bottom of the footbath body to generate an eddy for heating so as to heat bath liquid. The safe electromagnetically-heated footbath has the advantages that the footbath bottom is thin, and a gap between the heating plate and the coil is small, so that electrothermal conversion efficiency is high and electric energy is saved; maintenance is convenient and the service life of the footbath is long; and since the coil is integrally sealed and insulated from the heating plate by the nonmetal footbath body between the coil and the hating plate, electricity and heating are completed isolated, safety is greatly improved, and personal safety of a user taking foot bath is guaranteed.

Owner:HUAINAN UNITED UNIVERSITY

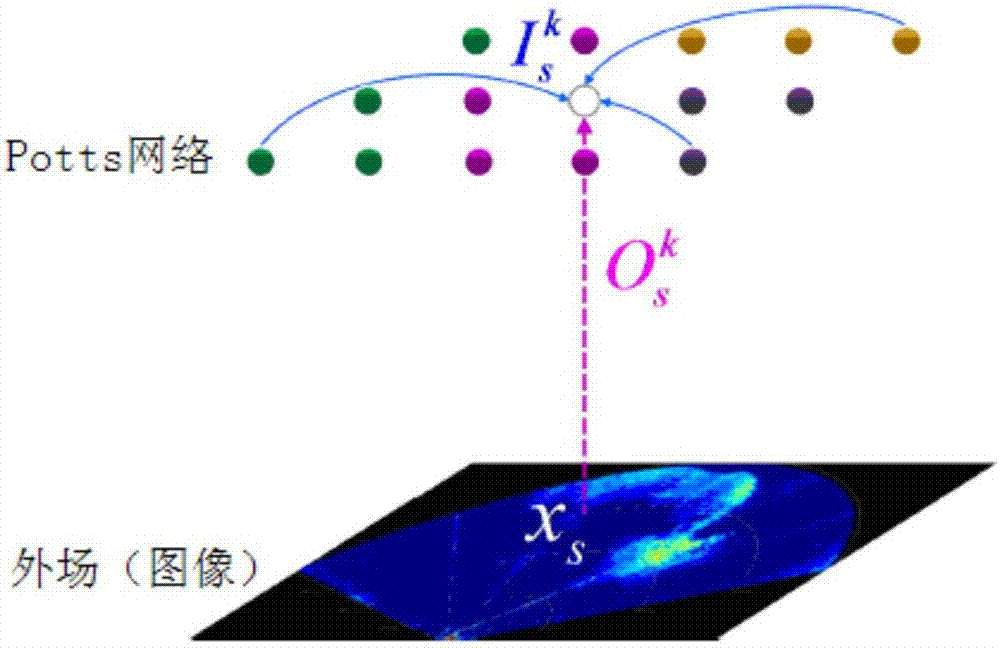

Modal MRF (Markov Random Field) based underwater forward-looking sonar image segmentation method

InactiveCN107545573ACognitive MechanismFast convergenceImage enhancementImage analysisUnderwaterImage segmentation

The invention relates to a modal MRF (Markov Random Field) based underwater forward-looking sonar image segmentation method. The core of the invention is that modeling and segmentation are performed on an image by using a modal Potts network. The method specifically comprises the steps of initializing a Potts state; estimating class conditional parameters by using an EM algorithm; updating each Potts unit according to heating bath power, wherein an internal field of the Potts unit meets Markov dependency, and an external field of the Potts unit is a logarithm of the class conditional probability of pixels; updating interaction parameters between the Potts units and interaction parameters between the Potts units and the external field; and judging whether to exit or not according to the convergence degree of the parameters. According to the invention, image segmentation is performed by adopting the heating bath power based Potts network, thereby conforming to a cognitive mechanism of the brain. The method can almost perfectly preserve edge information of a target while removing plaque noise.

Owner:KOREA INST OF ROBOT & CONVERGENCE

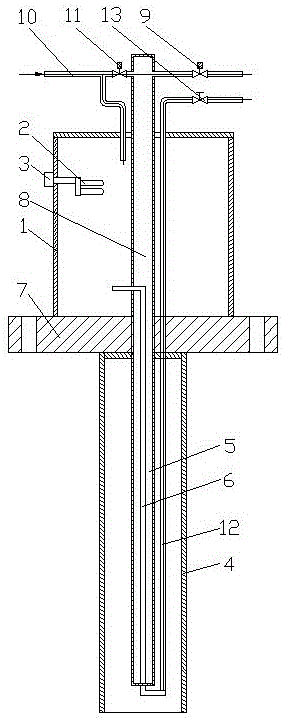

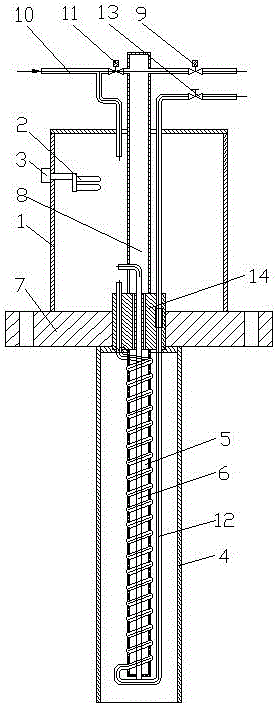

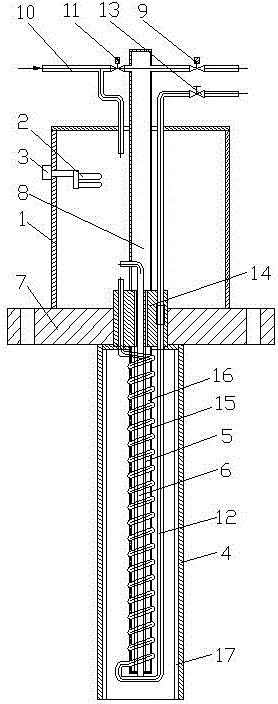

Full-automatic sampling device

The invention discloses a full-automatic sampling device, and belongs to the technical field of gas analysis. The full-automatic sampling device comprises a filter, and is characterized by further comprising a heat bath thermostat, wherein the heat bath thermostat comprises a stainless steel cylinder, an electric heater and a temperature control setter; the filter comprise a stainless steel tube and a stainless steel woven filter element; a heating tube is arranged inside the stainless steel woven filter element; the stainless steel tube and the stainless steel cylinder are connected through a flange; a sampling tube is arranged inside the stainless steel cylinder; a solenoid valve is connected with the sampling tube; the sampling tube is communicated with the sampling stainless steel woven filter element; a gas inlet tube is connected with the stainless steel cylinder; a back blowing solenoid valve is connected with the gas inlet tube; an escape pipe is arranged inside the stainless steel tube; a needle valve is connected with the escape pipe. Due to adoption of the heat bath thermostat, heat balance can be maintained, a sample gas is kept at relatively high temperature in the whole sampling process, moisture in the sample gas can be prevented from condensation and liquidation, the sample gas can be prevented from distortion, sampling stability can be ensured, and the sampling efficiency can be improved.

Owner:成都市倍诚分析技术有限公司

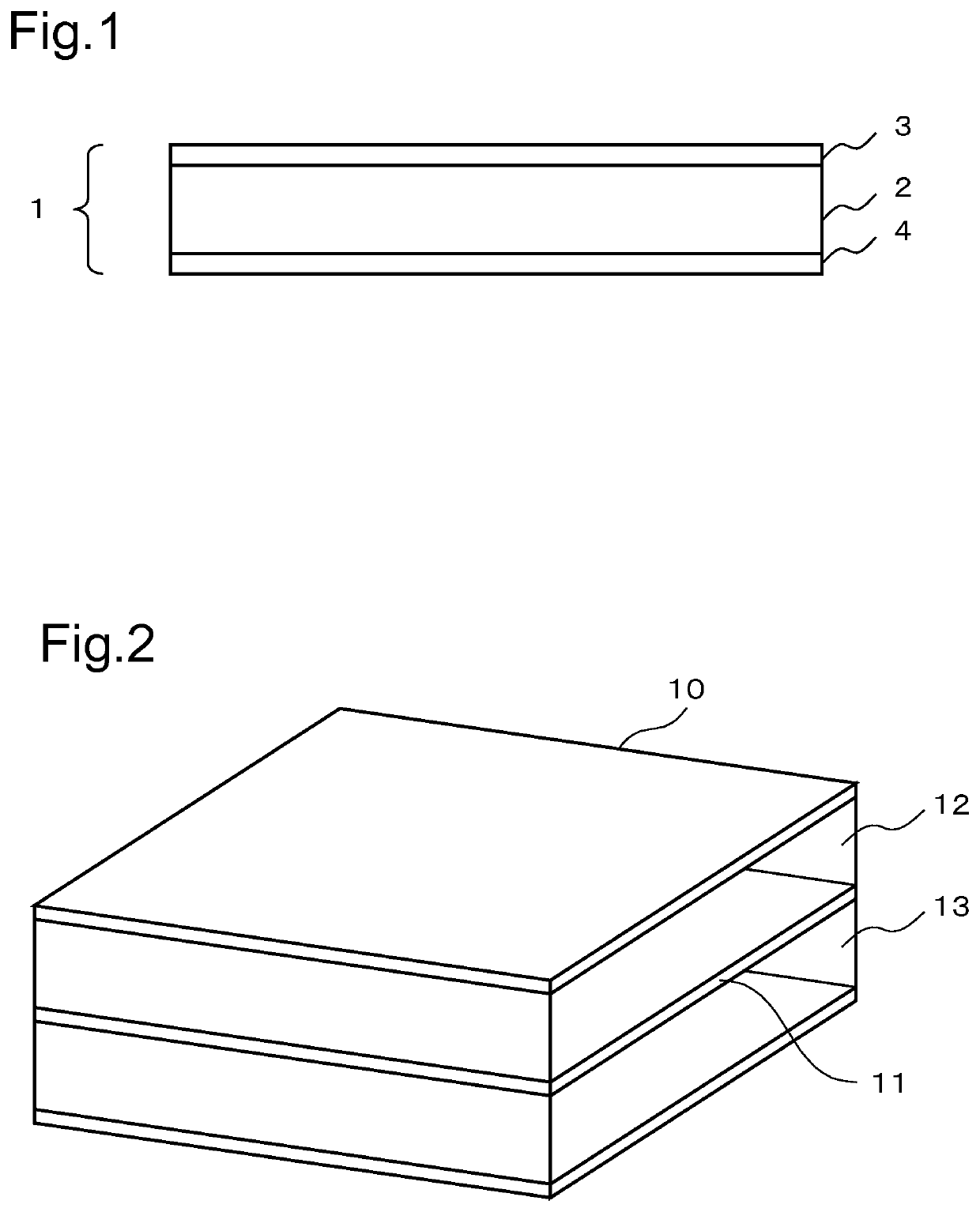

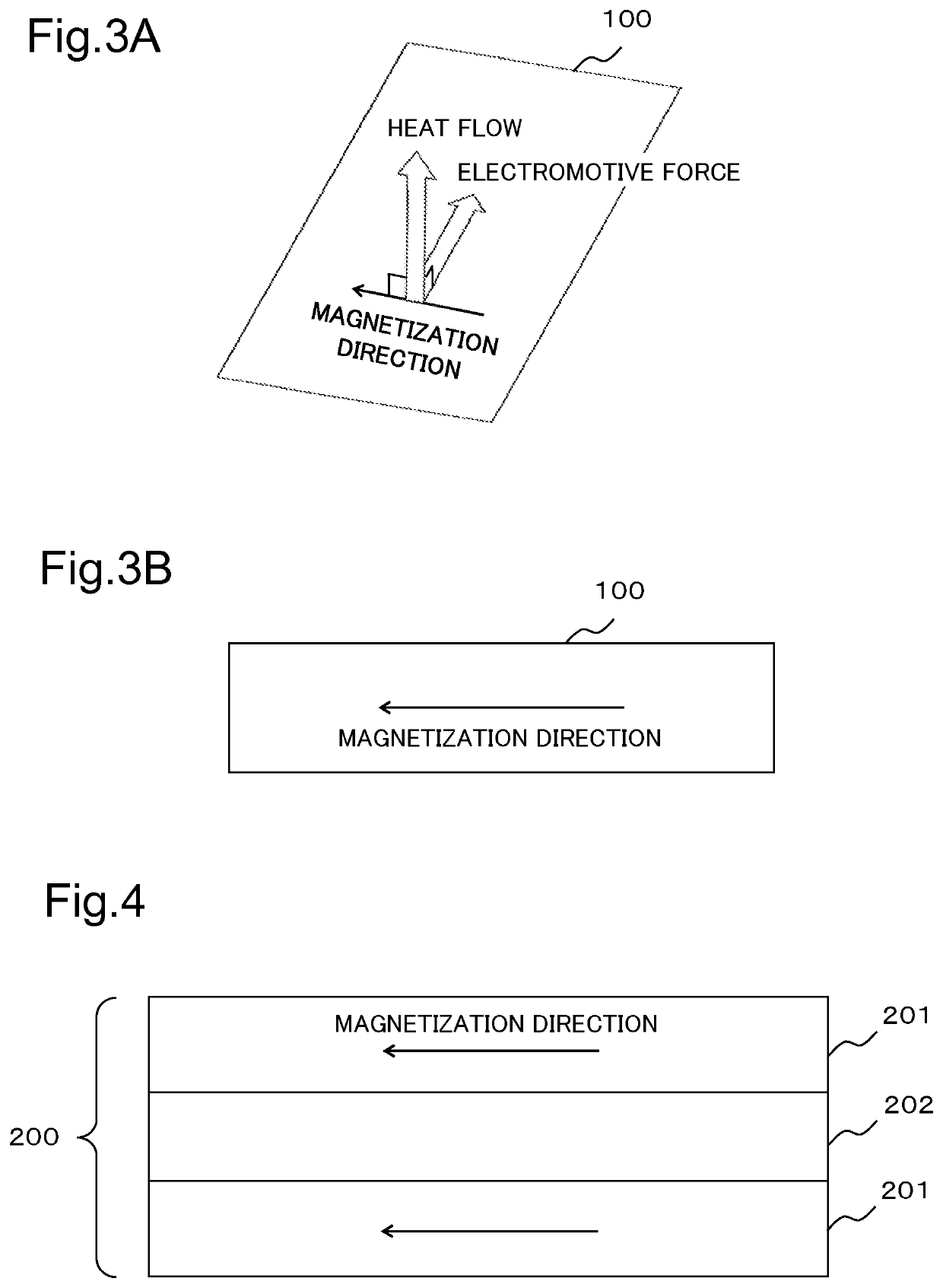

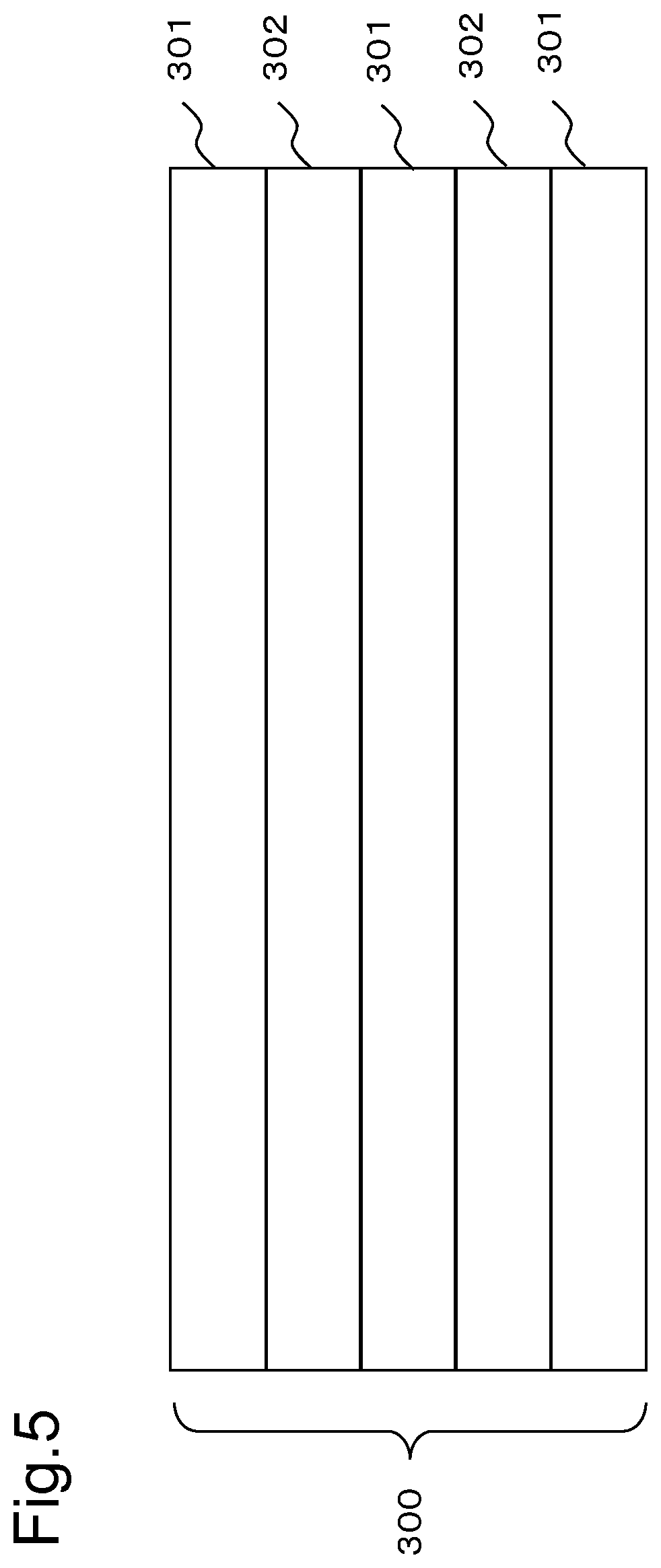

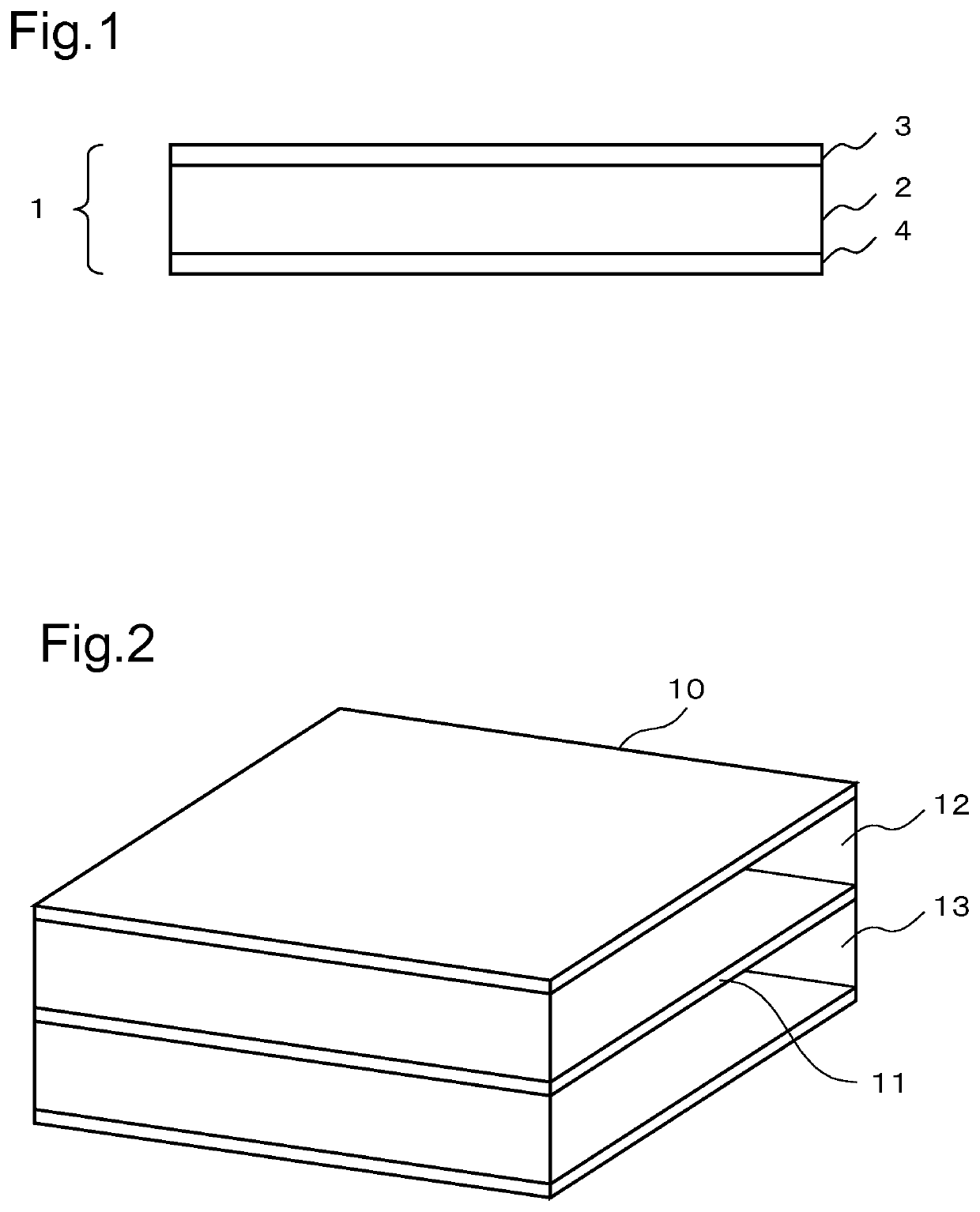

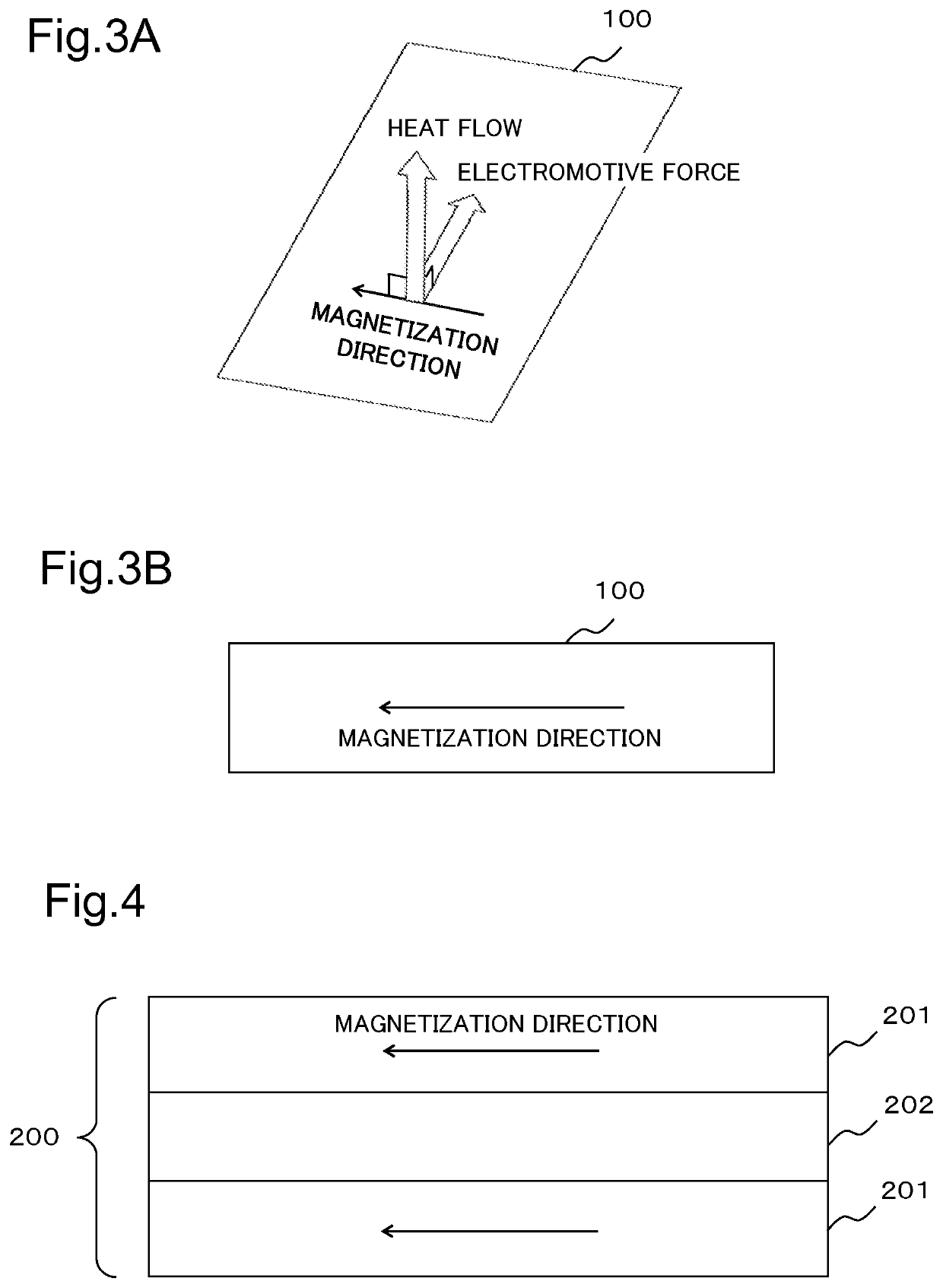

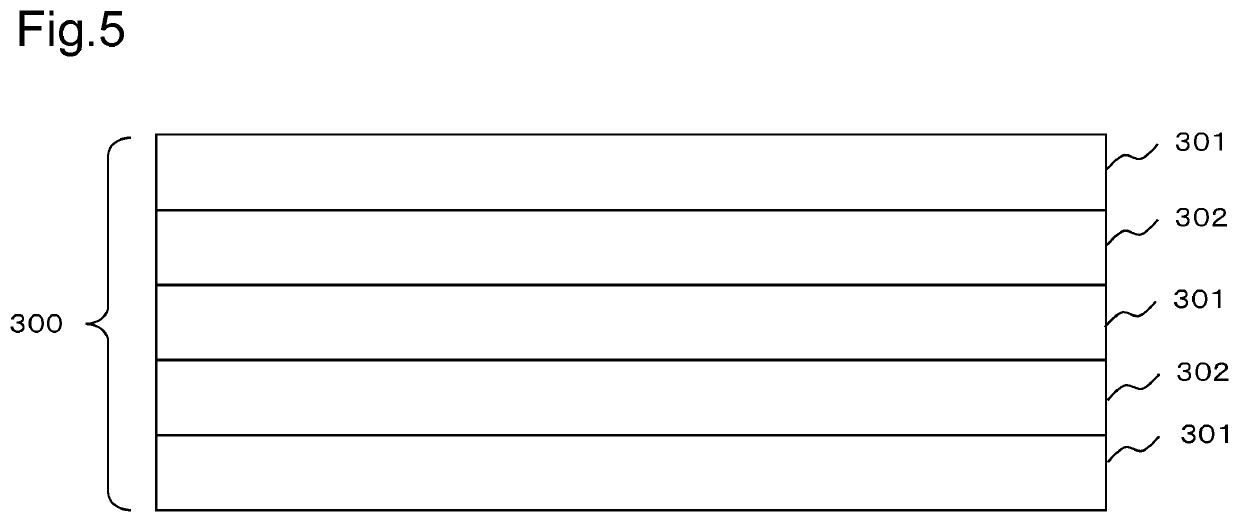

Heat exchange device, heat exchange system, and heat exchange method

ActiveUS11411156B2Efficient power generationMaintain heat transfer effectThermoelectric device with peltier/seeback effectHeat storage plantsThermodynamicsHeat flux

[Problem] To provide a heat exchange device with which efficient electric power generation can be performed while transfer of a heat amount is maintained. [Solution] A heat exchange device comprising a heat exchange section 1 and a magnetic body 2. The heat exchange section 1 includes a first heat transmission interface 3 in contact with a heat source, and a second heat transmission interface 4 in contact with a heat bath having a temperature different from that of the heat source. The magnetic body 2 is interposed between the first heat transmission interface 3 and the second heat transmission interface 4 of the heat exchange section 1, and includes a magnetization component in a direction intersecting a heat flux produced between the first heat transmission interface 3 and the second heat transmission interface 4.

Owner:NEC CORP

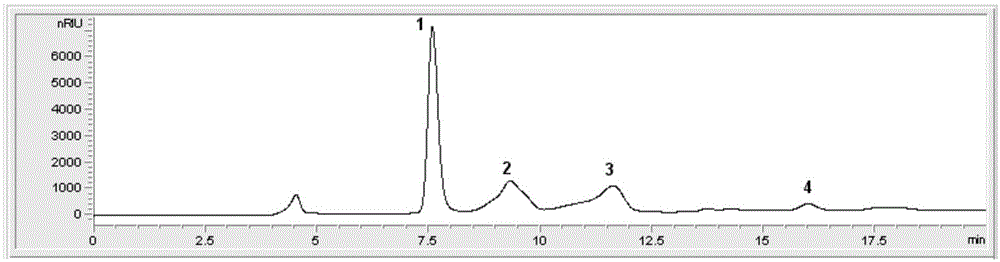

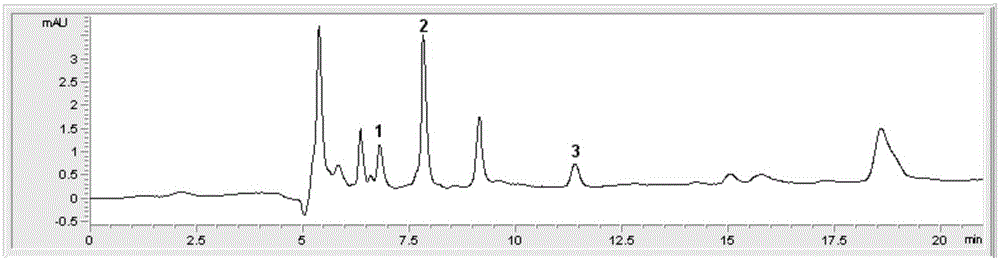

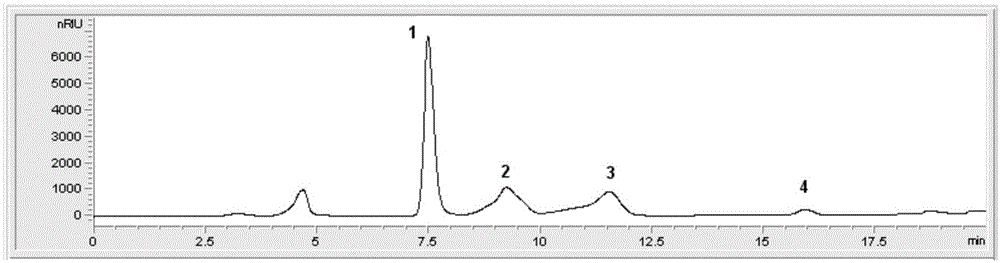

Method for simultaneously and efficiently extracting soluble sugar and organic acid from peach pulp

InactiveCN105021722AExtract efficiently and comprehensivelyReduce degradationComponent separationSucroseSaccharum

Owner:JIANGSU ACAD OF AGRI SCI

Dynamical isolation of a cryogenic processor

ActiveUS11105866B2Quantum computersMagnetic field measurement using superconductive devicesComputational physicsBroadband

A device is dynamically isolated via a broadband switch that includes a plurality of cascade elements in series, wherein each cascade element comprises a first set of SQUIDs in series, a matching capacitor, and a second set of SQUIDs in series. The broadband switch is set to a passing state via flux bias lines during programming and readout of the device and set to a suppression state during device's calculation to reduce operation errors at the device. A device is electrically isolated from high-frequencies via an unbiased broadband switch. A device is coupled to a tunable thermal bath that includes a broadband switch.

Owner:D WAVE SYSTEMS INC

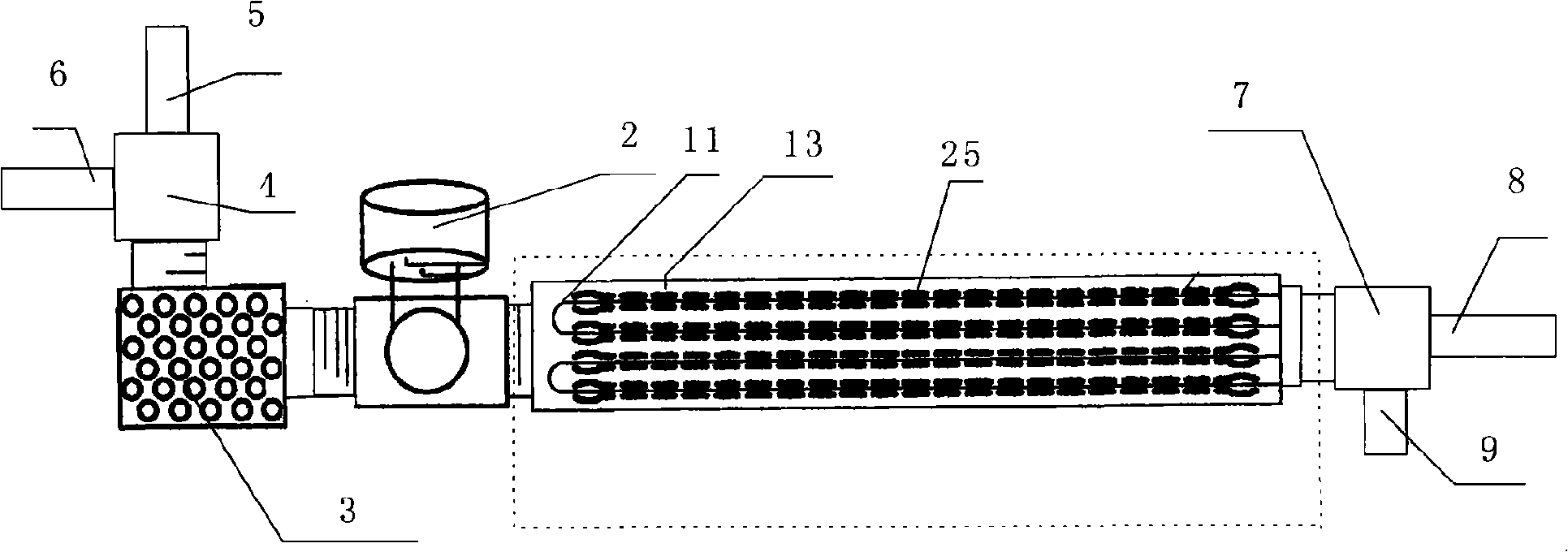

Multifunctional efficient circulation heating bath water heater

InactiveCN102478277ASolve the problem of water vaporSmooth circulationLighting and heating apparatusSpace heating and ventilation detailsEngineeringCirculating pump

The invention relates to a multifunctional efficient circulation heating bath water heater and an installing method thereof. The efficient circulation heating bath water heater is of an open box structure. A heating supply water feeding pipe is connected with the bottom of the efficient circulation heating bath water heater (called efficient circulation device for short hereinafter), a heating supply return water pipe is connected with the middle lower part of the efficient circulation device, an reinforced pressure boosting water supply pipe goes to the place between the return water pipe and the water feeding pipe from the top of the efficient circulation device, and the return water pipe is linked with a plurality of branched return water pipes and a balance adjusting valve. The efficient circulation device can improve the circulation power of water greatly and can serve as a circulating pump.

Owner:高闻利

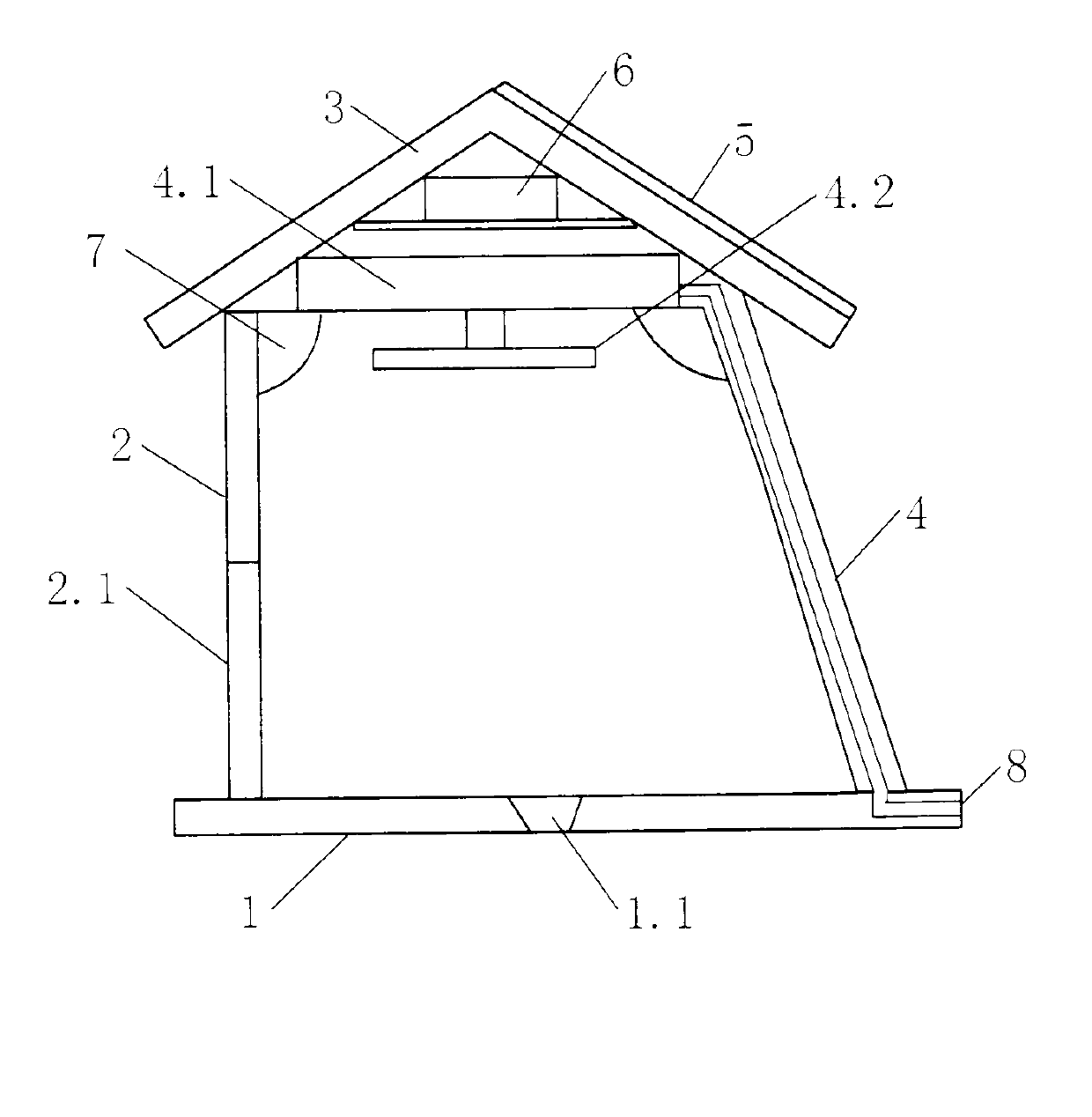

Offshore solar illuminating and heating heat preservation bathroom

InactiveCN102877666ABuoyantThermal insulationRoof covering using slabs/sheetsRoof covering using tiles/slatesBrickWater storage tank

The invention provides an offshore solar illuminating and heating heat preservation bathroom. A foaming cement brick wall is enclosed on a buoyancy bottom plate; a double-inclined-plane or four-inclined-plane foaming cement house cover plate is arranged on the upper part of the foaming cement brick wall; a solar thermal collector is arranged on the outer side of the foaming cement brick wall on the sun facing side; a water inflow pipe is arranged in the solar thermal collector; the upper end of the water inflow pipe is communicated with a water storage tank which is arranged on the lower part of the foaming cement house cover plate; the lower part of the water storage tank is connected with a spray head through a pipeline; a solar cell panel is arranged on one surface of the foaming cement house cover plate on the sun facing side, and is connected with a storage cell arranged on the lower part of the foaming cement house cover plate through a guiding wire; and the storage cell is connected with light-emitting diode (LED) illuminating lamps arranged at the upper corners of an indoor wall surface through guiding wires. The offshore solar illuminating and heating heat preservation bathroom has the characteristics that the bathroom has floating performance and heat preservation performance and can be used for heating bath water and generating electricity for illumination through solar energy; and the bathroom is suitable to be used as a bathroom for baths in a bathing beach.

Owner:SUIZHONG ZHONGWEI TECH

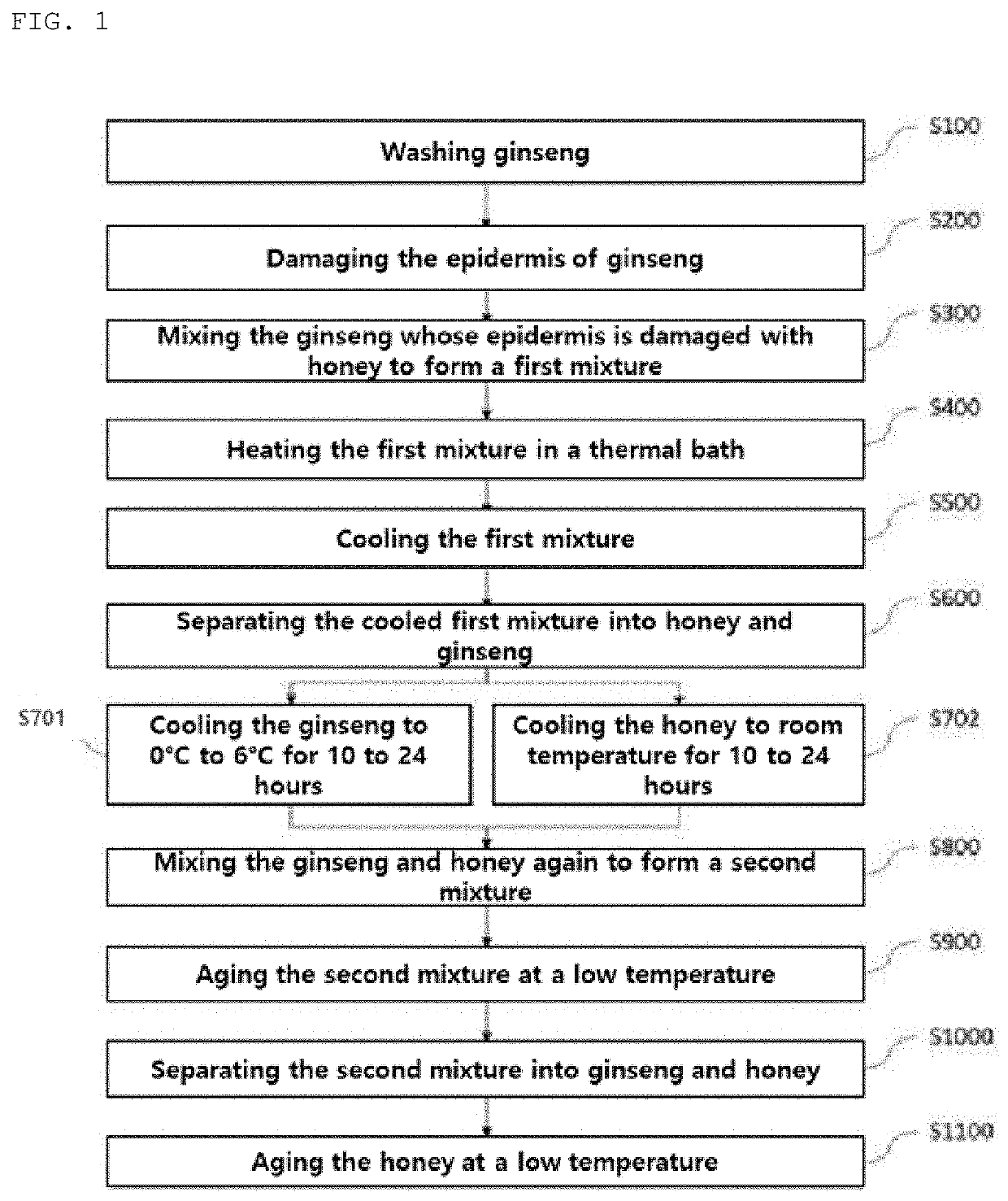

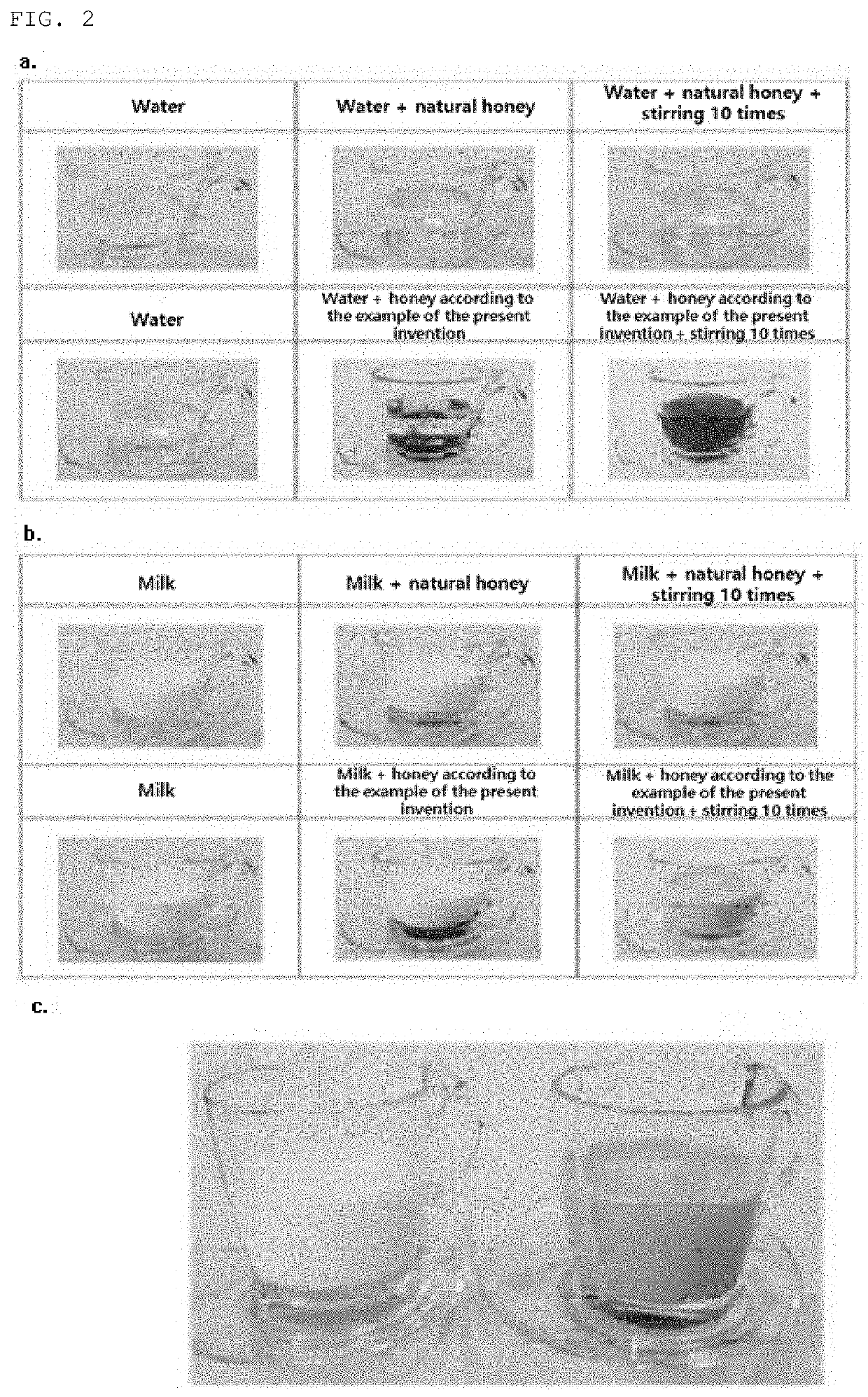

Method for producing honey containing low molecular weight ginsenosides

InactiveUS20200359669A1Easy to drinkHigh absorption rateFood thermal treatmentFood ingredient as taste affecting agentBiotechnologyHeat bath

A method for producing honey containing low molecular weight ginsenosides, includes steps of: washing ginseng; damaging epidermis of the ginseng; mixing the ginseng whose epidermis is damaged with honey to form a first mixture; heating the first mixture in a thermal bath; cooling the heated first mixture; separating the heated and cooled first mixture into honey and ginseng; cooling the separated ginseng to 0° C. to 6° C. and cooling the separated honey at room temperature, each cooled for 10 to 24 hours; mixing the cooled ginseng and honey again to form a second mixture; aging the second mixture at a low temperature; separating the low-temperature-aged second mixture into ginseng and honey; and aging the honey separated from the second mixture at a low temperature at least 12 hours.

Owner:RAPHADEO CO LTD

Heat exchange device, heat exchange system, and heat exchange method

ActiveUS20200020842A1Efficient power generationMaintain heat transfer effectThermoelectric device with peltier/seeback effectHeat storage plantsThermodynamicsHeat flux

[Problem] To provide a heat exchange device with which efficient electric power generation can be performed while transfer of a heat amount is maintained. [Solution] A heat exchange device comprising a heat exchange section 1 and a magnetic body 2. The heat exchange section 1 includes a first heat transmission interface 3 in contact with a heat source, and a second heat transmission interface 4 in contact with a heat bath having a temperature different from that of the heat source. The magnetic body 2 is interposed between the first heat transmission interface 3 and the second heat transmission interface 4 of the heat exchange section 1, and includes a magnetization component in a direction intersecting a heat flux produced between the first heat transmission interface 3 and the second heat transmission interface 4.

Owner:NEC CORP

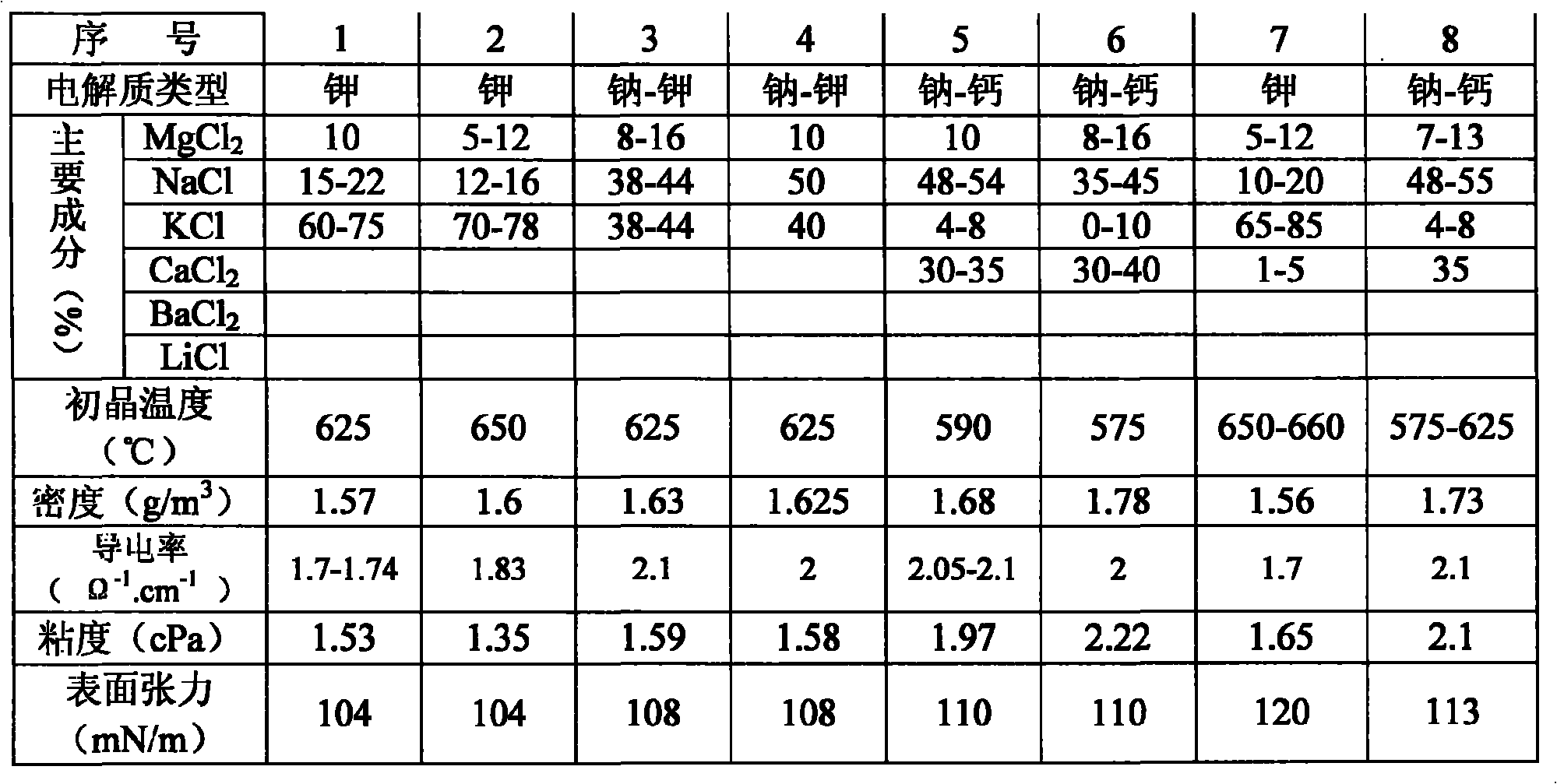

Ternary electrolyte molten salt magnesium electrolysis

The invention discloses a molten salt magnesium electrolyzing ternary electrolyte. The compositions in percentage by mass of the ternary electrolyte are: 16 to 20 percent of MgCl2, 51 to 59 percent of NaCl, 23 to 27 percent of CaCl2 and 1.5 to 2.0 percent of calcium fluoride. The ternary electrolyte solves the problem that part commonly used electrolyte is easy to boil during production, and greatly reduces the operating temperature during normal electrolysis of an electrolytic cell; under the condition of normal operating current, the electrolytic cell can maintain excellent self-heating balance, thereby greatly reducing heat-bath tendency, obtaining ideal protection effect of liquid magnesium and slightly changing electrolyte flow characteristic; therefore, the ternary electrolyte increases the current efficiency of the electrolytic cell to a certain extent, and can obviously reduce production cost, thereby having an extensive application prospect.

Owner:洛阳双瑞万基钛业有限公司

Thermoelectric material, thermoelectric conversion element, and module group composed of combination of thermoelectric conversion elements and pi-type module group made of thermoelectric material and pi-type module group made of thermoelectric material other than such pi-type module group

InactiveCN107155379AThermoelectric device with peltier/seeback effectGenerators/motorsThermoelectric materialsRoom temperature

The purpose of the present invention is to create a thermoelectric conversion system in which the thermoelectric conversion efficiency of a thermoelectric material is close to the Carnot efficiency, such thermoelectric material containing a "module group composed of a combination of thermoelectric conversion elements". The invention reduces as much as possible the thermal conductivity from anything other than a space portion or a working substance able to move inside a thermoelectric conversion element due to a connected space portion, in a new generation of thermoelectric materials which comprise a "module group composed of a combination of thermoelectric conversion elements", and which are thermoelectric materials that do not suffer damage from a load or heat retention and that are composed of thermoelectric conversion elements that do not suffer damage from a load or heat retention. The invention comprises reforming thermoelectric material surfaces sandwiching a space, or surfaces facing this thermoelectric material, to make an interface that is suitable for power generation, cooling, and heating operation. The purpose of the present invention is to produce an interspecific module superior to a "module group composed of a combination of thermoelectric conversion elements" and in contact with three or more different heat bath sources at room temperature or the like, and to produce a thermoelectric conversion system that comprises this module and has a thermoelectric conversion efficiency close to the Carnot efficiency.

Owner:马渊真人

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com